Toughened polylactic acid plastic and preparation method thereof

A technology of polylactic acid and toughening type, applied in the field of toughened polylactic acid plastics and its preparation, to achieve the effects of improving crystallinity, good nucleation induction, and good structural regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

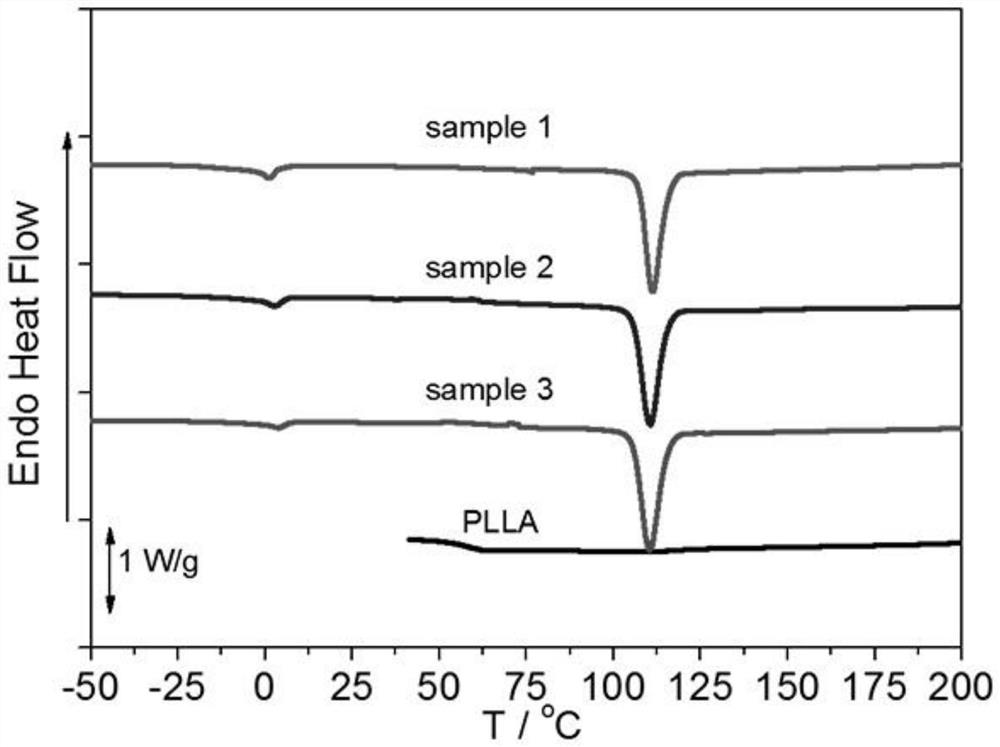

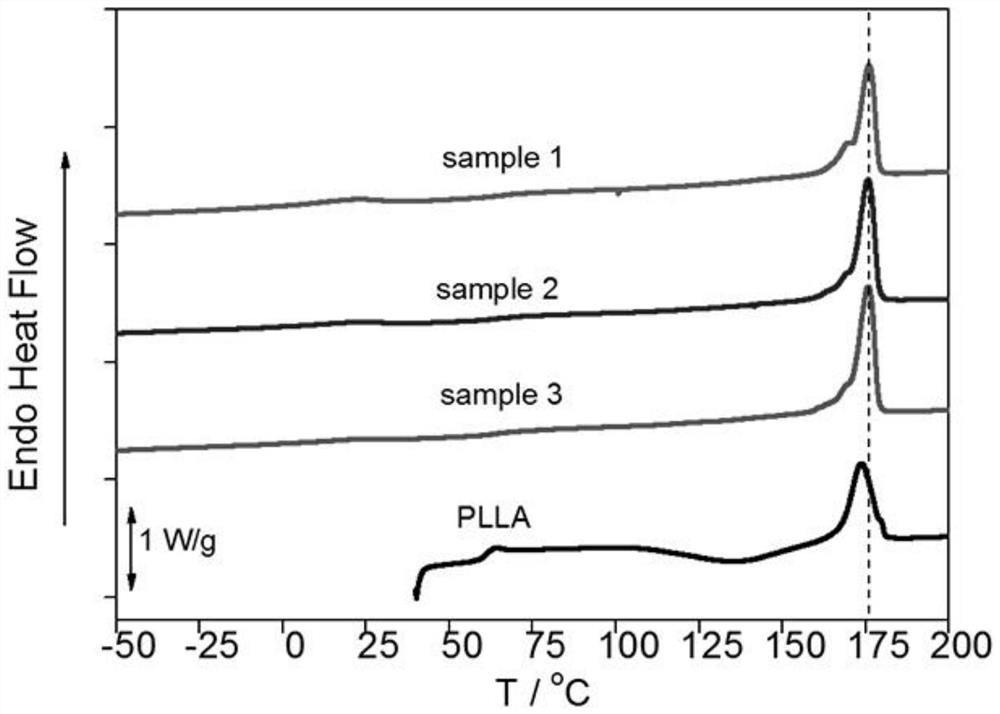

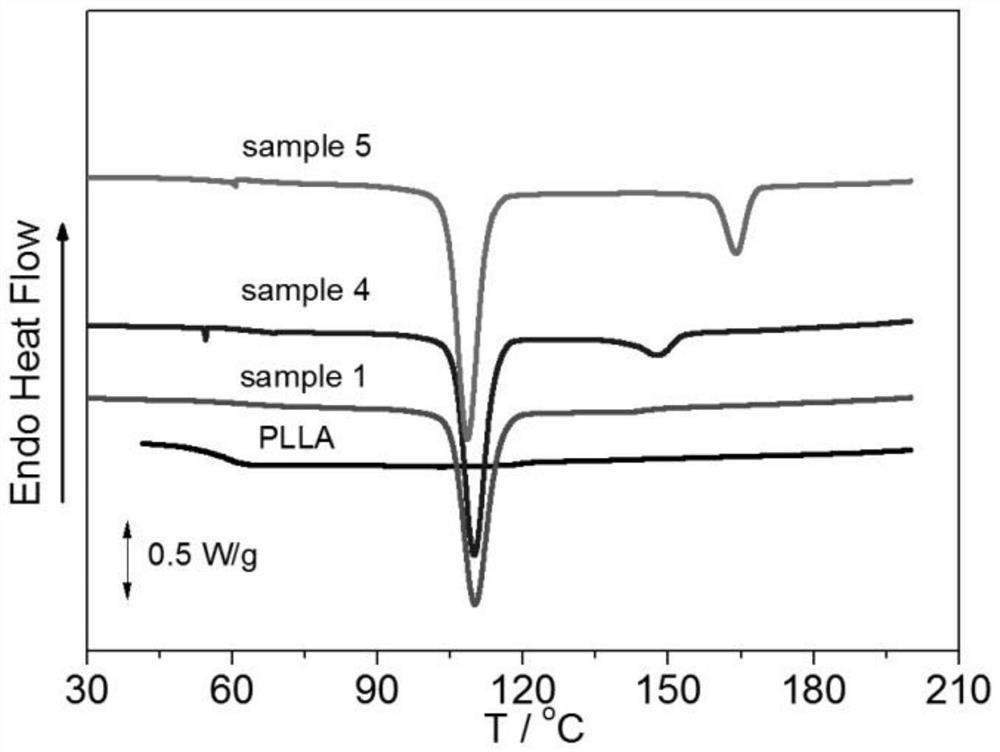

Embodiment 1

[0074] The present embodiment adopts raw materials and consumption as shown in Table 1, specifically:

[0075] The raw materials of the toughened polylactic acid plastics, in terms of percentage content, include: 85% of Plaque L130 L-polylactic acid (PLLA), 14.7% of polyamide thermoplastic elastomer (PAE) and 0.3% of antioxidant 1098;

[0076] Among them, the optical rotation of PLLA L130 L-polylactic acid (PLLA) is greater than 99%, Mw=155.0kg / mol, Mn=96kg / mol, PDI=1.62;

[0077] Polyamide thermoplastic elastomer (PAE) is a PA1012-PTMO copolymer composed of PA1012 hard segments and PTMO soft segments alternately. Elastomers with different modulus and strength can be prepared by the relative content of polyamide hard segments and polyether soft segments. For the specific preparation method, refer to the technical solution disclosed in the patent application 201610069156.4. The relative content of the PA1012 hard segment of the PAE elastomer (W PA ) is 25%.

[0078] The prepa...

Embodiment 2

[0083] The present embodiment adopts raw materials and consumption as shown in Table 1, specifically:

[0084] The raw materials of the toughened polylactic acid plastics, in percentage terms, include: 90% of Plaque L130 L-polylactic acid (PLLA), 9.7% of polyamide thermoplastic elastomer (PAE) and 0.3% of antioxidant 1098;

