Patents

Literature

483results about How to "Raise the crystallization temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant aluminum-alloy conductor material for cables and manufacture method thereof

InactiveCN101948971AImprove creep resistanceHigh tensile strengthSingle bars/rods/wires/strips conductorsMetal/alloy conductorsRare-earth elementElectrical conductor

The invention relates to a heat-resistant aluminum-alloy conductor material for cables and a manufacture method thereof. The aluminum-alloy conductor material is prepared from the following components in percentage by weight: 0.3-1.0 percent of Fe, 0.01-0.3 percent of Cu, 0.01-0.3 percent of Mg, 0.01-0.3 percent of one, two or three of Mg, Ca, Mo and Sb and 0.05-0.8 percent of one or more rear-earth elements of Sc, Y and Er, not larger than 0.1 percent of Si, not larger than 0.15 percent of other impurities and the balance of Al. The aluminum-alloy conductor material has excellent conductivity, tensile performance, flexible performance and excellent heat resistance, can be used as insulated cable cores of wires and cables and is particularly suitable for overhead insulated conductor wire cores.

Owner:绩溪欣意圣厚源电缆有限公司

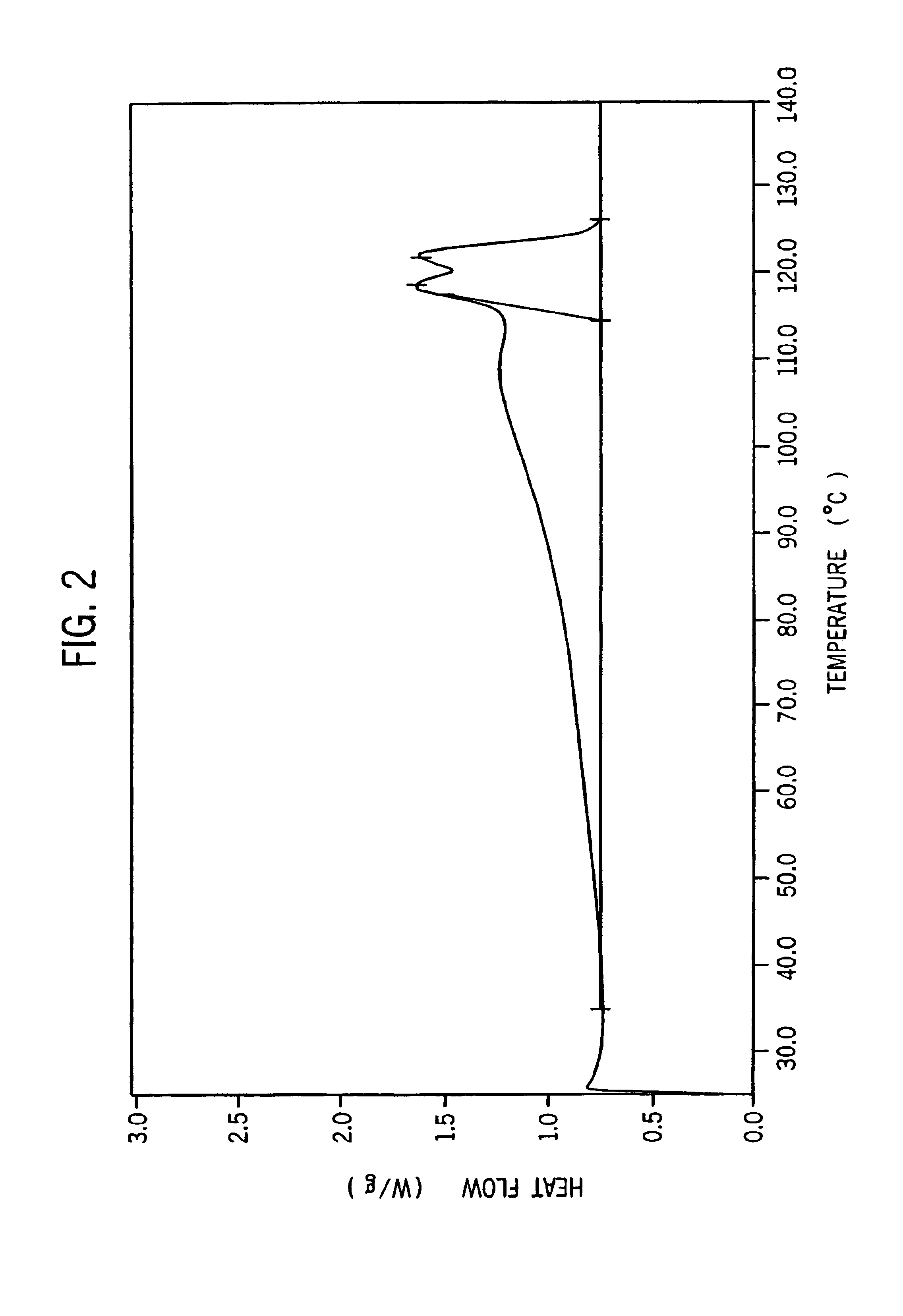

Ethylene interpolymer polymerizations

InactiveUS6916883B2Raise the crystallization temperatureImprove propertiesPolymer scienceCrystallization temperature

Owner:DOW GLOBAL TECH LLC

Doping modified phase change material and phase change storage unit containing same and preparation method thereof

ActiveCN101582485AFast phase changeLow melting pointElectrical apparatusDigital storageCrystallization temperaturePhase change

The invention relates to a doping modified phase change material and a phase change storage unit containing same and preparation thereof. The formula of the doping modified phase change material is (Sb2Se3)100-xYx, wherein, x is the atom percentage of an element and is more than 0 and less than or equal to 20, and Y is a doped element and is any one of Ni, Cr, Bi, As, Ga, In, Ge, Si, Sn, Ag, Al, C, N and O. The doping modified (Sb2Se3)100-xYx storage material not only remains the advantages of the fast phase change speed and the low melting point of Sb2Se3 storage material, but also increases crystallization temperature, thus overcoming the disadvantage of poor data retentivity of the Sb2Se3 storage material. The phase change storage containing the (Sb2Se3)100-xYx storage material has the advantages of high speed, low power consumption and favorable data retentivity and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

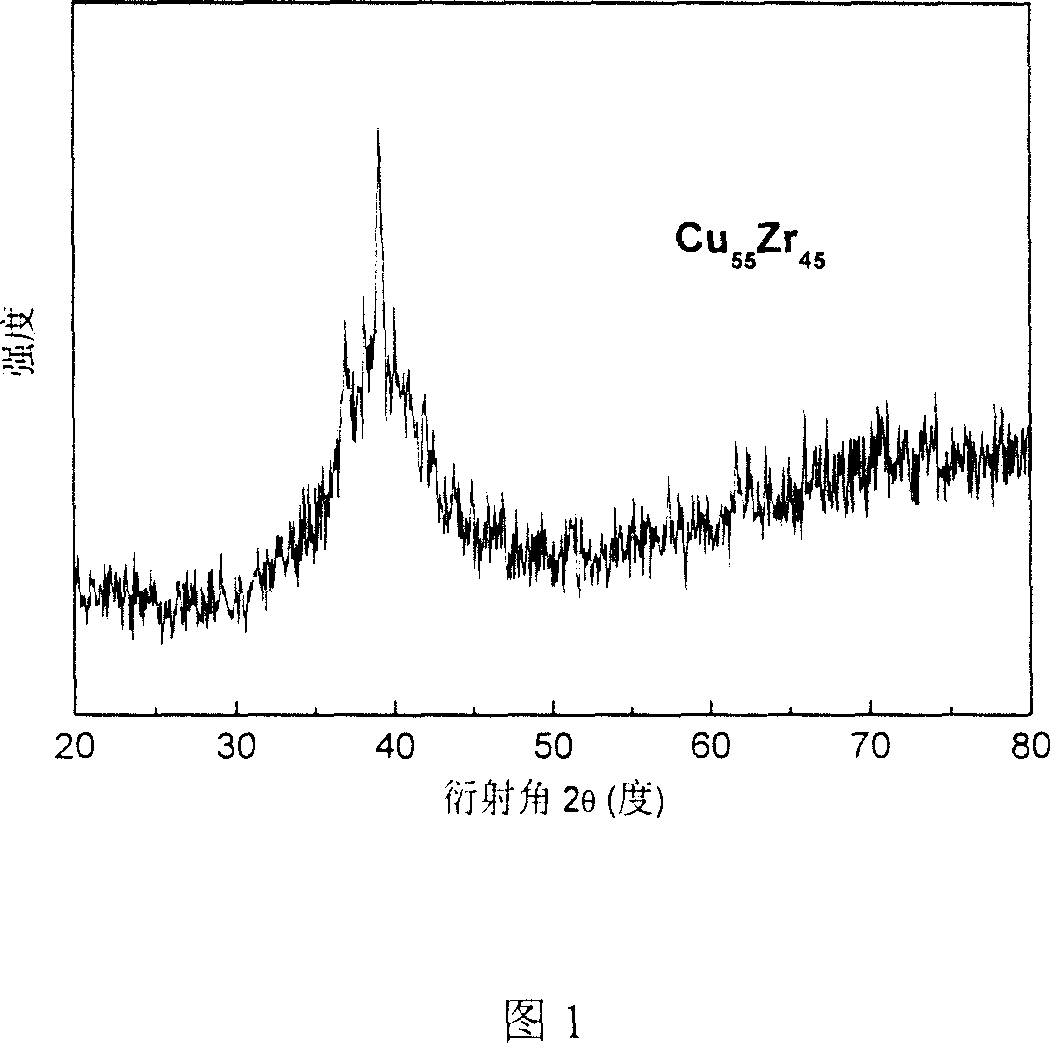

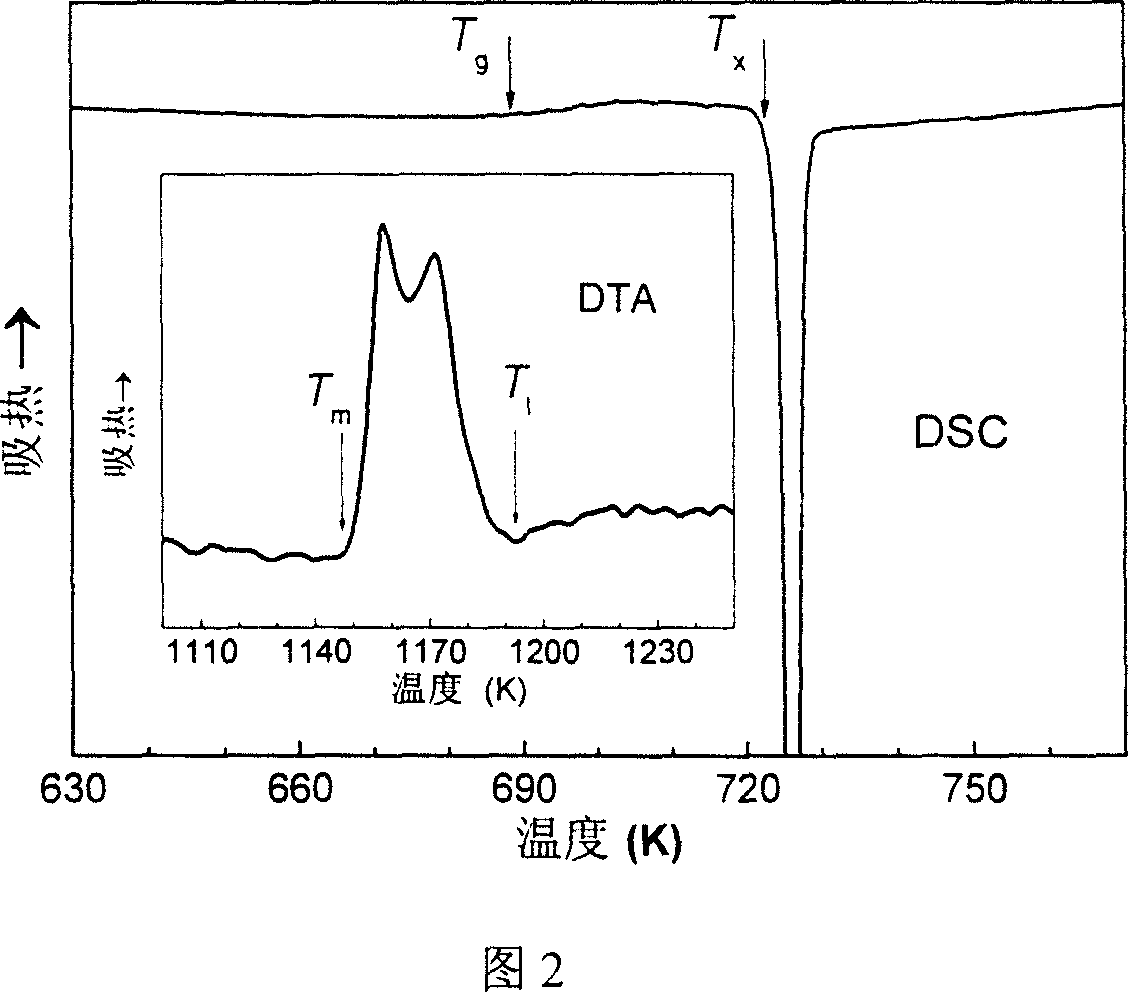

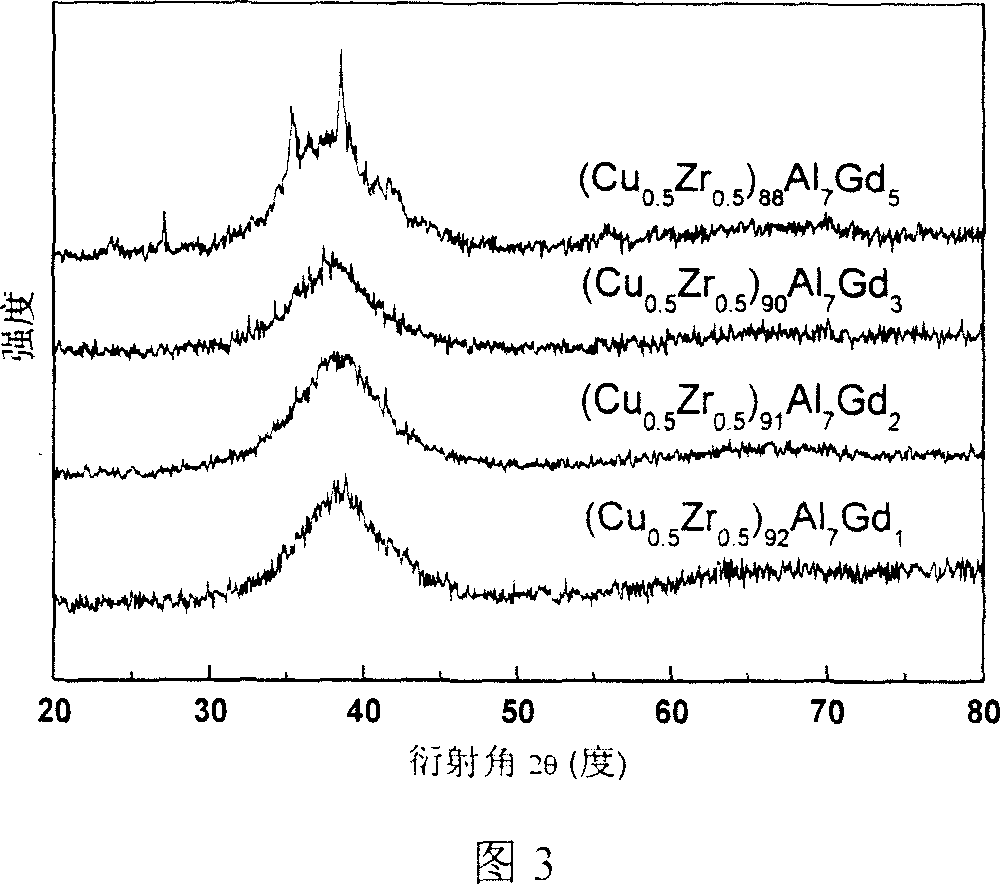

Copper-zirconium based amorphous alloy, and preparation method

InactiveCN1958831AImprove mechanical propertiesHigh plastic deformationMolten metal pouring equipmentsElectric arc furnaceAmorphous metal

This invention relates to a Cu-Zr-based amorphous alloy, whose general formula is (Cu1-xZrx)aAlbMc, where, x is 0.40-0.60; a is 80-100; b is 0-14; c is 0-20; a + b + c is 100; M is Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Er, Ti, Ag, Ga, Hf, Ta, Nb, Ni, Co or Fe. The preparation method comprises: (1) mixing Cu, Zr, Al and M according to the ratio in Ti-adsorbed Ar atmosphere in an arc furnace, smelting and cooling to obtain mother alloy ingot; (2) re-melting the mother alloy ingot in air, and casting into a water-cooling metal mold to obtain the Cu-Zr-based amorphous alloy. The alloy has high glass formation ability, high crystallization inhibition and large size at a very low cooling speed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Polypropylene nucleator and its prepn process

InactiveCN1432594AHigh transparencyRaise the crystallization temperatureOrganic phosphatesLithium compound

The present invention is polypropylene nucleator and its preparation process with alkyl metal phosphate as material. The nucleator is prepared with organic phosphate and its derivative, superfine inorganic oxide, aluminium-lithium compound and high level aliphatic salt as material. The organic phosphate includes alkyl methylene di(2,4-bialkyl phenoxy) phosphate and di[alkyl methylene di(2,4-bialkyl phenoxy)] phosphate. The preparation process includes mixing, grinding and sieving and obtains polypropylene nucleator to 0.5-100 micron diameter.

Owner:YANGZI PETROCHEM

Chalcogenide Compound Target, Method of Forming the Chalcogenide Compound Target and Method for Manufacturing a Phase-Change Memory Device

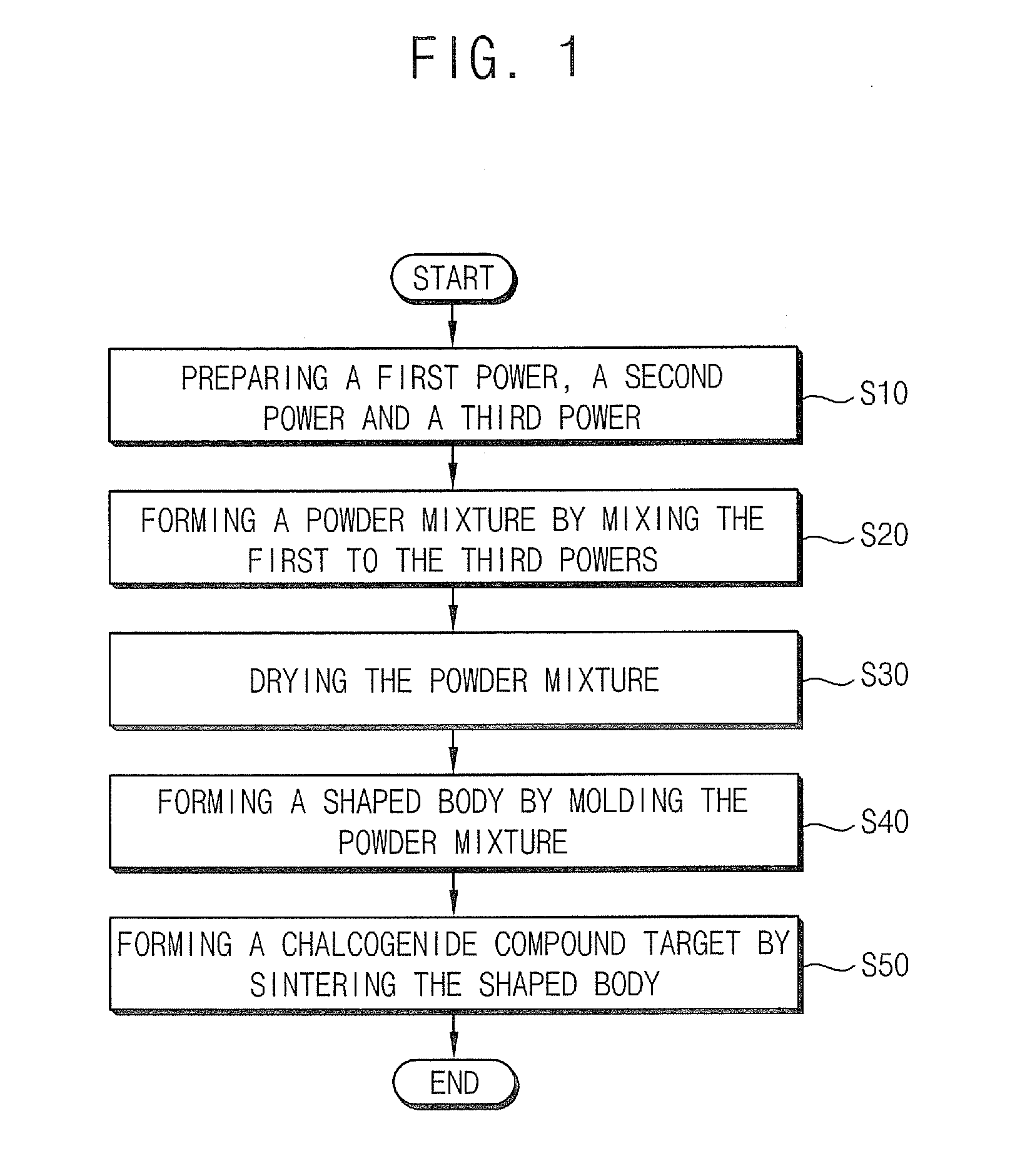

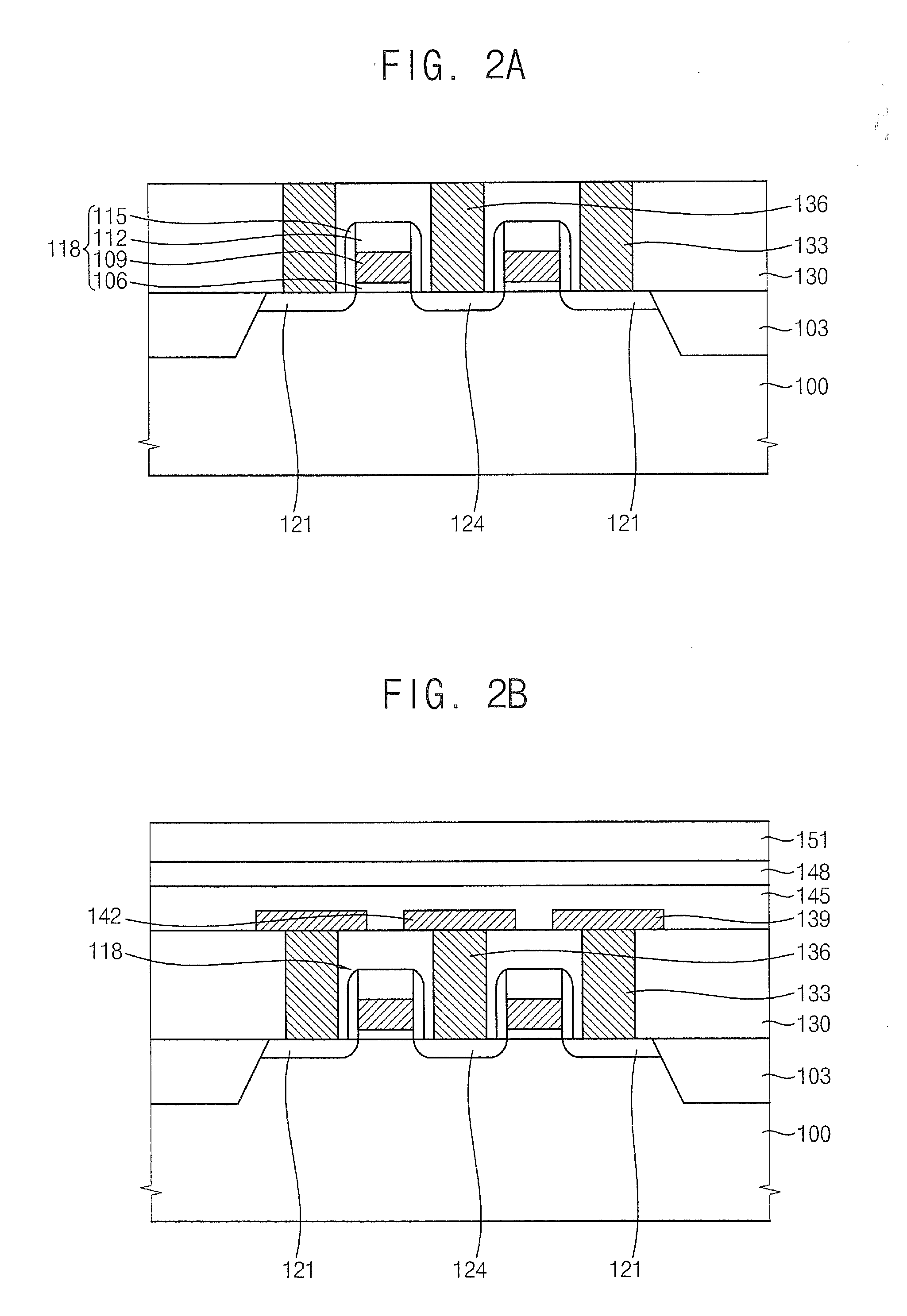

ActiveUS20080075844A1Raise the crystallization temperatureIncrease resistanceNitrogen-metal/silicon/boron binary compoundsSolid-state devicesPhase-change memoryPowder mixture

In a method of forming a chalcogenide compound target, a first powder including germanium carbide or germanium is prepared, and a second powder including antimony carbide or antimony is prepared. A third powder including tellurium carbide or tellurium is prepared. A powder mixture is formed by mixing the first to the third powders. After a shaped is formed body by molding the powder mixture. The chalcogenide compound target is obtained by sintering the powder mixture. The chalcogenide compound target may include a chalcogenide compound that contains carbon and metal, or carbon, metal and nitrogen considering contents of carbon, metal and nitrogen, so that a phase-change material layer formed using the chalcogenide compound target may stable phase transition, enhanced crystallized temperature and increased resistance. A phase-change memory device including the phase-change material layer may have reduced set resistance and driving current while improving durability and sensing margin.

