Graphene composite B4C superhard material preparation method

A technology of graphene composite and superhard materials, which is applied in the field of preparing graphene composite B4C superhard materials by sintering with high temperature and high pressure equipment, which can solve the problems of harsh preparation conditions and difficult materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

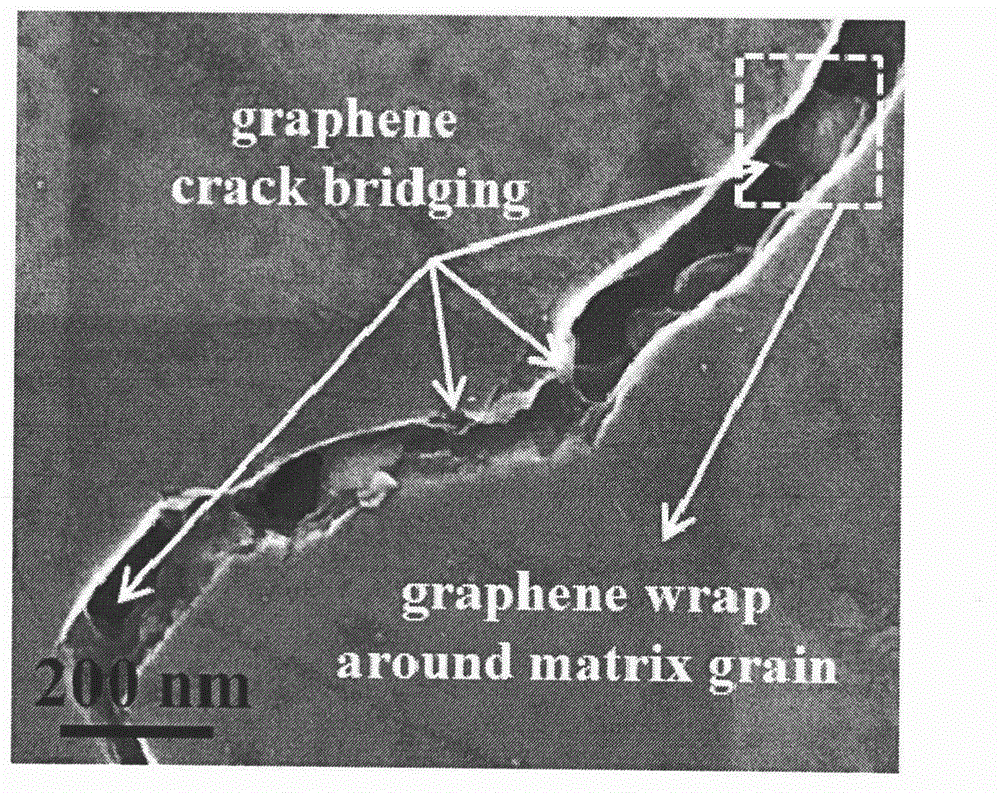

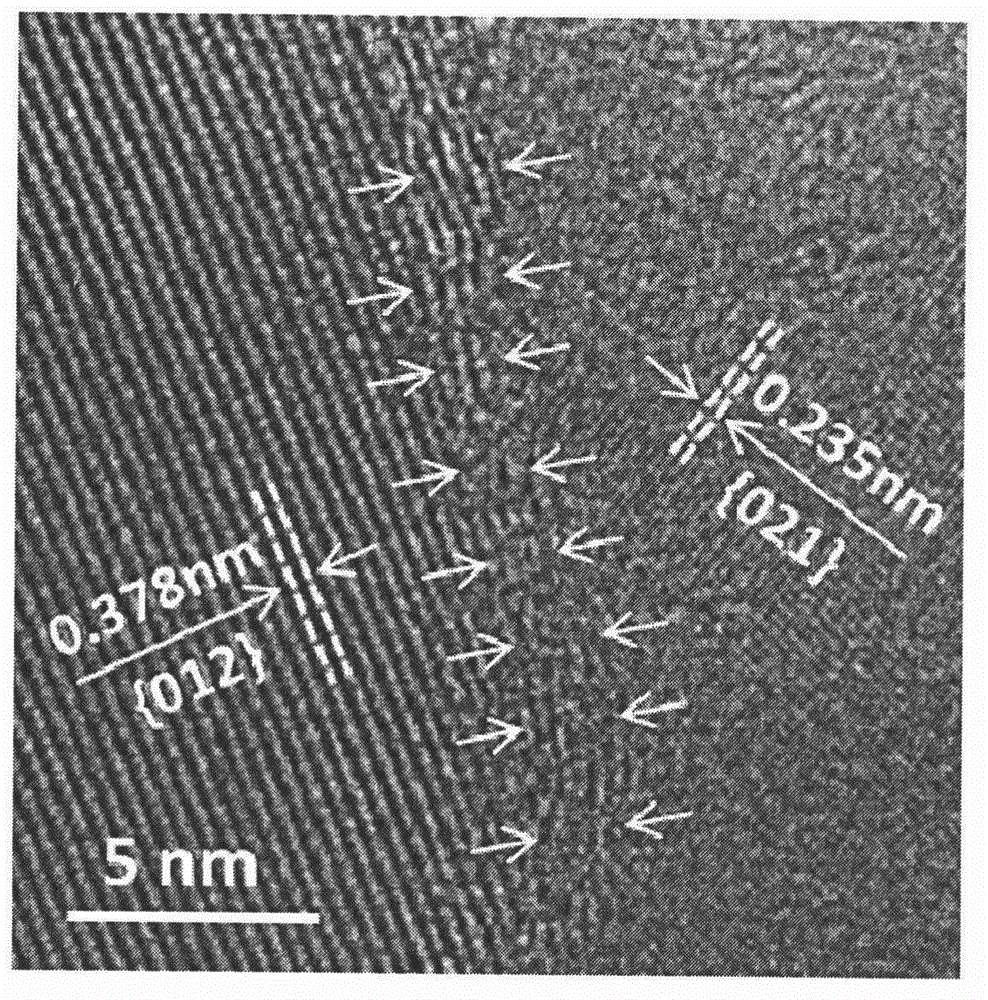

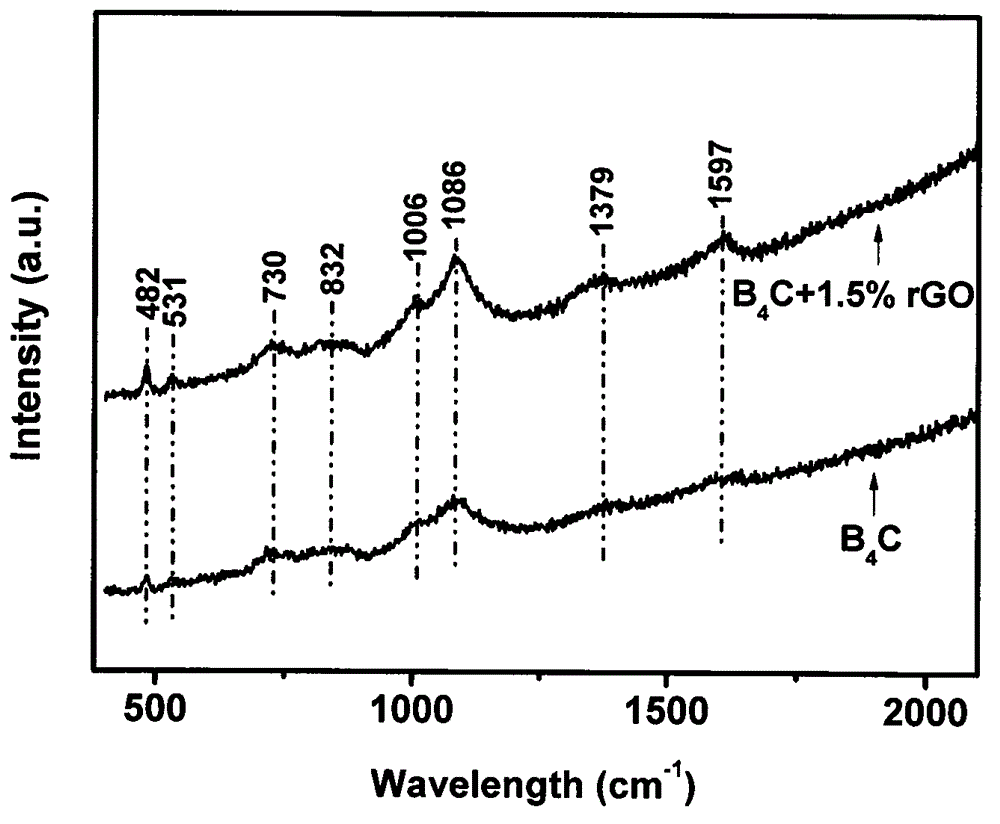

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 0.3g B 4 C mixed with graphene oxide with a volume fraction of 0.3%, added 20g of water, and ultrasonicated for 20min to obtain graphene oxide / B 4 C mixed solution; then stir with a magnetic stirrer for 3h to make it more uniform; finally the resulting graphene oxide / B 4 Mixed solution C was stirred and dried at 90° C. to obtain mixed powder.

[0022] (2) Compress the mixed powder into a cylindrical blank with a diameter of 8 mm and a height of 4 mm in a tablet press.

[0023] (3) Put the blank into a six-sided top press and sinter at 1400°C and 4.5GPa for 20min to obtain graphene composite B 4 C superhard material.

Embodiment 2

