Patents

Literature

114results about How to "Expand the range of material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

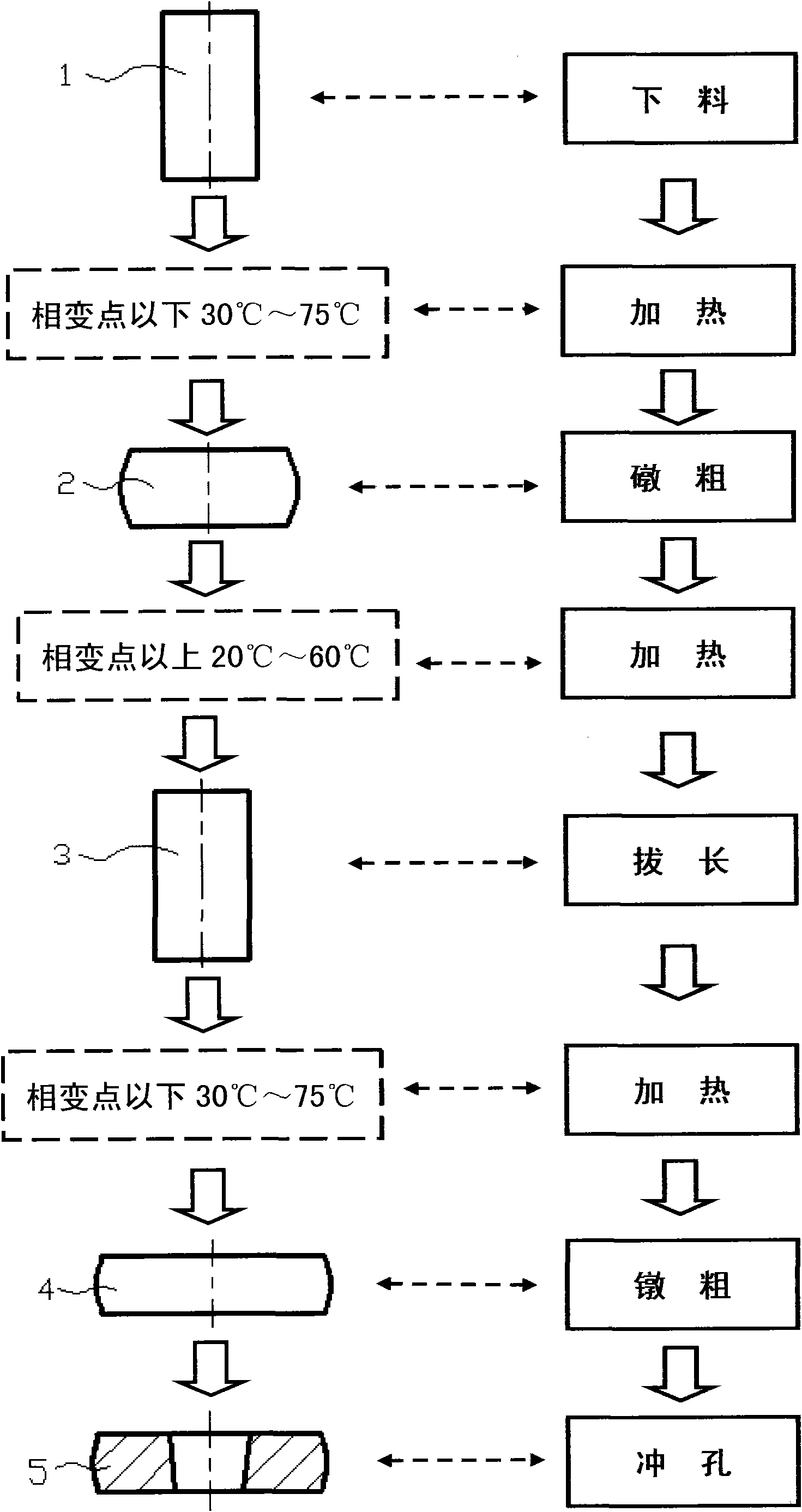

Near-isothermal forging method of TC17 biphase titanium alloy disc forge piece

ActiveCN101804441ASmall and uniform tissueMake up for the phase transition point errorWheelsAviationAir compressor

The invention discloses a near-isothermal forging method of a TC17 biphase titanium alloy disc forge piece, comprising the steps of: heating a TC17 titanium alloy disposable bar ingot to 30-75 DEG C below a phase change point, upsetting the disposable bar ingot into a disposable circular cake; heating the disposable circular cake to 20-60 DEG C over the phase change point, and drawing out the disposable circular cake till the length thereof returns the length of the disposable bar ingot to obtain a secondary bar ingot; heating the secondary bar ingot to 30-75 DEG C below the phase change point, upsetting the secondary bar ingot to form a secondary circular cake, then punching to form an annular blank; and heating the annular blank to 20-60 DEG C over the phase change point, heating an upper forging mold and a lower forging mold to 10-20 DEG C below the phase change point, and forging and stamping the annular blank by the upper forging mold and the lower forging mold under the pressure of 30-60mN to make the deformation degree of the annular blank reach 30-50% in the forging molds at a strain rate of 0.001s-1 to 0.01s-1, and then forming a disc forge piece on fire, wherein the heat treatment after forging is the combination of solution treatment and ageing treatment. The disc forge piece forged by using the method has ideal electrical plating basket structure and high performance and is suitable for manufacturing forge pieces of an air compressor chassis, a turbine disc and the like of an aero-engine.

Owner:GUIZHOU ANDA AVIATION FORGING

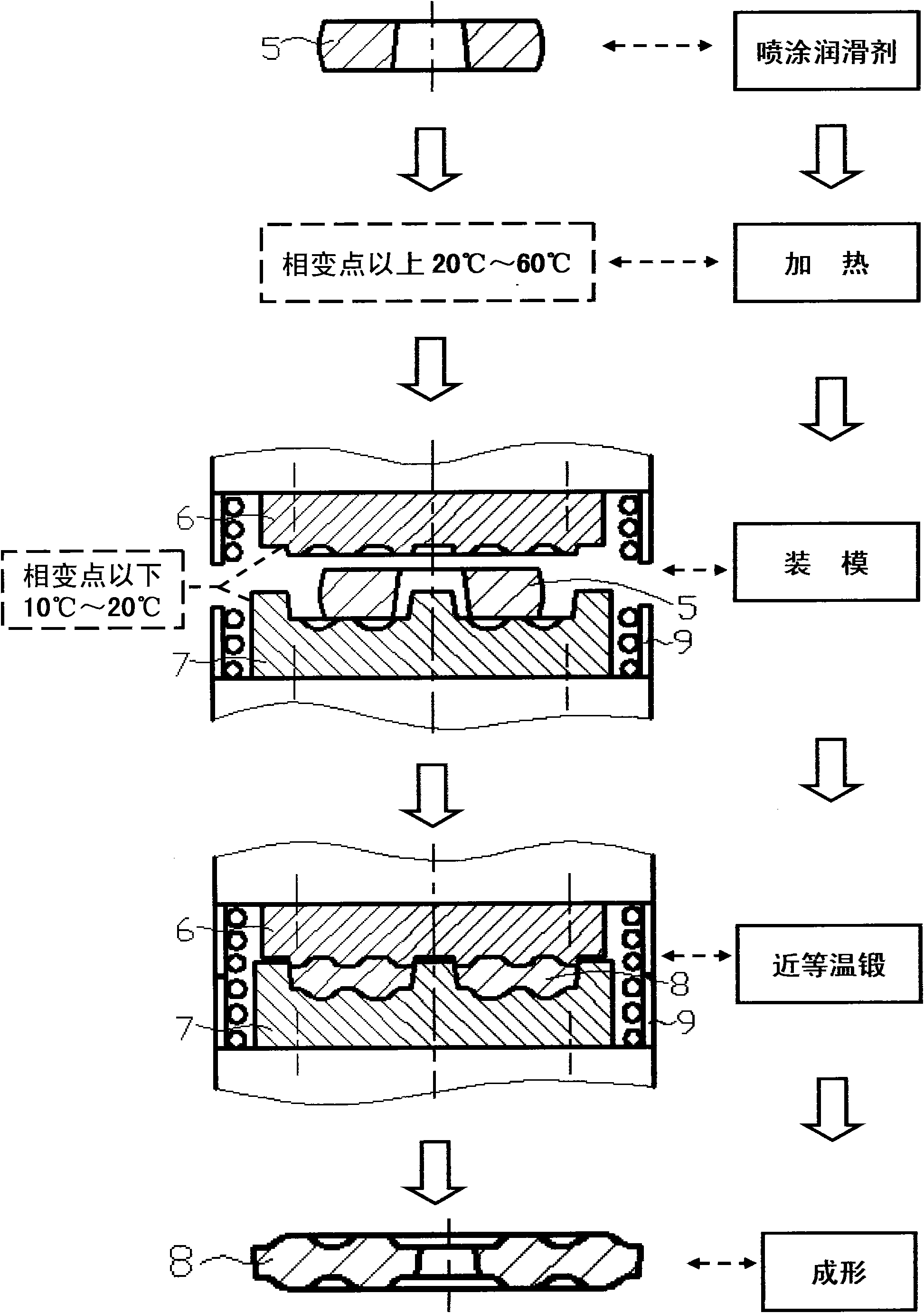

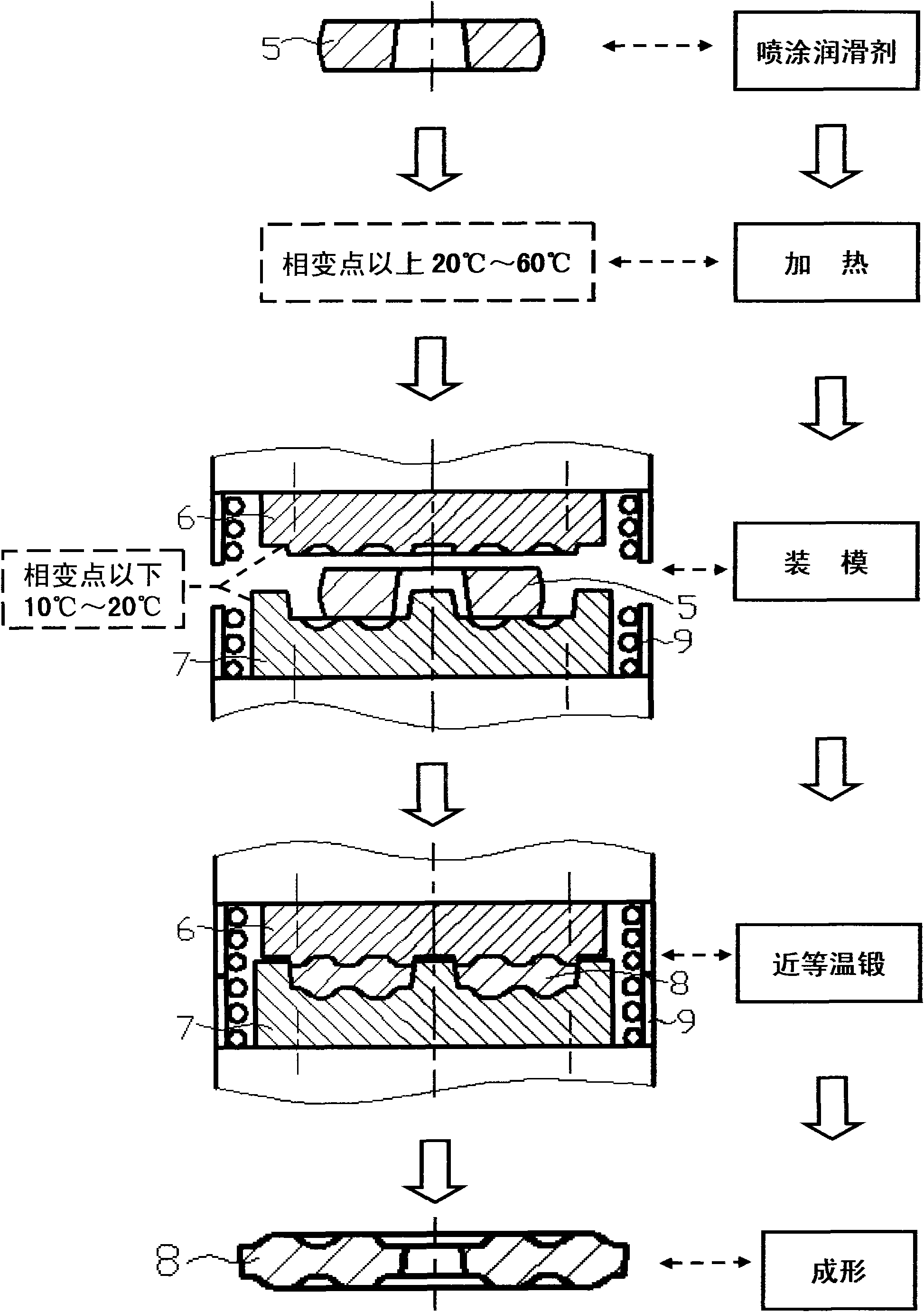

Approximate isothermal forging method of BT25 two-phase titanium alloy disk forge piece

ActiveCN101829749ASmall and uniform tissueMake up for the phase transition point errorMetal-working apparatusFurnace typesIngotTurbine

The invention discloses an approximate isothermal forging method of a BT25 two-phase titanium alloy disk forge piece. The process comprises the following steps of: heating a primary BT25 titanium alloy rod ingot to be below a phase transformation point by 30-75 DEG C and upsetting into a primary cake; heating the primary cake to be above the phase transformation point by 20-60 DEG C and drawing to return to the length of the primary rod ingot to obtain a secondary rod ingot; heating the secondary rod ingot to be below the phase transformation point by 30-75 DEG C, upsetting into a secondary cake and then punching into a ring blank; heating the ring blank to be above the phase transformation point by 20-60 DEG C, heating an upper forging die and a lower forging die to be below the phase transformation point by 10-20 DEG C, wherein the upper forging die and the lower forging die forge the ring blank by using the pressure of 30-60MN to ensure that the deformation of the ring blank in the forging dies reaches 30-50 percent by a strain rate of 0.001s<-1>-0.01s<-1> to form a disk forging piece by once heating, and heat treatment after forging adopts twice annealing treatment. The disk forging piece forged by using the method has better ideal network texture and high property, thus the method is suitable for manufacturing forging pieces such as compressor disks, turbine disks, and the like of aircraft engines.

Owner:GUIZHOU ANDA AVIATION FORGING

Microemulsion capsule for tobacco and preparation method of microemulsion capsule

ActiveCN106942787AExpand the range of material selectionRich fragrance and application rangeTobacco smoke filtersEssential-oils/perfumesWater in oilBiomass

The invention relates to a microemulsion capsule for tobacco and a preparation method of the microemulsion capsule. As for the capsule, a water-in-oil reversed-phase microemulsion serves as a core material and biomass glue or synthetic resin is taken as a capsule wall material; the capsule looks as a transparent or semitransparent elastic spherical body which is 2-4mm in grain size; and the wall material is 0.1-0.5mm thick and is 0.5-2.5kg in pop strength. With the application of the tobacco capsule prepared by the method, water-soluble essence, alcohol-soluble essence and oil-soluble essence can be covered well; and the obtained capsule core material is stable in properties, and the wall material is good in water retaining performance and moderate in pressure value. With the application of the tobacco capsule, fragrance can be enriched to a great extent and smoke moisture can be enhanced to a certain degree, so that smoking quality is improved; and the microemulsion capsule is simple and easily feasible in preparation process, safe and environment-friendly in materials and applicable to continuous industrial production.

Owner:YUNNAN XINYUN TECH DEV CO LTD

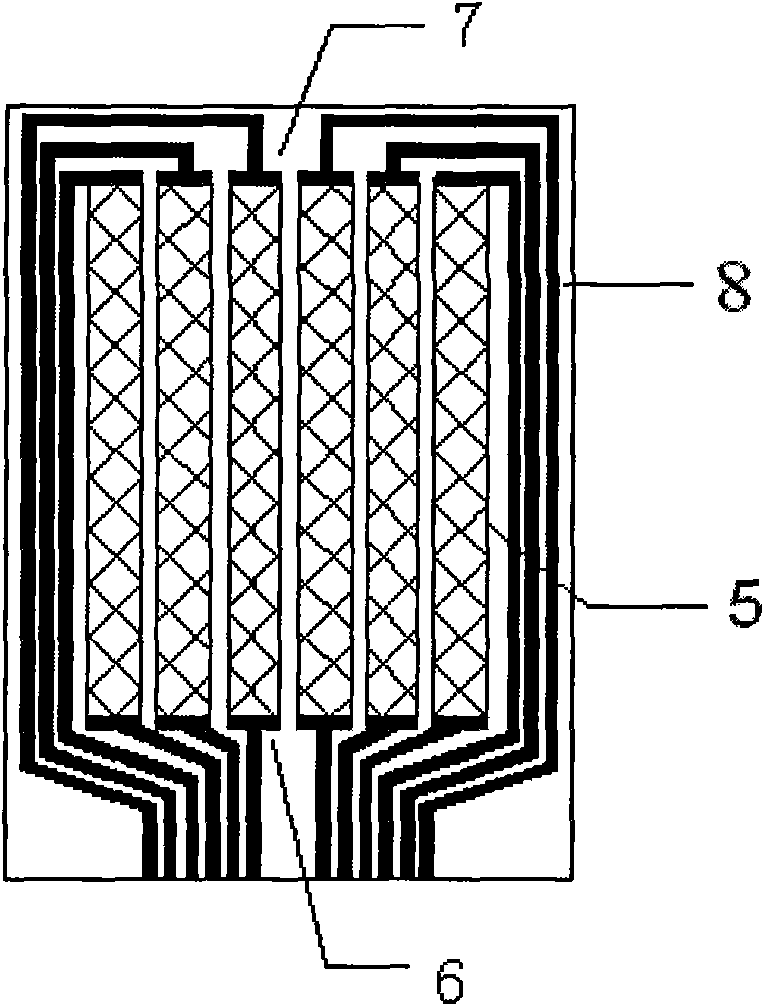

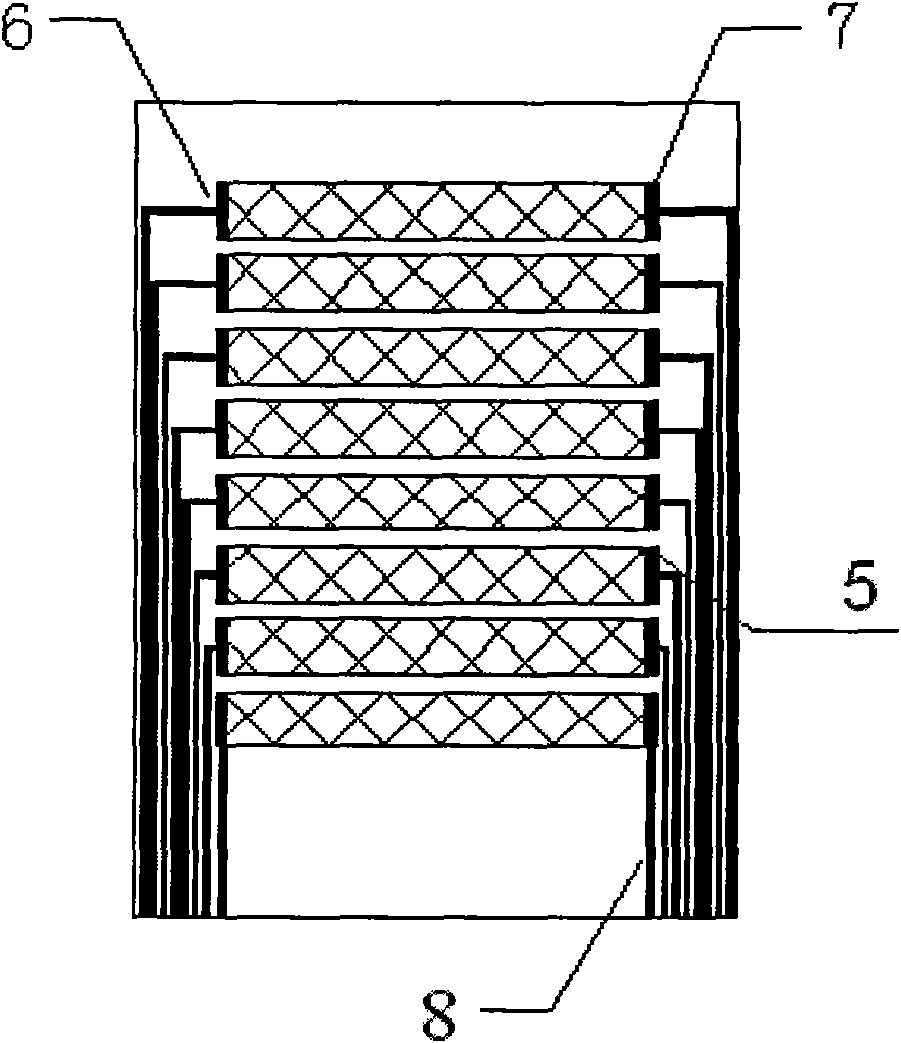

Projected capacitive touch screen

InactiveCN101571778AReduce scan timeImprove signal-to-noise ratioInput/output processes for data processingHigh volume manufacturingTouchscreen

The invention relates to a projected capacitive touch screen, which can greatly shorten scanning time and improve signal-to-noise ratio, and has accurate touch and sensitive response. The projected capacitive touch screen comprises a conductive layer covered on a substrate, the conductive layer comprises electrode strips, and each electrode strip is connected with more than two conducting wires which are connected with an external circuit. As a preferable mode, two ends of each electrode strip are connected with a conducting wire respectively. The substrate can be made of known various materials, preferably, the substrate is a membrane. By the projected capacitive touch screen, the problem that the face resistance value is overlarge when an ITO conductive layer uses the membrane as the substrate at present is well solved, the problems that the touch of the projected capacitive touch screen of an ITO membrane structure is inaccurate and the response is not sensitive are effectively solved, the dependency on raw materials is reduced, the material selection range of the projected capacitive touch screen of the ITO membrane structure is enlarged, and the projected capacitive touch screen of the membrane structure is feasible to be produced on a large scale.

