Patents

Literature

55results about How to "Bending will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

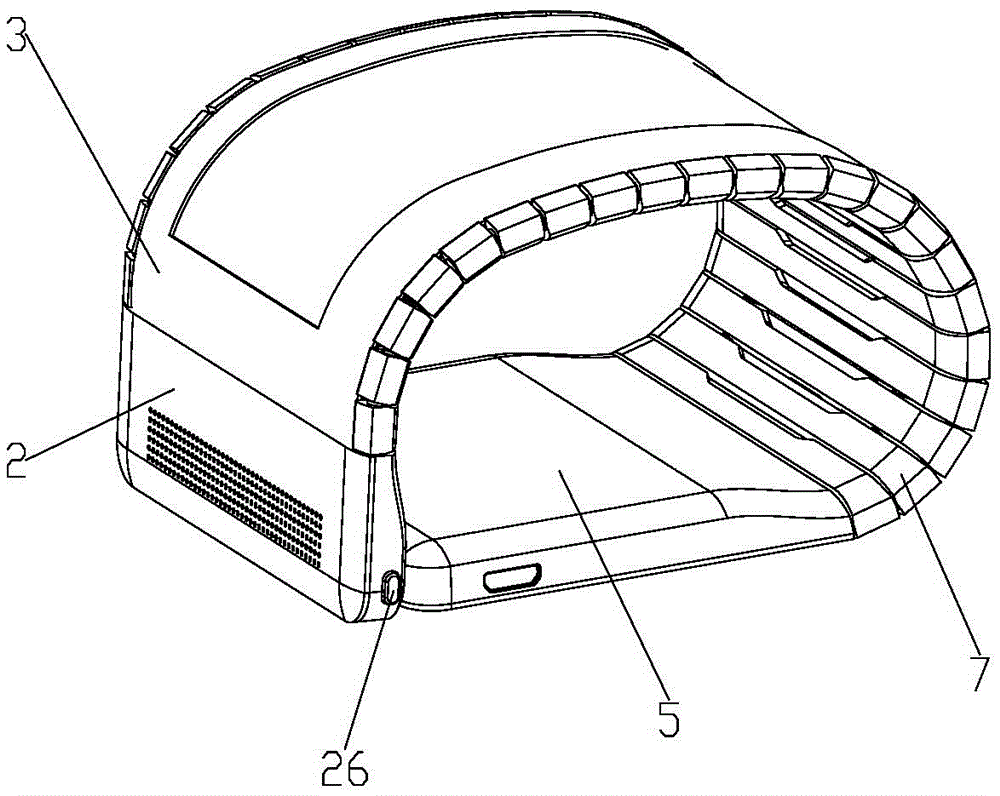

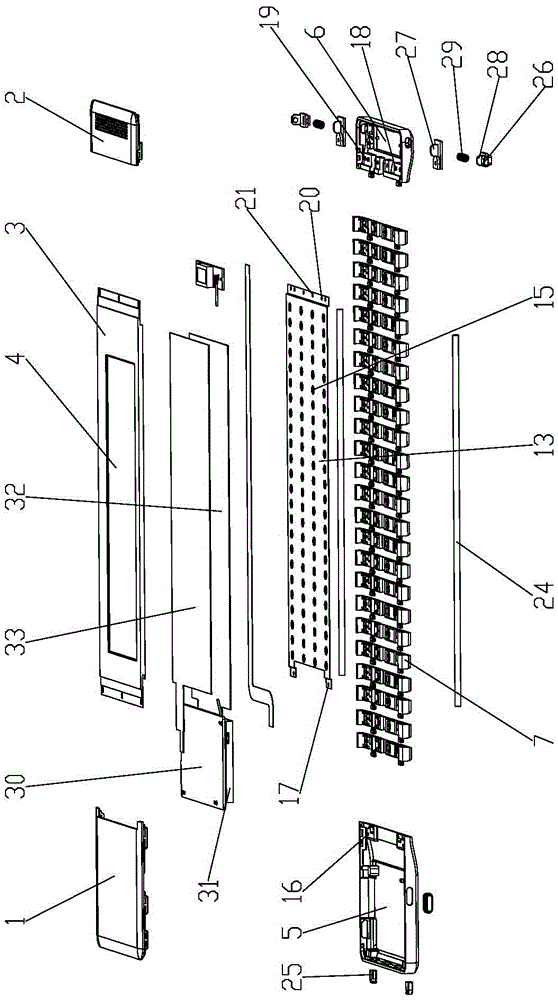

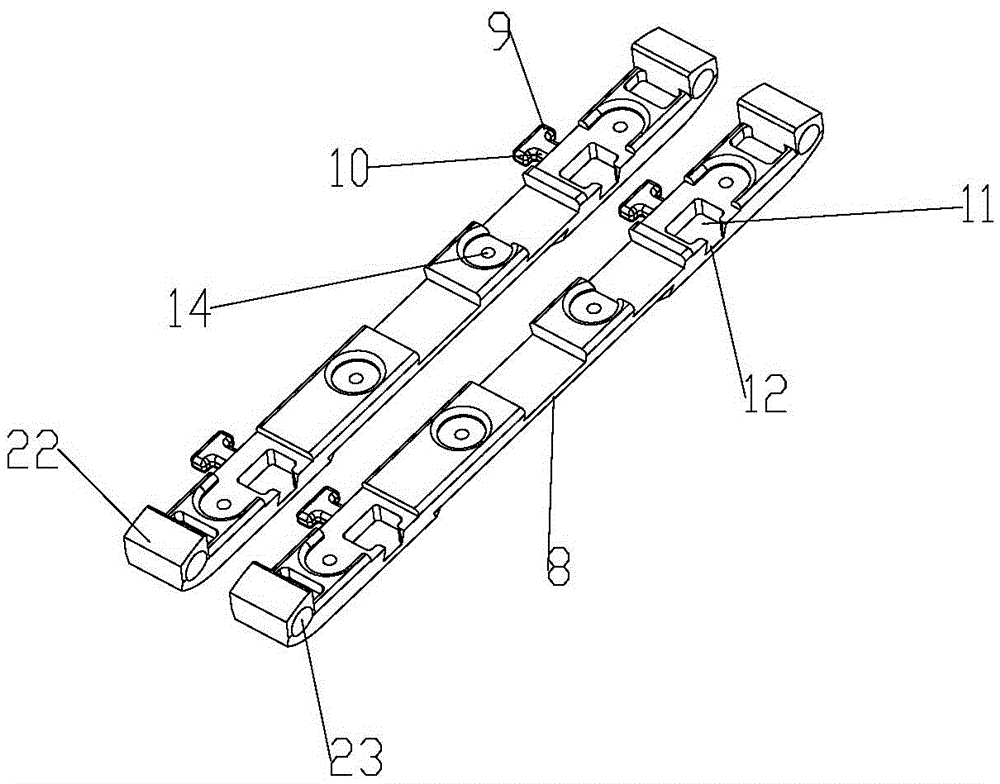

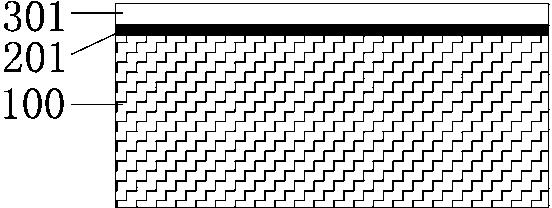

Flexible mobile phone and flexible shell

ActiveCN105933480AImprove flexibilityAvoid damageTelephone set constructionsBend radiusMechanical engineering

The invention discloses a flexible shell. The flexible shell comprises an upper cover and a lower cover. The upper cover comprises a front upper cover and a rear upper cover. A flexible connection cover is arranged between the front upper cover and the rear upper cover. The lower cover comprises a front lower cover and a rear lower cover. A bending skeleton mechanism is arranged between the front lower cover and the rear lower cover. The bending skeleton mechanism comprises skeletons arranged in parallel. Two adjacent skeletons, the front lower cover and the skeleton adjacent to the front lower cover, and the rear lower cover and the skeleton adjacent to the rear lower cover are connected by hinges; a bending radius limiting structure for limiting the minimum bending curvature radius of the bending skeleton mechanism bending towards the direction opposite to the direction of the flexible connection cover, and an anti-reverse rotation structure for preventing the bending skeleton mechanism from bending towards the direction of the flexible connection cover are arranged between two adjacent skeletons. A bending connection sheet is arranged between the bending skeleton mechanism and the flexible connection cover. A mounting cavity for mounting a flexible screen assembly is arranged between the flexible connection cover and the bending connection sheet. The invention also discloses a flexible mobile phone with the flexible shell.

Owner:CHONGQING GRAPHENE TECH

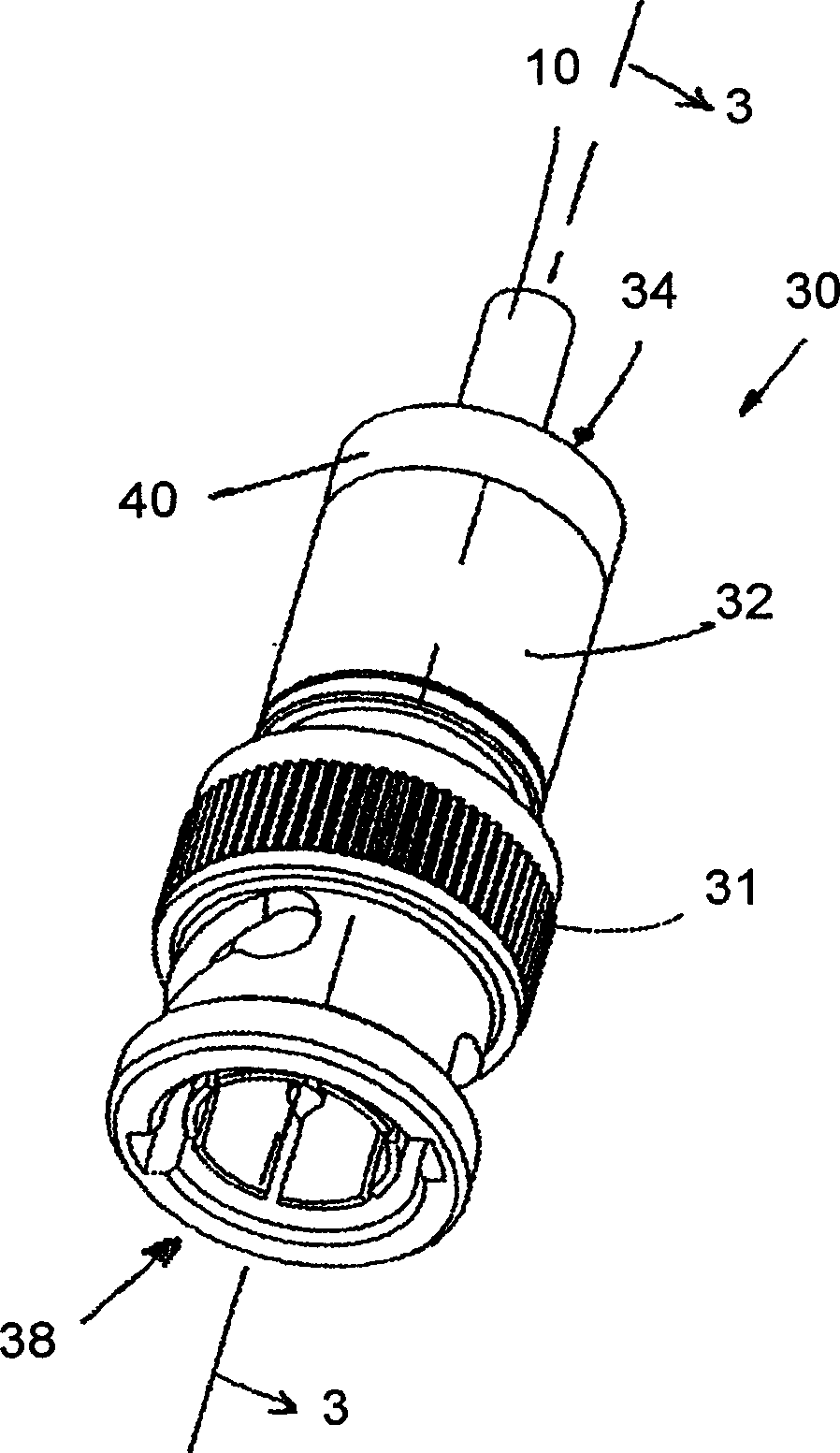

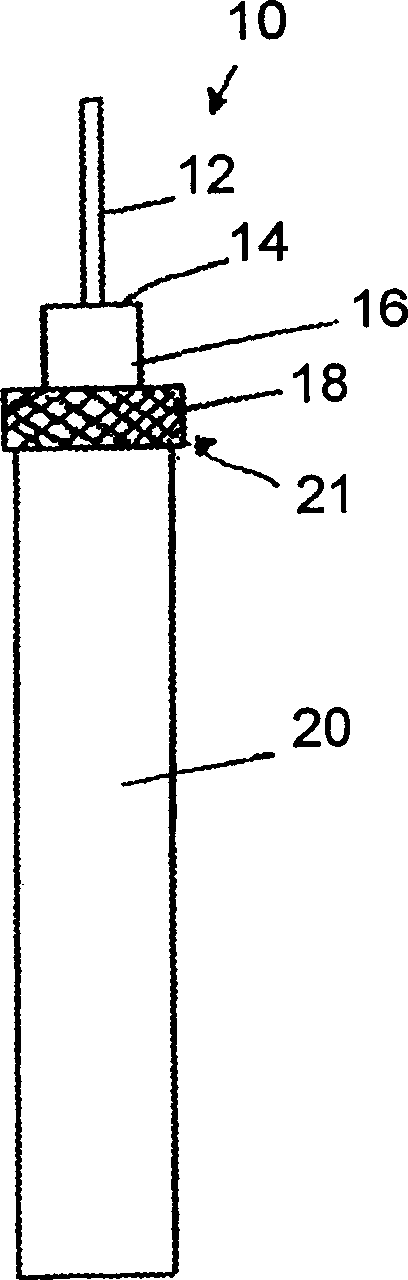

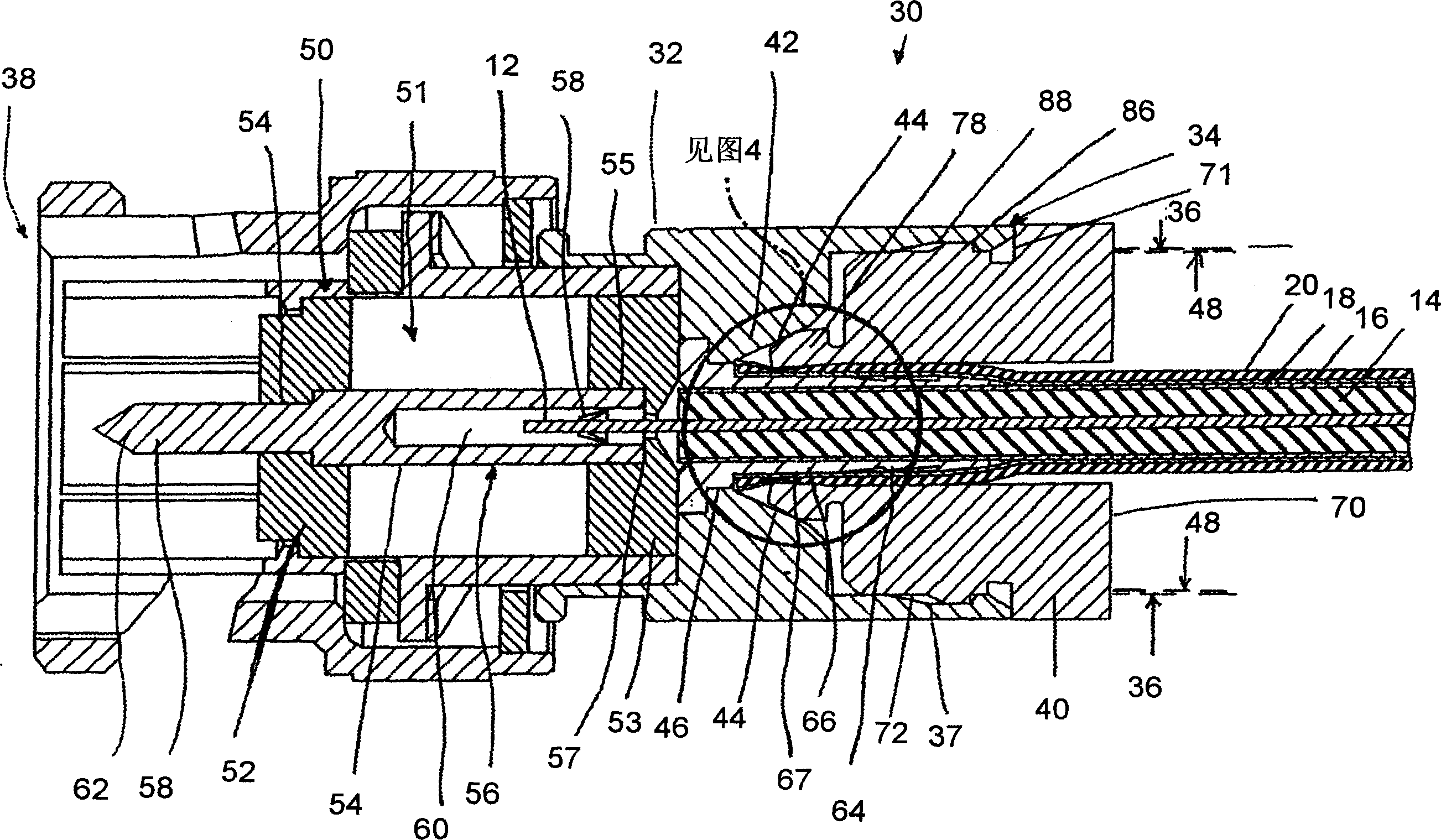

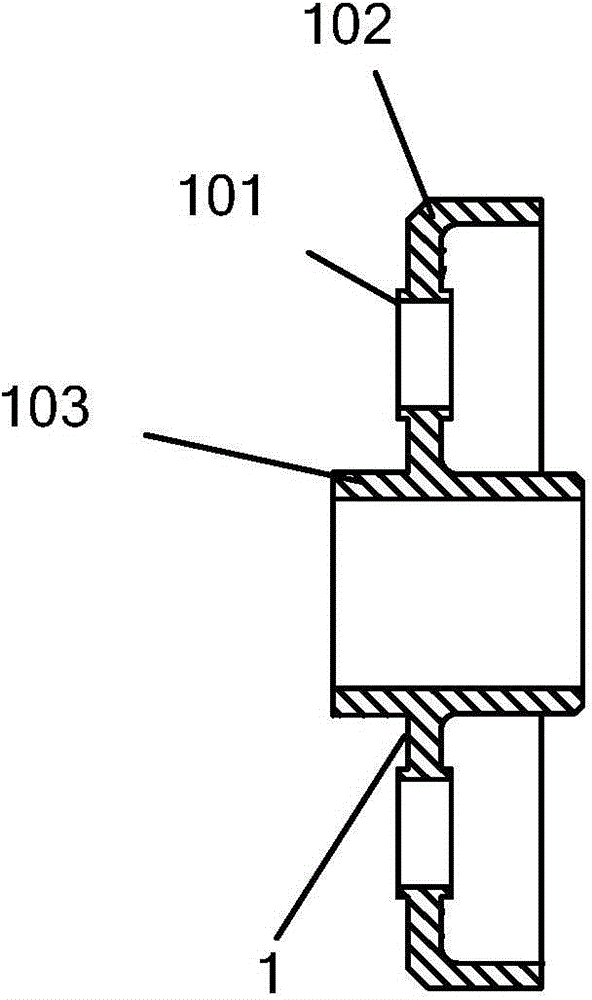

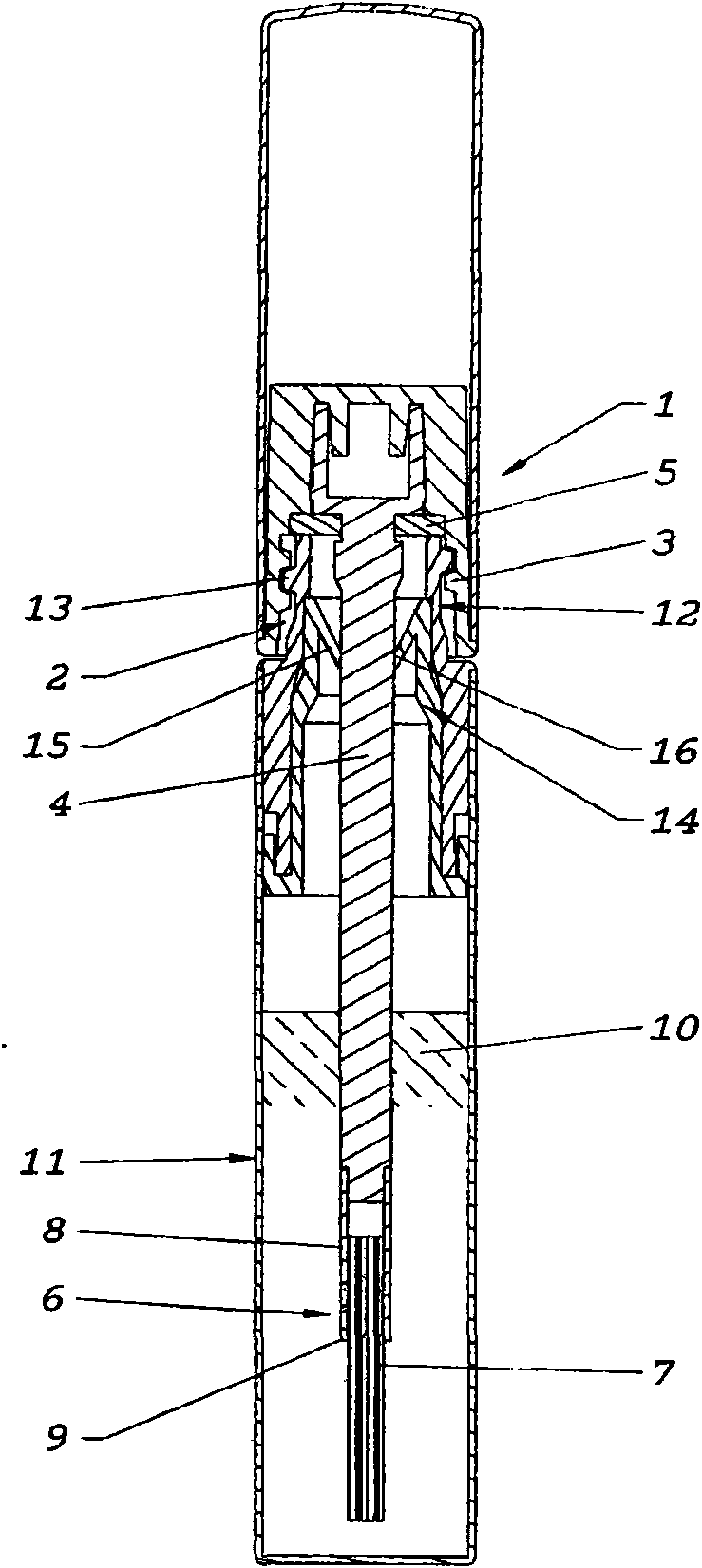

Coaxial connector with a cable gripping feature

InactiveCN1848529AAvoid bendingBending will notEngagement/disengagement of coupling partsElectrically conductive connectionsCoaxial cableMechanical engineering

A coaxial cable connector including a connector body having a rearward sleeve receiving end and an inner engagement surface and an axially movable locking sleeve seated in the rearward sleeve receiving end of the connector body is disclosed. The locking sleeve has a rearward cable receiving end and an opposite forward connector insertion end. The forward connector insertion end is formed with at least one flexible finger for gripping a cable inserted in the sleeve when the locking sleeve is moved from a first position to a second position.

