High-performance silicon-containing ferrite/martensitic steel

A martensitic steel, high-performance technology, applied in the field of metal materials, can solve the problems of general mechanical properties of F/M alloy steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

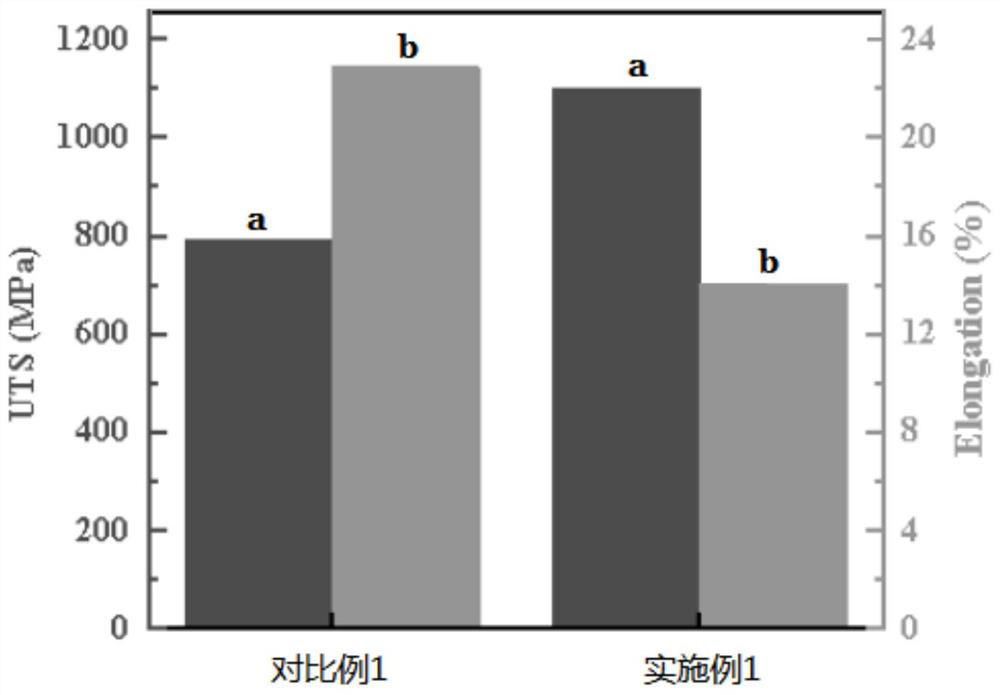

Embodiment 1

[0012] A high-performance silicon-containing ferritic / martensitic steel whose chemical composition consists of the following elements by weight: C0.12%, Cr 9%, W 1.5%, Mn 0.5%, Ta 0.1%, V 0.2% , Zr 0.01%, Si 1.0%, and the balance is Fe and unavoidable impurities.

[0013] It is prepared as follows:

[0014] S1. According to the above composition formula of alloy steel, vacuum induction melting is used to prepare 25kg grade F / M steel ingot, the ingot size is: diameter 90mm, height 100mm;

[0015] S2. Cut the ingot into round bars of Φ10×70mm, and then carry out the process on the equal-channel angular extrusion die according to route C (that is, after each extrusion, the sample is rotated 180° along the extrusion direction before the next extrusion) Extrusion, the intersection angle of the extrusion die is 90°, and then the extruded sample is annealed at 600°C & 2h in the heating furnace to reduce the internal stress caused by the severe extrusion deformation. After the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com