Method for preparing carbon quantum dot/flower-shaped indium and calcium sulfide composite photocatalysts and application thereof

A technology of carbon quantum dots and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and water treatment of special compounds. It can solve the problems of no literature reports, etc., to promote transmission, shorten the preparation cycle, and improve visible light response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] (1) Measure 10 mL of absolute ethanol and 10 mL of secondary deionized water into a beaker, where the volume ratio of absolute ethanol to secondary deionized water is 1:1. Weigh out 0.011 g calcium chloride, 0.044 g indium chloride, and 0.030 g thiourea, and stir to dissolve to obtain a mixed solution.

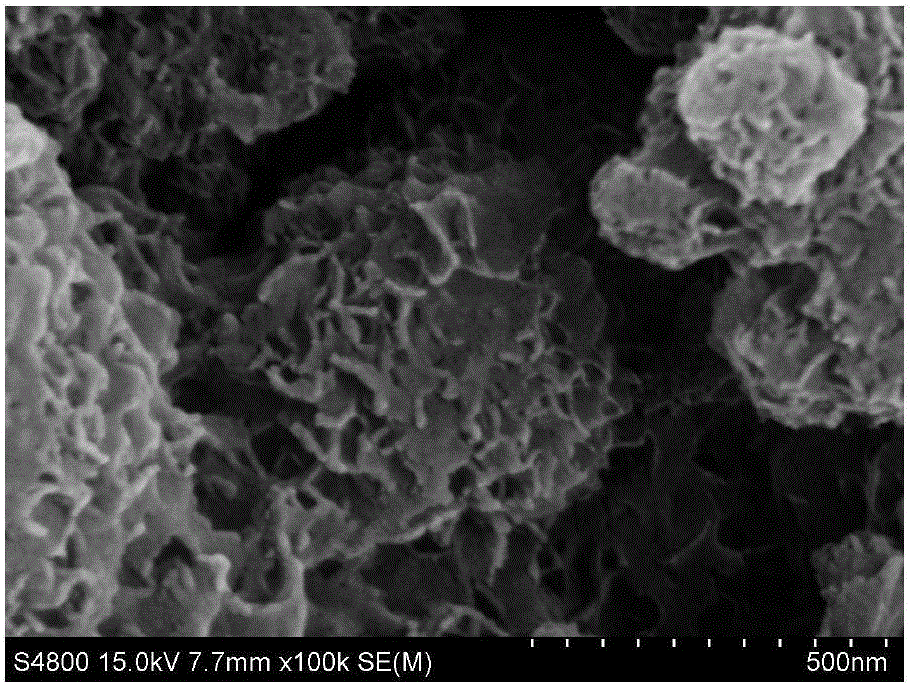

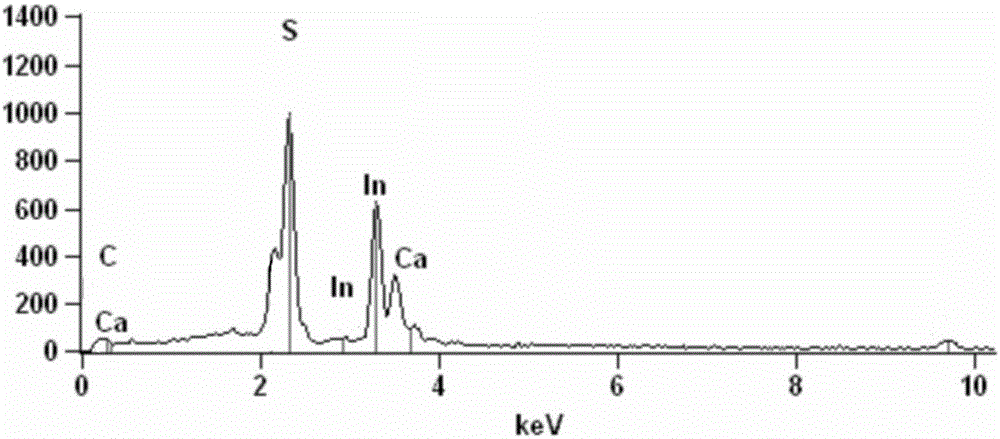

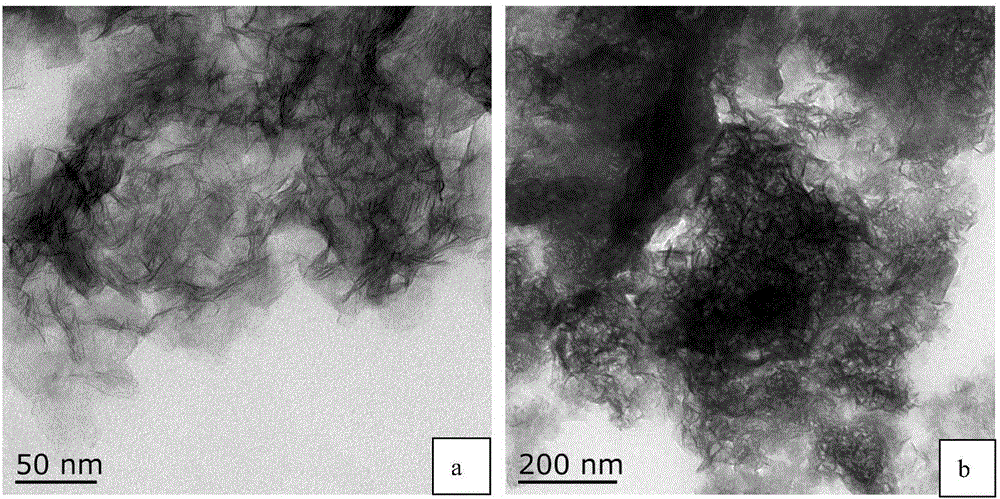

[0026] (2) Measure 1 mL of an aqueous solution of carbon quantum dots (CQDs) with a concentration of 0.003 g / mL to the solution prepared in step (1), where the diameter of the CQDs is in the range of 3 to 6 nm; after ultrasound for 5 minutes, stir for 10 minutes and transfer to The reaction kettle was treated at 120℃ for 24h, cooled naturally to room temperature, centrifuged, washed with absolute ethanol and water several times, and vacuum dried at 50℃ for 6h to obtain a carbon quantum dot / flower-like indium calcium sulfide composite photocatalyst, carbon The proportion of quantum dots in the composite is 7.0%.

[0027] Visible light for 2h, the photocatalytic degradation e...

example 2

[0030] (1) Measure 20 mL of absolute ethanol and 60 mL of secondary deionized water into a beaker, where the volume ratio of absolute ethanol to secondary deionized water is 0.33:1. Weigh out 0.033 g calcium chloride, 0.132 g indium chloride, and 0.090 g thiourea, and stir to dissolve to obtain a mixed solution.

