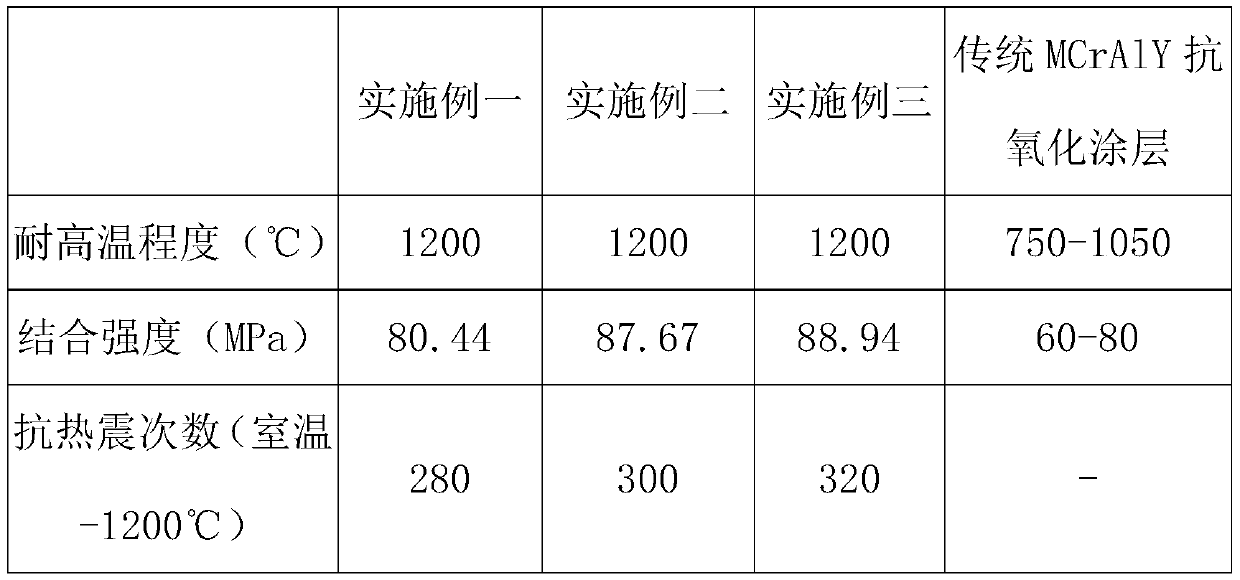

Anti-oxidation coating material resisting to high temperature of 1200 DEG C and preparation method thereof as well as coating preparation method

An anti-oxidation coating, high temperature technology, applied in the field of materials, can solve the problems of oxidation and corrosion of high-temperature components, and achieve the effects of improving high-temperature corrosion resistance, light weight, and improving gas corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The first step: according to the molar ratio of 1:16, take Ce(NO 3 )·6H 2 O and absolute ethanol, put them in the same beaker, stir and heat the solution under the water condition of 70°C, and form a colorless and transparent solution A after being completely dissolved. Under the condition of magnetic stirring, add HNO with a concentration of 1.5 mol / L dropwise to solution A 3 , adjust the pH of the solution to about 2.5, and continue to stir the mixed solution for 16 hours under the water condition of 70° C. to form an electrolytic solution for use. Weigh agar powder and NaNO 3 Pour into deionized water, in which agar powder and NaNO 3 The mass ratio of the solution is 12-14. Stir the solution evenly with a glass rod, heat it to 100°C, and keep stirring until it forms a gel, which becomes the standby salt bridge B.

[0026] The second step: use the electrolyte solution and salt bridge in the first step to build a secondary electrolytic cell, use high-purity Pt shee...

Embodiment 2

[0031] The first step: according to the molar ratio of 1:18, take Ce(NO 3 )·6H 2 O and absolute ethanol are placed in the same beaker, and the solution is stirred and heated at 80°C under water conditions, and a colorless and transparent solution A is formed after being completely dissolved. Under the condition of magnetic stirring, add HNO with a concentration of 1.5 mol / L dropwise to solution A 3 , adjust the pH of the solution to about 2.5, and continue to stir the mixed solution for 15 hours under the water condition of 80° C. to form an electrolytic solution for use. Weigh agar powder and NaNO 3 Pour into deionized water, in which agar powder and NaNO 3 The mass ratio of the solution is 13. Stir the solution evenly with a glass rod, heat it to 110°C, and keep stirring until it forms a gel, which becomes the standby salt bridge B.

[0032] The second step: use the electrolyte solution and salt bridge in the first step to build a secondary electrolytic cell, use high-pu...

Embodiment 3

[0037] The first step: according to the molar ratio of 1:19, take Ce(NO 3 )·6H 2 O and absolute ethanol, put them in the same beaker, stir and heat the solution under the water condition of 75°C, and form a colorless and transparent solution after completely dissolving. Add dropwise HNO with a concentration of 2 mol / L to the above solution under the condition of magnetic stirring 3 , adjust the pH of the solution to about 2.3, and continue to stir the mixed solution for 16 hours under the water condition of 80° C. to form an electrolytic solution for use. Weigh agar powder and NaNO 3 Pour into deionized water, in which agar powder and NaNO 3 The mass ratio of the solution is 14. Stir the solution evenly with a glass rod, heat it to 115°C, and keep stirring until it forms a gel and becomes a spare salt bridge.

[0038] The second step: use the electrolyte solution and salt bridge in the first step to build a secondary electrolytic cell, use high-purity Pt sheets as working ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com