Owner:NANJING WALLY ELECTRONICS TECH

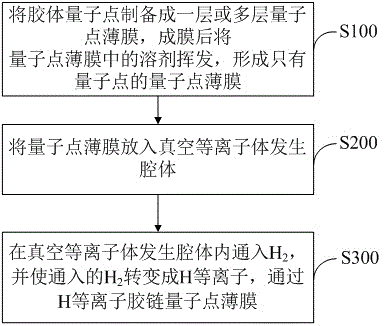

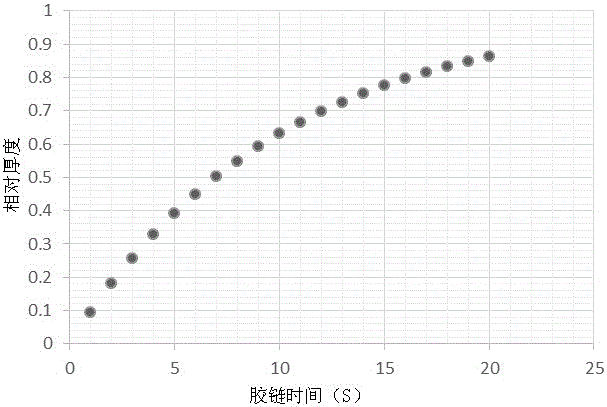

Method for gluing quantum dot film and quantum dot films

ActiveCN106229426AImprove stabilityIncrease the scope of applicationSolid-state devicesSemiconductor/solid-state device manufacturingSolventNew materials

The invention discloses a method for gluing quantum dot films and the quantum dot films. The method comprises the steps of preparing one or more layers of quantum dot films from colloidal quantum dots, volatilizing solvents in the quantum dot films after the films are formed, and forming the quantum dot films which only contain the quantum dots; putting the quantum dot films into a vacuum plasma generation cavity; and introducing H2 into the vacuum plasma generation cavity, then transforming the H2 into H plasma and gluing the quantum dot films through the H plasma. The quantum dot films are glued by use of HHIC and the process is improved, so that the quantum dot films have better effects of solvent resistance and mechanical force. The method for gluing the quantum dot films by HHIC is short in elapsed time, low in condition requirements and free of a special requirement on a reactant; and no new material is generated. Furthermore, the films glued by HHIC are better than traditional films which are glued in a heating manner in stability, and the electrical properties of the films are not changed. The application range and the material selection range of a solution method can be expanded by HHIC.

Owner:TCL CORPORATION

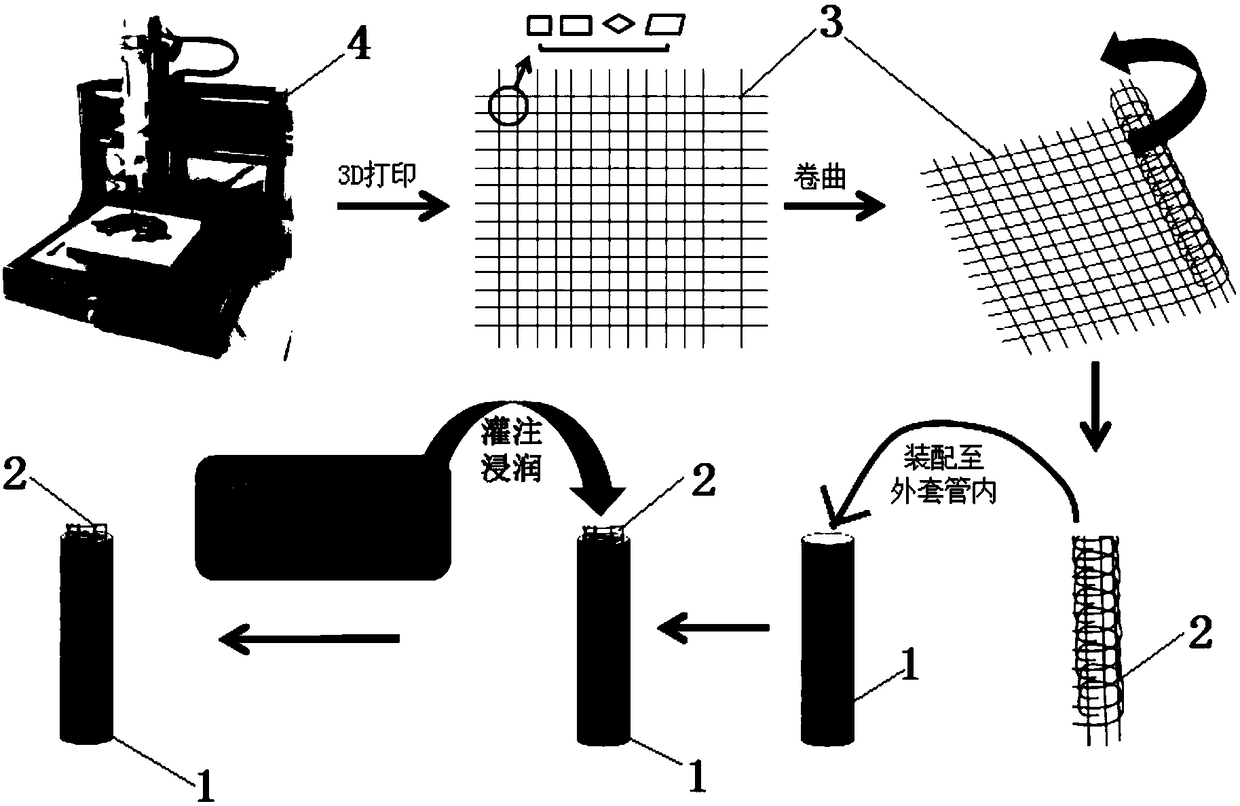

Slide block for rotary type compressor and manufacturing method thereof

ActiveCN102174936AHigh hardnessImprove toughnessRotary/oscillating piston pump componentsLiquid fuel engine componentsHardnessPre treatment

The invention discloses a slide block for a rotary type compressor and a manufacturing method thereof. The slide block which meets the requirement is manufactured by the following steps of: performing pretreatment on GCr15 or GCr15SiMn bearing steel serving as a material; performing cold rolling; cutting; performing heat treatment and dimension stability treatment, and the like. In the invention,the material is selected reasonably, and a proper heat treatment process is achieved, so that the material selection range of the slide block for the rotary type compressor is enlarged, the content of alloy elements of the material is low, the requirement on rare elements is reduced, loads to the environment are reduced, and the raw material cost of the slide block is reduced simultaneously; and a manufacturing process is simple, manufacturing cost is low, and the obtained slide block has high hardness, high toughness and high abrasion resistance and can meet the using requirement of the conventional rotary type compressor.

Owner:PANASONIC WANBAO GUANGZHOU COMPRESSOR

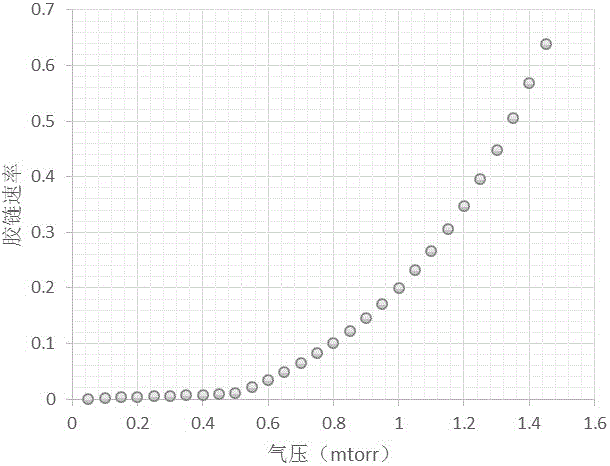

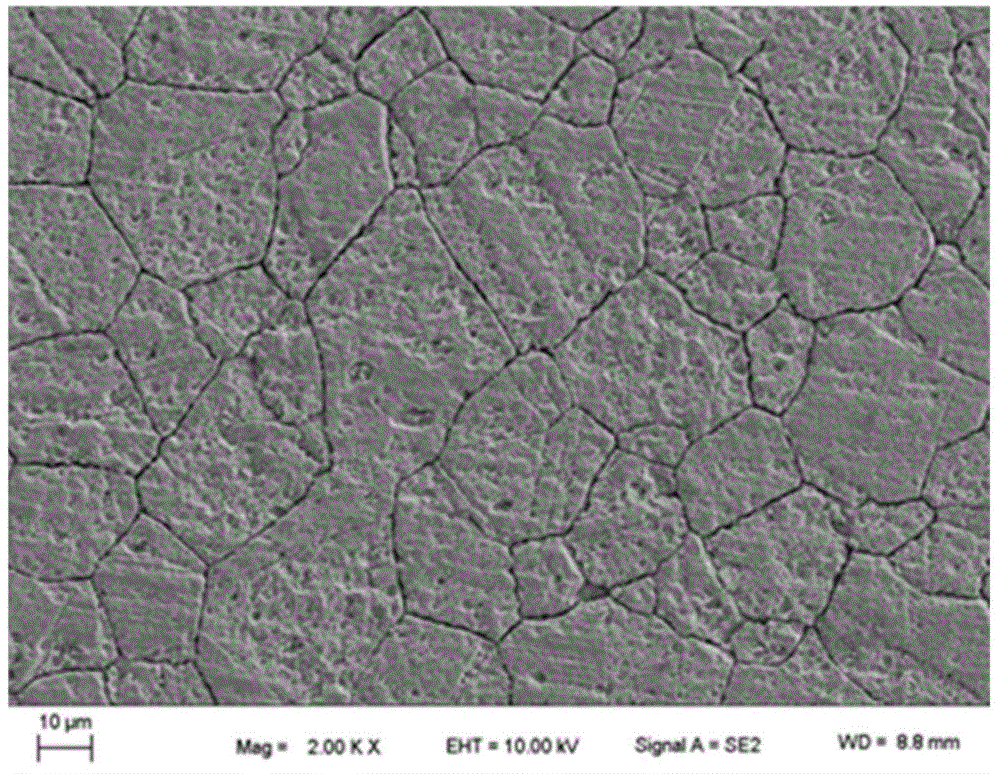

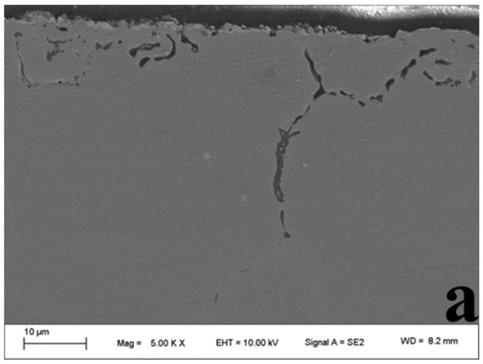

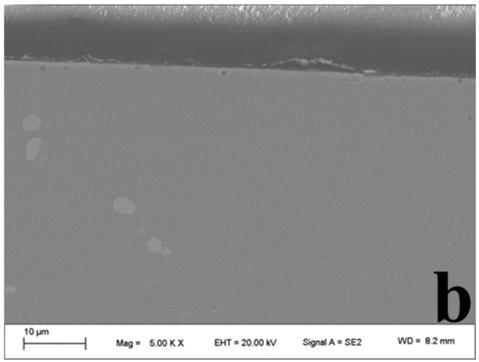

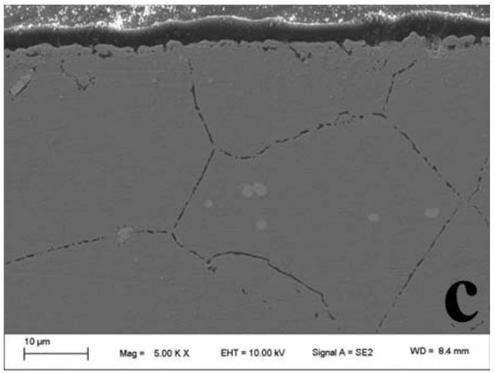

Corrosion protection method of fluoride molten salt and/or chloride molten salt and application of chrome

The invention discloses a corrosion protection method of fluoride molten salt and / or chloride molten salt and the application of chrome. The corrosion protection method comprises the step that chrome is added into a fluoride molten salt and / or chloride molten salt system served by stainless steel or corrosion-resistant alloy. The use amount of the chrome meets the requirement that the chrome exists all the time in the protection process. The corrosion protection method is simple, feasible, safe, environmentally friendly, easy to operate and control, and remarkable in effect; by means of the corrosion protection method, the corrosion speed of the high-temperature fluoride molten salt and the chloride molten salt can be decreased remarkably, especially intergranular corrosion of stainless steel can be effectively restrained and relieved, and the service life of the stainless steel in the high-temperature fluoride molten salt and the chloride molten salt is prolonged; in addition, by means of the corrosion protection method of the fluoride molten salt and / or the chloride molten salt and the application of the chrome, the material selection range of alloy structure materials used for fluoride molten salt and chloride molten salt media can be broadened; meanwhile, the unique advantages of the molten slat can be utilized, and the molten salt can serve as novel high-temperature heat transfer and storage media to be applied and popularized in the field of high-temperature energy.

Owner:上海联和日环能源科技有限公司

Probiotic binary mixed fermentation beverage and making method

InactiveCN101637287AExpand the range of material selectionRich sourcesBacteriaFood preparationStreptococcus thermophilusSlag

The invention relates to a probiotic binary mixed fermentation beverage. Squeeze juice of carrot and red jujube is used as a culture medium; fermentation is carried out under specific temperature andfor specific time to culture probiotics, such as bifidobacterium, lactobacillus bulgaricus, streptococcus thermophilus, lactic acid bacillus and the like; then, probiotic liquid after fermentation isinactivated, and then a proper amount of white granulated sugar, honey and drinking water is added to make a beverage. Slag generated in the production of the probiotic mixed beverage of carrot and red jujube can be also used for producing mixed probiotic jam of carrot and red jujube. The invention greatly broadens the application range of probiotic culture medium selection of materials, such as bifidobacterium and the like, provides a novel probiotic inactivation fermentation beverage, and has the advantages of rich material source, low cost, stable preparation process, little production equipment investment, simple operation, easy popularization and favorable market application prospect.

