Additive for pouring box dry vibrating material and preparation method and application thereof

A vibrating material and additive technology, which is applied in the field of steelmaking, can solve problems such as poor sintering strength, difficult demoulding, and difficult demoulding, so as to achieve the effect of reducing damage and improving high temperature corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

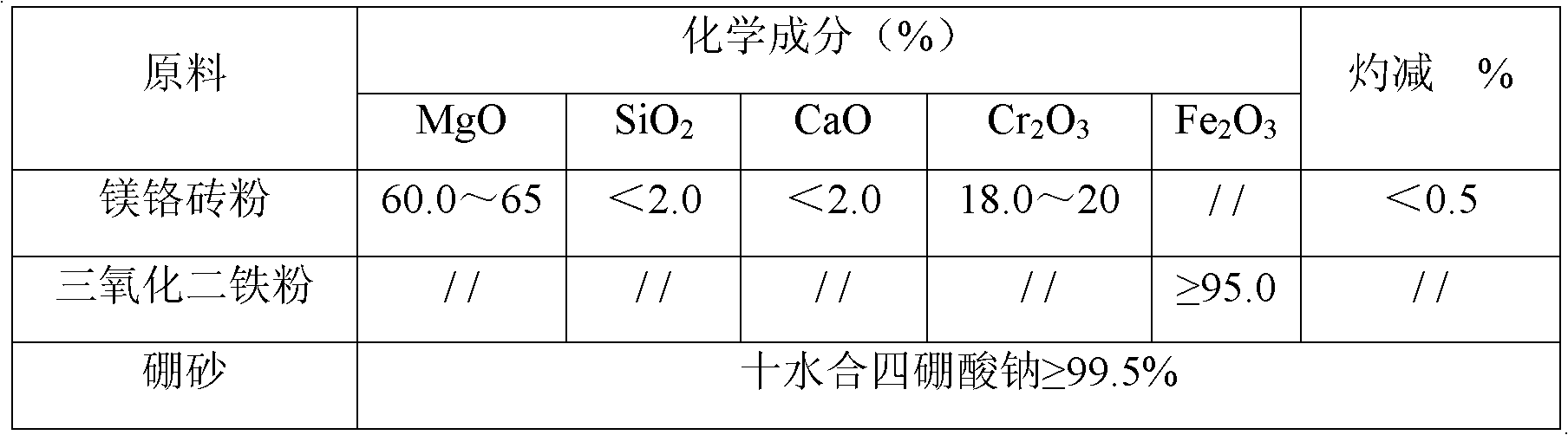

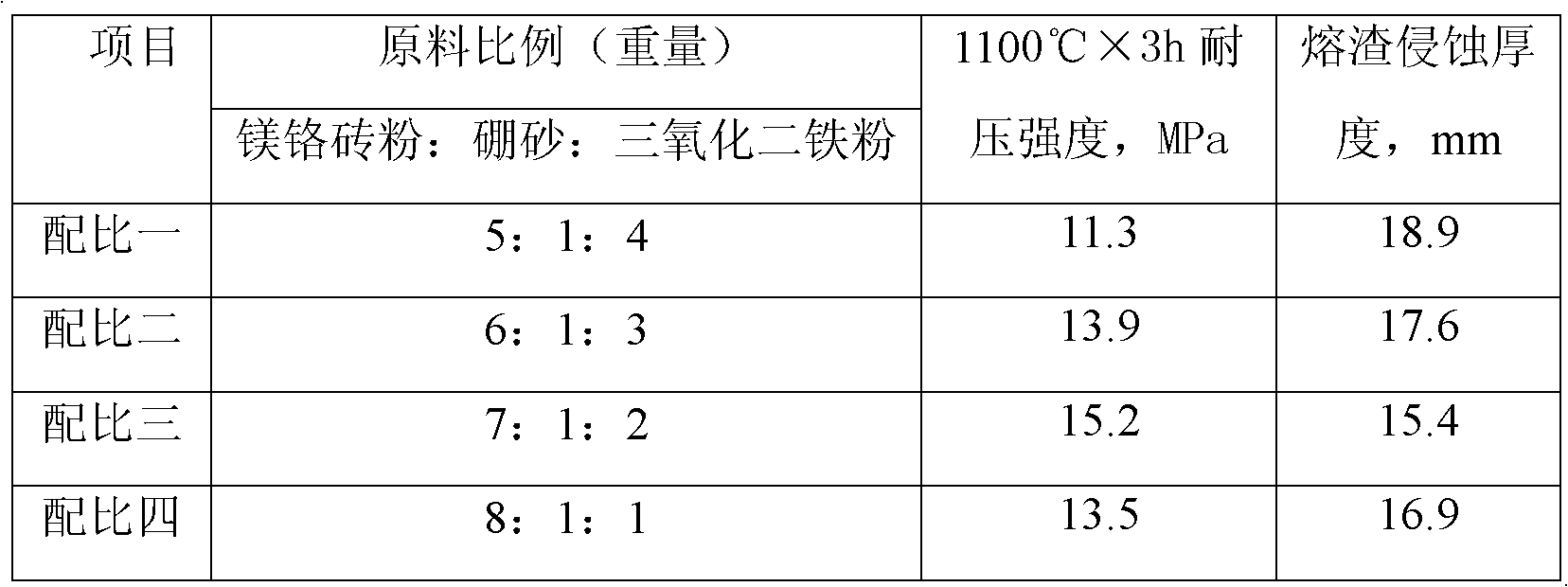

[0046] Weigh 50 parts of magnesia-chrome brick powder, 10 parts of borax, and 40 parts of ferric oxide powder, and mix the three weighed materials in a "V-shaped" mixing mixer for 5 minutes, and then MQG1200×3000 The ball mill is ground to -325 mesh to form a product.

Embodiment 2

[0048] Weigh 60 parts of magnesia-chrome brick powder, 10 parts of borax, and 30 parts of ferric oxide powder, and mix the three weighed materials in a "V-type" mixing mixer for 5 minutes, and then MQG1200×3000 The ball mill is ground to -325 mesh to form a product.

Embodiment 3

