Preparation method of pearl hydrolysate

A technology of pearl hydrolyzate and pearl powder, which is applied in the direction of medical preparations containing active ingredients, pharmaceutical formulas, cosmetic preparations, etc., and can solve the problems of pearl hydrolyzate with large molecular weight, difficult to absorb, and low product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

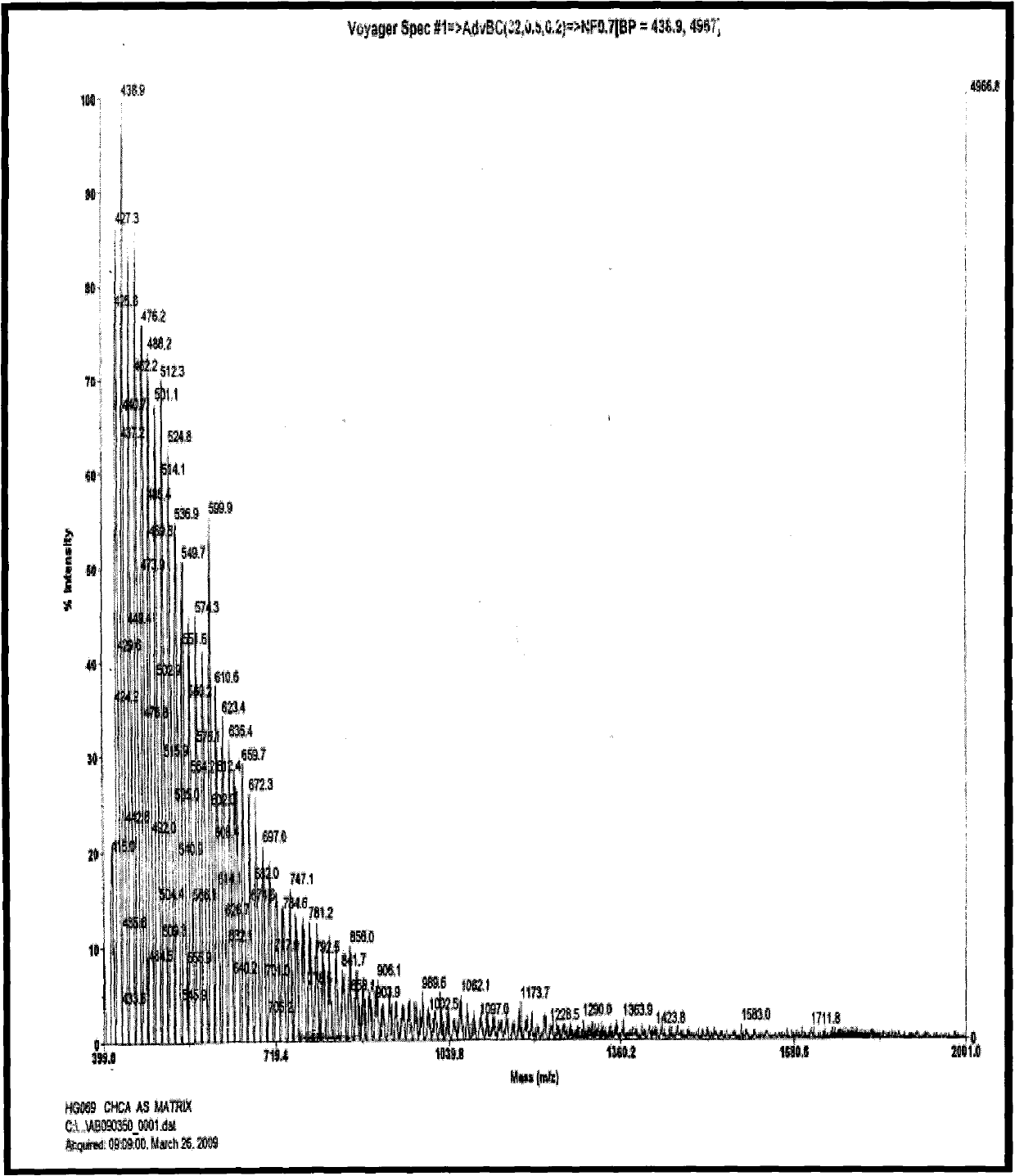

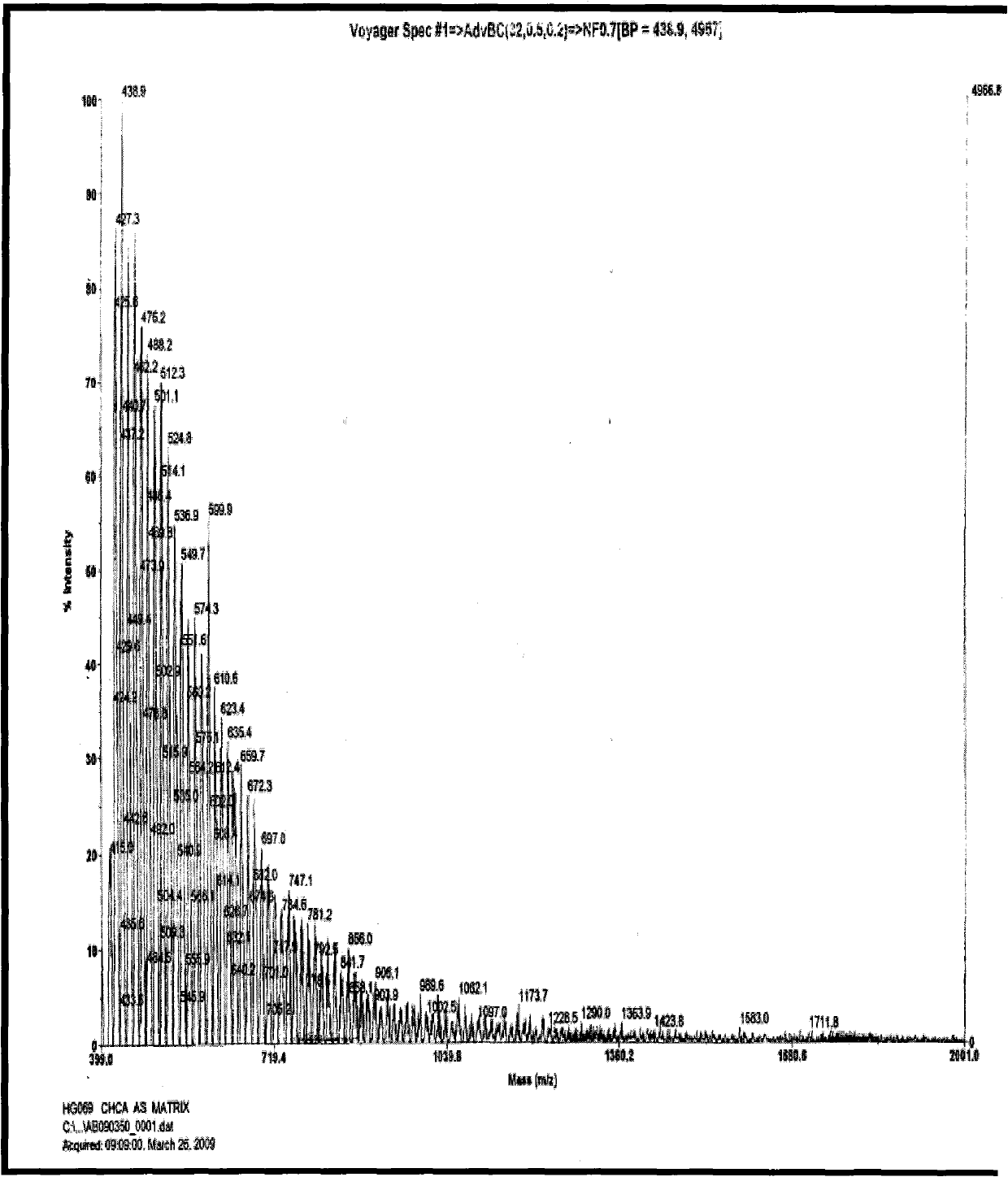

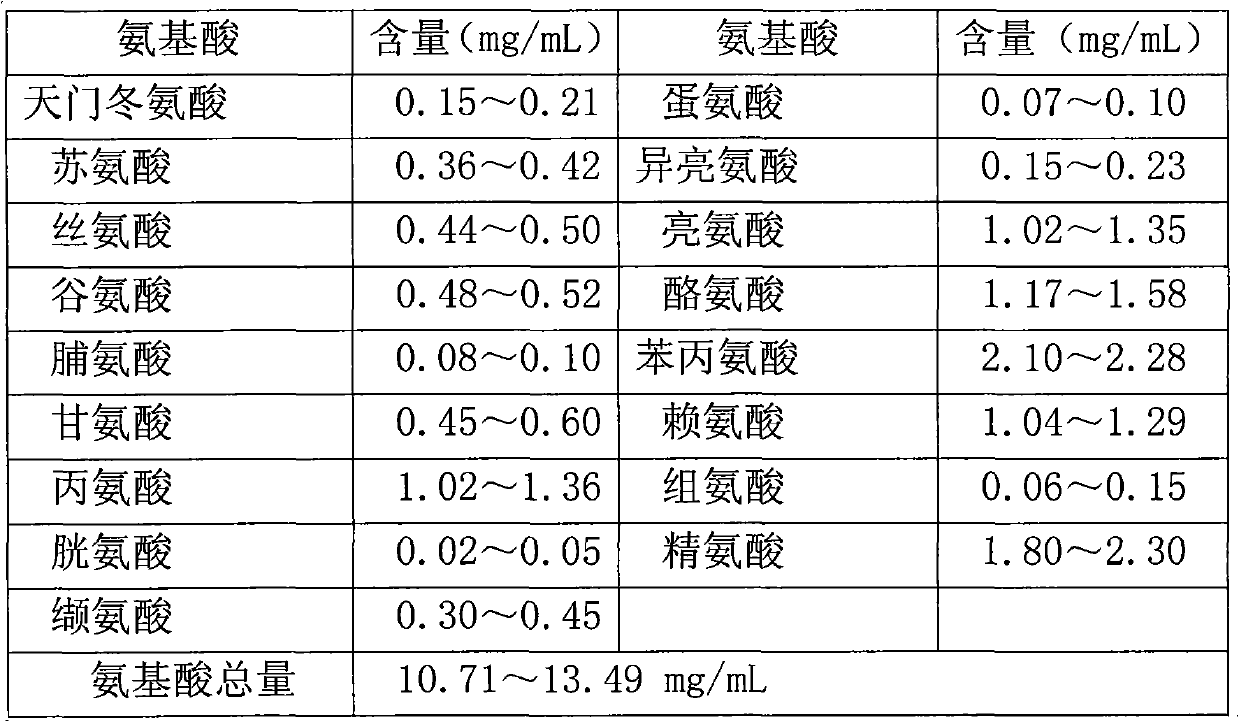

Image

Examples

Embodiment 1

[0040] 1) Get the pearl powder and place it in an aqueous hydrochloric acid solution with a molar concentration of 4mol / L equivalent to 10 times its weight (liter / kg, the same below), stir until the reaction is complete, and adjust the pH value of the mixed solution with ammonia water to Neutral, centrifuged, get precipitate A;

[0041] 2) Dissolve the precipitate A with purified water, adjust its pH value to 7.5 with ammonia water, and centrifuge to obtain the precipitate B;

[0042] 3) Dissolve 1 kg of wet precipitate B in purified water, add a total of 7 grams of enzymes (wherein snail protease and papain account for 10% and 90% of the total amount of enzymes) and enzymolyze at a temperature of 55°C 4 hours, centrifuged to obtain supernatant and precipitate C;

