Ceramic heater and manufacturing method therefor, and heating apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

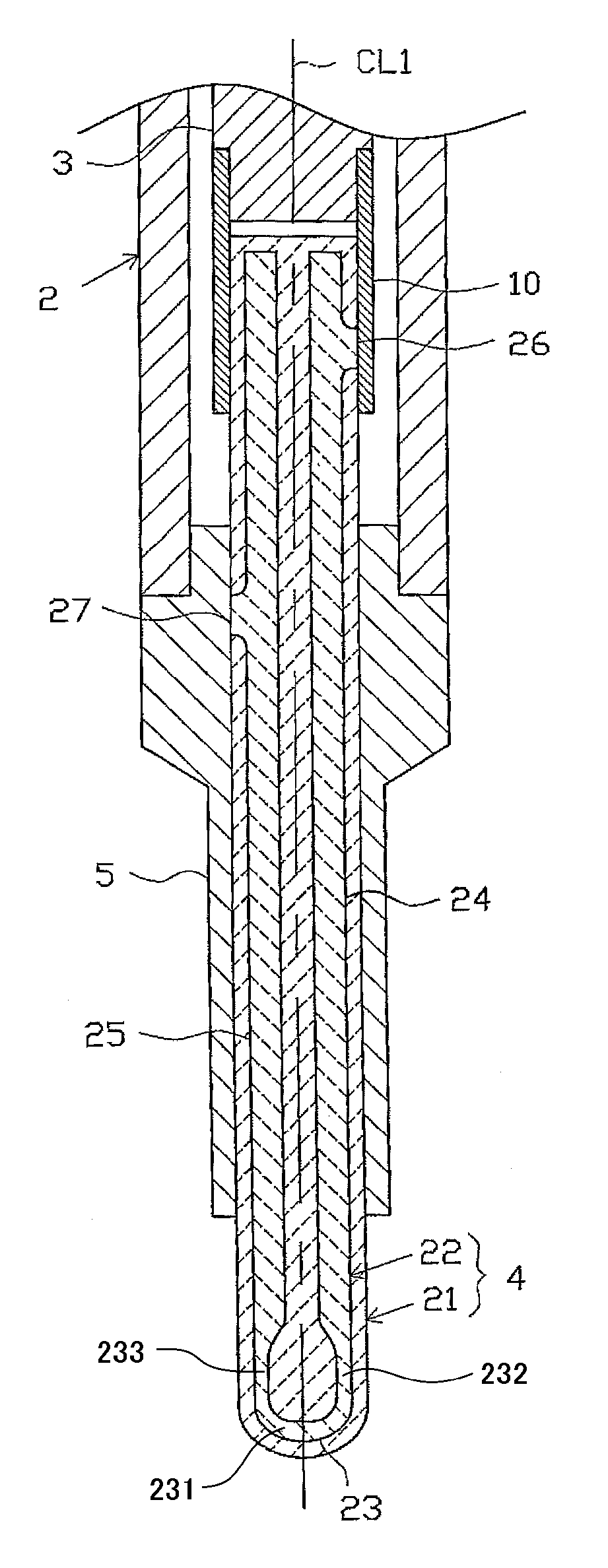

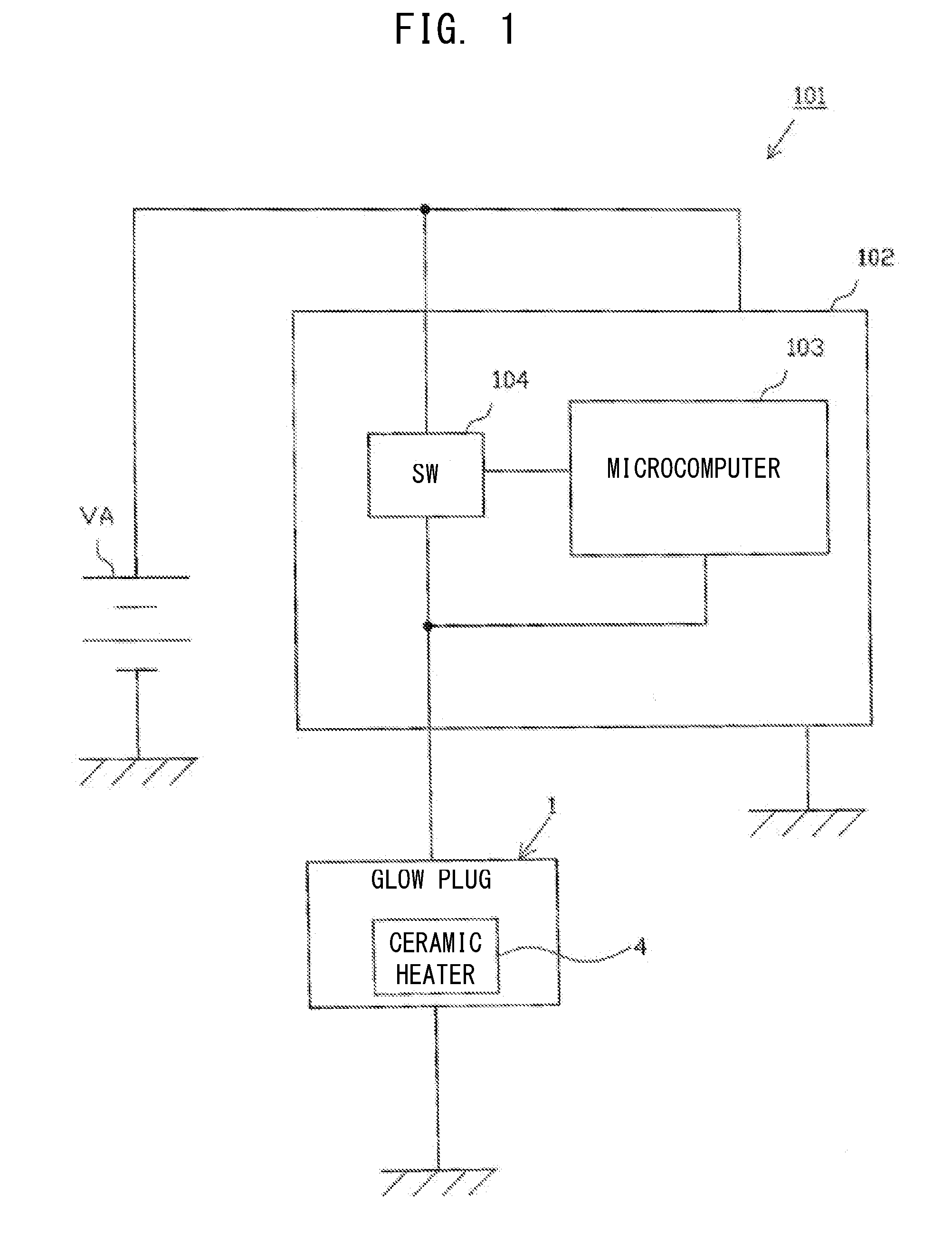

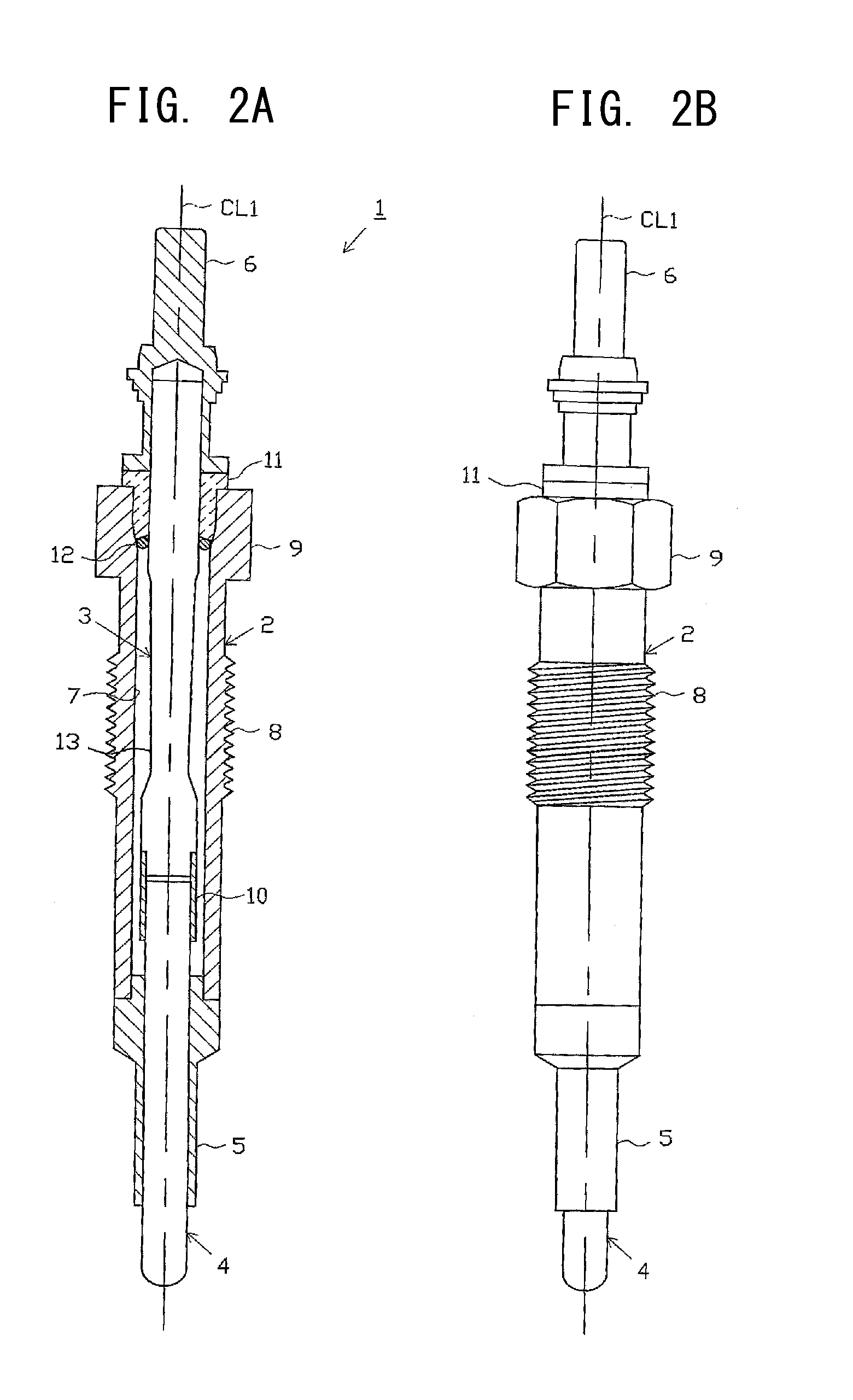

[0048]An embodiment of the present invention will next be described with reference to the drawings. FIG. 1 is a block diagram showing the schematic configuration of a heating apparatus 101.

[0049]The heating apparatus 101 includes a ceramic glow plug 1 (hereinafter, referred to as the “glow plug 1”) having a ceramic heater 4, and a glow control unit (GCU) 102 (an energization control unit) to control energization of the glow plug 1. FIG. 1 shows only a single glow plug 1. However, an actual engine has a plurality of cylinders, and the glow plug 1 and a switch 104, which will be described later, are provided for each of the cylinders.

[0050]The GCU 102 operates by power supplied from a battery VA and includes a microcomputer 103 having a CPU, a ROM, a RAM, etc., and the switch 104 adapted to turn ON / OFF the supply of power to the glow plug 1 from the battery VA.

[0051]The GCU 102 controls energization of the glow plug 1 under PWM control such that the switch 104 turns ON / OFF the supply ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com