Method for producing polyporous material based on solid/gas eutectic directional solidification

A porous material, directional solidification technology, used in manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problem of unable to obtain the variable cross-section pore diameter of the same axial direction, monitor the production process of porous materials, and unable to obtain porous materials. The effect of shortening the process time, widening the range of material selection, and uniform porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

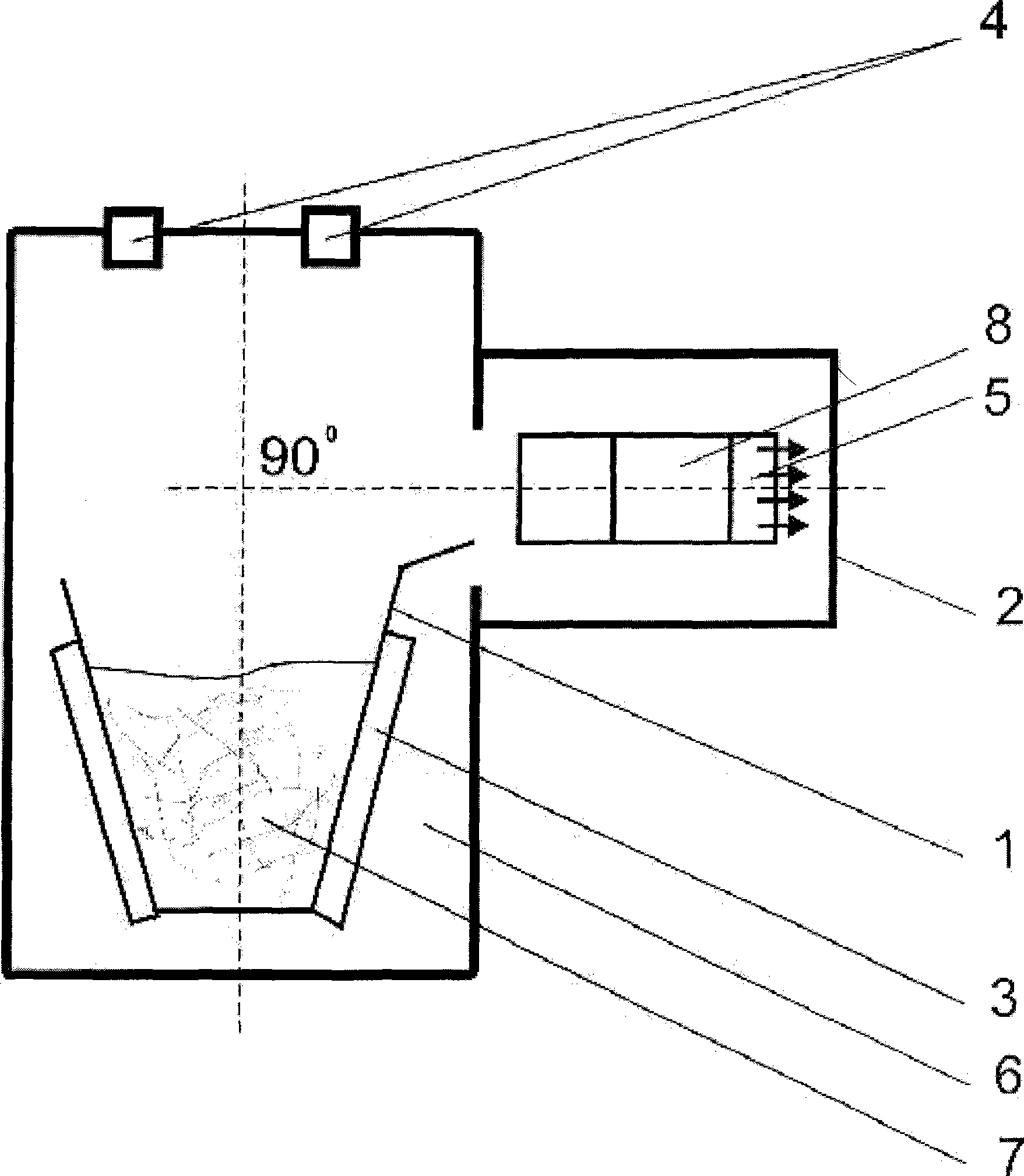

[0027] Add a certain quality of material into the melting crucible (1), make it heated and finally melted in the induction field of the electric induction heater (3), and detect the melting process and temperature in the furnace through the observation window (4) on the furnace shell Variety. After blowing saturated gas into the melt (7), the furnace body is inclined at 90°, and the melt is evenly layered and poured into the mold (5) of the crystallizer (2), and the refractory layer (6) of the furnace is in contact with the melt The time is shorter. The porous material (8) is crystallized by means of directional heat pipes on the mold. The crystallizer assembly can be easily disassembled and replaced, and can quickly change the shape, pore size, and direction of porous material castings.

[0028] The method of pressurized cooling to prepare porous materials is: melt the material to be prepared under the gas pressure of 0.005 ~ 10MPa, then pour the liquid material into the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com