Owner:THOMAS & BETTS INT INC

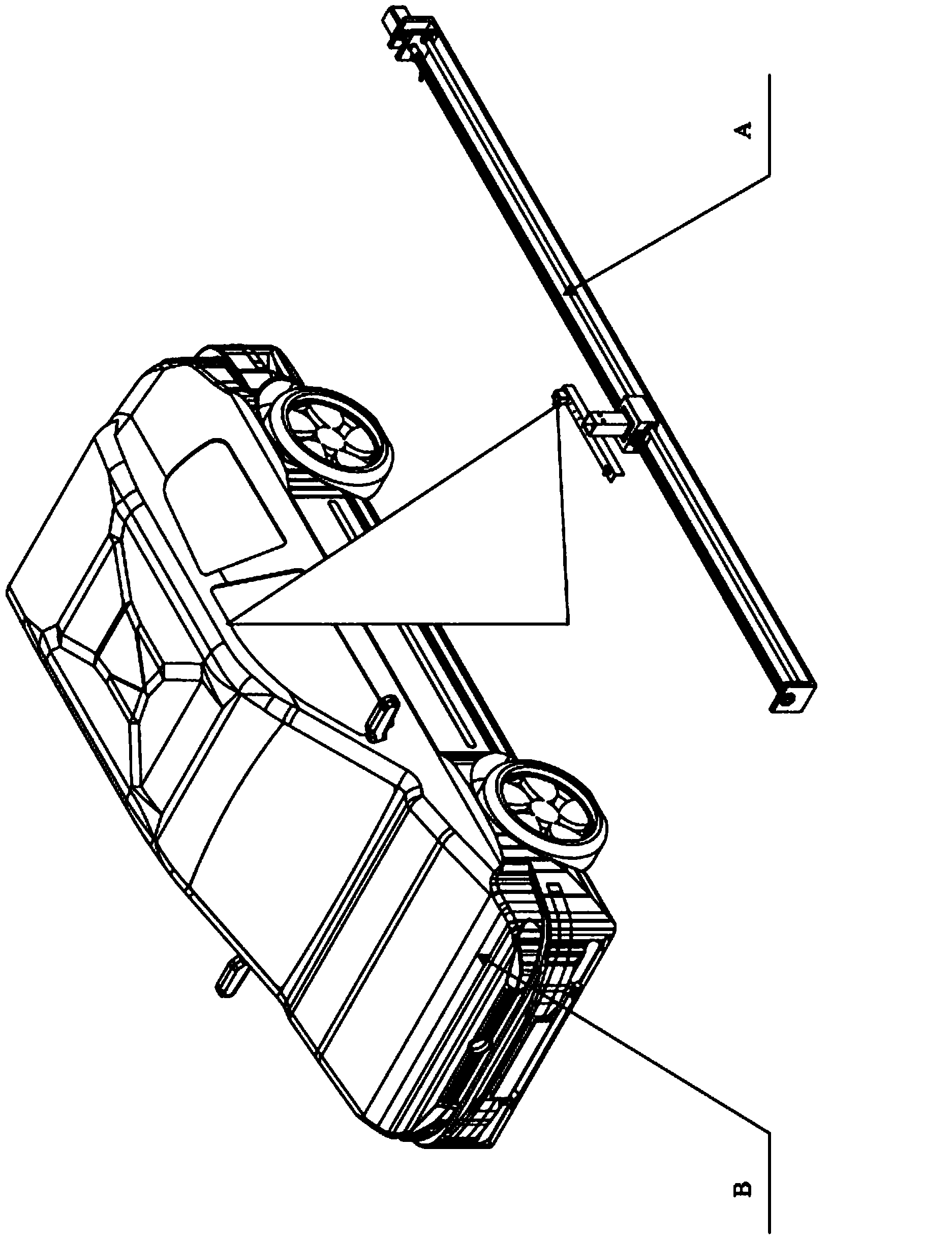

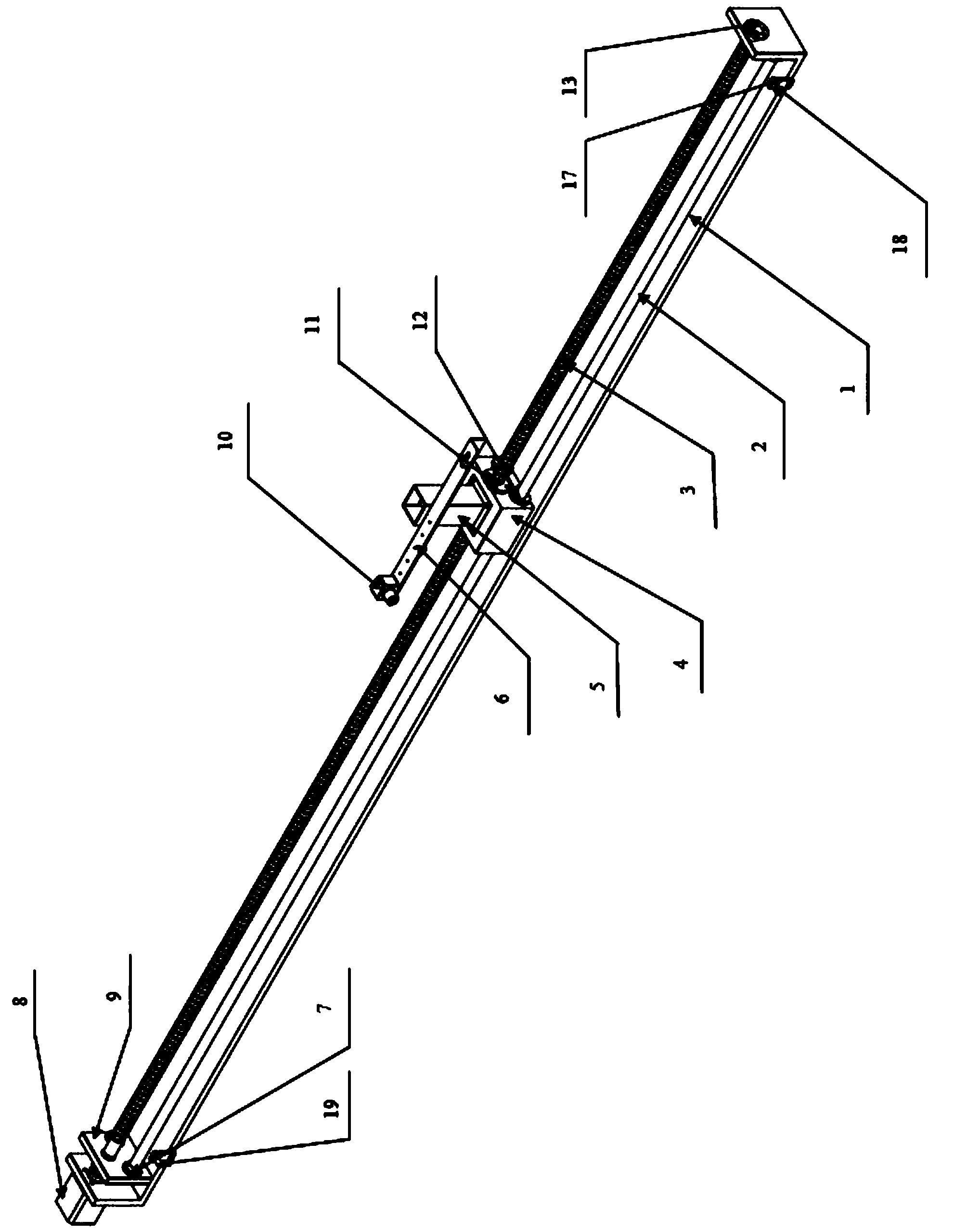

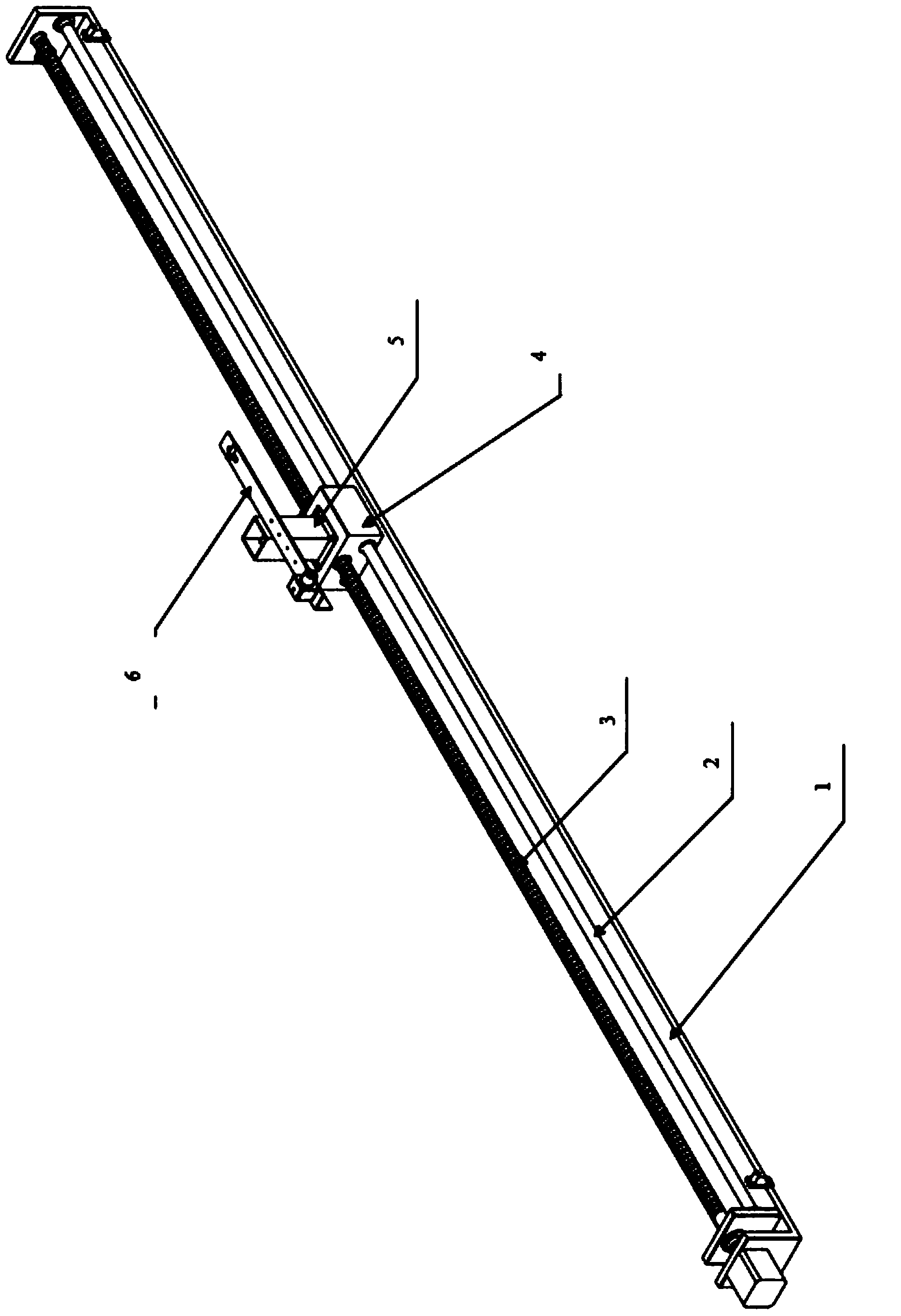

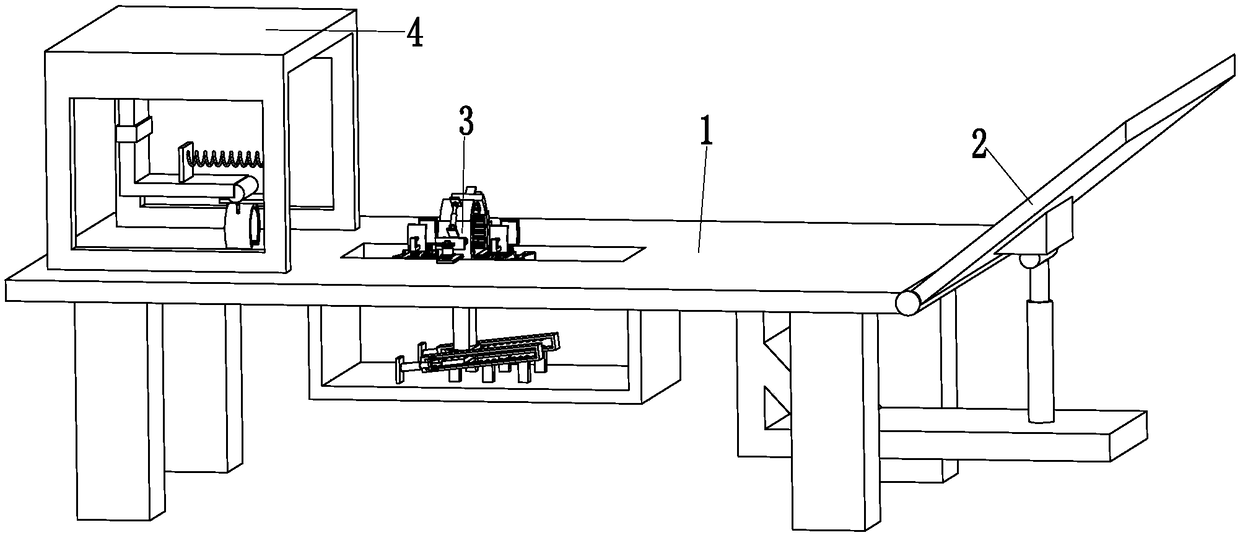

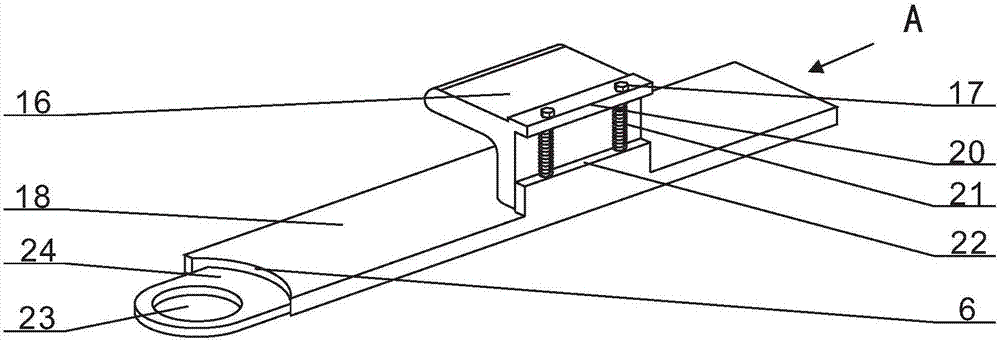

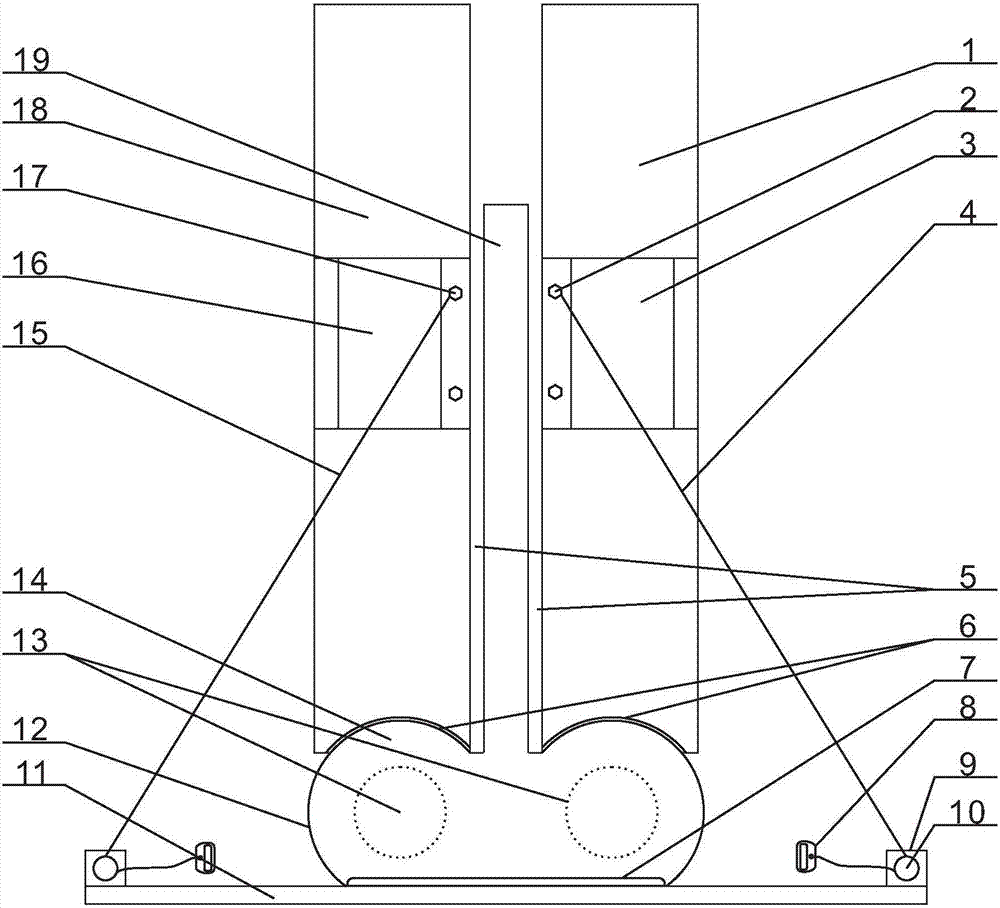

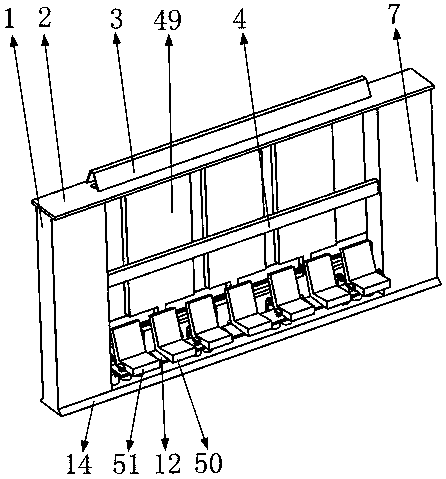

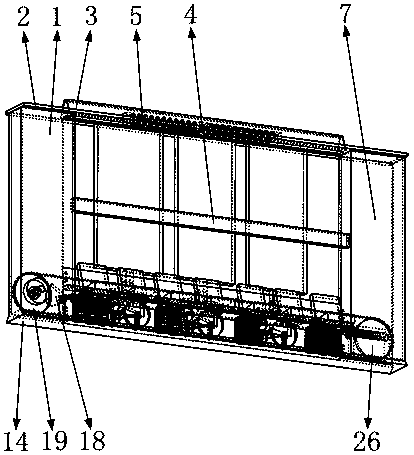

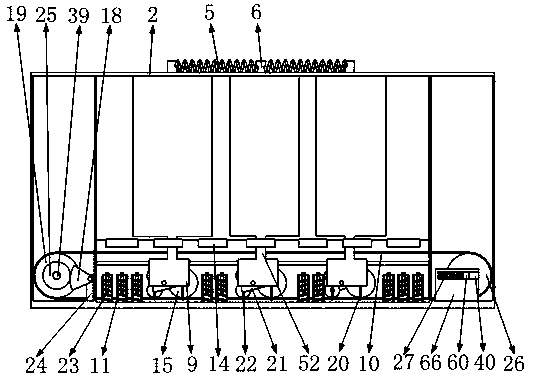

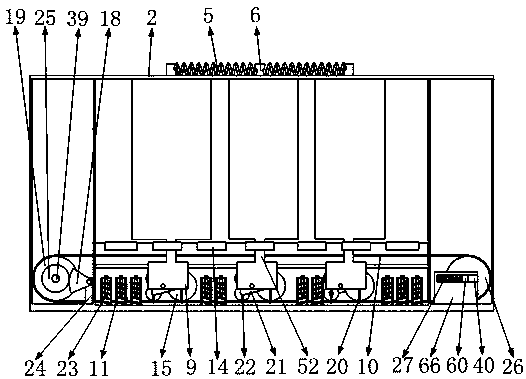

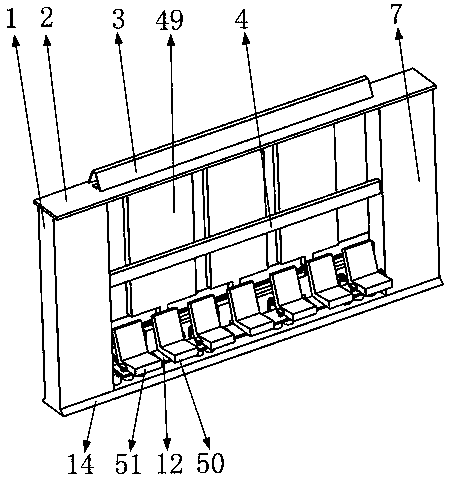

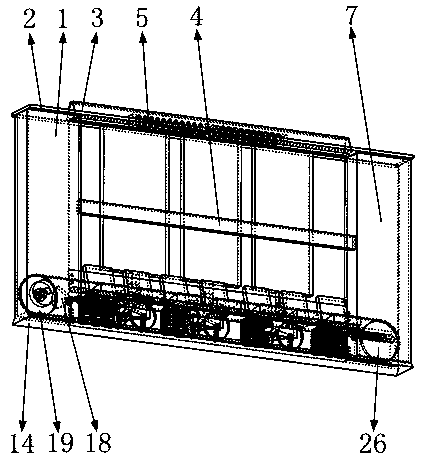

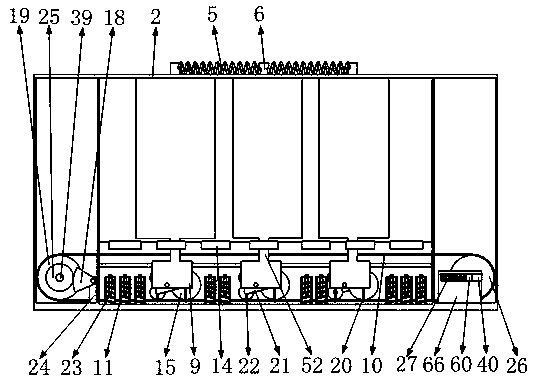

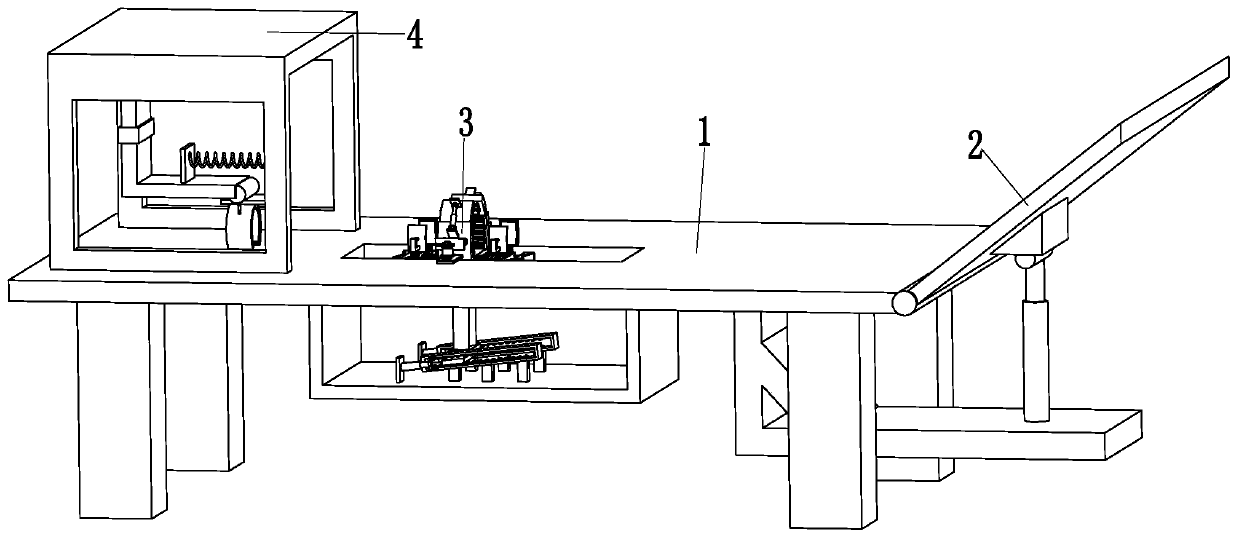

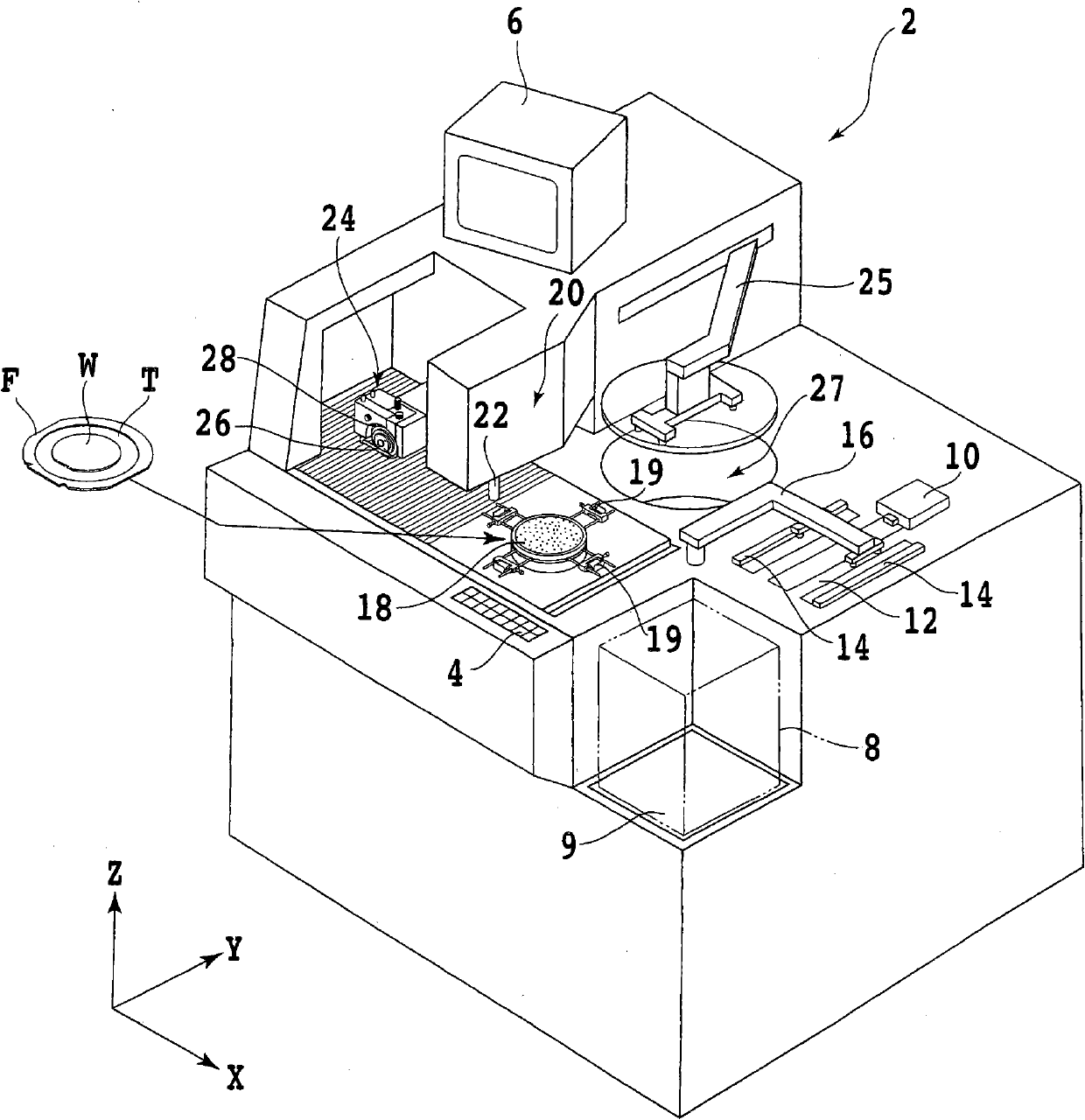

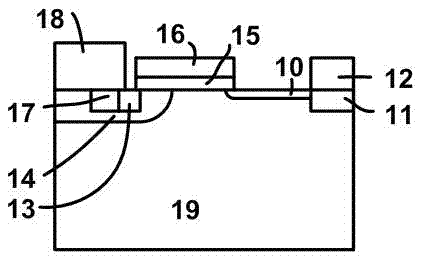

Surface structured light active vision based dynamic automobile body morphology reconstruction system

