Ti alloy with high performance

A titanium alloy, high-performance technology for materials science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following alloy chemical composition is a specific example of the chemical composition and mass percentage to realize the high performance titanium alloy of the present invention.

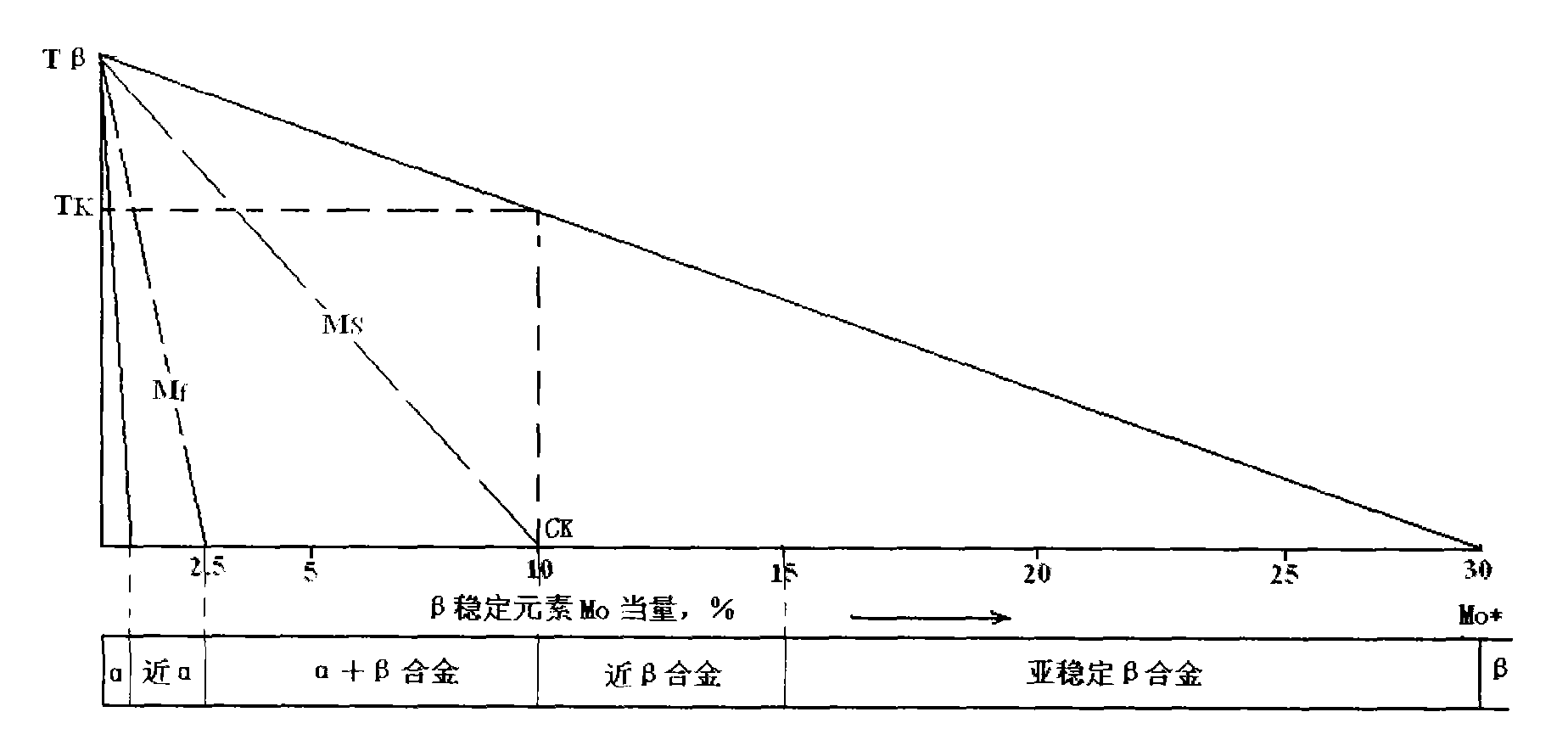

[0027] Al: 5% to 6%; Mo: 3% to 4%; V: 1.5% to 2.5%; Sn: 2% to 3%; Zr: 2% to 3%; Cr: 1% to 1.5%; Nb: 1% to 1.5%; Si: 0.1% to 0.15%; Ti is the balance.

[0028] The above-mentioned high-performance titanium alloys are obtained through the following smelting process:

[0029] The high-performance titanium alloy of the present invention is obtained by adopting vacuum smelting technology, and is smelted three times in a vacuum consumable electric arc furnace, so that the alloy elements are evenly distributed. Consumable electrodes are not allowed to be welded by argon tungsten arc welding.

[0030] Prepare the master alloys such as Al~Mo and Al~V required for smelting first, use first-grade sponge titanium with a thickness of 0.83mm~12.7mm as the raw material, dry the raw materials and mast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com