High-conductivity rare earth duralumin monofilament material for overhead conductors

A high-conductivity, overhead wire technology, applied in the direction of metal/alloy conductors, etc., can solve the problems that cannot meet the market demand of overhead aluminum wires, high transmission line loss, strength and surface hardness hinder the promotion and use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

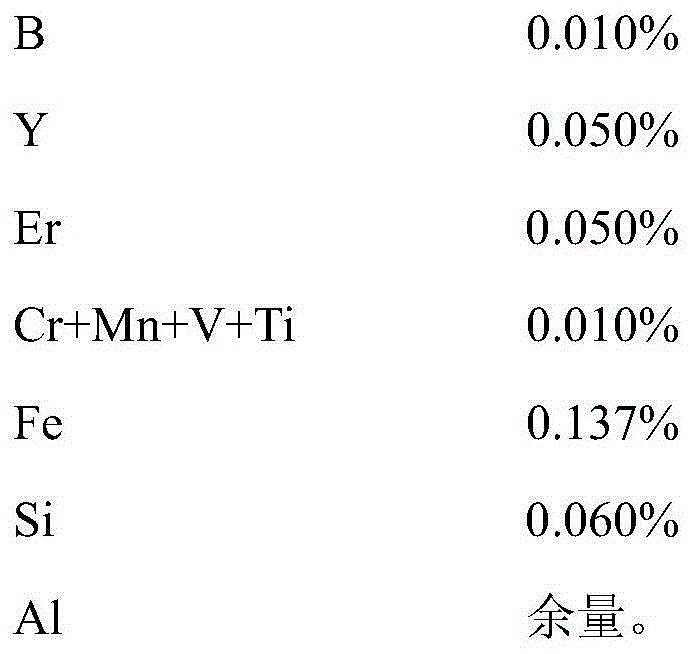

[0031] A high-conductivity rare earth duralumin monofilament material for overhead wires, the components and their mass percentages are:

[0032]

[0033]Each alloying element is added to a pure aluminum ingot with a purity of 99.7%, so that their final content is as shown above, and the alloying element is added in the form of Al-B, Al-Er, and Al-Y master alloys. The hard aluminum alloy ingot is formed by casting in a red copper mold; the aluminum alloy rod is hot-rolled through a rolling mill; the rolled round rod adopts the conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the cold drawing is carried out on a high-speed wire drawing machine. The diameter of the duralumin monofilament is 3.05mm, the conductivity is 63.08%IACS, the tensile strength is 168.12MPa, and the elongation is 2.48%.

Embodiment 2

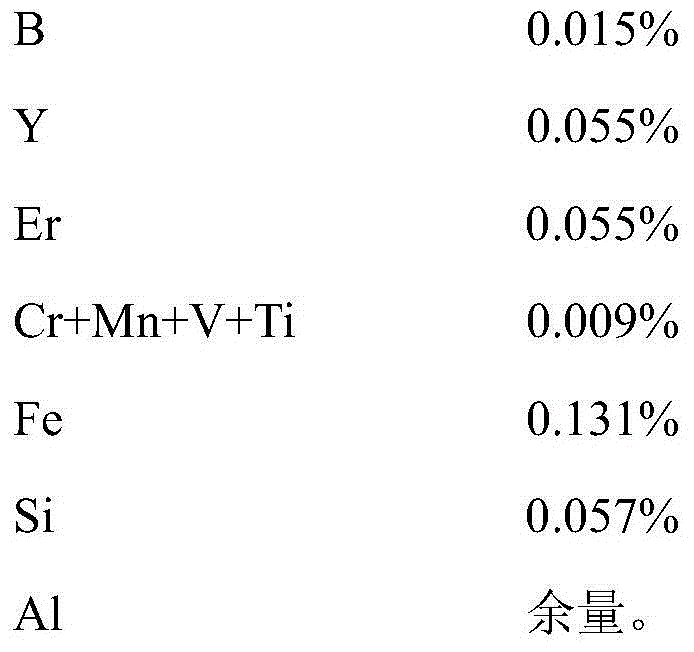

[0035] A high-conductivity rare earth duralumin monofilament material for overhead wires, the components and their mass percentages are:

[0036]

[0037] Each alloying element is added to a pure aluminum ingot with a purity of 99.7%, so that their final content is as shown above, and the alloying element is added in the form of Al-B, Al-Er, and Al-Y master alloys. The hard aluminum alloy ingot is formed by casting in a red copper mold; the aluminum alloy rod is hot-rolled through a rolling mill; the rolled round rod adopts the conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the cold drawing is carried out on a high-speed wire drawing machine. The diameter of the duralumin monofilament is 3.35mm, the conductivity is 63.24%IACS, the tensile strength is 167.28MPa, and the elongation is 2.50%.

Embodiment 3

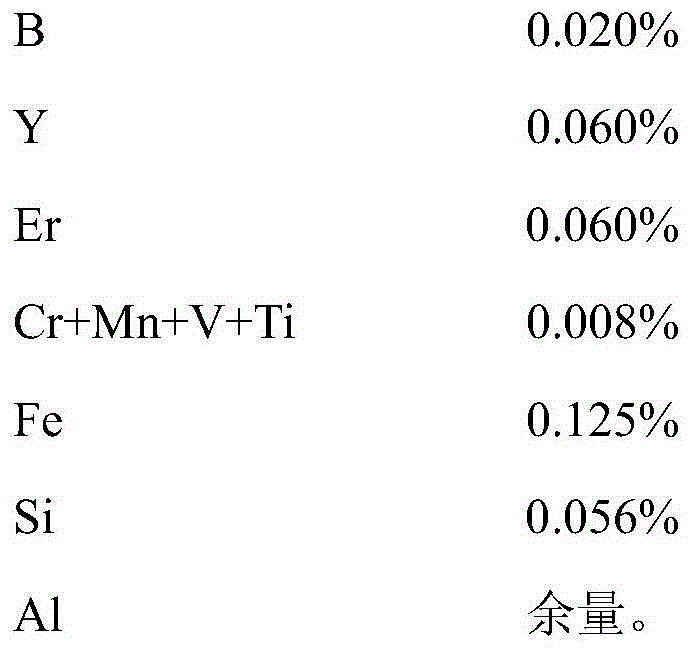

[0039] A high-conductivity rare earth duralumin monofilament material for overhead wires, the components and their mass percentages are:

[0040]

[0041] Each alloying element is added to a pure aluminum ingot with a purity of 99.7%, so that their final content is as shown above, and the alloying element is added in the form of Al-B, Al-Er, and Al-Y master alloys. The hard aluminum alloy ingot is formed by casting in a red copper mold; the aluminum alloy rod is hot-rolled through a rolling mill; the rolled round rod adopts the conventional aluminum monofilament preparation process, and the mold is sequentially matched, and the cold drawing is carried out on a high-speed wire drawing machine. The diameter of the duralumin monofilament is 3.50mm, the conductivity is 63.27%IACS, the tensile strength is 166.56MPa, and the elongation is 2.62%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com