Owner:赵敏

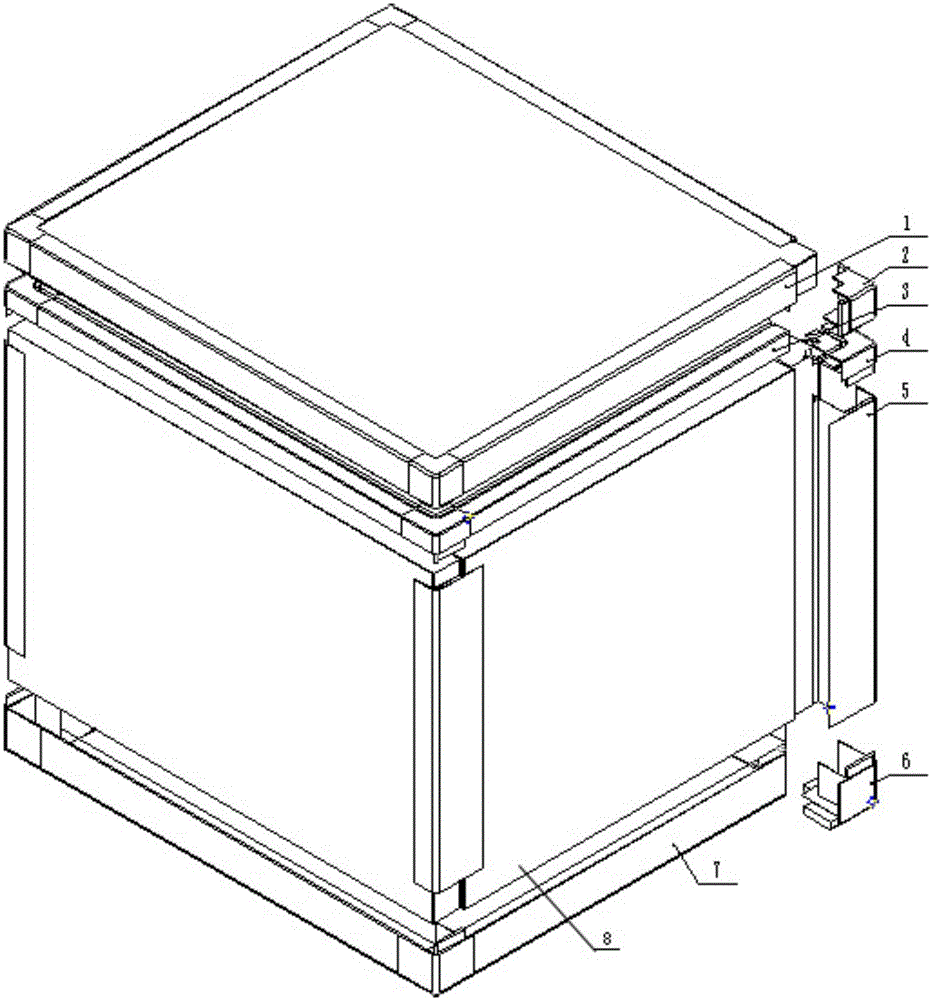

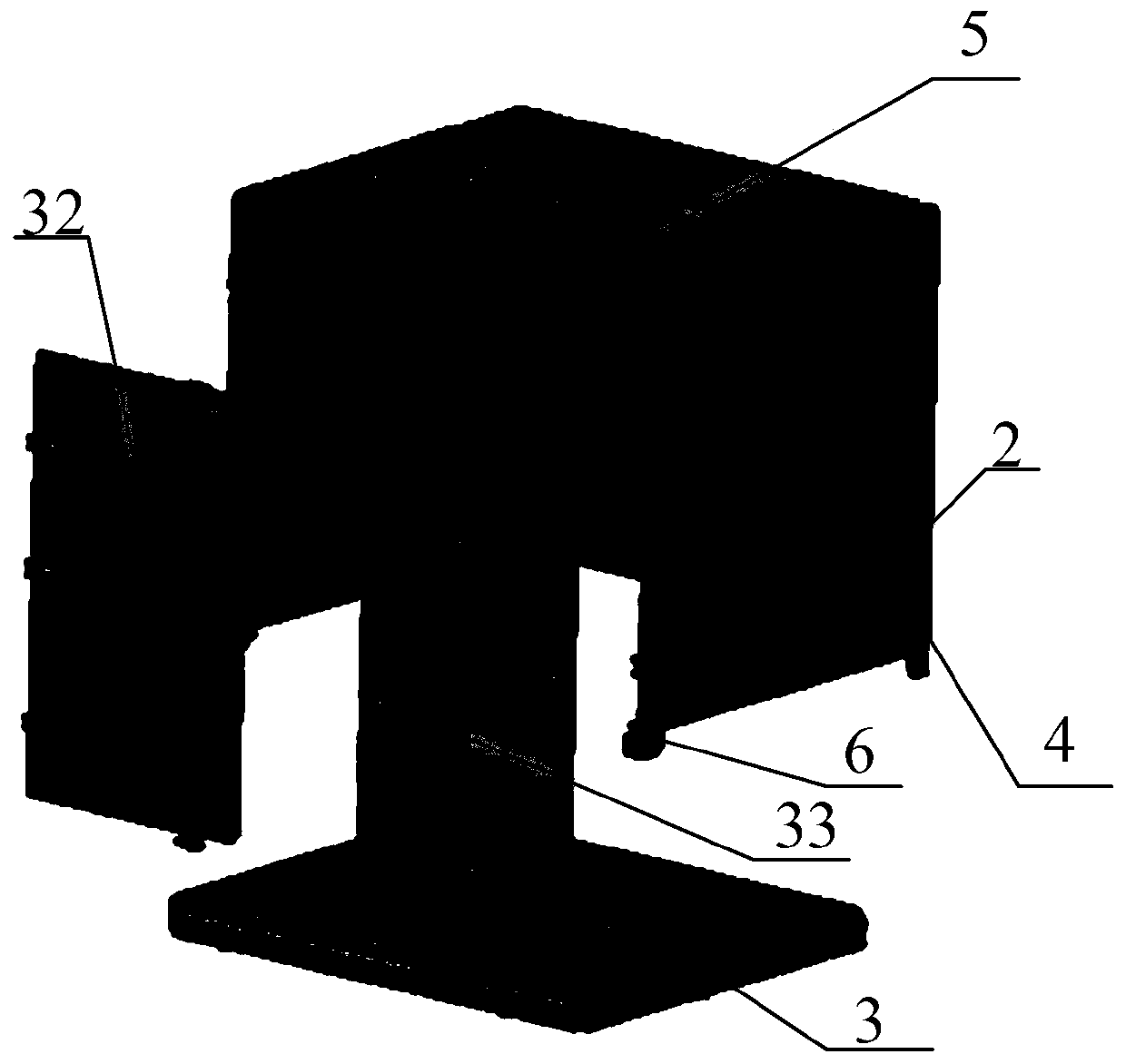

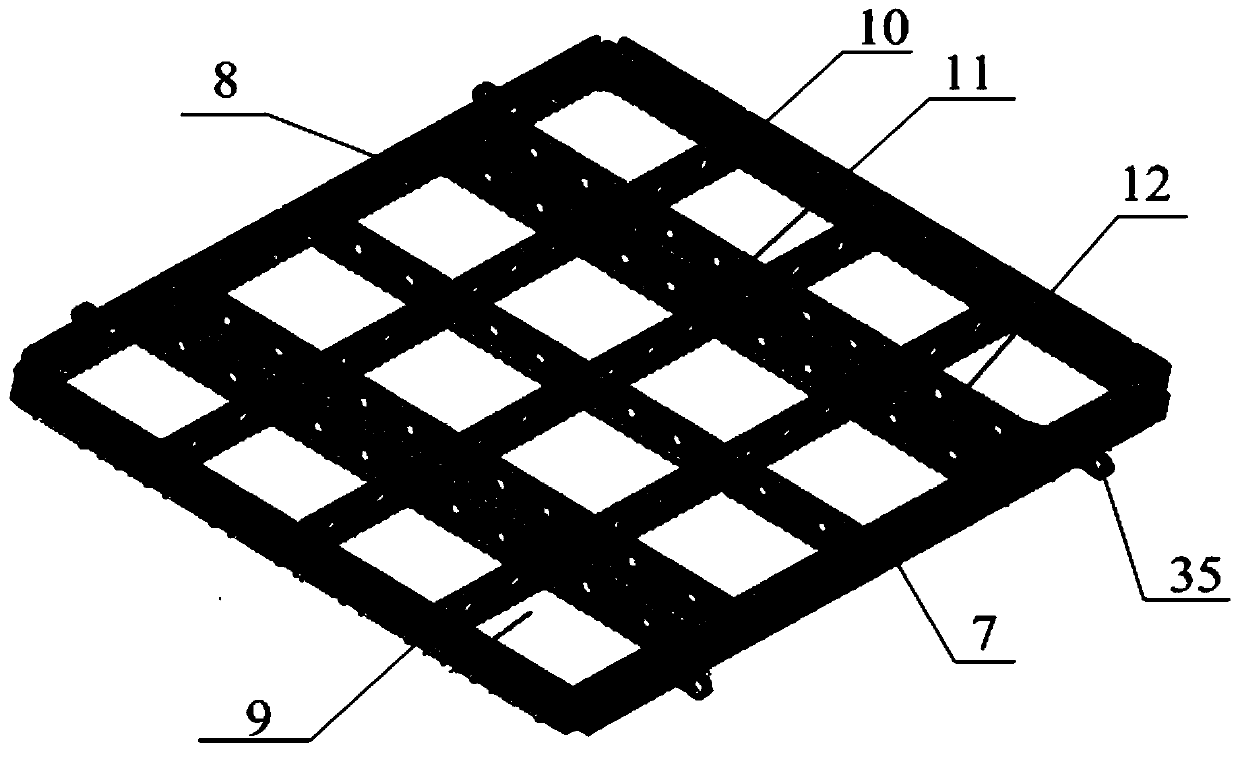

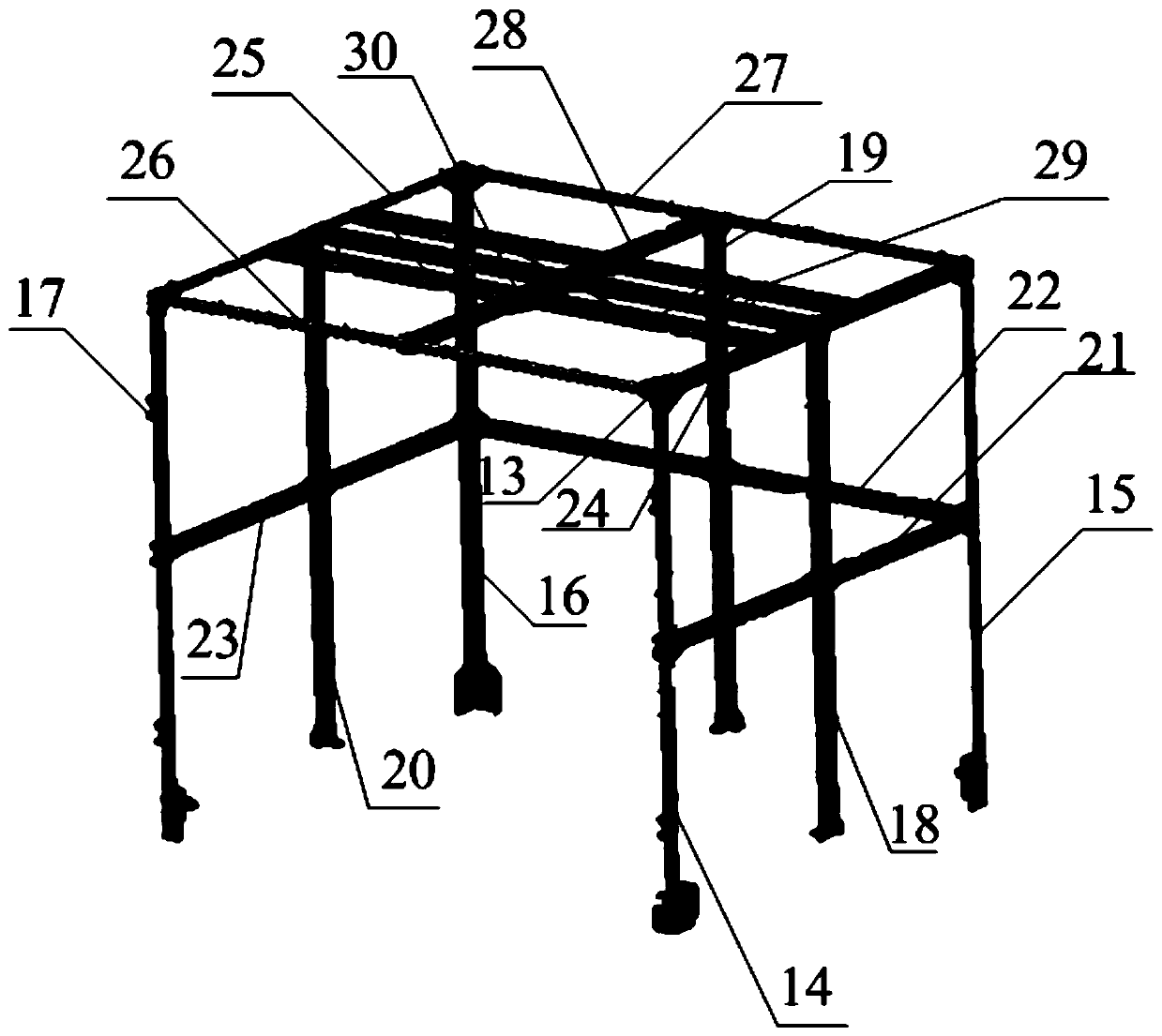

Light type rapid splicing warm box

InactiveCN106379624AGuaranteed stabilityGuaranteed carrying capacityDomestic cooling apparatusLighting and heating apparatusEngineering

Owner:SOLEE WUHAN SCI & TECH +1

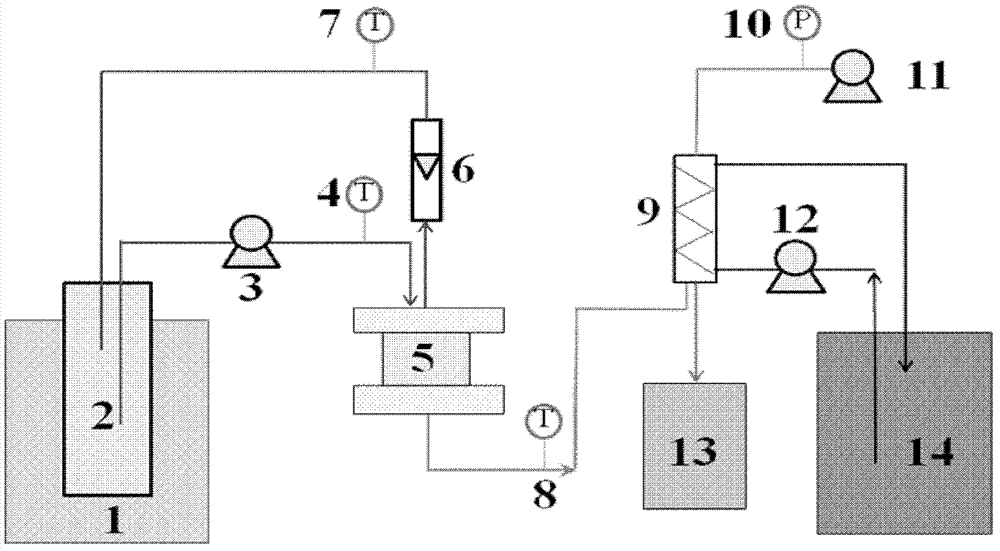

Polyether sulfone porous membrane for membrane distillation process and preparation method thereof

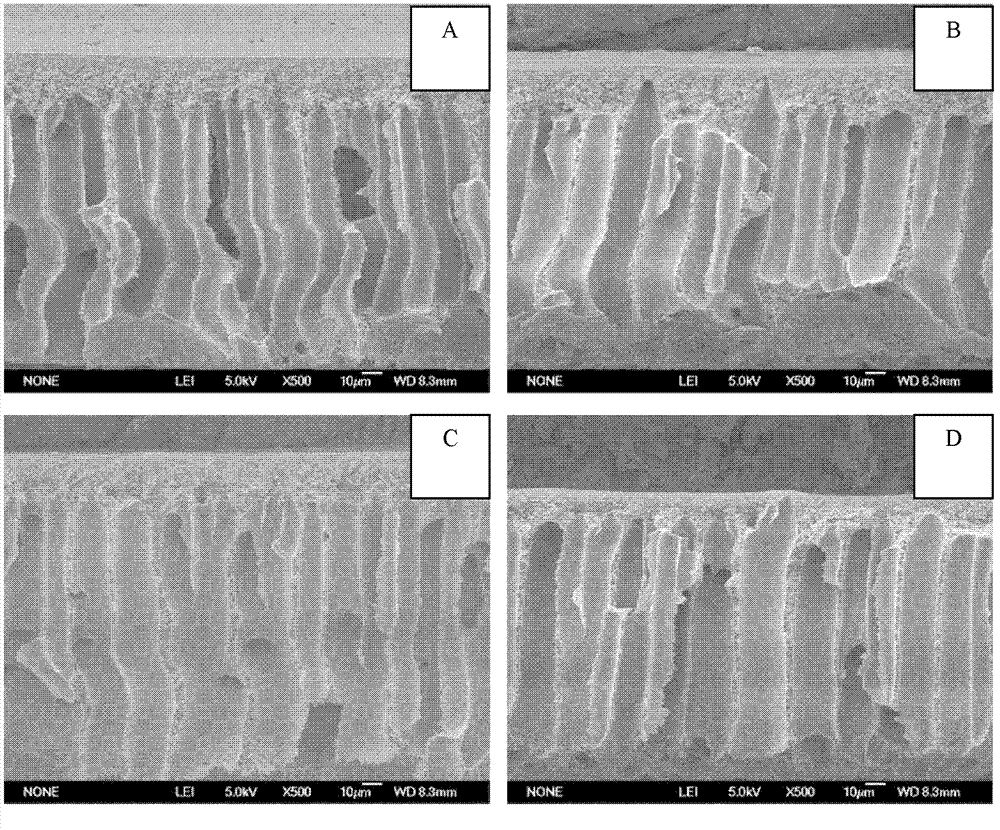

ActiveCN102698618AExcellent Membrane Distillation PerformanceThe film making process is simpleDistillationPorous membraneMembrane distillation

The invention provides a polyether sulfone porous membrane for a membrane distillation process and a preparation method of the polyether sulfone porous membrane, wherein before the polyether sulfone porous membrane for the membrane distillation process is prepared, no hydrophobic modification treatment on polyether sulfone body material is carried out, and no hydrophobic modification treatment on the membrane is carried out after membrane is prepared. The preparation method comprises the following steps: firstly preparing a wet polyether sulfone porous membrane by a lyotropic phase transformation method, and then drying the wet membrane so as to prepare the polyether sulfone porous membrane for the membrane distillation process. The polyether sulfone porous membrane provided by the invention has the advantages that membrane distillation flux is stable and high, the preparation method is mature and simple, the cost is low, the amplification is easy, and the application prospects in the fields such as desalination of seawater and bitter saline water, concentration of biological macromolecular solution and concentration of sugar-containing liquid are broad.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

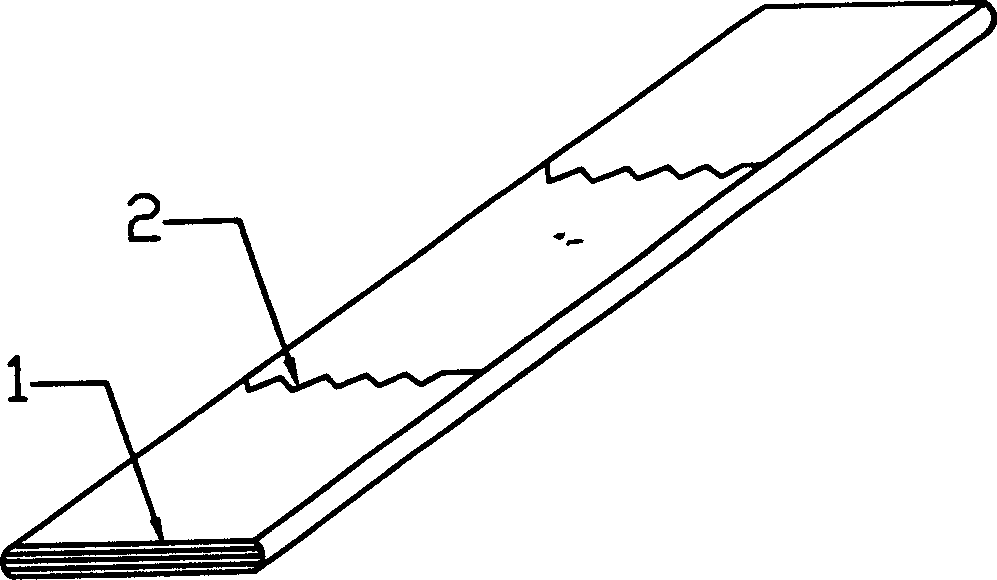

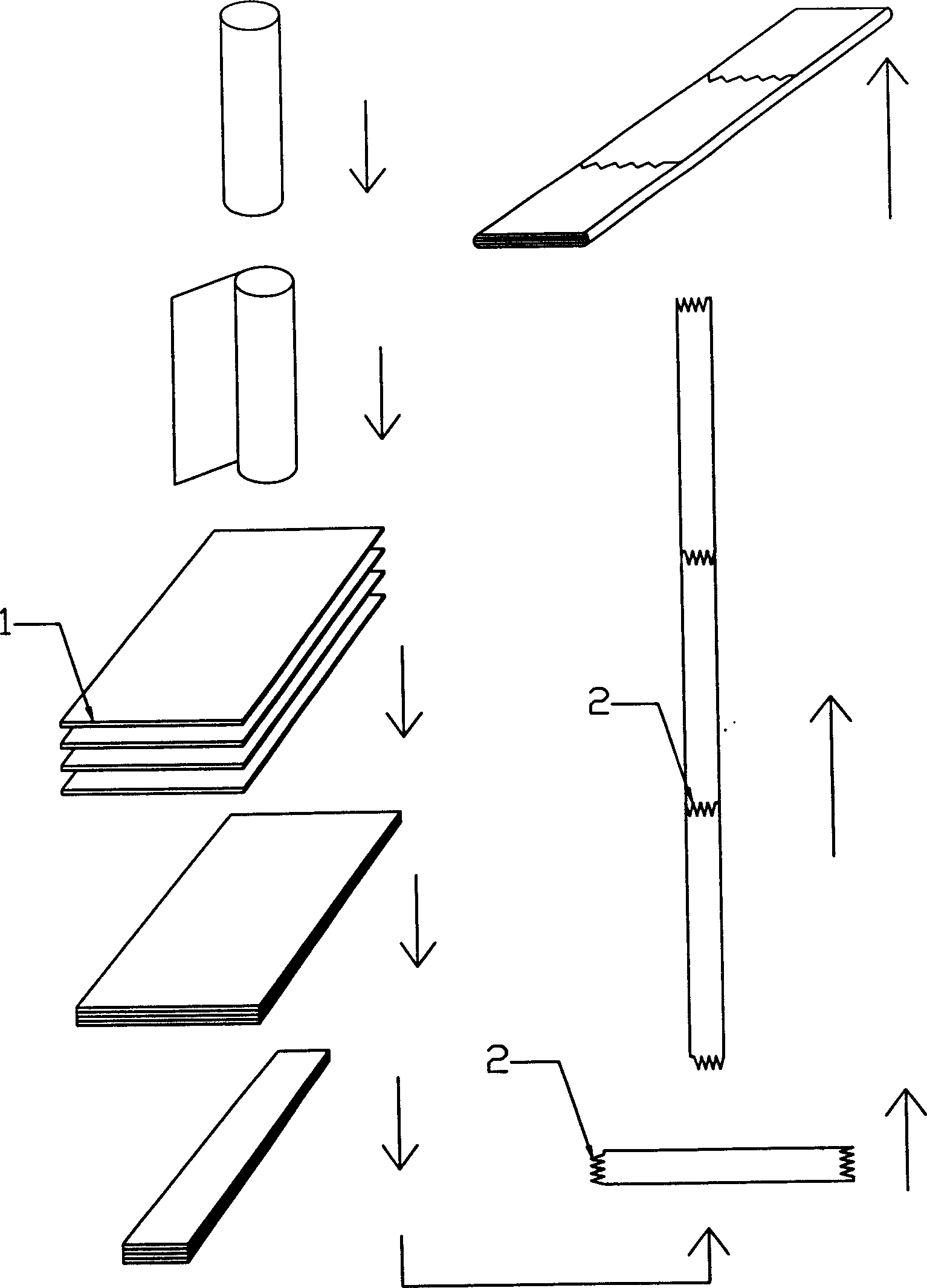

Bamboo blinds and method for making

InactiveCN1570343AOvercome bendingOvercome usabilityVentilation arrangementLight protection screensSuperimpositionEngineering

This invention discloses one kind of bamboo louver and its manufacture method; The bamboo louver piece rotary cutting veneer also at least has two including the bamboo to turn on lathe cuts the bamboo veneer, or has the multilayer to turn on lathe cuts the bamboo clappers in the thickness direction superimposition, the thermo-compression agglutination; The length direction opens has relates to the tenon docking agglutination to become; Its manufacture method including turns on lathe cuts, opens dryly, the agglutination, operates the tenon, the joint, the rough grinding, correct grinding and so on craft step; This invention uses the bamboo veneer after the bamboo which turns on lathe cuts obtains, has overcome the bamboo curving because of the difficult problem which but cannot use, simultaneously also changed the bamboo partial performance, causes the bamboo louver piece not to be easy to distort, opens relates to the tenon to refer carried forward theoretically may enable the bamboo agglutination plank the length to achieve wants the length, causes the person and the surface street window all can use the bamboo louver; Turns on lathe through the control cuts the bamboo veneer the superimposition layer, enable the louver piece also to have the certain flexibility in in the maintenance intensity situation, but uses this method production the bamboo louver piece, first expanded the bamboo raw material selection scope, second has solved the raw material, basic did not waste, third was the craft simple production cost is low.

