Production of foamed aluminium alloy deformed piece by secondary foam

A foamed aluminum alloy and foaming technology, which is applied in the field of preparation of foamed aluminum alloy, can solve the problems of high cost, unstable process, and difficulties, and achieve the effect of low cost, reliable process and uniform viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing foamed aluminum alloy profiled parts through secondary foaming, comprising the following steps:

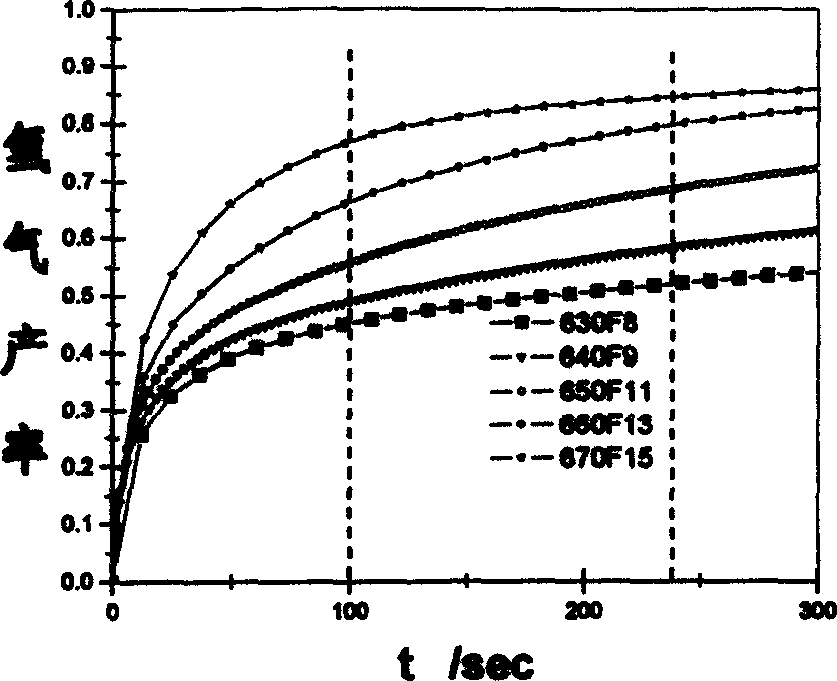

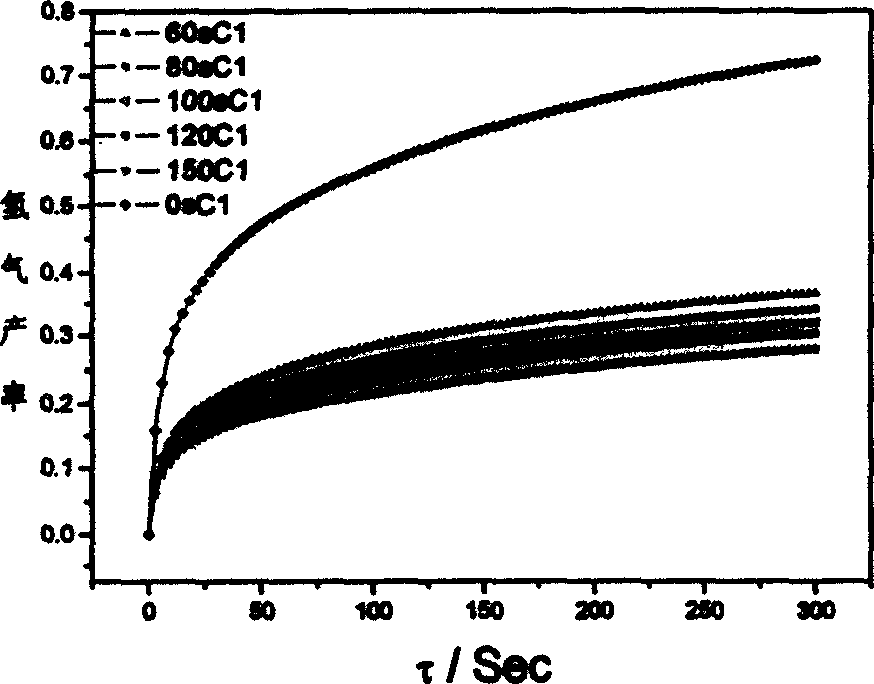

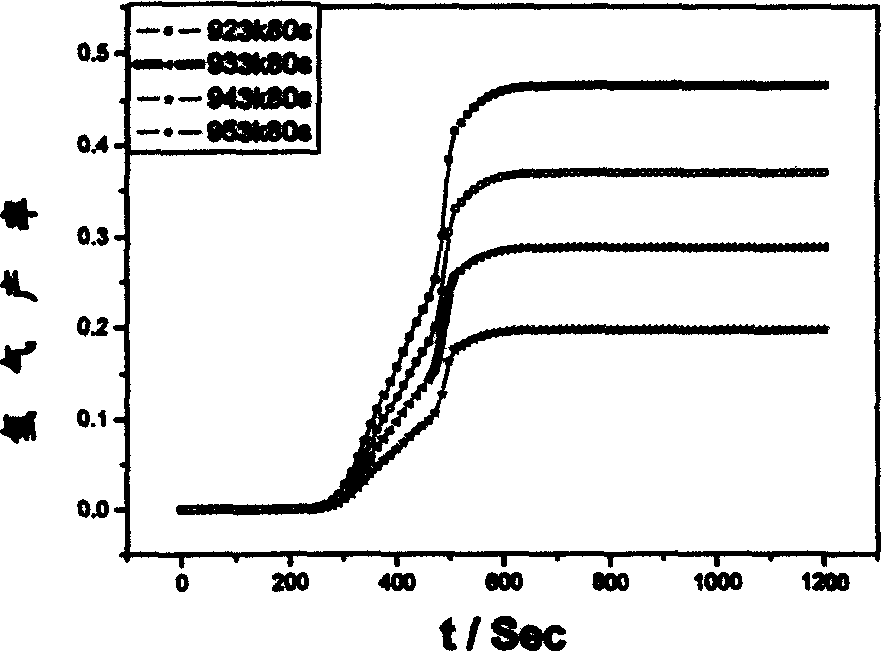

[0045] The first step: heating the aluminum alloy to melt, adding calcium equivalent to 0.5%-5% of the aluminum alloy addition (weight percentage) to the aluminum alloy melt, stirring evenly (stirring speed can be 300-600rpm); Add titanium hydride equivalent to 0.5%-5% of the weight of the aluminum alloy, stir at a speed of 800-5000rpm for 20-100 seconds, so that the titanium hydride is evenly mixed in the melt, and then raise the stirring paddle to obtain a foamed aluminum alloy melt , and then quickly cool the foamed aluminum alloy melt to obtain a foamed aluminum alloy; wherein, the aluminum alloy can be a cast aluminum-silicon alloy, such as ZL101, ZL102, ZL111 series alloys, or a cast aluminum-copper alloy, For example, ZL201, ZL202, ZL205 series alloys can also be deformed aluminum alloys mainly containing copper or silicon. After adding titaniu...

Embodiment 2

[0051] A method for preparing foamed aluminum alloy profiled parts through secondary foaming, comprising the following steps:

[0052] The first step: heating the aluminum alloy to melt, adding calcium equivalent to 0.5%-5% of the aluminum alloy addition (weight percentage) to the aluminum alloy melt, stirring evenly (stirring speed can be 300-600rpm); Add titanium hydride equivalent to 0.5%-5% of the weight of the aluminum alloy, stir at a speed of 800-5000rpm for 20-100 seconds, so that the titanium hydride is evenly mixed in the melt, and then raise the stirring paddle to obtain a foamed aluminum alloy melt , and then quickly cool the foamed aluminum alloy melt to obtain a foamed aluminum alloy; wherein, the aluminum alloy can be a cast aluminum-silicon alloy, such as ZL101, ZL102, ZL111 series alloys, or a cast aluminum-copper alloy, For example, ZL201, ZL202, ZL205 series alloys can also be deformed aluminum alloys mainly containing copper or silicon. After adding titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com