Process for preparing laminar zirconium boride superhigh-temperature ceramic by casting-impregnation method

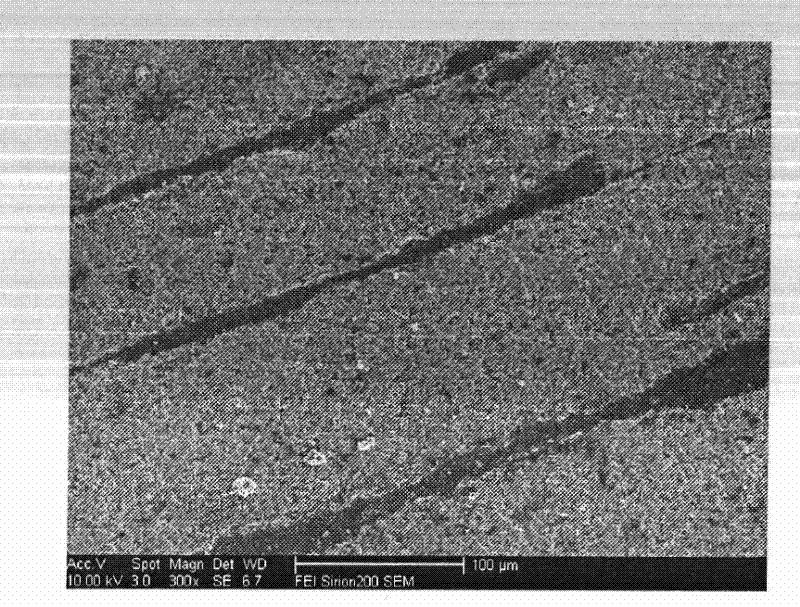

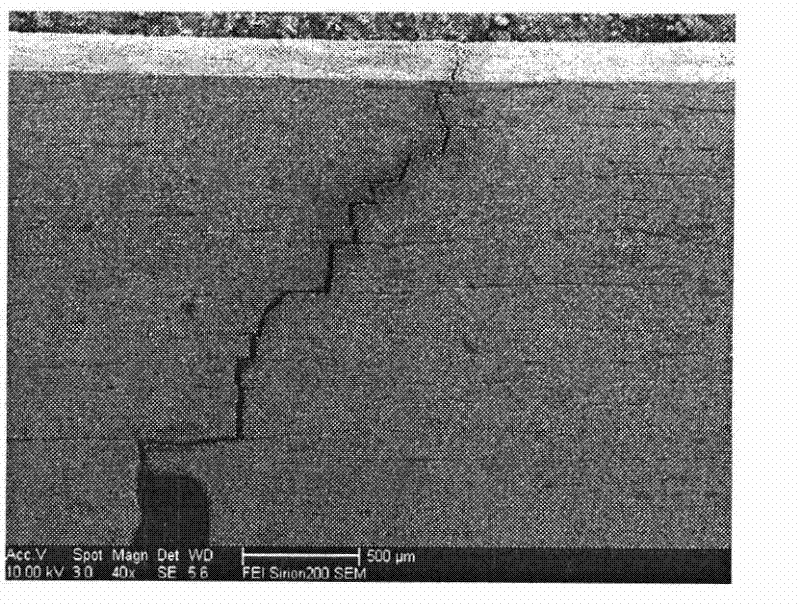

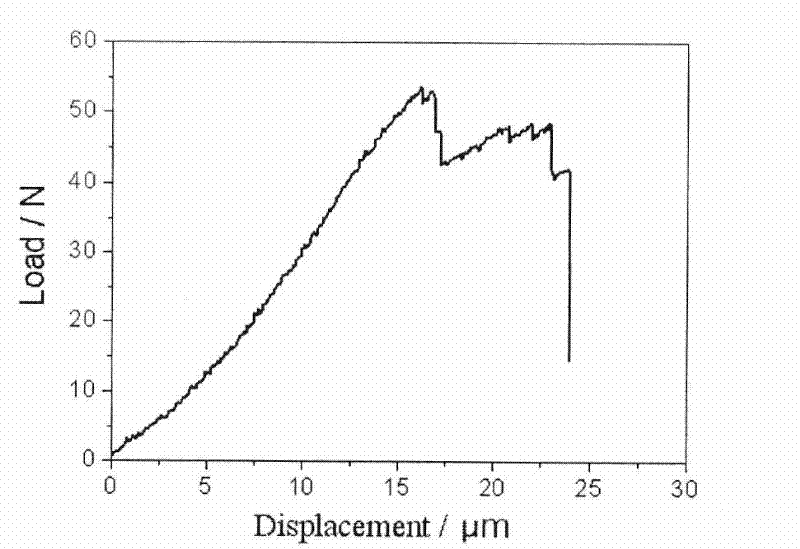

A technology of ultra-high temperature ceramics and zirconium boride, applied in chemical instruments and methods, ceramic layered products, layered products, etc., can solve the problems of poor toughness of zirconium boride ultra-high temperature ceramics, achieve improved fracture toughness, increase The effect of extending the path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of zirconium boride cast sheet: Weigh 2.61 grams of polyvinyl butyral, 2.61 grams of polyethylene glycol, and 52.23 grams of ethanol, stir to make the mixture uniform, and then add 42.63 grams of 1μm zirconium boride powder, 9.60 grams of 0.5μm silicon carbide powder, stir evenly to form a cast material, cast, dry and demold at room temperature to obtain a 1000μm thick cast sheet, in which zirconium boride powder and silicon carbide powder are 70%: 30% by volume Weigh

[0024] 2. Dipping: Weigh 2 grams of polyethylene glycol into 100 grams of deionized water and stir evenly, then add 10 grams of graphite to form a slurry; then use the dipping method to immerse the casting sheet in the graphite slurry, and immerse the casting sheet , Pull 1 time by dipping;

[0025] 3. Cut the cast sheet according to the size of the mold;

[0026] 4. Superimpose the sliced cast sheet into the abrasive tool, vacuum degreasing, and during degreasing, the heating rate is 2℃ / min,...

Embodiment 2

