Infrared stealth coating material and preparation method thereof

A stealth paint and infrared technology, applied in the field of infrared stealth paint and its preparation, can solve the problems that the paint cannot be stored, the particles cannot be monodispersed, and the compatibility between aluminum powder and resin is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

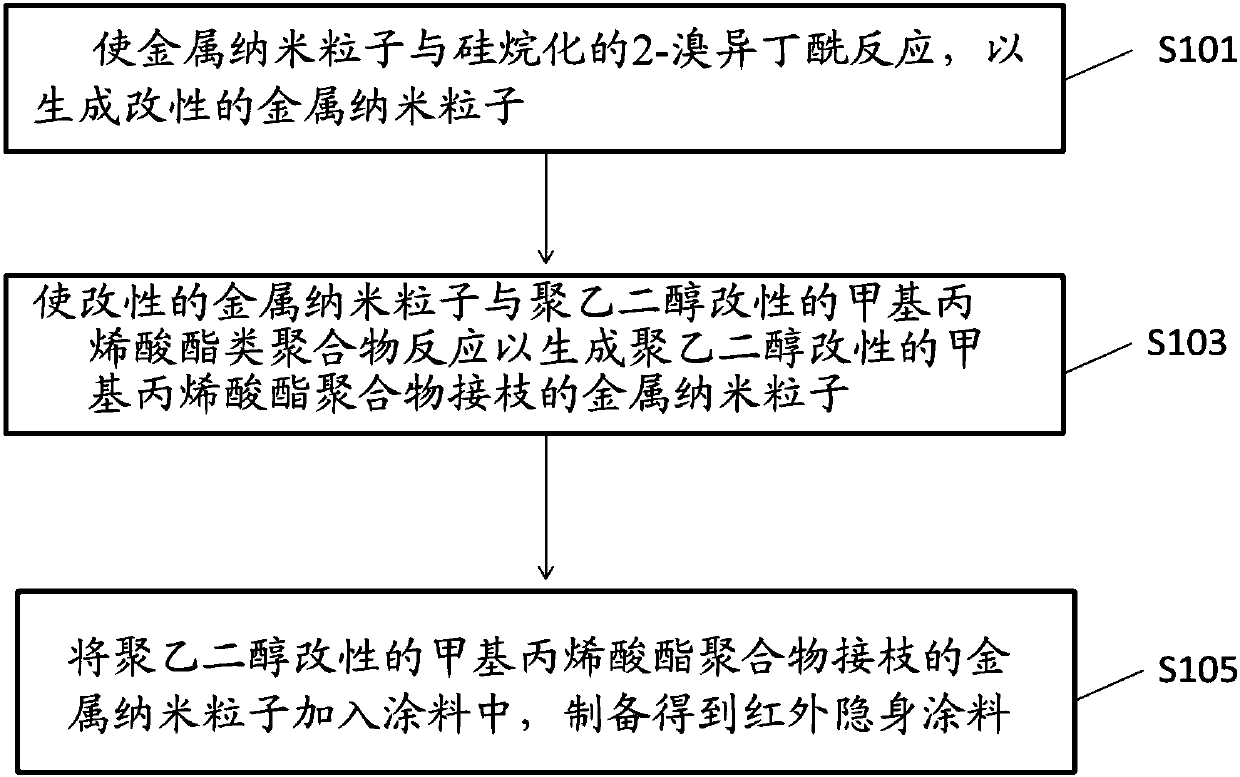

[0025] The preparation method of infrared stealth coating provided by the invention comprises the following steps:

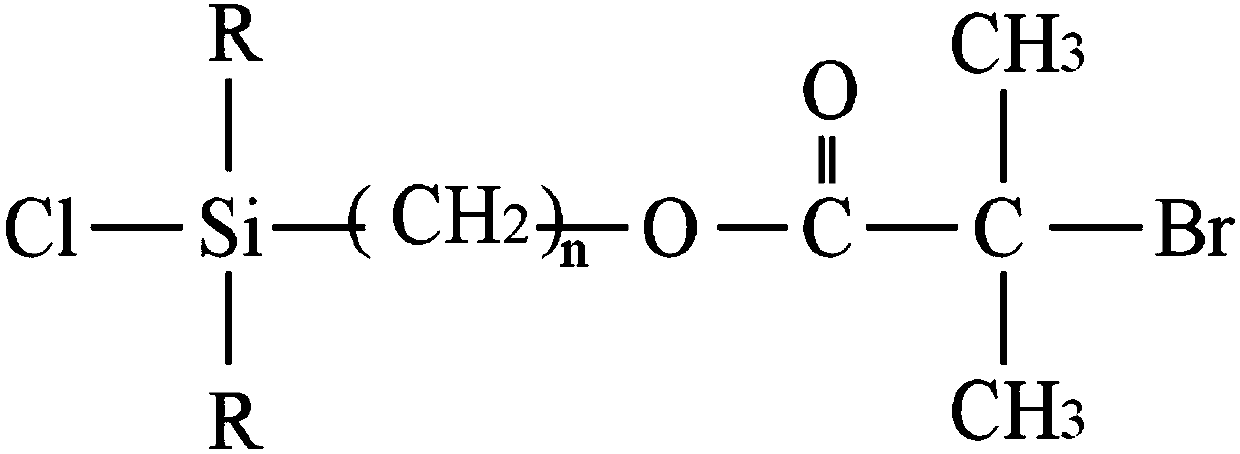

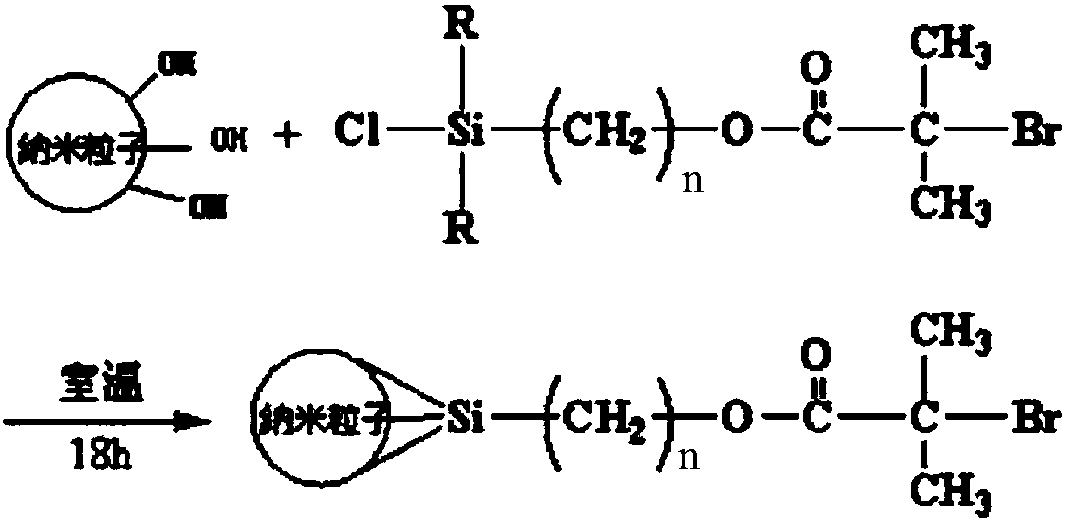

[0026] S101: if figure 1 As shown, metal nanoparticles were reacted with silylated 2-bromoisobutyryl to generate modified metal nanoparticles; specifically, metal nanoparticles such as aluminum powder, copper powder or zinc powder were dispersed in toluene and isobutyryl In the mixed solvent composed of propanol, the mixed solvent composed of ethylbenzene and isobutanol or the mixed solvent composed of toluene and isobutanol, wherein, in the mixed solvent, the volume ratio of benzene solvent to alcohol is not more than 20:1, It is preferred to use a mixed solvent composed of toluene and isopropanol; then, add triethylamine or trimethylamine as a catalyst and silanized 2-bromoisobutyryl, and stir slowly at room temperature for 16-20 hours, preferably, use triethylamine Amine is used as a catalyst, and stirred slowly for 18 hours to fully react the metal nanopart...

Embodiment 1

[0033] 1. At room temperature, disperse the aluminum powder in a mixed solvent composed of toluene and isopropanol, add the catalyst triethylamine and silanized 2-bromoisobutyryl, and stir slowly at room temperature for 18 hours to make the surface of the aluminum powder The hydroxyl group of the product fully reacted with silanized 2-bromoisobutyryl, and the obtained solid reaction product was suction-filtered, washed three times with isopropanol, and the solid part was vacuum-dried to obtain modified aluminum nanoparticles.

[0034] 2. Disperse the above solid (i.e., modified aluminum nanoparticles) in isopropanol, feed nitrogen, add catalyst copper bromide, complexing agent bipyridine and polyethylene glycol-modified methyl methacrylate The ester is reacted at room temperature for 2 hours, so that the modified aluminum nano-particles fully react with the polyethylene glycol-modified methyl methacrylate under the action of a catalyst and a complexing agent. Dilute with isopr...

Embodiment 2

[0039] 1. At room temperature, disperse the copper powder in a mixed solvent composed of ethylbenzene and isobutanol, add the catalyst trimethylamine and silanized 2-bromoisobutyryl, and stir slowly at room temperature for 16 hours to make the surface of the copper powder The hydroxyl group of the product fully reacted with silanized 2-bromoisobutyryl, and the obtained solid reaction product was suction-filtered, washed 4 times with isobutanol, and the solid part was vacuum-dried to obtain modified copper nanoparticles.

[0040] 2. Disperse the above solid (i.e., modified copper nanoparticles) in isobutanol, feed nitrogen, add catalyst cuprous bromide, complexing agent pentamethyldiethylenetriamine and polyethylene glycol to modify The hydroxyethyl methacrylate was reacted at room temperature for 4 hours, so that the modified copper nanoparticles fully reacted with the polyethylene glycol-modified hydroxyethyl methacrylate under the action of a catalyst and a complexing agent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com