Owner:傅玉双

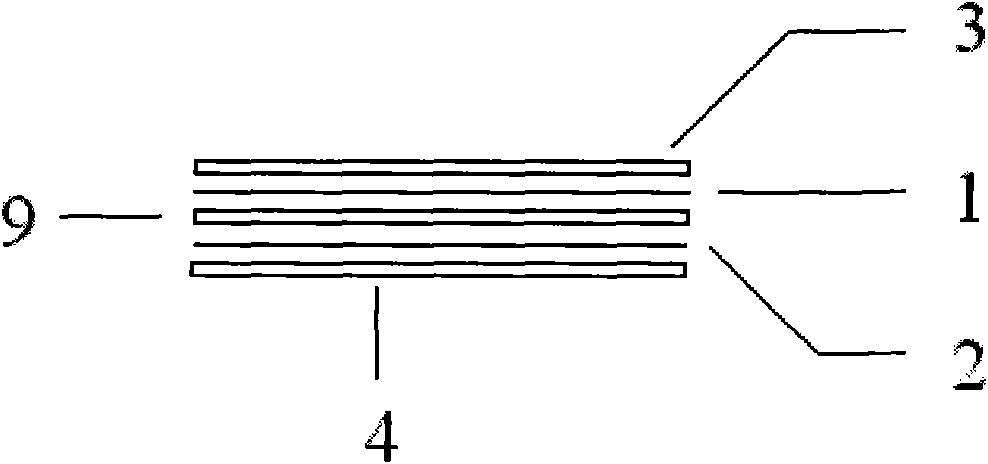

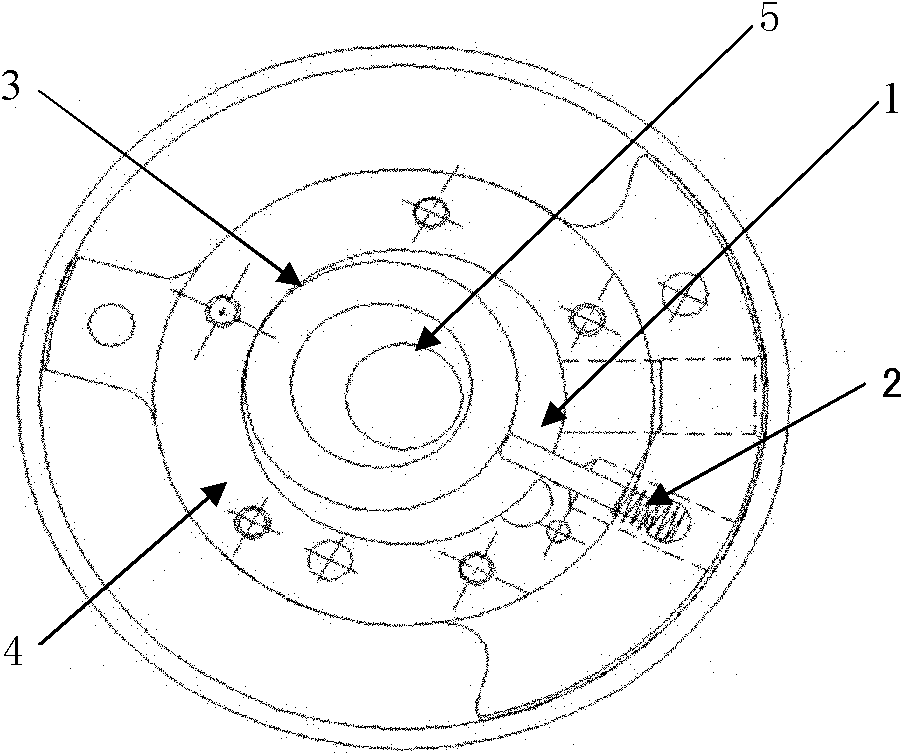

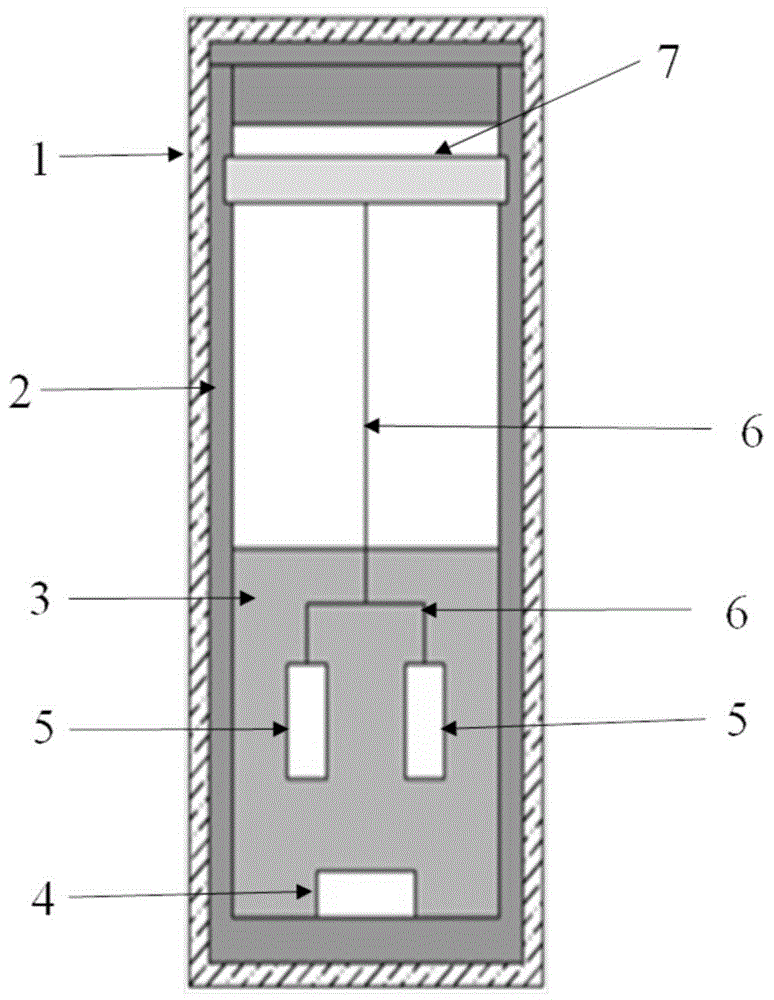

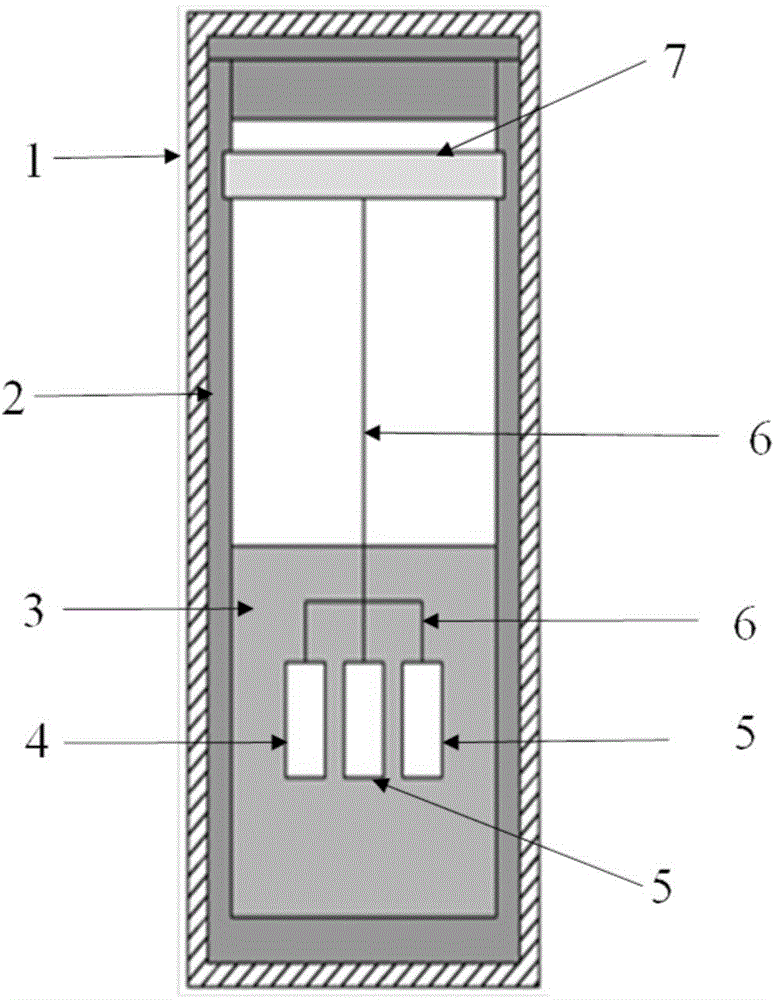

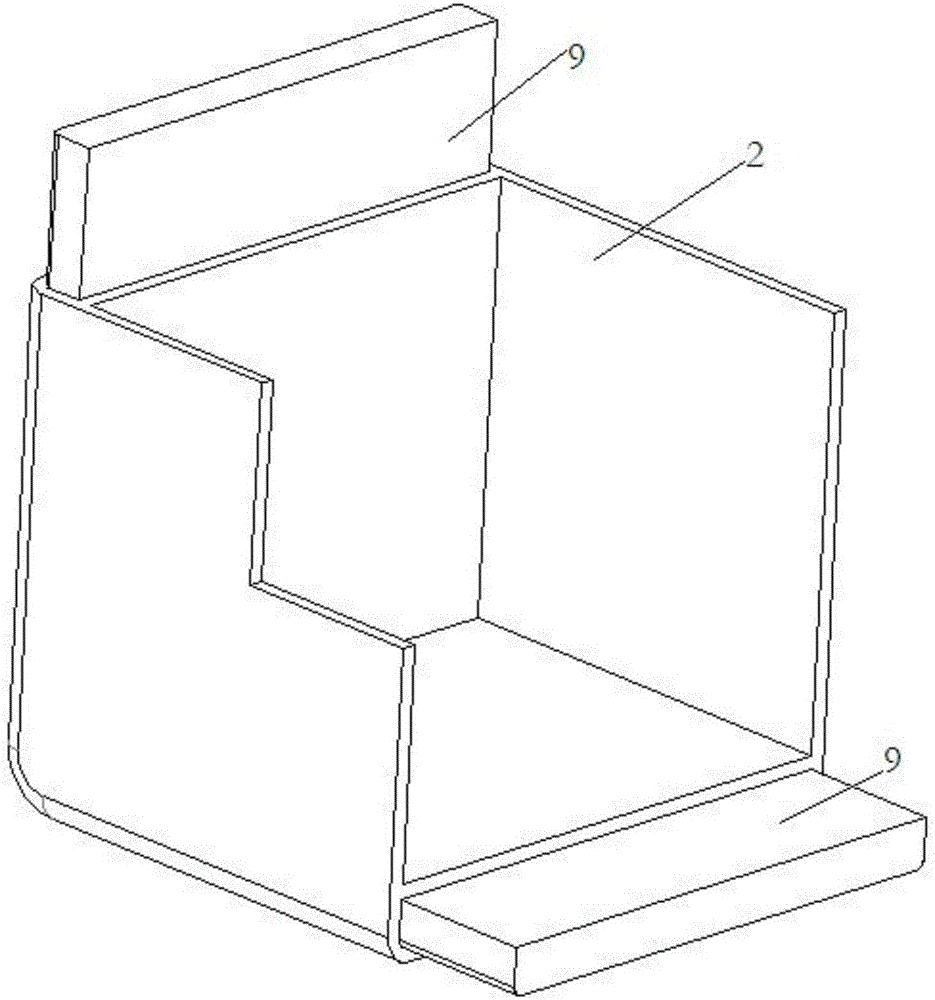

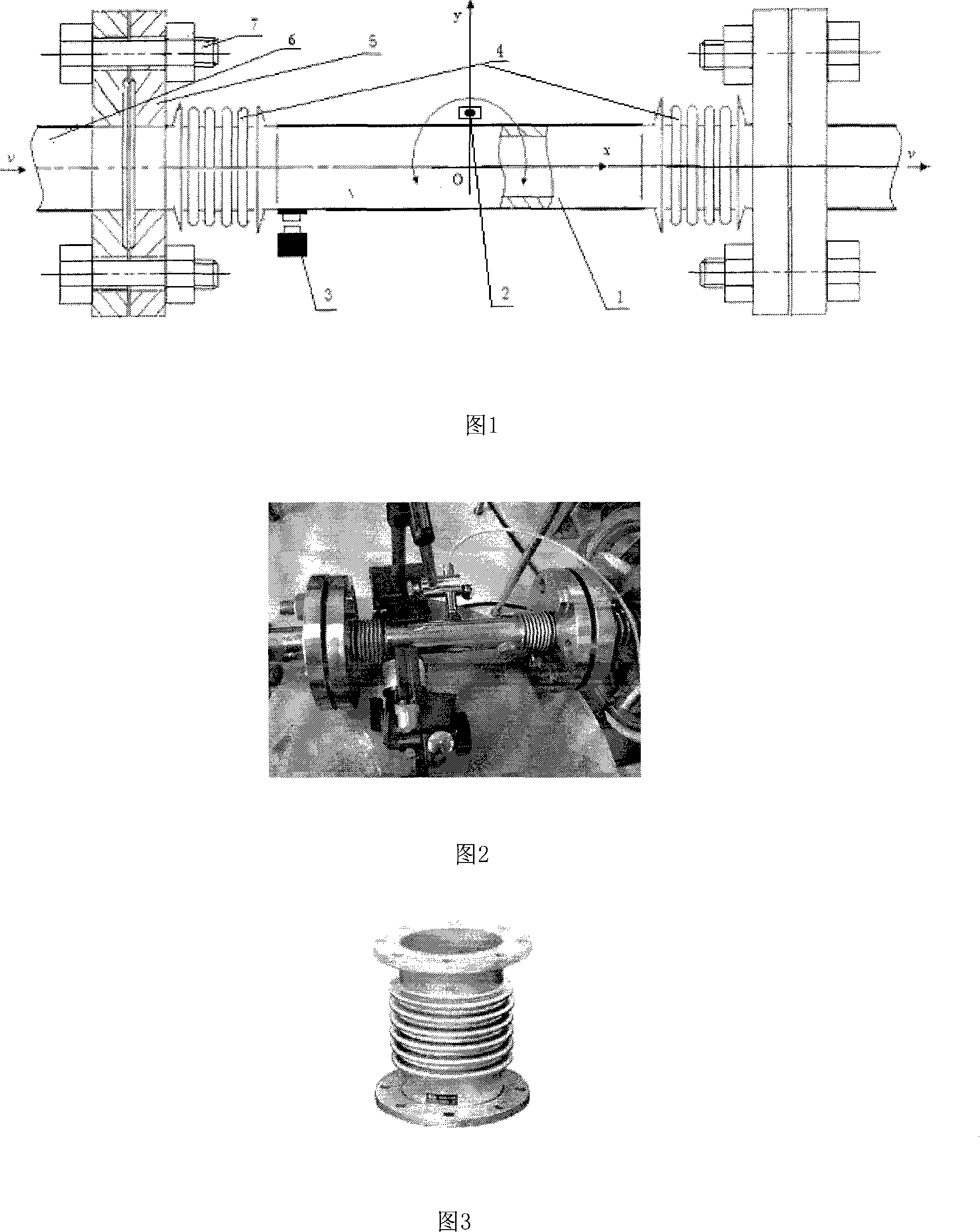

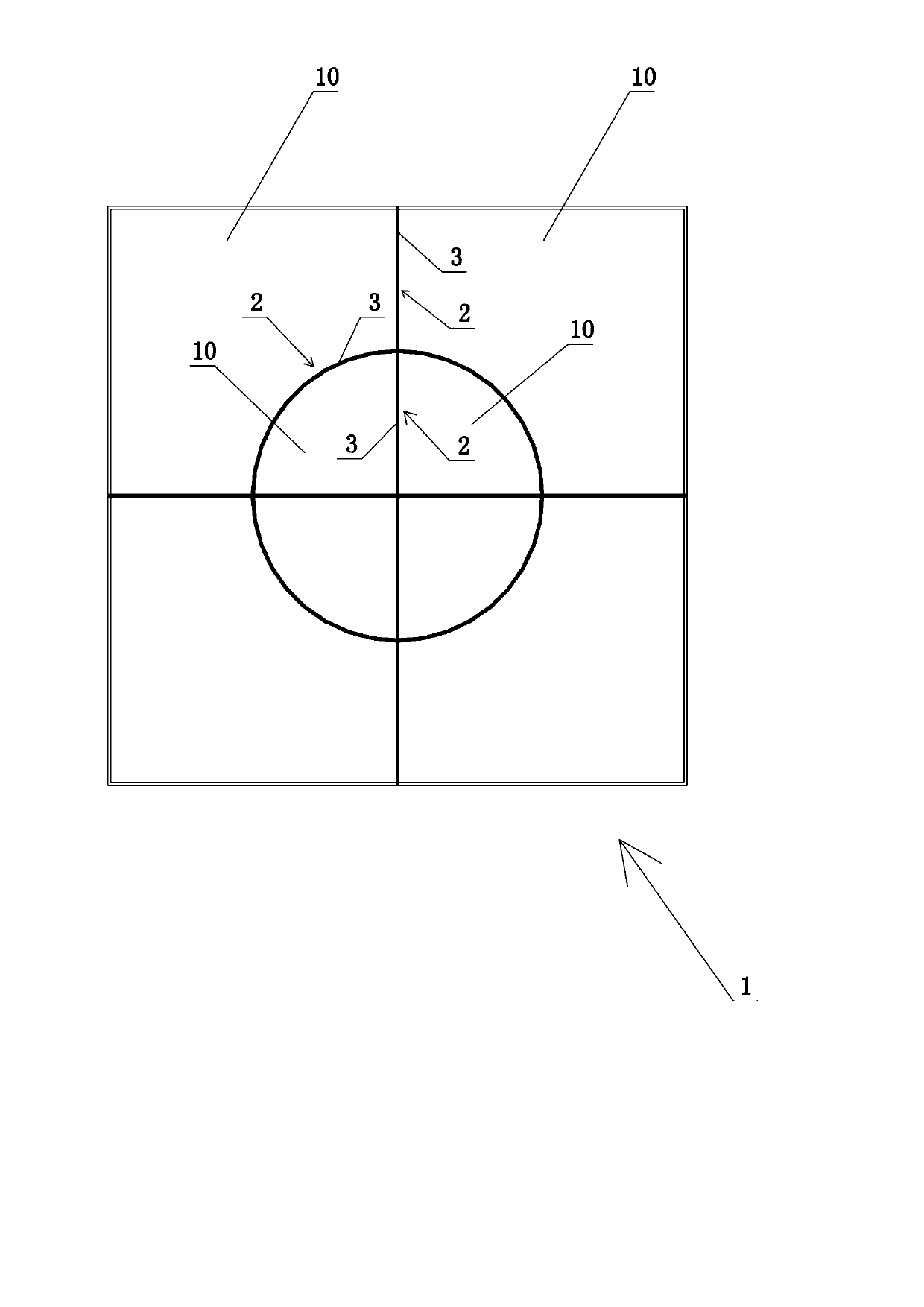

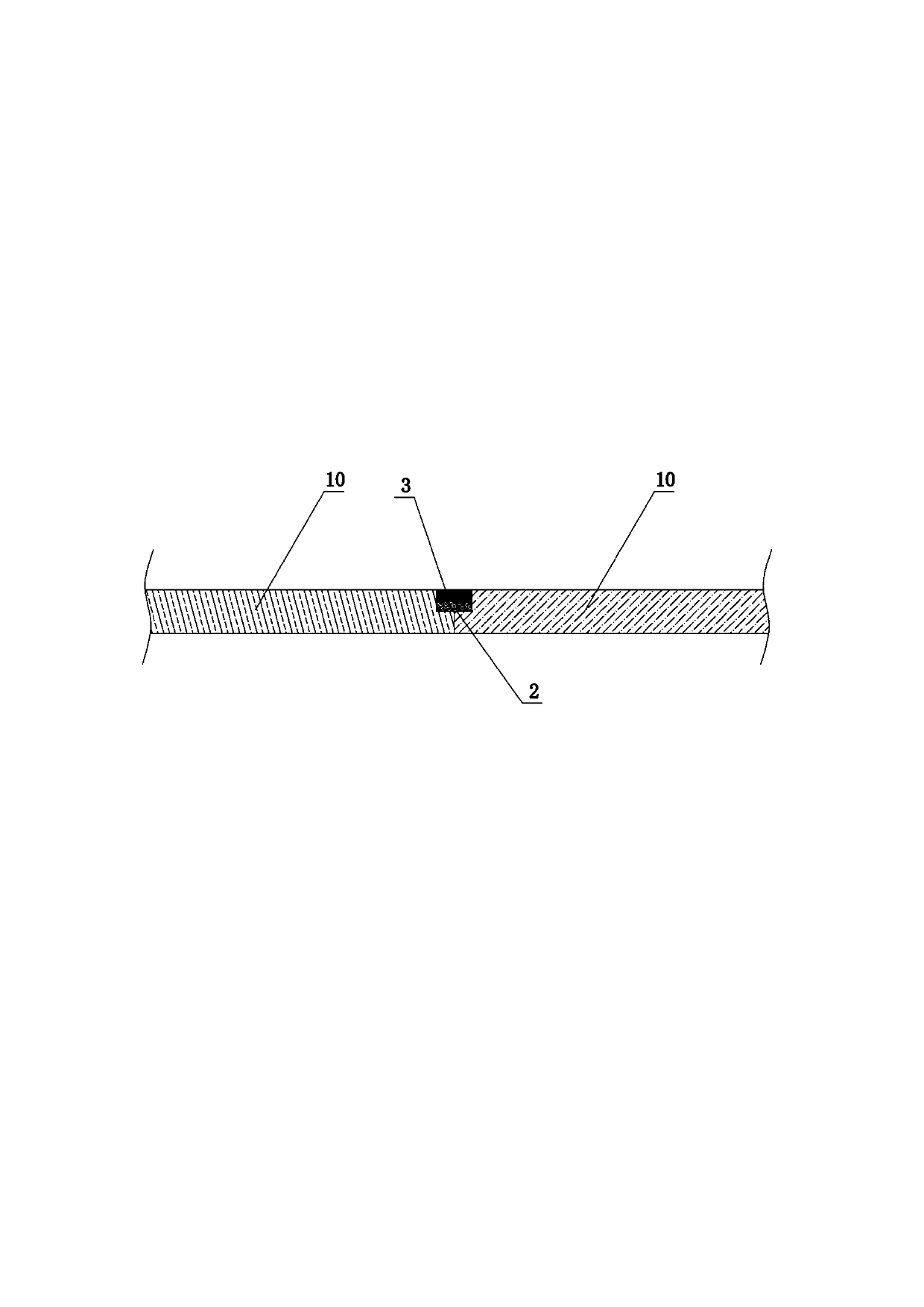

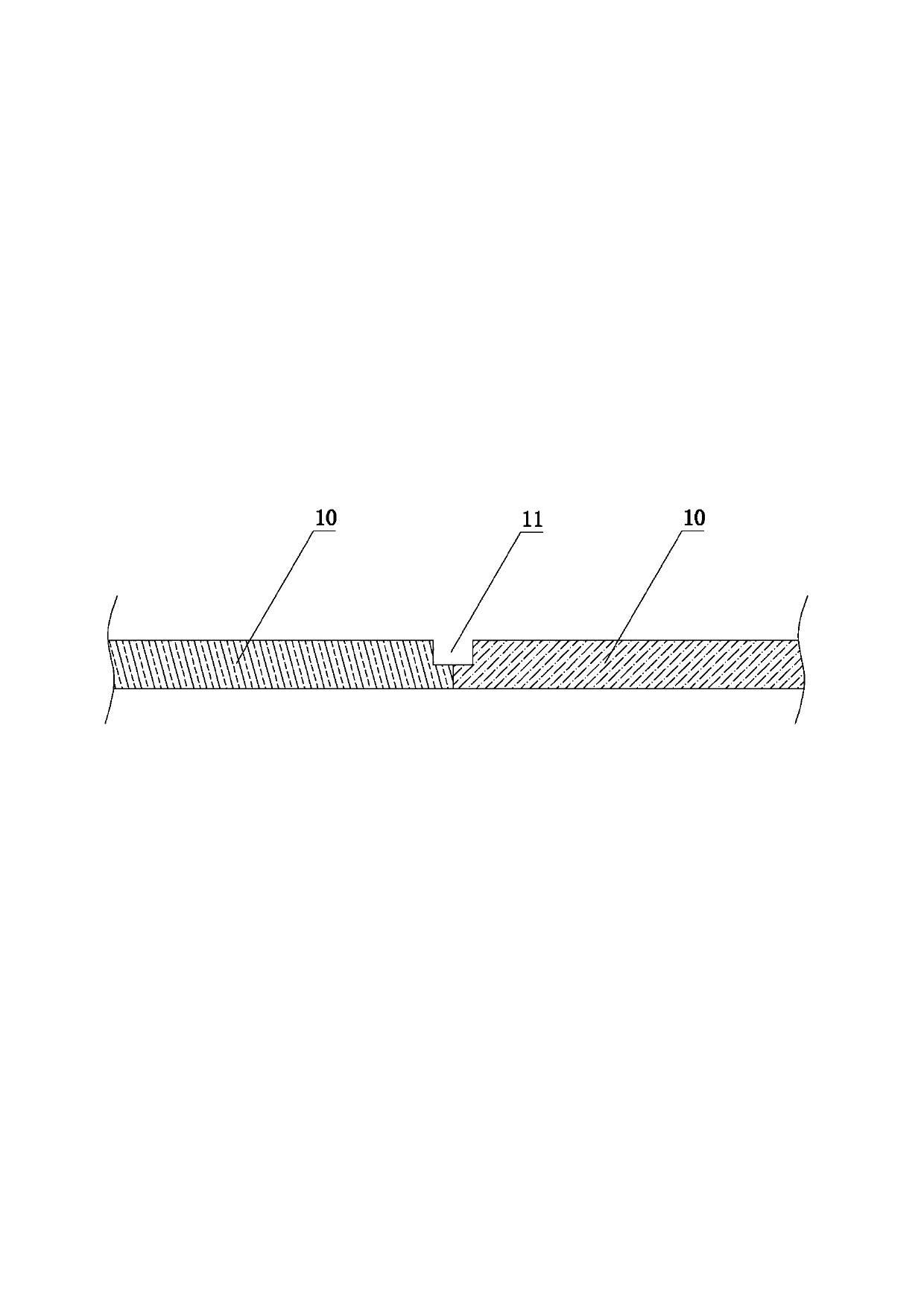

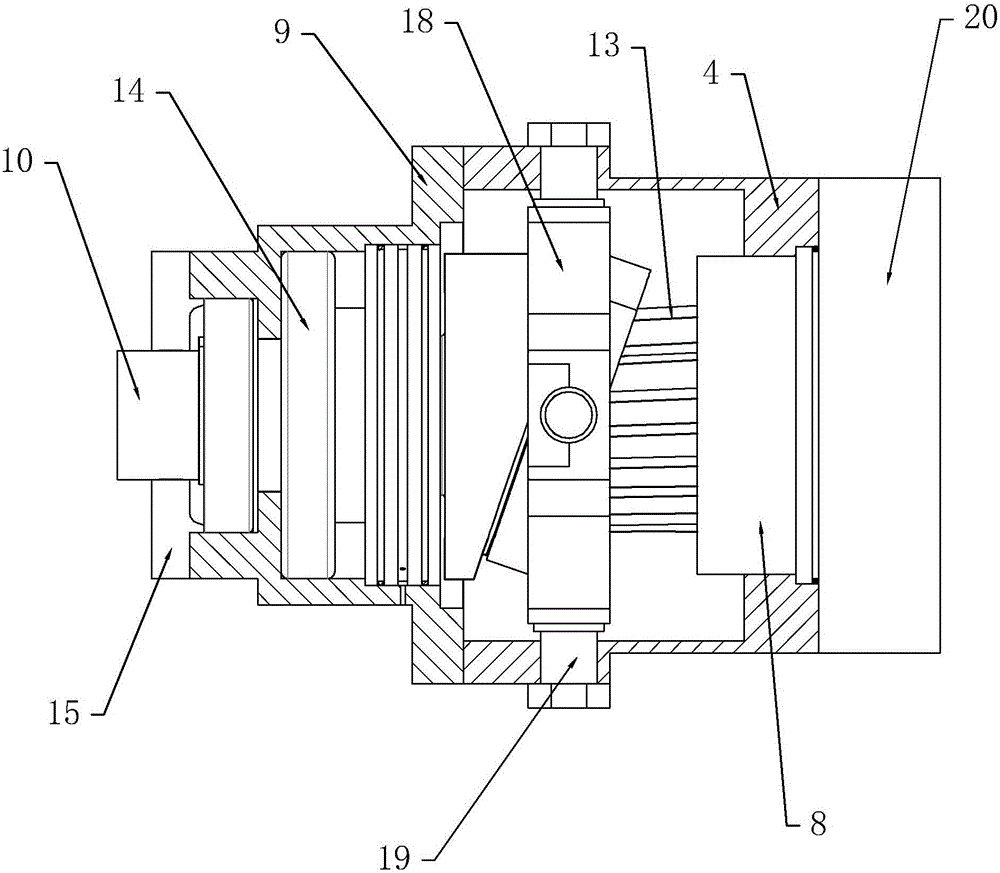

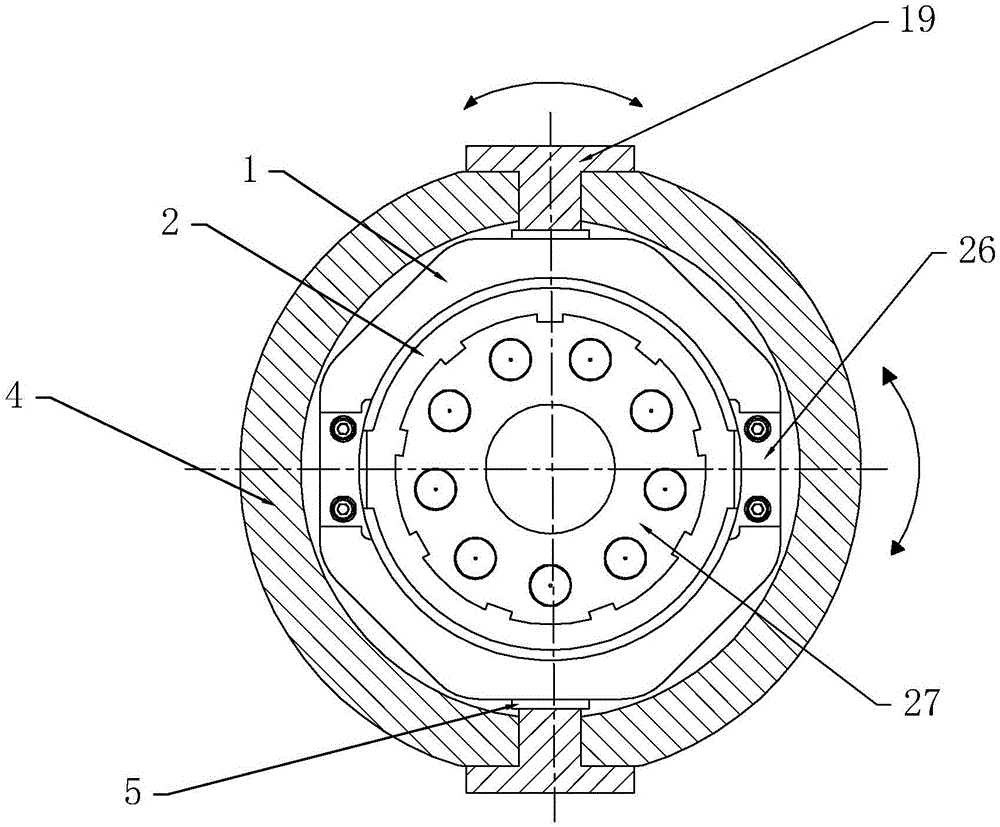

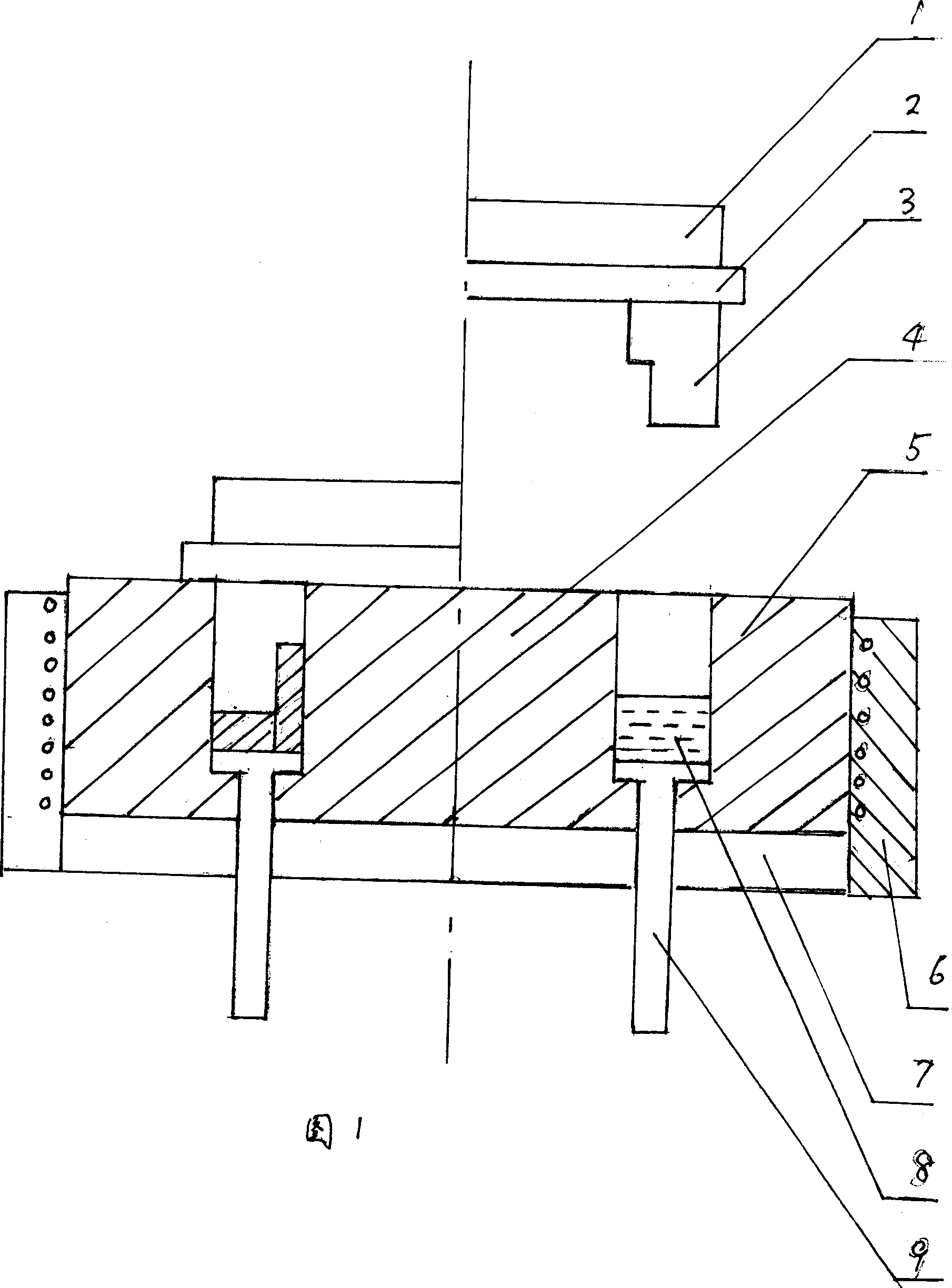

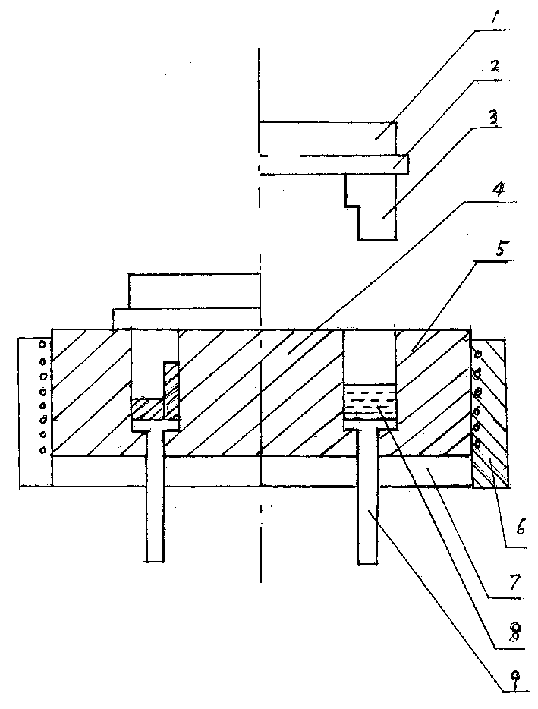

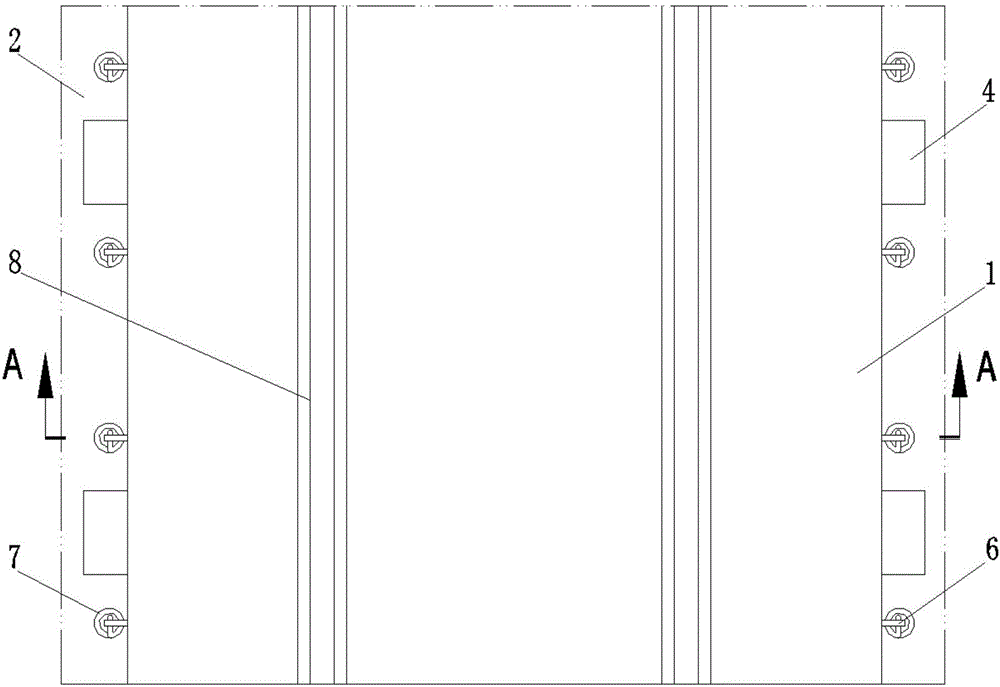

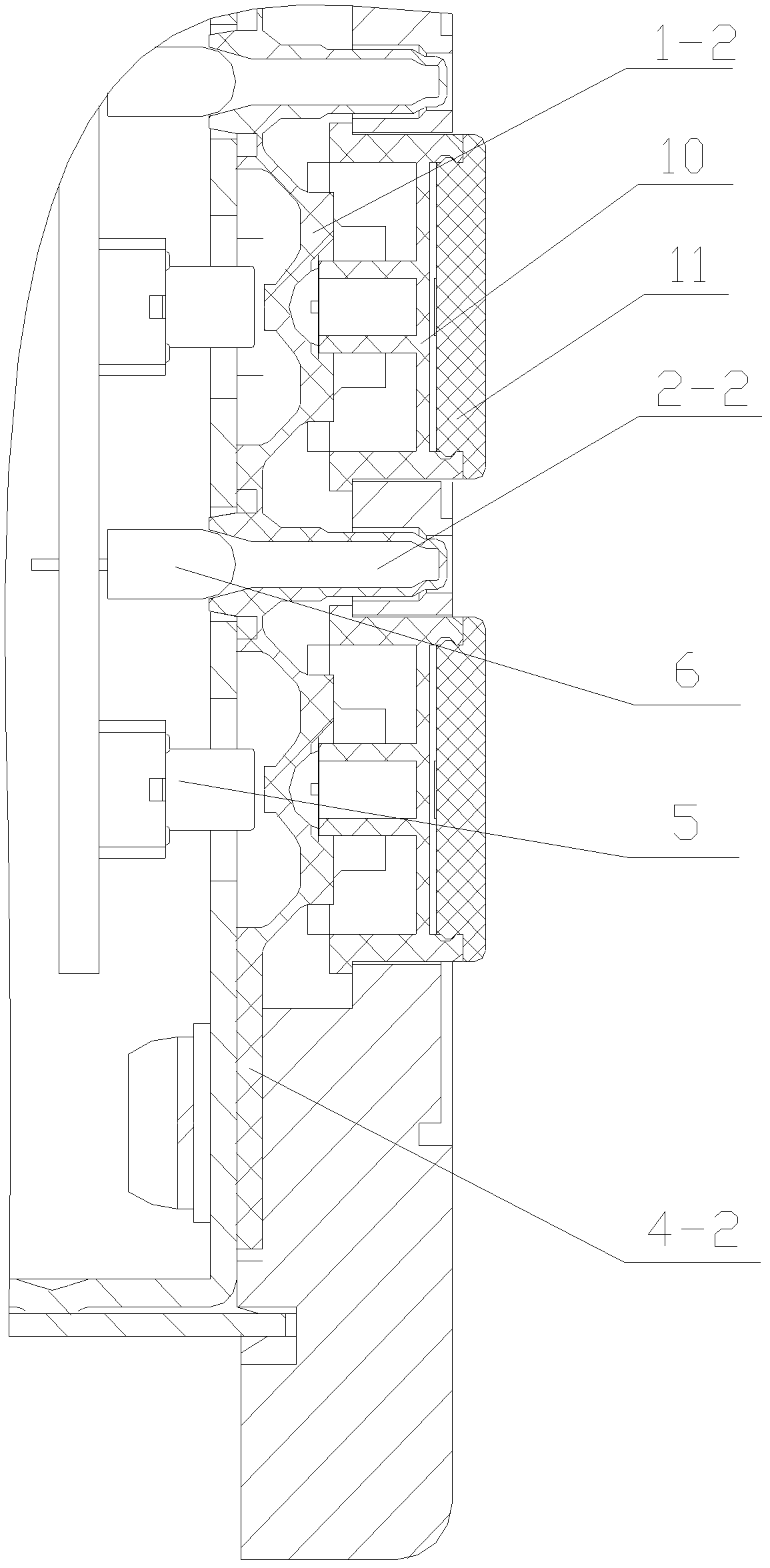

Single straight tube Coriolis mass flowmeter

InactiveCN101221059ALow pipe requirementsLow priceDirect mass flowmetersMeasuring instrumentStraight tube

The invention relates to a Coriolis mass flow meter, belonging to the technical field of test and measuring instrument. The invention comprises a measuring tube (1), an inspecting device (2), an exciting device (3), a wave tube (4), a connection flange (5), a feeding pipe (6) of the liquid to be measured and a connection bolt (7). Two ends of the measuring tube (1) are respectively connected with the wave tube (4), and the other two ends of each wave tube (4) are respectively connected two connection flanges (5), and the connection flange is connected with the feeding pipe (6) of the liquid to be measured through the connection bolt (7). The inspecting device (2) and the exciting device (3) are respectively arranged at the positions 3 to 5mm from the center of the measuring tube (1) and the outer tube wall at one end, and the three parts are on the same plane. Arranging the invention