[0031] (2) Measure 2 mL of an aqueous solution of carbon quantum dots (CQDs) with a concentration of 0.002 g / mL to the solution prepared by step (1), where the diameter of CQDs is in the range of 3 to 6 nm; after sonicating for 10 minutes, stirring for 15 minutes, transfer to The reaction kettle was treated at 140℃ for 20h, cooled naturally to room temperature, centrifuged, washed with absolute ethanol and water several times, and vacuum dried at 40℃ for 8h to obtain a carbon quantum dot / flower-like indium calcium sulfide composite photocatalyst. The proportion of quantum dots in the composite is 3.2%.

[0032] Visible light for 2h, the photocatalytic degradation efficie...

example 3

[0035] (1) Measure 40 mL of absolute ethanol and 20 mL of secondary deionized water in a beaker, respectively, where the volume ratio of absolute ethanol to secondary deionized water is 1:0.5. Weigh out 0.055 g of calcium chloride, 0.22 g of indium chloride, and 0.150 g of thiourea, and stir to dissolve to obtain a mixed solution.

[0036] (2) Measure 2 mL of an aqueous solution of carbon quantum dots (CQDs) with a concentration of 0.005 g / mL to the solution prepared by step (1), where the diameter of CQDs is in the range of 3 to 6 nm; after 15 minutes of ultrasound, after stirring for 20 minutes, transfer to The reaction kettle was treated at 160℃ for 16h, cooled naturally to room temperature, centrifuged, washed with absolute ethanol and water several times, and vacuum dried at 60℃ for 5h to obtain a carbon quantum dot / flower-like indium calcium sulfide composite photocatalyst, carbon The proportion of quantum dots in the composite is 4.8%.

[0037] Visible light for 2h, the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com