InactiveCN104101309ASmooth and Controlled MovementAvoid vibrationUsing optical meansEngineeringStationary state

The invention discloses a surface structured light active vision based dynamic automobile body morphology reconstruction system which aims at solving the problem that the automobile morphology active vision measurement on automobiles cannot be achieved through the surface structured light in the stationary state. The surface structured light active vision based dynamic automobile body morphology reconstruction system is mainly formed by a base (1), a lead screw (3), a stepper motor (8), a camera (10), a line projection instrument (15), a right proximity switch (18), a left proximity switch (19), a computer (20), an IO card (21), a switch power supply (22), a stepper motor driver (23), a left relay (24), a right relay (25) and the like. The surface structured light active vision based dynamic automobile body morphology reconstruction system is smooth in scanning, simple in structure, high in detection accuracy, convenient to operate, easy to install, low in cost and reliable in performance.

Owner:JILIN UNIV

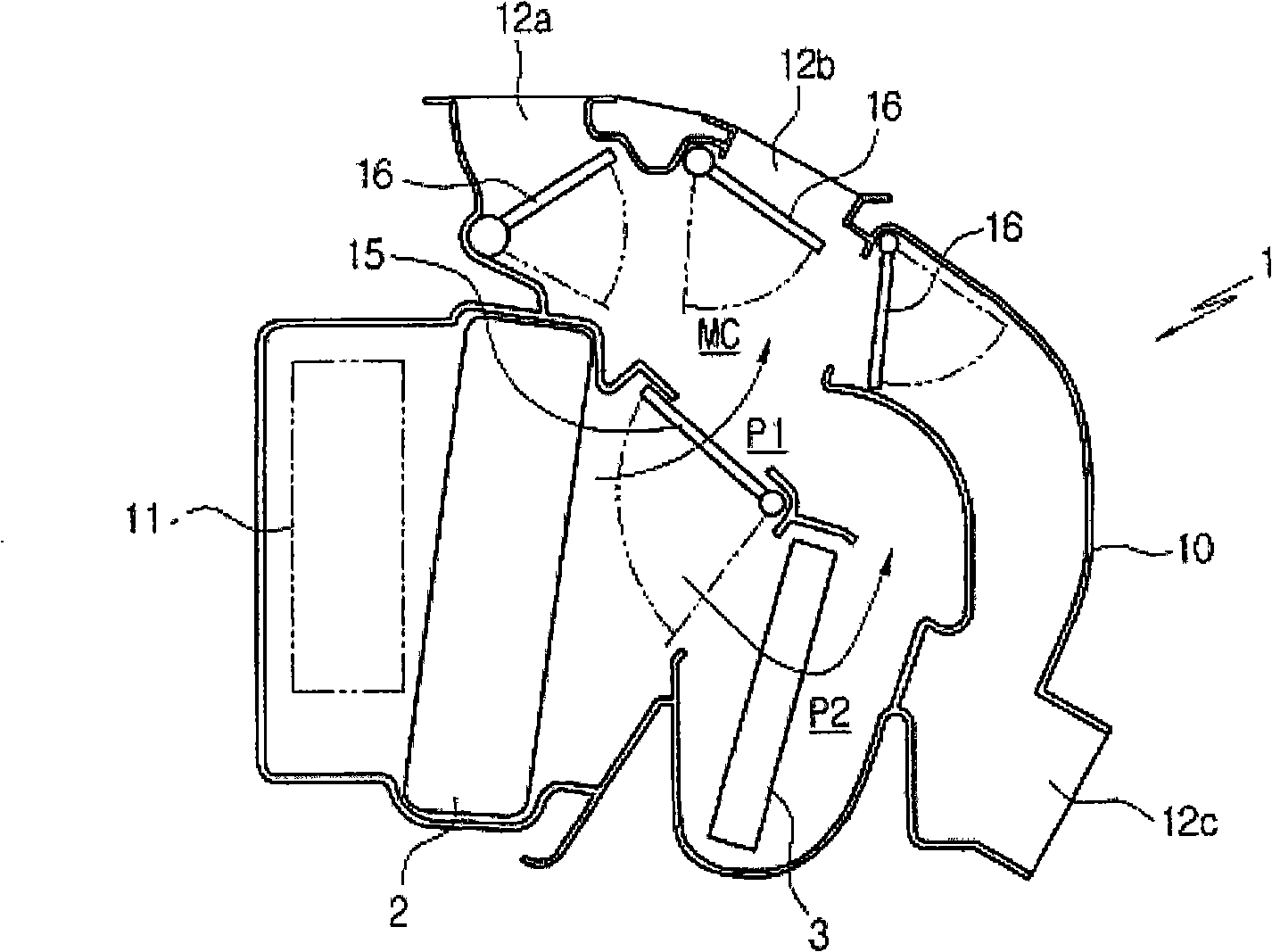

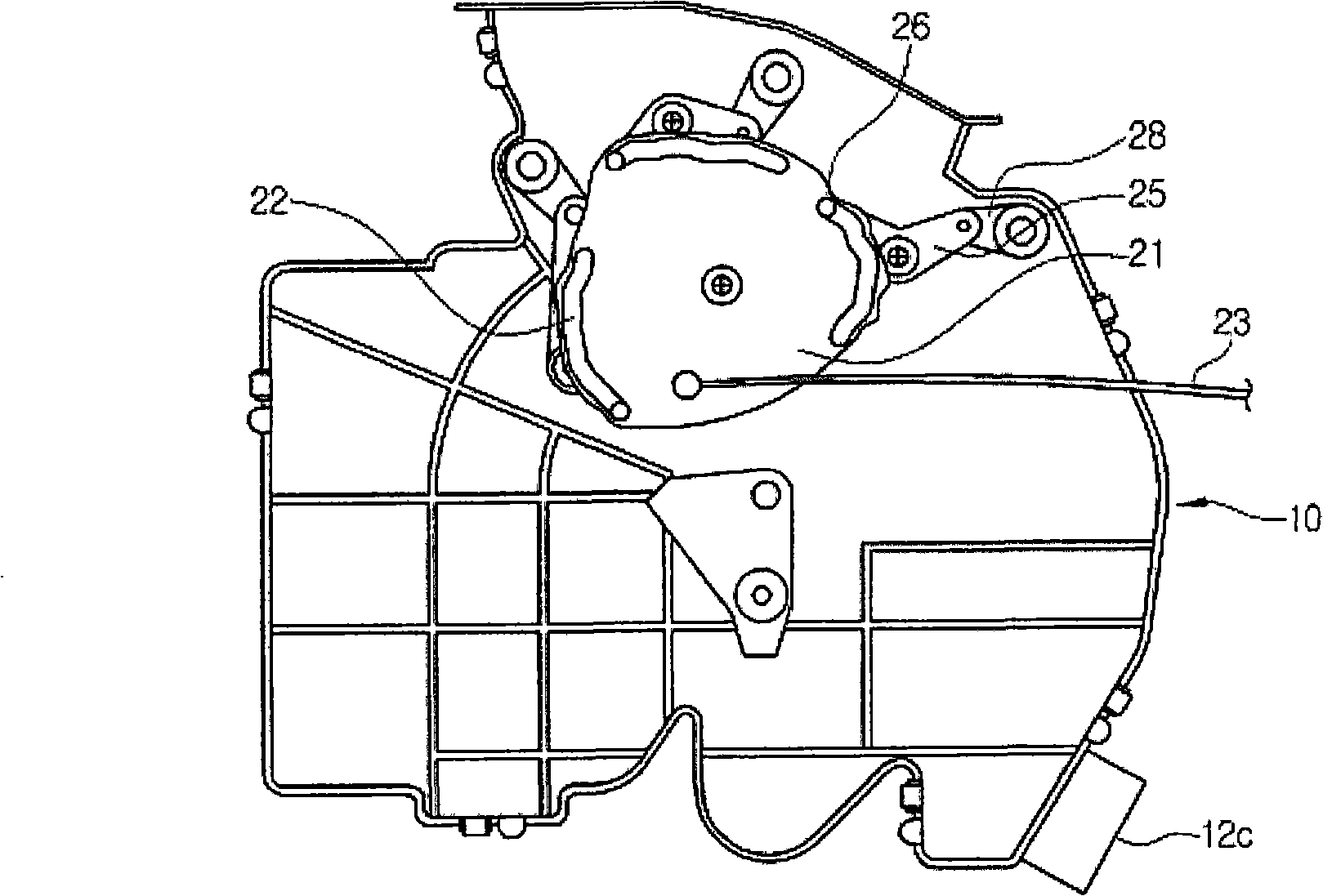

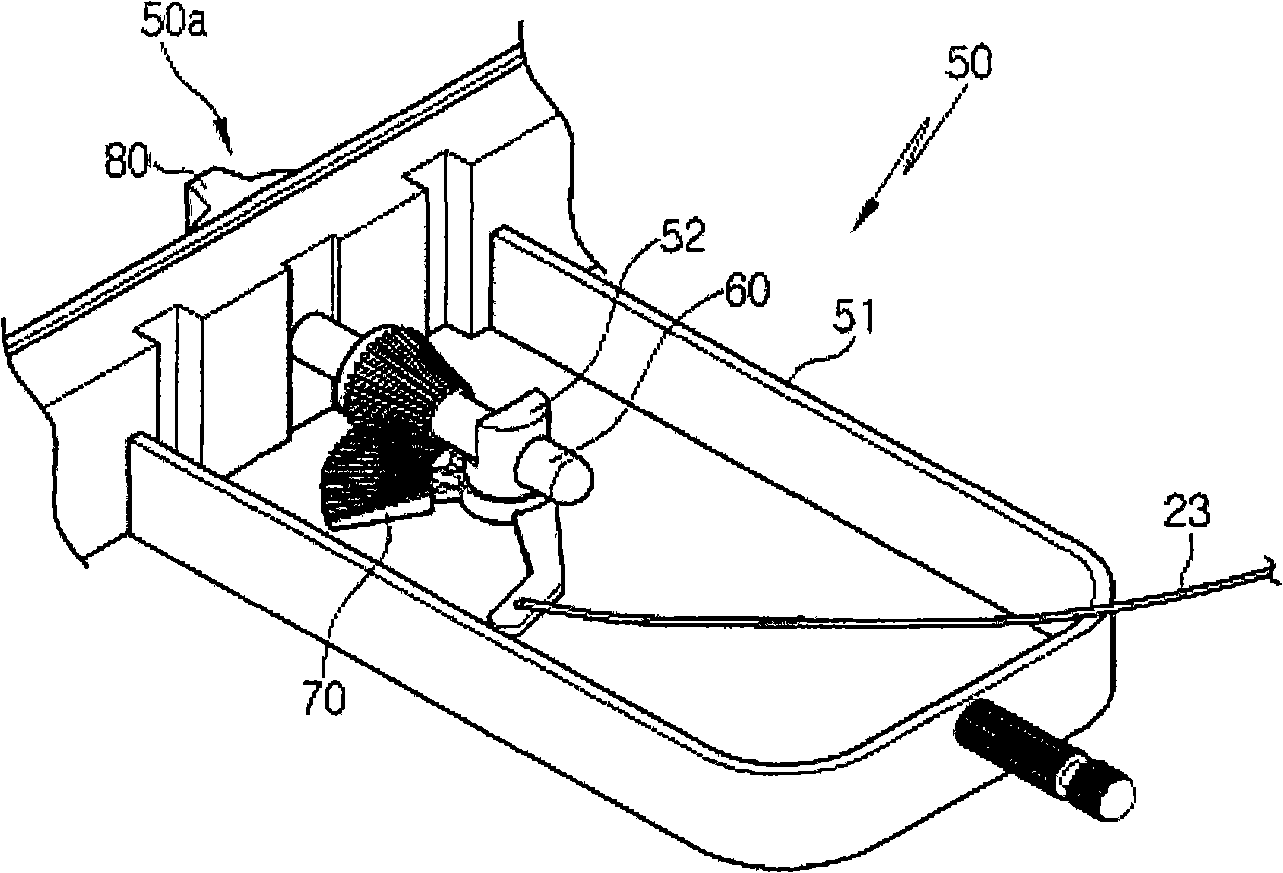

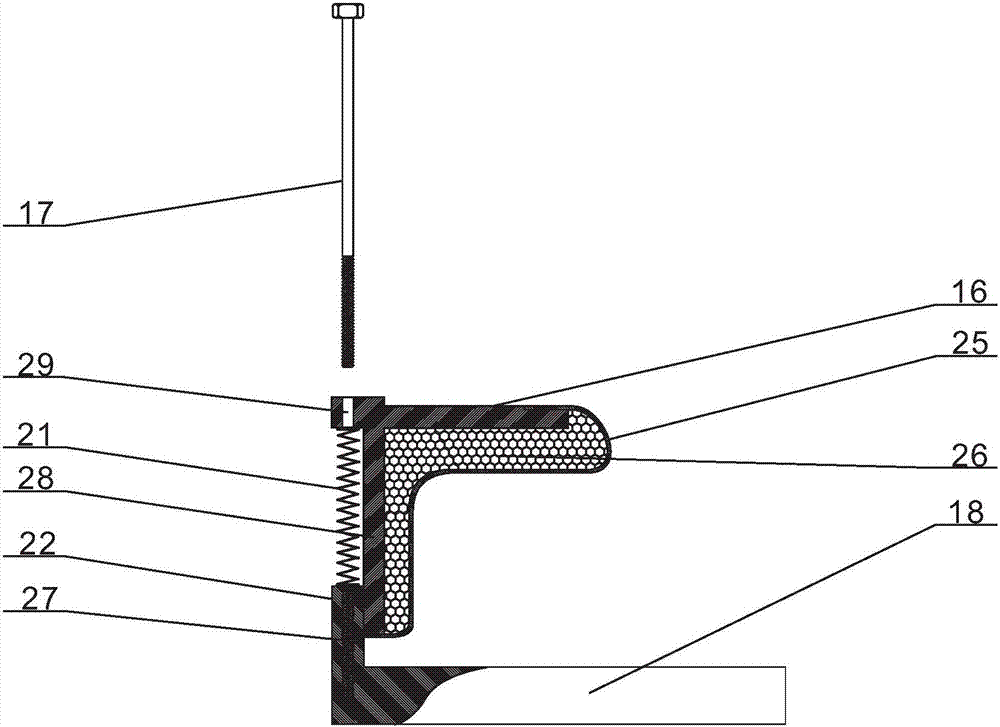

Cable connecting apparatus of controller for air conditioner in vehicle

InactiveCN101539324ABending will notSmall diameterSpace heating and ventilation safety systemsLighting and heating apparatusManufacturing cost reductionIn vehicle

The present invention relates to a cable connecting apparatus of a controller for an air conditioner in a vehicle, which connects actuating means of the controller and actuating means of an air-conditioning case with a single cable to actuate a door, wherein the cable connecting apparatus includes bending preventing means mounted thereon for connecting an end portion of the cable with the actuating means, thereby enhancing durability and a manipulation feeling, minimizing abrasion of components, using the cable as a flexible cable without any restriction in route of the cable and without bending of the cable, and reducing a manufacturing cost since the connecting apparatuses respectively mounted on the air-conditioning case and on the controller have the same structure.