Owner:SAMSUNG ELECTRONICS CO LTD

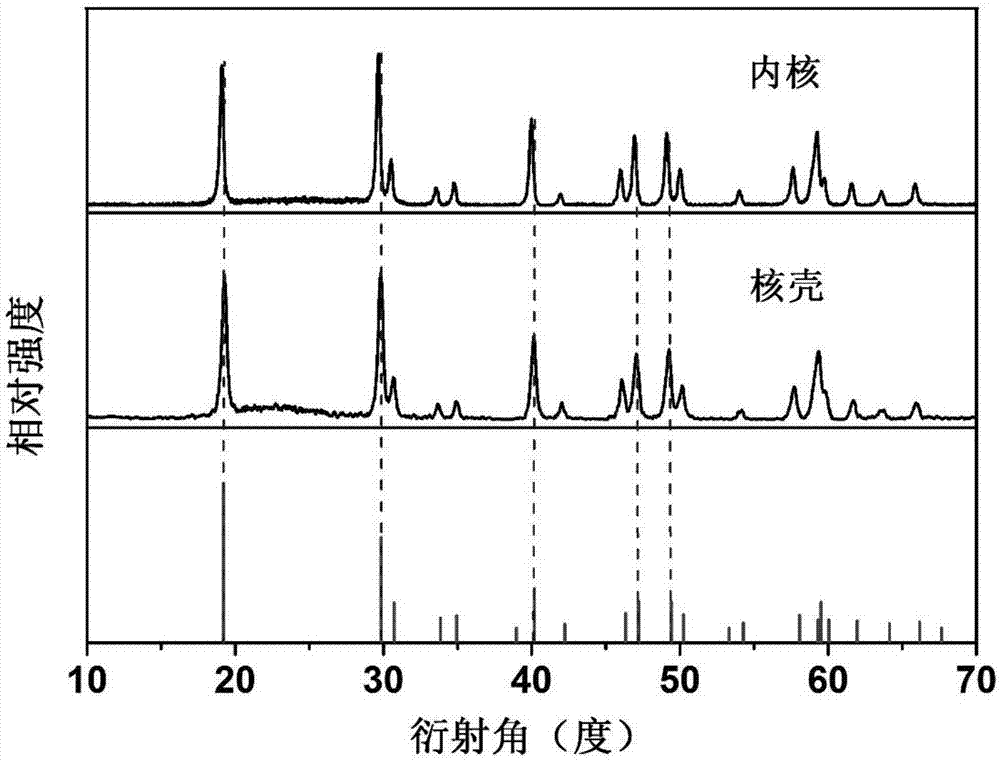

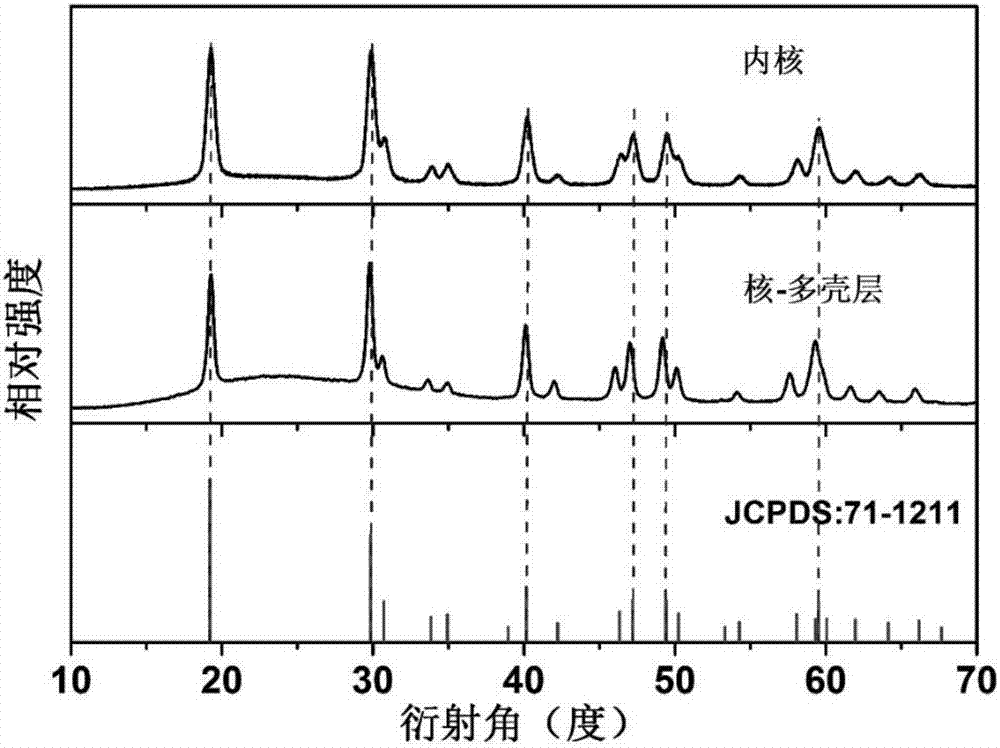

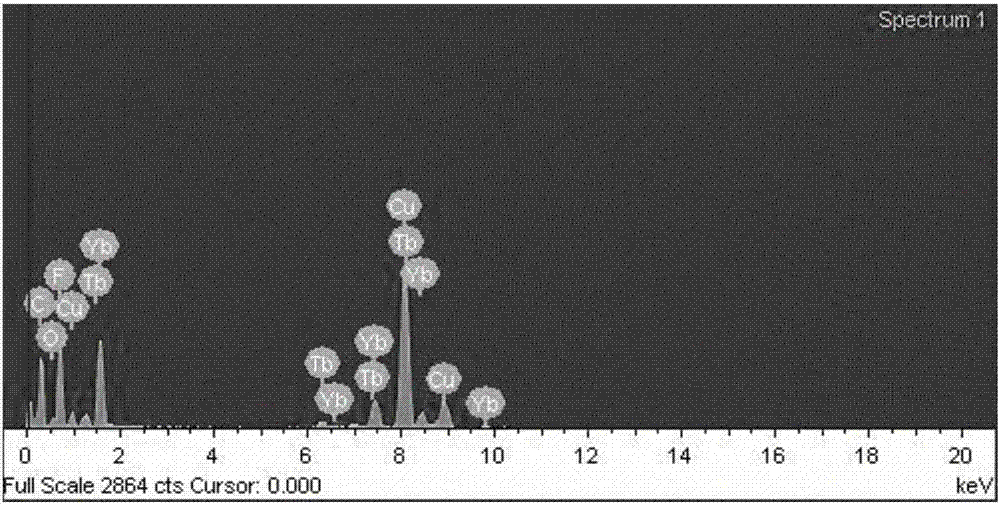

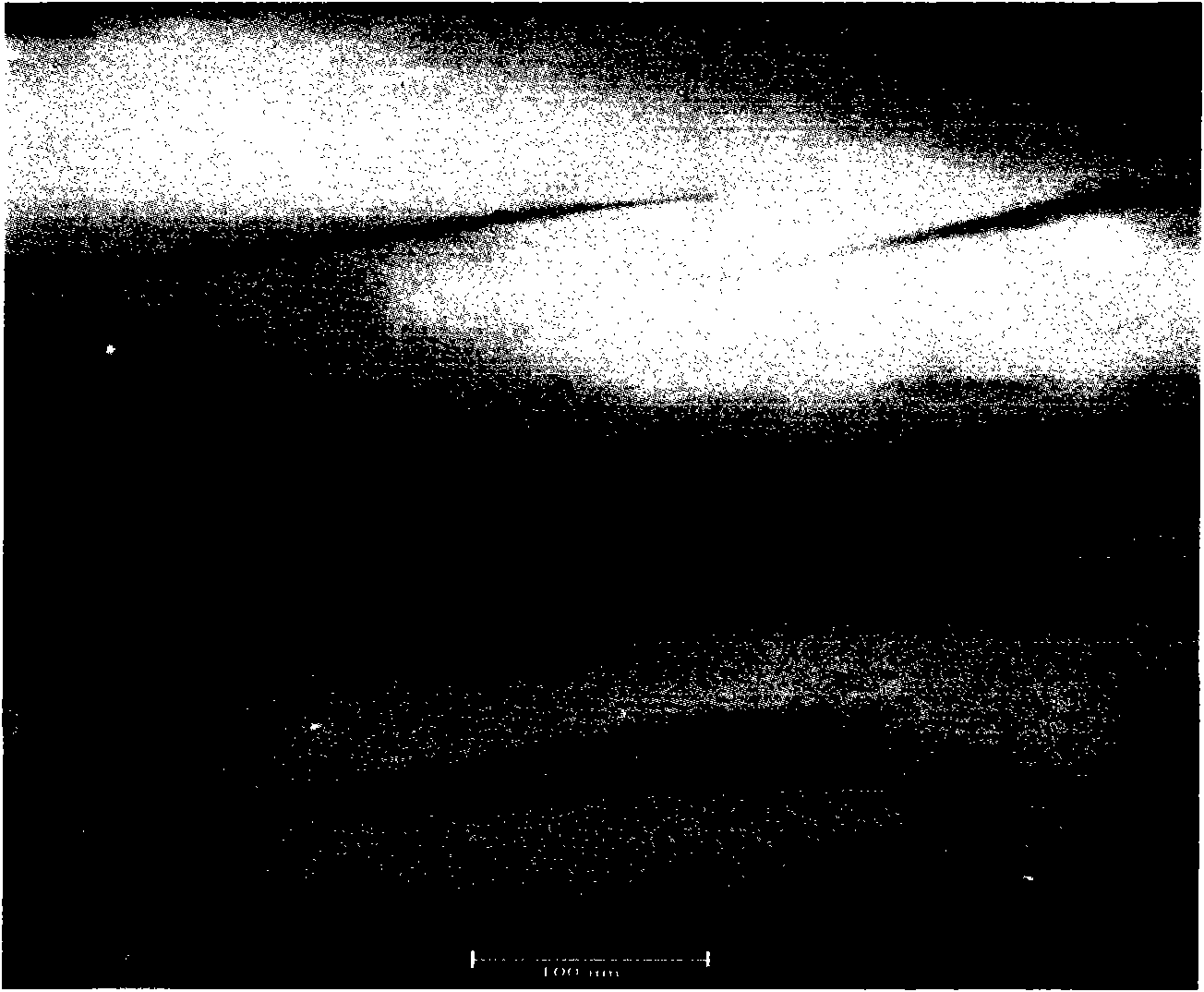

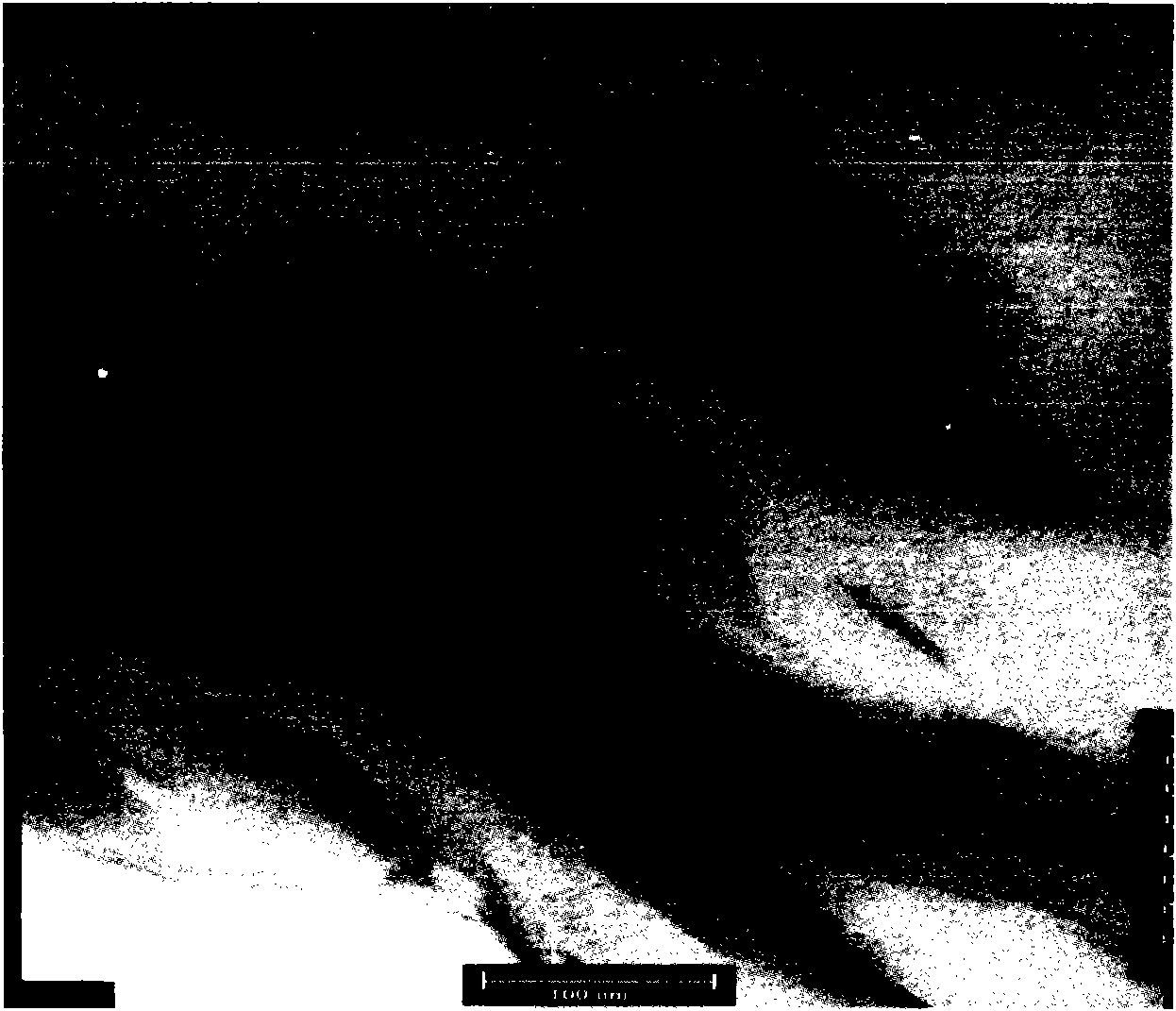

Rare earth doped lithium yttrium fluoride nanometer material and preparation method and application thereof

InactiveCN107033905AGood monodispersityImprove luminous efficiencyNanoopticsLuminescent compositionsBiological imagingRare earth

The invention relates to a rare earth doped lithium yttrium fluoride nanometer material and a preparation method and application thereof. A modified high-temperature coprecipitation method is adopted to synthesize the rare earth doped lithium yttrium fluoride nanometer material with upper conversion / lower transfer luminescence, at the same time, epitaxial growth is conducted on the basis of a core, a mono-layer core-shell structure nanometer material which is uniformly covered can be obtained, and a lithium yttrium fluoride based multi-layer core-shell nanometer material is further prepared. The three prepared and obtained materials are good in monodispersity, uniform in particle size and excellent in luminescent property, after acid pickling treatment, water-soluble nanometer particles can be used for biological detection and biological imaging.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Polypropylene/ organic montmorillonite nano composite material and preparation method thereof

ActiveCN101880421AImprove melt strengthRaise the crystallization temperatureMontmorilloniteCrystallization temperature

The invention discloses a polypropylene / organic montmorillonite nano composite material which is prepared by the components in part by weight: 80-100 parts of polypropylene, 1-15 parts of organic montmorillonite, 0.02-0.10 part of organic peroxide initiator, 2.0-5.0 parts of cross-linking agent and 5-15 parts of compatilizer. The invention also discloses a preparation method of the polypropylene / organic montmorillonite nano composite material. The polypropylene / organic montmorillonite nano composite material has higher crystallization temperature, toughness and modulus as well as better strength, realizes low cost and high performance of polypropylene foam material, and improves the application competitiveness of polypropylene plastic.

Owner:CHINA PETROLEUM & CHEM CORP

Polyformaldehyde composition and preparation method thereof

The invention discloses a polyformaldehyde composition and a preparation method thereof. The polyformaldehyde composition contains by part of weight: 100 parts of acetal resins, 0.01-2 parts of oxidation inhibitors, 0.01-2 parts of formaldehyde catching agents, 0.01-2 parts of formic acid catching agents and 0.01-5 parts of crosslinking acetal resins. Compared with the prior art, the crosslinking acetal resins serve as nucleating agents and are obvious in nucleating effects, and a great number of crystal nucleuses are formed before crystallization of the acetal resins, so that crystallization of the acetal resin is induced, the number of the crystal nucleuses is improved, crystallization degree and temperature are improved, sphaerocrystal dimension is lowered, and accordingly crystallization structure of the acetal resin is improved. Further, due to the fact that the adding amount of the crosslinking acetal resins is small, and bad influence on mechanical property, thermal performance and surface morphology of the polyformaldehyde composition is avoided. Experiment results prove that the sphaerocrystal dimension of the polyformaldehyde composition is about 40 mu m, and the polyformaldehyde composition has good crystalline structure and good mechanical property.

Owner:YUNNAN YUNTIANHUA

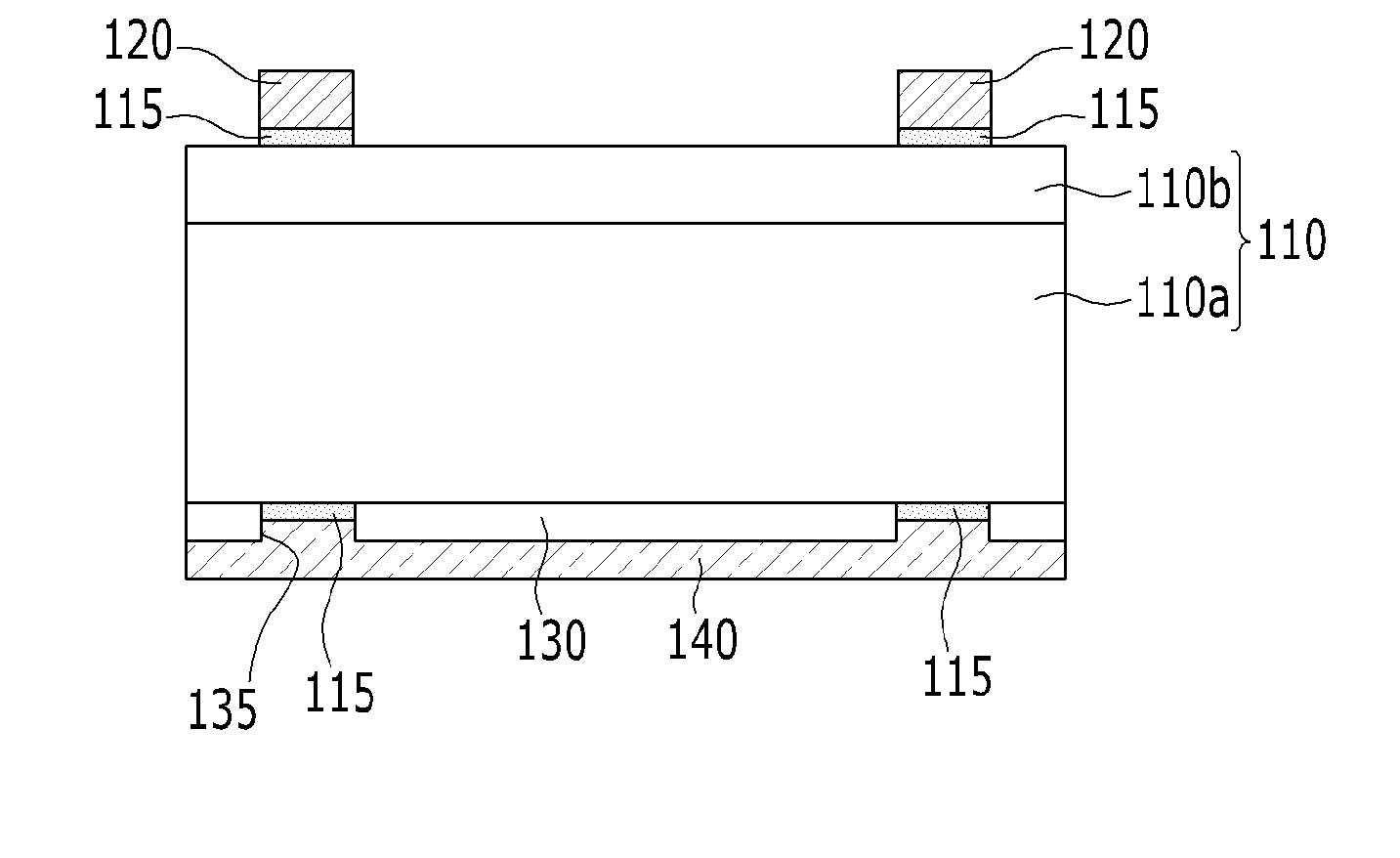

Conductive paste and electronic device and solar cell including an electrode formed using the conductive paste

InactiveUS20120037216A1Improve conductivityLower glass transition temperatureConductive materialNon-conductive material with dispersed conductive materialConductive pasteFree energies

A conductive paste including a conductive powder, a metallic glass, and an organic vehicle, wherein the metallic glass includes an alloy of at least two metals selected from a first metal having a low resistivity, a second metal which forms a solid solution with the conductive powder, a third metal which extends a supercooled liquid region of the metallic glass, or a fourth metal having a higher standard free energy of formation of oxide than a standard free energy of formation of oxide of the first, the second, and third metals.

