Single crystal anatase titanium dioxide nano-tube array and preparation method thereof

A technology of nanotube array and titanium dioxide, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the titanium dioxide nanotube array is not prepared, and achieve good electron transport and strong controllability , The effect of fast electron transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046](1) TiNbZr alloy is prepared by arc melting method, the molar ratio of each element in the TiNbZr alloy is Ti: Nb: Zr=72: 22: 6;

[0047] (2) Process the TiNbZr alloy into thin slices with a thickness of 1mm, use 360#, 600#, 800#, 1000#, 1200#, 1500# water-grinding paper to mechanically polish the surface in turn, and use distilled water, acetone, ethanol and Distilled water was used as the lotion and ultrasonically cleaned for 10 minutes each, then rinsed in distilled water and dried for later use;

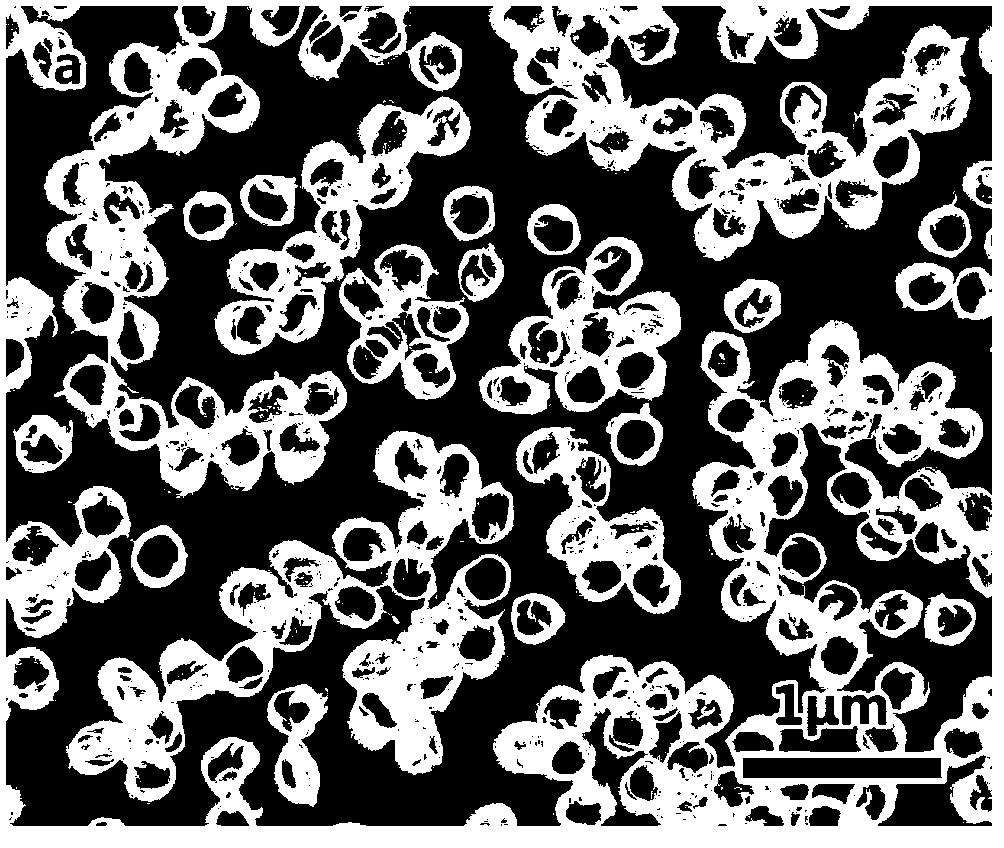

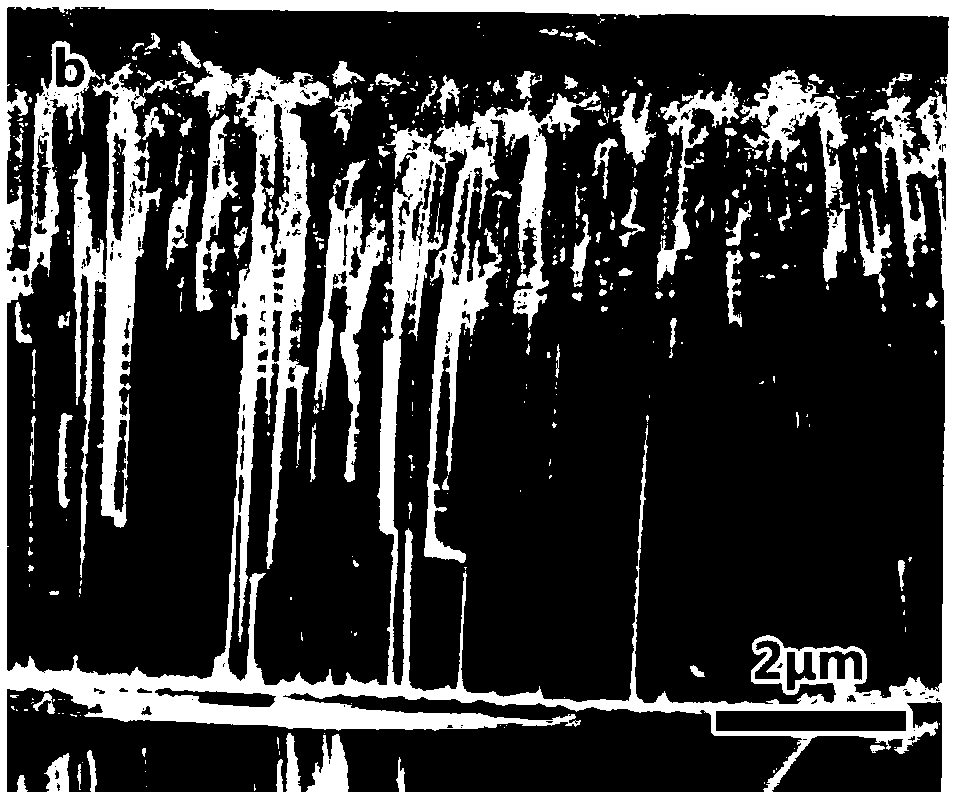

[0048] (3) at 1M H 3 PO 4 And in the electrolytic solution of 0.5wt%NaF, control voltage is 40V, with step (2) gained TiNbZr alloy sheet is anode, high-purity Pt sheet carries out anodic oxidation as cathode, carries out anodic oxidation at room temperature, and oxidation time is 3h, namely Amorphous titanium dioxide nanotube arrays can be obtained on the surface of TiNbZr alloy flakes; the length of the gained amorphous titanium dioxide nanotube arrays is 6mm (such as ...

Embodiment 2

[0056] (1) TiNbZr alloy is prepared by arc melting method, the molar ratio of each element in the TiNbZr alloy is Ti: Nb: Zr=71: 21: 8;