Owner:HANON SYST

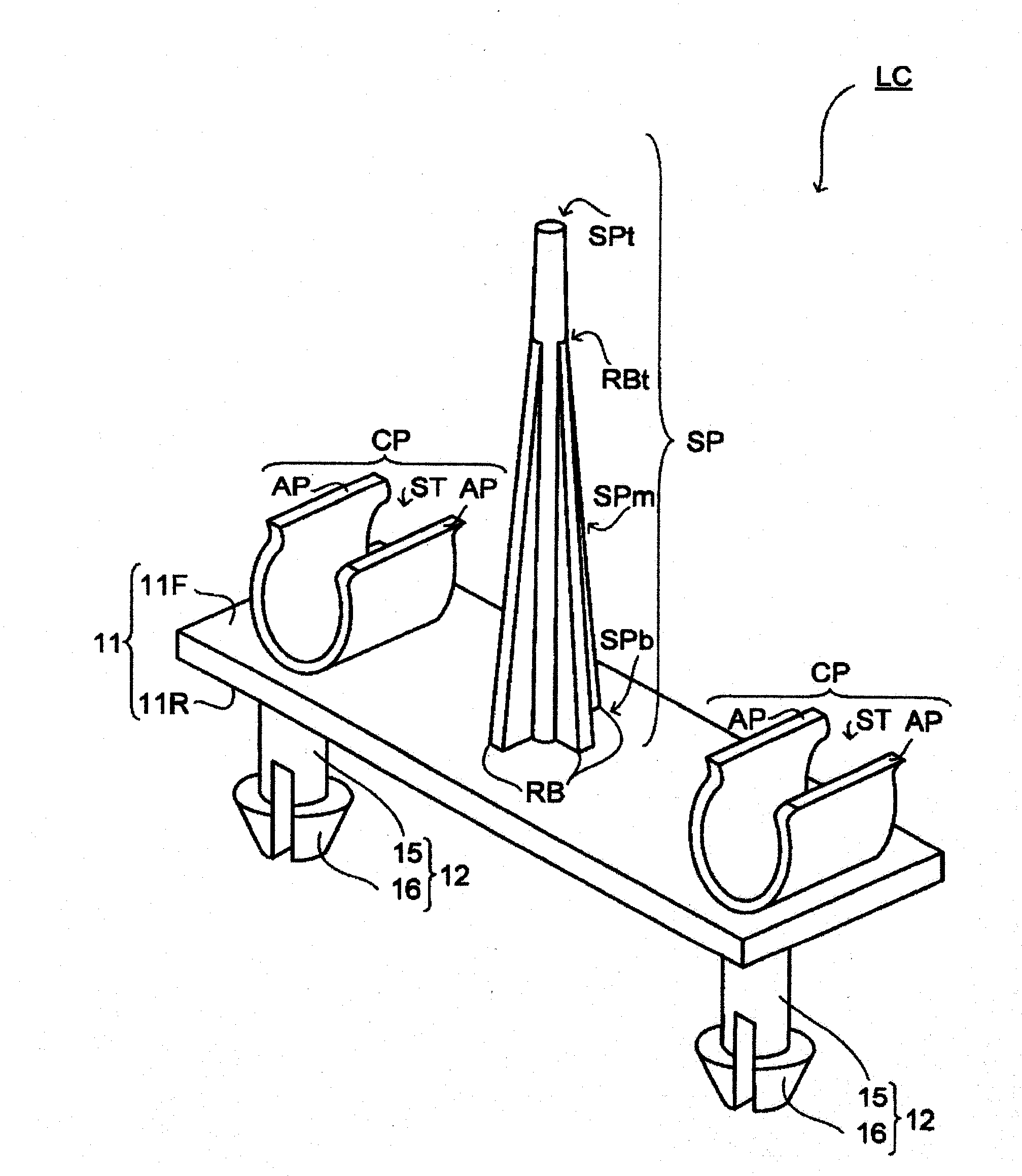

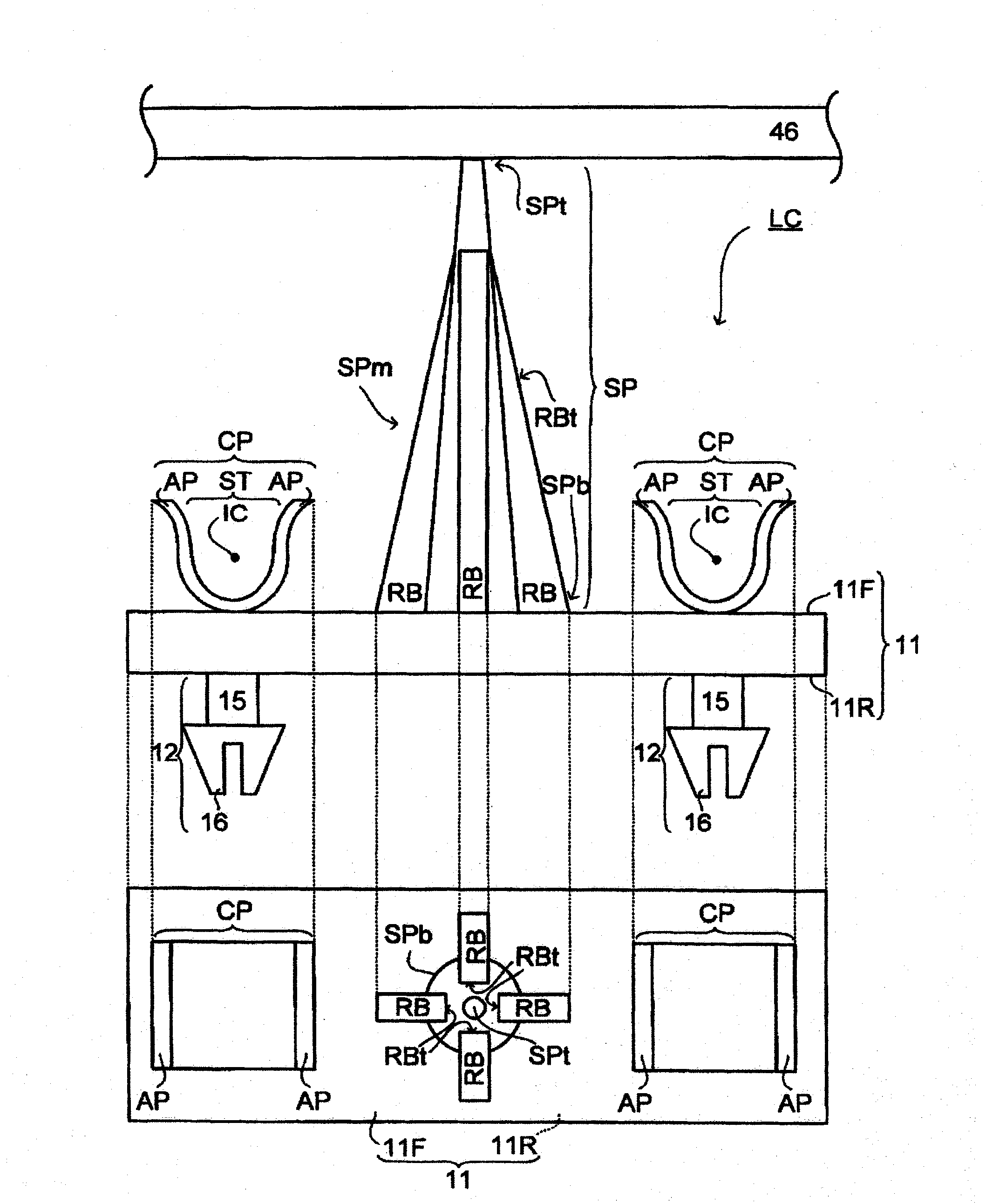

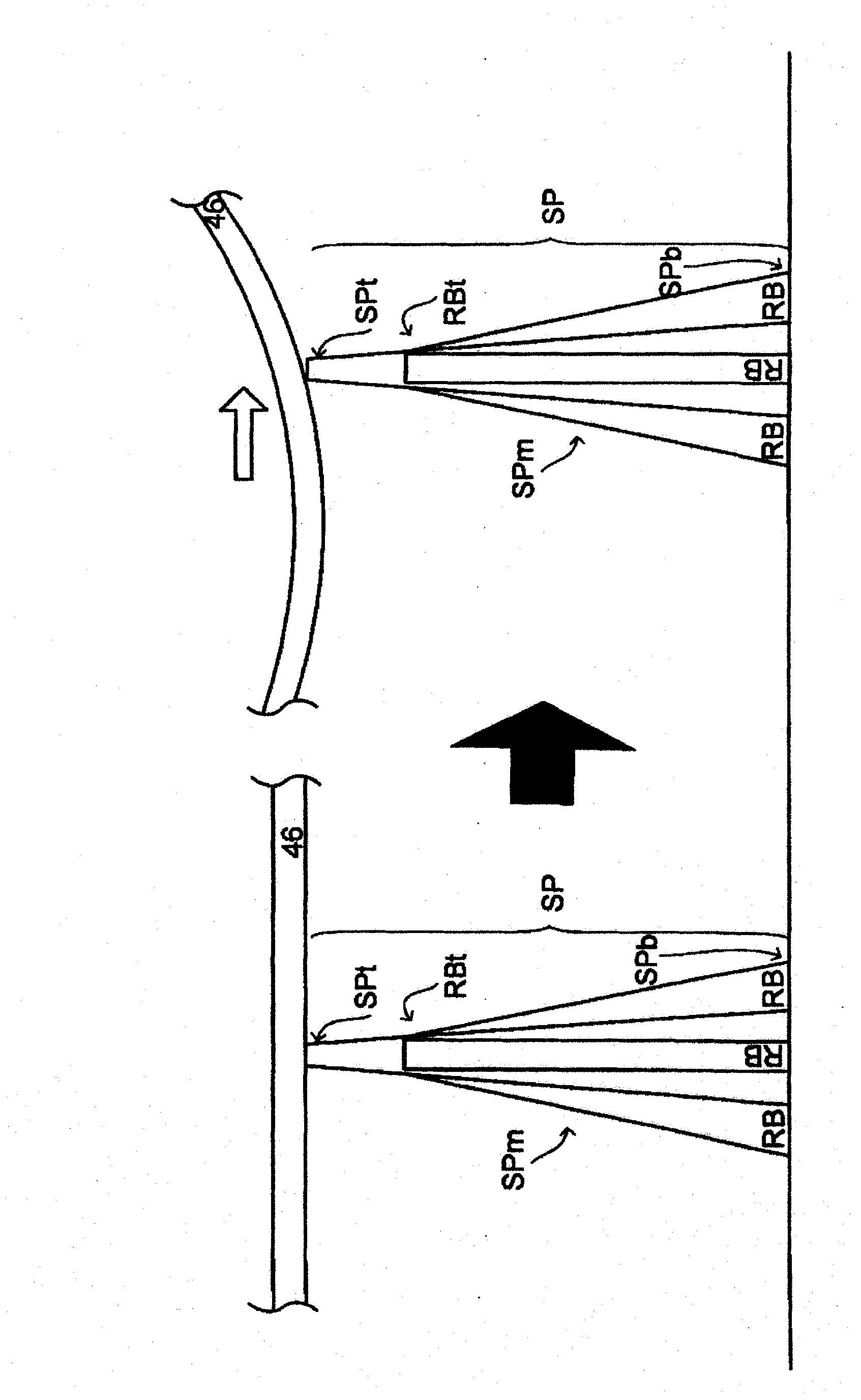

Support unit, lighting device, and display device

InactiveCN102159883AHigh strengthBending will notElongate light sourcesElectric lightingDisplay deviceEngineering

The invention provides a support unit, a lighting device and a display device. A lamp clip (LC) includes a support pin (SP) making contact with and supporting an optical sheet such as a diffusion plate (46), and also includes ribs (RB) rising from the outer periphery of the support pin (SP) and reinforcing the support pin (SP).

Owner:SHARP KK

Knee osteoarthritis rehabilitation bed

InactiveCN109009741ABending will notEasy to get hurt when bentElectrotherapyNursing bedsPatient needEnarthrosis

The invention relates to a knee osteoarthritis rehabilitation bed, which comprises a bed board, a backrest, a lifting massage device and a correcting device. The right end of the bed board is connected with the angle-adjustable backrest in the hinged mode. A square hole is formed in the middle of the bed board, and supporting columns are arranged at the bottom of the bed board. The lifting massagedevice is located in the square hole formed in the middle of the bed board. The lifting and massaging device is installed on the lower end face of the bed board. The correcting device is connected with the top of the left end of the bed board. The correcting device comprises a correcting frame, a correcting sliding column, a correcting connecting column, a correcting spring, a correcting rotary frame, two correcting clamping jaws, a clamping jaw adjustment push rod and a clamping jaw positioning board. The knee joint rehabilitation device can solve the problems in the prior art that, the position of the knee cannot be automatically adjusted during rehabilitation treatment of an existing knee arthritis patient in the prior art, the knee of the patient needs to be massaged manually, the magnet therapy of the knee cannot be carried out when the knee of the patient is massaged, and the shank of the patient cannot be bent when the knee of the patient is lifted.

Owner:刘云畅

Split training device

Owner:南京横溪农业发展有限公司

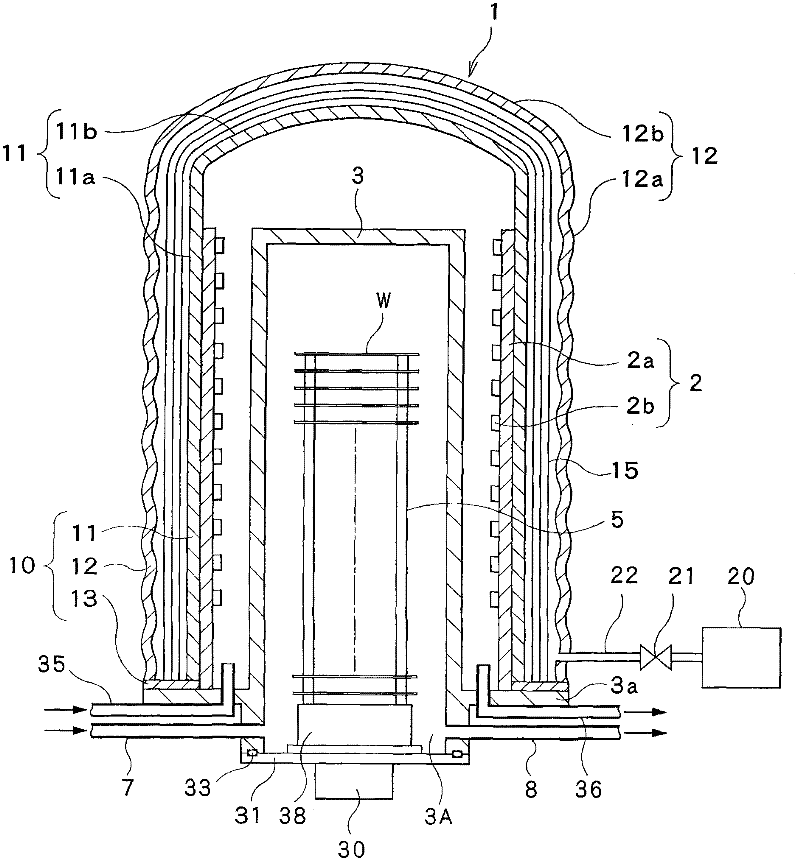

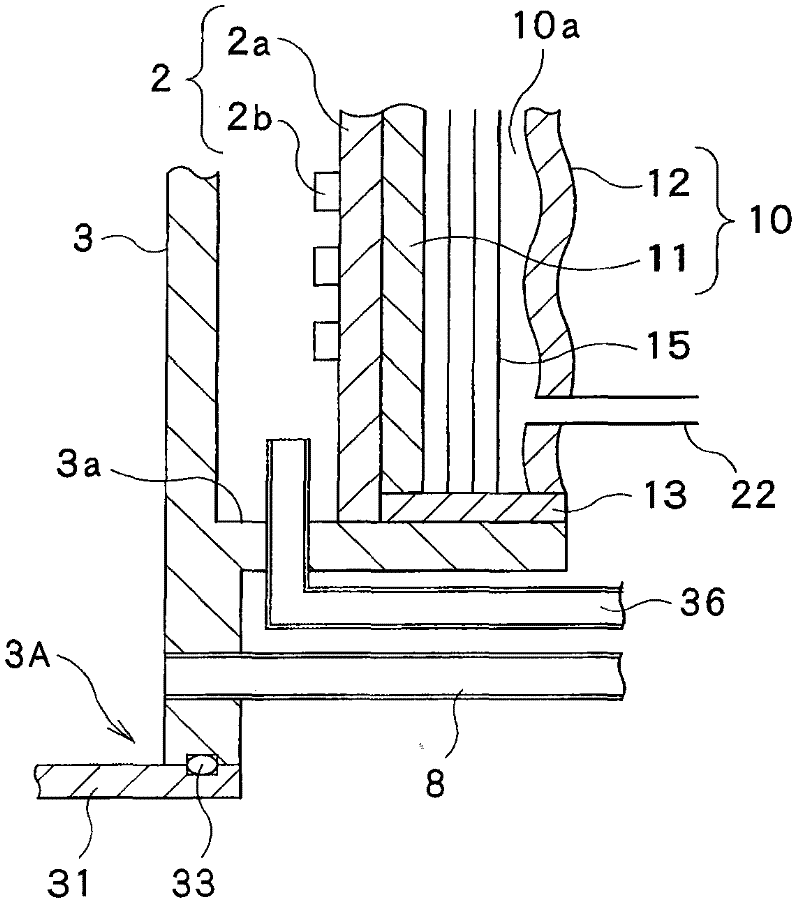

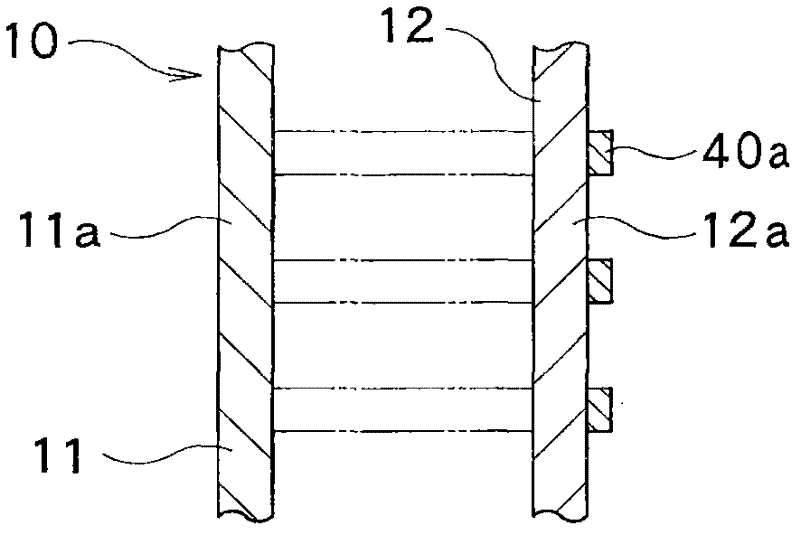

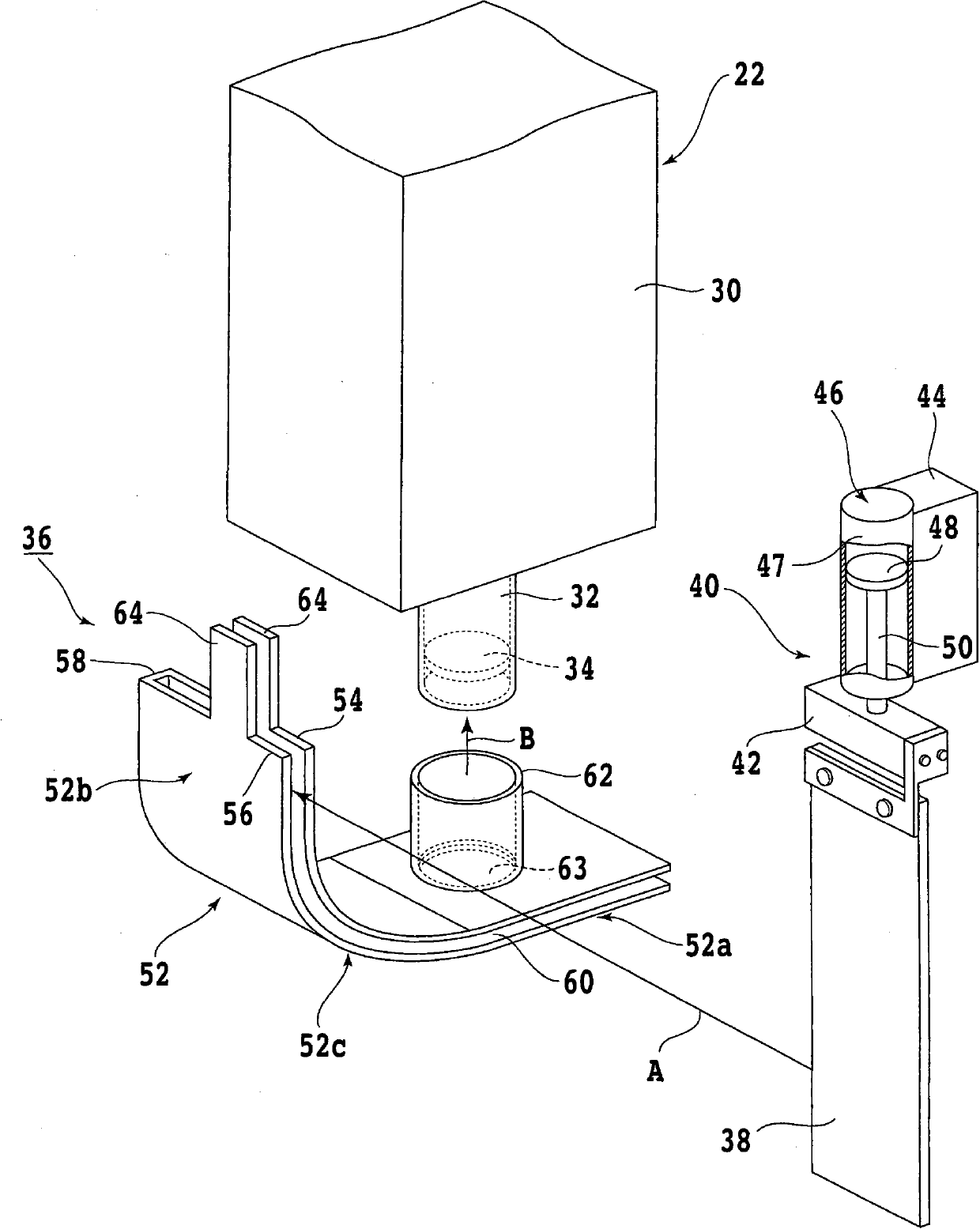

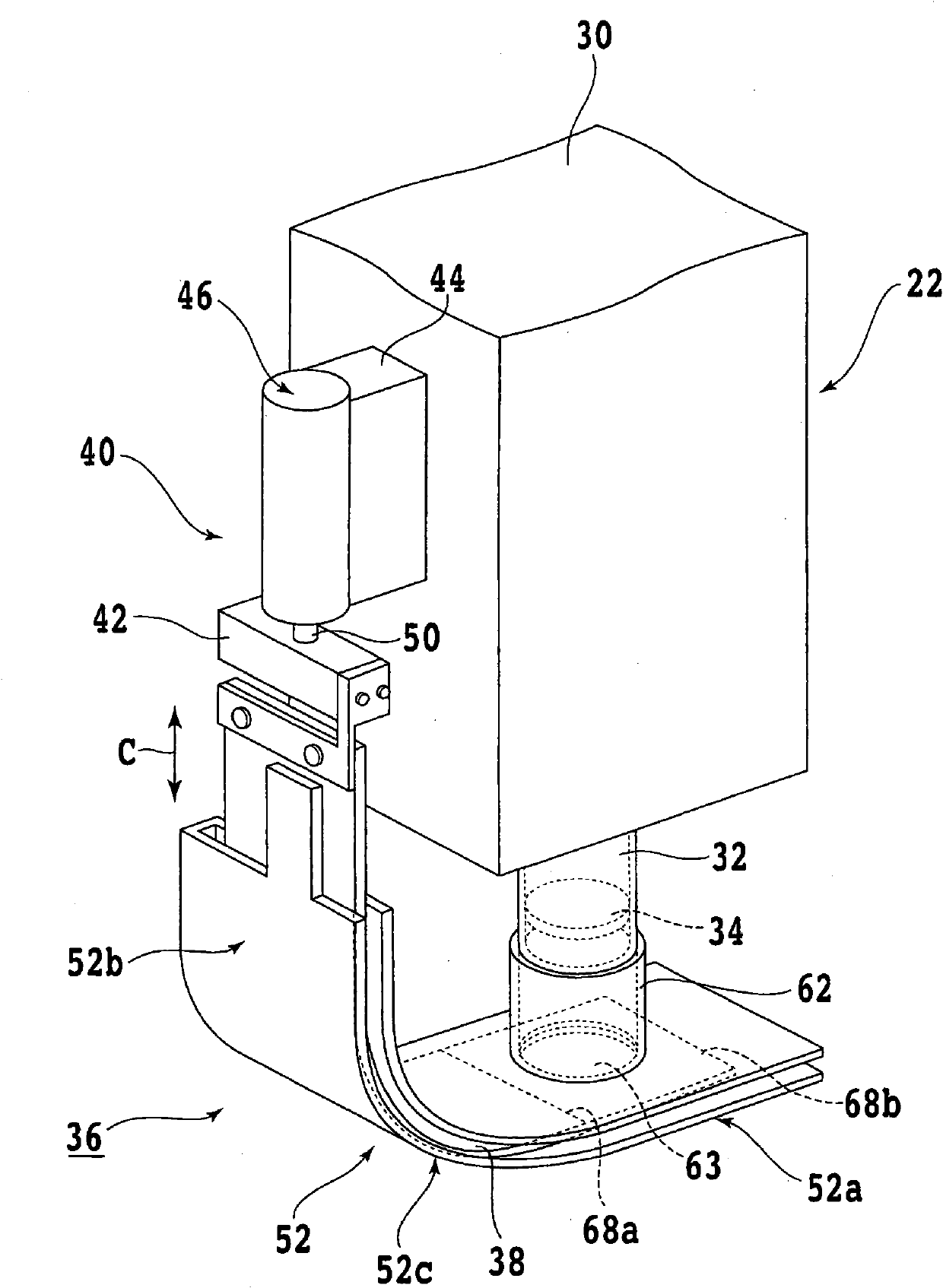

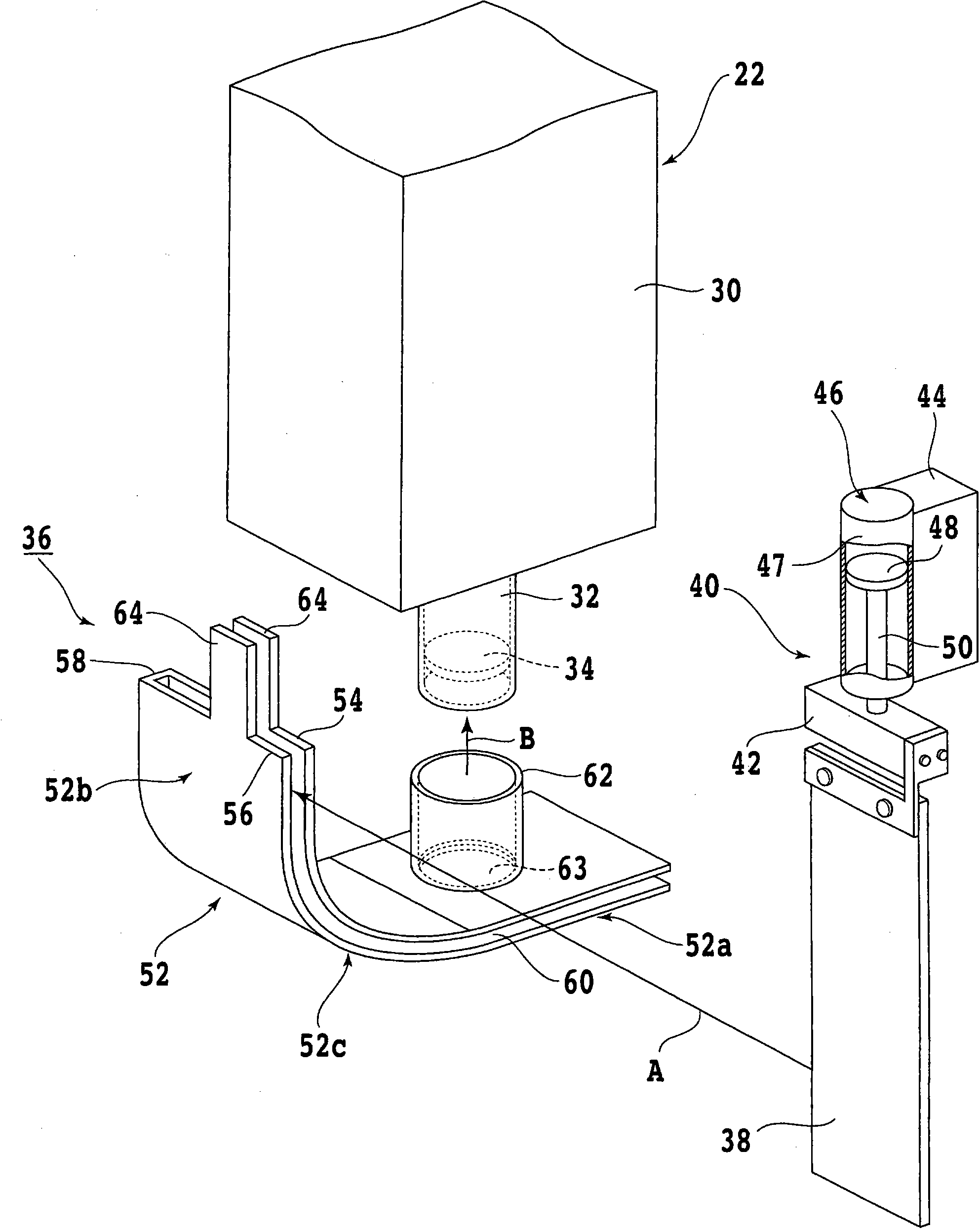

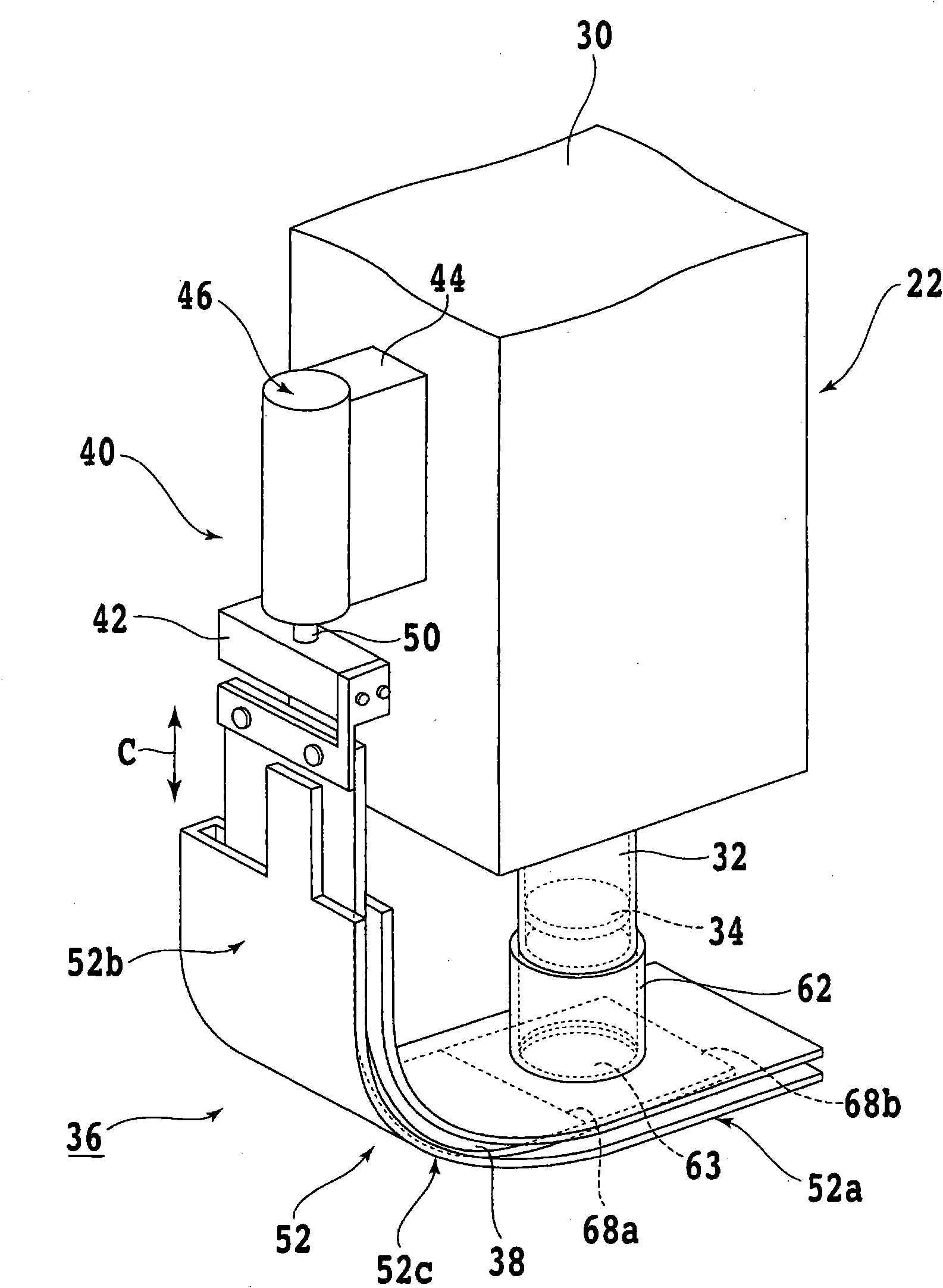

Thermal processing apparatus

InactiveCN102383112AImprove bending strengthBending will notAfter-treatment apparatusPolycrystalline material growthInsulation layerFlexural strength

