Preparation method of toughened cutter material

A tool material and toughening technology, which is applied in the field of preparation of toughened tool materials, can solve the problems of composite material toughness decrease, high production cost, and fracture work reduction, and achieve good bending strength, good material performance, and improved toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

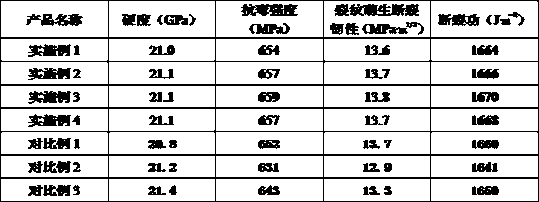

Examples

Embodiment 1

[0027] A preparation method of a toughened tool material, the components are calculated by weight, comprising the following steps:

[0028] (1) Stir and dissolve 3 parts of lecithin and 40 parts of tert-butanol;

[0029] (2) Add 5 parts of boron carbide, 5 parts of rosin modified alkyd resin, 20 parts of nano silicon nitride, 1 part of polyvinyl alcohol, 3 parts of modified nano silicon dioxide, 5 parts of magnesium borate whiskers and 5 parts of snail shell powder, stir well;

[0030] (3) Add ammonia water to make the pH of the system 8.5;

[0031] (4) Transfer to a ball mill for ball milling, the ball milling time is 8 hours, and the speed is 100r / min;

[0032] (5) Transfer to a vacuum degasser for degassing for 20 minutes;

[0033] (6) Pour into the mold, and immerse the mold in liquid nitrogen to make the slurry solidify quickly to obtain a porous body;

[0034] (7) Put the porous body into a freeze dryer, and freeze-dry it at -57°C and 7MPa for 48h;

[0035] (8) Insu...

Embodiment 2

[0037] A preparation method of a toughened tool material, the components are calculated by weight, comprising the following steps:

[0038] (1) Stir and dissolve 4 parts of nonylphenol polyoxyethylene ether and 50 parts of tert-butanol;

[0039] (2) Add 6 parts of boron carbide, 6 parts of polyvinyl butyral, 30 parts of nano-silicon nitride, 1.5 parts of polyvinyl alcohol, 4 parts of modified nano-silica, 6 parts of magnesium borate whiskers and 6 parts of escargot shell powder, stir well;

[0040] (3) Add ammonia water to make the pH of the system 8.5;

[0041] (4) Transfer to a ball mill for ball milling, the ball milling time is 8.5h, and the rotating speed is 110r / min;

[0042] (5) Transfer to a vacuum degasser for degassing for 25 minutes;

[0043] (6) Pour into the mold, and immerse the mold in liquid nitrogen to make the slurry solidify quickly to obtain a porous body;

[0044] (7) Put the porous body into a freeze dryer, freeze-dry at -58°C, 7MPa for 48h;

[0045]...

Embodiment 3

[0047] A preparation method of a toughened tool material, the components are calculated by weight, comprising the following steps:

[0048] (1) Stir and dissolve 5 parts of cetyl alcohol and 60 parts of tert-butanol;

[0049] (2) Add 8 parts of boron carbide, 7 parts of dammar resin, 40 parts of nano-silicon nitride, 1.5 parts of polyvinyl alcohol, 4 parts of modified nano-silicon dioxide, 8 parts of magnesium borate whiskers and 7 parts of snail shell powder, Stir well;

[0050] (3) Add ammonia water to make the pH of the system 8.5;

[0051] (4) Transfer to a ball mill for ball milling, the ball milling time is 8.5h, and the rotating speed is 110r / min;

[0052] (5) Transfer to a vacuum degasser for degassing for 25 minutes;

[0053] (6) Pour into the mold, and immerse the mold in liquid nitrogen to make the slurry solidify quickly to obtain a porous body;

[0054] (7) Put the porous body into a freeze dryer, freeze-dry at -57°C, 6MPa for 48h;

[0055] (8) Insulate the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com