has the proposals that the exciting frequency is set as a second-step stationary frequency; the liquid mass flow is obtained by a central swing inserted value of the fully loaded measuring tube. The invention enlarges the material range of the measuring tube so as to reduce manufacturing cost, and reduces integrated volume and liquid pressure loss.

Owner:TSINGHUA UNIV

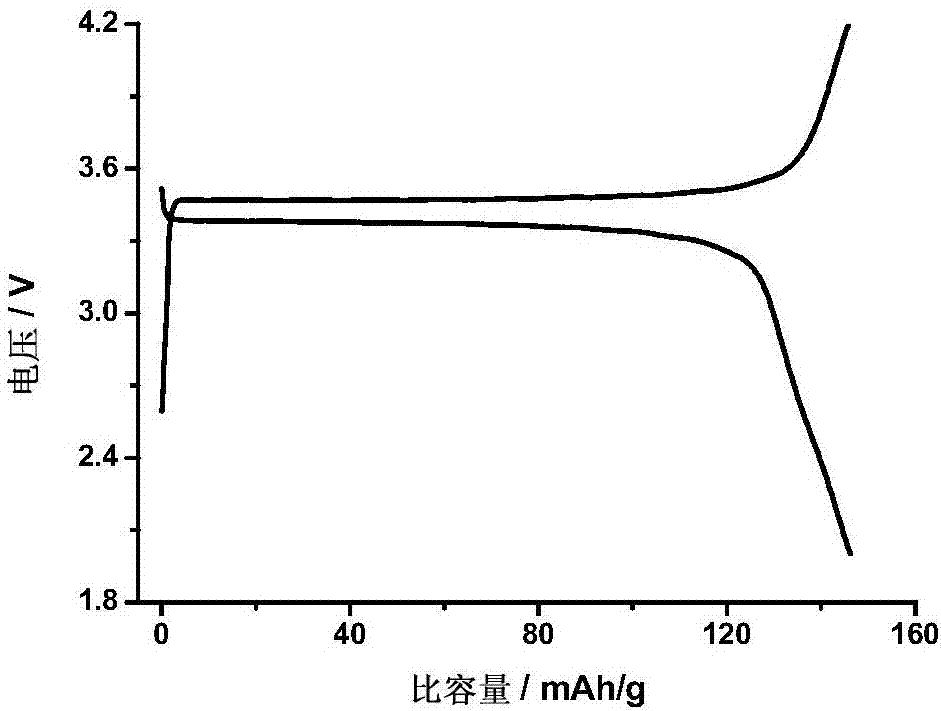

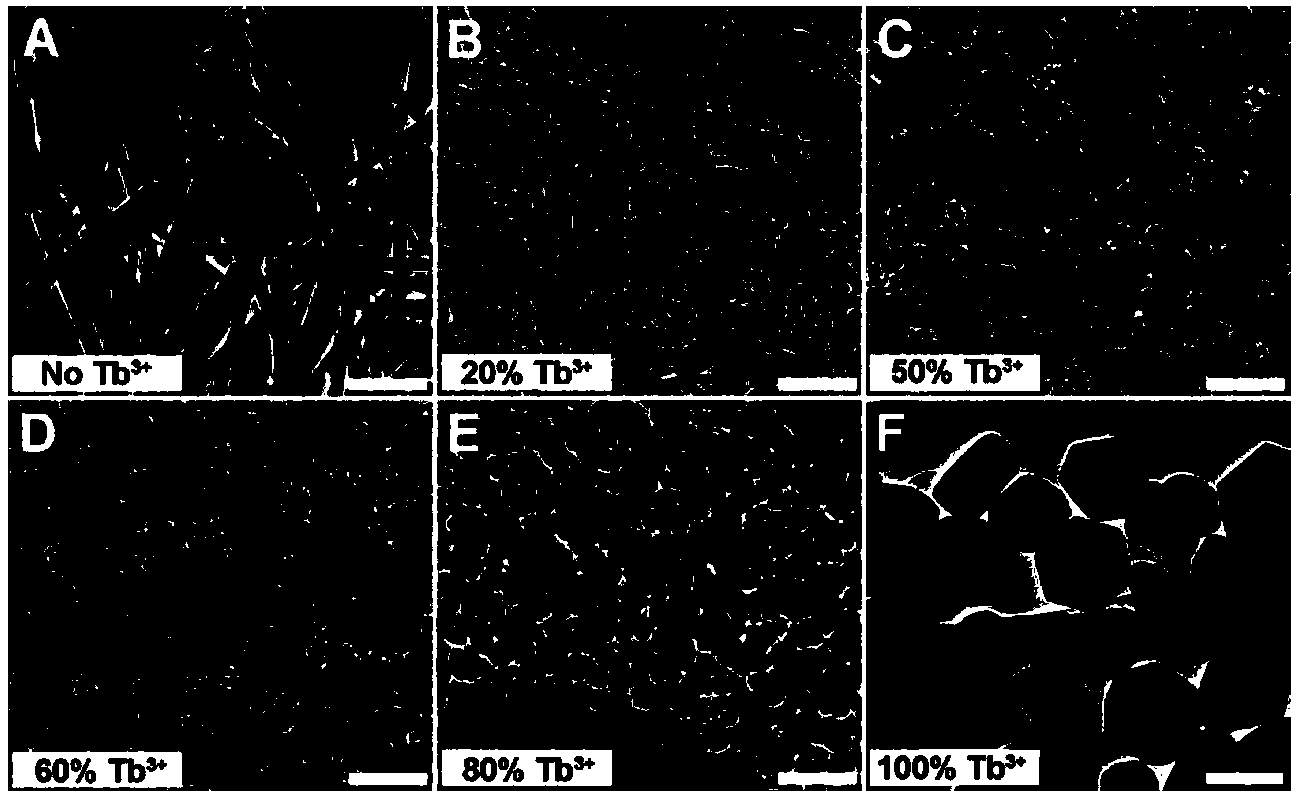

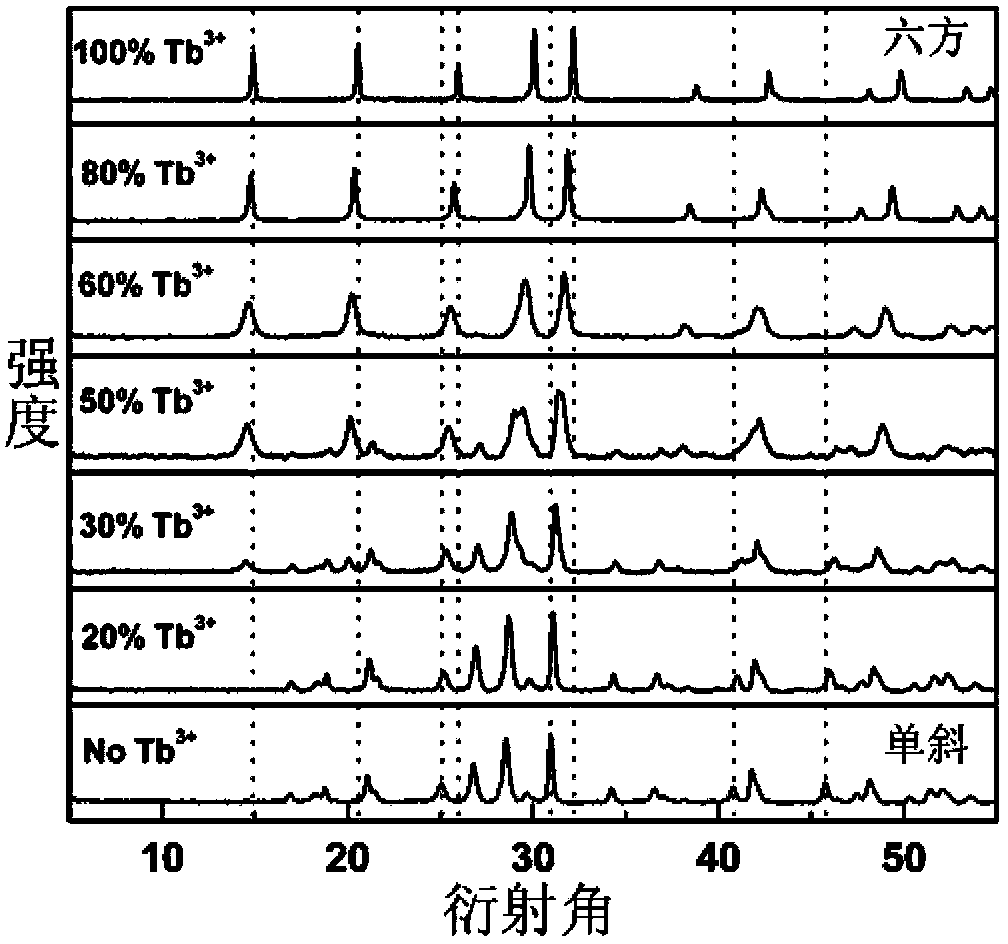

Carbohydrate modified lithium conductive polymer/inorganic hybrid electrolyte and application thereof

InactiveCN107069082ARich sourcesLower Electrolyte CostsSolid electrolytesFuel and secondary cellsConductive polymerLithium–air battery

The invention discloses a carbohydrate modified lithium conductive polymer / inorganic hybrid electrolyte and application thereof. The electrolyte comprises a carbohydrate modified lithium conductive polymer and a lithium salt, wherein the carbohydrate modified lithium conductive polymer is obtained by crosslinking reaction or direct mixing of a carbohydrate compound and a lithium conductive polymer and / or a lithium conductive micromolecule compound. The electrolyte is compatible with high conductivity of an inorganic material and flexibility of a polymer material, has high lithium ion conductivity and good processability, and is suitably used for preparing a lithium ion battery, a lithium-sulfur or lithium-air battery and the like with large capacity and good cycle property; and the electrolyte is low in cost and is simple to prepare, and the selection range and the application field of a lithium battery material are expanded.

