Preparation method of organic silicon modified epoxy resin

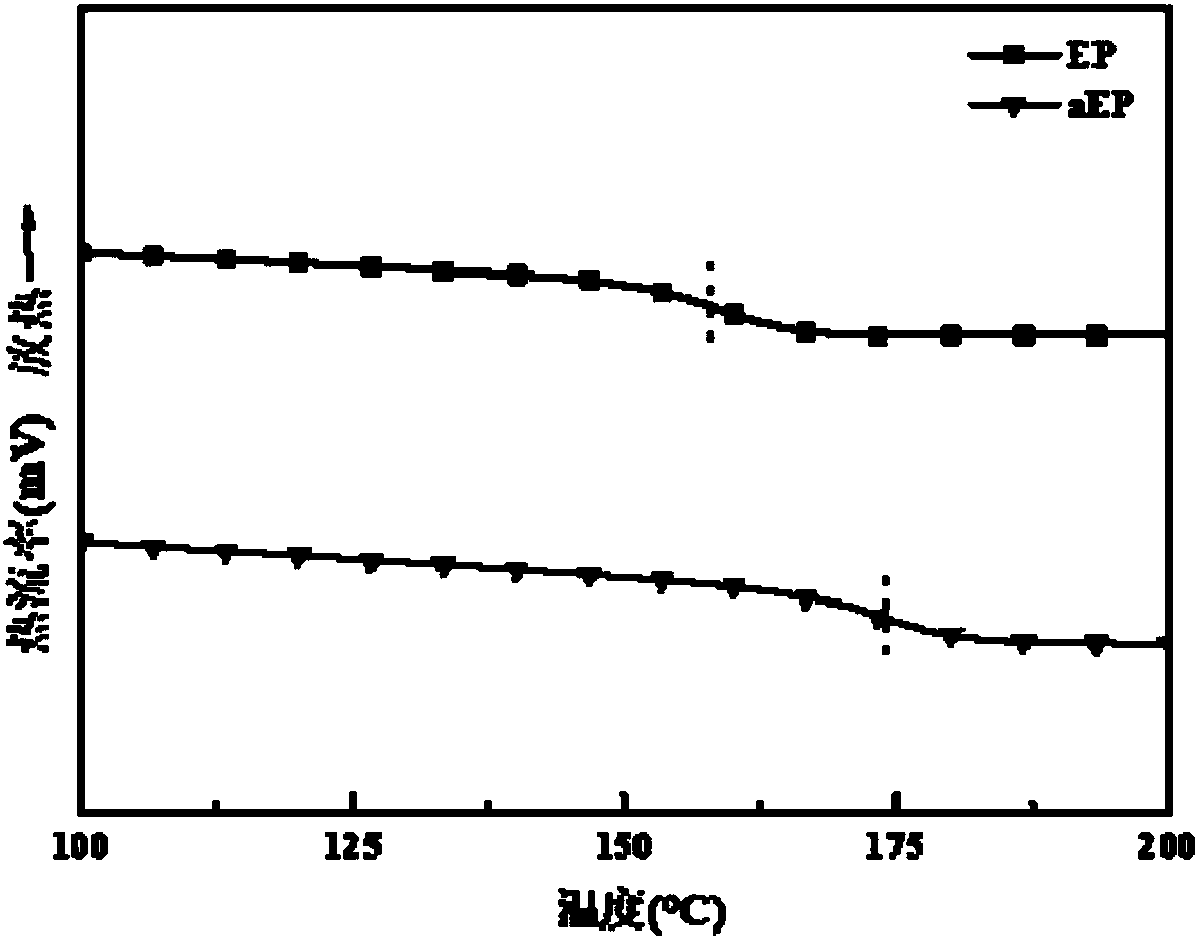

A technology of epoxy resin and organosilicon, which is applied in the field of preparation of organosilicon modified epoxy resin, can solve the problems of poor toughness and poor thermal stability of epoxy resin, so as to increase the glass transition temperature and realize the glass transition temperature , Improve the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the proportioning of reactant, the dibutyltin dilaurate of 100g two parts of A-type epoxy resin E44 and 0.1g is placed in the there-necked flask equipped with condensing reflux and constant pressure dropping funnel, and 8g is housed in the constant pressure funnel Methylvinyldimethoxysilane, slowly add methylvinyldimethoxysilane dropwise in an oil bath at 70°C with mechanical stirring at a speed of 600rpm, and wait until the addition of methylvinyldimethoxysilane is complete Finally, about 1 g of distilled water was added dropwise, and the modified product of the first step was obtained after 4 hours of reaction. On the basis of the modified product in the first step, continue to drop 1g of hydrogen-containing double head in an oil bath at 60°C and stir at 600rpm, and react under the catalysis of 300ppm chloroplatinic acid for 30min to obtain the organosilicon modification epoxy resin.

