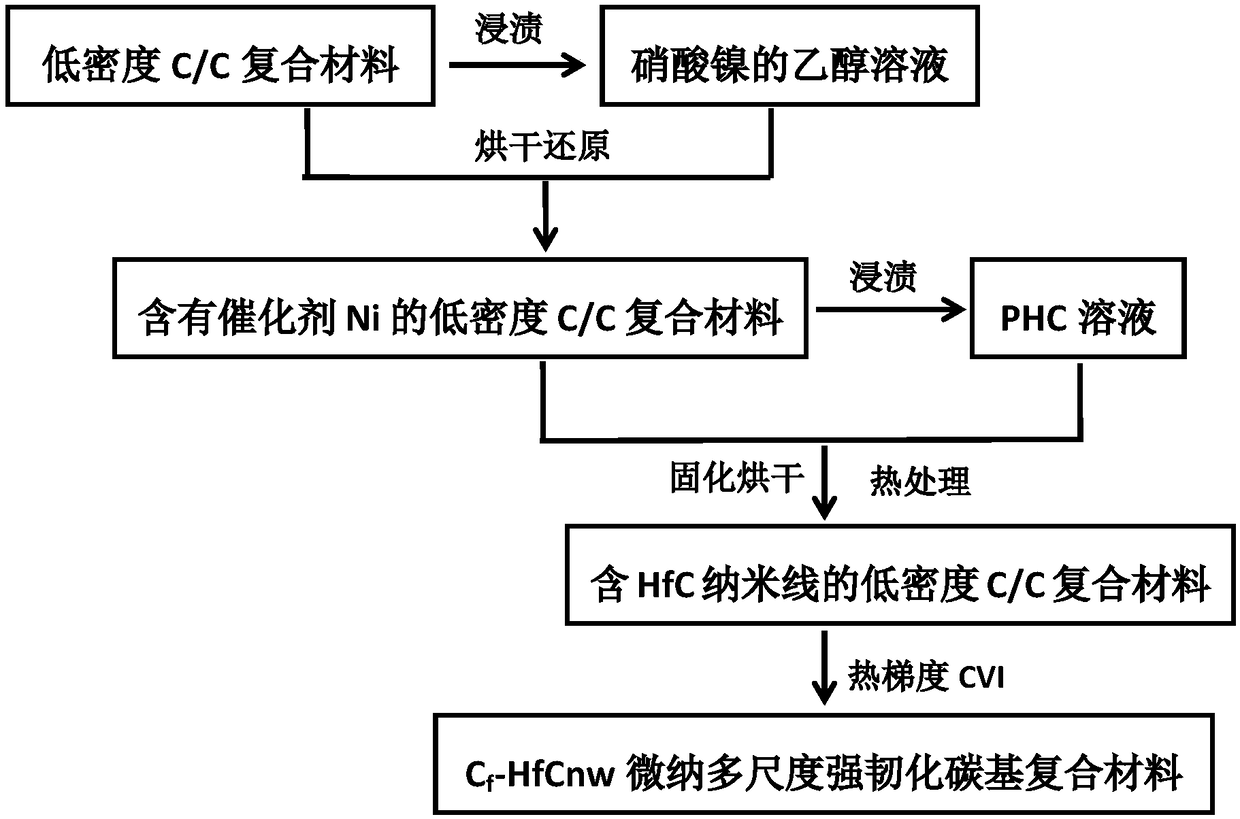

Preparation method of Cf-HfCnw micronano multiscale toughened carbon matrix composite

A cf-hfcnw and composite material technology, applied in the field of preparation of strong and tough carbon-based composite materials, can solve problems such as high requirements for process equipment, long cycle time, and complicated preparation process, and achieve simple preparation method, short cycle time, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Prepare an ethanol solution with a molar concentration of 0.2mol / L nickel nitrate, and use a glass rod to stir until the nickel nitrate is completely dissolved at room temperature, in order to obtain a uniform mixed solution;

[0035] 2) Set the density to 0.8g / cm 3 The low-density C / C composite material was cleaned, soaked in the ethanol solution of nickel nitrate described in step 1 for 12 hours, and then taken out and dried in an oven at 50°C for later use.

[0036] 3) Put the low-density C / C composite material containing nickel nitrate obtained in step 2 into a tube furnace, and pass through H at 500°C 2 A low-density C / C composite material preform containing catalyst Ni is obtained through reduction.

[0037] 4) Weigh an appropriate amount of HfC precursor PHC and divinylbenzene in a beaker with a mass fraction of 1:10, heat and stir with a magnetic stirrer at room temperature for 3 hours, so that the HfC precursor PHC is fully dissolved in the divinylbenzene s...

Embodiment 2

[0041] 1) Prepare an ethanol solution with a molar concentration of 0.5mol / L nickel nitrate, and use a glass rod to stir until the nickel nitrate is completely dissolved at room temperature, in order to obtain a uniform mixed solution;

[0042] 2) Set the density to 0.8g / cm 3 The low-density C / C composite material was cleaned, soaked in the ethanol solution of nickel nitrate described in step 1 for 12 hours, and then taken out and dried in an oven at 50°C for later use.

[0043] 3) Put the low-density C / C composite material containing nickel nitrate obtained in step 2 into a tube furnace, and pass through H at 500°C 2 A low-density C / C composite material preform containing catalyst Ni is obtained through reduction.

[0044] 4) Weigh an appropriate amount of HfC precursor PHC and divinylbenzene in a beaker with a mass fraction of 3:10, heat and stir with a magnetic stirrer at room temperature for 3 hours, so that the HfC precursor PHC is fully dissolved in the divinylbenzene s...

Embodiment 3

[0048] 1) Prepare an ethanol solution with a molar concentration of 1mol / L nickel nitrate, and use a glass rod to stir until the nickel nitrate is completely dissolved at room temperature, in order to obtain a uniform mixed solution;

[0049] 2) Set the density to 0.8g / cm 3 The low-density C / C composite material was cleaned, soaked in the ethanol solution of nickel nitrate described in step 1 for 12 hours, and then taken out and dried in an oven at 50°C for later use.

[0050] 3) Put the low-density C / C composite material containing nickel nitrate obtained in step 2 into a tube furnace, and pass through H at 500°C 2 A low-density C / C composite material preform containing catalyst Ni is obtained through reduction.

[0051] 4) Weigh an appropriate amount of HfC precursor PHC and divinylbenzene in a beaker with a mass fraction of 5:10, heat and stir with a magnetic stirrer at room temperature for 3 hours, so that the HfC precursor PHC is fully dissolved in the divinylbenzene sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com