Effective stress level test device and method of vertical prestressed reinforcement

A technology of vertical prestress and effective stress, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., to ensure effectiveness, eliminate limitations, and have the effect of tensioning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

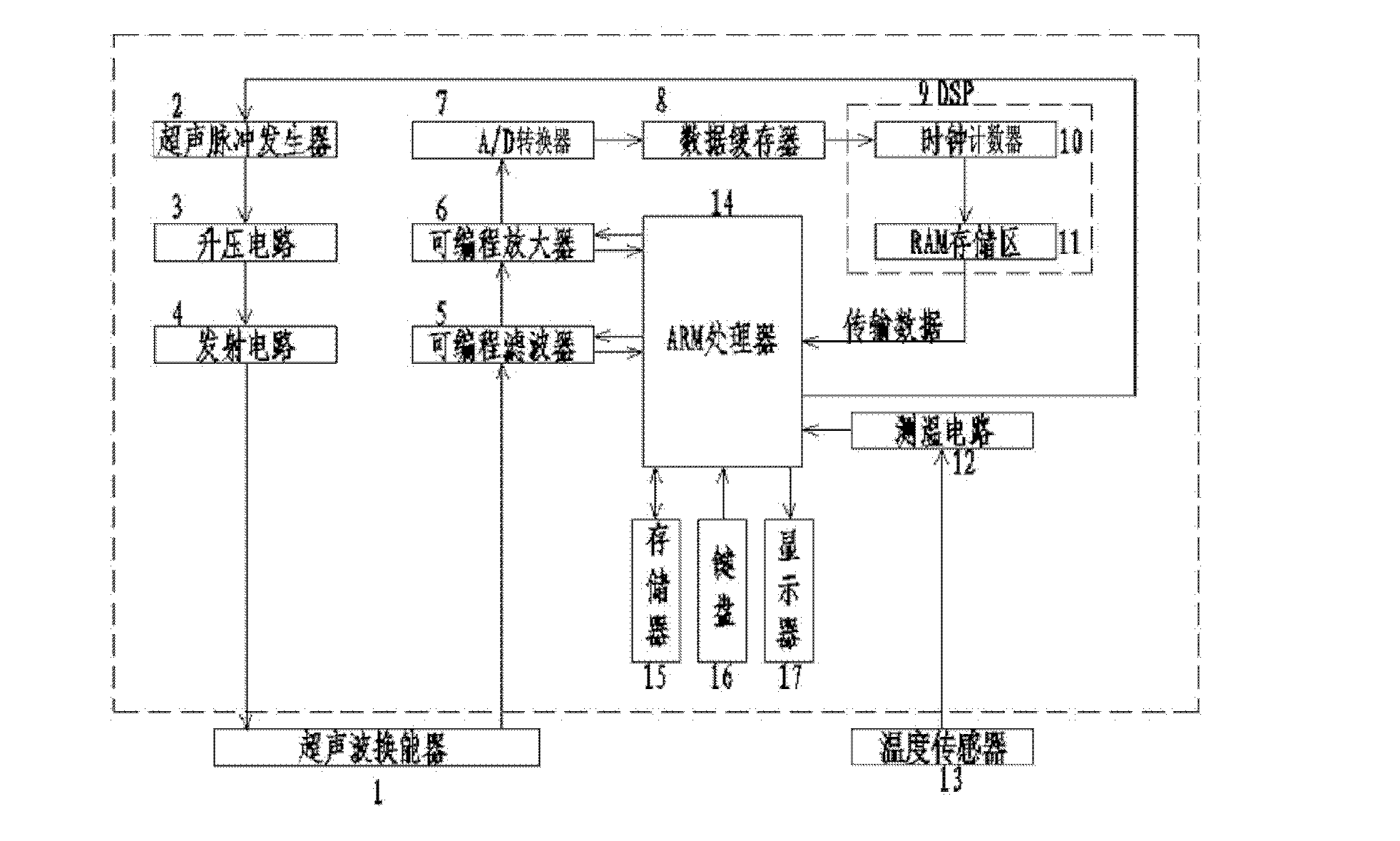

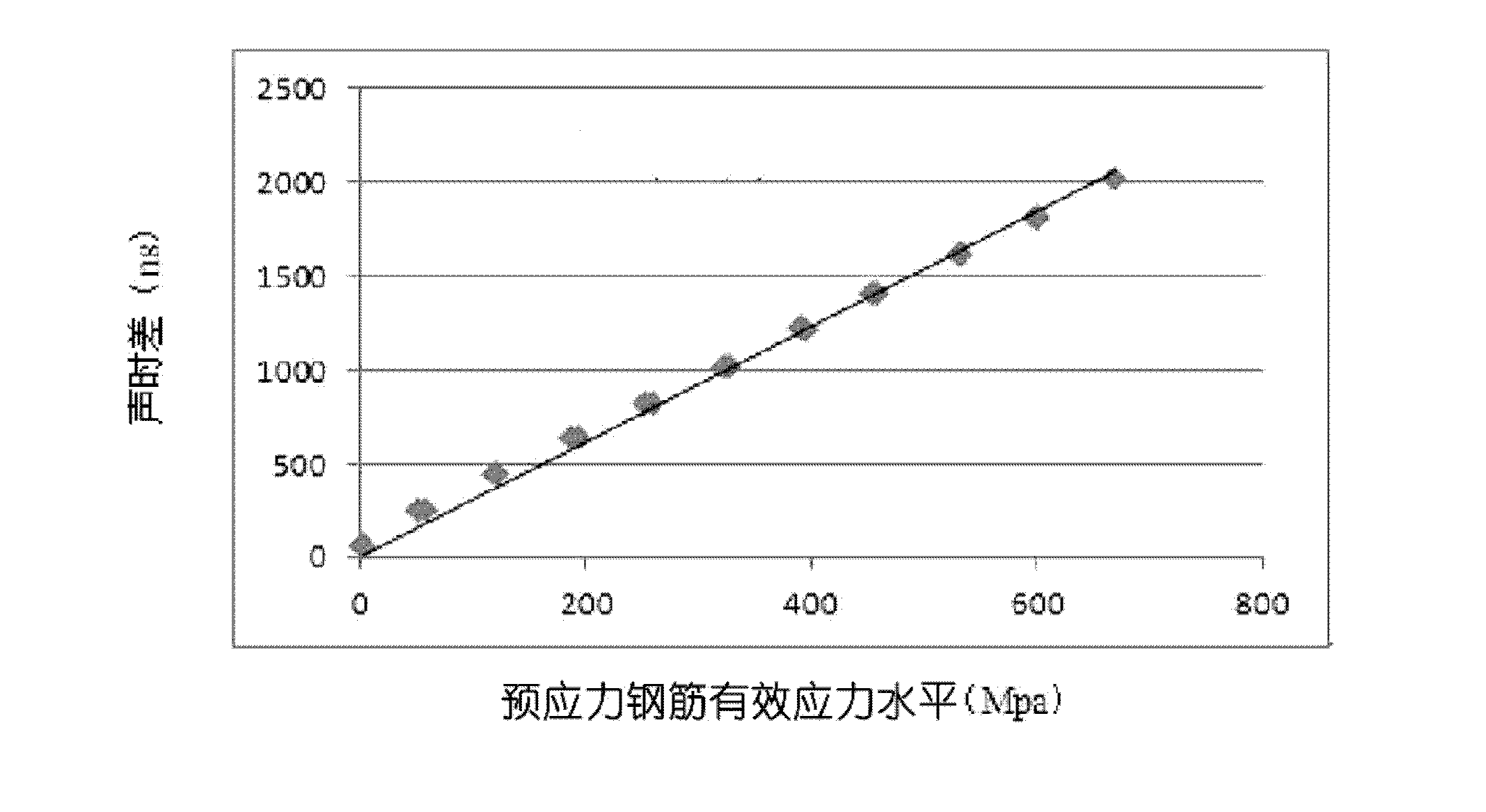

Method used

Image

Examples

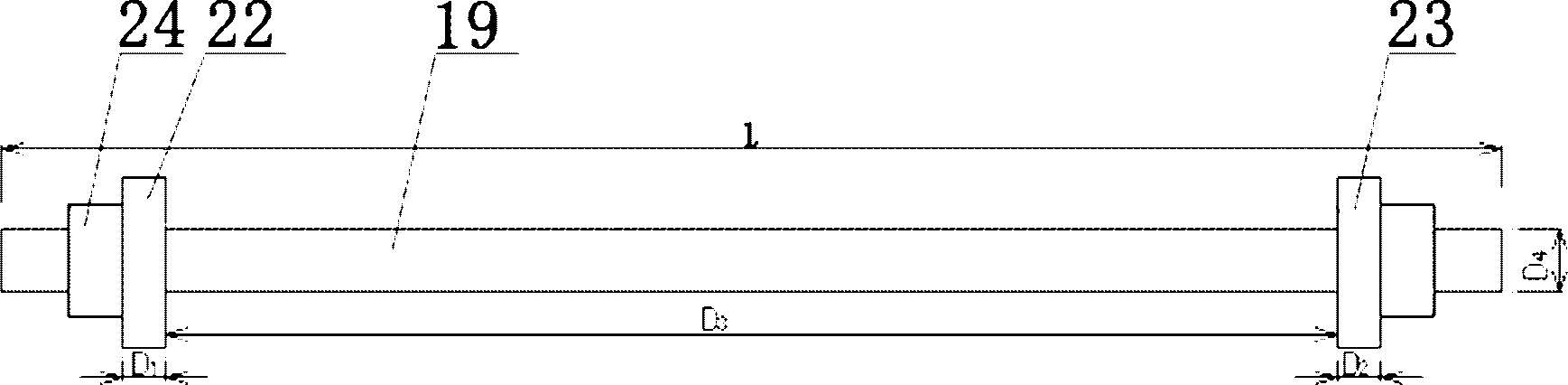

specific Embodiment

[0098] The specific embodiment is as follows: according to step one to step seven, the total length L of the vertical prestressed reinforcement obtained through measurement is 3.030m, and the thickness D of the upper anchor backing plate 1 and the thickness D of the lower anchor plate 2 Both are 0.020m, the distance D between the upper and lower anchor plates 3 is 2.657m, the outer diameter D of the vertical prestressed reinforcement 4 = 32mm, the effective stress length L of the steel bar e =D 1 +D 2 +D 3 +D 4 =2.729m; the acoustic time values of the vertical prestressed steel bars collected by the ultrasonic transducer before and after loading are S 1 =508559ns, S 2 =513927ns, the temperature values before and after the vertical prestressed steel bar are stressed are respectively t 1 =25°C, t 2 = 28°C, calculated by the ARM processor, using the formula obtained in step 6 to calculate the effective stress level of the vertical prestressed steel bar is 610.454MPa,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com