There is provided a thermal processing apparatus in which the outer shell of a vacuum insulation layer-forming structure has an increased buckling strength. The thermal processing apparatus (1) includes a cylindrical reaction tube (3), a boat (5) for holding wafers W, a heater (2) provided around the reaction tube (3), and a vacuum insulation layer-forming structure (10) provided around the heater (2). The vacuum insulation layer-forming structure (10) includes an inner shell (11) and an outer shell (12) which forms a vacuum insulation layer (10a) between the outer shell (12) and the inner shell (11). The outer shell (12) is comprised of a thin plate having an undulating cross-sectional shape formed by plastic forming.

Owner:TOKYO ELECTRON LTD

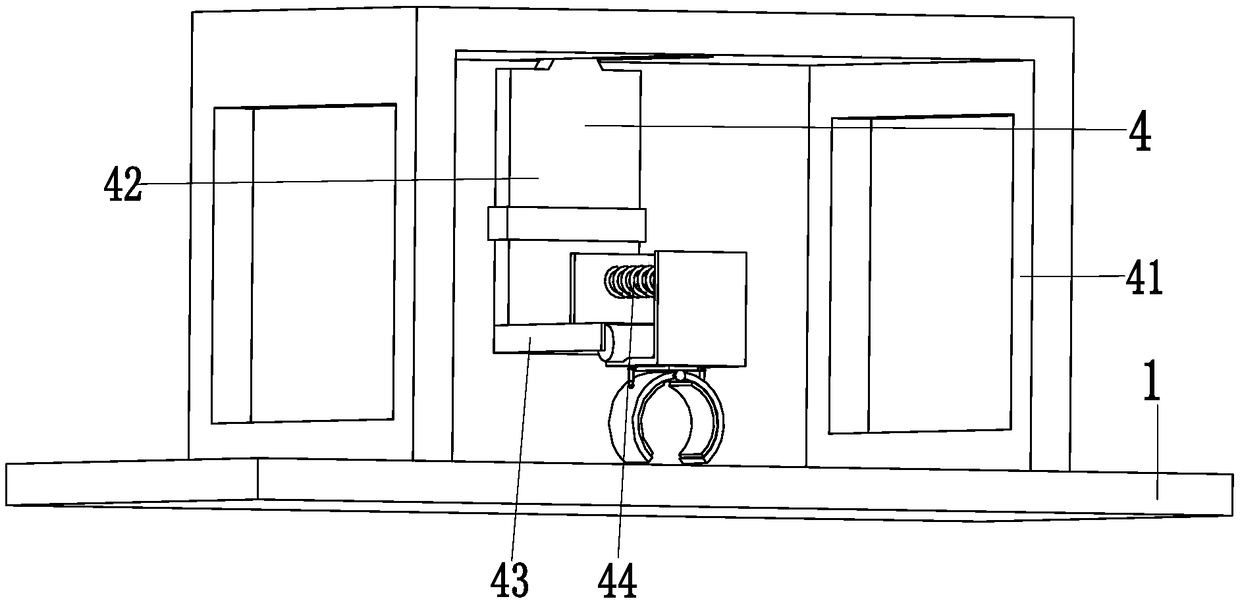

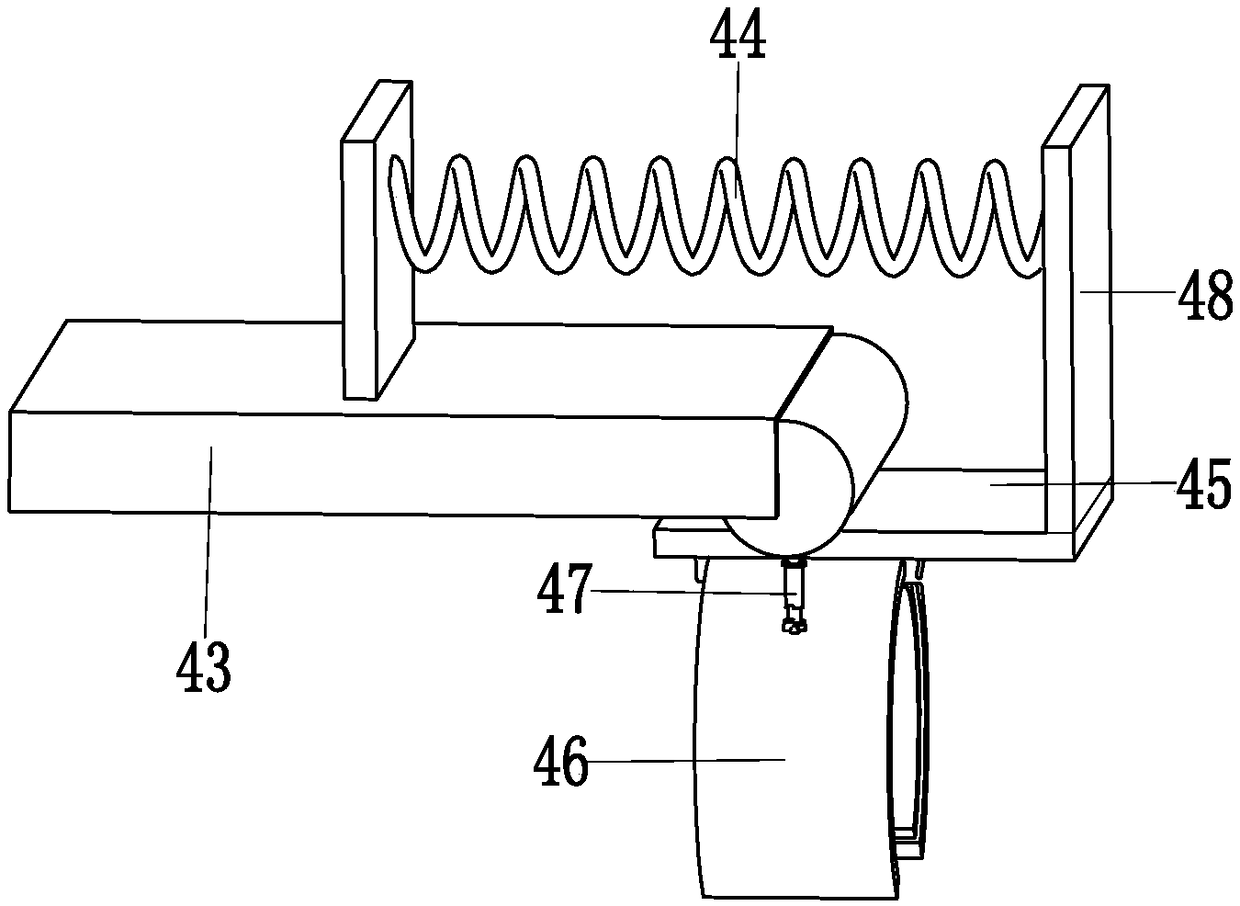

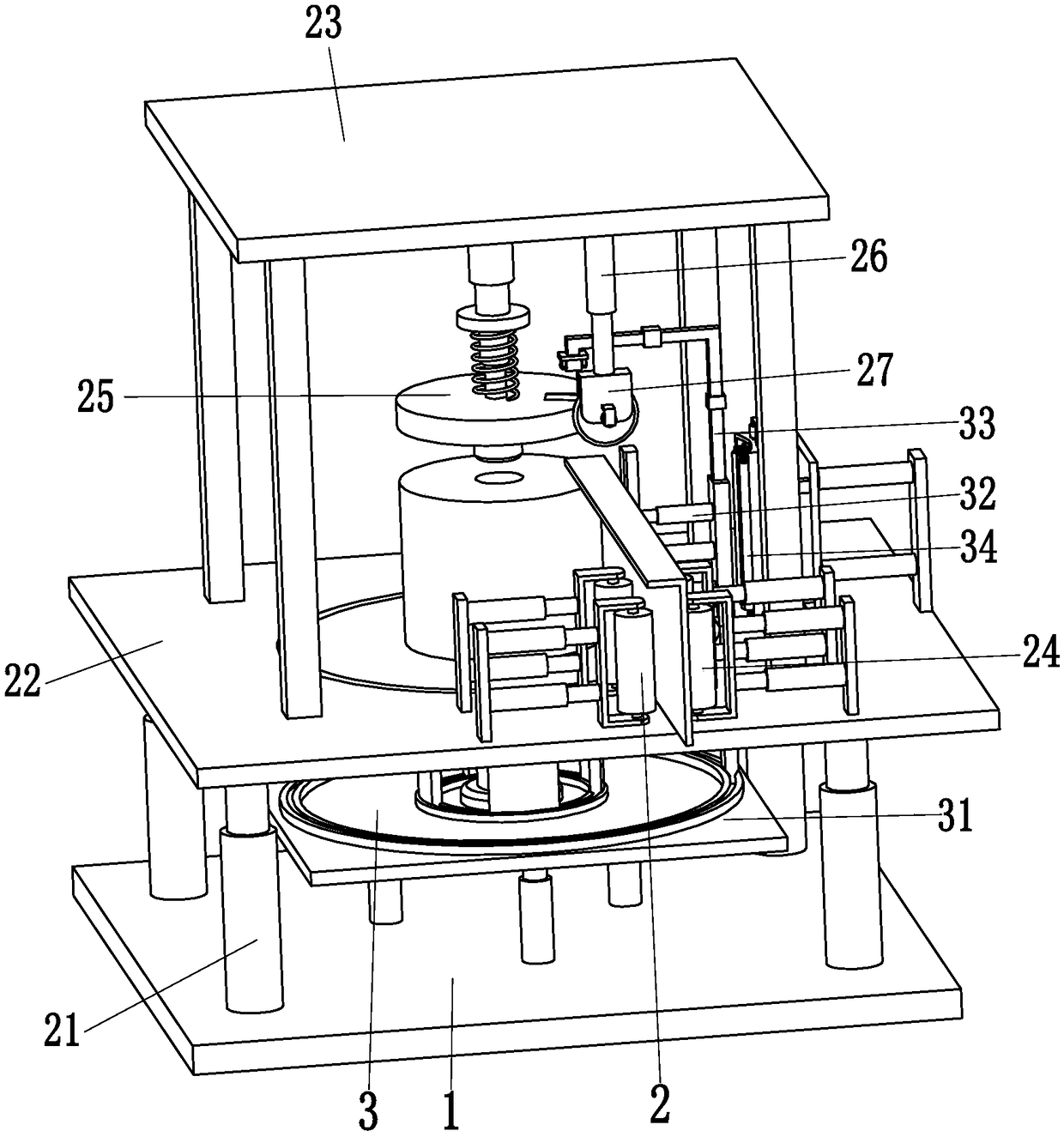

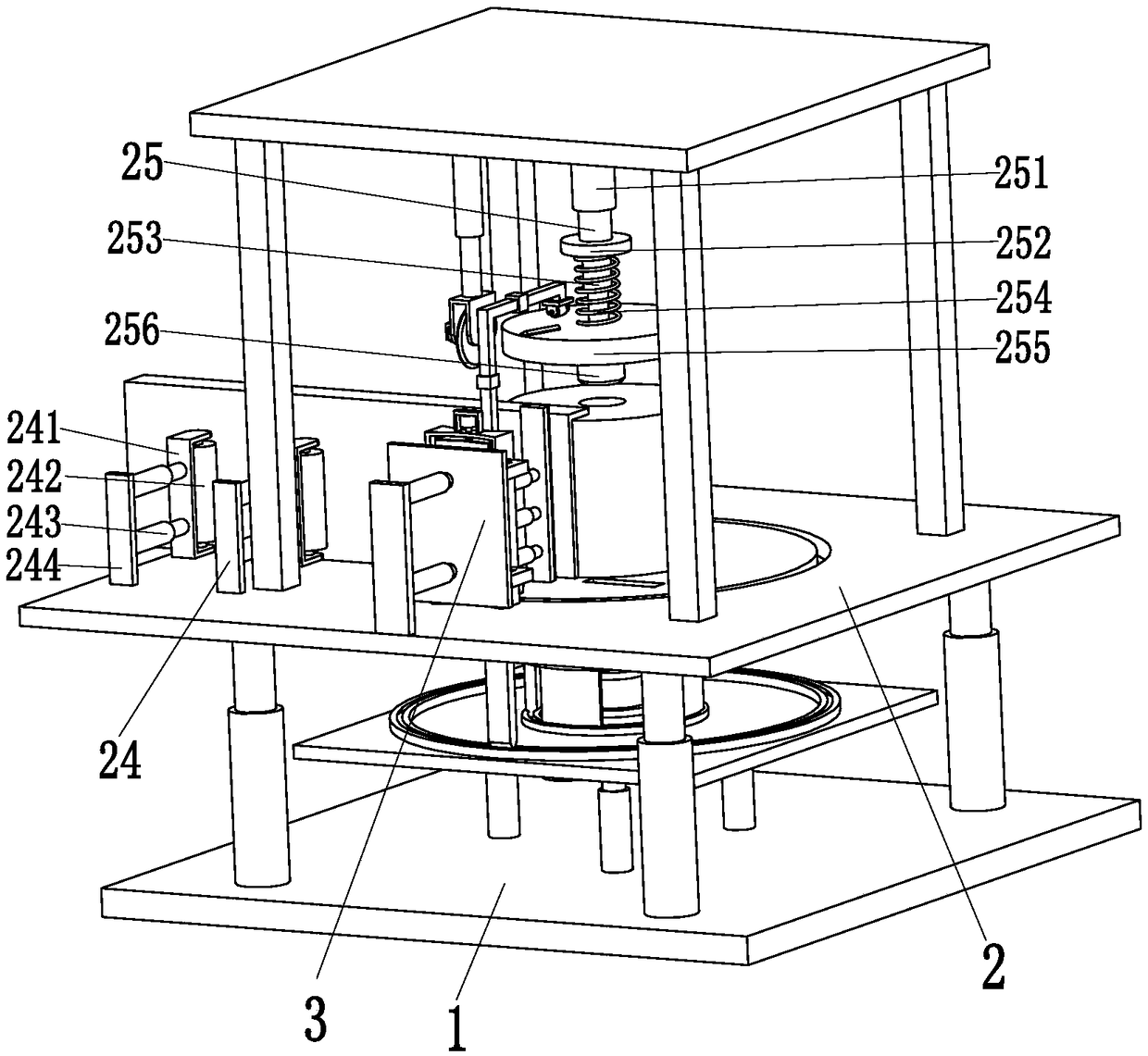

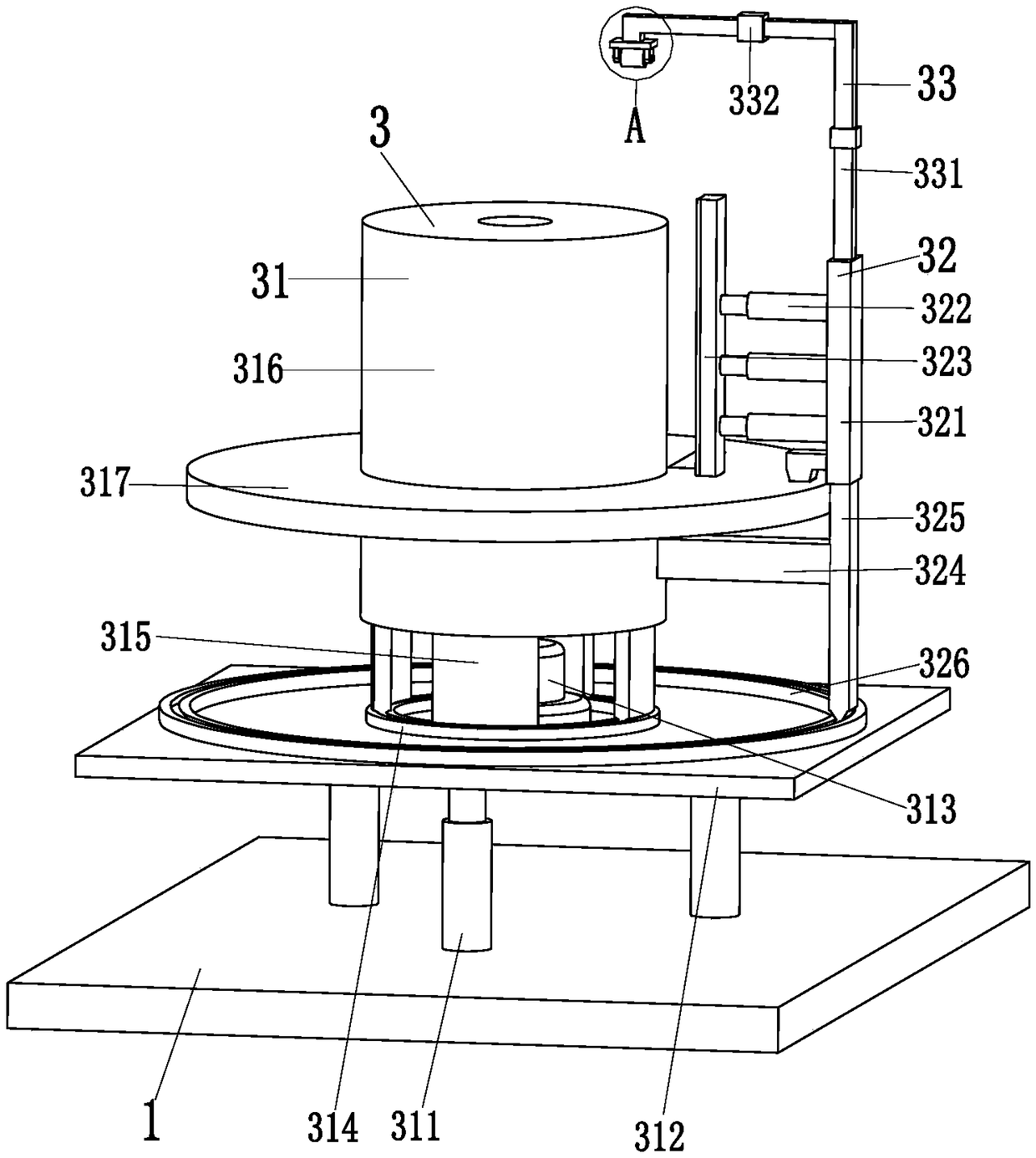

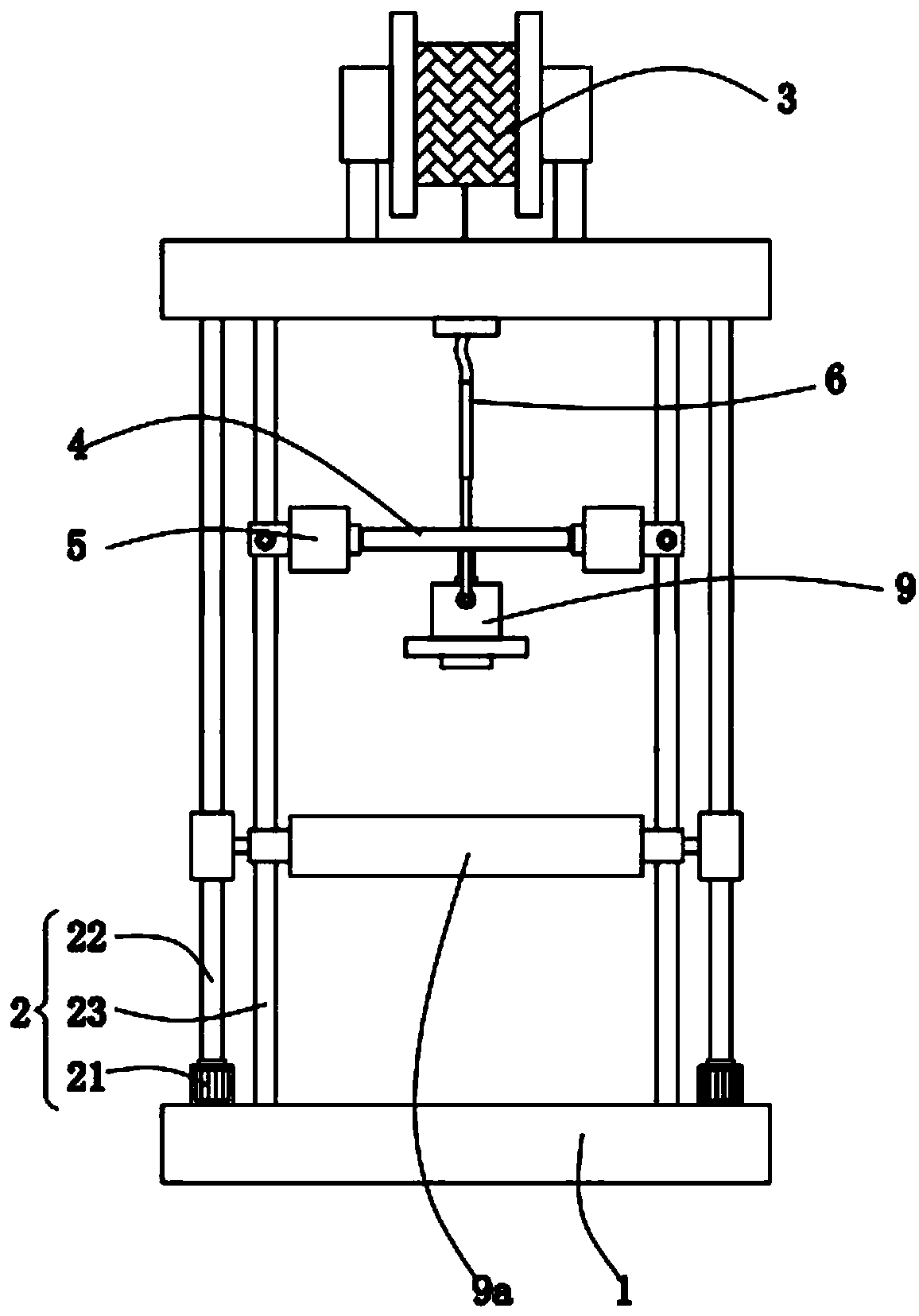

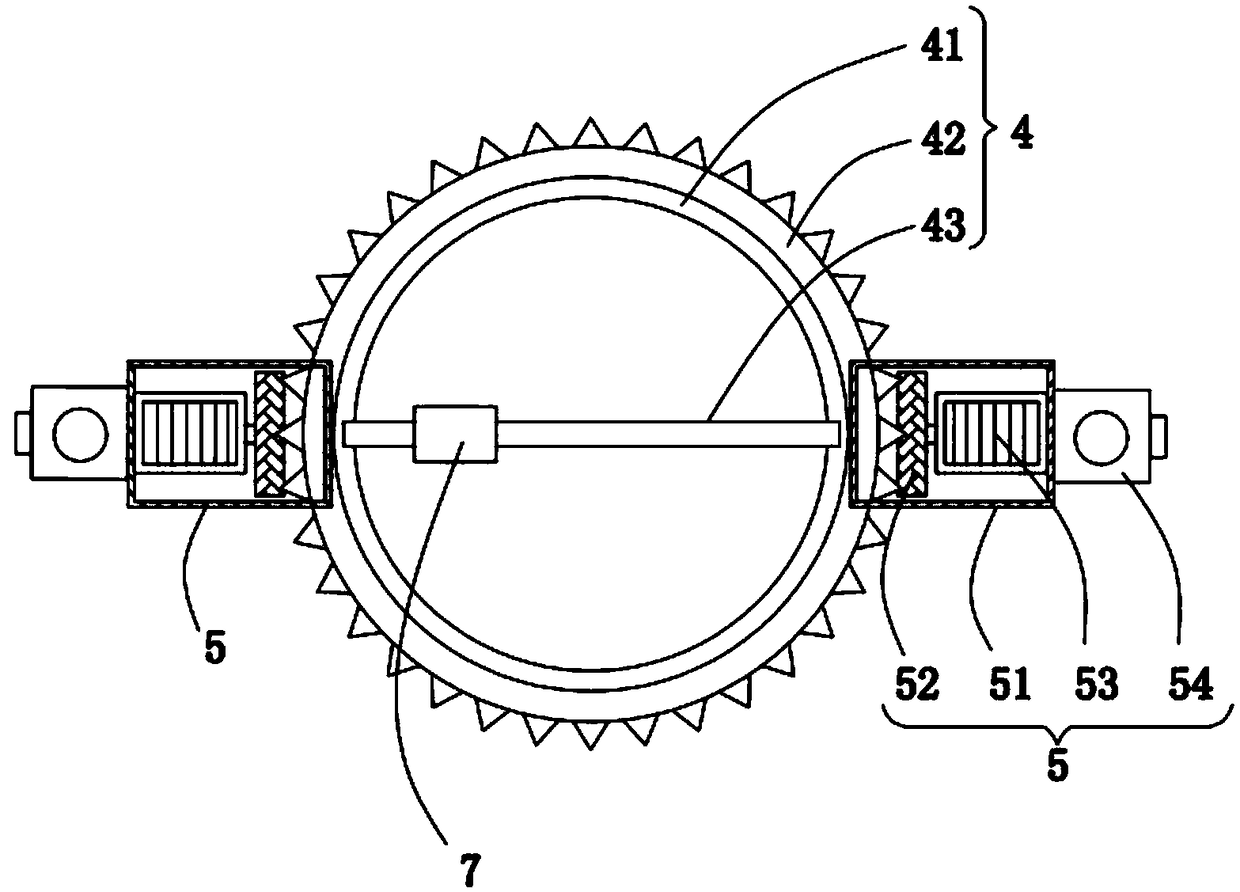

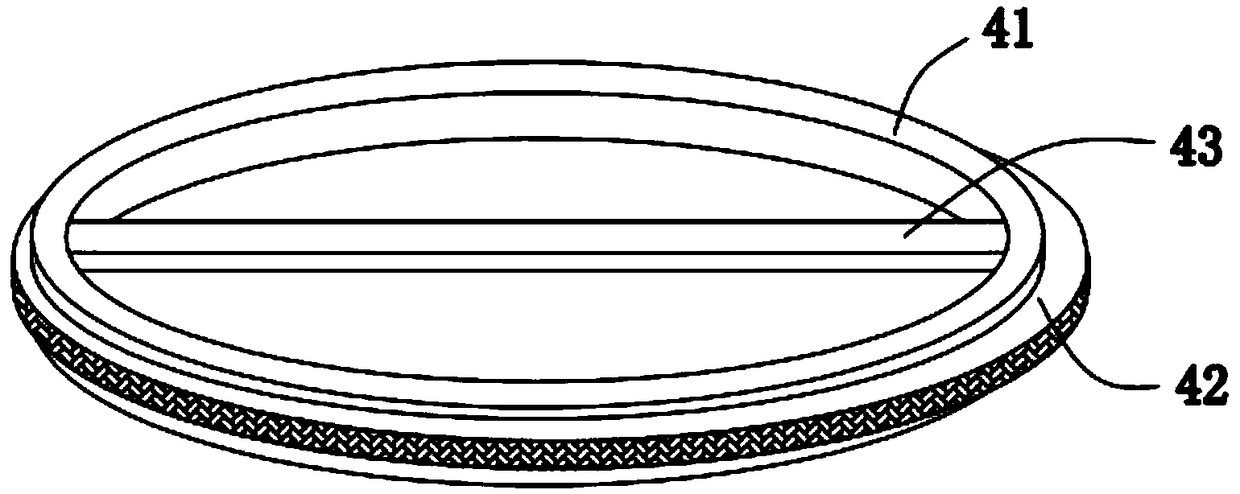

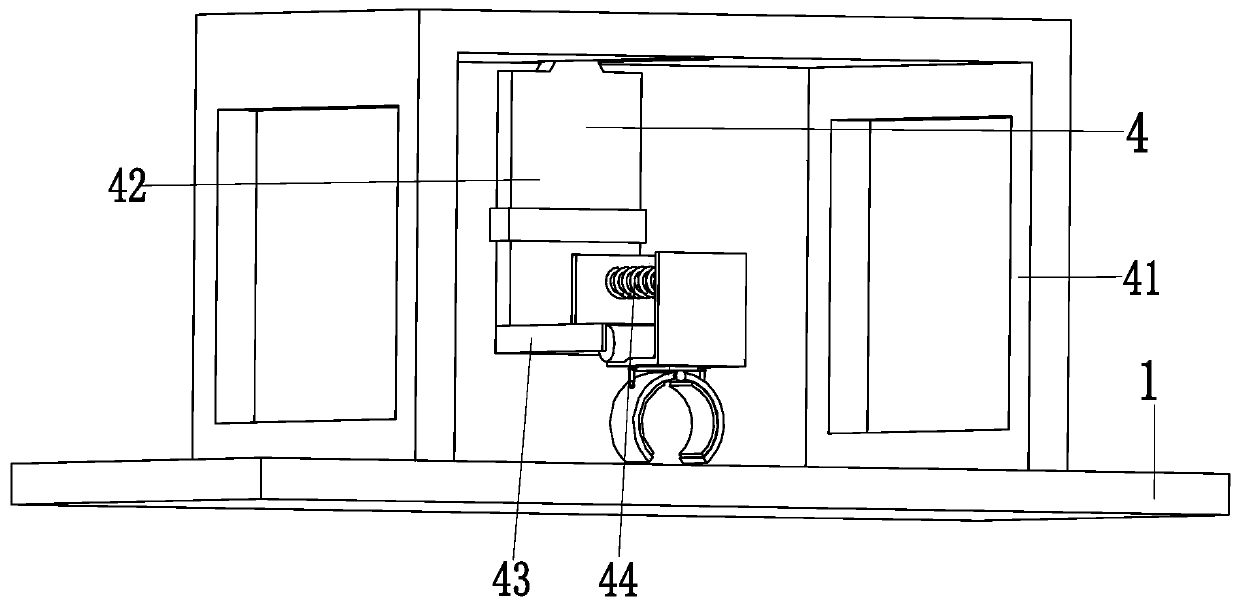

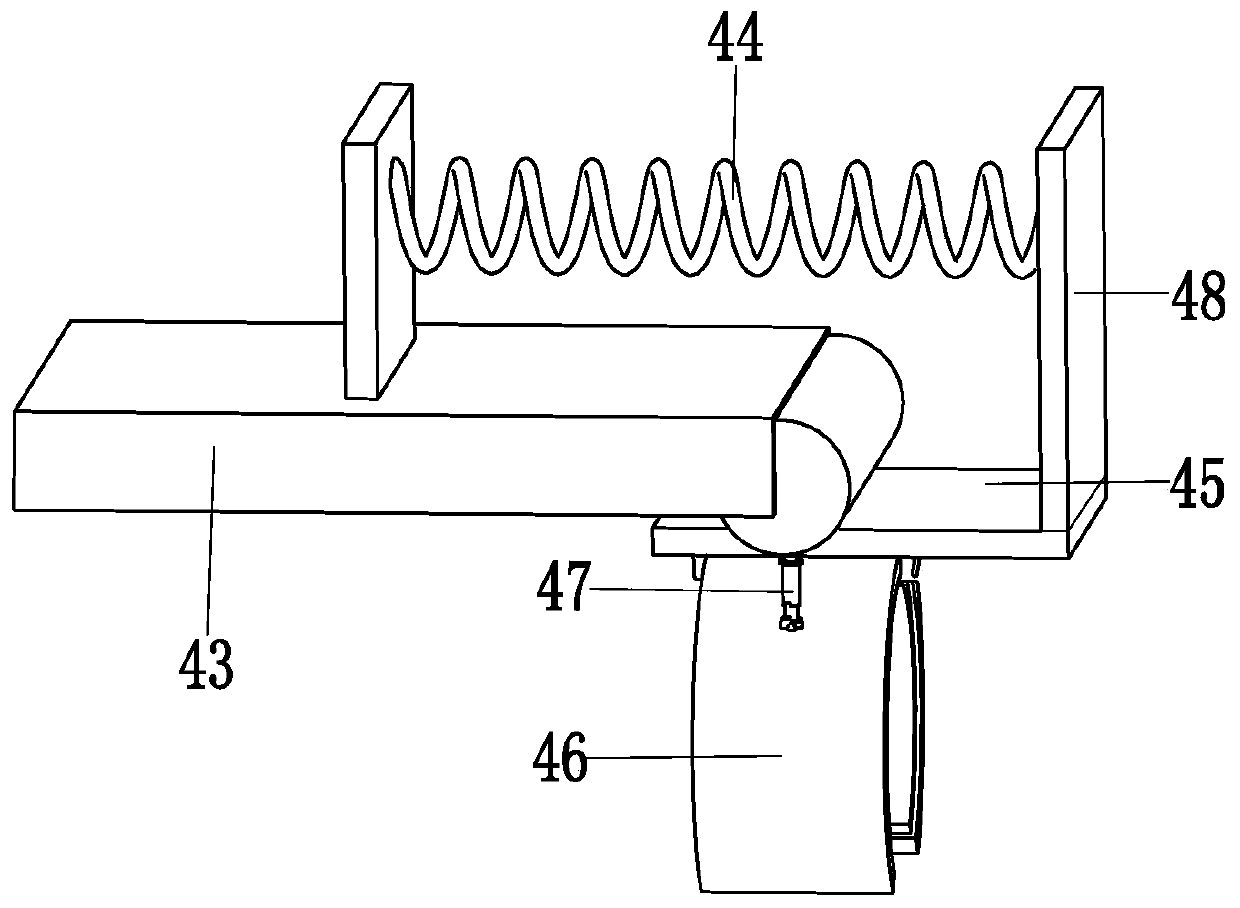

Automatic angle iron bending equipment for steel structure processing

ActiveCN108655261ASleek shapeBending will notMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention relates to automatic angle iron bending equipment for steel structure processing. The automatic angle iron bending equipment for steel structure processing comprises a supporting bottomplate, a lifting device and a bending device, wherein the bending device is mounted in the middle of the supporting bottom plate; the lifting device is mounted on the top of the outer end of the supporting bottom plate; the lifting device comprises a lifting push rod, a lifting supporting plate, a pressing supporting rack, a straightening mechanism, a pressing mechanism, a cutting hydraulic cylinder and an electric cutter. The automatic angle iron bending equipment for steel structure processing provided by the invention can solve the problems that the extrusion shape of angle iron is unsmoothwhen the angle iron is extruded annularly, the top of the angle iron will deform if being bent, the angle iron cannot be cut automatically, the unbent part cannot be limited in position when the angle iron is bent and the angle iron needs to be bent by matching with manpower and the like, and can achieve the functions of bending the angle iron, automatically cutting the angle iron and extruding the angle iron annularly.

Owner:南通蓝天彩钢结构工程有限公司

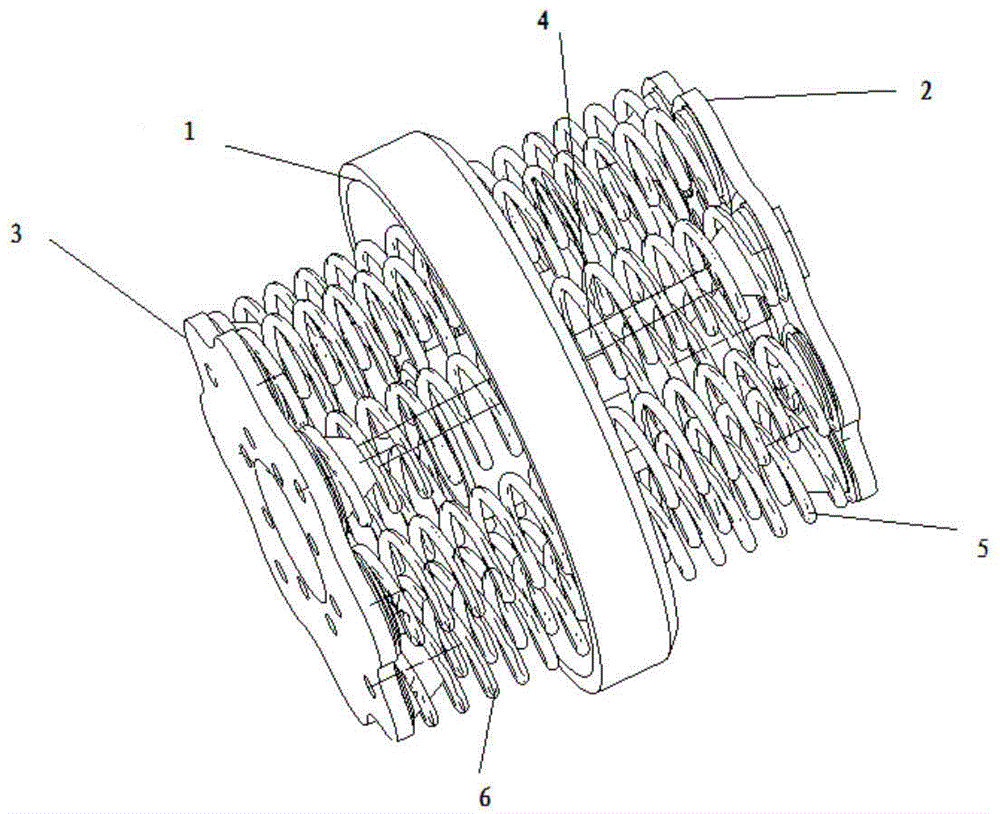

Linear compressor resonator system and linear compressor

InactiveCN105201775AAvoid bendingBending will notPositive displacement pump componentsPiston pumpsLinear compressorEngineering

