Ge/Sb type superlattice phase-change film material for high-speed low-power phase-change memory and preparation method of material

A technology of phase-change memory and thin-film materials, applied in nanotechnology for materials and surface science, metal material coating technology, ion implantation plating, etc., can solve the problem of not fully meeting the requirements of semiconductor chips and information storage , poor film thermal stability and other issues, to achieve the effects of shortening the crystallization time, inhibiting crystallization, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

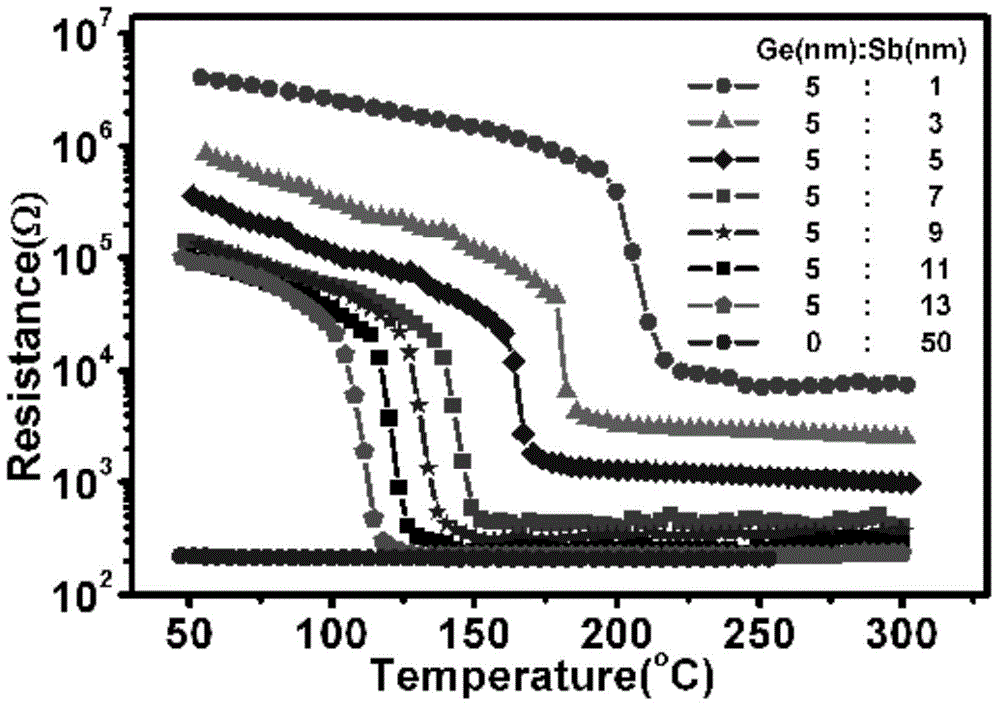

[0027] The Ge / Sb-based superlattice phase-change thin film material used for high-speed and low-power phase-change memory in this embodiment is a multilayer film structure with a thickness of 6-80 nm; it is formed by alternately depositing and compounding Ge layers and Sb layers, namely In the thin film, the sequence of Ge layer-Sb layer-Ge layer-Sb layer... is repeated and alternately arranged. One layer of Ge and one layer of Sb are used as an alternating cycle, and the Ge layer of the latter alternate cycle is deposited on the Sb layer of the previous alternate cycle.

[0028] The general formula [Ge(a) / Sb(b)] for the film structure of the above-mentioned GeSb-based superlattice phase-change thin film material x where a is the thickness of a single layer of Ge, 1nm≤a≤50nm; b is the thickness of a single layer of Sb, 1nm≤b≤50nm; x is the number of alternating cycles of Ge and Sb layers, or a layer of Ge layer and a layer of Sb as a group, and the film material is composed of ...

Embodiment 2)

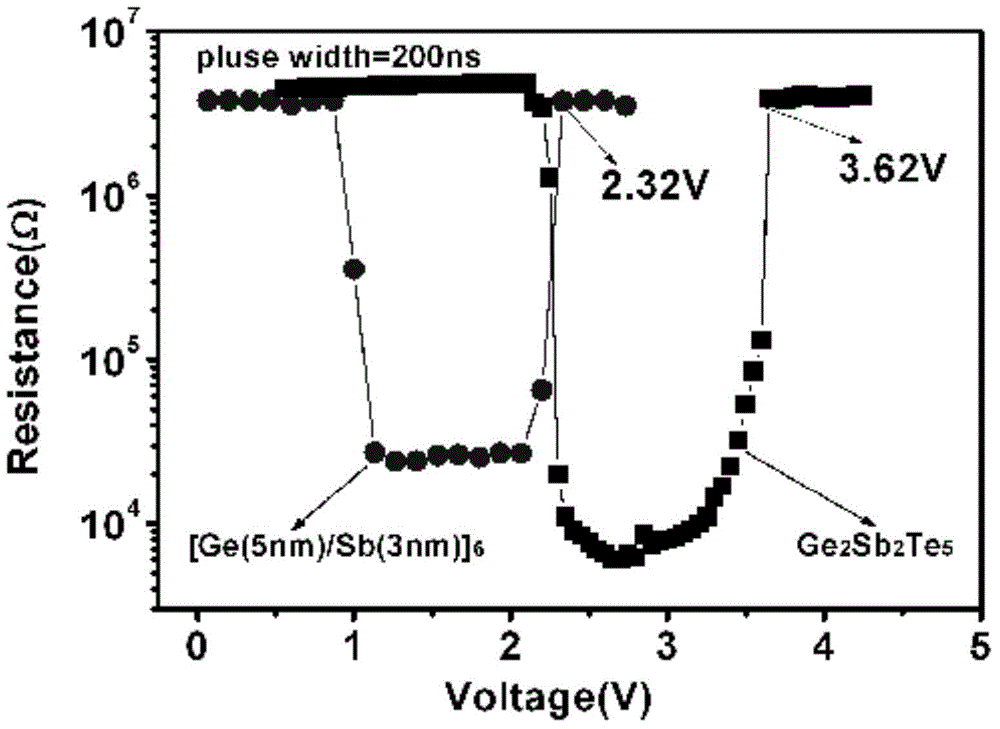

[0042] The film structure of the Ge / Sb class superlattice phase-change film material used for high-speed low-power phase-change memory of the present embodiment is [Ge (5nm) / Sb (3nm)] 6 , that is, the thickness of each layer of Ge layer is 5nm, the thickness of each layer of Sb layer is 3nm, the number of alternating periods of Ge layer and Sb layer is 6, and the thickness of Ge / Sb superlattice phase change thin film material is 48nm.

[0043] All the other preparation methods are the same as in Example 1, the difference is: step 3. magnetron sputtering preparation [Ge(a) / Sb(b)] x For multilayer composite films, the sputtering time of each layer of Sb is 9s. The Ge layer and the Sb layer were alternately sputtered 6 times.

Embodiment 3)

[0045] The film structure of the Ge / Sb class superlattice phase-change film material used for high-speed low-power phase-change memory of the present embodiment is [Ge (5nm) / Sb (5nm)] 6 , that is, the thickness of each layer of Ge layer is 5nm, the thickness of each layer of Sb layer is 5nm, the number of alternating cycles of Ge layer and Sb layer is 6, and the thickness of Ge / Sb superlattice phase change thin film material is 60nm.

[0046] All the other preparation methods are the same as in Example 1, the difference is: step 3. magnetron sputtering preparation [Ge(a) / Sb(b)] x For multilayer composite films, the sputtering time for each layer of Sb is 15s. Ge layer and Sb layer were alternately sputtered 6 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com