Owner:CENT SOUTH UNIV

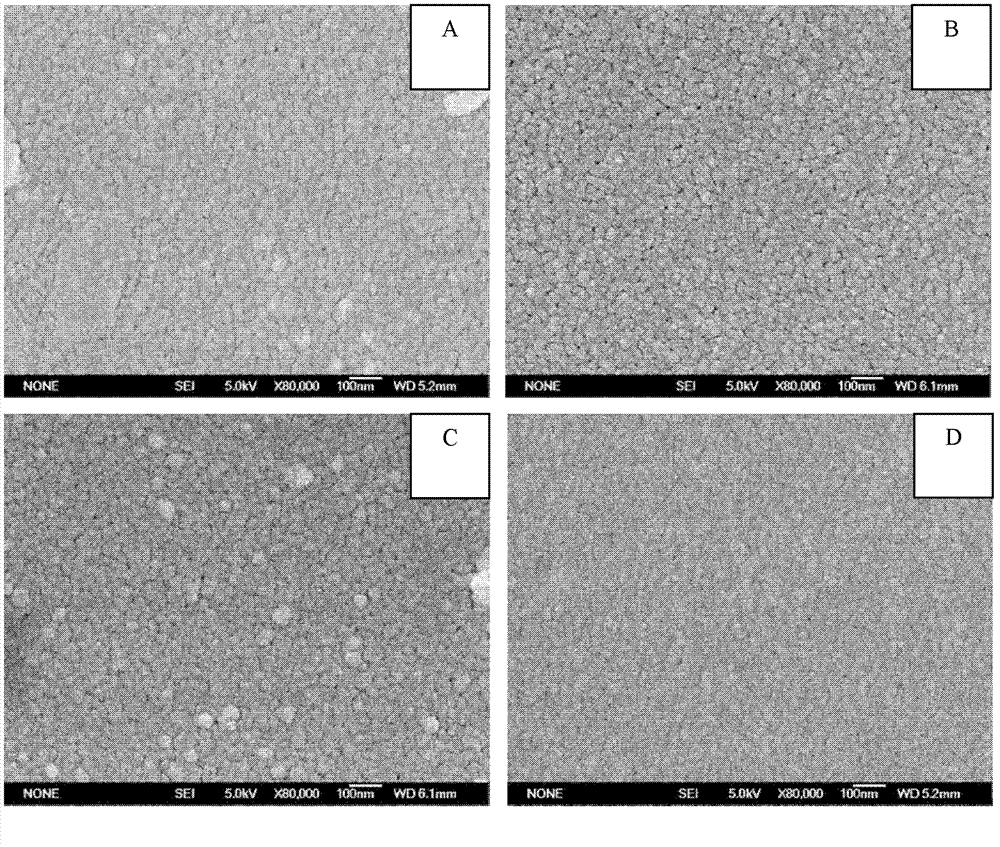

Polymer nanocomposite optical material and preparation method thereof

ActiveCN104250329AExpand the range of material selectionGood optical performanceNon-linear opticsPolymer nanocompositeOptical communication

The invention discloses a preparation method of a polymer nanocomposite optical material, wherein the method particularly includes three steps: synthesis of nanoparticles with specific optical properties, dispersion of the nanoparticles in polymer monomers, and mass polymerization of the nanoparticles in the polymer monomers. The invention aims to overcome the deficiencies in the prior art that construction cost is high, a preparation process is relatively complicated and crystals with good optical quality are difficult to get, and provides the preparation method simple in preparation process, convenient to operate, low in cost, wide in applicability and friendly to the environment. The polymer nanocomposite optical material obtained by the method can greatly expand the material selection range of optical materials, and also provides an idea for the study on nanomaterials as bulk-phase optical materials. The novel optical material can show attractive application prospects in the fields of modern laser technology, optical communication, data storage, optical information processing and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Splicing stone and splicing process

InactiveCN102717648AArt appreciation value is highTo beautifyCovering/liningsOrnamental structuresWhole bodyAdditional values

The invention provides a splicing stone, comprising a stone main body formed by splicing different block-shaped sheet materials with different patterns and further comprising decorative moldings, wherein grooves adapted to the decorative moldings are arranged on all splicing seams on the upper surface of the stone main body; the decorative moldings are formed in the grooves through utilizing a manner of electroplating or spraying paint or chemically plating or embedding gold; and transparent protection layers can be coated on the upper surfaces of the decorative moldings. After the block-shaped sheet materials with the different patterns are spliced to form the stone main body, all the splicing seams on the upper surface of the stone main body are further subjected to beautifying treatment; glue in the splicing seams on the upper surface of the stone main body can be better covered up and a certain separation effect on a color difference of the stone main body exists; and a range of selecting materials is improved and the decorative moldings have beautifying and decoration effects on the splicing stone, so that the total body of the splicing stone can be more beautiful and the additional value of a product is further improved.

Owner:FUJIAN XISHI

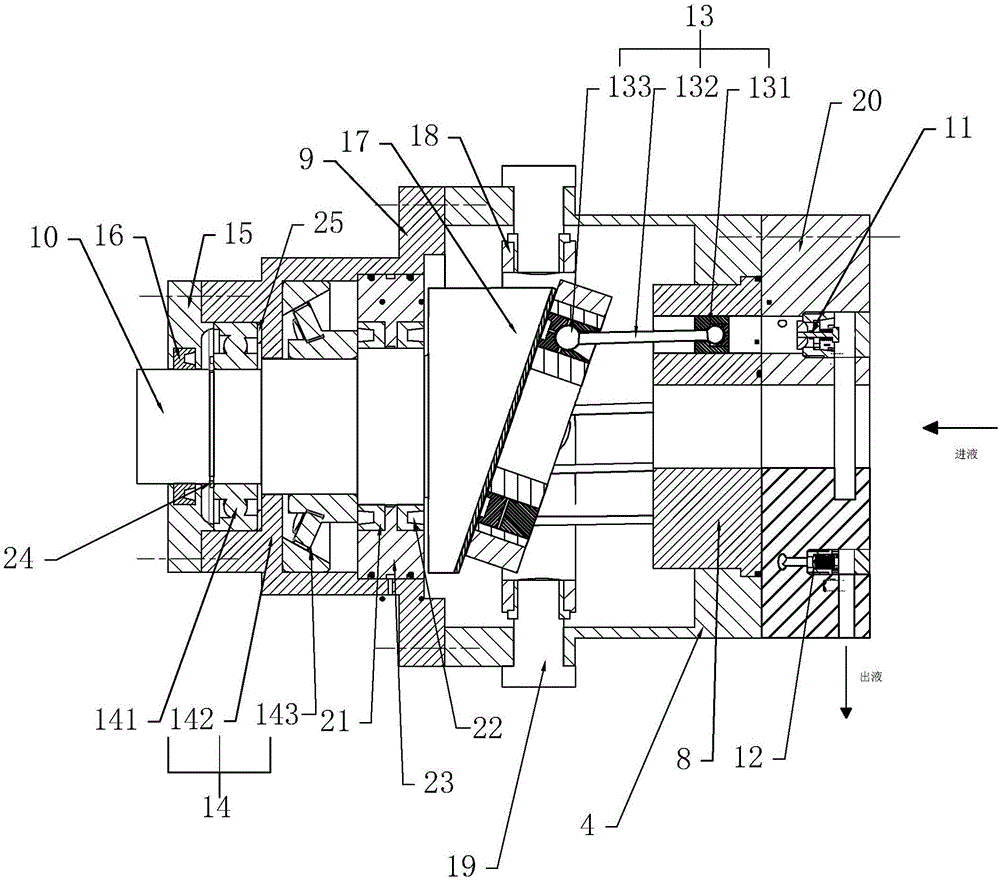

Novel axial plunger pump

ActiveCN105090008AImprove loosenessImprove the phenomenon of pulling off or even crackingPositive displacement pump componentsLiquid fuel engine componentsMechanical engineeringAxial piston pump

The invention discloses a novel axial plunger pump. According to the technical scheme, the novel axial plunger pump is characterized by comprising an end cover, a front shell, a pump shaft arranged inside the front shell, a rear shell, a swash plate and a cylinder, wherein the swash plate and the cylinder are installed inside the rear shell; the end cover, the front shell, the rear shell and the cylinder are sequentially and fixedly connected, and the swash plate is connected to the end, back on to the shell, of the pump shaft; a cross-shaped swinging plate and a plunger assembly are further arranged inside a plunger pump; a plunger hole, a valve hole, a pressing-out valve set and a pressing-in valve set are arranged inside the cylinder, the pressing-out valve set and the pressing-in valve set are located in the valve hole, one end of the plunger assembly is embedded in the plunger hole, and the other end of the plunger assembly is connected with the cross-shaped swinging plate; the cross-shaped swinging plate abuts against the swash plate in a contact manner; and due to the fact that in the prior art a retainer plate and a piston shoe are embedded into a whole through a piston shoe plate, and the piston shoe and the a plunger bulb are embedded into a whole through the piston shoe plate, lateral force of the cylinder and a plunger base is decreased, meanwhile, the tilt angle of the swash plate is increased, the return distance of the plunger base is enlarged, displacement of the plunger pump is improved, the efficiency of the plunger pump is improved, and the design of the cylinder is further simplified.

Owner:HANGZHOU LVJU TECH +1

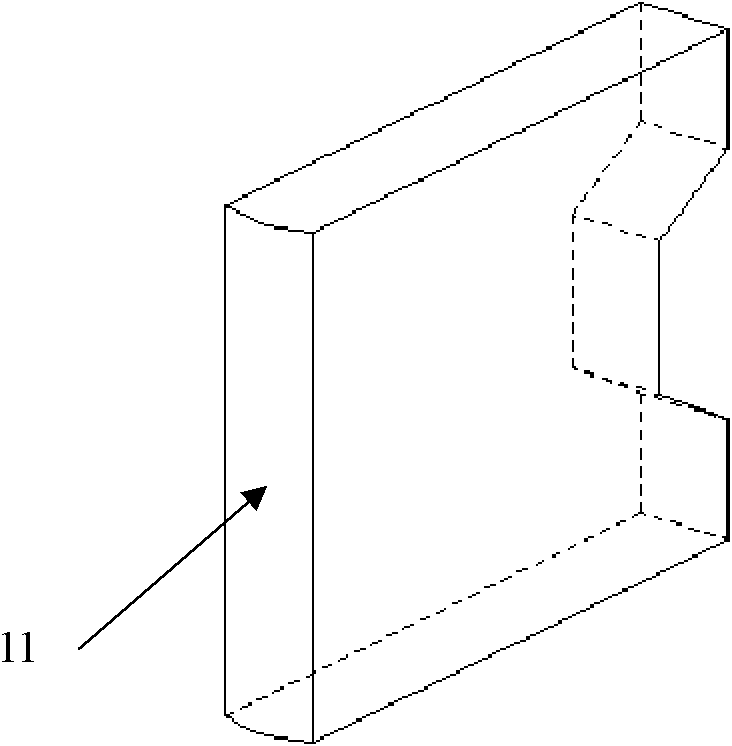

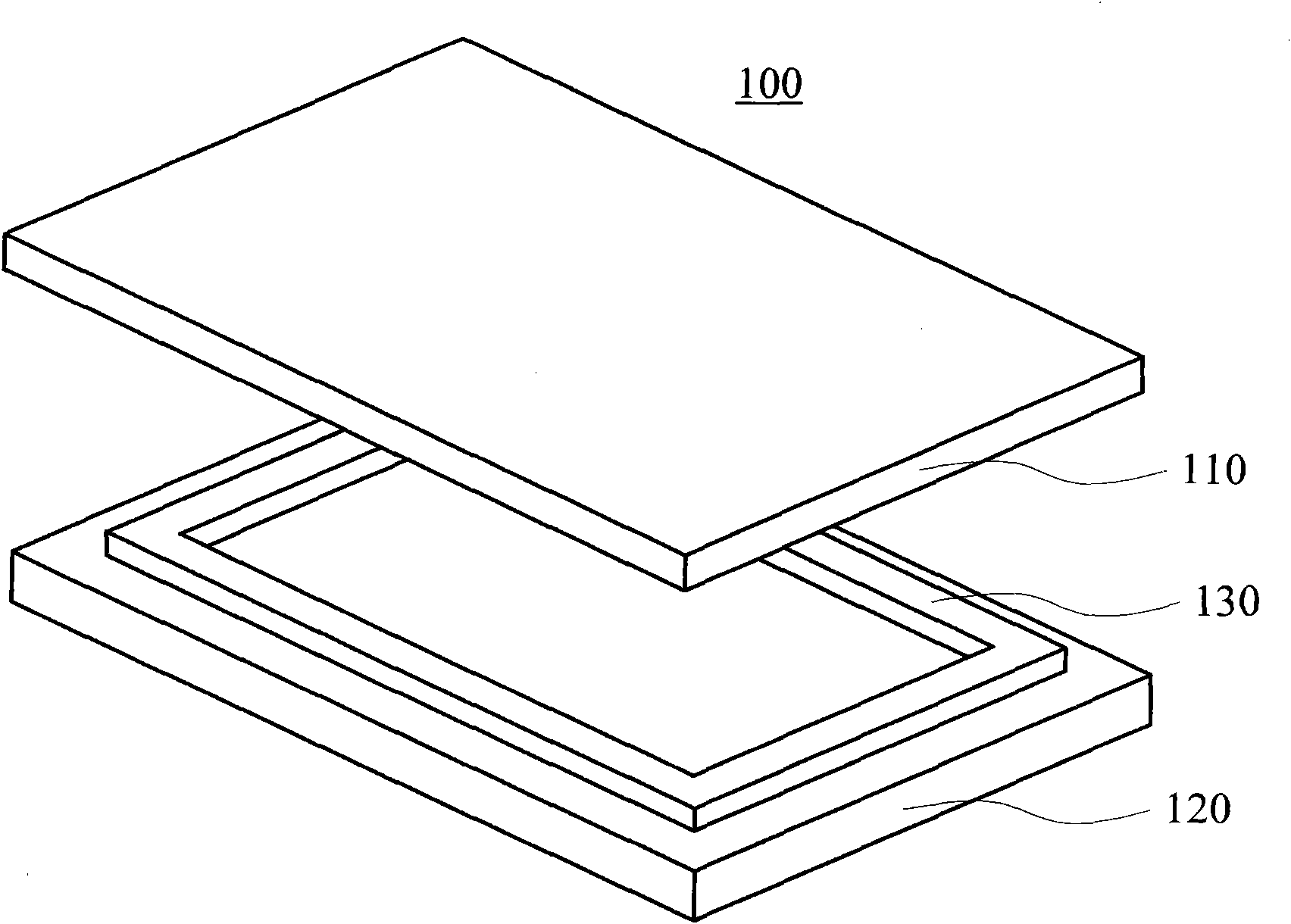

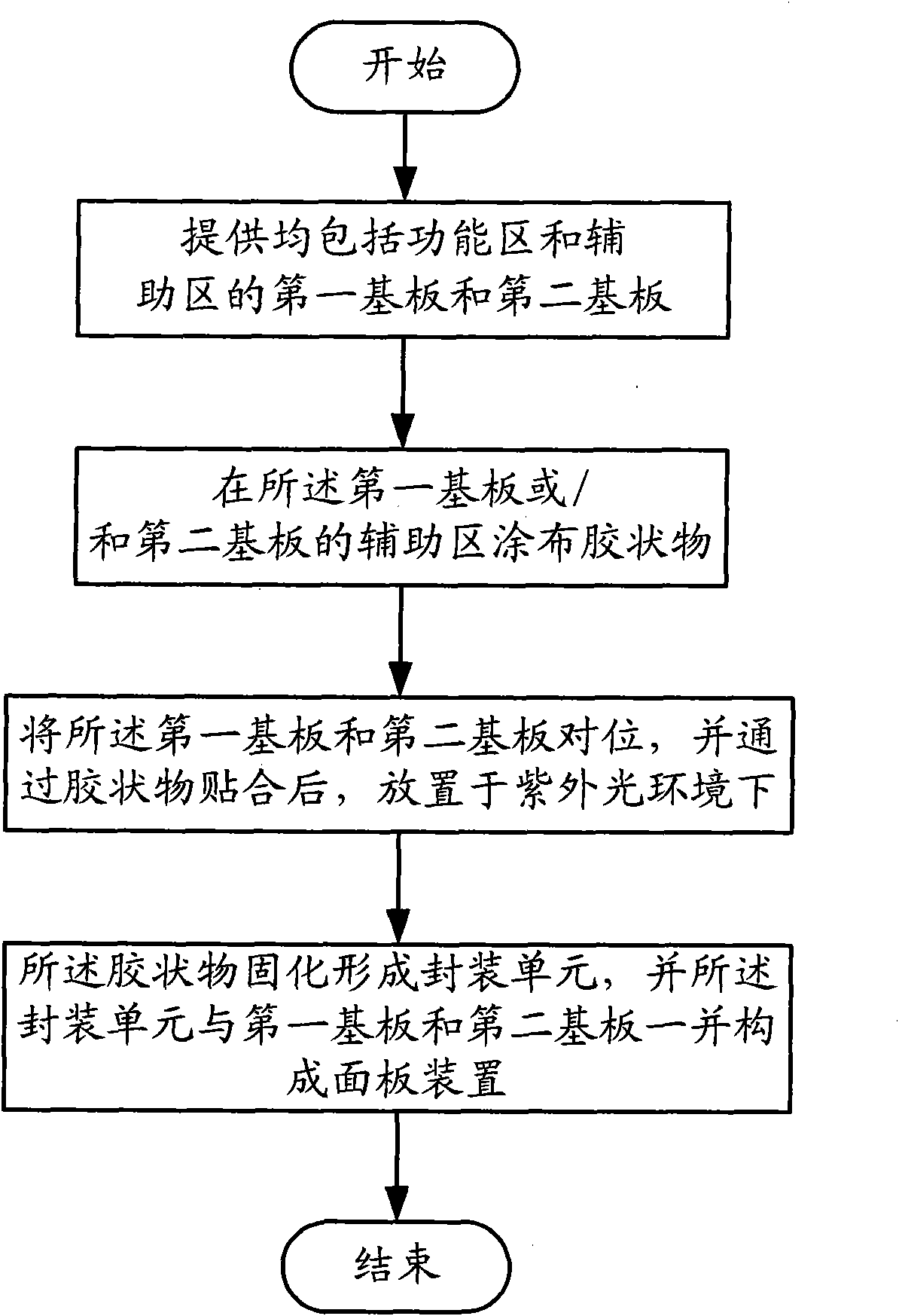

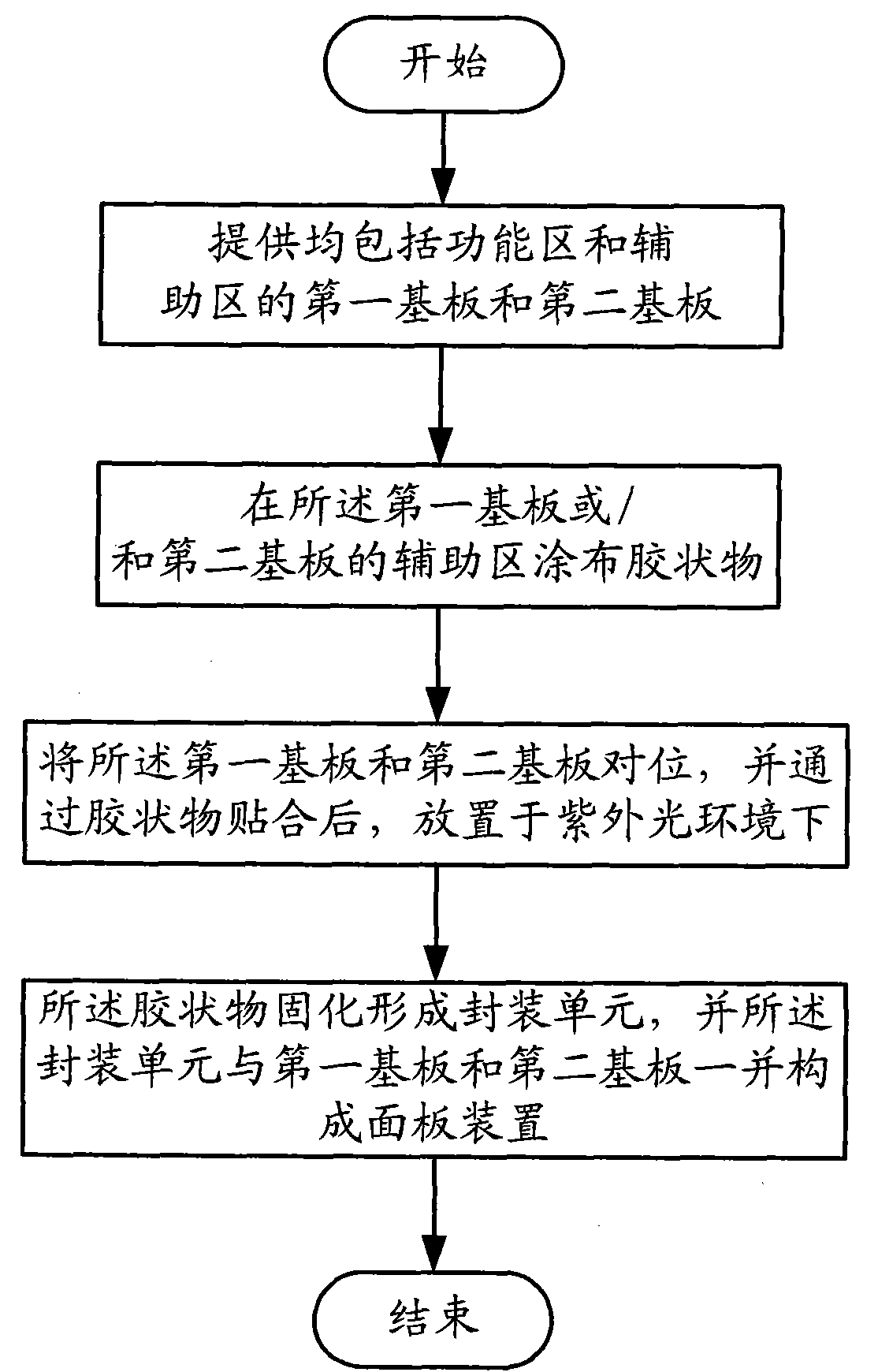

Method for preparing panel device

InactiveCN101840114AExpand the range of material selectionSolid-state devicesNon-linear opticsBiochemical engineeringFlat panel display

The invention relates to the technical field of flat panel display, in particular to a method for preparing a panel device. The method comprises the following steps of: providing a first base plate and a second base plate both provided with a function area and an auxiliary area; coating jelly on the auxiliary areas of the first base plate or / and the second base plate; making the first base plate and the second base plate bonded by the jelly, and placing the base plates under an ultraviolet environment; after the jelly is cured, forming a packaging unit, and forming the panel device by the combination of the packaging unit, the first base plate and the second base plate.