A linear compressor resonator system comprises a first press plate, a second press plate and a rotor skeleton located between the first press plate and the second press plate, resonator springs are fixed between the rotor skeleton and the first press plate as well as between the rotor skeleton and the second press plate respectively, and the resonator springs between the rotor skeleton and the first press plate and the resonator springs between the rotor skeleton and the second press plate are equal in number, correspond one to one in position and arrayed coaxially. The invention further discloses a linear compressor. As the resonator springs are coaxially and uniformly arranged, bending deformation, caused by lateral force, of the resonator springs is avoided, the performance of the compressor is ensured, and the reliability of the compressor is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

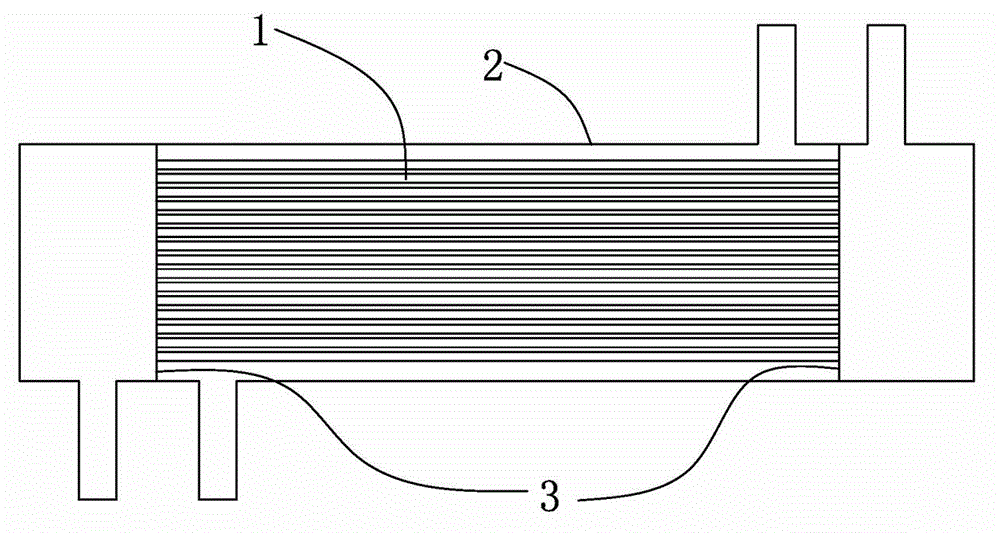

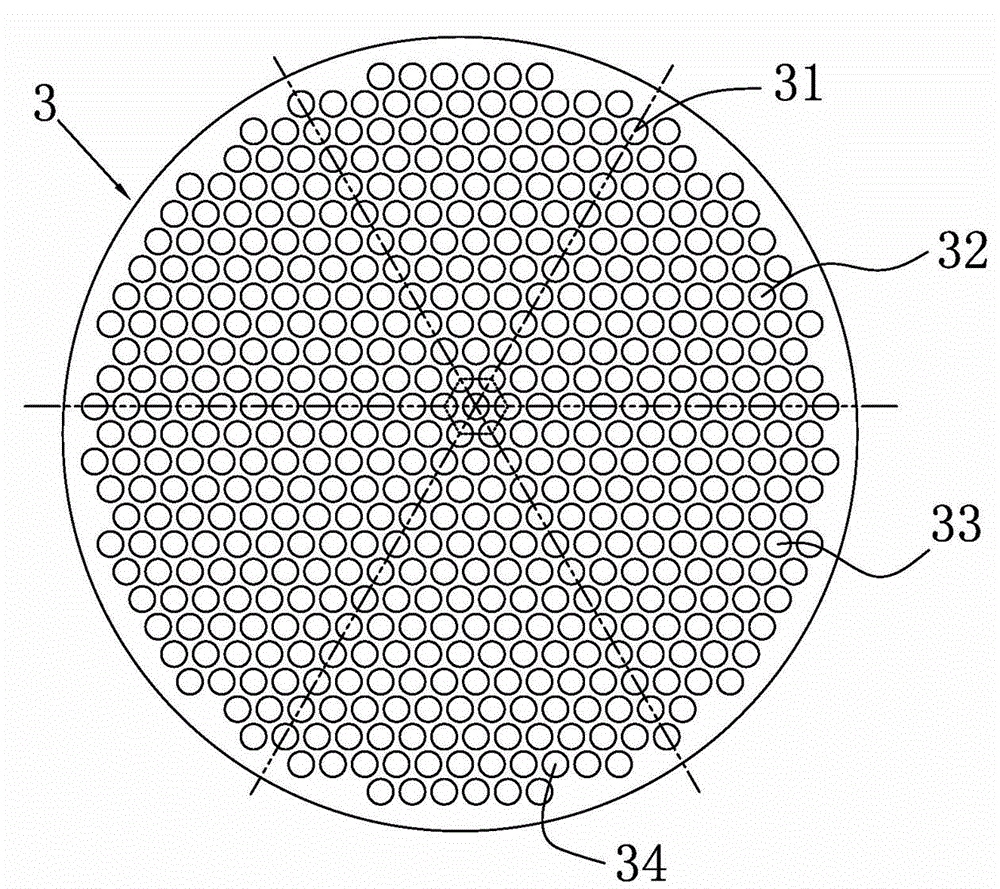

Technology for manufacturing heat exchanging device

The invention provides a technology for manufacturing heat exchanging device, and relates to the technical field of machinery manufacturing. The technology comprises the following steps: (1) opening a hole; intercepting a section of tube with opening in two ends thereof as a housing of the heat exchanging device based on the dimension requirements of a blueprint; (2) fixing disk; welding two heating exchanging tube fixing disks inside the tube, wherein the heat exchanging tube fixing disks are provided with a plurality of through holes; (3) inserting tube; vertically placing the tube which is welded with the heat exchanging tube fixing disks on a welding platform, and inserting the heat exchanging tubes into the through holes of the heat exchanging tube fixing disks; (4) grinding; adjusting the lengths of the heat exchanging tubes and removing the burrs of the heat exchanging tubes; and (5) welding; using a laser welding device to weld the heat exchanging tubes on the heat exchanging tube fixing disks under the protection of an inert gas. The provided technology for manufacturing heat exchanging device is able to weld the heat exchanging tubes having a 0.4 mm to 0.5 mm tube wall thickness on the heat exchanging tube fixing disks, and is able to prevent the heat exchanging tubes from being bent in the welding process.

Owner:涂友本

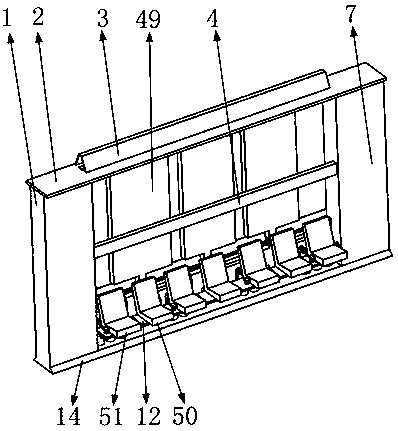

Observation deck for municipal engineering

ActiveCN109025382AWith wind resistanceTo achieve the purpose of windproofBenchesSpecial buildingEngineering

The invention belongs to the field of a windproof observation deck for municipal engineering, and particularly to the observation deck for municipal engineering. The observation deck comprises windproof observation deck unit which are successively arranged. The windproof observation deck unit comprises a seat mechanism, a windproof moving mechanism and a windproof action mechanism. The seat mechanism is mounted above the windproof action mechanism. The windproof moving mechanism is mounted on the windproof action mechanism. The seat mechanism realizes resting of sightseeing visitors and landscape observing. Furthermore the seat mechanism can trigger motion of the windproof action mechanism, thereby driving action of the windproof moving mechanism so that a wind shield mounted on the windproof moving mechanism prevents harm of blown wind to visitors, thereby performing a windproof function.

