HfxZr1-xC ceramic solid solution nanowire and preparation method thereof

A nanowire, solid solution technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the loss of toughening effect, no ceramic solid solution nanowire preparation and application reports, nanowire impact Toughening effect and other problems, to achieve the effect of simple preparation process, large specific surface area, and easy operation of preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

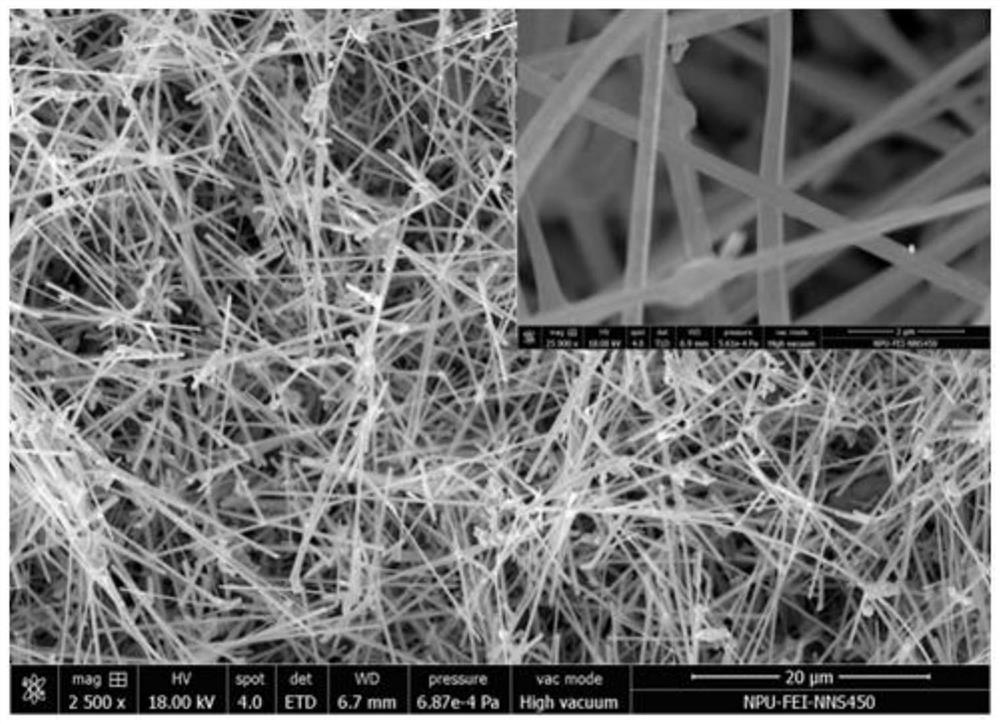

Embodiment 1

[0037] A new type of Hf x Zr 1-x C The preparation method of ceramic solid solution nanowire, this preparation method comprises the following steps:

[0038] Step S1: Grind and polish the C / C composite material matrix with a size of (8mm*8mm*2mm), ultrasonically clean it for 10-30 minutes, and put it in an oven to dry for later use;

[0039] Step S2: Ni(NO 3 ) 2 Configured as a solution with a concentration of 0.5mol / L;

[0040] Step S3: Put the prepared C / C composite material into the Ni(NO 3 ) 2 Soak in the solution for 8 hours, then dry in an oven at 80°C for 4 hours to obtain the initial sample;

[0041] Step S4: Preparation of Hf by LPCVD x Zr 1-x The specific method of C nanowire is as follows:

[0042] Step S41: Hang and place the first sample dried in step S3 in a tubular chemical vapor deposition furnace, and weigh HfCl according to a molar ratio of 3:7 4 and ZrCl 4 Powder, placed in a volatilization container;

[0043] Step S42: Use a vacuum pump to pump ...