[0025] (1) Add 0.5g B 4 C mixed with graphene oxide with a volume fraction of 0.6%, added 30g of water, and ultrasonicated for 20min to obtain graphene oxide / B 4 C mixed solution, then stirred with a magnetic stirrer for 3h to make it more uniform, and finally the resulting graphene oxide / B 4 Mixed solution C was stirred and dried at 80° C. to obtain mixed powder.

[0026] (2) Compress the mixed powder into a cylindrical blank with a diameter of 8 mm and a height of 6 mm in a tablet press.

[0027] (3) Put the blank into a six-sided top press and sinter at 1350°C and 4.5GPa for 30min to obtain graphene composite B 4 C superhard material.

Embodiment 3

[0029] (1) Add 1g B 4 C is mixed with graphene oxide with a volume fraction of 0.9%, adding 25g of water, and ultrasonicating for 25min to obtain graphene oxide / B 4 C mixed solution, then stirred with a magnetic stirrer for 5h to make it more uniform, and finally the resulting graphene oxide / B 4 Mixed solution C was stirred and dried at 80° C. to obtain mixed powder.

[0030](2) Compress the mixed powder into a cylindrical blank with a diameter of 12 mm and a height of 5 mm in a tablet press.

[0031] (3) Put the blank into a six-sided top press and sinter at 1300°C and 5GPa for 25min to obtain graphene composite B 4 C superhard material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tenacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com