Owner:威海区域创新中心有限责任公司

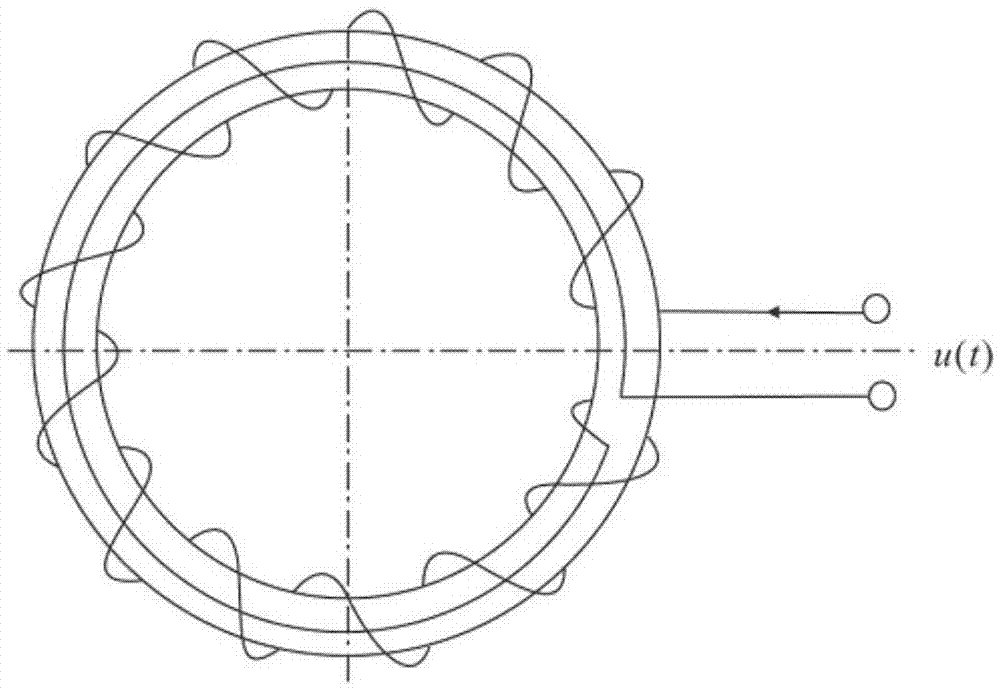

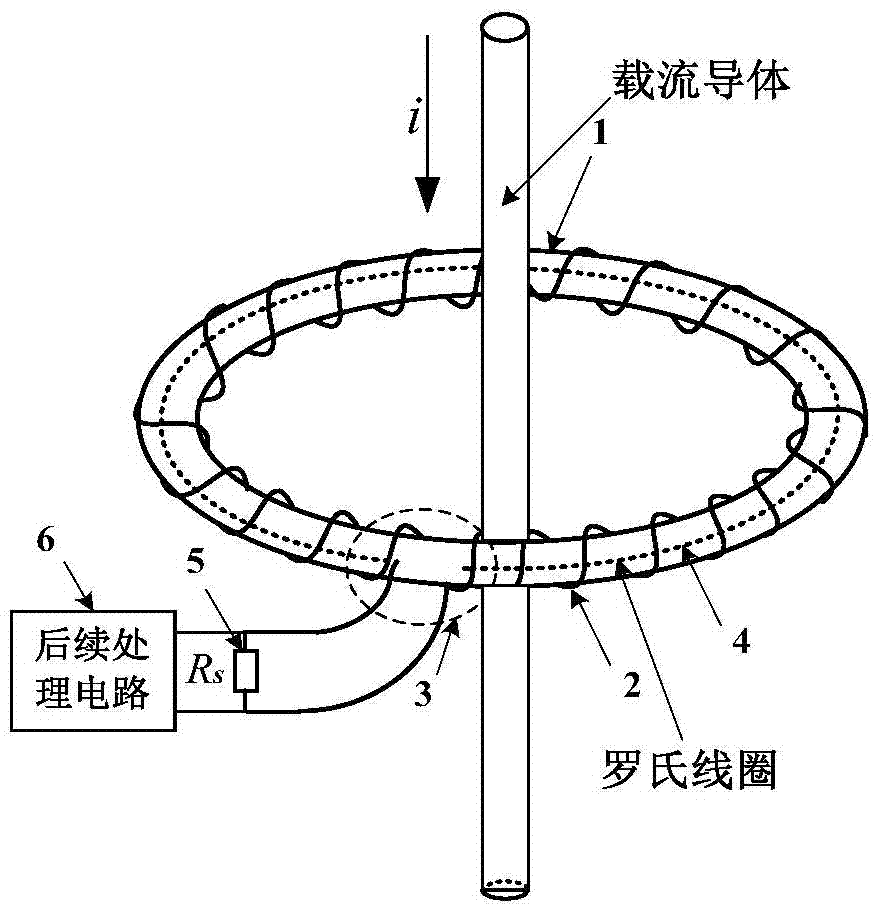

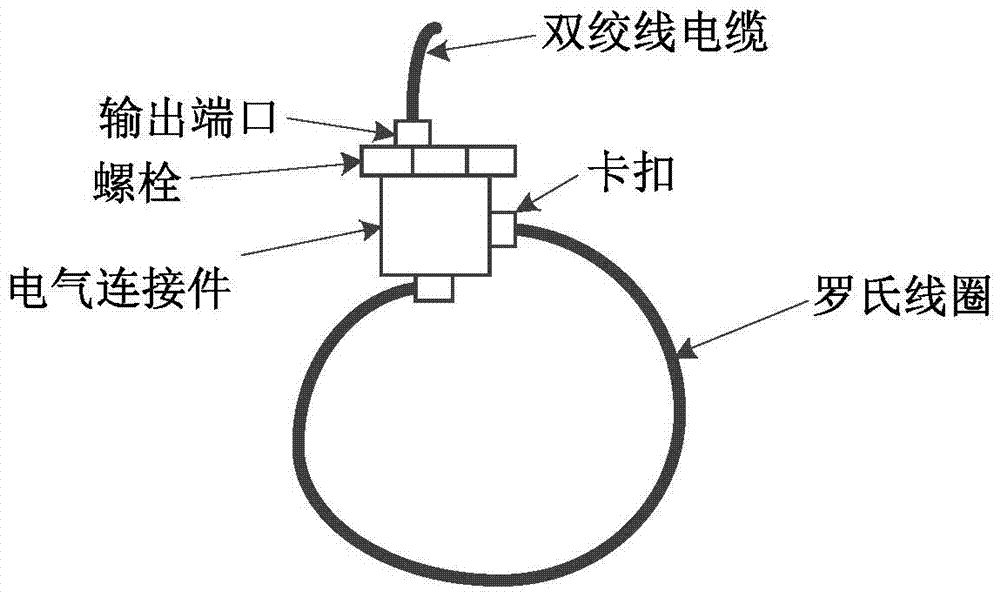

Rogowski coil based on coaxial cable framework

The invention discloses a Rogowski coil based on a coaxial cable framework. The Rogowski coil is manufactured by taking a coaxial cable from which a shielding layer is removed as a framework, taking a core wire of the coaxial cable as an unrolling wire, and uniformly winding the framework with an enameled wire. The obtained coil is arranged in an insulating bush. An active differential integrating circuit is taken as an integrating unit, and an external power supply is used for supplying power, so that a measurement frequency band of the Rogowski coil can be expanded effectively, and a current differential signal output by the Rogowski coil is reduced. A signal processing unit is used for transmitting data to a protection channel and a metering system through an output interface circuit. The Rogowski coil has high flexibility, is provided an opening, can be suitable for various complex application fields, is low in cost, is easy to manufacture, is easy for realizing mass production, and has high consistency. By adopting the Rogowski coil, high-accuracy measurement of steady-state signals and rapid response to transient signals can be realized, nanosecond high-amplitude pulse current can be measured, and very high temperature stability and vibration resistance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

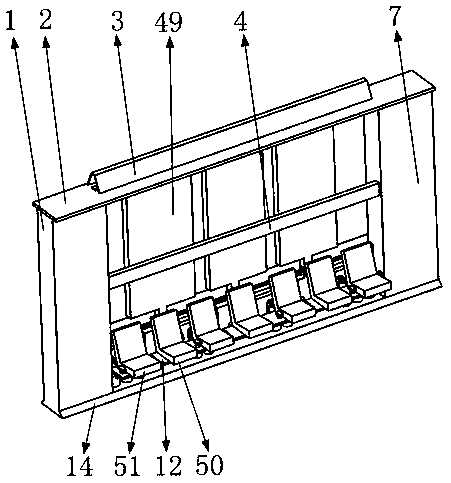

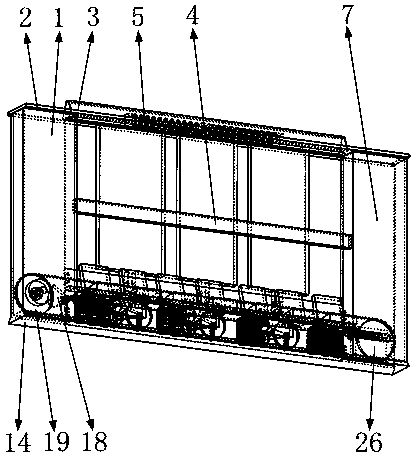

Movable windproof observation deck for municipal engineering

ActiveCN109025383AWith wind resistanceTo achieve the purpose of windproofBenchesSpecial buildingEngineering

The invention belongs to the field of a windproof observation deck for municipal engineering, and particularly to a movable windproof observation deck for municipal engineering. The movable windproofobservation deck comprises windproof observation deck unit which are successively arranged. The windproof observation deck unit comprises a seat mechanism, a windproof moving mechanism and a windproofaction mechanism. The seat mechanism is mounted above the windproof action mechanism. The windproof moving mechanism is mounted on the windproof action mechanism. The seat mechanism has realizes resting and landscape observing of sightseeing visitors. Furthermore the seat mechanism can trigger motion of the windproof action mechanism, thereby driving action of the windproof moving mechanism so that a wind shield mounted on the windproof moving mechanism prevents harm of blown wind to visitors, thereby performing a windproof function.

Owner:威海区域创新中心有限责任公司

Windproof observation deck for municipal engineering

ActiveCN109025384AWith wind resistanceTo achieve the purpose of windproofBenchesSpecial buildingEngineering

The invention belongs to the field of a windproof observation deck for municipal engineering, and particularly relates to the windproof observation deck for municipal engineering. The windproof observation deck comprises windproof observation deck unit which are successively arranged. The windproof observation deck unit comprises a seat mechanism, a windproof moving mechanism and a windproof action mechanism. The seat mechanism is mounted above the windproof action mechanism. The windproof moving mechanism is mounted on the windproof action mechanism. The seat mechanism realizes functions of resting of sightseeing visitors and landscape observing. Furthermore the seat mechanism can trigger motion of the windproof action mechanism, thereby driving action of the windproof moving mechanism sothat a wind shield mounted on the windproof moving mechanism prevents harm of blown wind to visitors, thereby performing a windproof function.

Owner:山东可可西里科技有限公司

Off-line type 3D intelligent printing device

ActiveCN109203475AShort strokeImprove processing efficiencyManufacturing driving means3D object support structuresEngineeringInjection molding machine

The invention relates to the technical field of 3D printers, in particular to an off-line type 3D intelligent printing device. The off-line 3D type intelligent printing device comprises a fixed seat,first driving mechanisms, an injection molding head, a machining plate, and a coiling frame, and further comprises an orientation adjusting mechanism, second driving mechanisms, a protecting mechanism, a displacement mechanism and a connecting mechanism. According to the off-line type 3D intelligent printing device, the injection molding head can realize an oblique line movement and does not needto carry out a transverse movement and a longitudinal movement, and thus movement course of the injection molding head is effectively shortened and the machining efficiency is improved; because the injection molding head is connected to a connecting rod through a movable joint, and thus the injection molding head does not follow a center rod to move under the gravity action, discharging position is more accurate and has no deviation, and profile distortion can further be avoided; and in the moving process of the displacement mechanism, a limiting rod rotates and carries out a telescopic movement along a limiting pipe at the same time, a hose can follow moving position of the displacement mechanism to bend, and thus profile can be transferred in a straight-line mode without bending drastically.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

A knee osteoarthritis rehabilitation bed

InactiveCN109009741BBending will notEasy to get hurt when bentElectrotherapyNursing bedsPhysical medicine and rehabilitationKnee Joint

The invention relates to a knee osteoarthritis rehabilitation bed, which comprises a bed board, a backrest, a lifting massage device and a correcting device. The right end of the bed board is connected with the angle-adjustable backrest in the hinged mode. A square hole is formed in the middle of the bed board, and supporting columns are arranged at the bottom of the bed board. The lifting massagedevice is located in the square hole formed in the middle of the bed board. The lifting and massaging device is installed on the lower end face of the bed board. The correcting device is connected with the top of the left end of the bed board. The correcting device comprises a correcting frame, a correcting sliding column, a correcting connecting column, a correcting spring, a correcting rotary frame, two correcting clamping jaws, a clamping jaw adjustment push rod and a clamping jaw positioning board. The knee joint rehabilitation device can solve the problems in the prior art that, the position of the knee cannot be automatically adjusted during rehabilitation treatment of an existing knee arthritis patient in the prior art, the knee of the patient needs to be massaged manually, the magnet therapy of the knee cannot be carried out when the knee of the patient is massaged, and the shank of the patient cannot be bent when the knee of the patient is lifted.

Owner:刘云畅

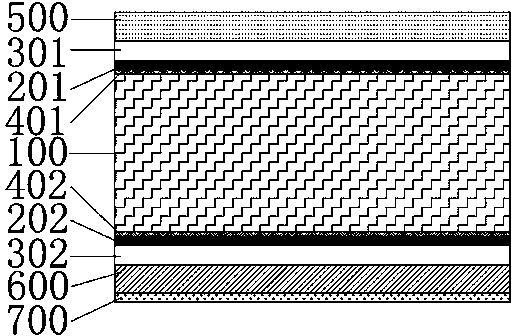

Method for manufacturing substrate of LED thin film chip and structure of substrate

ActiveCN104362224AImprove reliabilityImprove adhesionSemiconductor devicesThermal dilatationSemiconductor materials

The invention provides a method for manufacturing a substrate of an LED thin film chip and a structure of the substrate. The method and the structure have the advantages that an alloy preparation layer is manufactured on the surface of a substrate support material, a binary blended layer is formed by alloy and the substrate support material, and accordingly a semiconductor material and metal interface which is high in reliability can be obtained; a stress modulation layer is formed below the substrate support material, and a thermal expansion coefficient of the stress modulation layer can be adjusted, so that stress which is exerted to the substrate by an LED thin film positioned on the upper side of the substrate can be balanced, and the problem of bending of existing substrates can be solved; the structural strength and the thickness of the stress modulation layer can be adjusted, so that the bending resistance of the can be improved.

Owner:NANCHANG UNIV +1

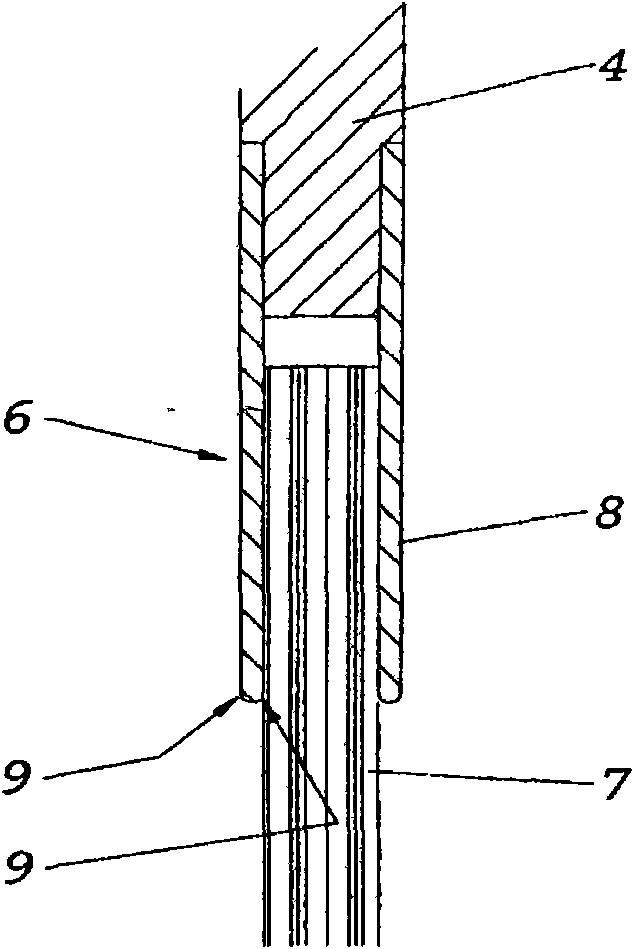

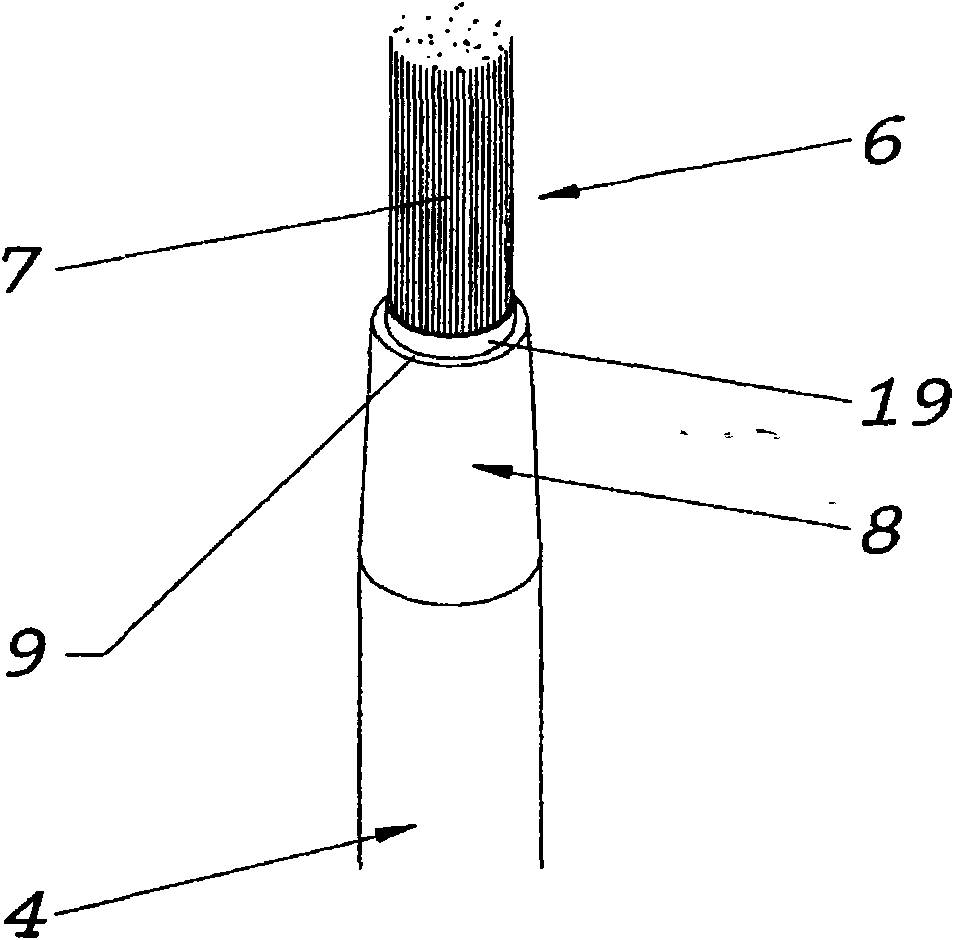

Cosmetic applying device

The invention provides a cosmetic applying device with a brush embedded in the tail end, wherein the bristles of the brush can be prevented from being fractured. The cosmetic applying device comprises an applying stick (4) and an applying part (6), wherein the applying part (6) is provided with the brush (7) which is fixedly installed on the tail end of the applying stick (4) by a cylindrical bag (8). The cosmetic applying device is characterized in that the corner parts of the inner surface and the outer surface of the bag (8) are subjected to chamfering and have no sharpen-pointed edges; besides, a thin and soft protection pipe (19) is arranged between the brush (7) and the bag (8), and the tail end of the pipe (19) extends a little bid out of the tail end of the bag (8), thereby preventing the brush (7) from bending into an acute angle to cause the fracture of the bristles of the brush.