Owner:SAMSUNG ELECTRONICS CO LTD

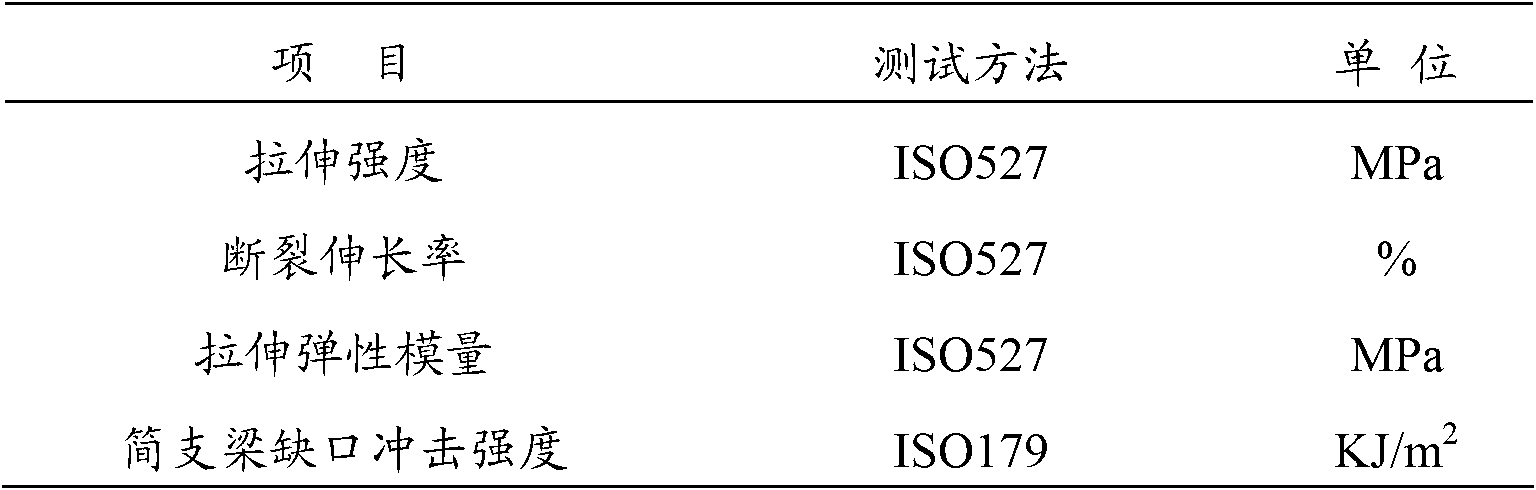

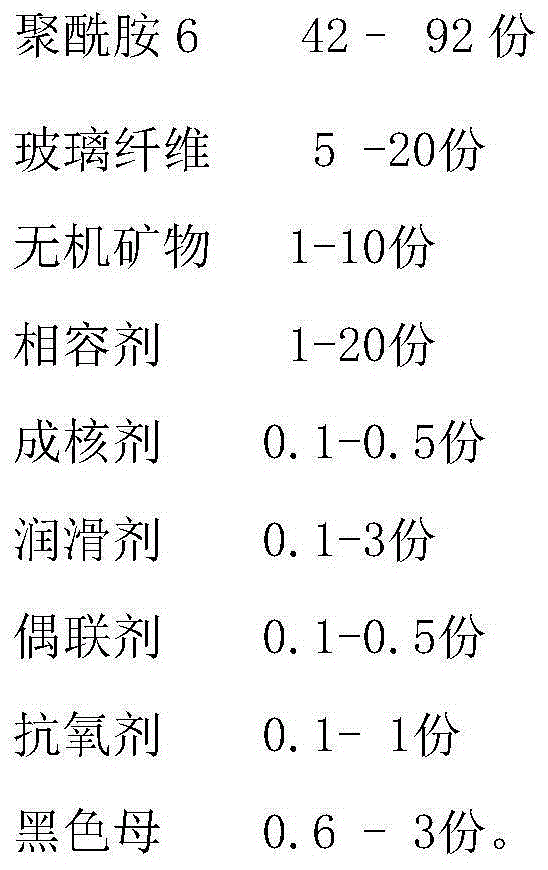

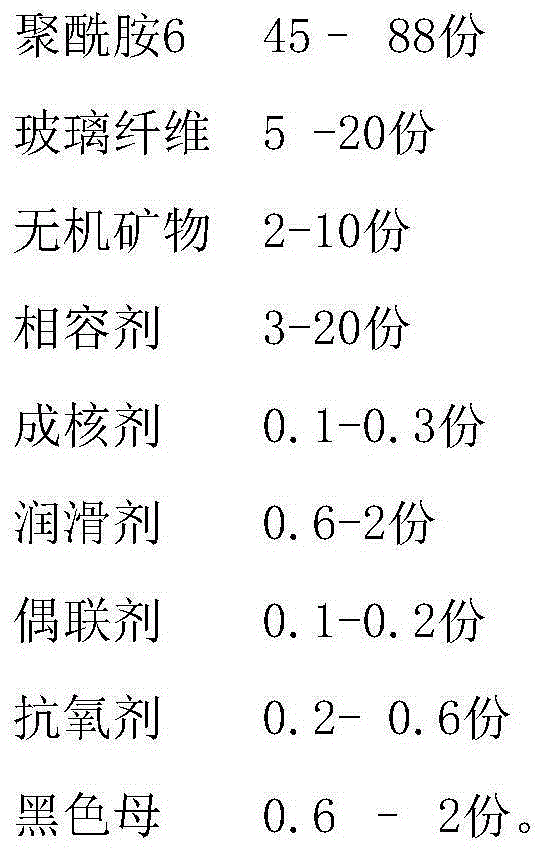

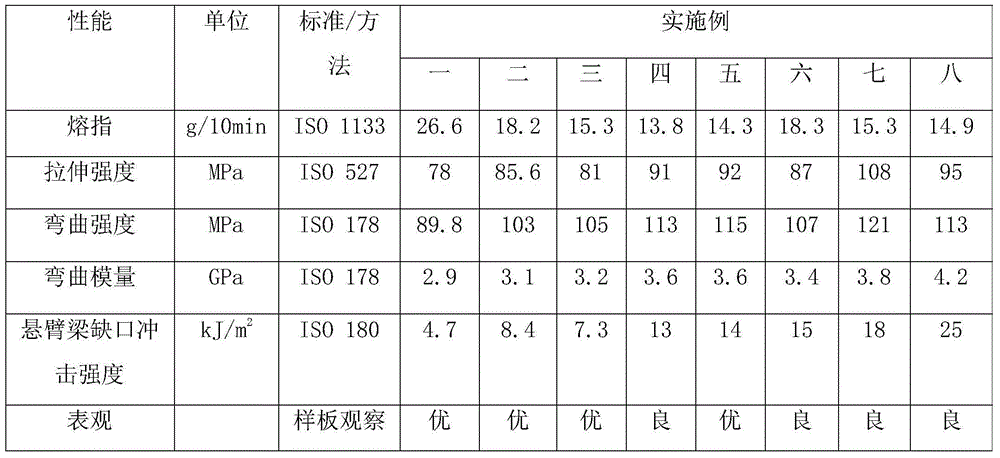

Polyamide 6 composite and preparation method thereof

The invention relates to a composite and a preparation method thereof, in particular to a polyamide 6 composite and a preparation method thereof. Non-alkali chopped fibers are selected to serve as a reinforcing agent of the pyamide 6 composite, and compatilizer is added to improve fatigue durability and low-temperature brittleness of glass fiber reinforcing materials. Coupling reagents, lubricating agents and inorganic minerals are added to improve the combination of the polyamide 6 composite and the glass fibers, and dispersion of the glass fibers in the polyamide 6 composite is enhanced, so that the glass fibers are not prone to being exposed outside the surface, and a good surface is achieved. The polyamide 6 composite and the eparation method thereof have the advantages that the polyamide 6 composite can be used for injection molding of automobile doors and window frame decoration strips.

Owner:NANJING JULONG SCI&TECH CO LTD

Lightweight high-elasticity EVA shoe sole and preparation method thereof

ActiveCN104804297ARaise the crystallization temperatureIncrease temperatureSolesCross-linkPolyolefin

The invention relates to the technical field of high-molecular compounds, and provides a lightweight high-elasticity EVA shoe sole and a preparation method thereof. The lightweight high-elasticity EVA shoe sole is prepared by the steps of performing internal mixing, open milling and pelleting on the materials of EVA, polyolefin segmented copolymer, ethylene propylene diene monomer, chlorinated polyethylene, a foaming agent, a cross-linking agent, zinc stearate, stearic acid, an abrasion-resistant agent and talcum powder, so as to obtain lightweight high-elasticity pellets, and performing injection molding at one time to obtain the lightweight high-elasticity EVA shoe sole. The lightweight high-elasticity EVA shoe sole provided by the invention has the characteristics that the resilience is high, the dimensional stability is high, the compression deformation rate is low, the surface is not easy to wrinkle, the weight is light, the comprehensive performance is good, the product percent of pass is high, and in addition, the EVA shoe sole is lighter in weight and is particularly suitable for production of top-grade EVA sport shoes and casual shoes.

Owner:MAOTAI FUJIAN SOLES CO LTD

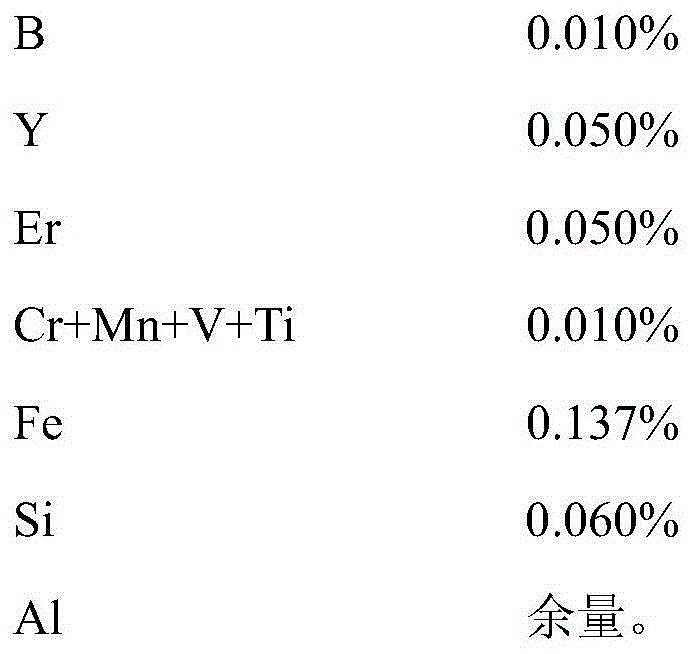

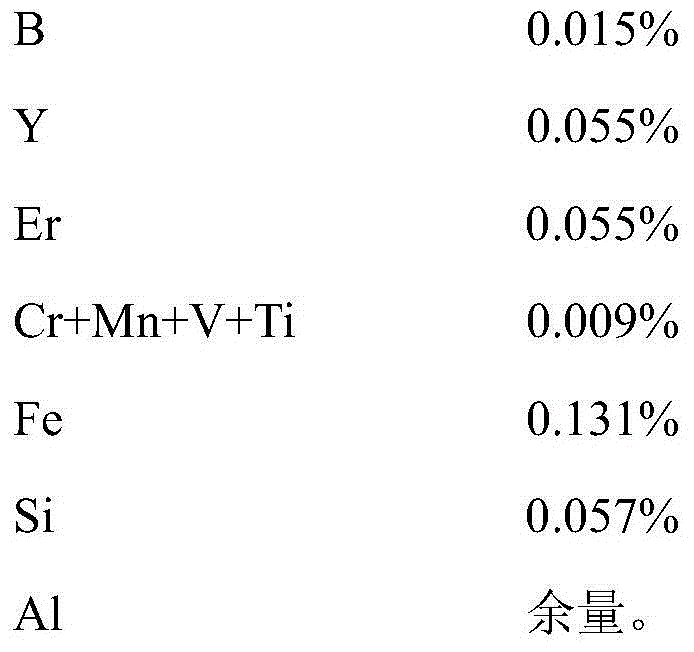

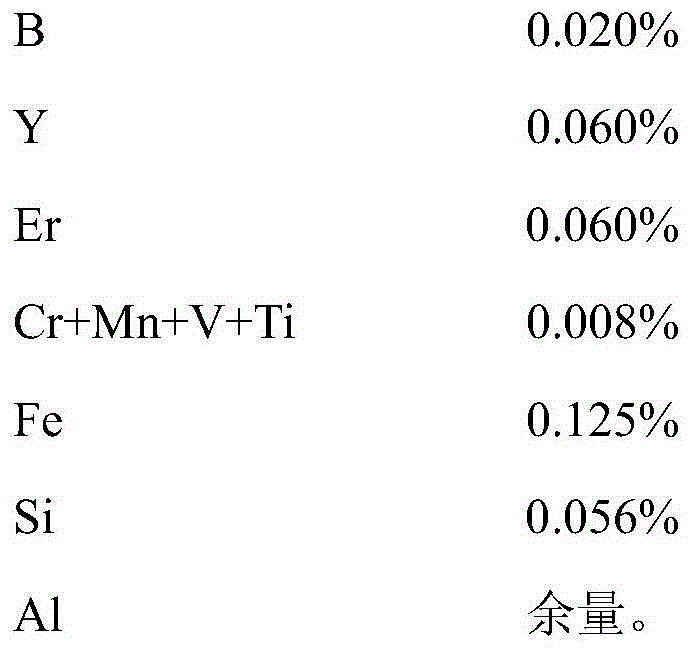

High-conductivity rare earth duralumin monofilament material for overhead conductors

ActiveCN104946936AImprove conductivityImprove mechanical propertiesMetal/alloy conductorsRare earthDuralumin

The invention discloses a high-conductivity rare earth duralumin monofilament material for overhead conductors. The high-conductivity rare earth duralumin monofilament material comprises 0.002-0.05% of B, 0.02-0.20% of Er, 0.02-0.20% of Y, 0-0.060% of Si, 0-0.140% of Fe, 0.01% or less of V+Ti+Cr+Mn, and the balance of Al and inevitable impurity elements. The conductivity of the duralumin monofilament material prepared through adding a tiny amount of alloyage elements and optimally controlling the components of alloy is greater than 63.0% IACS, the tensile strength is greater than 165MPa, and the normal temperature mechanical properties and electrical performances can meet high-conductivity duralumin conductor requirements, so the high-conductivity rare earth duralumin monofilament material can be used in the field of overhead conductors in the electric power industry in order to meet energy saving and consumption reduction demands.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +5

Deposition method for a transition-metal-containing dielectric

InactiveUS7666752B2Inhibition formationRaise the crystallization temperatureTransistorLiquid surface applicatorsDielectricWater vapor

The present invention relates to a method for depositing a dielectric material comprising a transition metal compound. After providing a substrate, a first pre-cursor comprising a transition metal compound and a second pre-cursor predominantly comprising at least one of water vapour, ammonia and hydrazine are successively applied on the substrate for forming a first layer of transition metal containing material. In a next step the first pre-cursor and a third pre-cursor comprising at least one of ozone and oxygen are successively applied on the first layer for forming a second layer of the transition metal containing material.

Owner:POLARIS INNOVATIONS LTD

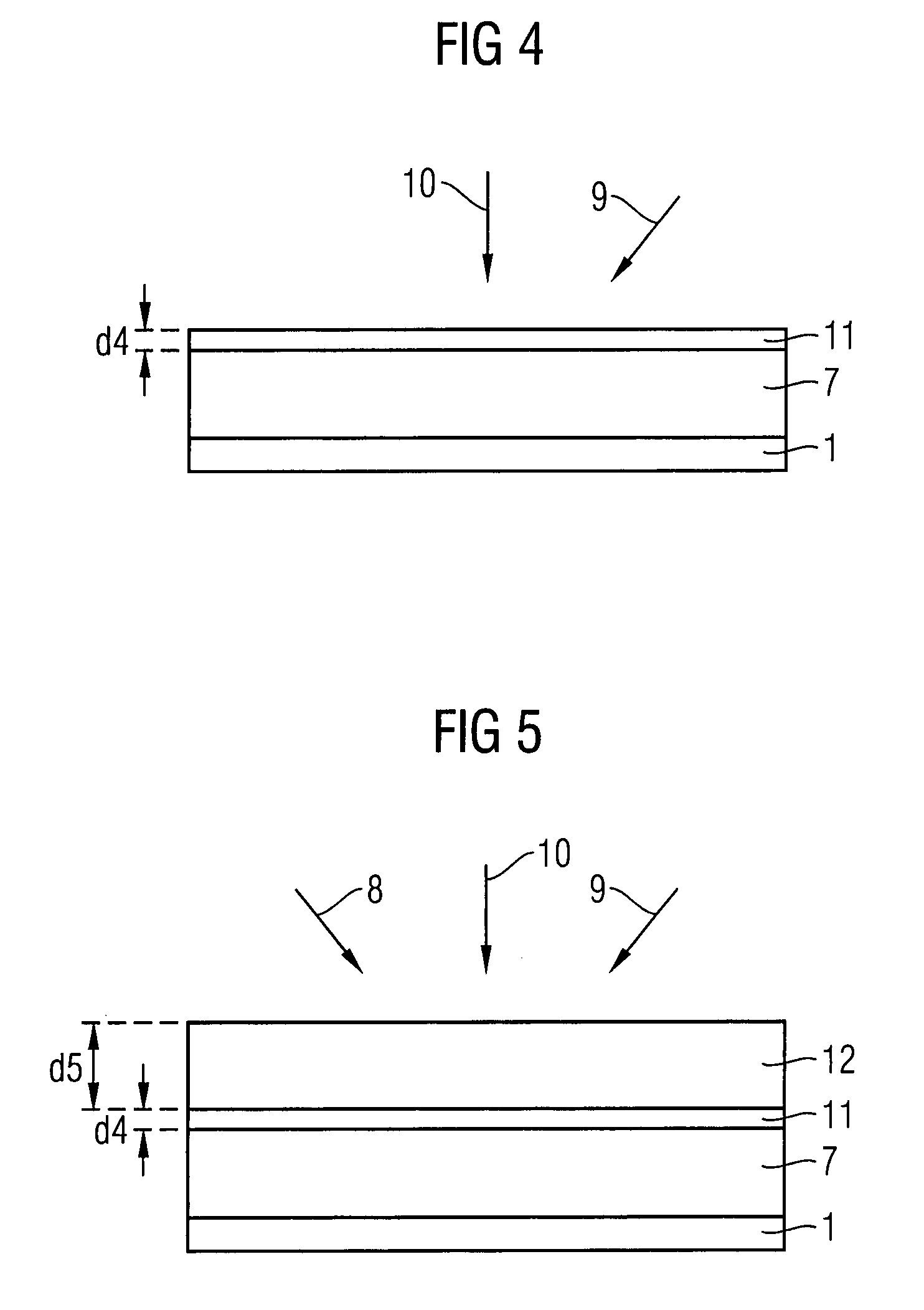

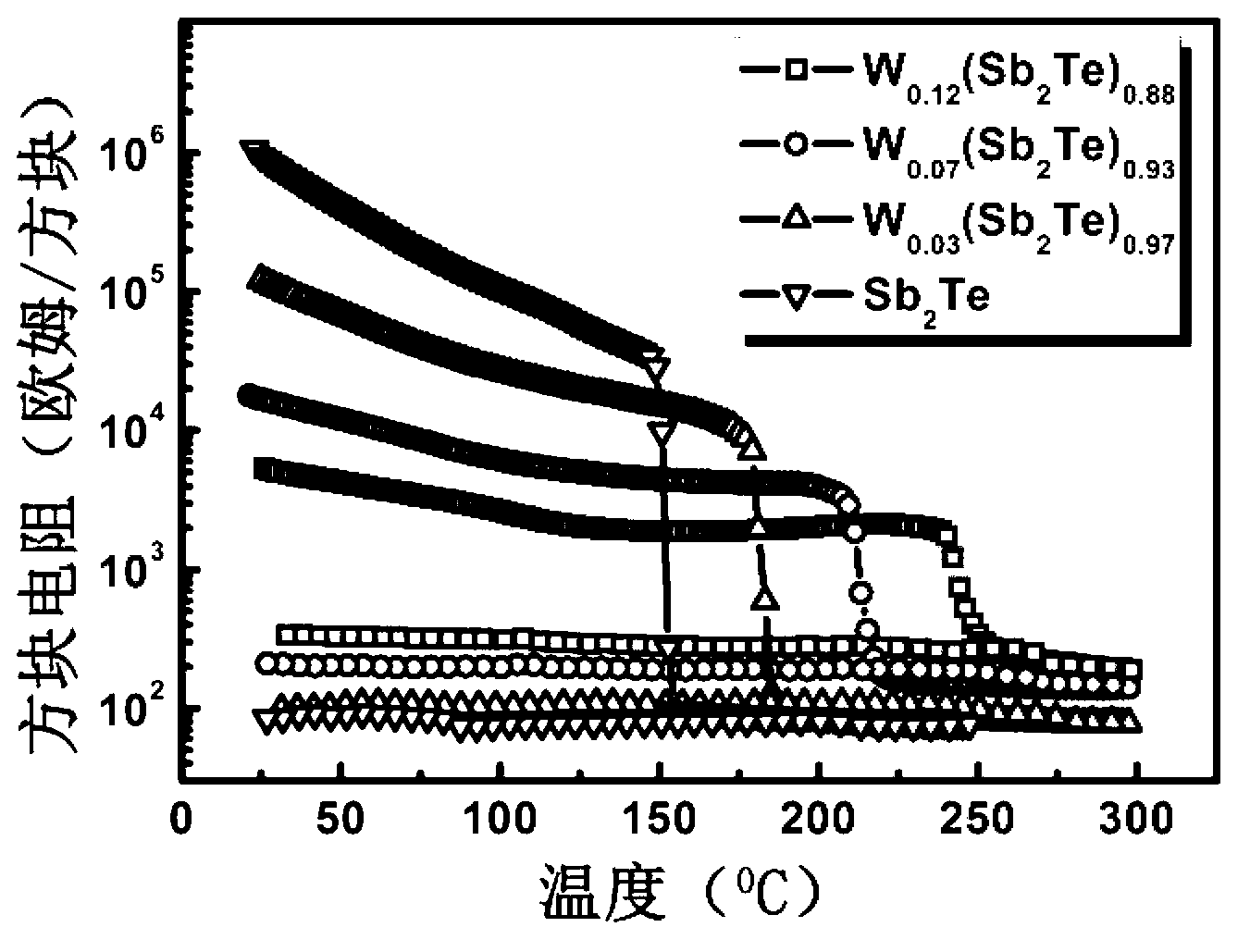

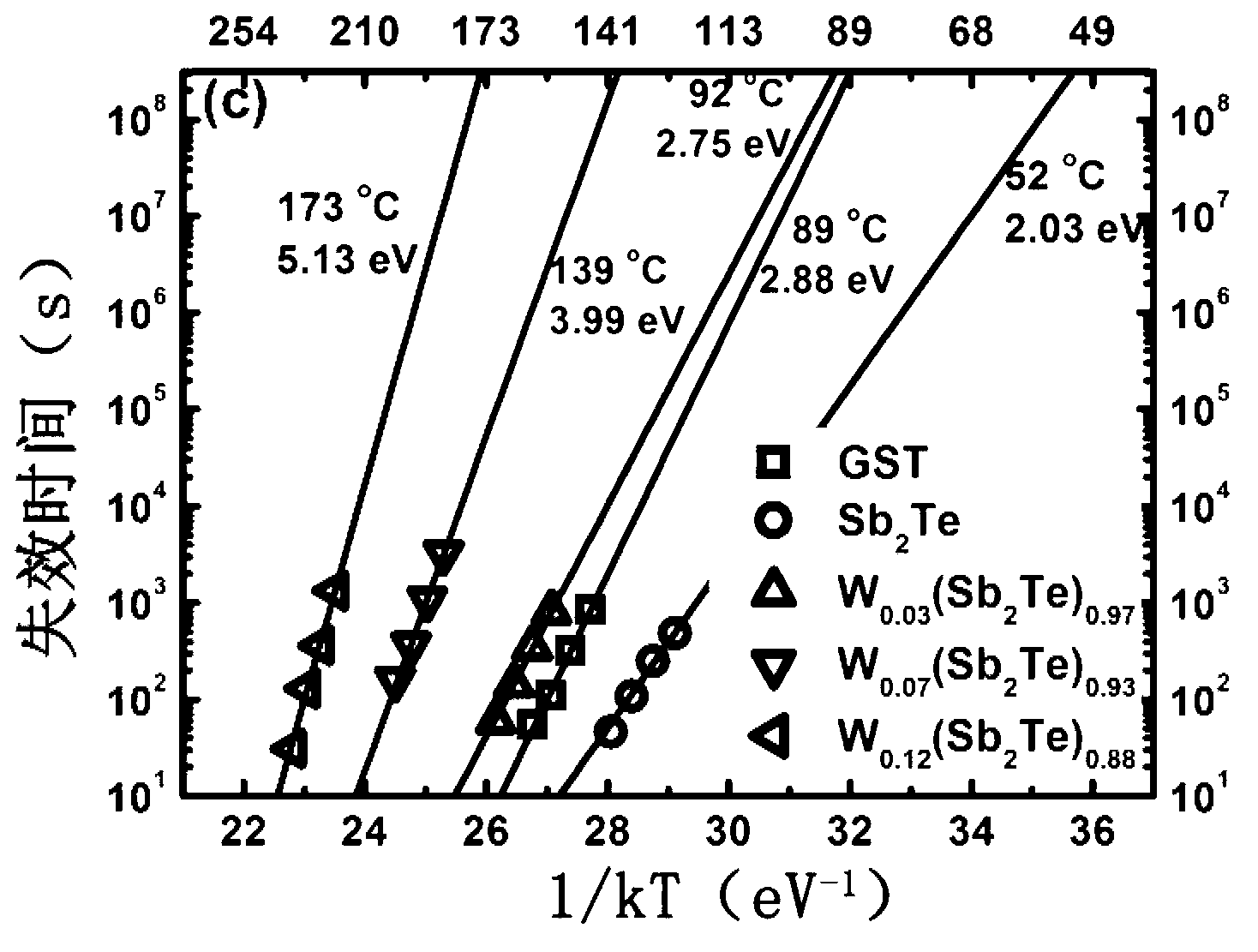

Antimony-rich high-speed phase change material for phase change memory, method for preparing antimony-rich high-speed phase change material and application of material

ActiveCN102800808ARegulated contentAchieve High Density StorageElectrical apparatusVacuum evaporation coatingPhase-change memoryHigh density

The invention relates to a phase change material doped with metallic elements in the microelectronic technical field, and in particular relates to an antimony-rich high-speed phase change material for a phase change memory, a method for preparing the antimony-rich high-speed phase change material and an application of the material. The antimony-rich high-speed phase change material for the phase change memory has a chemical formula of Ax(Sb2Te)(1 minus x), where the x is atomic percent, A is selected from W, Ti, Ta or Mn, and x is larger than zero and less than 0.5. The phase change material provided by the invention is similar to the common GeSbTe materials, and is contributed to realizing high density storage. The phase change material can be performed on reversible phase change under the action that nanosecond-level pulse is driven by external electricity. The phase change speed of a W-Sb-Te phase change material is three times that of the GeSbTe materials, and is contributed to realizing the high density storage.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

