Multi-crystal-nucleus composite transparent glass ceramic and preparation method thereof

A technology of transparent glass and glass ceramics, which is applied in the field of polycrystalline core composite transparent glass ceramics and its preparation, and can solve problems such as display covers that cannot be used for electronic products, affecting the visible light transmittance of glass ceramics, and limiting the application range of glass ceramics. , to achieve the effect of enhanced practicability, small crystal size and enhanced fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

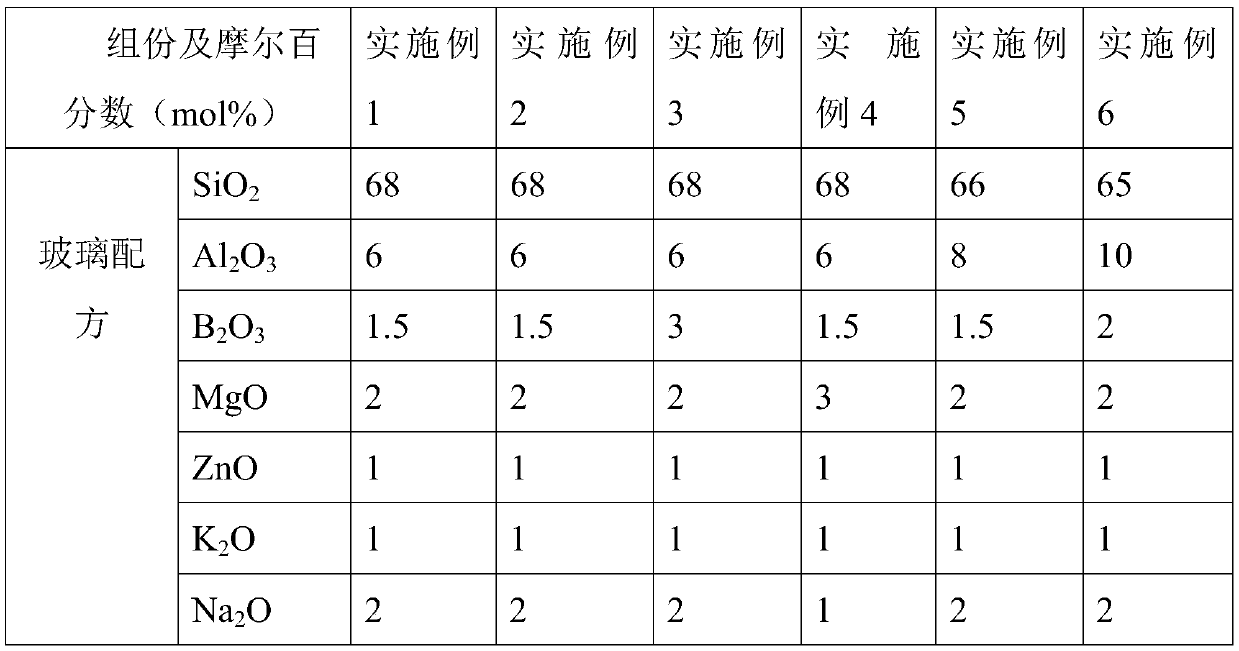

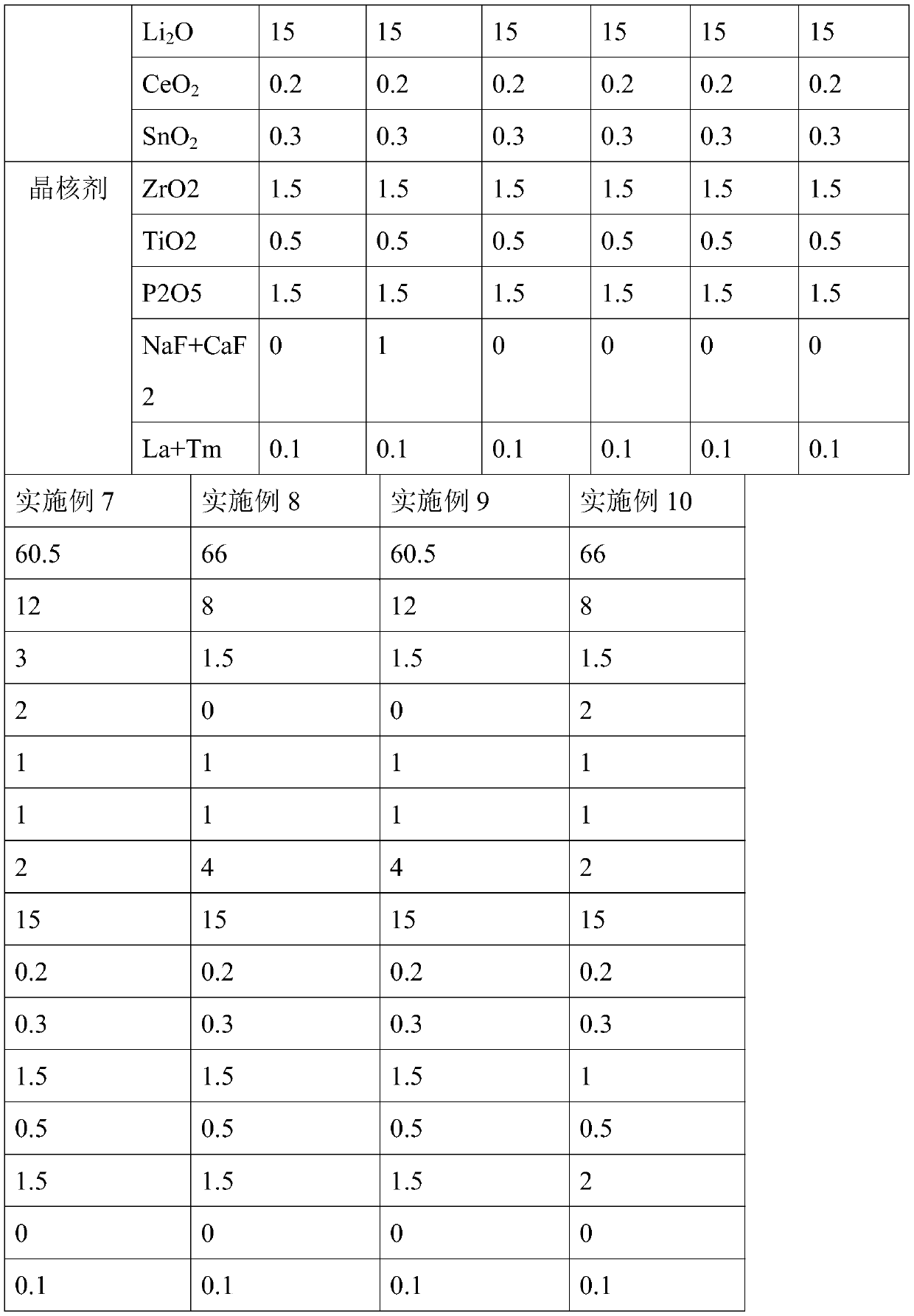

Examples

preparation example Construction

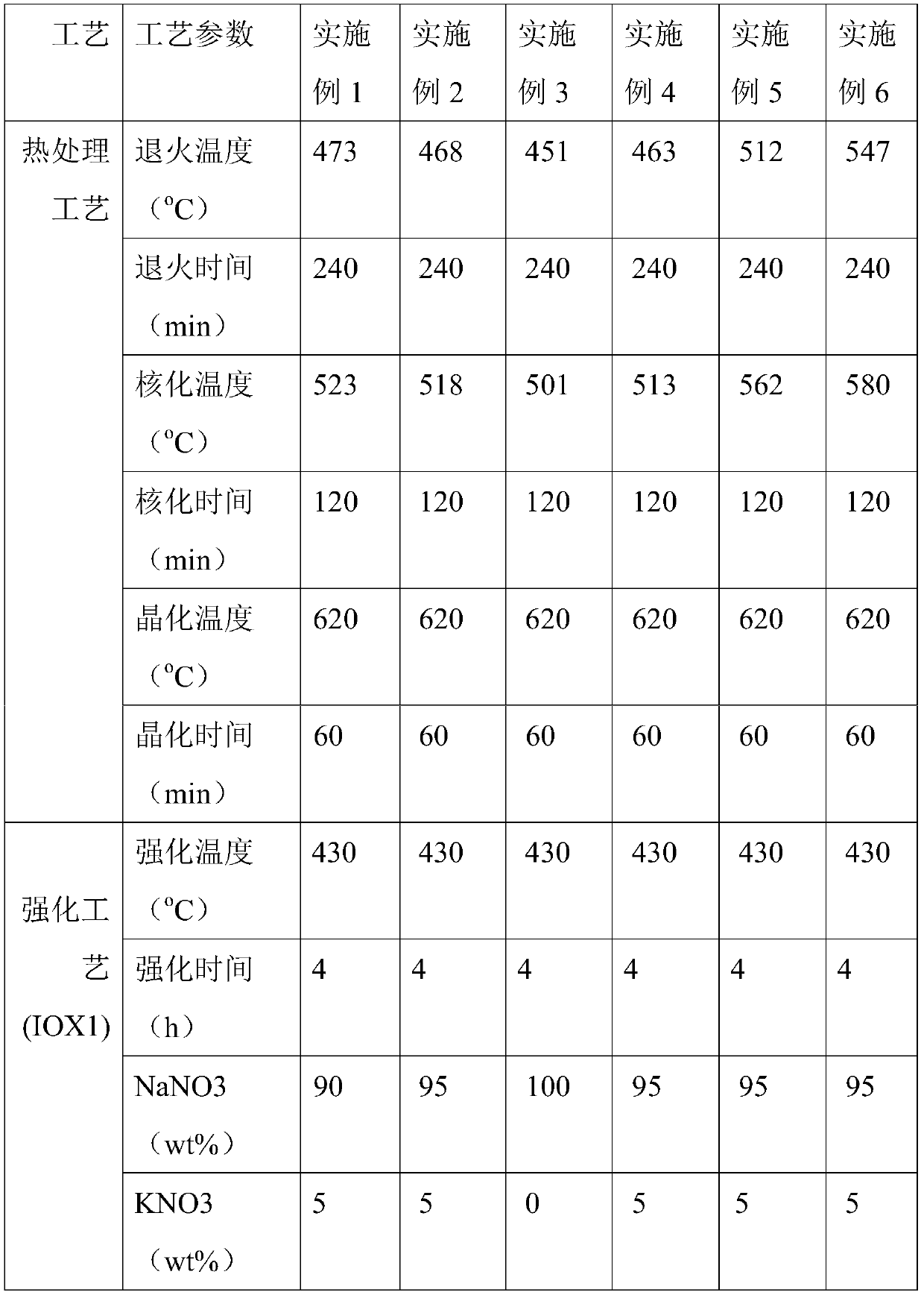

[0026] The present invention also provides a preparation method of polycrystalline core composite transparent glass ceramics, comprising the following steps:

[0027] S1: When melting glass, add crystal nucleating agent to prepare glass;

[0028] S2: Obtain plain glass with a certain external dimension from the glass obtained in S1;

[0029] S3: Place the plain glass obtained in S2 under the condition of temperature T1, heat for 1h~6h for annealing treatment, after the annealing treatment is completed, put it under the condition of temperature T2, heat for 1h~6h, do nucleation treatment, After the chemical treatment is completed, place it under the condition of temperature T3, heat for 0-3 hours for crystallization treatment, and prepare glass ceramics; the range of the temperature T1 is 450°C-550°C, and the range of the temperature T2 is 500°C- 580°C, the temperature T3 ranges from 600°C to 800°C, and the T1<T2.

[0030] Specifically, in the embodiment of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com