Owner:SHENZHEN LAIBAO HI TECH

Flange with neck

The present invention relates to a pipe connecting piece flange. In order to raise utilization rate of material and ensure product quality said invention provides a flange with neck, and it is characterized by that said flange is made up by adopting extrusion casting method, it has no welded seam, its texture possesses continuous streamline structure characteristics, and its streamline form is identical to the member form in alignment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

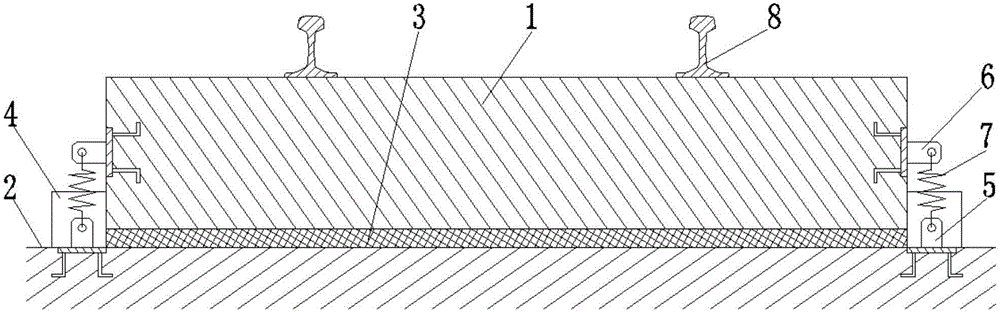

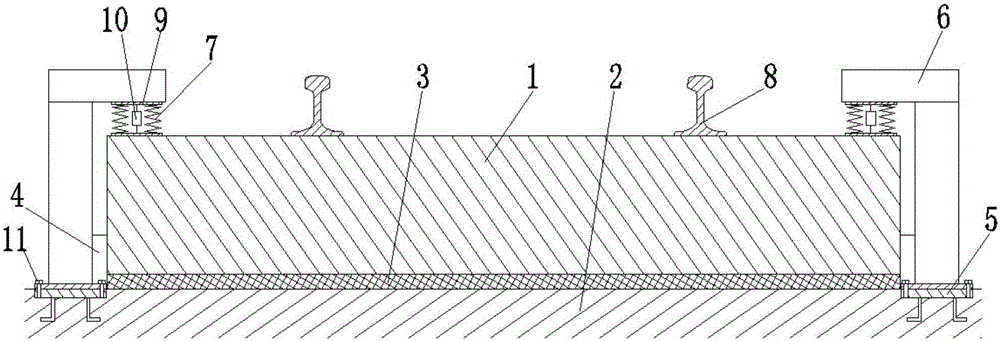

Plate type ballastless track bed with reverse pressure device

The invention relates to a plate type ballastless track bed with a reverse pressure device and belongs to the technical field of rail transportation. The problems that for an existing ballastless track, a track plate and an under-plate filling layer are more likely to strip and bulge are solved. The plate type ballastless track bed includes a base, a track plate is arranged above the base, an under-plate filling layer is arranged between the track plate and the base, and a limiting structure is also arranged between the track plate and the base. The plate type ballastless track bed further includes the reverse pressure device, and the reverse pressure device includes a reverse pressure elastic component, a connecting piece and an anchoring piece; the anchoring piece is fixedly arranged on the base, the reverse pressure elastic component is arranged between the connecting piece and the anchoring piece, or one end of the reverse pressure elastic component acts on the track plate, the other end of the reverse pressure elastic component acts on the connecting piece, and the connecting piece is connected with the base through the anchoring piece. According to the plate type ballastless track bed with the reverse pressure device, the problem that the track plate is stripped off from the under-plate filling layer can be effectively avoided, the vibration reduction and noise reduction performance is good, the service life is long, and the plate type ballastless track bed with the reverse pressure device can be widely used in various high-speed railway ballastless track lines.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH +1

Preparation method and application of high-purity chloride molten salt

InactiveCN109207128AMitigates corrosive effectsEasy to prepareHeat-exchange elementsPotassiumImpurity

The invention relates to a preparation method of a high-purity chloride molten salt. The method is: providing an untreated chloride molten salt having a purity of 95% or more; heating the untreated chloride molten salt to a liquid state to obtain a molten chloride molten salt; adding an active metal into the molten chloride molten salt, standing to allow the active metal and water and oxidizing impurities in the untreated chloride molten salt to respectively perform redox reaction to generate precipitates, wherein the active metal comprise at least one of lithium, potassium, calcium, sodium, magnesium, aluminum, zinc and iron; the oxidizing impurities comprise OH<->, SO4 < 2->, SO4 < 2->, NO3 < 3-> and NO2 < 2->; filtering and removing residual solid-state active metals and precipitates inthe molten chloride molten salt so as to obtain the high-purity chloride molten salt, wherein the high-purity chloride molten salt contains the dissolved active metals. The invention also relates toapplication of the high-purity chloride molten salt. The preparation method of the high-purity chloride molten salt provided by the invention is simple, is safe and solves the problem that a structural material is easy to corrode in the molten salt and restricts the industrial large-scale application of the chloride molten salt.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

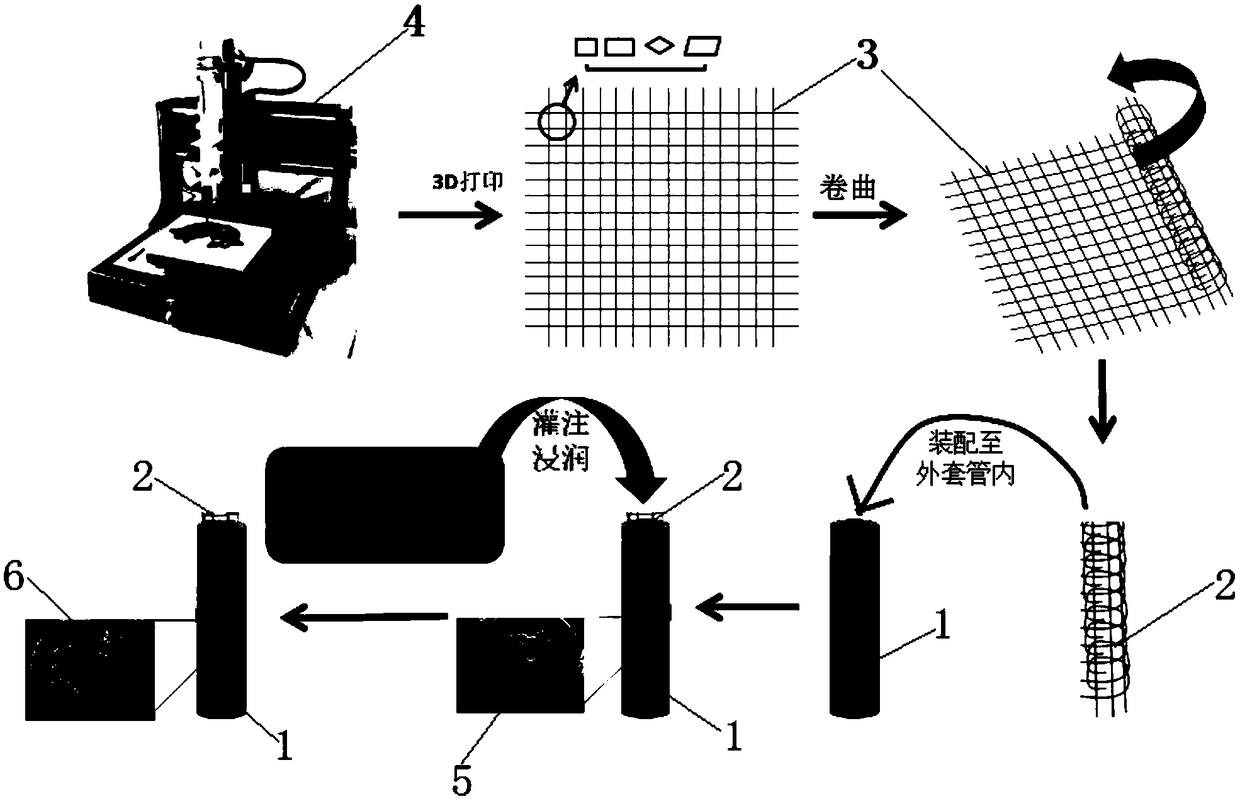

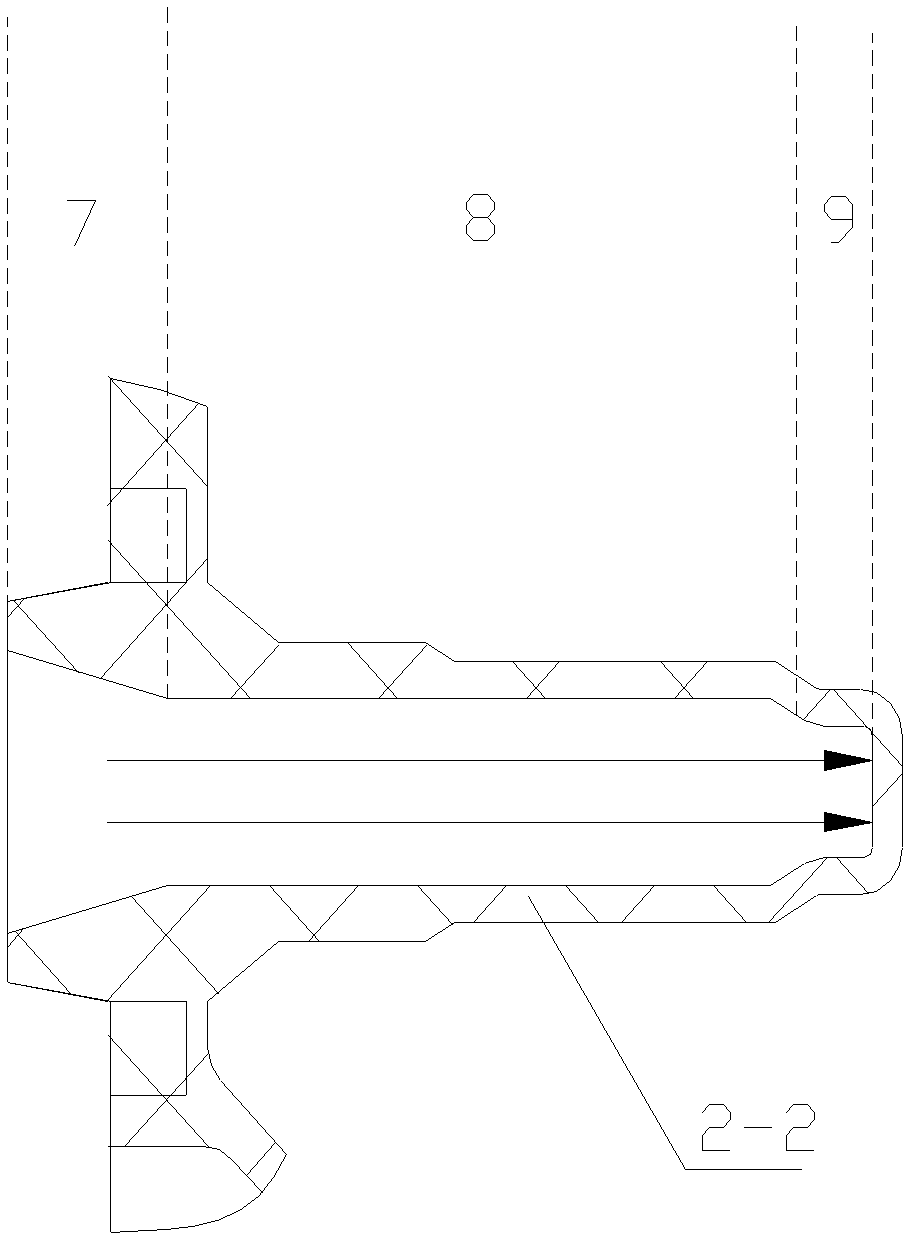

Peripheral nerve stent based on 3D (three-dimensional) printing and preparation method thereof

InactiveCN108853583AWith bionic elementsSufficient structural stabilityAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingOuter Cannula

The invention discloses a peripheral nerve stent based on 3D (three-dimensional) printing. The peripheral nerve stent comprises an outer cannula and a filler, wherein the filler is arranged in the outer cannula; the filler is a three-dimensional stent which is curved by a gauze net; the gauze net is made of biological ink. The invention also discloses a preparation method of the peripheral nerve stent. The peripheral nerve stent prepared by the preparation method has the advantages that the bionic elements of structure and composition of natural peripheral nerve are realized; on the basis of ensuring the biocompatibility, the outer cannula of electrospinning material can provide the full structure stability of the stent, the requirement on the ink forming strength can be reduced by the filler in the manufacturing process, the material selection range of the filler is expanded, and the ink can select more biological functions; by injecting or soaking special functional components into the stent, the corresponding biology characteristics are provided for the filler, such as acceleration of axone growth, and acceleration of vascularization.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Integrated sealing elastic keyboard pad

ActiveCN102592873ASimple manufacturing processLow manufacturing costElectric switchesInjection molding processLight guide

The invention discloses an integrated sealing elastic keyboard pad which comprises a plurality of key pads and a plurality of light guide pillars. A plurality of key pads and a plurality of light guide pillars are combined into an integrated structure; each key pad is positioned on a corresponding key on a keyboard; each light guide pillar is positioned on a corresponding indicating lamp on the keyboard; the light guide pillars are of a hollow structure; the ends of the light guide pillars, which are connected with the indicating lamps, are open ends; and the other ends of the light guide pillars are closed ends. According to the integrated sealing elastic keyboard pad, a plurality of parts are combined into the integrated structure and a protection sheet is saved, so that the materials are saved, the possibility of generating gaps when the parts are matched is also avoided and the integrated sealing elastic keyboard pad has a better sealing effect; in the manufacturing process, the integrated sealing elastic keyboard pad can be formed in one step by adopting a conventional compression molding or injection molding process, so that the manufacturing process of the integrated sealing elastic keyboard pad is simplified and the manufacturing cost is reduced; in the using process, the integrated sealing elastic keyboard pad is used as one part, so that the defects of large number of the parts of a conventional keyboard pad and fussiness for installation are overcome and the integrated sealing elastic keyboard pad is convenient to use; and the light guide pillars are of a hollow structure, so that the light guide rate of the integrated sealing elastic keyboard pad is improved, the material selection range can also be enlarged and the hollow structure of the light guide pillars is beneficial for reducing the production cost.

Owner:GSK CNC EQUIP

Probiotic ternary mixed fermentation beverage and making method

InactiveCN101637286AExpand the range of material selectionRich sourcesBacteriaFood preparationSlagStreptococcus thermophilus

The invention relates to a probiotic ternary mixed fermentation beverage. Squeeze juice of hawthorn, carrot and red jujube is used as a culture medium; fermentation is carried out under specific temperature and for specific time to culture probiotics, such as bifidobacterium, lactobacillus bulgaricus, streptococcus thermophilus, lactic acid bacillus and the like; then, probiotic liquid after fermentation is inactivated, and then a proper amount of white granulated sugar, honey and drinking water is added to make a beverage. Slag generated in the production of the probiotic mixed beverage of hawthorn, carrot and red jujube can be also used for producing mixed probiotic jam of hawthorn, carrot and red jujube. The invention greatly broadens the application range of probiotic culture medium selection of materials, such as bifidobacterium and the like, provides a novel probiotic inactivation fermentation beverage, and has the advantages of rich material source, low cost, stable preparationprocess, little production equipment investment, simple operation, easy popularization and favorable market application prospect.

Owner:赵敏

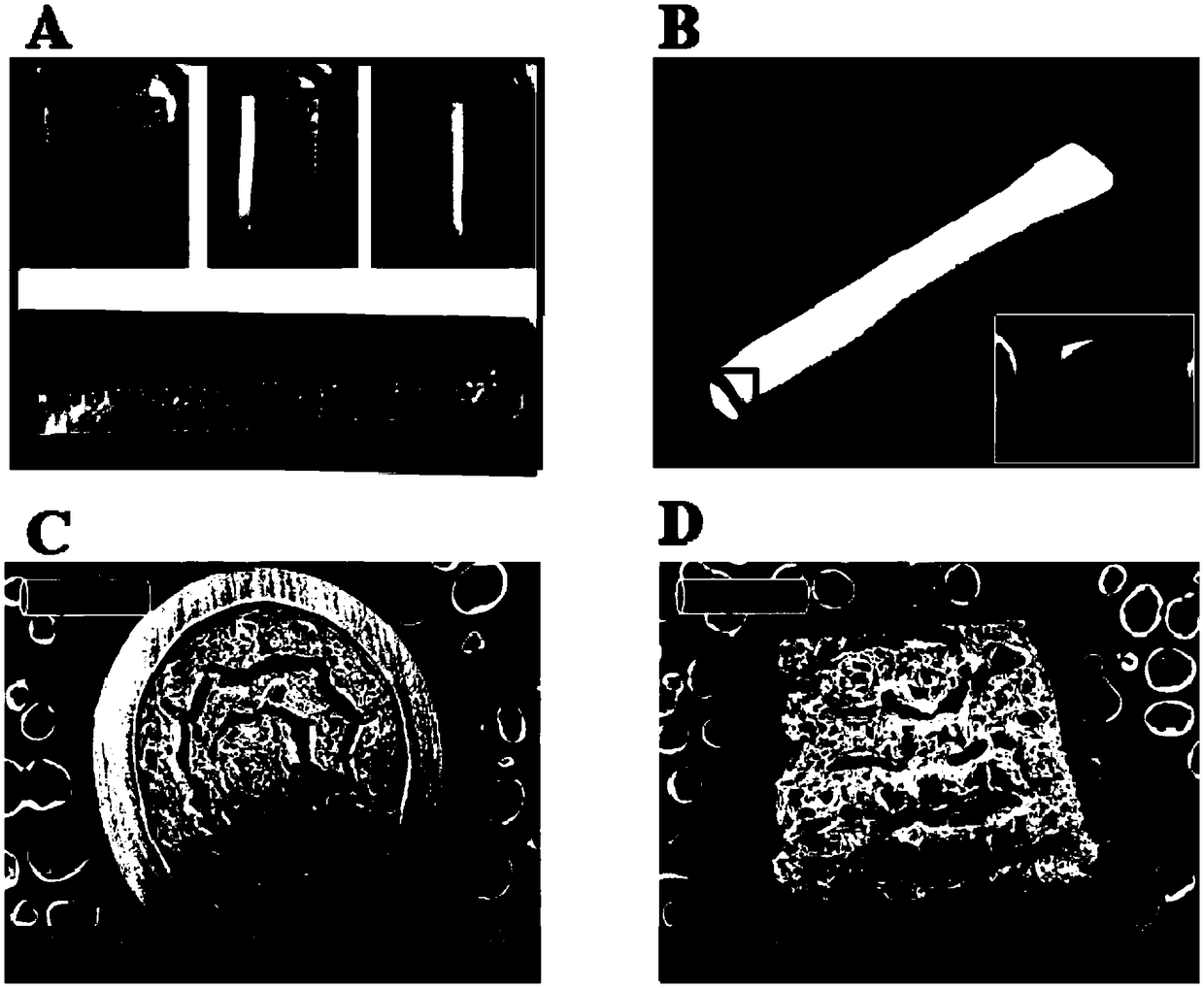

Peripheral nerve scaffold and preparation method of same

InactiveCN108939165ASufficient structural stabilityExpand the range of material selectionAdditive manufacturing apparatusTissue regenerationYarnBiological property

The invention discloses a peripheral nerve scaffold including an external sleeve tube and packing disposed therein. The packing is a three-dimensional framework formed by reeling a yarn mesh made frombio-ink. The invention also discloses a preparation method of the peripheral nerve scaffold. The peripheral nerve scaffold has the bionic factors, such as structure and composition, of the natural peripheral nerve; on the basis that the magnesium alloy external sleeve tube guarantees biocompatibility, the scaffold has sufficient structural stability. During manufacturing, the packing can reduce the demand on shaping strength of ink, so that selection range of the packing is enlarged, and more bio-functions may be achieved in the ink. The two-dimensional yarn mesh is formed through 3D-printing, and then the yarn meshes are stacked or reeled to form the packing framework, wherein structure and permeability of same can be accurately regulated. The framework is infused or infiltrated with special functional components, so that the packing has corresponding biological features, e.g. promoting growth of axons or promoting vascularization.