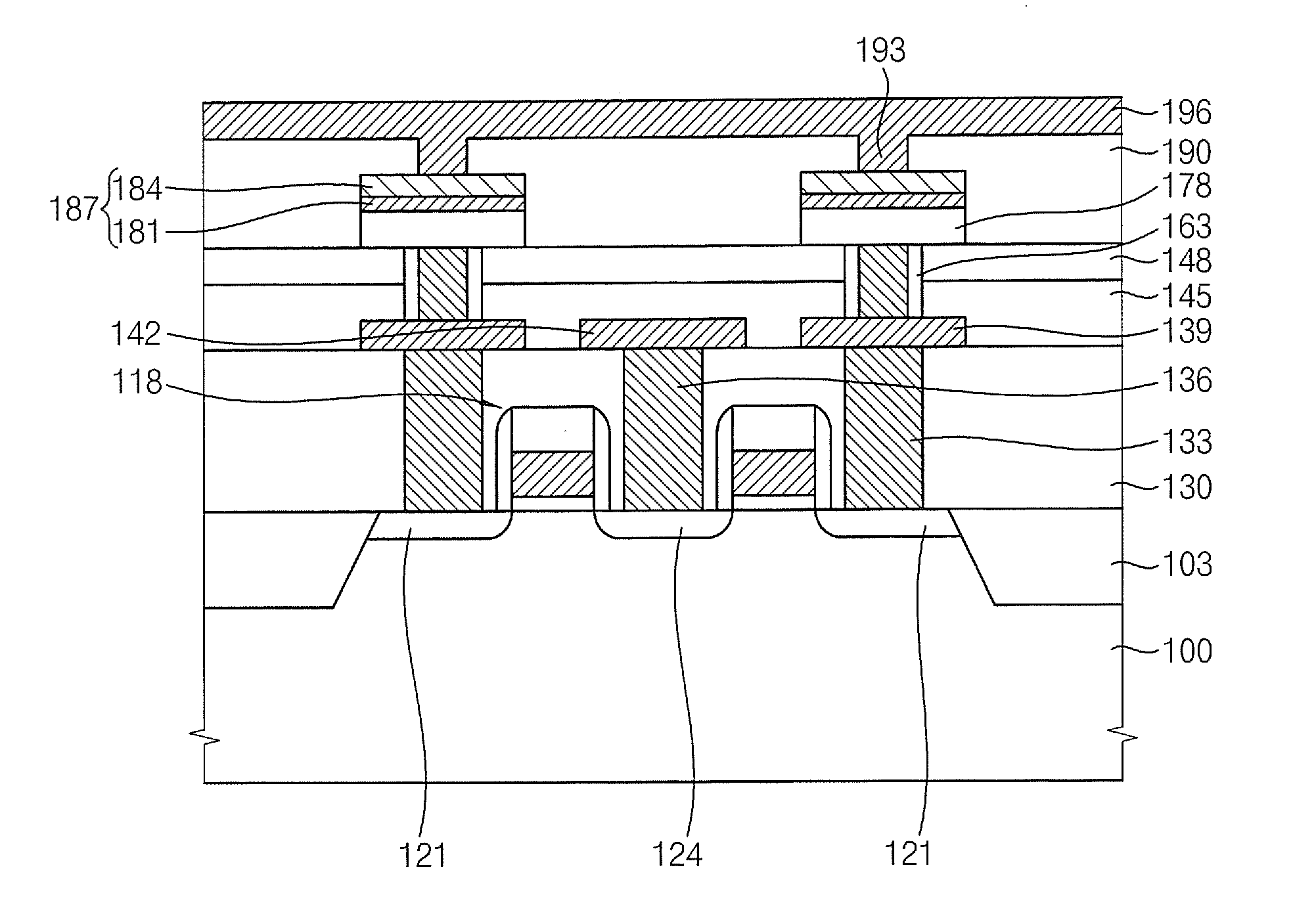

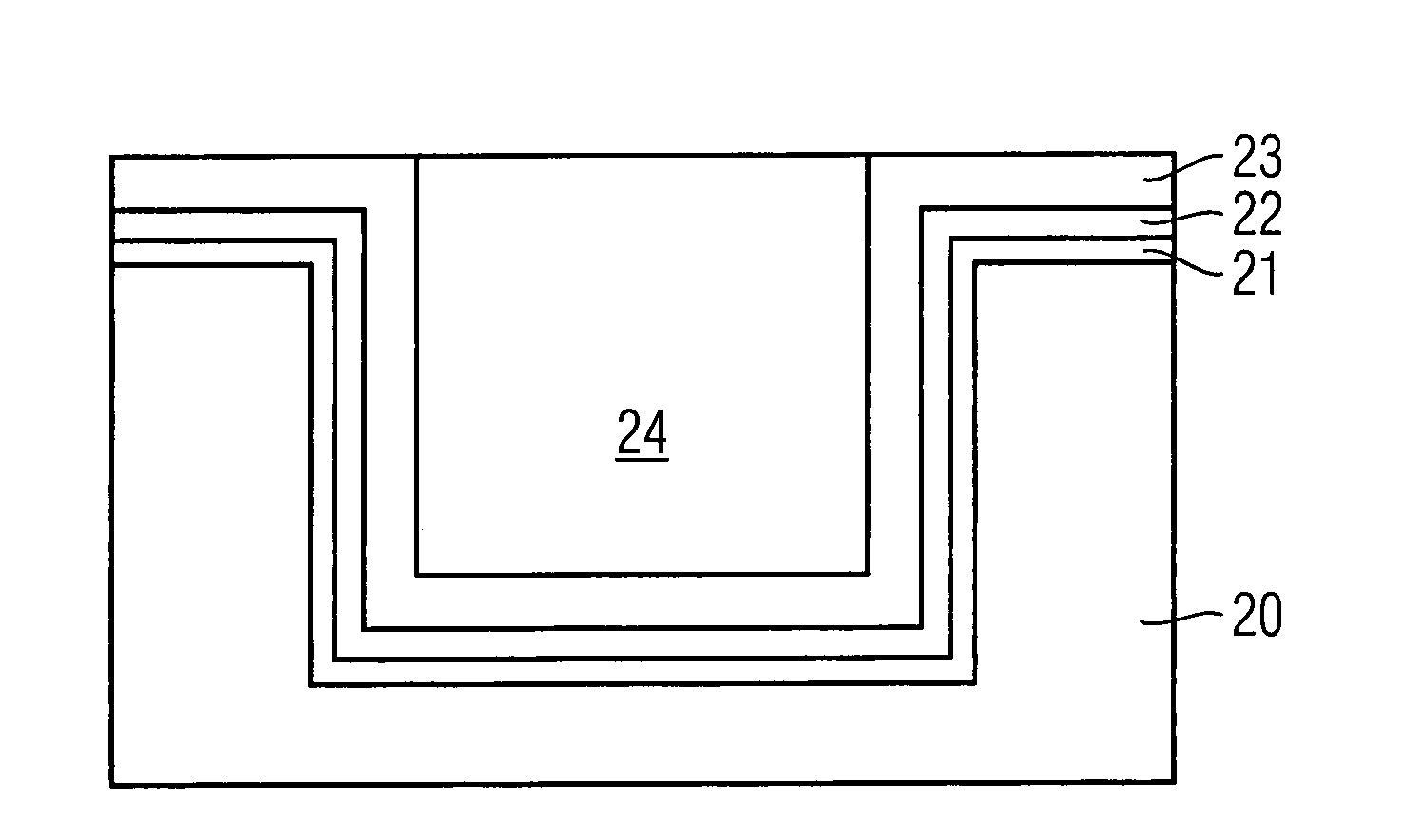

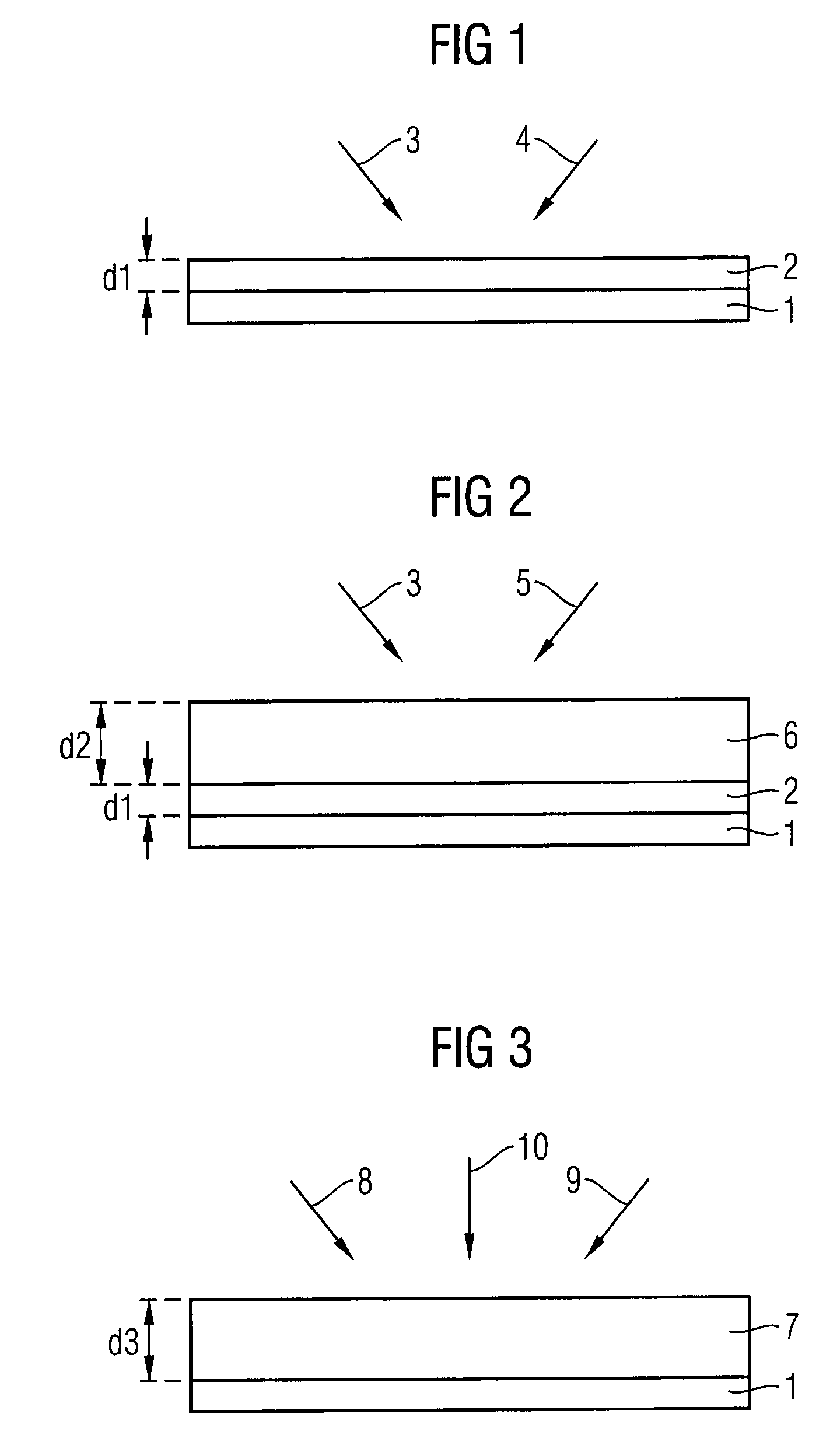

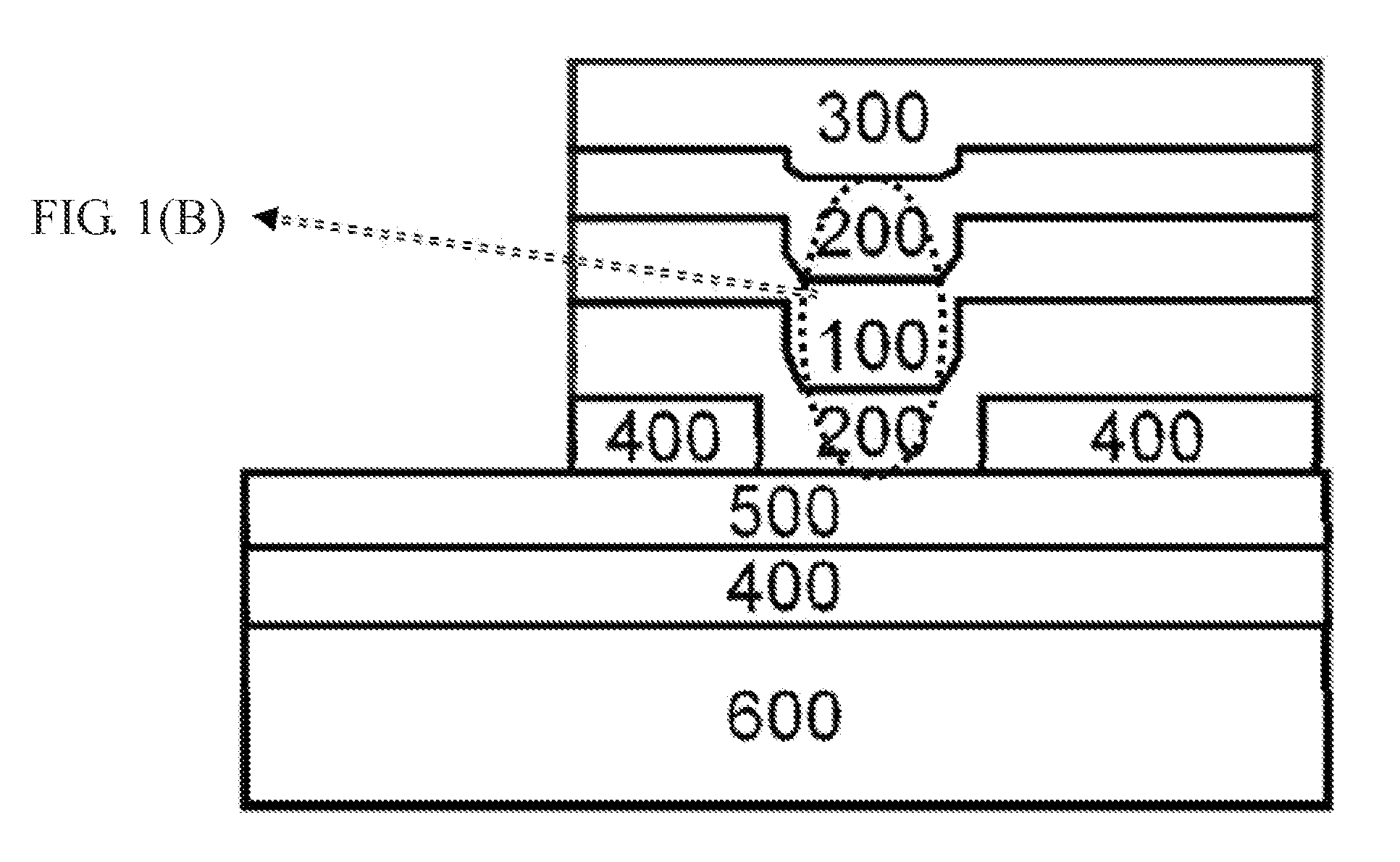

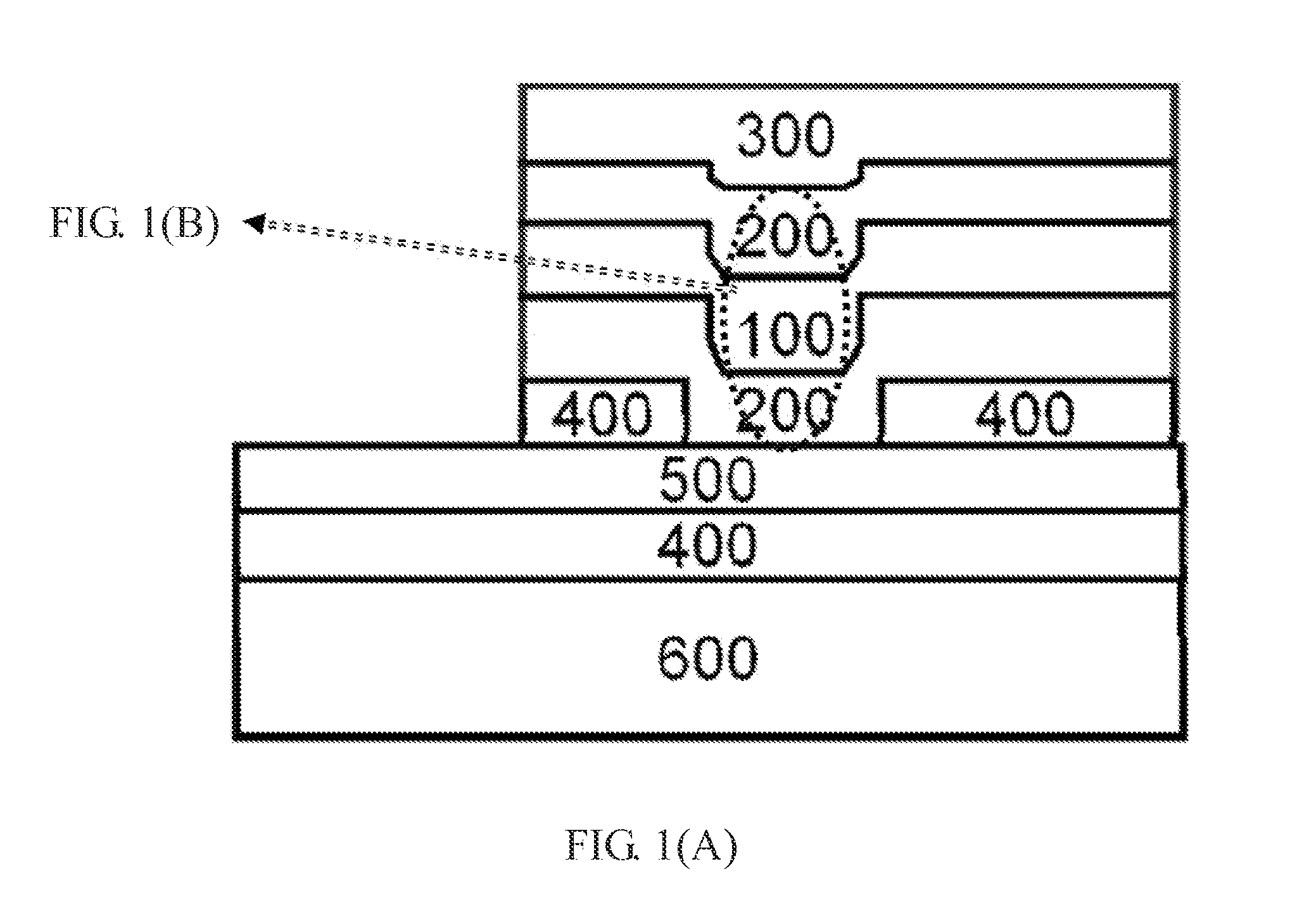

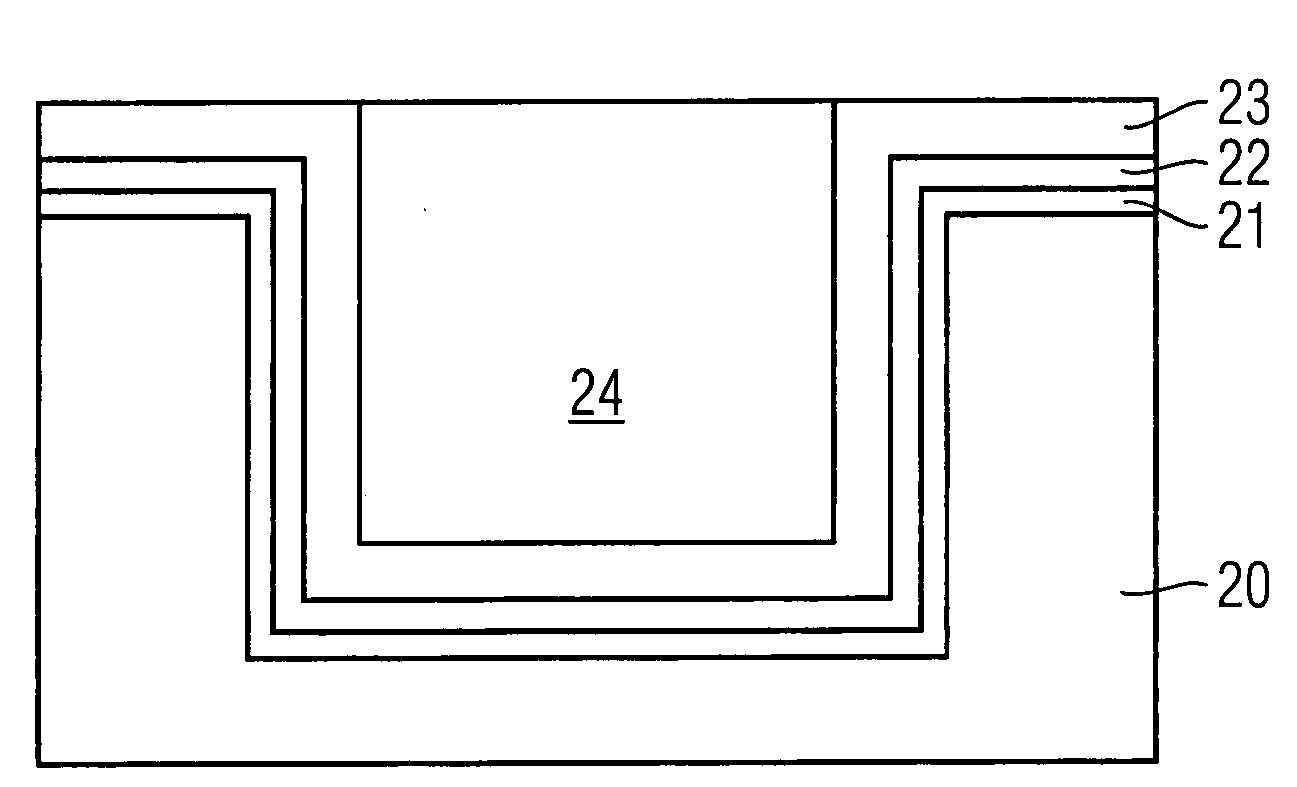

Multi-Layered Phase-Change Memory Device

ActiveUS20130292631A1Raise the crystallization temperatureImprove concentrationNanoinformaticsBulk negative resistance effect devicesPhase-change memoryElectrical conductor

The invention discloses a phase-change memory device structure and the materials used. The structure includes a substrate; a single or multiple sandwich-memory-unit(s); a first and a second electrode electrically connecting to the first and the second sides of the sandwich-memory-units and a dielectric layer used as the insulator required by the memory device. The sandwich-memory-unit composes of a memory-layer, thinner than 30 nm, sandwiched between an upper and a lower barrier-layers. The barrier-layer is either an electrical conductor in case of vertical memory-cells or an electrical insulator in case of parallel memory-cells. The sandwich-memory-unit is characteristic of increased crystallization temperature of at least 50° C. as the thickness of the memory-layer is reduced from 15 to 5 nm; and the volume change of the memory-layer is less than 3% during phase change. The thickness and memory-material in each sandwich-memory-unit can be different in the multiple sandwich-memory-units.

Owner:FENG CHIA UNIVERSITY

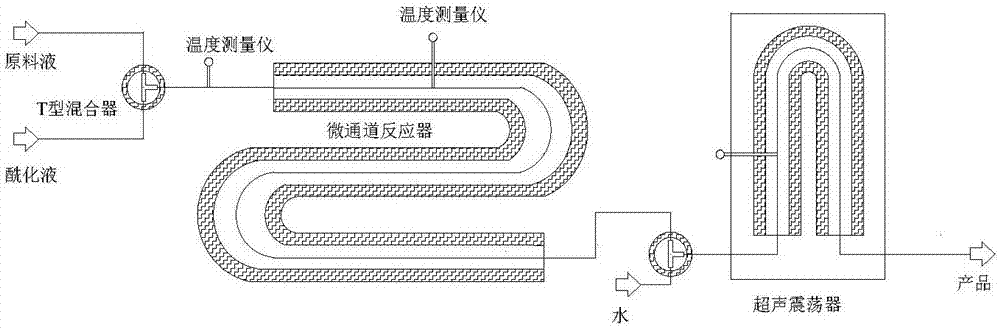

Method for synthesizing acyl naphthalene by using micro-channel reactor

InactiveCN107879909AImprove airtightnessImprove securityCarbonyl compound preparation by condensationCarbonyl compound separation/purificationWater bathsIce water

The invention discloses a method for synthesizing acyl naphthalene by using a micro-channel reactor. The method comprises the following steps: (1) preparing acylation liquid, namely adding nitrobenzene and anhydrous aluminum chloride into a reactor in a low-temperature tank, finally adding acyl chloride, and controlling the temperature in the reactor to be 0-3 DEG C; (2) preparing a feed solution,namely adding nitrobenzene and 2-methyl naphthalene into a reactor provided with a stirrer; (3) reacting, namely injecting the feed solution and the acylation liquid into a micro mixer to be mixed, and feeding into the micro-channel reactor to be reacted; (4) washing, namely enabling the product discharged from the micro-channel reactor to enter the micro mixer again so as to be washed, enablingthe mixture into the micro-channel reactor, controlling the reactor temperature to 40-50 DEG C, and performing ultrasonic oscillation outside the reactor; (5) performing reduced pressure distillation,namely separating the products obtained in the step (4), and performing vacuum decompression to 500-1000Pa so as to obtain a crude product 2-methyl-6-acyl naphthalene; and (6) recrystallizing, namelyadding the crude product obtained in the step (5) into a solvent of 50-60 DEG C, stirring and dissolving, naturally cooling and crystallizing, continuously cooling and crystallizing in an ice-water bath, and finally filtering to obtain the purified product 2-methyl-6-acyl naphthalene.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

