Bamboo blinds and method for making

A technology of blinds and bamboo blinds, which is applied in the field of building materials processing, can solve problems such as complex processes, waste of resources, and cracking, and achieve the effects of expanding the range of material selection, low production costs, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

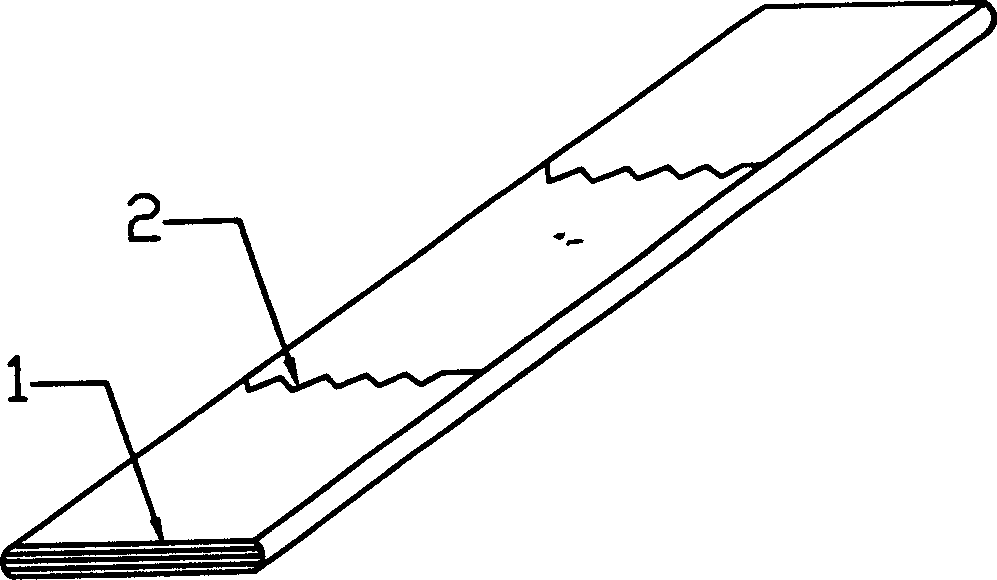

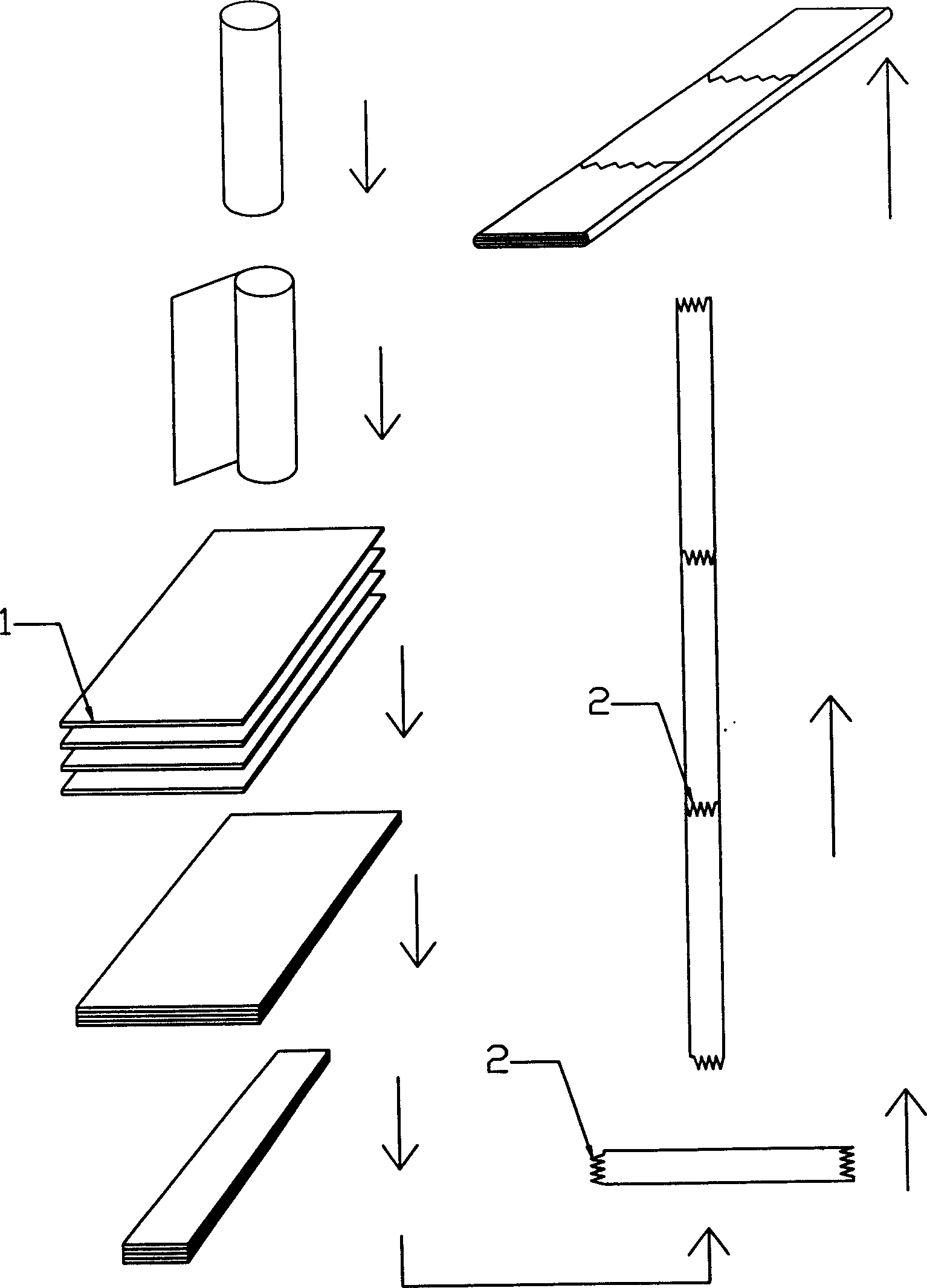

[0022] Bamboo blinds include rotary-cut bamboo veneers 1, which are superimposed in the thickness direction and hot-pressed and glued; they are formed by butt jointing and gluing with fingers and tenons 2 in the length direction.

[0023] The method for manufacturing bamboo shutters comprises the technological steps carried out in the following order:

[0024] Firstly, select the root bamboo material after insect-proof, mildew-proof and anti-corrosion treatment, cut it into a certain length, and process it into a 0.5mm bamboo veneer 1 by rotary cutting with a bamboo veneer rotary cutter;

[0025] Secondly, the bamboo rotary-cut veneer 1 is dried, after the drying reaches the standard, an adhesive is applied, and three layers of bamboo rotary-cut veneers are superimposed and pressed into a bamboo plywood with a thickness of 2.0mm and a format of 1220×630-1050mm;

[0026] Then the above-mentioned plywood is cut into a specified width, finger-jointed into a certain length, and th...

Embodiment 2

[0030] Bamboo blinds include rotary-cut bamboo veneers 1, which are superimposed in the thickness direction and hot-pressed and glued; they are formed by butt jointing and gluing with fingers and tenons 2 in the length direction.

[0031] The method for manufacturing bamboo shutters comprises the technological steps carried out in the following order:

[0032] Firstly, select the bamboo at the root after insect-proof, mildew-proof and anti-corrosion treatment, cut it to a certain length, and process it into a bamboo veneer 1 with a thickness of 1.2 mm by rotary cutting with a bamboo veneer rotary cutter;

[0033] Secondly, the bamboo rotary-cut veneer 1 is dried, and after the drying reaches the standard, an adhesive is applied, and three layers of bamboo rotary-cut veneers are superimposed and pressed into a bamboo plywood with a thickness of 3.8mm and a format of 1220×630-1050mm;

[0034] Then the above-mentioned plywood is cut into a specified width, finger-jointed into a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com