Owner:THE FIRST AFFILIATED HOSPITAL OF SUN YAT SEN UNIV

Probiotic mixed fermentation beverage and making method

InactiveCN101637289AExpand the range of material selectionMake full use ofBacteriaFood preparationBifidobacteriumSlag

The invention relates to a probiotic mixed fermentation beverage. Squeeze juice of carrot and sea-buckthorn is used as a culture medium; fermentation is carried out under specific temperature and forspecific time to culture probiotics, such as bifidobacterium, lactobacillus bulgaricus, streptococcus thermophilus, lactic acid bacillus and the like; then, probiotic liquid after fermentation is inactivated, and then a proper amount of white granulated sugar is added to make a beverage. Slag generated in the production of the probiotic mixed beverage of carrot and sea-buckthorn can be also used for producing mixed probiotic jam of carrot and sea-buckthorn. The invention greatly broadens the application range of probiotic culture medium selection of materials, such as bifidobacterium and the like, provides a novel probiotic inactivation fermentation beverage, and has the advantages of rich material source, low cost, stable preparation process, little production equipment investment, simpleoperation, easy popularization and favorable market application prospect.

Owner:赵敏

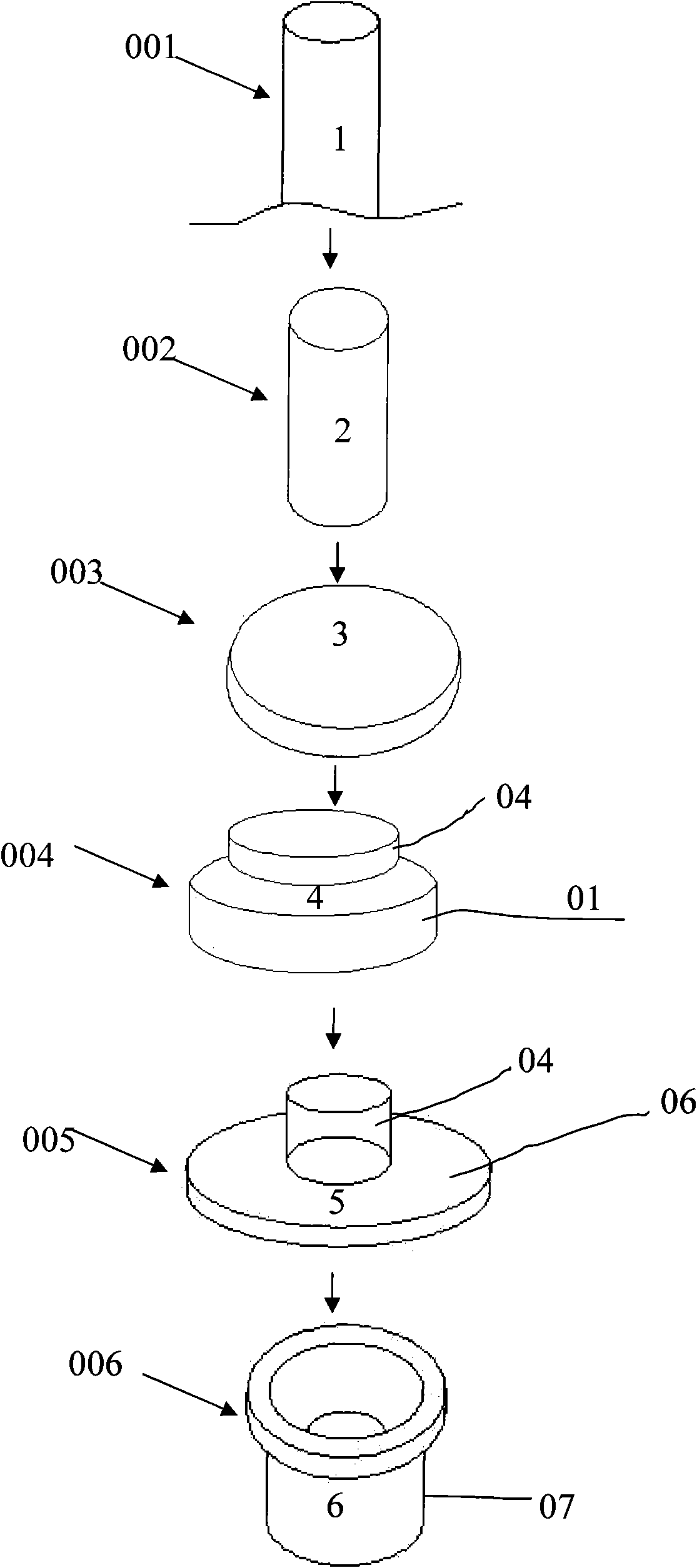

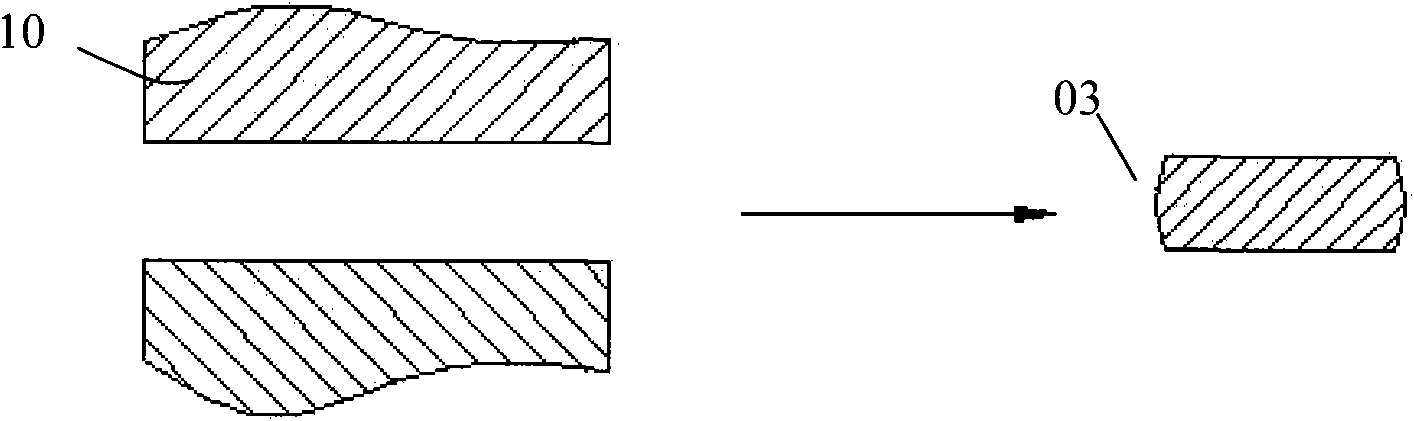

Method for manufacturing deep-groove U-shaped iron for loudhailer

InactiveCN101579799AReduce lossesBeautiful appearanceElectrical transducersMetal-working apparatusHigh volume manufacturingLoudspeaker

The invention relates to a method for manufacturing a deep-groove U-shaped iron for a loudhailer, which is characterized by comprising the following steps: 1, calculating the weight of a finished product according to the size of the product and intercepting bar steel materials with equal weight; 2, performing forging for the first time, i.e. forging and pressing the intercepted bar steels to proper size; 3, performing the forging for the second time, i.e. providing two sections of different diameters in a die cavity of an adopted die and forging one end of a processed member into a straight cylinder part with a smaller diameter; 4, performing the forging for the third time, i.e. forging the other end of the processed member into a chassis with a larger size by using a special die, and arranging a groove on the chassis; and 5, stretching and shaping the processed member by using a stretching die and stretching the processed member into a setting size of the U-shaped iron with the deep groove to obtain the finished product. By the process, the invention can effectively solve the problems of waste excess materials, material management expenses, and the like, and greatly reduce the cost. Because of the short manufacture time, the invention can realize mass production with beautiful finished product and easy control for the precision, and improve the quality and the competitiveness of the product.

Owner:葛锦明

High-strength ceramic tile

The invention discloses a high strength ceramic tile, which comprises the following steps: allocating mass percent of each component as 60-68% SiO2, 16-19% ALO3, 0. 5-2% Fe2O3, 0. 5-3% TiO2, 1-3% CaO, 1-3% MgO, 2-5% K2O, 1-3% NaO2 and 4-8% IL; setting the balling slip glaze fineness at 9-13% of 250 order sieve residue; setting the specific gravity of serous at 1. 68-1. 82g / cm3; setting the current rate of the slurry at about 15-50S; choosing the warehousing moisture mass percent at 7-8% of the powder and the deliver from godown moisture percent at 6. 8-7. 85; setting the particle size of the powder at 50-60% of 40 order sieve residue and 30-40% of 60 order sieve residue. This invention can increase bearing force by about 40% of glazed tile, which decreases damage ratio and cost.

Owner:霍镰泉

Glass fiber enhanced nylon 6 material for improving transparency

InactiveCN101955656AExpand the range of material selectionHigh transparencyEnvironmental resistanceGlass fiber

The invention relates to a glass fiber enhanced nylon 6 material for improving the transparency, comprising the following components in percentage by weight: 38.5-95 percent of nylon 6, 5-60 percent of alkali-free glass fiber, 0.5-6.0 percent of clarifier, 0.1-3.0 percent of glass fiber treating agent and 1.3-5.5 percent of other assistants. The glass fiber enhanced nylon 6 material for improving the transparency has approximate performance to that of the like materials, is convenient to produce and purchase, improves the transparency and also meets all other environment-friendly requirements, so that the material can also be used in places through which the condition can be seen by the shield of products, which increases the application fields, widens the material selecting range of product designers, solves the problem of design limitation of products and improves the competitiveness of the products.

Owner:KECHUANG POLYMER SUZHOU

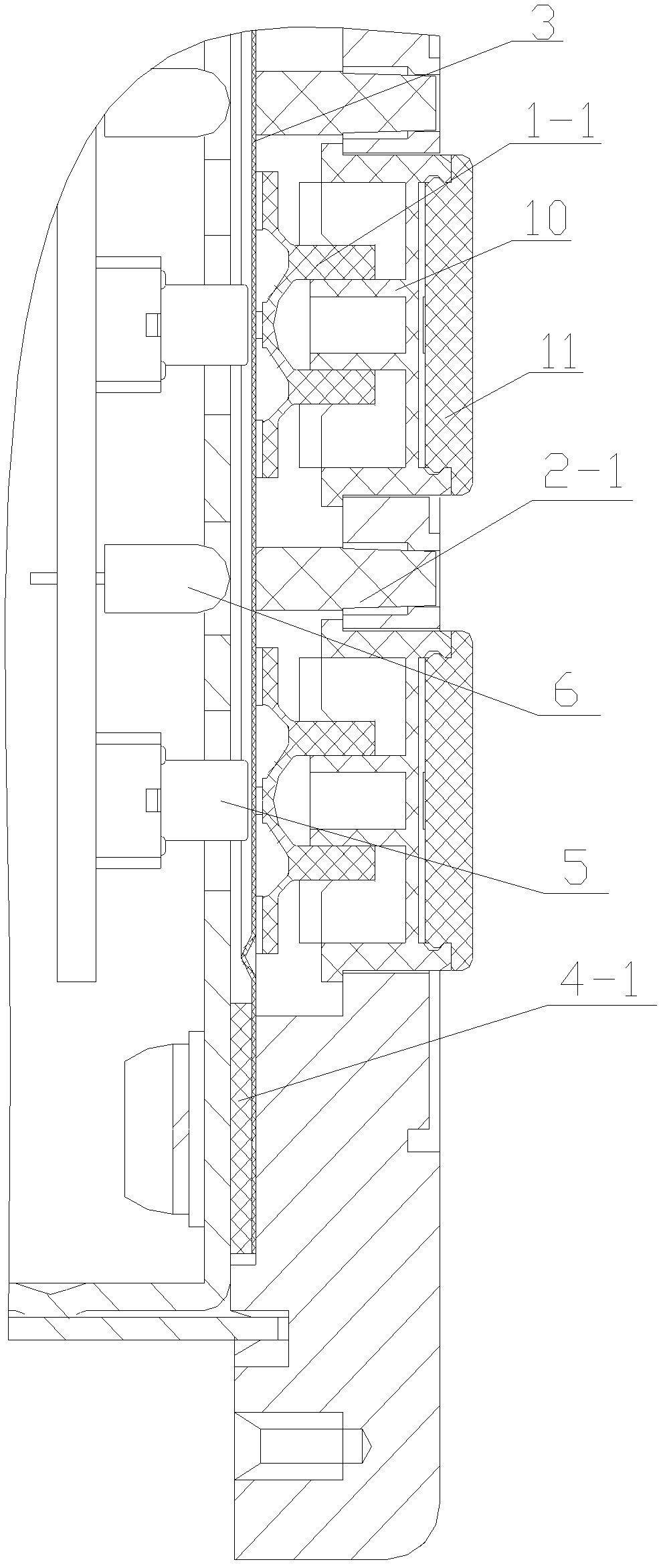

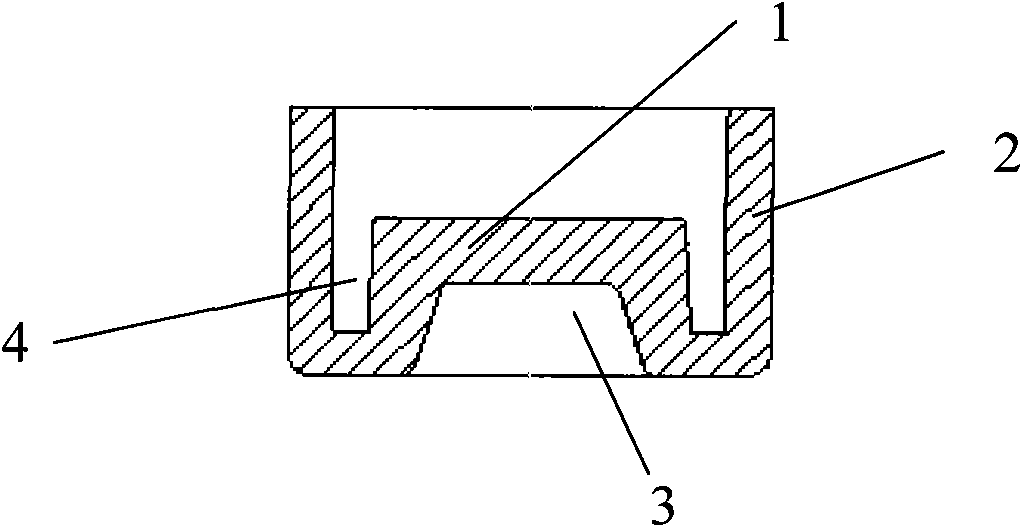

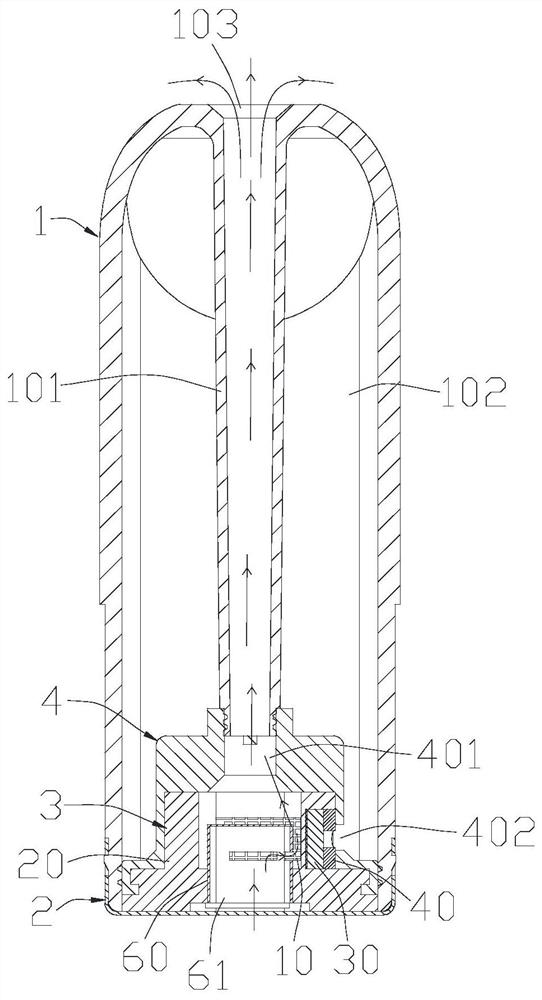

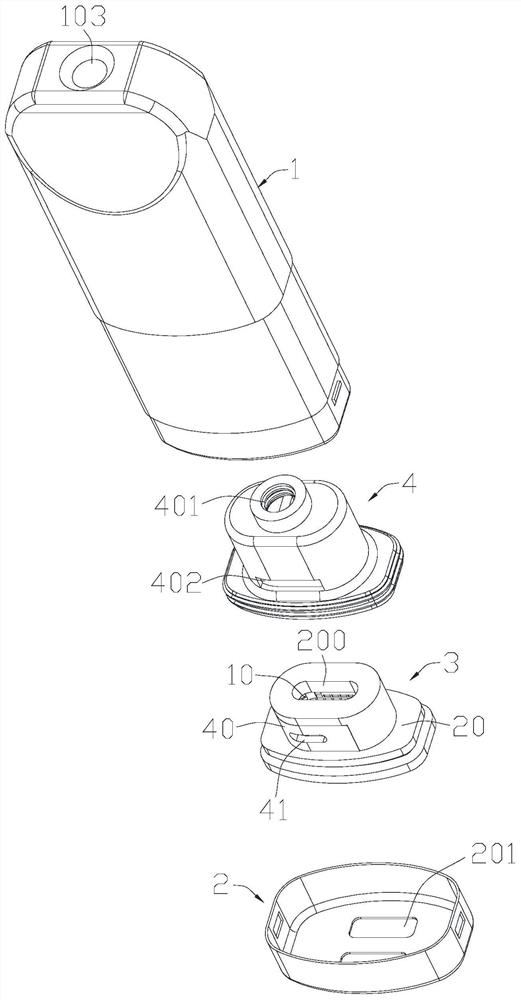

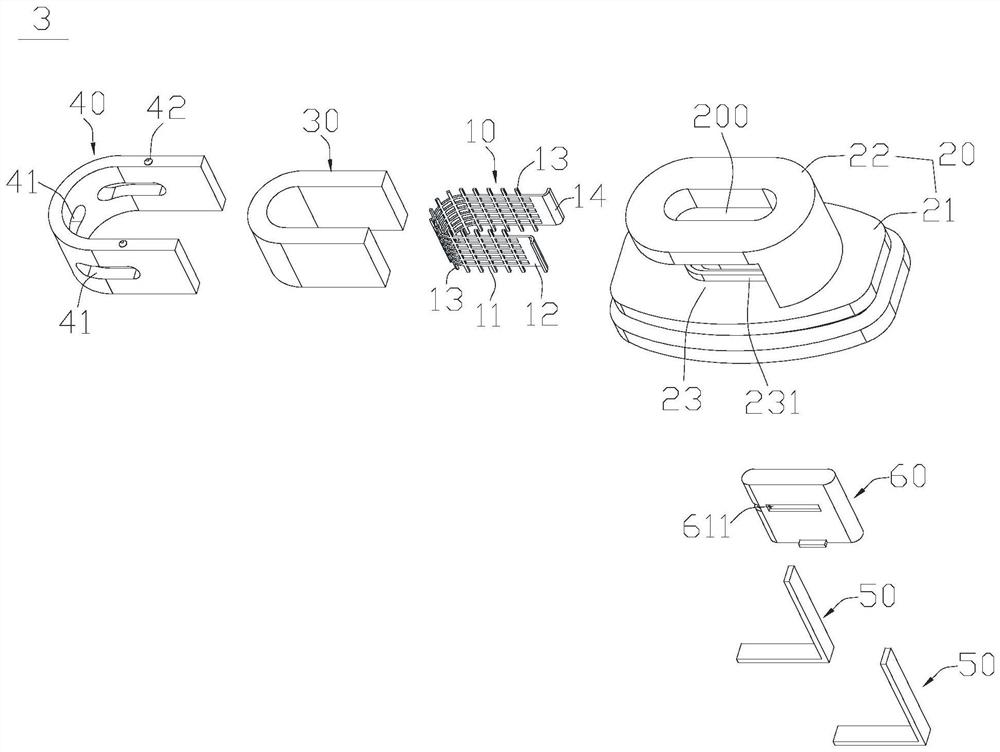

Atomization unit and atomization device

PendingCN112493558AGood for thinning settingsFully contactedTobacco devicesEngineeringMechanical engineering

The invention discloses an atomization unit and an atomization device. The atomization unit comprises a net-shaped U-shaped heating piece, a supporting and fixing base with a central through hole, liquid guide cotton and a side sealing piece. The supporting and fixing base comprises a base and a supporting column body arranged on the base, and a center through hole penetrates through the supporting column body and the base. A U-shaped notch is formed in the side face of the supporting column body. The U-shaped heating sheet is arranged in the notch and abuts against the base; the liquid guidecotton wraps the outer side surface, far away from the central through hole, of the U-shaped heating sheet; the side sealing piece is matched in the notch to fix the liquid guide cotton between the side sealing piece and the U-shaped heating piece; and at least one liquid guide hole communicated with the liquid guide cotton is formed in the side sealing piece. According to the invention, the heating body is supported and fixed on the supporting and fixing base in a lateral assembly manner, and the liquid guide cotton and the heating body are fixed on the supporting and fixing base through thelateral sealing piece, so that the liquid guide cotton is in full contact with the heating body and is prevented from being extruded and deformed; thinning arrangement of the heating body is facilitated, and the material selection range is expanded.

Owner:SHENZHEN HUACHENGDA PRECISION IND CO LTD

Air container for aviation loading

PendingCN110745395AMeet the loading strength requirementsReduce manufacturing costLarge containersAviationUltimate tensile strength

The embodiment of the invention provides an air container for aviation loading. The air container for aviation loading is composed of a container body frame and skin. The container body frame comprises a bottom plate frame, lateral plate frames and a top plate frame. The bottom plate frame and the lateral plate frames are connected in a riveted mode, and the top plate frame and the lateral plate frames are connected in a riveted mode. An existing aluminum container is formed in a welding mode, so that the material selection range of air containers is limited. In contrast, the air container inthe invention is assembled in a riveted mode, when the manufacturing materials of the container are selected, on the premise of meeting the loading strength requirement of the container, it is unnecessary to select materials with good welding performance, the material selection range is broadened, and the manufacturing cost of the air container is lowered.

Owner:西安兴航航空科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com