Rod piece cutting-off device

A cutting device and rod technology, applied in shearing devices, shearing machine equipment, metal processing equipment, etc., can solve problems such as rod deformation, rod bending deformation, affecting product quality, etc., to overcome rod bending, improve Flatness, the effect of facilitating subsequent processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further elaborated below in conjunction with the accompanying drawings.

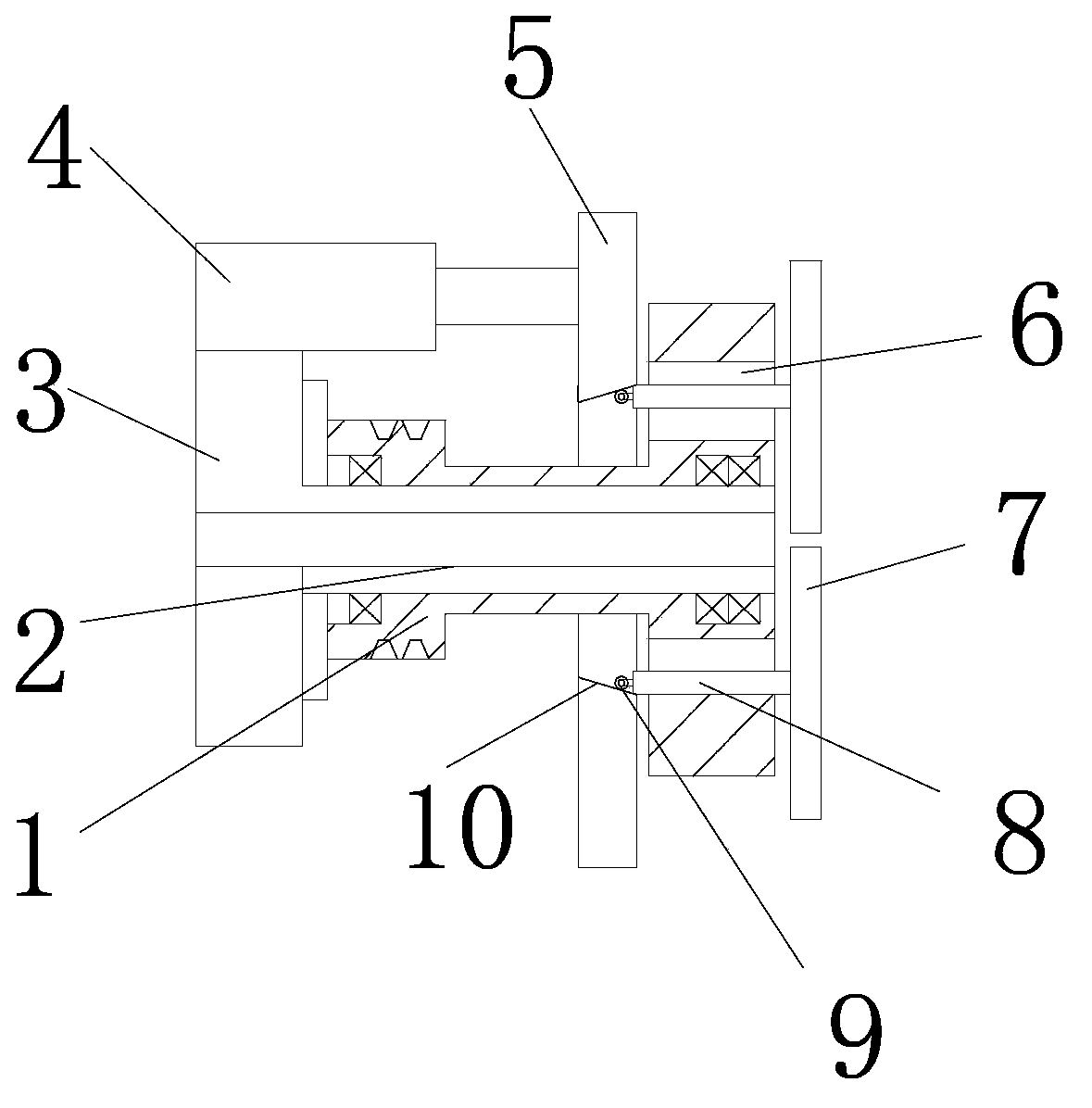

[0011] Such as figure 1 The shown rod cutting device includes a mounting plate 3, and the center of one side of the mounting plate 3 is extended outwardly with a mounting shaft 2, and a mounting shaft 2 is provided between the mounting shaft 2 and the mounting plate 3 for the rod to pass through. The feeding hole is characterized in that: the installation shaft 2 is covered with a rotatable rotating disk 1, the left side of the rotating disk 1 is provided with a pulley, and the right side of the rotating disk 1 is symmetrically provided with a waist-shaped Holes 6, the waist-shaped hole 6 is provided with a sliding rod 8, one end of the sliding rod 8 is connected with a cutter 7, the other end of the sliding rod 8 is connected with a pressure wheel 9, and the mounting plate 3 is also provided with Compression cylinder 4, the output end of the compression cylinder 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com