Composite ceramic coating containing precious metal intermediate layer and preparation process thereof

A composite ceramic and preparation process technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of easy corrosion damage, decreased mechanical properties of alloys, unsatisfactory bonding strength, etc., to achieve excellent mechanical properties, improve bonding strength and Effects of stability, high bond strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

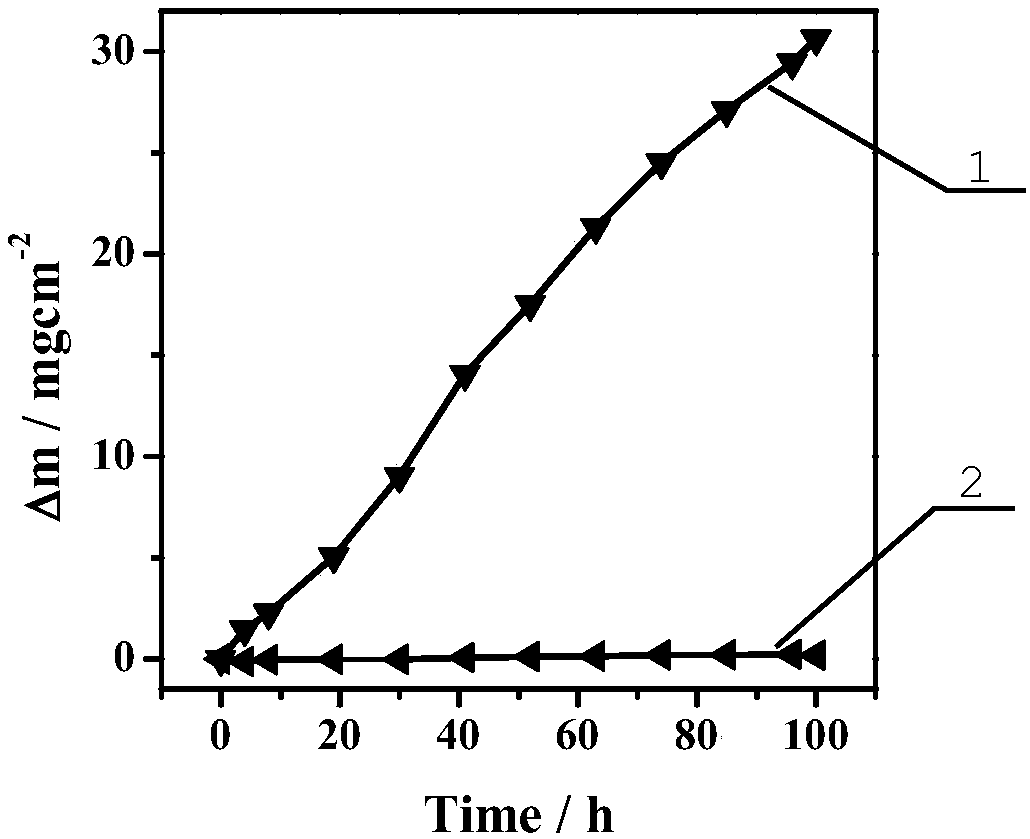

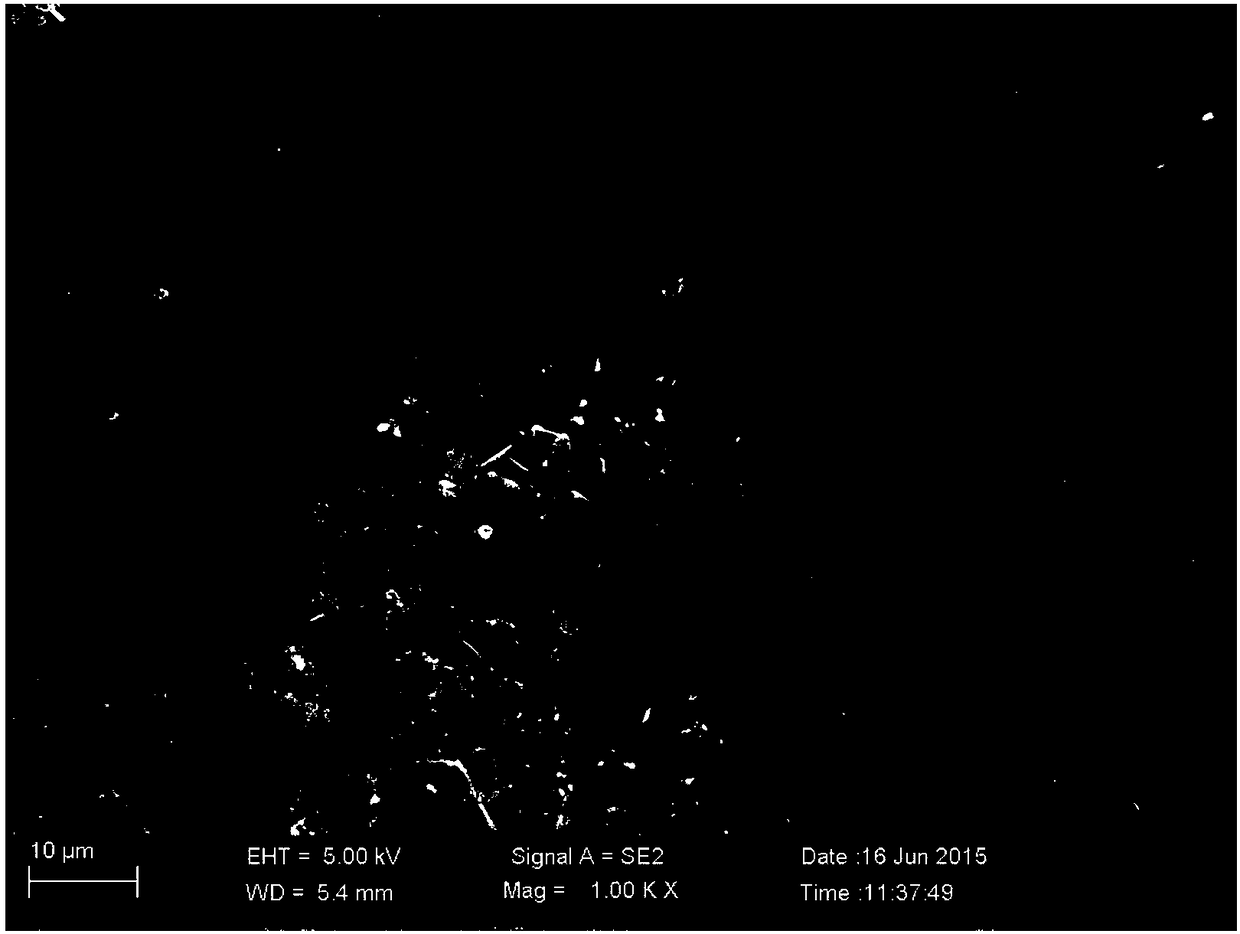

Embodiment 1

[0040] First, the aluminum-containing titanium-based alloy substrate (titanium-aluminum atomic ratio is 1:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. Add 0.1mol / L sulfuric acid solution into 0.1mmol / L hexachloroplatinic acid to obtain precursor solution A; add prepared precursor solution A into the two electrode tanks, use titanium-based alloy as the working electrode, and use platinum as the working electrode. The sheet was used as the counter electrode, the electrode distance was controlled at 1 cm, the control voltage was -0.1 V, the deposition time was 300 s, washed with water and dried at 40 ° C to obtain a platinum layer on the surface of the titanium-based alloy. Then take the beaker and add 20ml of absolute ethanol, 20ml of sodium nitrate solution with a molar concentration of 0.1mol / L and 1ml of precursor alkyl silicate (TEOS) to mix, adjust the pH of the...

Embodiment 2