[0057] (2) Process the TiNbZr alloy into thin slices with a thickness of 1.5mm, use 360#, 600#, 800#, 1000#, 1200#, 1500# water-grinding sandpaper to mechanically polish the surface in turn, and use distilled water, acetone, ethanol in turn Ultrasonic cleaning with distilled water for 10 minutes each, followed by rinsing in distilled water and drying for later use;

[0058] (3) at 1M H 3 PO 4 In the electrolyte of 1wt%NaF, the control voltage is 40V, the TiNbZr alloy flake obtained in step (2) is used as the anode, and the high-purity Pt sheet is used as the cathode for anodic oxidation, and the anodic oxidation is carried out at room temperature, and the oxidation time is 3h. Amorphous titania nanotube arrays were obtained on the surface of TiNbZr alloy flakes;

[0059] The length of the amorphous titania nanotube array is about 6 mm, an...

Embodiment 3

[0064] (1) TiNbZr alloy is prepared by arc melting method, and the molar ratio of each element in the TiNbZr alloy is Ti: Nb: Zr=63: 35: 2;

[0065] (2) Process the TiNbZr alloy into thin slices with a thickness of 5mm, use 360#, 600#, 800#, 1000#, 1200#, 1500# water-grinding paper to mechanically polish the surface in turn, and use distilled water, acetone, ethanol and Distilled water was used as the lotion and ultrasonically cleaned for 10 minutes each, then rinsed in distilled water and dried for later use;

[0066] (3) at 5M H 3 PO 4 In the electrolyte solution of 1wt% NaF, the control voltage is 20V, the TiNbZr alloy flake obtained in step (2) is used as the anode, and the high-purity Pt sheet is used as the cathode for anodic oxidation, and the anodic oxidation is carried out at room temperature, and the oxidation time is 3h. Amorphous titania nanotube arrays were obtained on the surface of TiNbZr alloy flakes; Figure 11-a1 It is the top view of the scanning electron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com