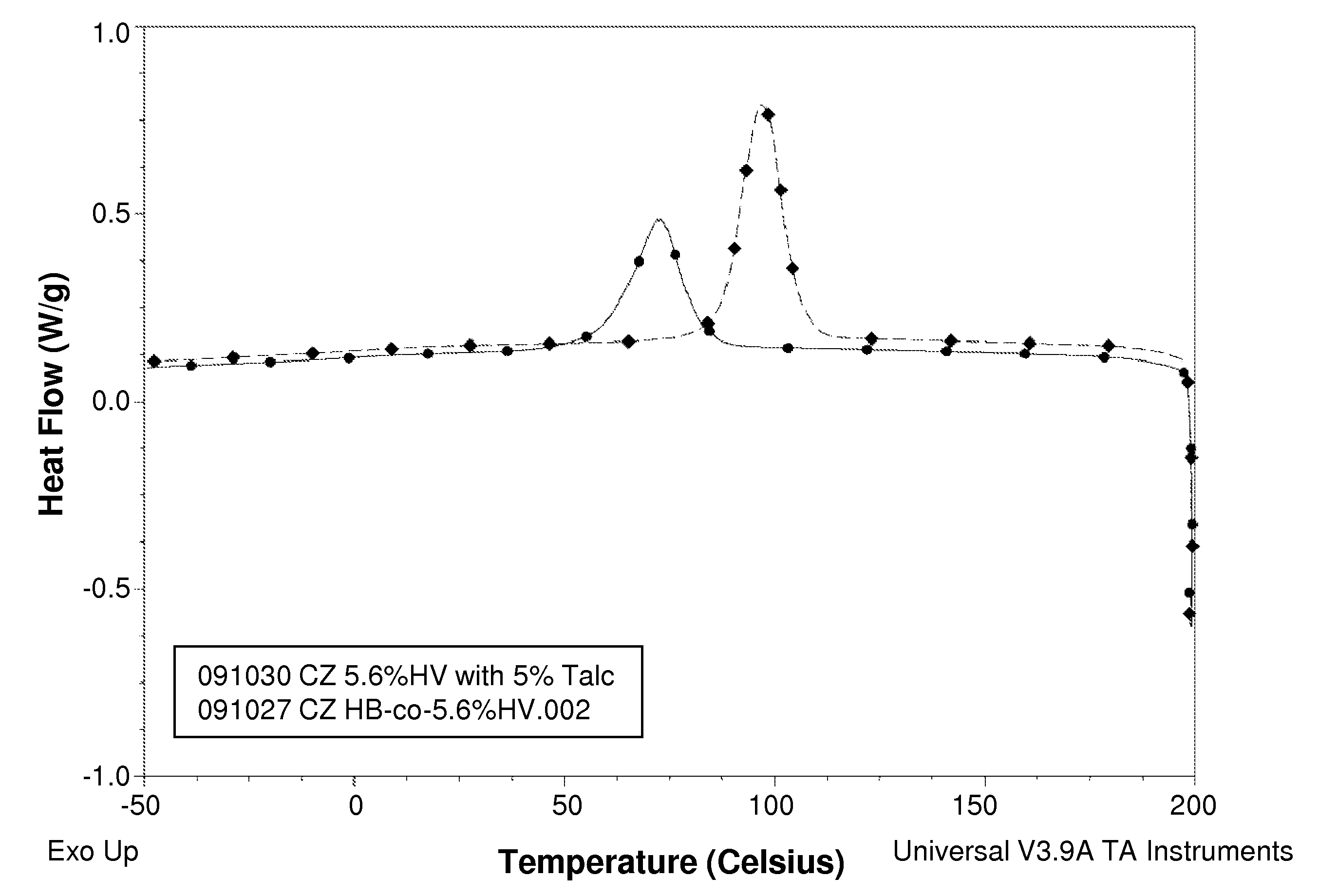

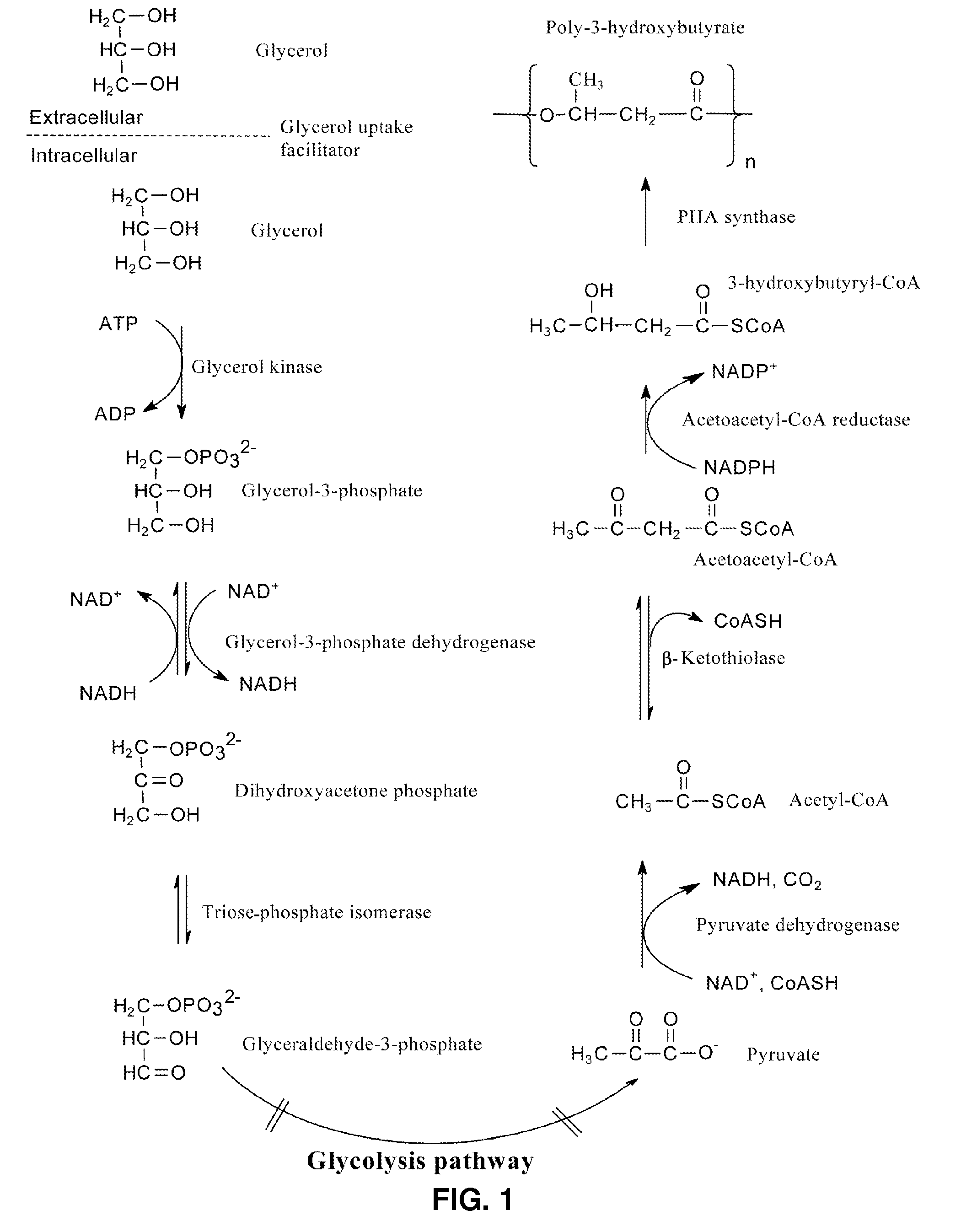

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

ActiveUS20120135480A1Increased elongation-to-breakIncreased resistance to breakingBiofuelsFermentationBiodieselGlycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA; e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Deposition method for a transition-metal-containing dielectric

InactiveUS20080173919A1Inhibition formationRaise the crystallization temperatureTransistorThin/thick film capacitorDielectricHydrazine compound

The present invention relates to a method for depositing a dielectric material comprising a transition metal compound. After providing a substrate, a first pre-cursor comprising a transition metal compound and a second pre-cursor predominantly comprising at least one of water vapour, ammonia and hydrazine are successively applied on the substrate for forming a first layer of transition metal containing material. In a next step the first pre-cursor and a third pre-cursor comprising at least one of ozone and oxygen are successively applied on the first layer for forming a second layer of the transition metal containing material.

Owner:POLARIS INNOVATIONS LTD

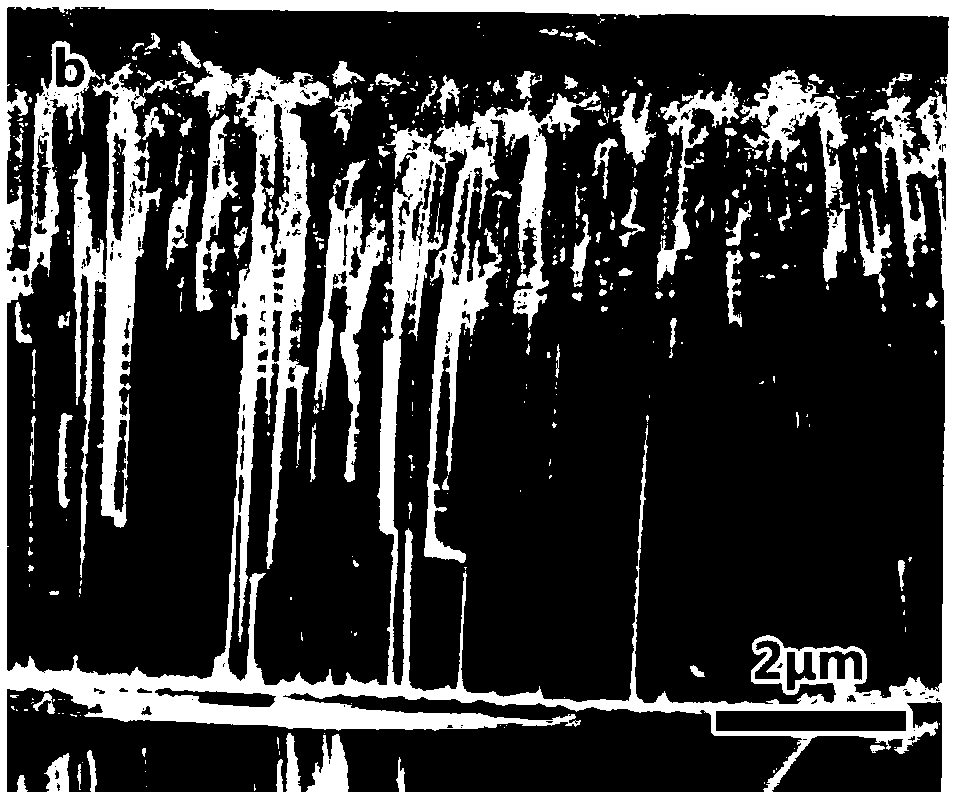

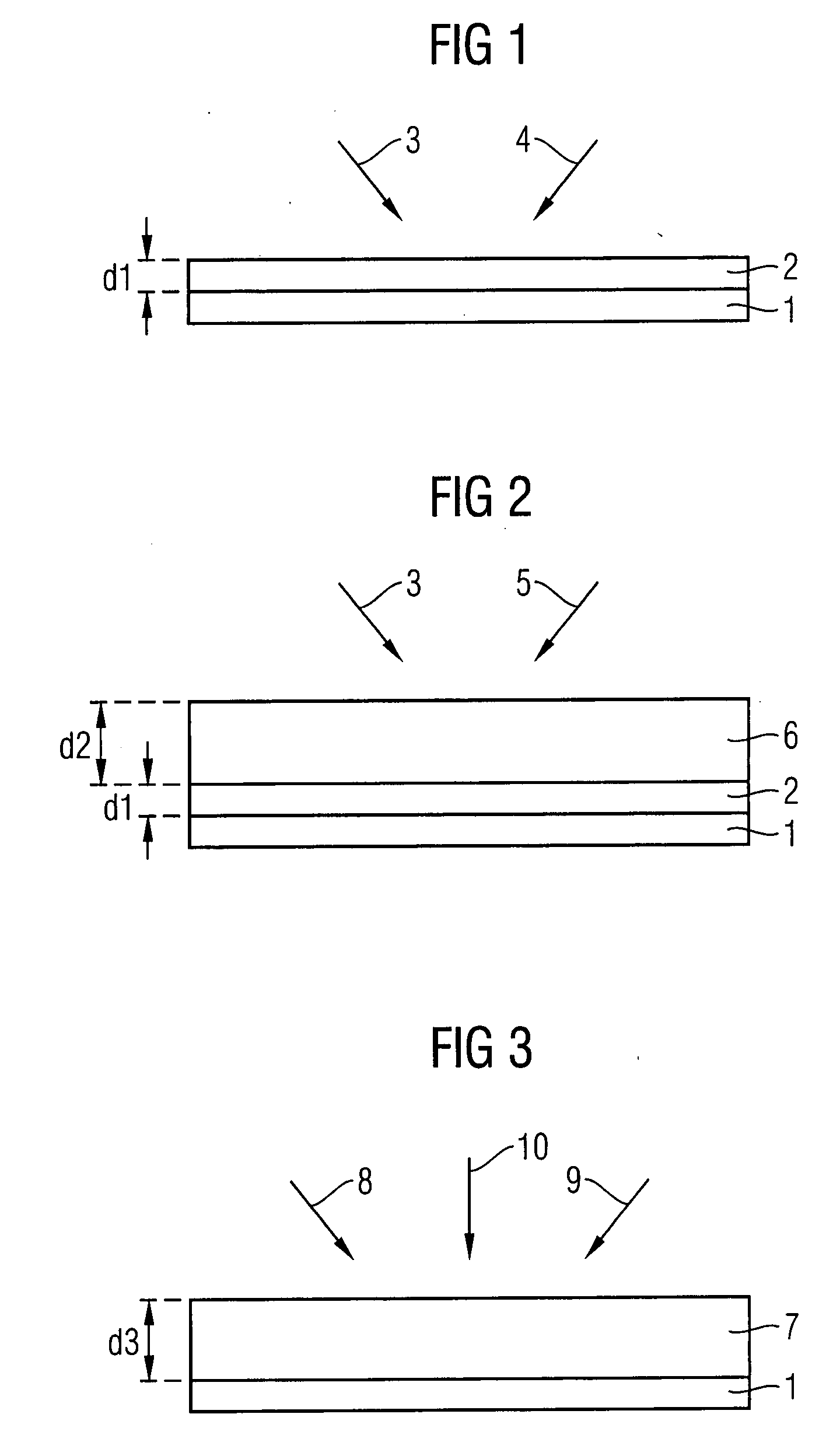

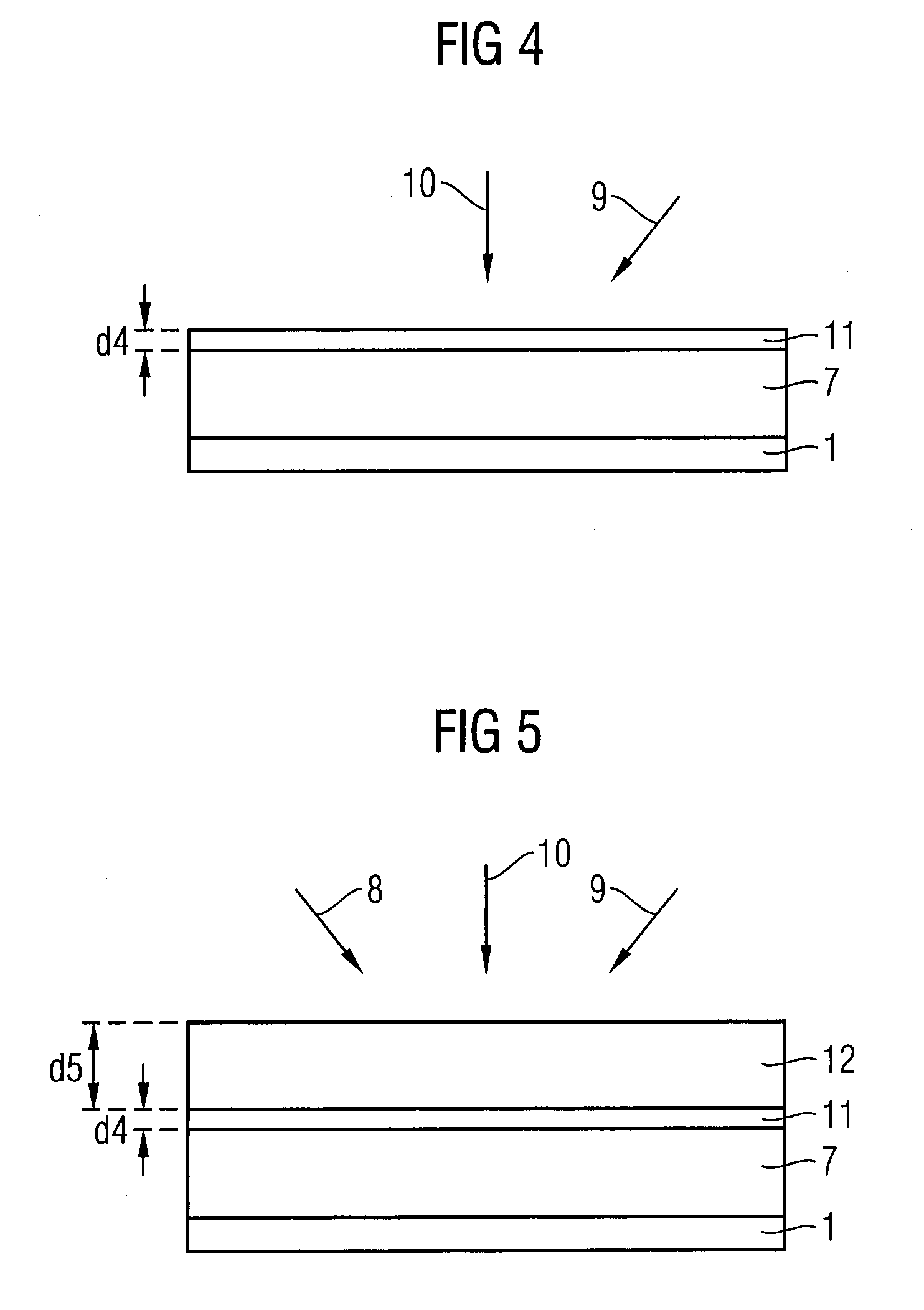

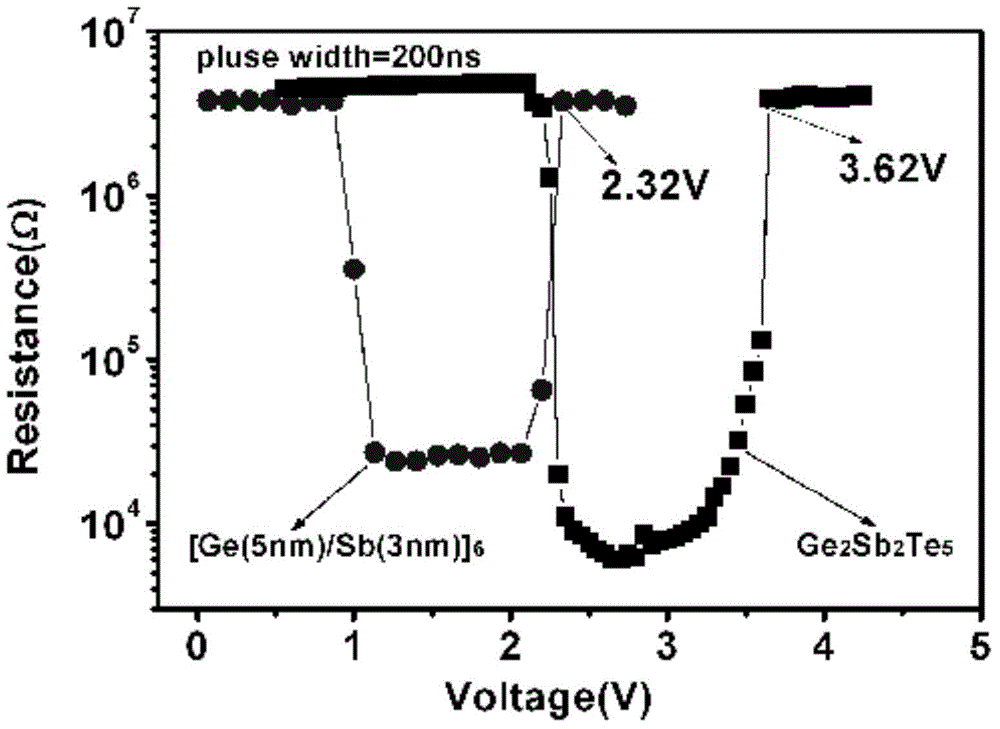

Ge/Sb type superlattice phase-change film material for high-speed low-power phase-change memory and preparation method of material

ActiveCN104934533AImprove thermal stabilitySmall grain sizeMaterial nanotechnologyElectrical apparatusVoltage pulsePhase-change memory

The invention discloses a Ge / Sb type superlattice phase-change film material for a high-speed low-power phase-change memory. The material is characterized in that the material of a multilayer film structure is formed by depositing and combining Ge and Sb layers alternatively, one Ge layer and one Sb layer serve as an alternative period, and the Ge layer of the latter alternative layer is deposited on the Sb layer of the former alternative period. The Ge / Sb type superlattice phase-change film material utilizes the clamping effect of a multilayer interface in the superlattice structure, the size of the crystal grains is reduced, the crystallization time is shortened, crystallization is inhibited, the thermal stability of the material is improved, and the phase change speed is improved. The RESEST voltage of the Ge / Sb type superlattice phase-change film material is over 30% lower than that of a GE2Sb2Te5 film under the same voltage pulses, and thus, the power consumption of the Ge / Sb type superlattice phase-change film material is lower.

