Interruptible perovskite type organic halide thin-film solar cell photo-anode preparing method

A solar cell, organic halide technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex operation, low battery efficiency, and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

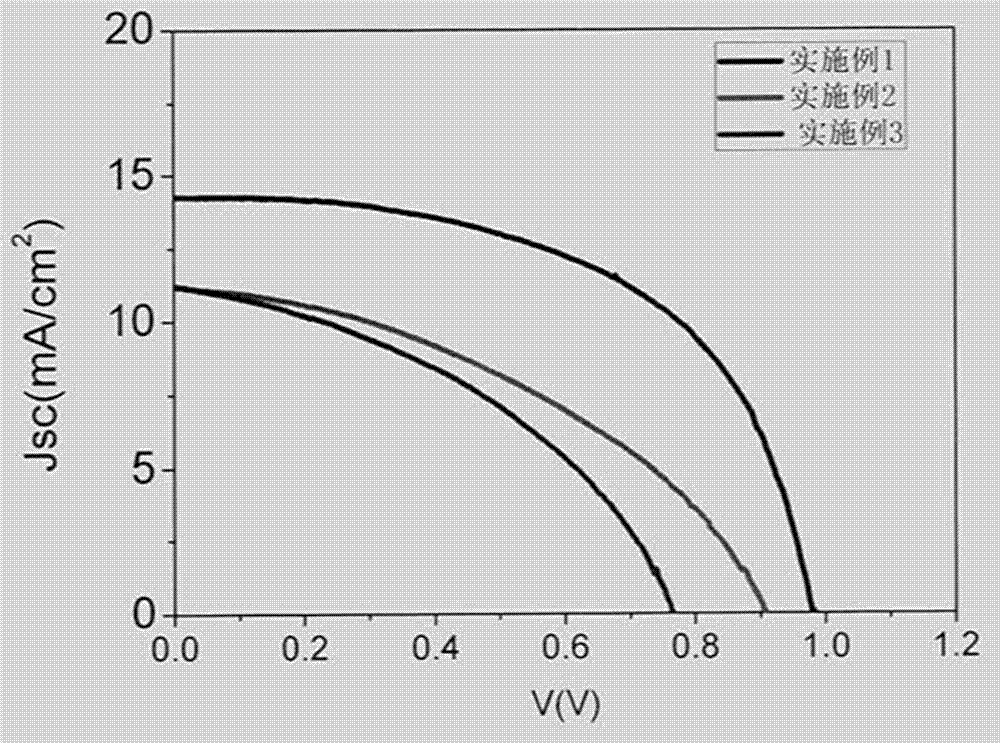

Embodiment 1

[0022] (1) Preparation of dense zinc oxide layer

[0023] Zn(CH 3 COO) 2 Dissolve in ethanol, stir magnetically for 0.5 hours, add DEA (the molar ratio is CH 3 COOH:Zn(CH 3 COO) 2 :DEA=66:1:1), after stirring for 10 minutes, a zinc ion precursor sol was made.

[0024] Spin coating: Add the above-mentioned zinc ion precursor sol dropwise on the FTO glass, spin coating at a speed of 3500r / min for 30s; sinter the spin-coated sheet at 200-500°C for 30 minutes; prepare a dense zinc oxide film.

[0025] (2) Preparation of Hierarchical Porous Zinc Oxide Layer

[0026] Electrodeposition solution configuration: Zn(NO 3 ) 2 and C 6 h 12 N 4 The aqueous solution mixing solution, stirring, obtains the electrochemical solution (the molar ratio is Zn(NO 3 ) 2 : C 6 h 12 N 4 :H 2 O=1:1:5556).

