Fumaric acid-diol polyester, copolyester of fumaric acid-diol polyester, polyester nucleating agent containing fumaric acid-diol polyester and application of fumaric acid-diol polyester

A polyfumarate diol and copolyester technology is applied in the field of polyfumarate and its copolyester, polyester nucleating agent, and can solve the problem of high cost of nucleating agent materials, Achieve the effect of shortening the molding cycle, increasing the crystallization temperature, and large application advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment is to prepare polybutylene fumarate by bulk melting method.

[0038] Add fumaric acid and 1,4-butanediol (molar ratio: 1:1.05) into a three-neck flask, protect it under nitrogen atmosphere, put it in an oil bath, stir and react at 160°C, 180°C and 220°C for 1 hour respectively ; Then add a transesterification catalyst (such as tetrabutyl titanate) 0.0005g / 1g polymer under a nitrogen atmosphere, stir rapidly to make the catalyst disperse evenly; then evacuate to 60Pa, react at 230°C for 3 hours; discharge to obtain poly Butylene glycol fumarate. The number average molecular weight was 35000 g / mol, and the molecular weight distribution was 2.21.

Embodiment 2

[0040] In this example, a random copolymer of 40 mol% butylene fumarate and 60 mol% butylene succinate was prepared by bulk melting method.

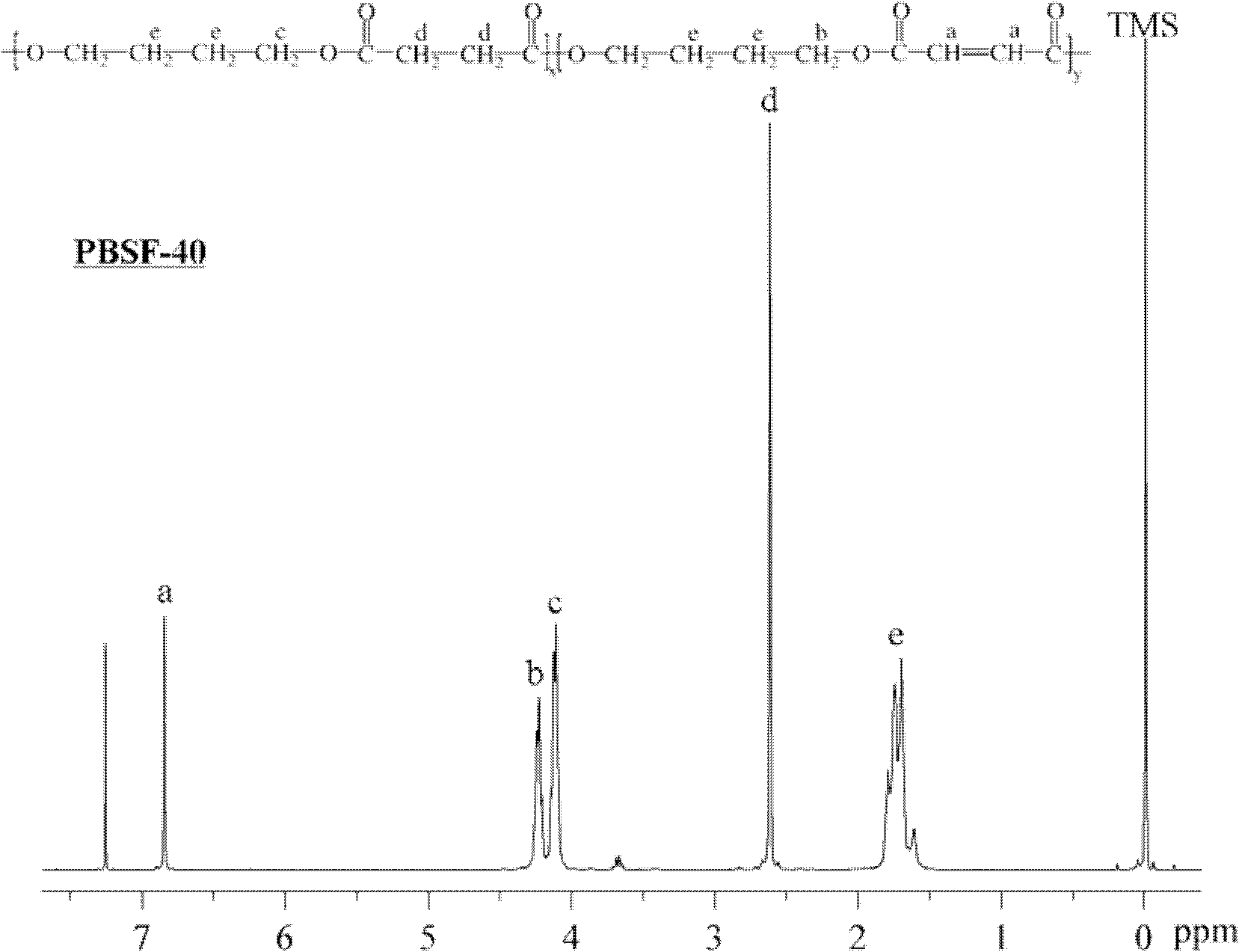

[0041] Add fumaric acid, succinic acid and 1,4-butanediol (molar ratio: 0.4:0.6:1.05) into a three-necked flask, protect it under a nitrogen atmosphere, and place it in an oil bath at 160°C, 180°C and 220°C Stirring and reacting for 1 hour under nitrogen atmosphere; then add a transesterification catalyst (such as tetrabutyl titanate) 0.0005g / 1g polymer under a nitrogen atmosphere, stir rapidly to make the catalyst evenly dispersed; then vacuumize to 100Pa, and react at 230°C for 3 hours; discharging to obtain a random copolymer of 40 mol% butylene fumarate and 60 mol% butylene succinate. figure 1 Its 1H NMR map. The number average molecular weight was 47000 g / mol, and the molecular weight distribution was 1.96.

Embodiment 3

[0043] In this example, random copolymers of various dibasic acids and various dibasic alcohols were prepared by the bulk melting method.

[0044] A certain mole of fumaric acid, succinic acid, adipic acid, malonic acid and 1,4-butanediol, hexanediol, pentanediol, decanediol (the molar ratio is 0.8:0.1:0.05:0.05 : 0.85: 0.1: 0.05: 0.05) was added in the there-necked flask, under nitrogen atmosphere protection, placed in an oil bath at 160°C, 180°C and 220°C and stirred for 2 hours respectively; then under nitrogen atmosphere, the transesterification catalyst ( Such as tetrabutyl titanate) 0.0005g / 1gPBF, stirring quickly to disperse the catalyst evenly; then vacuumize to 80Pa, and react at 230°C for 3 hours; the random copolymer. The number average molecular weight was 31000 g / mol, and the molecular weight distribution was 2.50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com