[0085] Among them, the optical rotation of PLLA L130 L-polylactic acid (PLLA) is greater than 99%, Mw=155.0kg / mol, Mn=96kg / mol, and PDI=1.62.

[0086]Polyamide thermoplastic elastomer (PAE) is PA1012-PTMO copolymer composed of PA1012 hard segment and PTMO soft segment alternately. Elastomers with different modulus and strength can be prepared by the relative content of polyamide hard segment and polyether soft segment. For the specific preparation method, refer to the technical solution disclosed in the patent application 201610069156.4. The relative content of PA1012 hard segment of PAE elastomer (W PA ) is 25%.

[0087] The preparation method of this ...

Embodiment 3

[0089] The present embodiment adopts raw materials and consumption as shown in Table 1, specifically:

[0090] The raw materials of the toughened polylactic acid plastics, in terms of percentage content, include: Plaque L130 L-polylactic acid (PLLA) 92.5%, polyamide thermoplastic elastomer (PAE) 7.2% and antioxidant 1098 0.3%;

[0091] Among them, the optical rotation of PLLA L130 L-polylactic acid (PLLA) is greater than 99%, Mw=155.0kg / mol, Mn=96kg / mol, and PDI=1.62.

[0092] Polyamide thermoplastic elastomer (PAE) is PA1012-PTMO copolymer composed of PA1012 hard segment and PTMO soft segment alternately. Elastomers with different modulus and strength can be prepared by the relative content of polyamide hard segment and polyether soft segment. For the specific preparation method, refer to the technical solution disclosed in the patent application 201610069156.4. The relative content of PA1012 hard segment of PAE elastomer (W PA ) is 25%.

[0093] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com