Owner:JIANGSU UNIV OF TECH

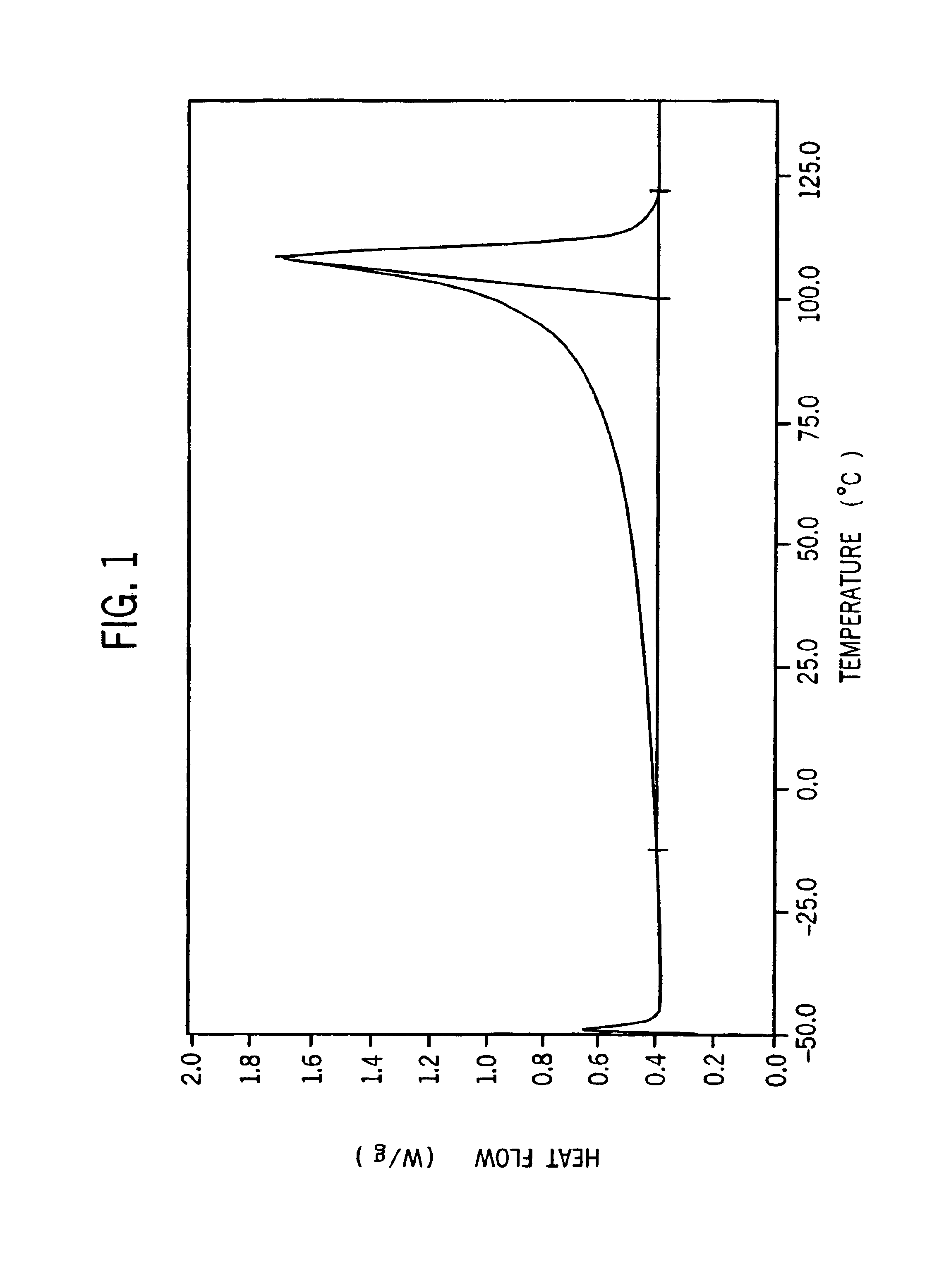

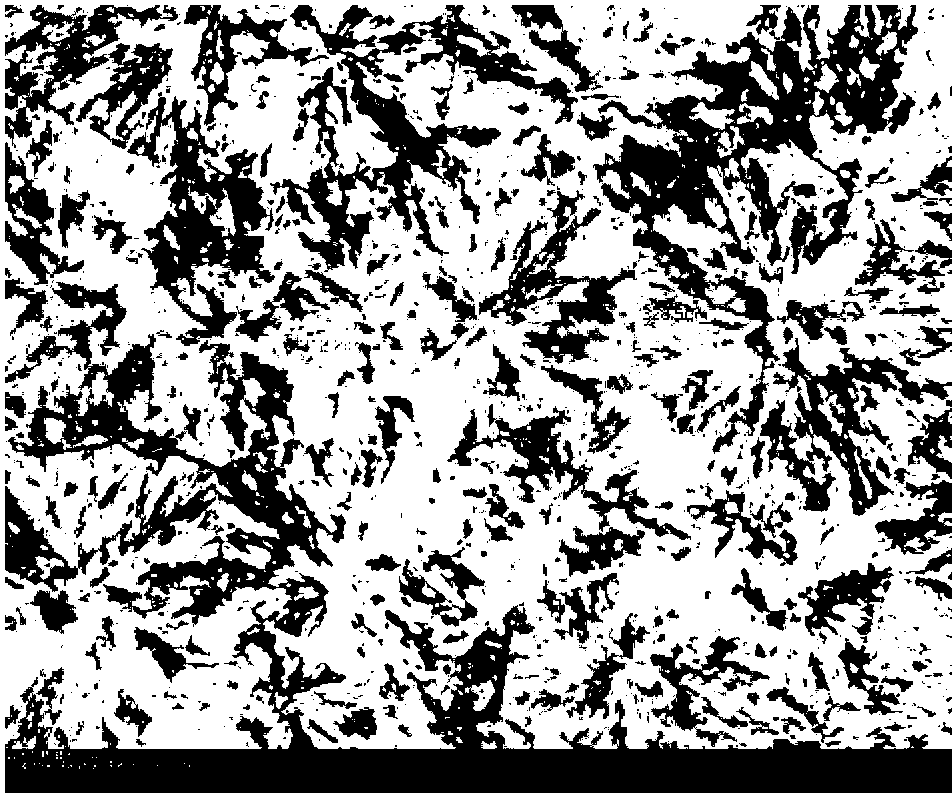

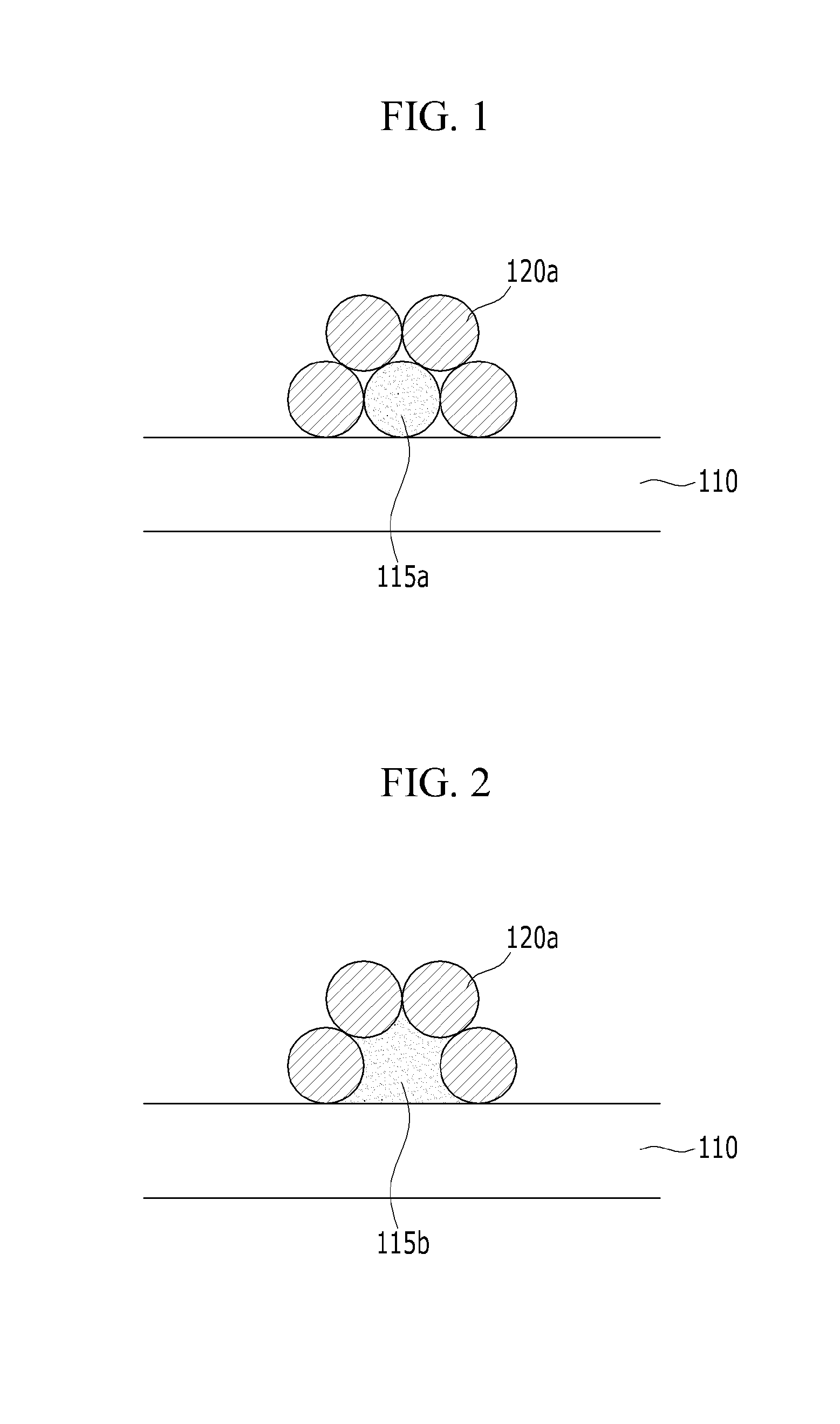

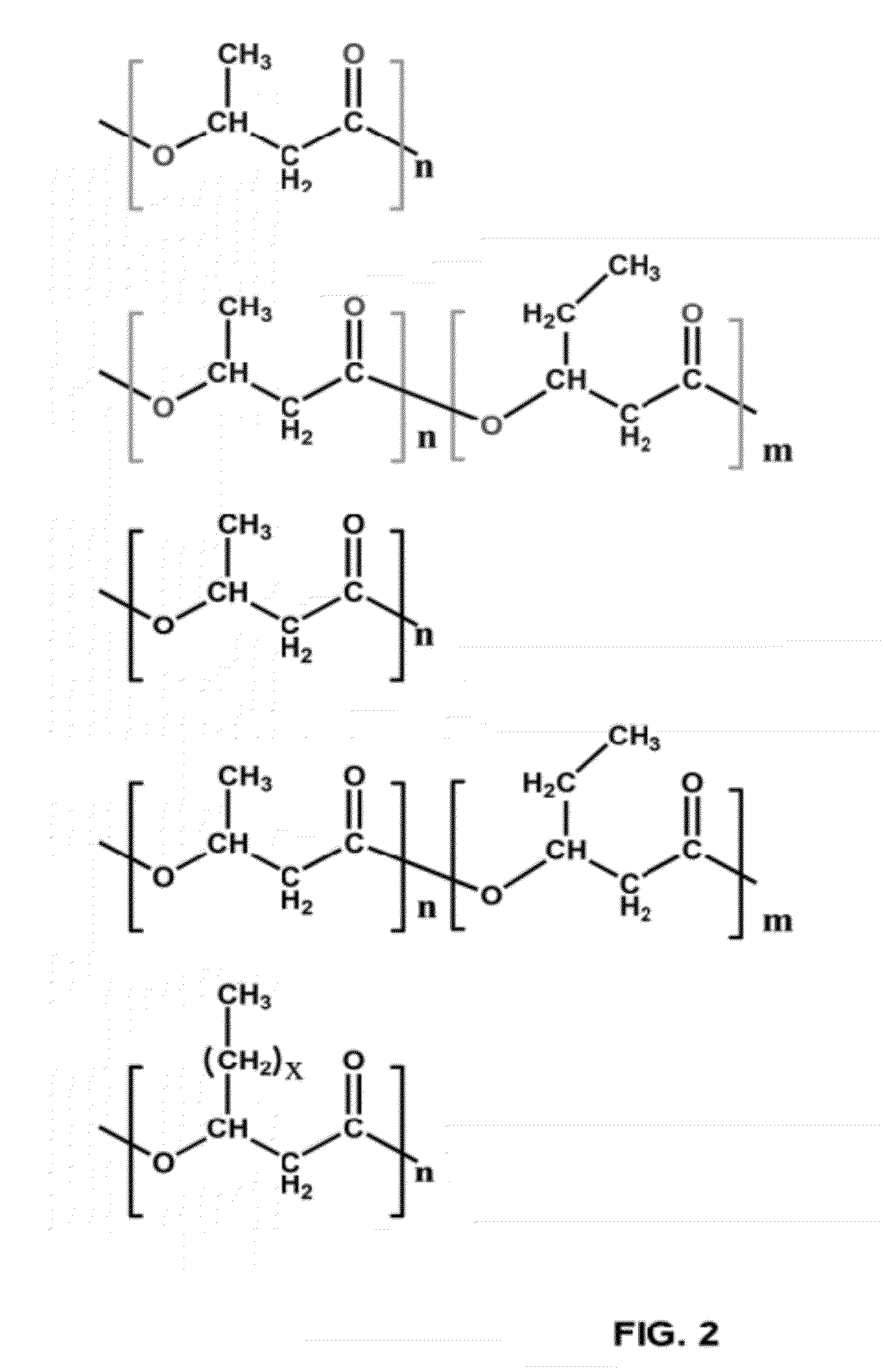

Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts

InactiveUS6946507B2Apparent dispersionReduce measurementFibre treatmentSynthetic resin layered productsThermoplasticAnticaking agent

Milled, small particle size, solid bicyclo[2.2.1]heptane dicarboxylate salt-containing thermoplastic nucleating additive formulations further comprising at least one anticaking agent for improved haze reduction, improved nucleation performance, and prevention of potential cementation (via agglomeration) of the salt component present therein are provided. Such small particle size dicarboxylate salts provide desirable properties within thermoplastic articles, particularly as nucleating agents, but apparently suffer from certain clarity issues and agglomeration problems (due to the flat and thin plate structures of such compounds and the propensity they exhibit to cohere to each other during storage), making utilization thereof less desirable for certain applications. Thus, an improvement has been provided to permit full benefit of the excellent crystallization temperatures, stiffness, and calcium stearate compatibility such dicarboxylate salts accord within target low haze thermoplastics. Furthermore, unexpected improvements in dusting reduction have been found upon the utilization of such anticaking additives in combination with the aforementioned nucleating salts. Thermoplastic additive compositions and methods of producing thermoplastics with such nucleator / anticaking additive combinations are also contemplated within this invention.

Owner:MILLIKEN & CO

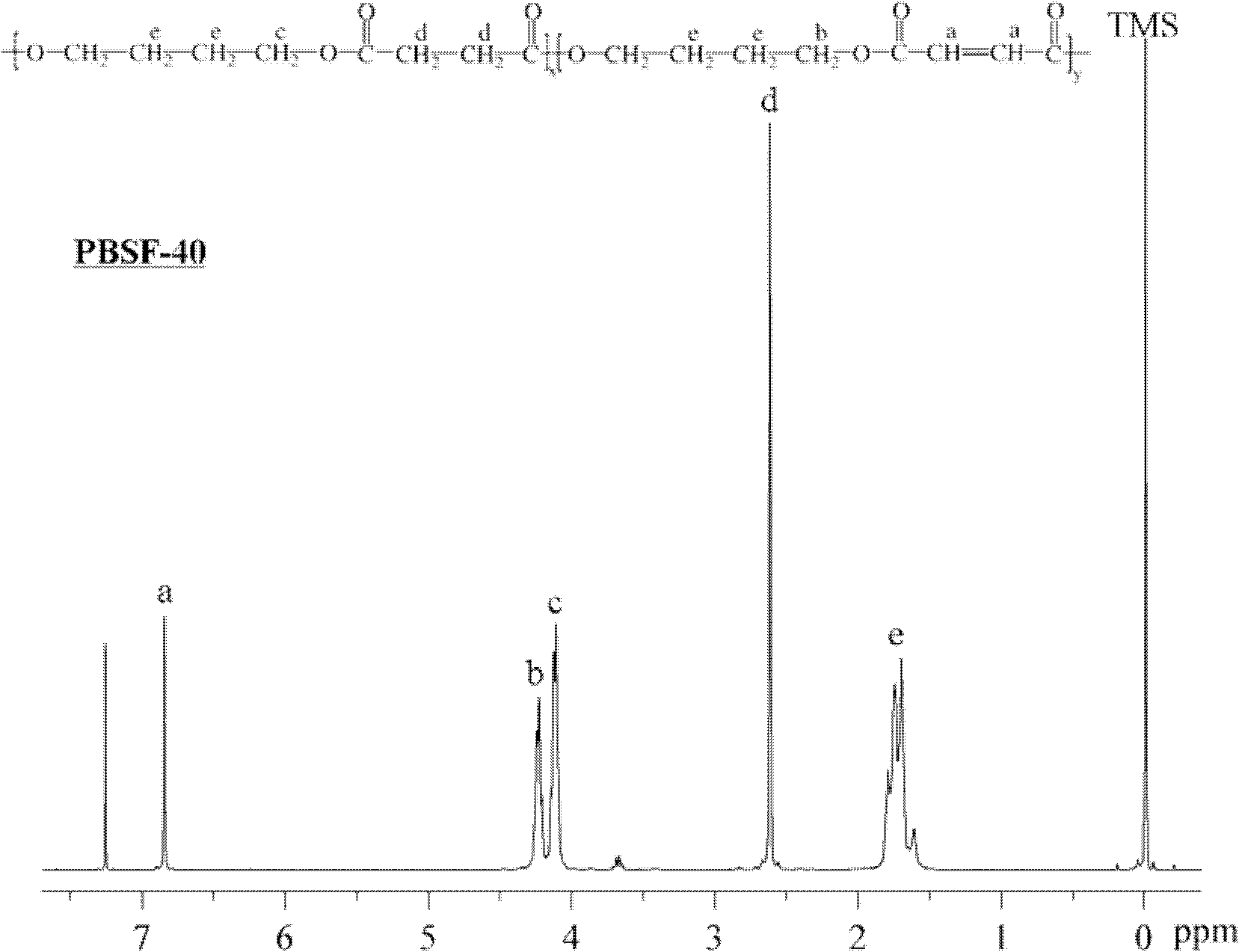

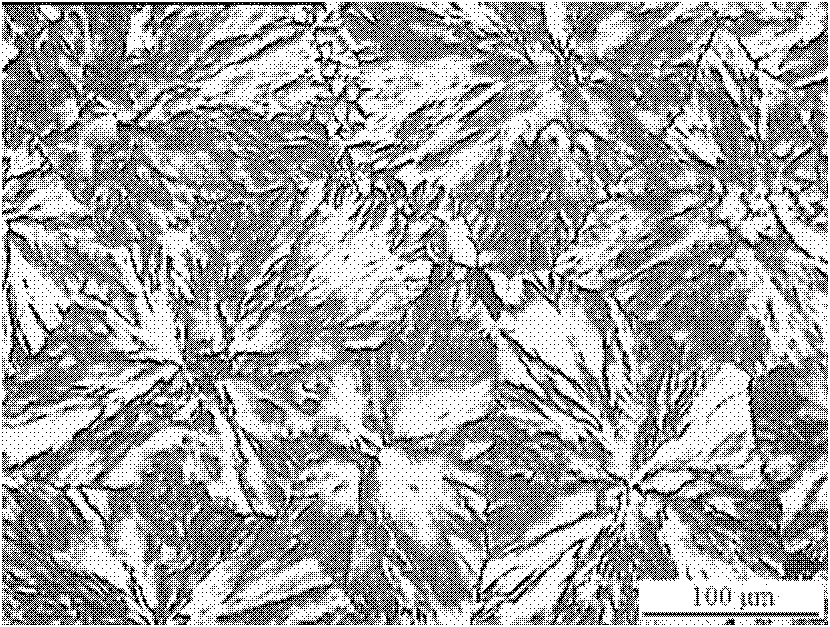

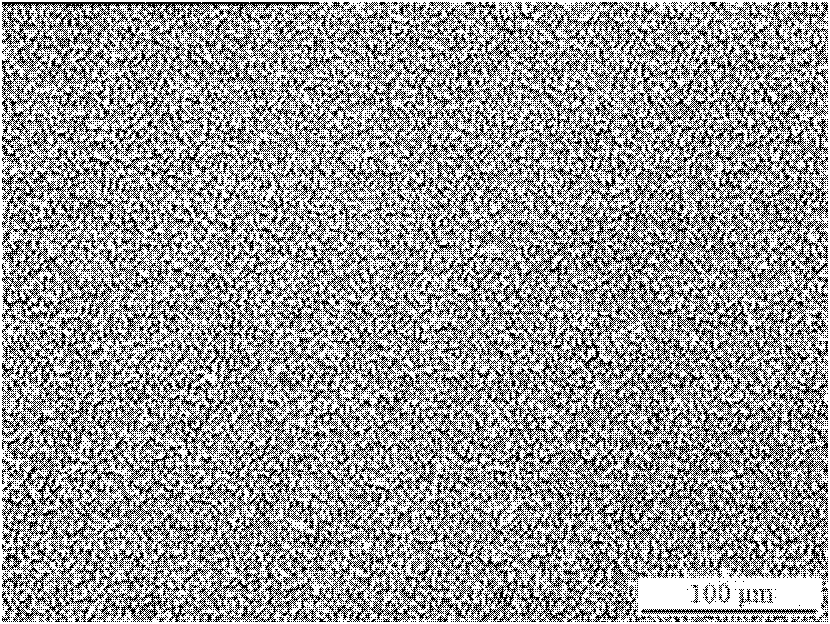

Fumaric acid-diol polyester, copolyester of fumaric acid-diol polyester, polyester nucleating agent containing fumaric acid-diol polyester and application of fumaric acid-diol polyester

ActiveCN102558521ARaise the crystallization temperatureDecreased crystallization timeCrystallization temperatureCopolyester

The invention provides fumaric acid-diol polyester, copolyester of fumaric acid-diol polyester and a polyester nucleating agent containing the fumaric acid-diol polyester. The invention simultaneously provides a polyester complex containing the polyester nucleating agent. The fumaric acid-diol polyester and copolyester thereof can effectively raise the crystallization temperature of aliphatic polyester or aliphatic and aromatic copolyester materials, lower the crystallization time and reduce the spherocrystal sizes, are beneficial to improvement of the transparency and other relevant performances of the materials and shortening of the molding cycle of the products.

Owner:TSINGHUA UNIV

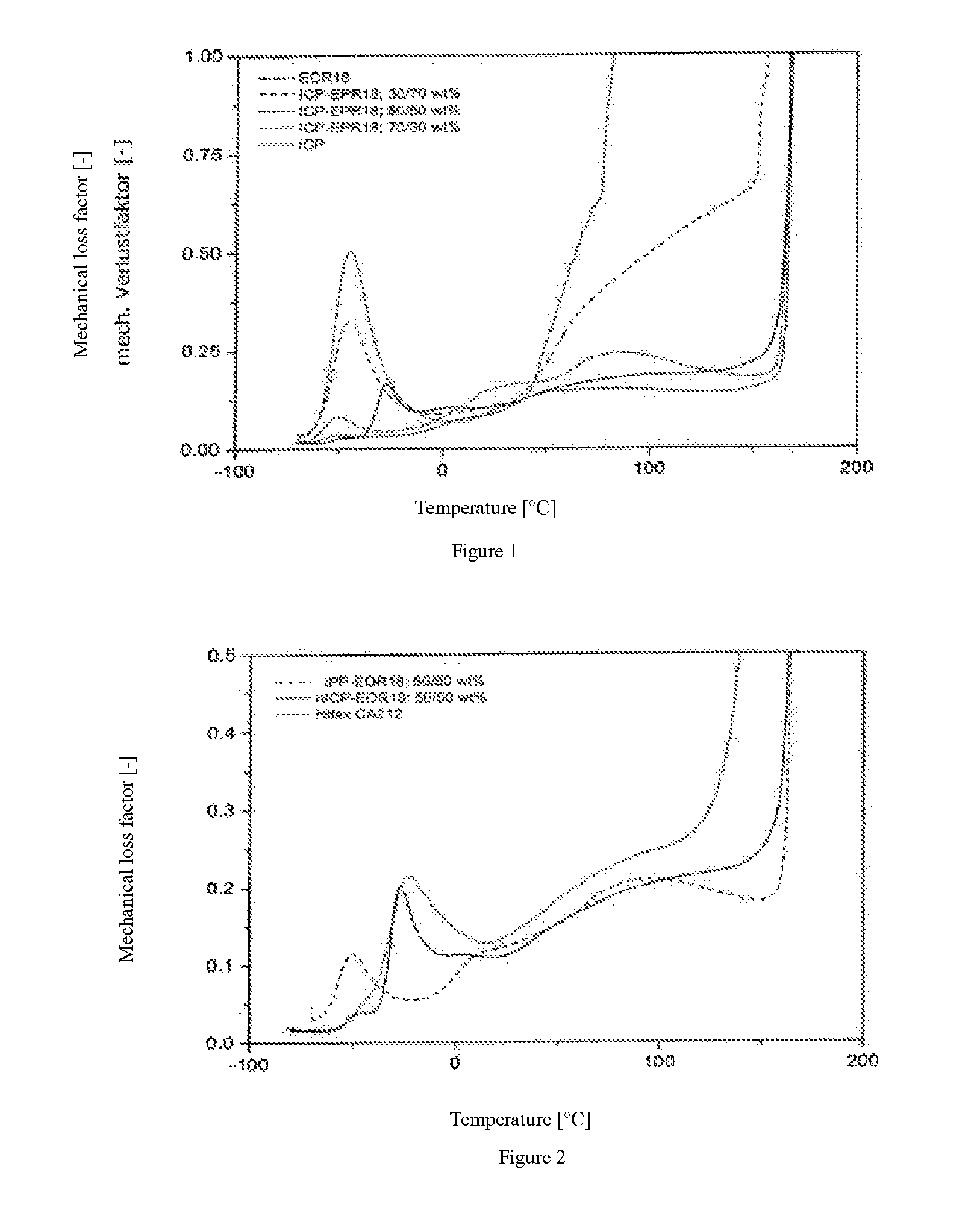

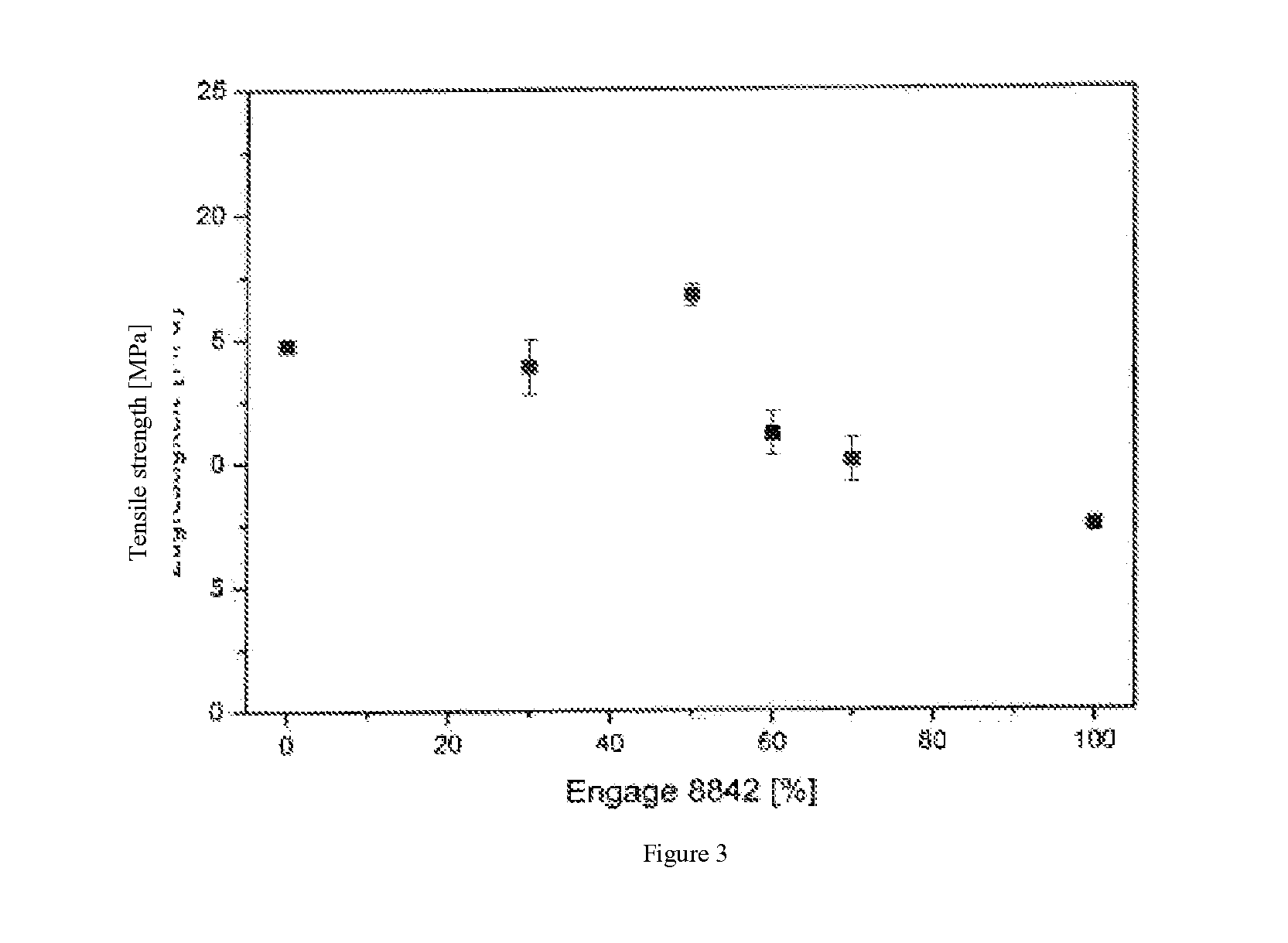

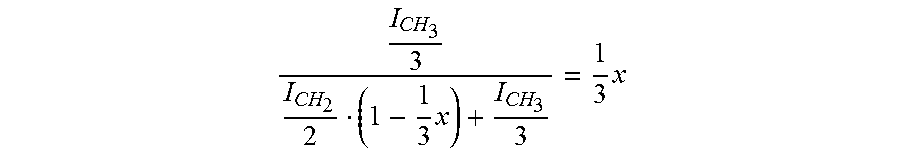

Thermoplastic mixture with high flexibility and high melting point

ActiveUS20150232651A1Low modulusRaise the crystallization temperatureAntifouling/underwater paintsPaints with biocides1-OctenePolypropylene

A thermoplastic mixture is described that includes at least one impact-resistant polypropylene copolymer and at least one ethylene-1-octene copolymer. The weight ratio of impact-resistant polypropylene copolymer to ethylene-1-octene copolymer can be in the range of 35:65 to 65:35. The thermoplastic mixture has a high melting point and excellent flexibility. The mixture is suitable in particular for roof membranes and waterproofing membranes.