[0050] Weigh 70 parts of magnesia-chrome brick powder, 10 parts of borax, and 20 parts of Fe2O3 powder, and mix the three weighed materials in a "V-shaped" mixing mixer for 5 minutes, and then grind them with a MQG1200×3000 ball mill As fine as -325 mesh, form a product.

[0051] Add the product of embodiment 1-3 and the effect contrast of original dry type vibrating material in dry vibrating material

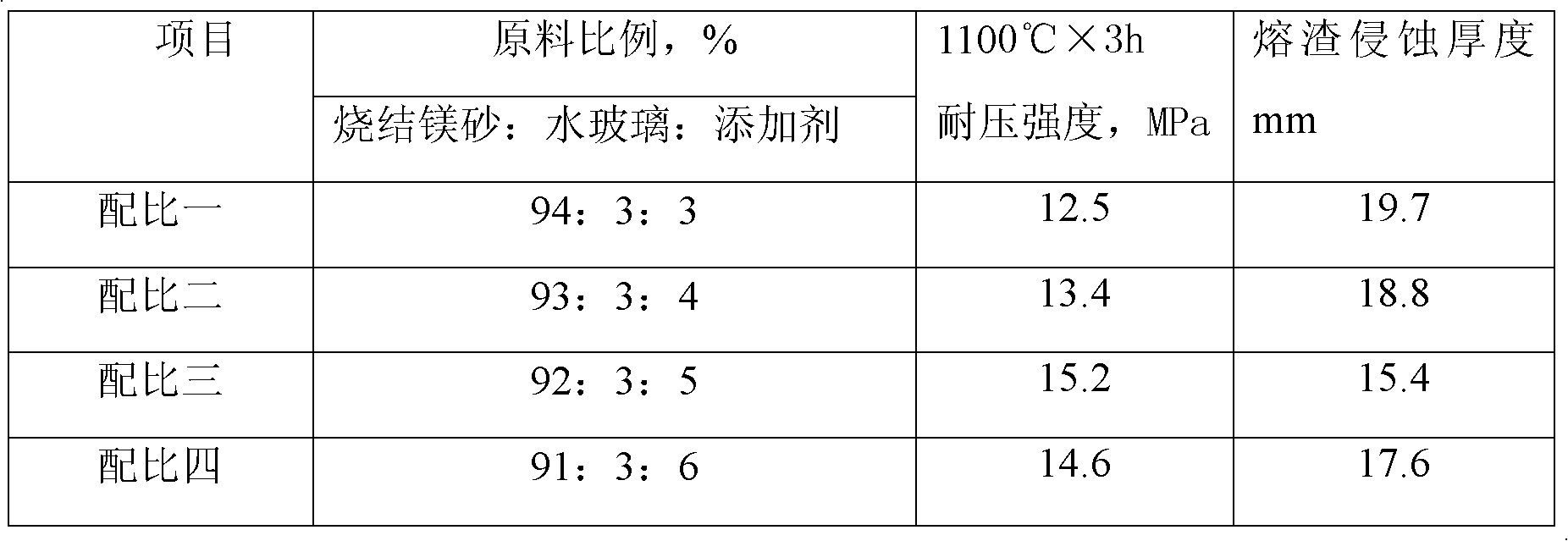

[0052] The products of Examples 1-3 were added to the dry vibrating material, and their 1100°C×3h compressive strength and slag erosion thickness were compared. See Table 4 for the comparison.

[0053] Table 4 Detection and use of each product

[0054]

[0055] From the usage situation in Table 4, by adding the special additive of the present invention to the dry vibrating material, the performance indicators of the dry vibrating material are all improved, and the compressive strength of the proportion three 1100 ° C × 3h is improved 5MPa, the slag erosion thickness is reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com