[0043] 4) Precipitate C is dissolved with purified water, adding a total amount of 2 grams of enzyme (wherein trypsin, papain and neutral protease each account for 10%, 20% and 70% of the total amount of enzyme) at...

Embodiment 2

[0049] 1) Take the pearl powder and place it in an aqueous hydrochloric acid solution with a molar concentration of 2 mol / L equivalent to 9 times its weight, stir until the reaction is complete, adjust the pH value of the mixed solution to neutral with ammonia water, and centrifuge to obtain Precipitation A ;

[0050] 2) Dissolve the precipitate A with purified water, adjust its pH value to 8 with ammonia water, and centrifuge to obtain the precipitate B;

[0051] 3) Dissolve 1 kg of wet precipitate B in purified water, add a total of 3 grams of enzymes (wherein snail protease and papain account for 15% and 85% of the total amount of enzymes) and enzymolyze at a temperature of 52°C Centrifuge for 3 hours to obtain supernatant and precipitate C;

[0052] 4) Precipitate C is dissolved with purified water, adding a total amount of 3 grams of enzyme (wherein trypsin, papain and neutral protease each account for 25%, 15% and 60% of the total amount of enzyme) at a temperature of 55 ...

Embodiment 3

[0058] 1) Take the pearl powder and place it in an aqueous hydrochloric acid solution with a molar concentration of 2 mol / L equivalent to 8 times its weight, stir until the reaction is complete, adjust the pH value of the mixture to neutral with ammonia water, and centrifuge to obtain precipitate A ;

[0059] 2) Dissolve the precipitate A with pure water, adjust its pH value to 8.5 with ammonia water, and centrifuge to obtain the precipitate B;

[0060] 3) Dissolve 1 kg of wet precipitate B in purified water, add a total of 9 grams of enzymes (wherein snail protease and papain account for 12% and 88% of the total amount of enzymes) and enzymolyze at a temperature of 50°C Centrifuge for 2 hours to obtain supernatant and precipitate C;

[0061] 4) Precipitate C is dissolved with purified water, adding a total amount of 4 grams of enzyme (wherein trypsin, papain and neutral protease each account for 15%, 18% and 67% of the total amount of enzyme) at a temperature of 55 ° C Enzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com