Owner:SIKA TECH AG

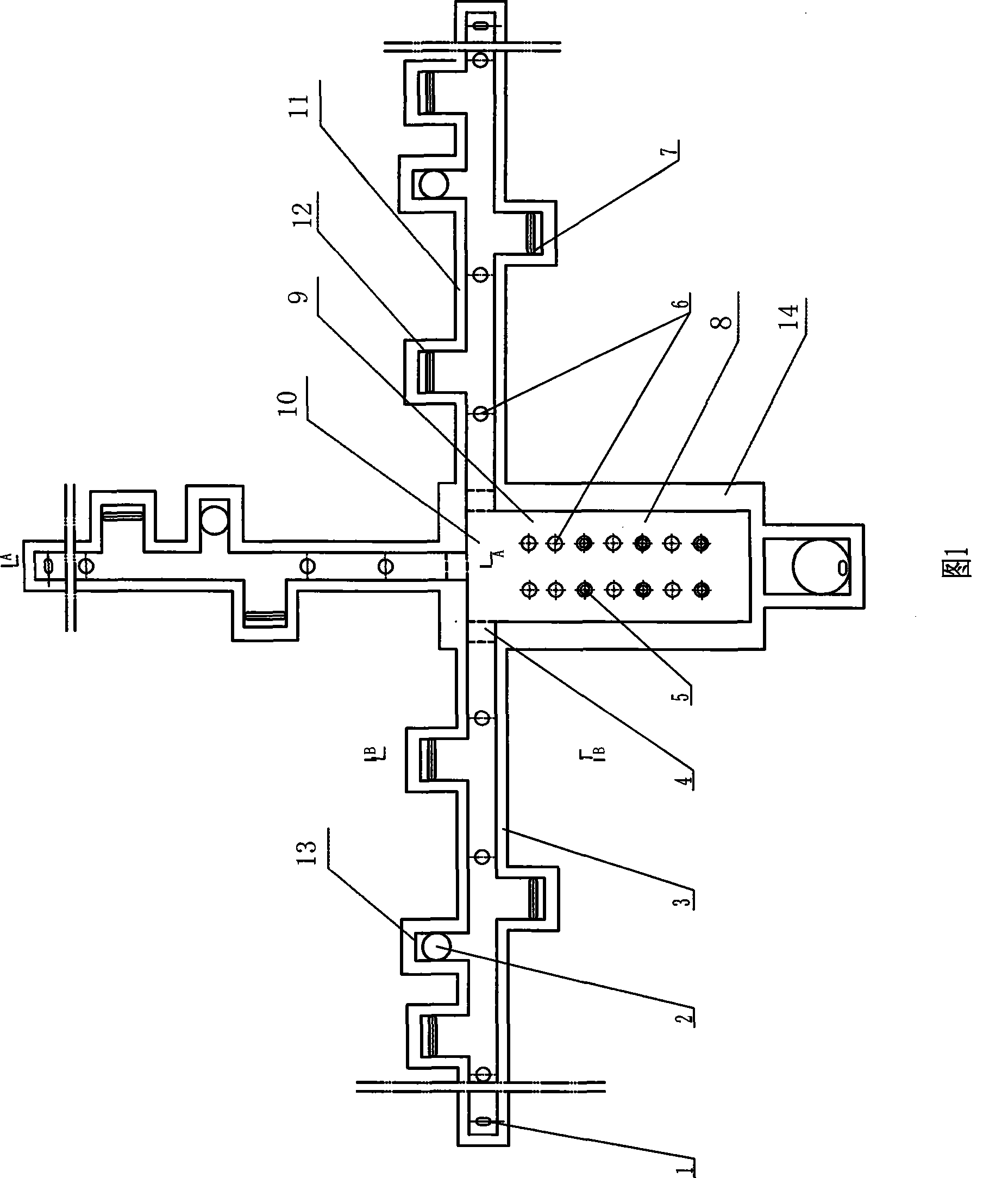

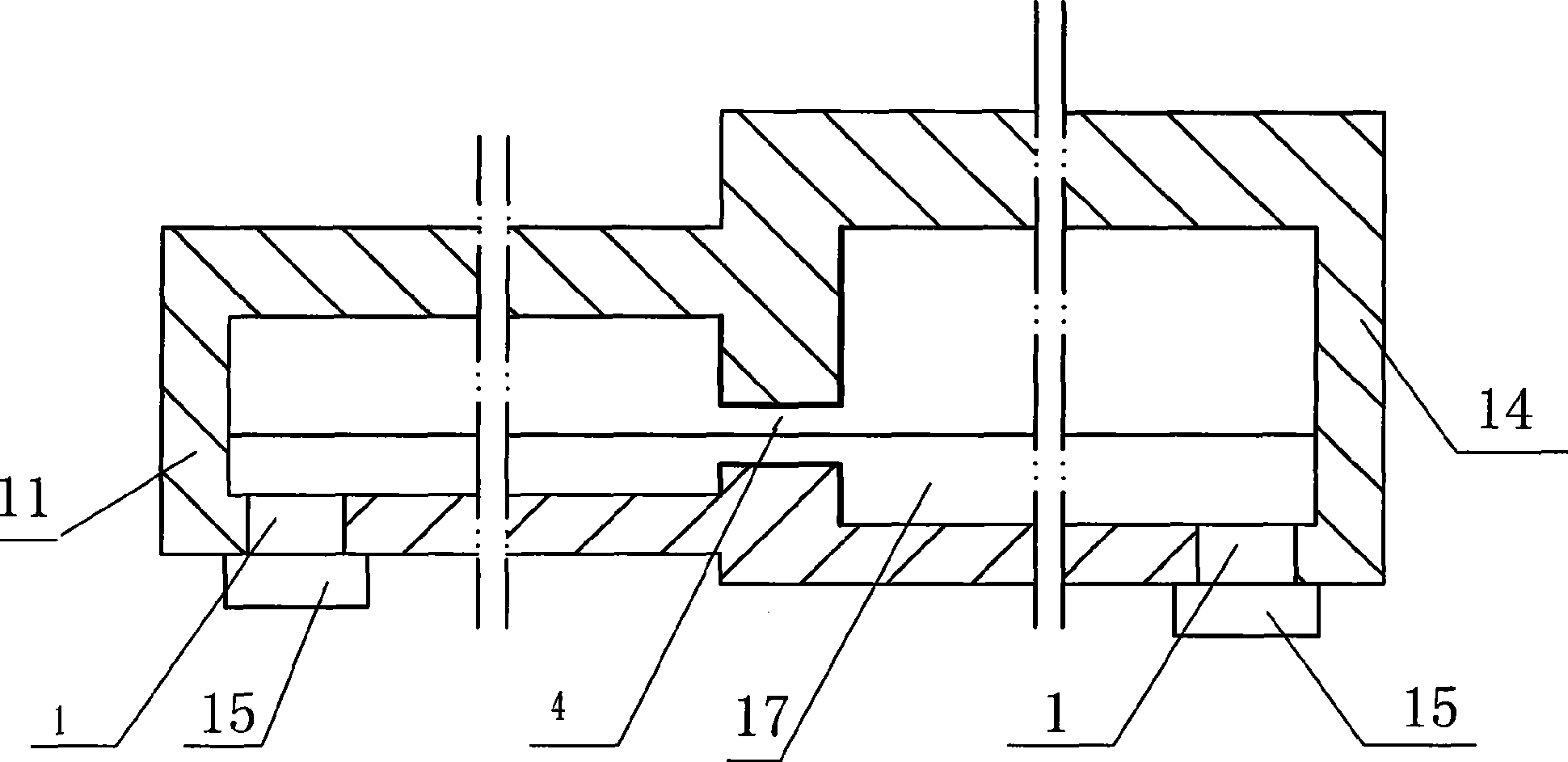

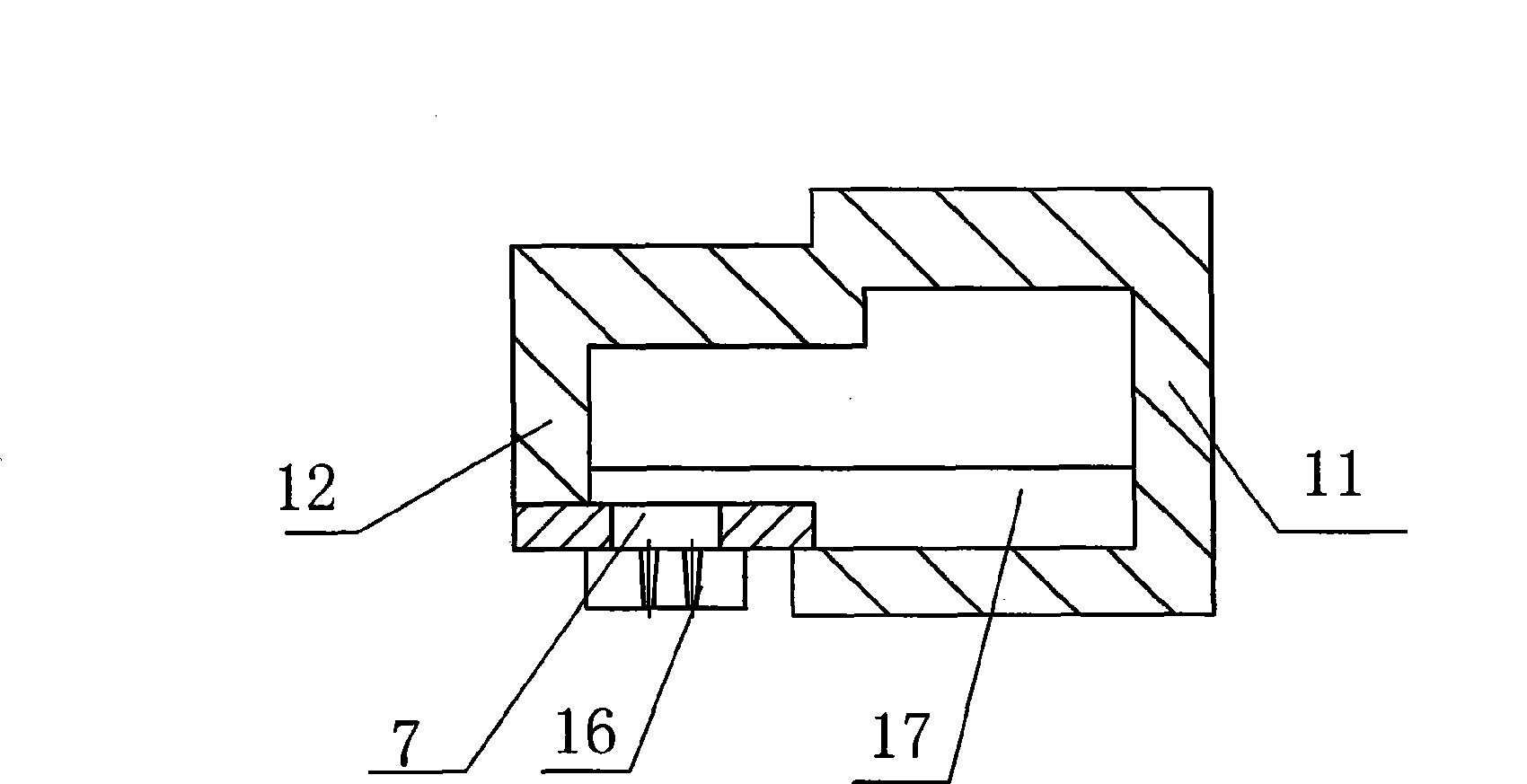

Tank furnace for producing basalt continuous fiber

ActiveCN101397182AHigh melting temperatureGuaranteed temperatureForehearthsTank furnacesMelting tankFiber

The invention relates to a tank furnace for producing basalt continuous filament and pertains to the technical field of novel inorganic non-metallic material processing equipment, the main characteristics are that the furnace body consists of a melting tank and material channels, the melting tank and the material channels are connected by non-submerged dog-holes, the melting tank is divided into a melting area and a homogenization area, a burner is arranged at the top of the furnace vertically, the burner guns of melting area and the feeding pipes are arranged in intervals, and the strong melting area of even feeding and even heating is formed. The material channels are arranged in three directions in the homogenization area of the melting tank, burner guns are arranged in the material channel in sections, the temperature of the fused mass in the material channels is guaranteed, more than 12 wiredrawing shaping areas are evenly arranged in each material channel so as to supply basalt melt mass for the wiredrawing bushing well, emptying devices are arranged at the tail part of the melting tank and the tail parts of all material channels, during the operation, the operation of discharging the meltwater can be carried out when impurities are stored in the meltwater for a long time or the varieties of raw materials are changed. The invention is in favor of improving the quality and industrialized production of the basalt continuous filament.

Owner:江苏天龙玄武岩连续纤维股份有限公司

High heat stability block ferromagnetic metal glas synthetic method

InactiveCN1552940ARational Ingredient DesignStrong Amorphous Formation AbilityMagnetic materialsCopperFerromagnetism

This invention relates to high thermally stable ferromagnetic metal glass blocks and their synthesis. The constituent of the said blocks comprises Co 35 - 45 at%, Fe 12 - 35 at%, Hf 2 - 10 at%, Mo 0 - 8 at%, Ti 2 - 8 at%, B 22 - 35 at%, and V 0 - 3 at%. The blocks can be prepared in copper molds, with excellent amorphization at >650 deg.C and the constituent designed more reasonable than the present materials, and used widely at higher temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

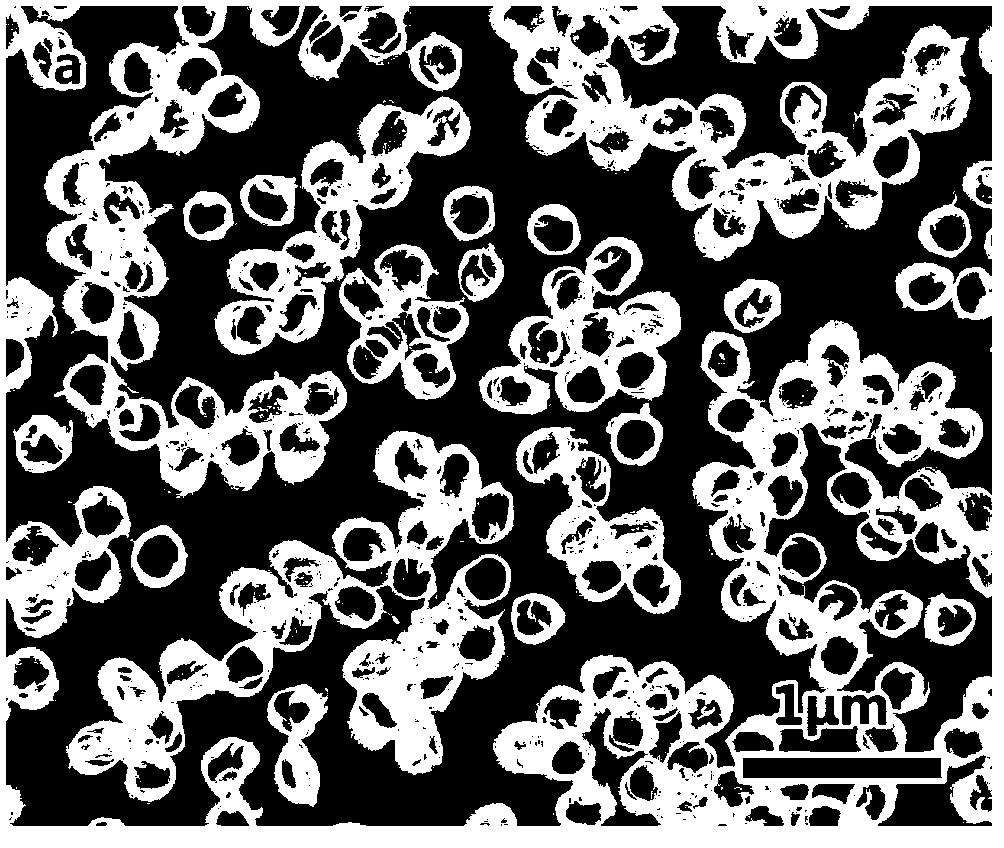

Single crystal anatase titanium dioxide nano-tube array and preparation method thereof

InactiveCN103225104AGood electron transport propertiesPromote absorptionFrom normal temperature solutionsNanotechnologyUltraviolet lightsSingle crystal

The present invention discloses a single crystal anatase titanium dioxide nano-tube array and a preparation method thereof. The method comprises: adopting an electrical arc melting method to prepare a TiNbZr alloy; carrying out burnishing, washing and drying on the matrix alloy; adopting the dried matrix alloy as an anode, adopting a Pt sheet as a cathode, and carrying out anode oxidation for 0.5-20 h at a room temperature, wherein a voltage is 10-100 V; placing the prepared nanometer titanium dioxide nano-tube array and the matrix alloy in a muffle furnace to carry out a heat treatment in air; and finally adopting hydrofluoric acid steam to remove an amorphous layer and the matrix alloy to obtain the single crystal anatase titanium dioxide nano-tube array. The single crystal anatase titanium dioxide nano-tube array has good cell compatibility and a visible ultraviolet light absorption performance. The preparation method has characteristics of strong controllability, high efficiency and simple operation.

Owner:SOUTH CHINA UNIV OF TECH

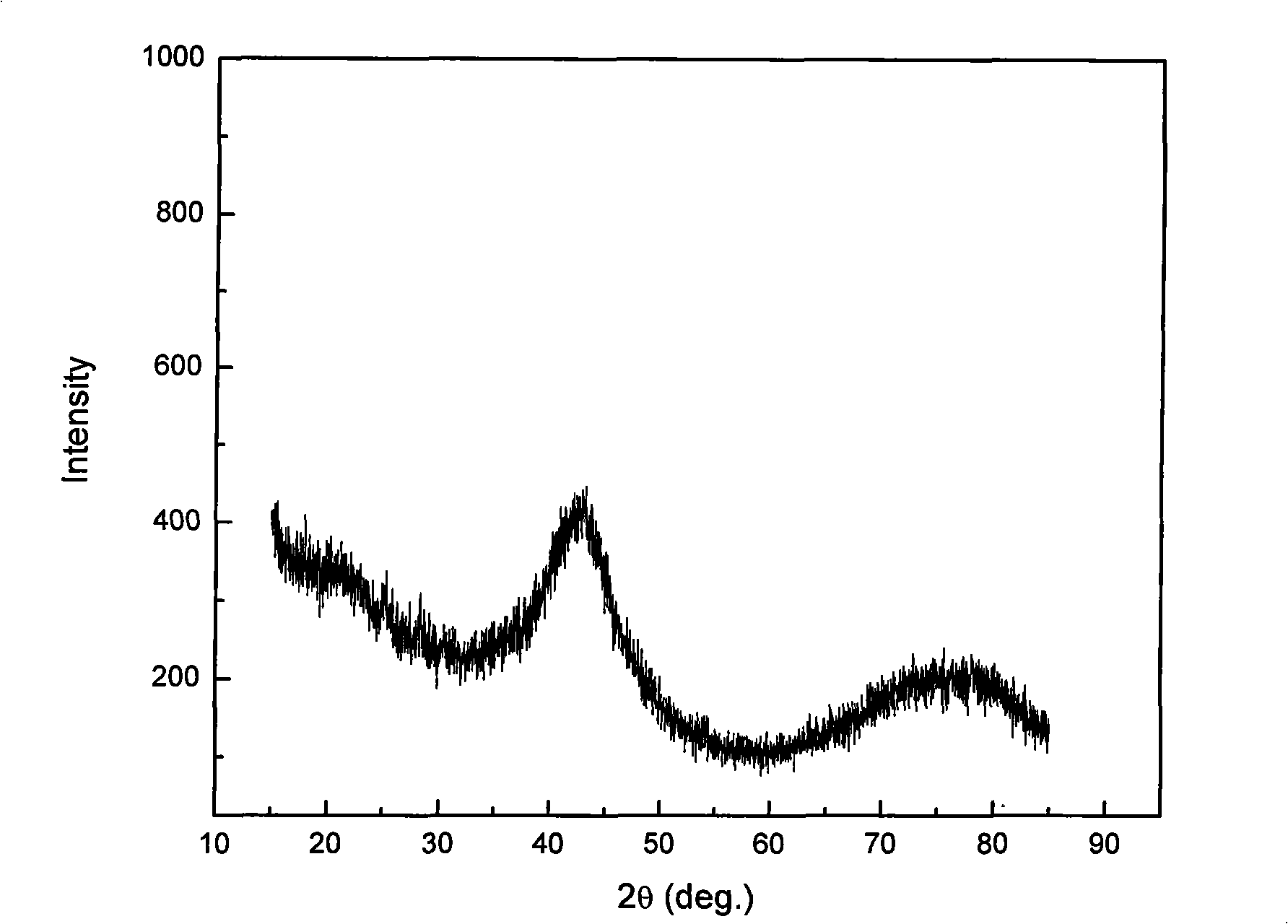

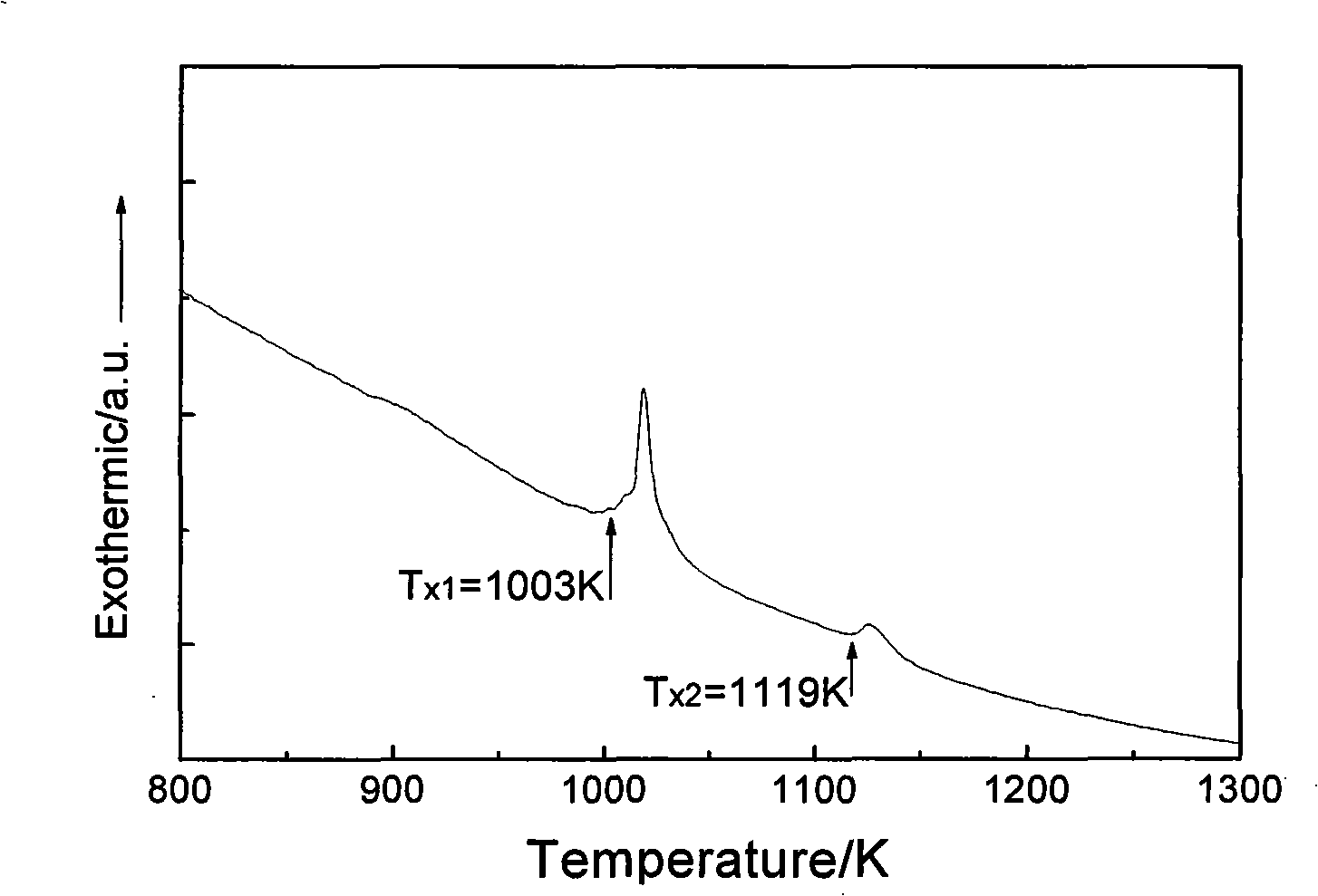

Tungsten based amorphous alloy

ActiveCN101353771ARaise the crystallization temperatureImprove thermal stabilityHigh stiffnessChemical composition

The invention relates to a tungsten-base amorphous alloy which is characterized in that the chemical composition of the tungsten-base amorphous alloy calculated by atom fraction comprise: 30 percent to 40 percent of W, 10 percent to 30 percent of Fe, 10 percent of 30 percent of C, 0 percent to 10 percent of Si, 0 percent to 10 percent of Ni, 0 percent to 15 percent of Cr, 0 percent to 10 percent of Mn, 0 percent to 10 percent of Mo, 0 percent to 10 percent of Co, 0 percent to 2 percent of Y, 0 percent to 2 percent of Sc, 0 percent to 2 percent of Er and 0 percent to 2 percent of Gd; the thickness of an amorphous alloy strap is 25Mum to 40Mum; and crystallization temperature is 900K to 1100K. The tungsten-base amorphous alloy of the invention has the advantages of high crystallization temperature, and good thermal stability of amorphous alloy, high stiffness, good abrasive resistance and comparatively low cost, etc.

