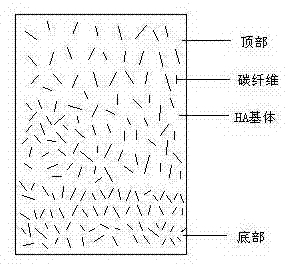

Preparation method of gradient carbon fiber/hydroxyapatite (HA) composite material

A technology of hydroxyapatite and composite materials, which is applied in the field of preparation of gradient carbon fiber/hydroxyapatite composite materials, can solve the problem of reducing the osteoinductivity and affinity of HA materials, reducing the content of HA matrix, and reducing the mechanical properties of composite materials, etc. problems, to achieve the effect of improving osteoinductivity and biocompatibility, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] 1. Composite modification of carbon fiber

[0026] a. Put the carbon fiber in the crucible and put it in a box-type resistance furnace that has been heated to 300 ℃ for 30 minutes, and the carbon fiber that has been pretreated by low-temperature oxidation is ready for use;

[0027] b. Ca(NO 3 ) 2 Alcoholic solution 100 mL, concentration of 4 mol / L P 2 o 5 Alcohol solution 117 mL, to ensure that the Ca / P ratio is 1.67, the P 2 o 5 Alcoholic solution to Ca(NO 3 ) 2 Alcohol solution was added dropwise at 1mL / min, and magnetically stirred for 2 hours. After the reaction, it became a transparent viscous sol;

[0028] c. Soak the previously pretreated carbon fiber in the prepared HA sol for 5 minutes, then take it out and put it in an oven at 80 °C to dry for 1 h, so that the HA sol turns into HA gel. Repeat this process 5 times to make the surface of the carbon fiber Form a layer of HA coating that is well combined with the substrate. The modified carbon fibers w...

example 2

[0036] 1. Composite modification of carbon fiber

[0037] a. Put the carbon fiber in a crucible and put it in a box-type resistance furnace that has been heated to 500 °C for 30 minutes, and the carbon fiber that has been pretreated by low-temperature oxidation is ready for use;

[0038] b. Ca(NO 3 ) 2 Alcoholic solution 100 mL, concentration of 4 mol / L P 2 o 5 Alcohol solution 117 mL, to ensure that the Ca / P ratio is 1.67, the P 2 o 5 Alcoholic solution to Ca(NO 3 ) 2 Alcohol solution was added dropwise at 1mL / min, and magnetically stirred for 2 hours. After the reaction, it became a transparent viscous sol;

[0039] c. Soak the previously pretreated carbon fiber in the prepared HA sol for 5 minutes, then take it out and put it in an oven at 80 °C to dry for 1 h, so that the HA sol turns into HA gel. Repeat this process 5 times to make the surface of the carbon fiber Form a layer of HA coating that is well combined with the substrate. The modified carbon fibers were...

example 3

[0047] 1. Composite modification of carbon fiber

[0048] a. Put the carbon fiber in a crucible and put it in a box-type resistance furnace that has been heated to 400 °C for 30 minutes, and the carbon fiber that has been pretreated by low-temperature oxidation is ready for use;

[0049] b. Ca(NO 3 ) 2 Alcoholic solution 100 mL, concentration of 4 mol / L P 2 o 5 Alcohol solution 117 mL, to ensure that the Ca / P ratio is 1.67, the P 2 o 5 Alcoholic solution to Ca(NO 3 ) 2 Alcohol solution was added dropwise at 1.5mL / min, and magnetically stirred for 2 hours, and it turned into a transparent viscous sol after the reaction;

[0050] c. Soak the previously pretreated carbon fiber in the prepared HA sol for 5 minutes, then take it out and put it in an oven at 80 °C to dry for 1 h, so that the HA sol turns into HA gel. Repeat this process 5 times to make the surface of the carbon fiber Form a layer of HA coating that is well combined with the substrate. The modified carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com