Diamond-silicon carbide combination drill teeth for petroleum probe boring and manufacture method thereof

A diamond and silicon carbide technology, which is applied in the field of high-strength nanostructure diamond-silicon carbide composite drill teeth and its preparation, can solve the problem of reduced thermal stability of polycrystalline diamond composite sheets, direct bonding between diamond particles and strong fractures, and diamond composite sheets. Cracks and other problems, to achieve the effect of improved fracture toughness, easy to grasp, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

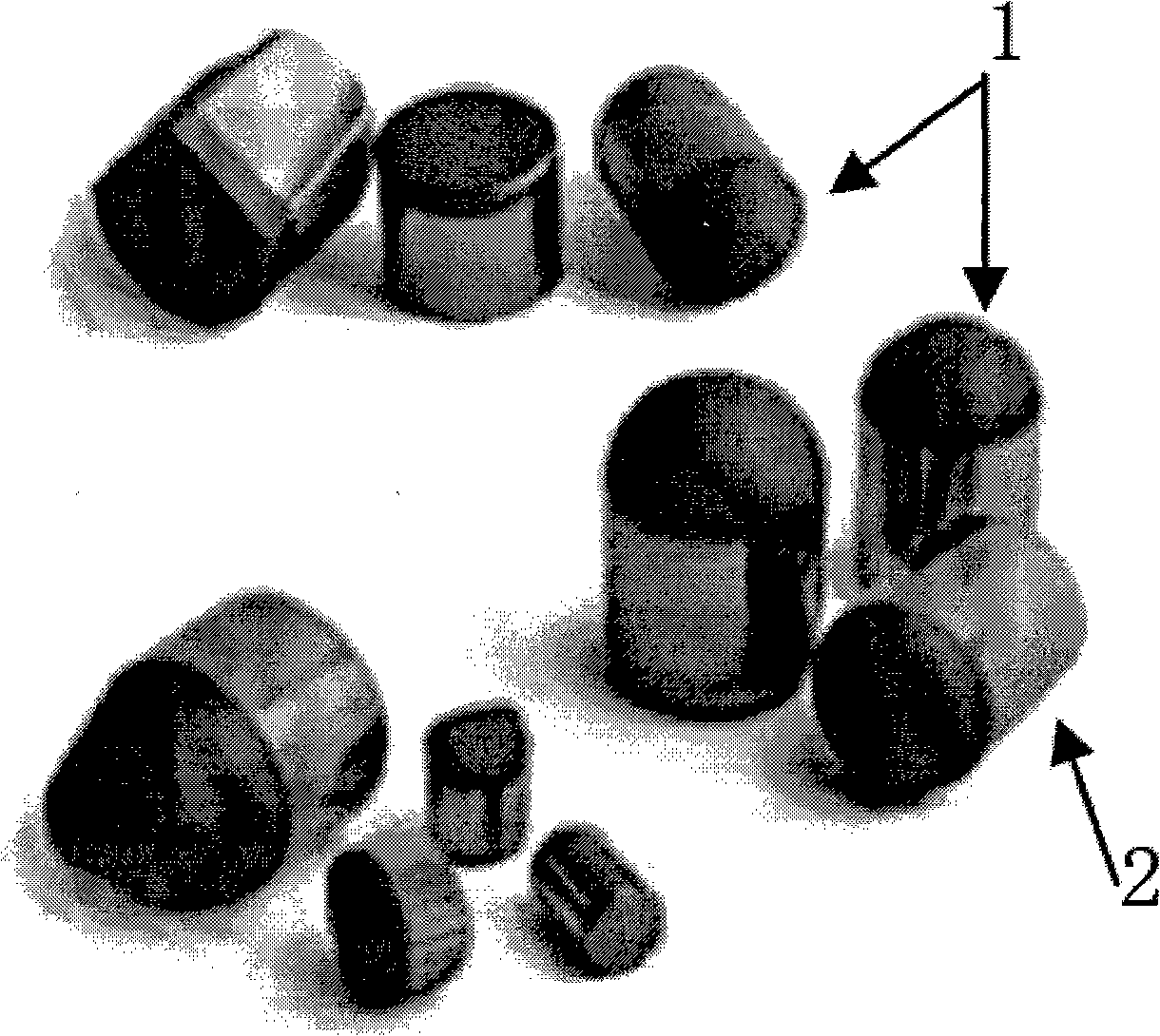

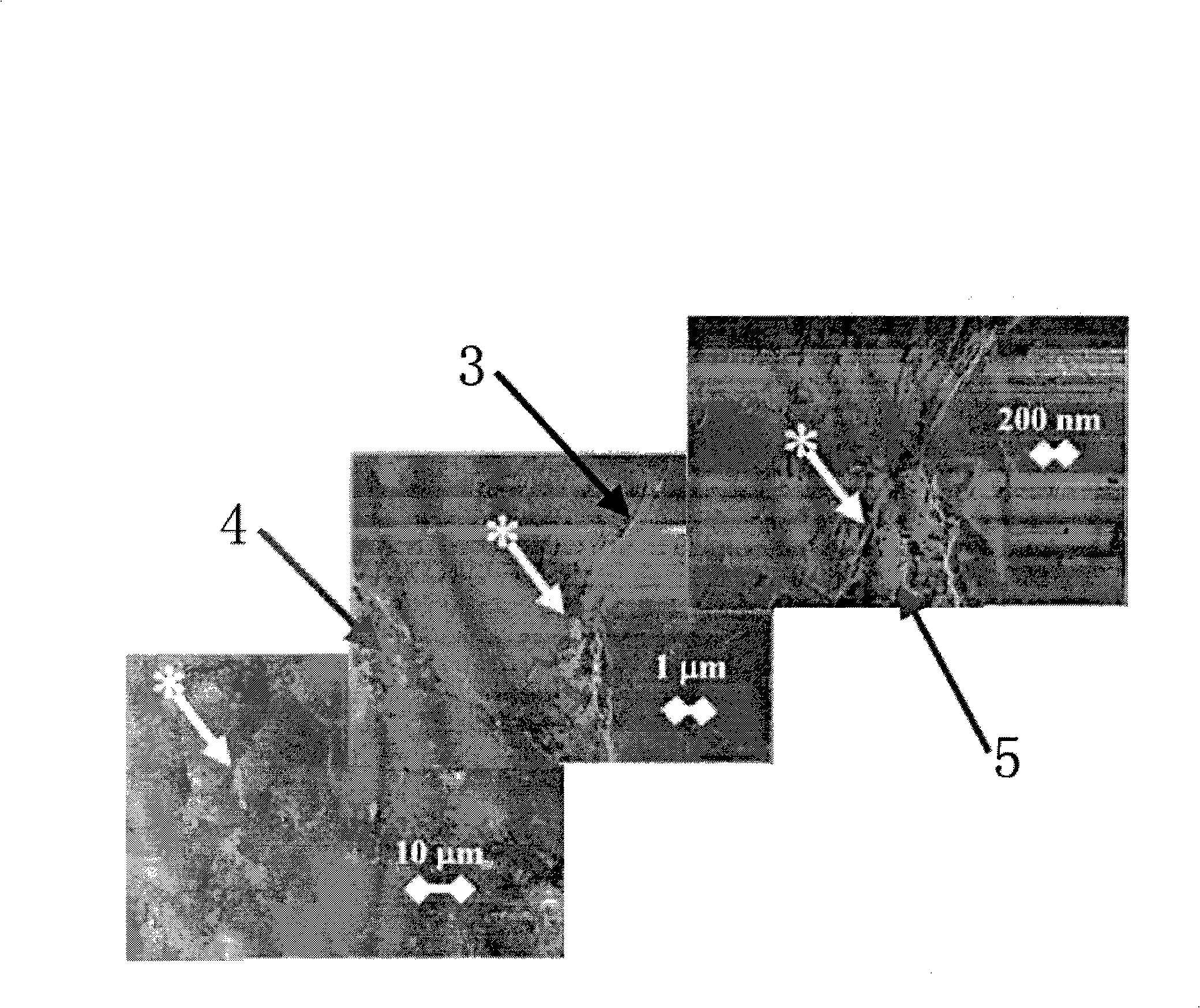

[0034] In this embodiment, the preparation method of diamond-silicon carbide composite drill teeth for oil drilling is as follows:

[0035] (1) material preparation

[0036] 3 grams of diamond powder with a grain size of 5 microns to 10 microns, 2 grams of diamond powder with nanoscale grains, 1.25 grams of silicon powder with a grain size of 1 micron to 20 microns, and 1 gram of carbon nanotube fiber; cylindrical tungsten carbide substrate ;

[0037] (2) Raw material processing and molding