[0029] 1. Preparation of zirconium boride cast sheet: first weigh 5.51g polyvinyl butyral, 5.51g polyethylene glycol, 82.68g ethanol, stir to mix evenly, then add 48.72g 2μm zirconium boride powder, 6.40 grams of 1μm silicon carbide powder, stir evenly to form a cast material, cast, dry and demold at room temperature to obtain a 300μm thick cast sheet, in which zirconium boride powder and silicon carbide powder are weighed according to the volume percentage of 80%:20% take;

[0030] 2. Immersion: Weigh 3 grams of polyethylene glycol into 200 grams of deionized water and stir evenly, then add 10 grams of boron nitride to form a slurry; then use the dipping method to immerse the casting sheet in the graphite slurry, and cast The sheet is dipped and pulled twice by dipping;

[0031] 3. Cut the cast sheet according to the size of the mold;

[0032] 4. Superimpose the sliced cast sheet into the abrasive tool, vacuum degreasing, and during degreasing, the heating rate is 2.5°C / min, the...

Embodiment 3

[0035] 1. Preparation of zirconium boride cast sheet: first weigh 4.06 grams of polyvinyl butyral, 4.06 grams of polyvinyl alcohol, and 116.02 grams of ethanol, stir to mix evenly, then add 54.81 grams of 5μm zirconium boride powder, 3.20 G 2μm silicon carbide powder, stir evenly to form a cast material, cast, dry and demold at room temperature to obtain a 200μm thick cast sheet, in which zirconium boride powder and silicon carbide powder are weighed at a volume percentage of 90%: 10% ;

[0036] 2. Impregnation: Weigh 2.5 grams of polyvinyl alcohol and add 150 grams of deionized water and stir evenly, then add 10 grams of graphite to form a slurry; then use the dipping method to immerse the casting sheet in the graphite slurry and immerse the casting sheet. Pull 3 times by dipping;

[0037] 3. Cut the cast sheet according to the size of the mold;

[0038] 4. Superimpose the sliced cast sheet into the abrasive tool, vacuum degreasing, and during degreasing, the heating rate is 3°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com