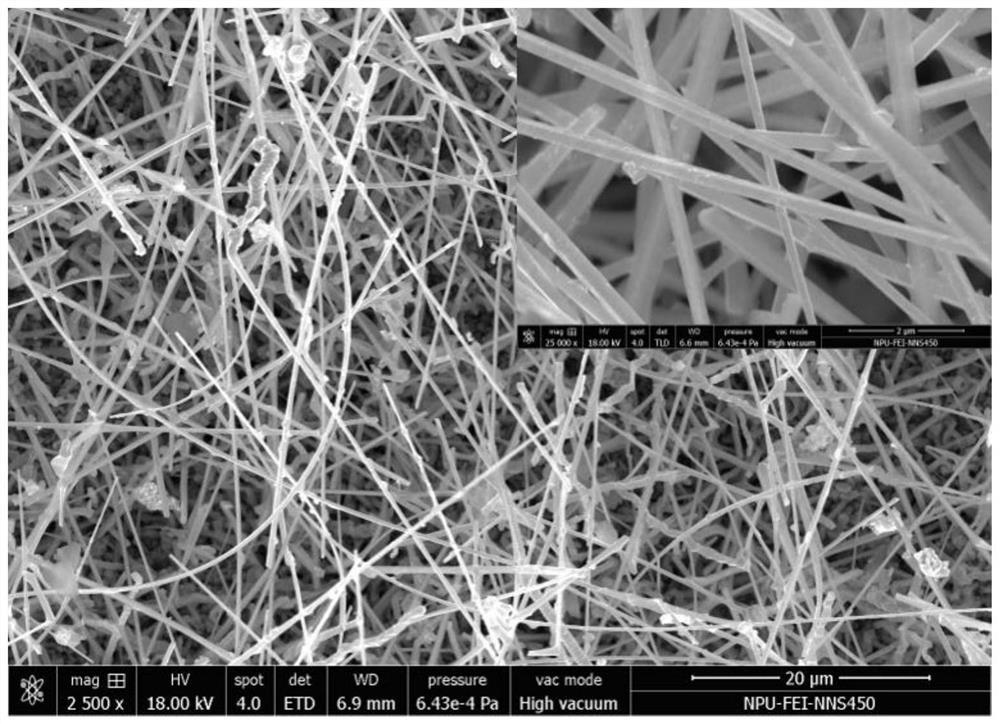

Embodiment 2

[0047] A new type of Hf x Zr 1-x C The preparation method of ceramic solid solution nanowire, this preparation method comprises the following steps:

[0048] Step S1: Grind and polish the C / C composite material matrix with a size of (8mm*8mm*2mm), ultrasonically clean it for 10-30 minutes, and put it in an oven to dry for later use;

[0049] Step S2: Ni(NO 3 ) 2 Configured as a solution with a concentration of 0.8mol / L;

[0050] Step S3: Put the prepared C / C composite material into the Ni(NO 3 ) 2 Soak in the solution for 8 hours, then dry in an oven at 80°C for 4 hours to obtain the initial sample;

[0051] Step S4: Preparation of Hf by LPCVD x Zr 1-x The specific method of C nanowire is as follows:

[0052] Step S41: Hang and place the first sample dried in step S3 in a tubular chemical vapor deposition furnace, and weigh HfCl according to a molar ratio of 5:5 4 and ZrCl 4 Powder, placed in a volatilization container;

[0053] Step S42: Use a vacuum pump to pump ...

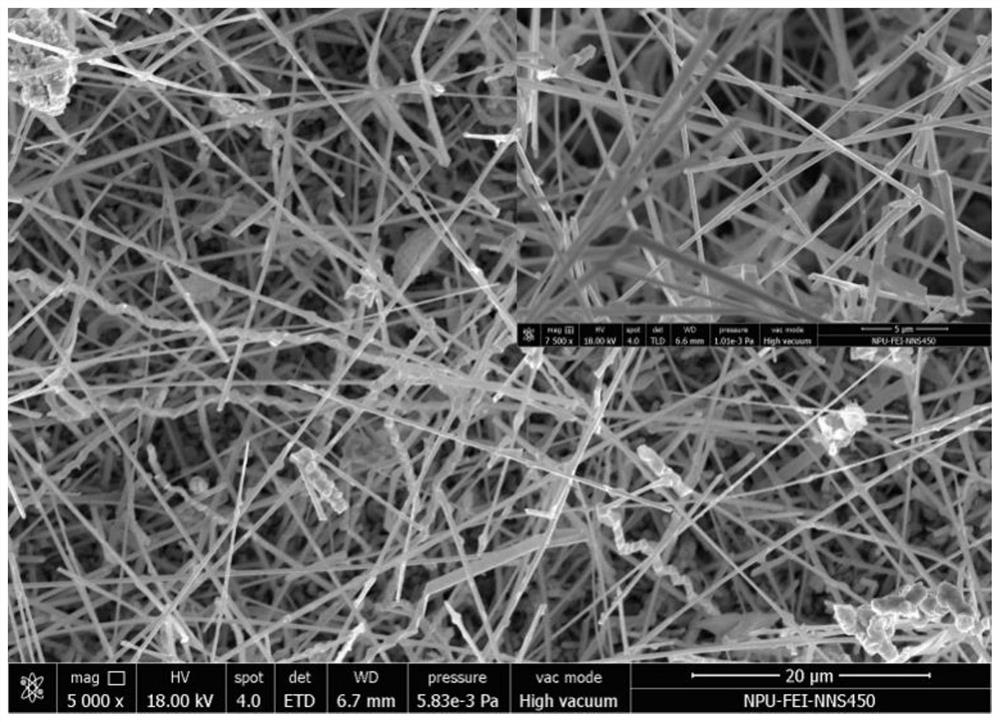

Embodiment 3

[0057] A new type of Hf x Zr 1-x C The preparation method of ceramic solid solution nanowire, this preparation method comprises the following steps:

[0058] Step S1: Grind and polish the C / C composite material matrix with a size of (8mm*8mm*2mm), ultrasonically clean it for 10-30 minutes, and put it in an oven to dry for later use;

[0059] Step S2: Ni(NO 3 ) 2 Configured as a solution with a concentration of 1.0mol / L;

[0060] Step S3: Put the prepared C / C composite material into the Ni(NO 3 ) 2 Soak in the solution for 8 hours, then dry in an oven at 80°C for 4 hours to obtain the initial sample;

[0061] Step S4: Preparation of Hf by LPCVD x Zr 1-x The specific method of C nanowire is as follows:

[0062] Step S41: Hang and place the first sample dried in step S3 in a tubular chemical vapor deposition furnace, and weigh HfCl according to a molar ratio of 7:3 4 and ZrCl 4 Powder, placed in a volatilization container;

[0063] Step S42: Use a vacuum pump to pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com