[0038] Put the diamond powder and silicon powder in step (1) into a tungsten carbide vial with tungsten carbide balls after mixing. The vials were then placed in a CERTIPREP SPEX 8000-D high energy ball mill (Metuchen, NJ). The ball mill was located in a closed glove box purged with argon. The ball milling of the mixed powder is to ball mill all the silicon powder into amorphous amorphous silicon, which requires at least 10 hours of ball milling. The mixed powder after ball milling s...

Embodiment 2

[0045] In this embodiment, the preparation method of diamond-silicon carbide composite drill teeth for oil drilling is as follows:

[0046] (1) material preparation

[0047] 6 grams of diamond powder with a grain size of 5-10 microns, 1 gram of silicon powder with a grain size of 1-20 microns, and 0.75 grams of carbon nanotube fibers; cylindrical tungsten carbide substrate;

[0048] (2) Raw material processing and molding

[0049] Put the diamond powder and silicon powder in step (1) into a tungsten carbide vial with tungsten carbide balls after mixing. The vials were then placed in a CERTIPREP SPEX 8000-D high energy ball mill (Metuchen, NJ). The ball mill was located in a closed glove box purged with argon. The ball milling of the mixed powder is to ball mill all the silicon powder into amorphous amorphous silicon, which requires at least 10 hours of ball milling. The mixed powder after ball milling should be analyzed by X-ray diffraction to confirm whether the silicon p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com