[0044] First, the aluminum-containing titanium-based alloy substrate (titanium-aluminum atomic ratio is 3:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. Add 2mol / L sulfuric acid solution to 10mmol / L potassium chloroplatinate to obtain precursor solution A; add the prepared precursor solution A into the two electrode tanks, use titanium-based alloy as the working electrode, and graphite as the counter electrode , the electrode distance is controlled at 10cm, the control voltage is -2V, the deposition time is 10s, after washing with water, it is dried at 150°C to obtain a platinum layer on the surface of the titanium-based alloy. Then take the beaker and add 100ml of absolute ethanol, 100ml of sodium nitrate solution with a molar concentration of 2.0mol / L and 10ml of precursor alkyl silicate (TMOS) to mix, adjust the pH of the mixture to 6.0 with HAc, and stir at room ...

Embodiment 3

[0048] First, the aluminum-containing titanium-based alloy substrate (titanium-aluminum atomic ratio is 3:1) was polished to remove surface oxides with sandpaper, then ultrasonically cleaned in acetone and ethanol for 10 min, and finally dried with hot air for use. Add 1mol / L sulfuric acid solution into 5mmol / L sodium chloroplatinate to obtain precursor solution A; add the prepared precursor solution A into the two electrode tanks, use titanium-based alloy as the working electrode, and platinum sheet as the For the opposite electrode, the distance between the electrodes was controlled at 5 cm, the voltage was controlled at -1.0 V, the deposition time was 150 s, and after washing with water, it was dried at 95 ° C to obtain a platinum layer on the surface of the titanium-based alloy. Then take the beaker and add 50ml of absolute ethanol, 50ml of sodium nitrate solution with a molar concentration of 0.2mol / L and 5ml of precursor alkyl silicate (TEOS) to mix, adjust the pH of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com