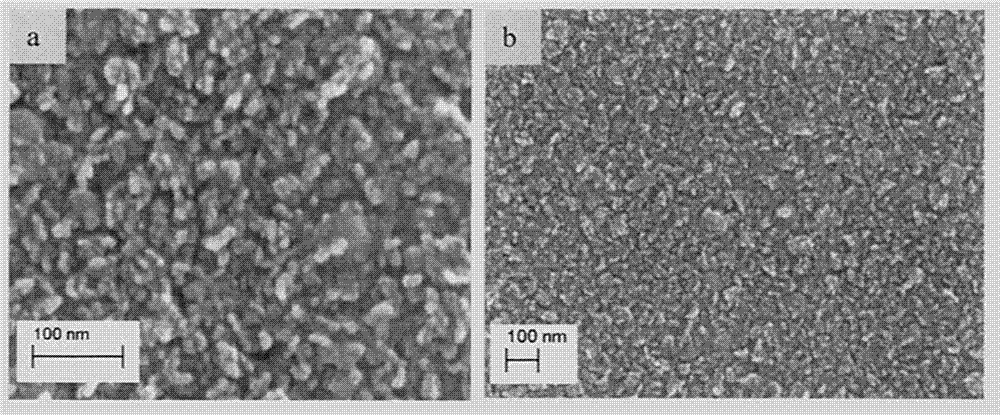

[0027] At 25°C, a hierarchical porous zinc oxide film was prepared on the dense zinc oxide layer prepared above, the deposition voltage was -1V, and the deposition time was 1800s. The...

Embodiment 2

[0033] (1) Preparation of dense zinc oxide layer

[0034] Zn(CH 3 COO) 2Dissolve in ethanol, stir magnetically for 0.5 hours, add DEA (the molar ratio is CH 3 COOH:Zn(CH 3 COO) 2 :DEA=66:1:1), after stirring for 10 minutes, a zinc ion precursor sol was made.

[0035] Spin coating: Add the above-mentioned zinc ion precursor sol dropwise on the FTO glass, spin coating at a speed of 3500r / min for 30s; sinter the spin-coated sheet at 200-500°C for 30min; prepare a dense zinc oxide layer.

[0036] (2) Preparation and assembly process of solar cells

[0037] Refer to the preparation and assembly process of the solar cell in Example 1.

Embodiment 3

[0039] (1) Preparation of Zinc Oxide Hierarchical Porous Layer

[0040] Electrodeposition solution configuration: Zn(NO 3 ) 2 and C 6 h 12 N 4 The aqueous solution mixing solution, stirring, obtains the electrochemical solution (the molar ratio is Zn(NO 3 ) 2 : C 6 h 12 N 4 :H 2 O=1:1:5556).

[0041] At 25°C, a hierarchical porous zinc oxide film was prepared on a flexible transparent conductive substrate, the deposition voltage was -1V, and the deposition time was 1800s. The laminated film after electrochemical deposition was baked at 130°C for 1 hour to obtain a hierarchical porous zinc oxide film. layer.

[0042] (2) Preparation and assembly process of solar cells

[0043] Refer to the preparation and assembly process of the solar cell in Example 1.

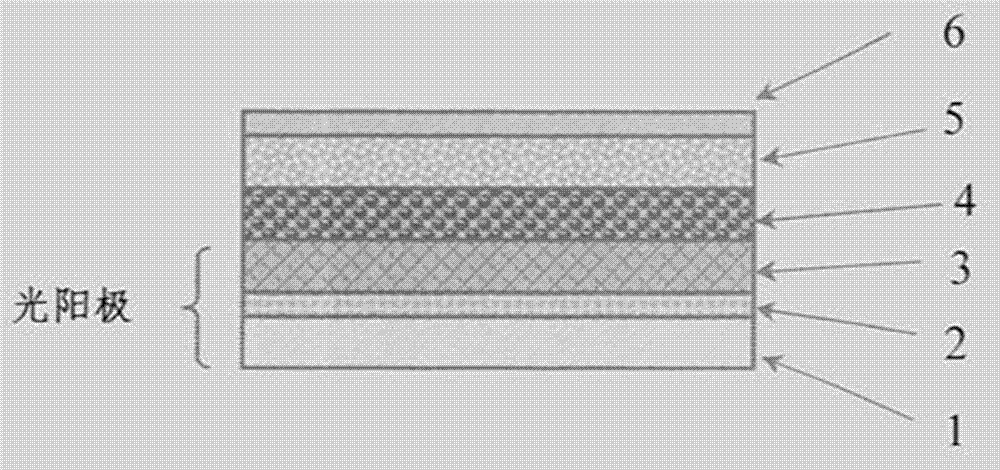

[0044] combined with figure 1 Schematic representation of the structure of perturbable perovskite-type organic halide thin-film solar cells, in which the transparent conductive substrate ( figure 1 Schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com