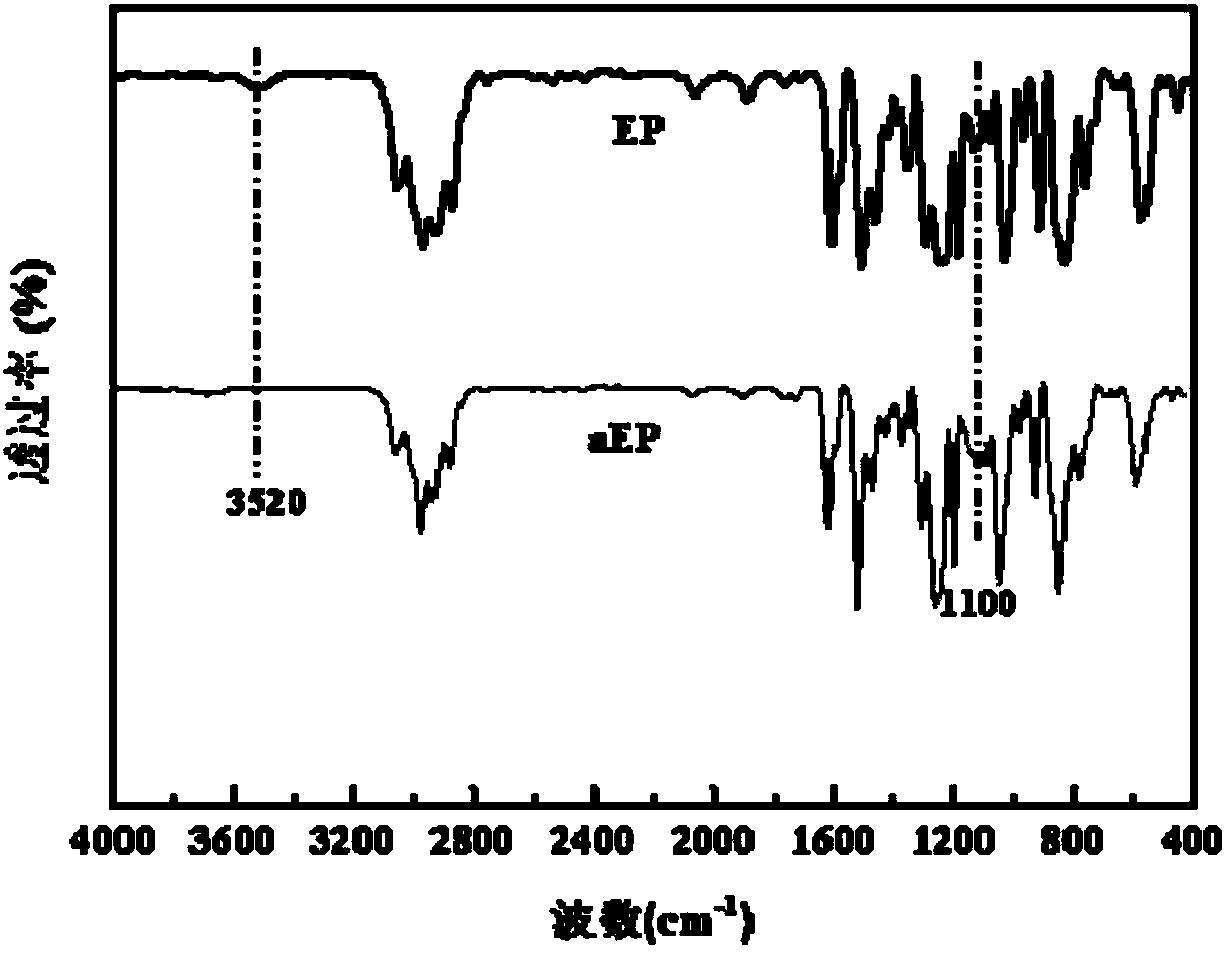

[0026] The infrared spectrum comparison of the final product of the p...

Embodiment 2

[0030] According to the ratio of the reactants, get 100g double parts of A-type epoxy resin E51 and 0.2g of titanate and place it in a three-necked flask equipped with condensing reflux and a constant pressure dropping funnel, and 9g of formazan is housed in the constant pressure funnel. Vinyl dimethoxysilane, in an oil bath at 80°C, slowly add methyl vinyl dimethoxy silane dropwise in a mechanical stirrer at 500rpm, after the methyl vinyl dimethoxy silane is added dropwise, Then about 1.5 g of distilled water was added dropwise, and the modified product of the first step was obtained after 5 hours of reaction. On the basis of the modified product in the first step, continue to drop 3g of hydrogen-containing silicone oil in an oil bath at 70°C and stir at 600rpm, and react for 60min under the catalysis of 500ppm Karstedt catalyst to obtain a silicone-modified epoxy resin .

Embodiment 3

[0032] According to the proportioning of reactant, get 100g two-part A-type epoxy resin E44 and the titanate of 0.3g and place in the there-necked flask equipped with condensing reflux and constant pressure dropping funnel, 10g of dimethicone is housed in the constant pressure funnel For methyldimethoxysilane, add dimethyldimethoxysilane slowly in an oil bath at 90°C with mechanical stirring at a speed of 300rpm. After the addition of dimethyldimethoxysilane is completed, add dropwise About 1g of distilled water, after 6 hours of reaction, the modified product of the first step can be obtained. On the basis of the modified product in the first step, continue to drop 15g of hydrogen-containing double head in an oil bath at 80°C while stirring at 400rpm, and react for 50min under the catalysis of 400ppm Karstedt catalyst to obtain the silicone modified ring oxygen resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com