Owner:SHENYANG RES INST OF FOUNDRY

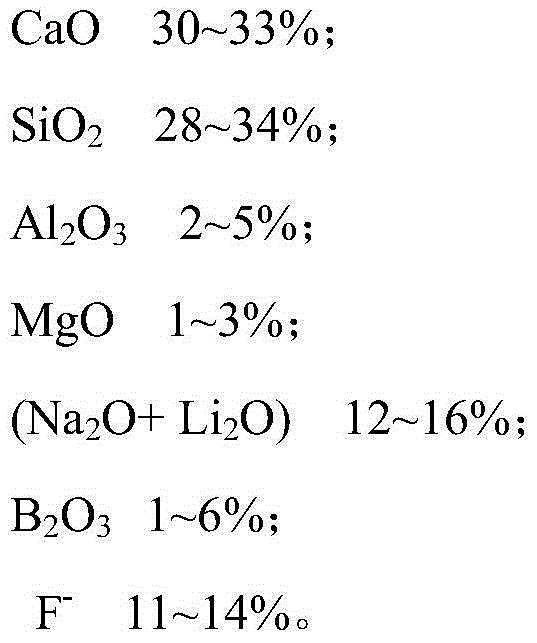

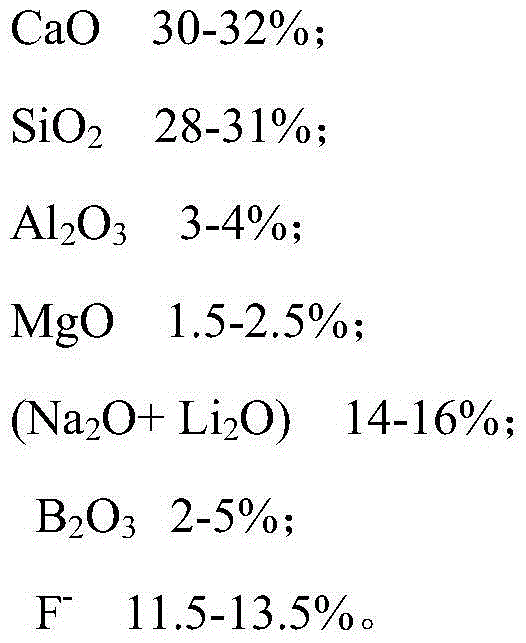

Novel casting powder and application thereof

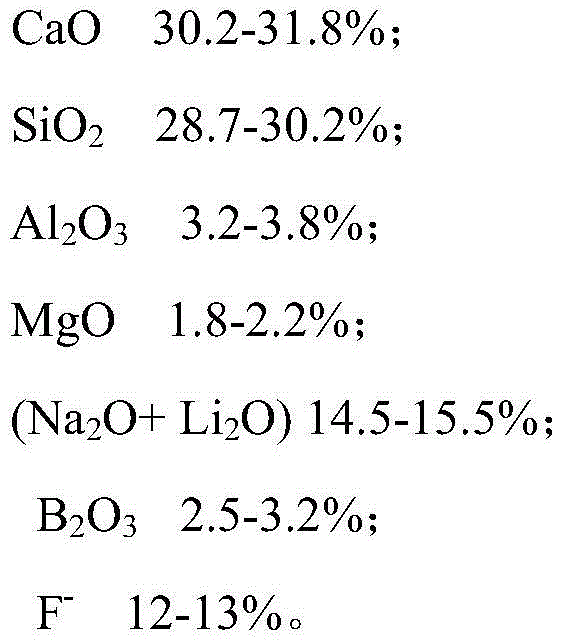

The invention relates to novel casting powder and application thereof, and belongs to the technical field of steel continuous casting powder. The casting powder comprises the following components according to mass percentage, 30-33% of CaO, 28-34% of SiO2, 2-5% of Al2O3, 1-3% of MgO, 12-16% of (Na2O+Li2O), 1-6% of B2O3, and 11-14% of F-. The casting powder has the characteristics of low melting point (950 to 1,050 DEG C), low viscosity (the viscosity is 0.06 to 0.10Pa.s at the temperature of 1,300 DEG C), high crystallization temperature (1,215 to 1,302 DEG C) and the like. The casting power designed by the invention is suitable for the continuous casting of high-carbon chromium-containing steel of which the mass percentage of C is 1.3-1.8% and the mass percentage of Cr is 10-15%. When the casting powder is applied to the continuous casting production of a high-carbon chromium-containing steel slab, Cr2O3 and other impurities with a high melting point in a crystallizer can be effectively absorbed, the infiltration capability of the casting powder is improved, and the slow cooling of a meniscus is implemented, so that the objectives of increasing the lubricating of a casting blank, controlling the heat transferring at the meniscus, reducing the cracking and inclusion of the casting blank and improving the quality of the casting blank are achieved.

Owner:CENT SOUTH UNIV

SiO2/Sb superlattice nano phase change thin film material and preparation method and application thereof

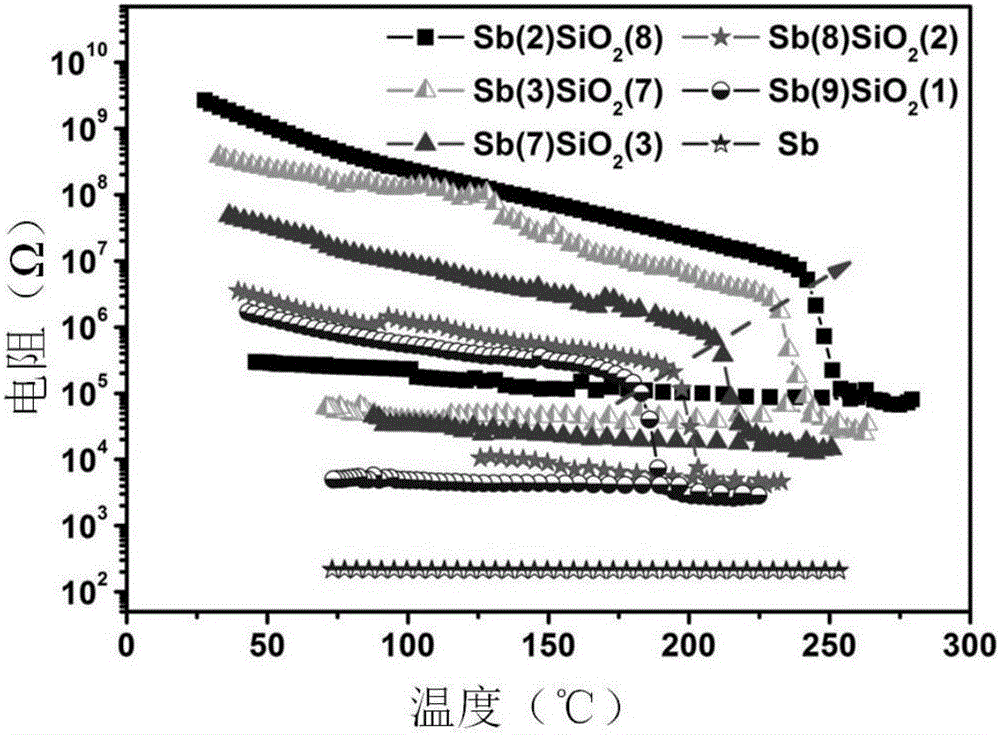

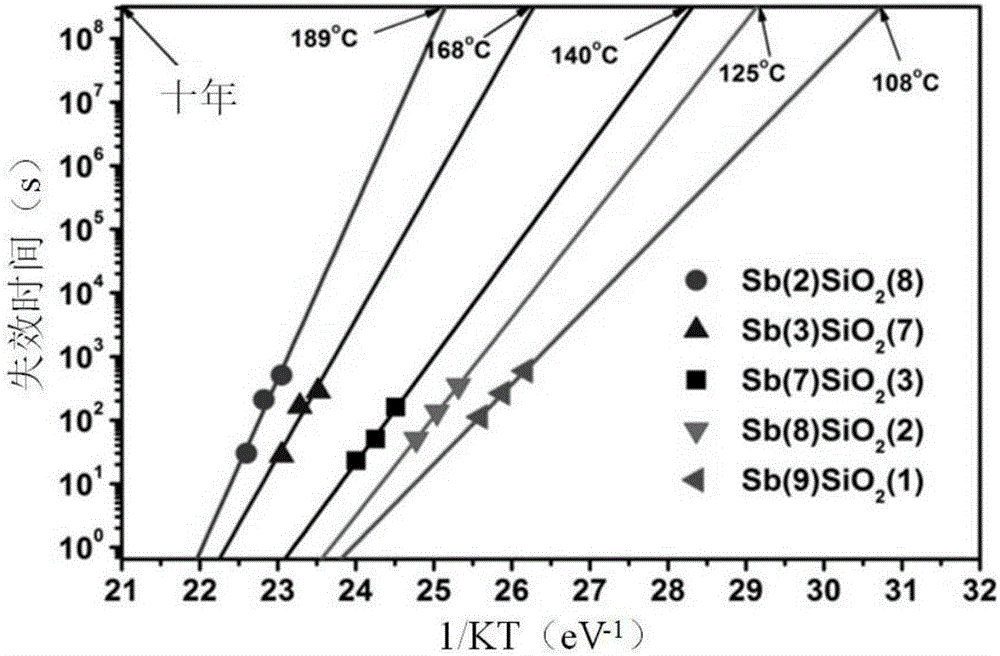

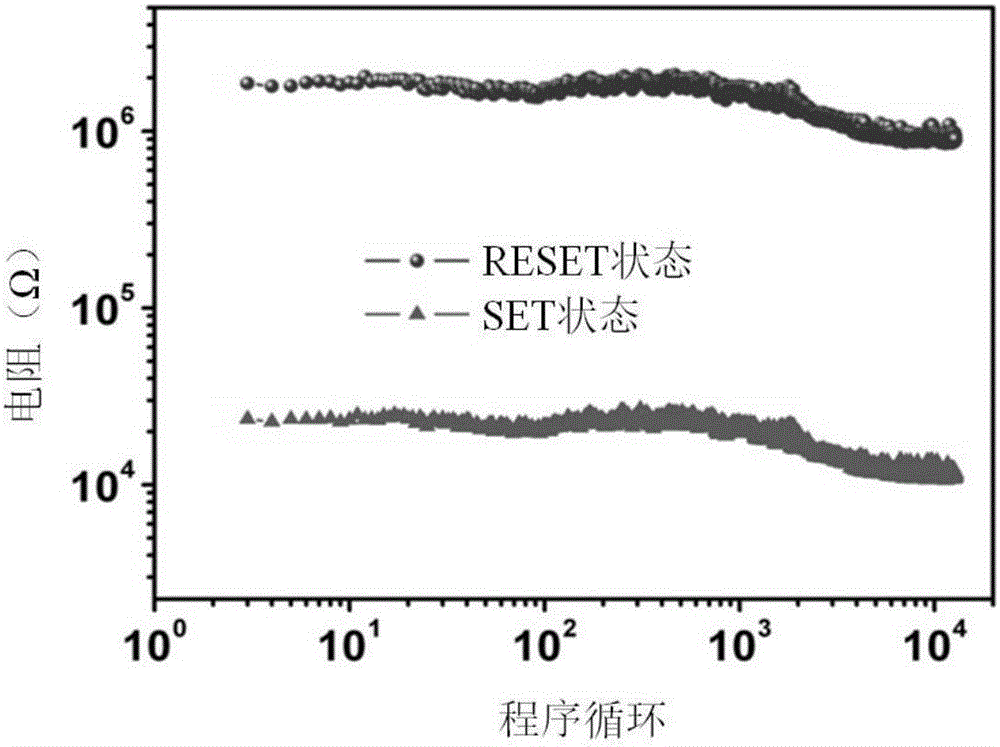

ActiveCN106185799AImprove stabilityReduce power consumptionMaterial nanotechnologyElectrical apparatusSputteringHeat stability

The invention relates to the technical field of nano materials and relates to a SiO2 / Sb superlattice nano phase change thin film material and a preparation method and application thereof. The material comprises a silicon dioxide thin film material and an elemental antimony thin film material. The silicon dioxide thin film material and the elemental antimony thin film material carry out nano-scale alternate superposition through magnetron sputtering. The structural general formula of the material is [SiO2(a) / Sb(b)]x, wherein a indicates the thickness (nm) of a single layer of SiO2 thin film, and a is larger than or equal to 1 and smaller than or equal to 9; b indicates the thickness (nm) of a single layer of Sb thin film, and b is larger than or equal to 1 and smaller than or equal to 8; x indicates the alternate periodicity of the single layer of SiO2 thin film and the single layer of Sb thin film, and x is any positive integer. The SiO2 / Sb superlattice nano phase change thin film material has high phase change speed, good heat stability and low operation power consumption, is suitable for preparing high-speed, high-stability and low-power-consumption phase change memorizers, and has wide market prospects.

Owner:JIANGSU UNIV OF TECH

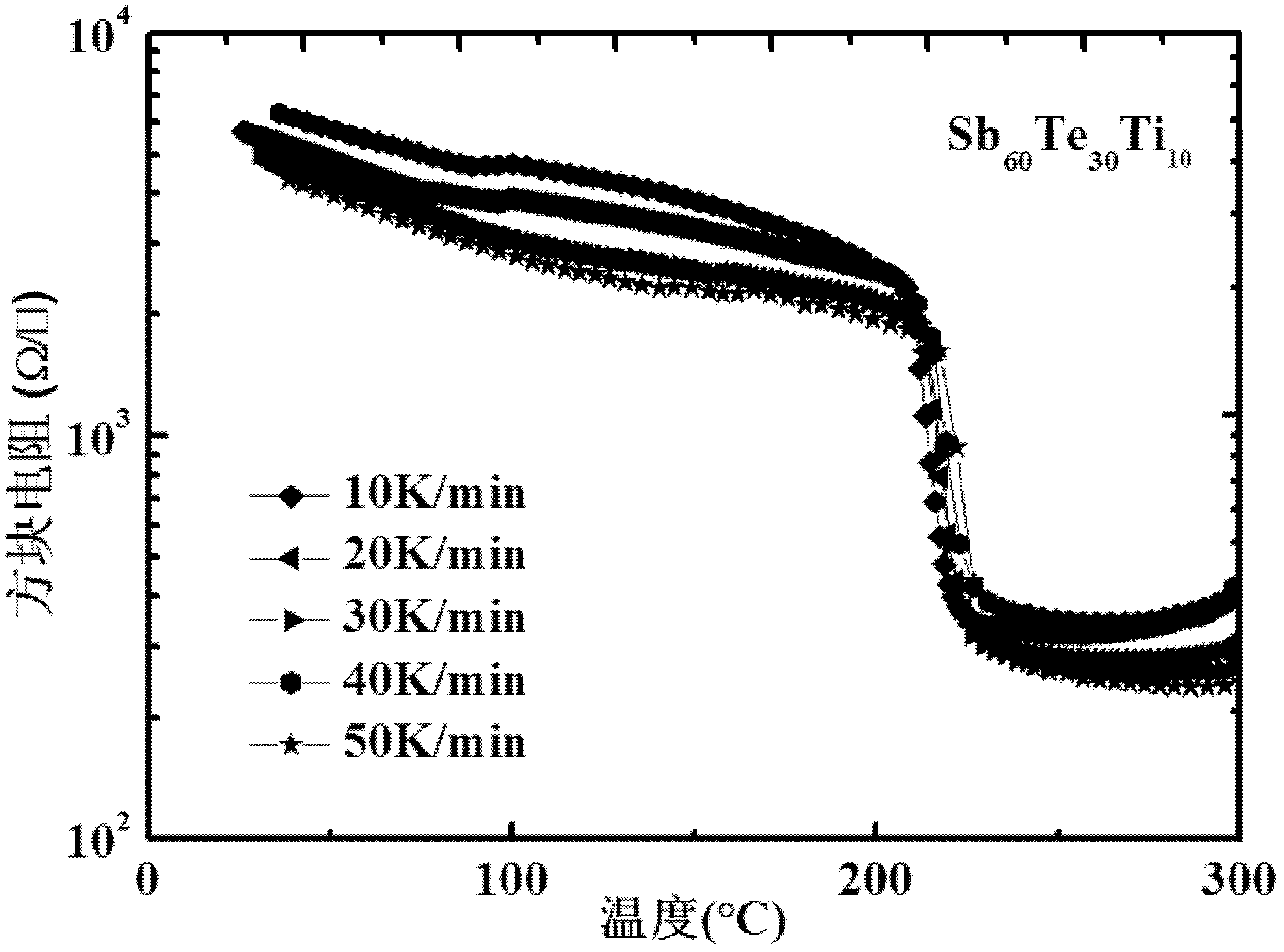

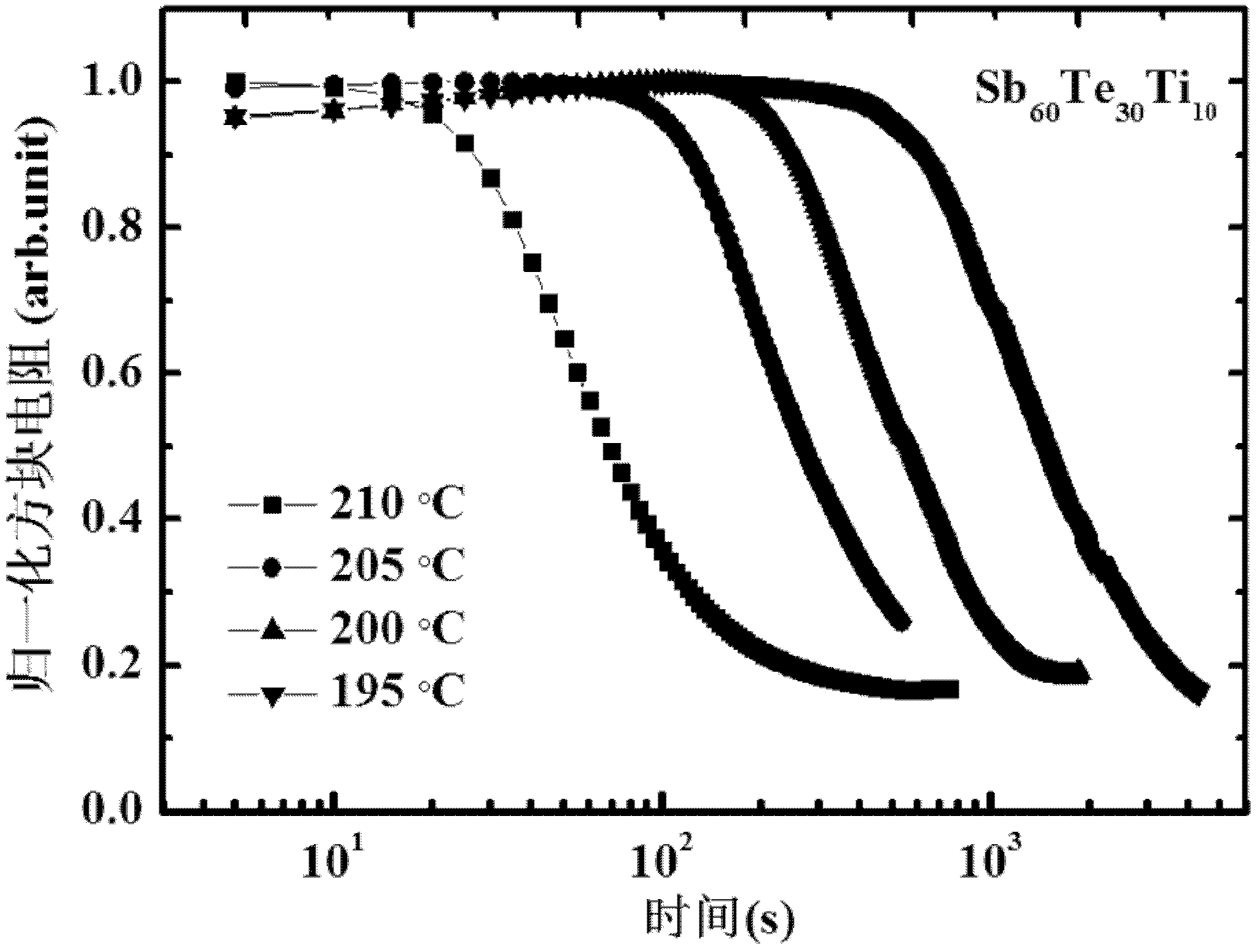

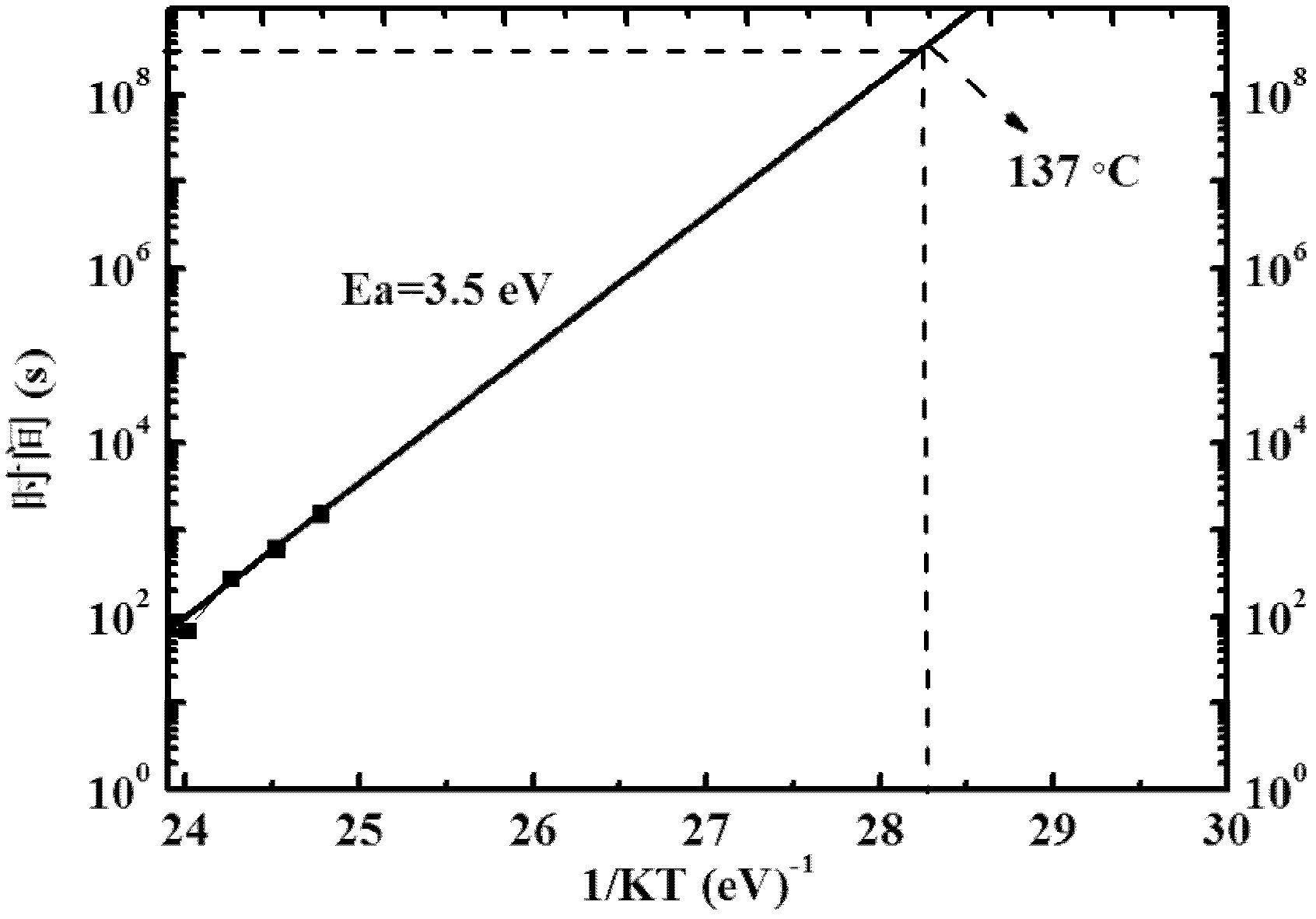

Sb-Te-Ti phase-change storage material and Ti-Sb2Te phase-change storage material

ActiveCN102569652AFast operationHigh repetition rateElectrical apparatusPhase-change memoryCrystallization temperature

The invention relates to a Sb-Te-Ti phase-change thin-film material capable of being used for a phase-change memory, and preparation and application of the Sb-Te-Ti phase-change thin-film material. The novel Sb-Te-Ti phase-change storage material is prepared by doping Ti into a Sb-Te phase-change material, the doped Ti forms bonds with both Sb and Te, and the chemical general formula of the Sb-Te-Ti phase-change storage material is SbxTeyTi100-x-y, wherein x is more than 0 and less than 80, and y is more than 0 and less than 100-x. When the phase-change storage material is a Ti-Sb2Te phase-change storage material, a Ti atom replaces a Sb atom without phase separation. The grain growth is dominant in the crystallization process of the conventional Sb-Te phase-change material, so that the phase change rate is high, but the retention cannot meet industrial requirements. The crystallization temperature of the novel Sb-Te-Ti phase-change storage material is greatly raised, the retention is promoted, and the thermal stability is enhanced; simultaneously, the non-crystalline state resistance is reduced and the crystalline state resistance is increased; and the novel Sb-Te-Ti phase-change storage material can be widely applied to the phase-change memory.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts](https://images-eureka.patsnap.com/patent_img/b6fab942-afa2-40d1-8bad-64626af95506/US06946507-20050920-C00001.png)

![Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts](https://images-eureka.patsnap.com/patent_img/b6fab942-afa2-40d1-8bad-64626af95506/US06946507-20050920-C00002.png)

![Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts Nucleating additive formulations of bicyclo[2.2.1]heptane dicarboxylate salts](https://images-eureka.patsnap.com/patent_img/b6fab942-afa2-40d1-8bad-64626af95506/US06946507-20050920-C00003.png)