Owner:KATSUSHIKA

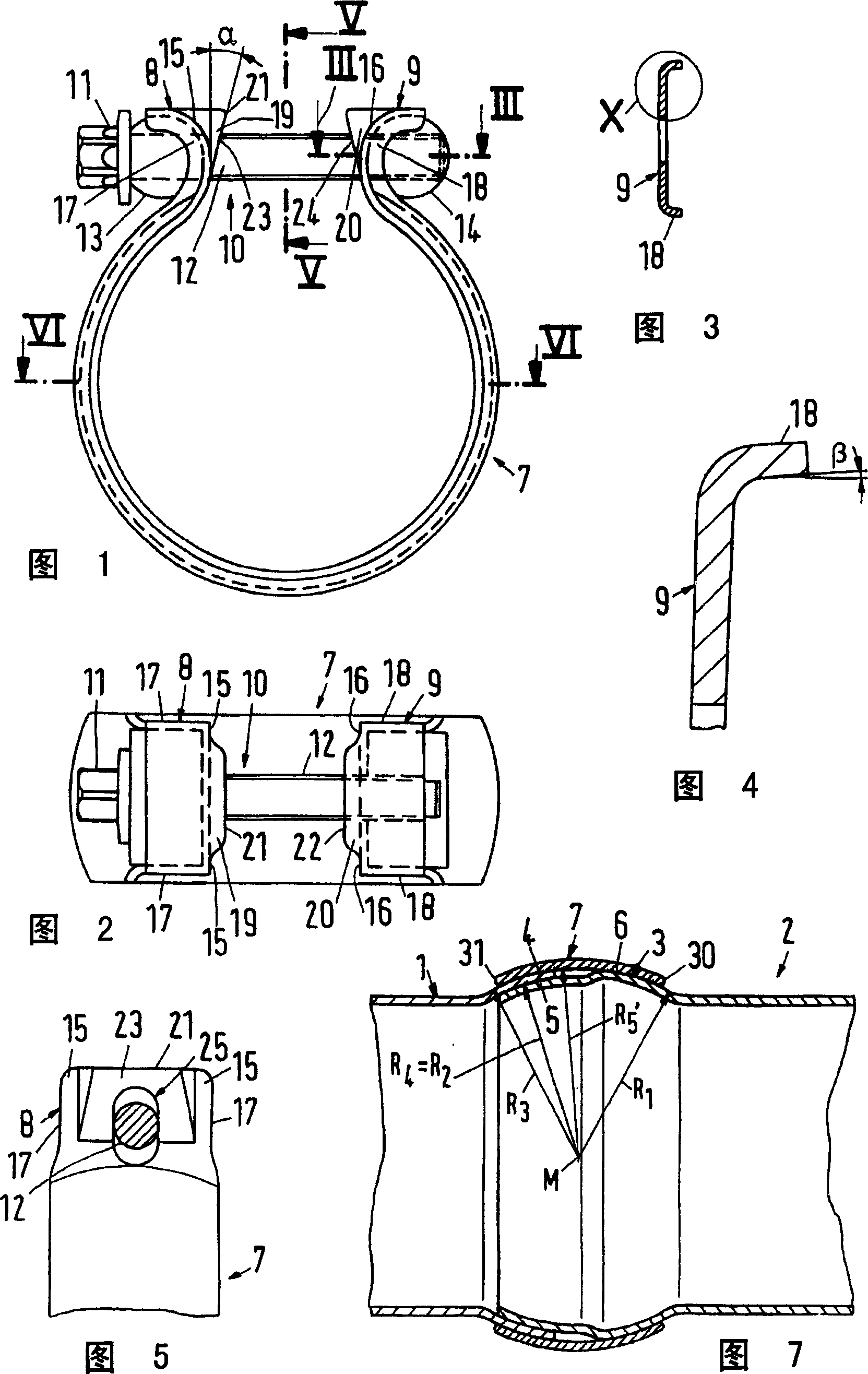

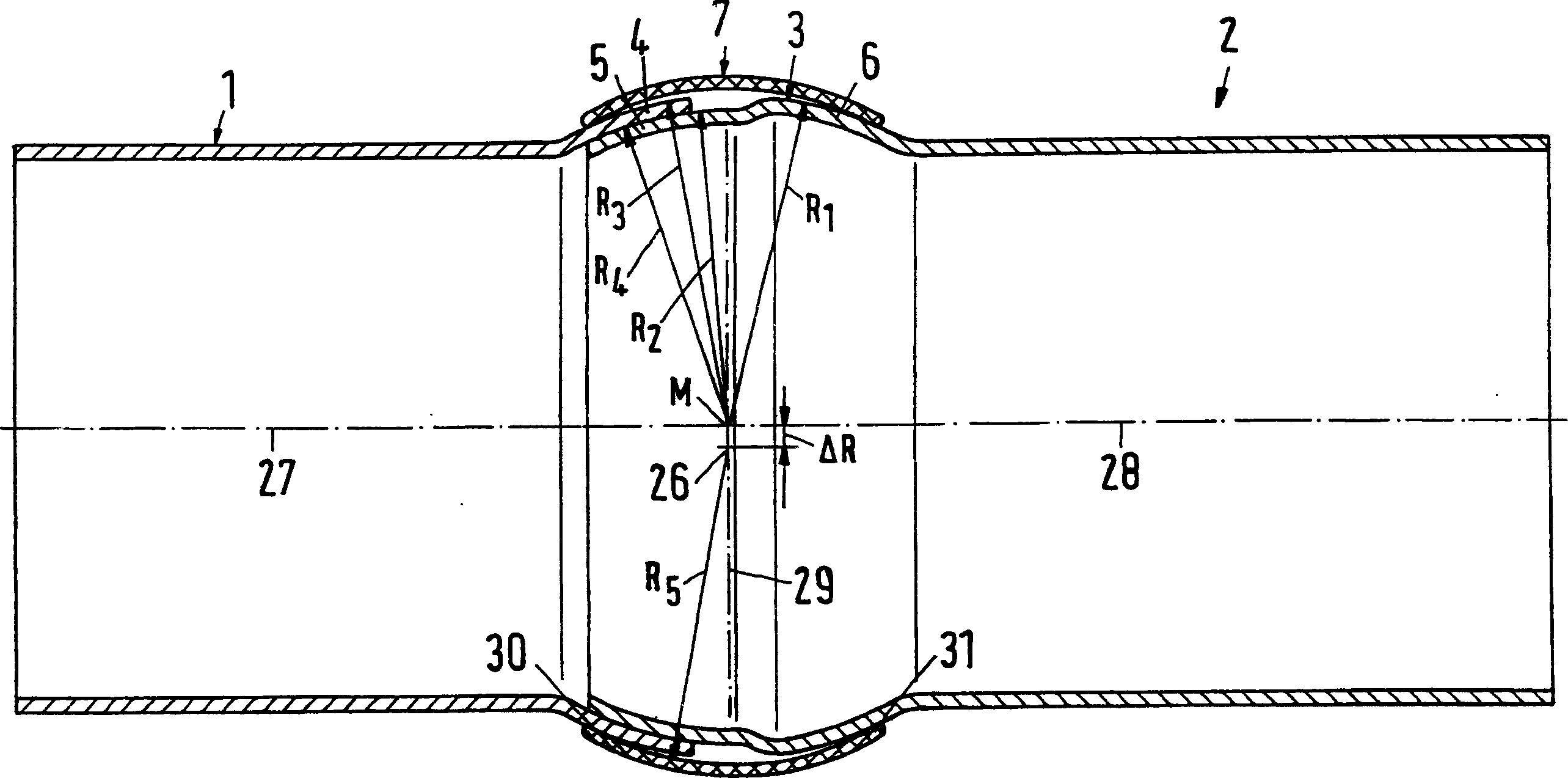

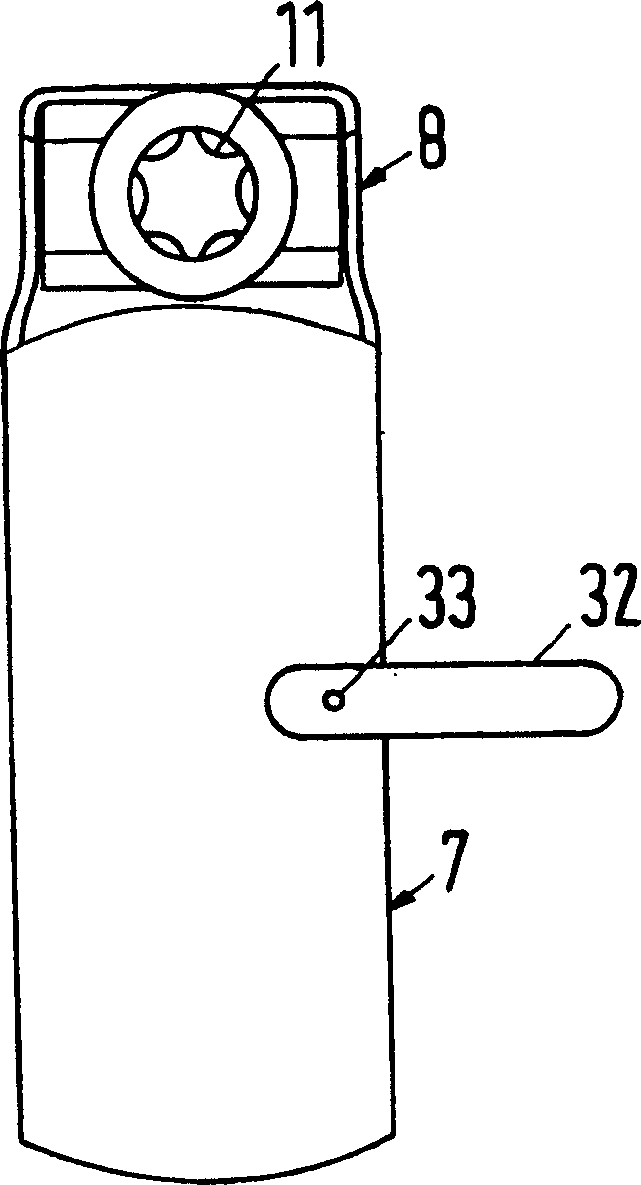

Pipe clamp

InactiveCN1580622ABending will notReduce surface pressureSleeve/socket jointsExhaust apparatusEngineeringMechanical engineering

Pipe clip has a transverse axis (26) around which a tensioned clip band (7) is bent at a distance (DELTAR) from the middle point of ball zones (4, 5, 6). The inner radius of the bent of the tensioned clip band around the transverse axis is smaller than the outer radius of the ball zones so that the sum of the distance (DELTAR) and the inner radius of the bend is larger than the outer radius of the ball zones. An Independent claim is also included for a connecting arrangement of two pipes and the pipe clip. Preferred Features: The inner peripheral edges (30, 31) of the clip band are rounded.

Owner:NORMA GERMANY GMBH

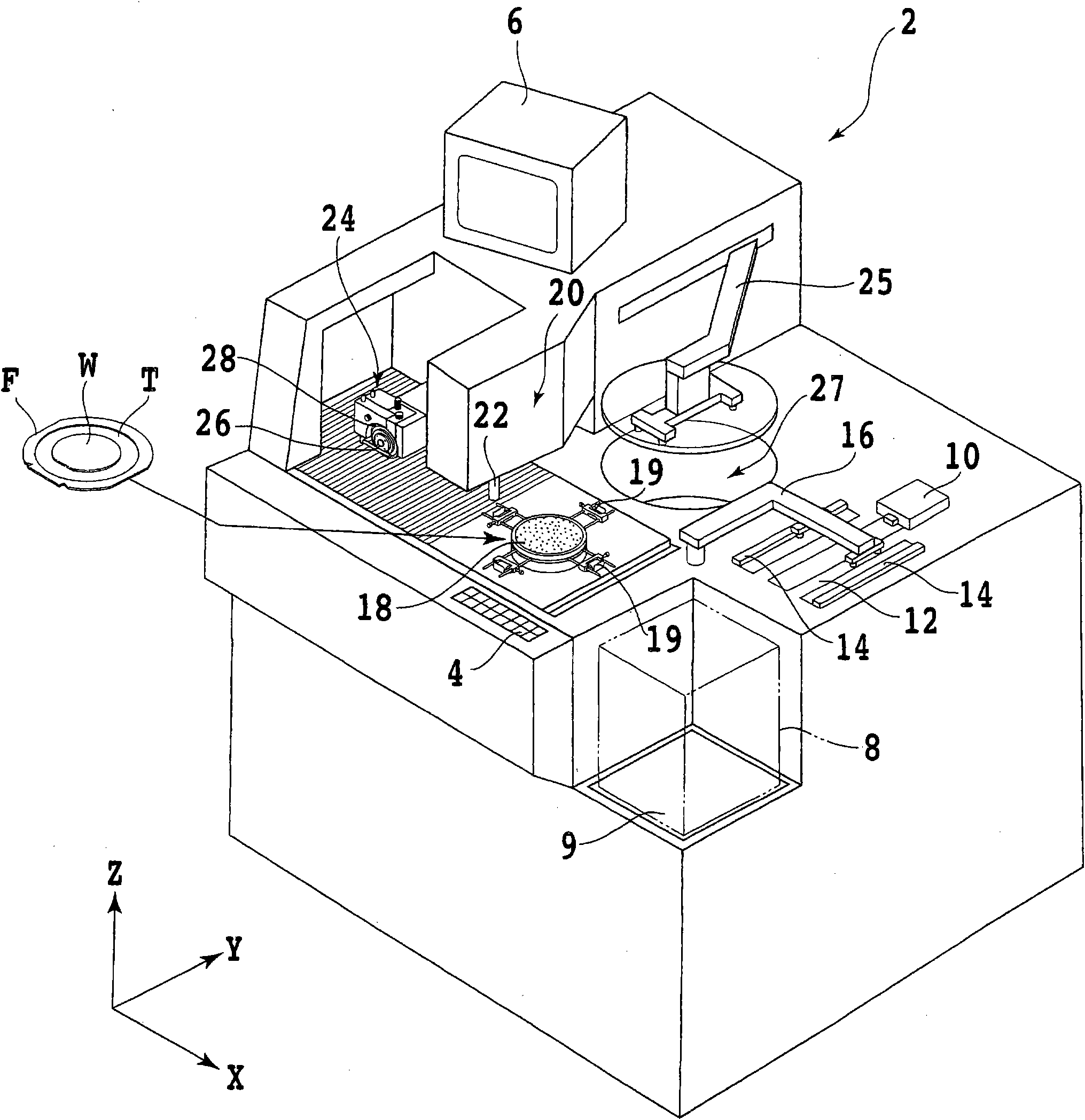

Photographic device

ActiveCN101995737ABending will notAvoid bendingSemiconductor/solid-state device manufacturingCamera body detailsOptical axisEngineering

The present invention provides a photographic device, having a reliable shielding component with a simple structure. The photographic device comprises the shielding component for selectively shielding an opening of a housing of an objective lens, wherein the shielding component includes a shielding piece with flexibility configured to slide on a lower side edge of the housing of the objective lens in a direction vertical to an optical axis of the objective lens; a movable component configured to make the shielding piece to move between a shielding position of shielding the opening of the housing and an opening position of baring the opening; and a guiding component configured to limit a moving path of the shielding piece, wherein the guiding component includes a horizontal guiding part configured to limit a lower moving path of the housing of the objective lens in a horizontal direction, a vertical guiding part configured to limit a moving path in a vertical direction, and a bending guiding part configured to guide the shielding piece from the vertical guiding part to the horizontal guiding part.

Owner:DISCO CORP

Support rack for power transmission line of power system

The invention discloses a support frame for a transmission line of an electric power system, which includes an arm frame, the arm frame is a U-shaped groove, the arm frame is fixed on the wall, bolt holes are arranged on both sides of the arm frame, and the support seat is fixed by fixing bolts On the arm frame, the support seat is a triangle; the lower end of the support seat is a rib of the triangle, and the upper end is a surface; the upper end surface of the support seat is provided with an arc-shaped wire groove guide rail, and the wire groove guide rail is provided with a wire groove. The length of the trunking is 0.5-1m, and the trunking is made of plastic. When in use, the ledge is installed on the wall, the cable can be laid after the supporting frame is installed, and the cable can be placed in the wire groove after the cable is laid. The support length is increased, and the use of the support frame of the present invention can prevent the cable from bending without increasing the installation support point, which solves the problem of cable bending caused by point support when the cable is laid in the tunnel, and the increase in the use length wastes the cable. If support points are added, it will be time-consuming and labor-intensive.

Owner:田喜桂

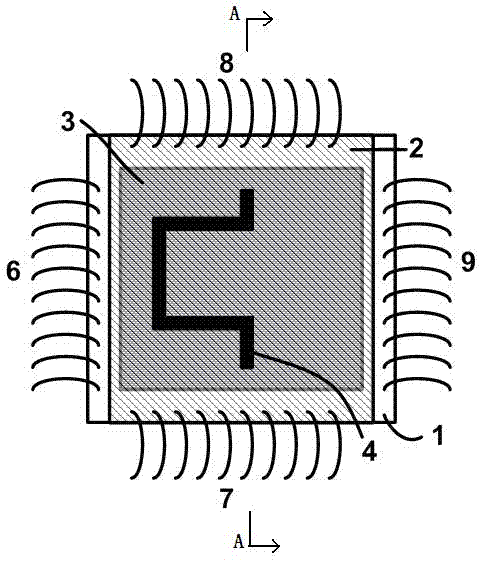

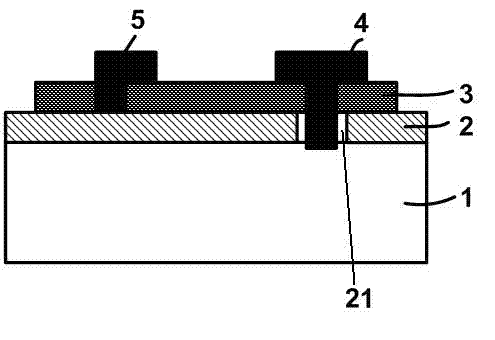

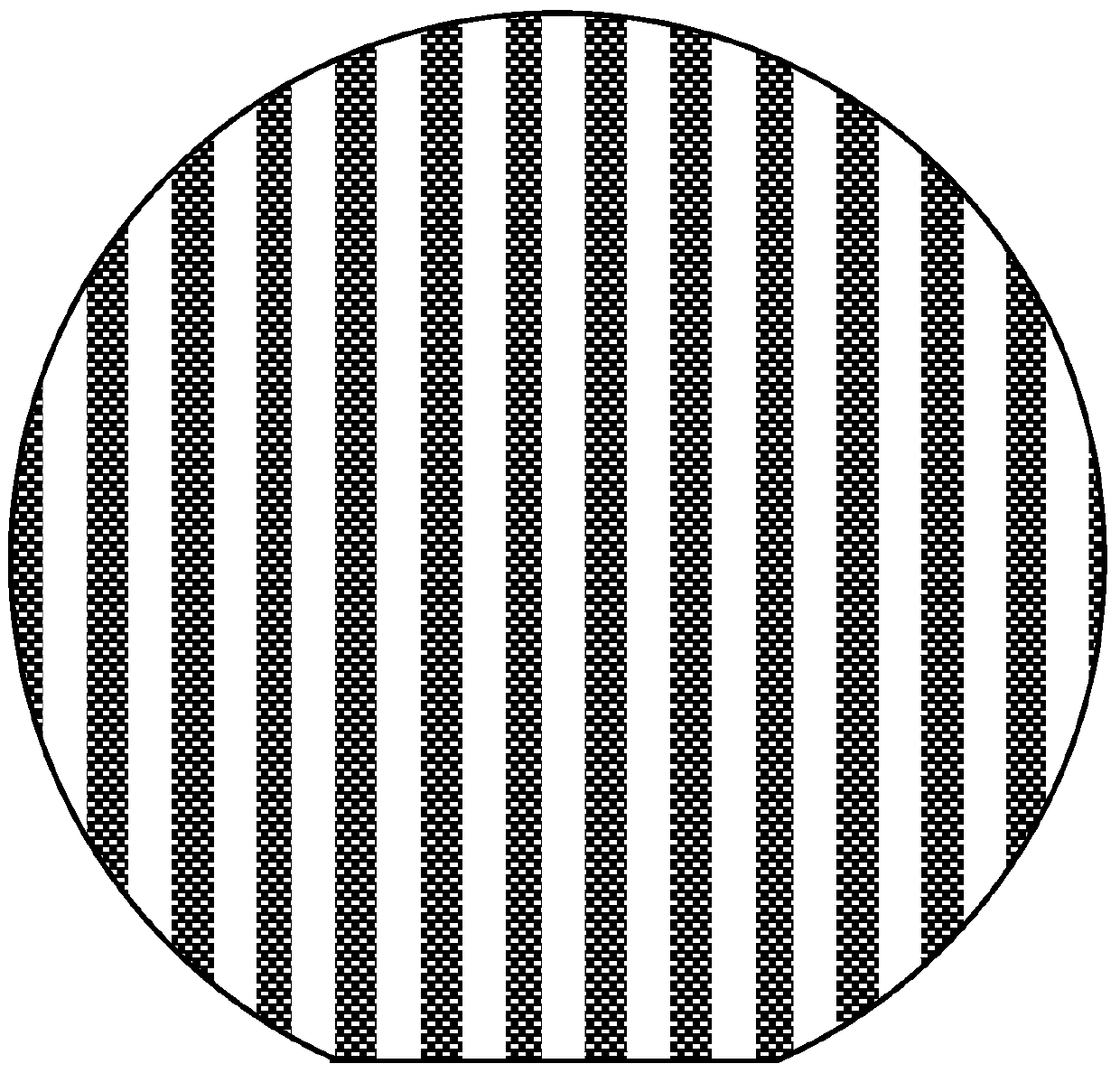

Structure for improving performance of passive device of power integrated circuit

InactiveCN102820286AReduce areaReduce lossSemiconductor/solid-state device detailsSolid-state devicesEngineeringSilicon chip

The invention discloses a structure for improving the performance of a passive device of a power integrated circuit. A metal plate is arranged in a chip of the power integrated circuit. The passive device is separated from an active device, the passive device is piled on a substrate and an area of the integrated circuit is reduced. One layer serving as the passive device is free from complex wiring, therefore, the thickness of a metal can be increased and the loss of the device can be reduced. A large metal plate can separate an electric field, and the passive and active devices do not affect each other. No electromagnetic field enters the substrate which is usually damaged, therefore, the energy loss can be reduced, and the performance of the passive device can be improved. The thickness of the chip is increased by pile-up on a power chip, so that the thickness of a silicon wafer can be reduced, and the silicon wafer is not bended, a radiating capacity of the chip is greatly improved. A source end is directly connected with the large metal plate, and the substrate is not used as a conductive layer, so that doping concentration of the substrate is reduced, and performances of the passive and active devices are improved.

Owner:KUNSHAN HUATAI ELECTRONICS TECH CO LTD

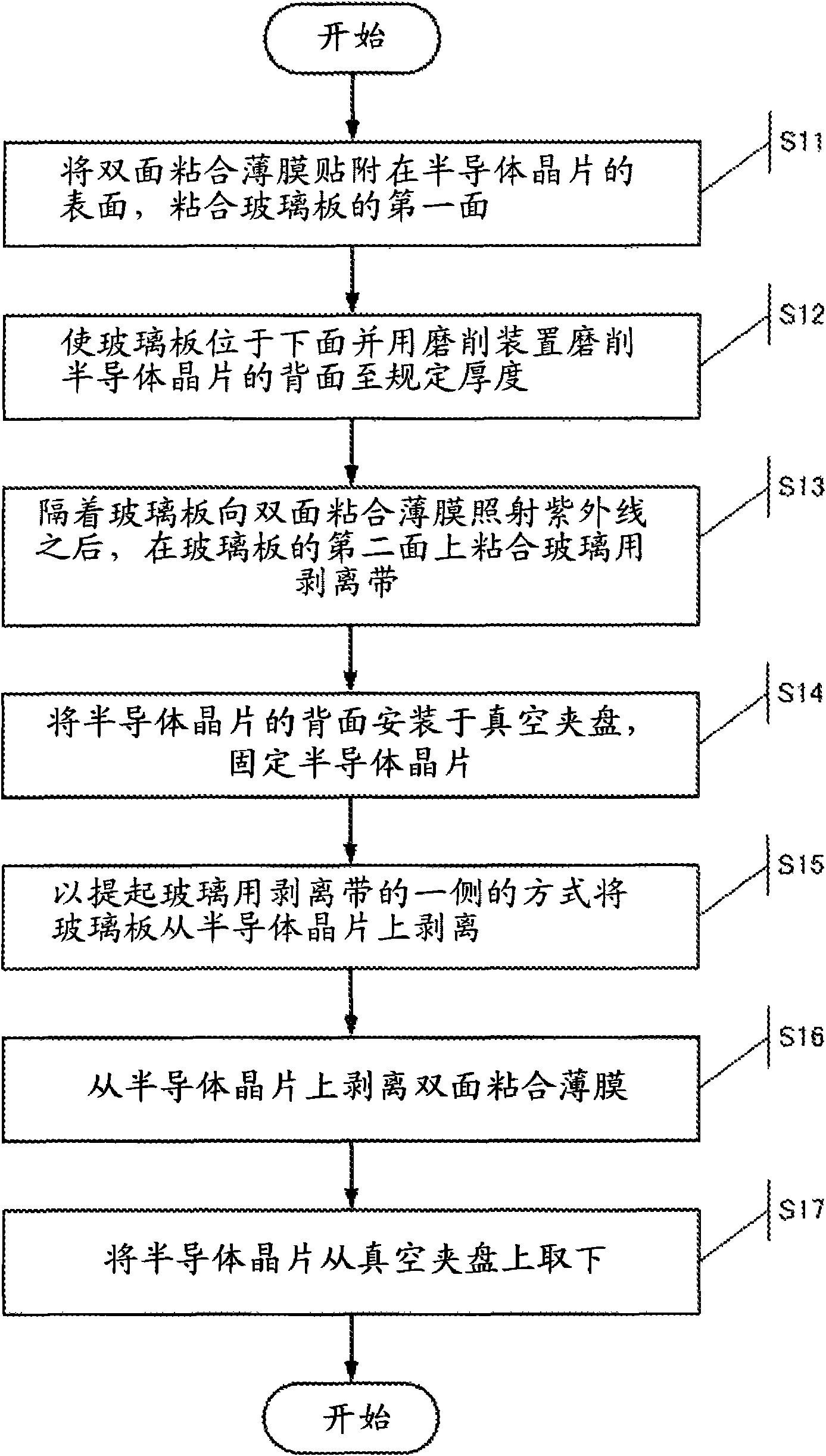

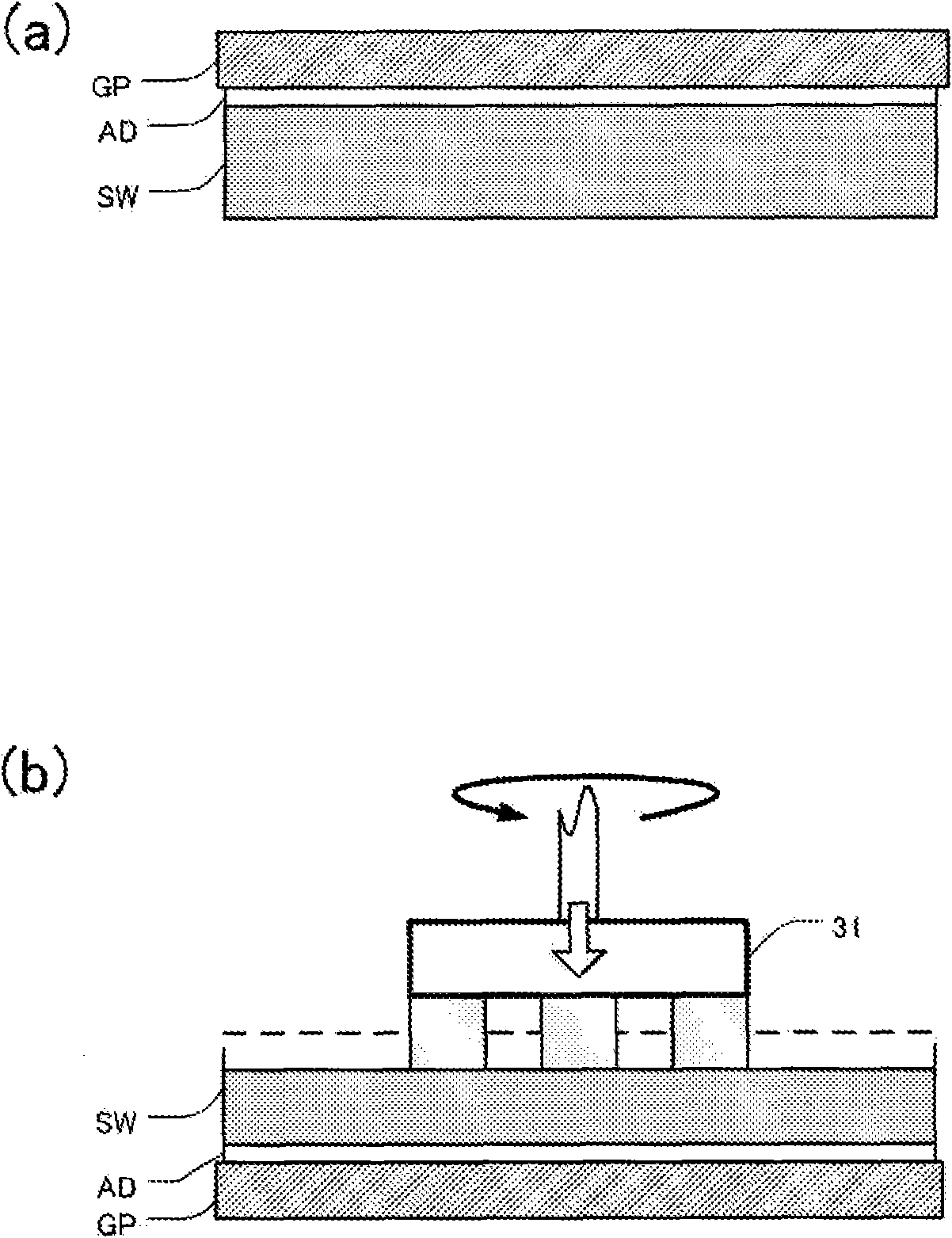

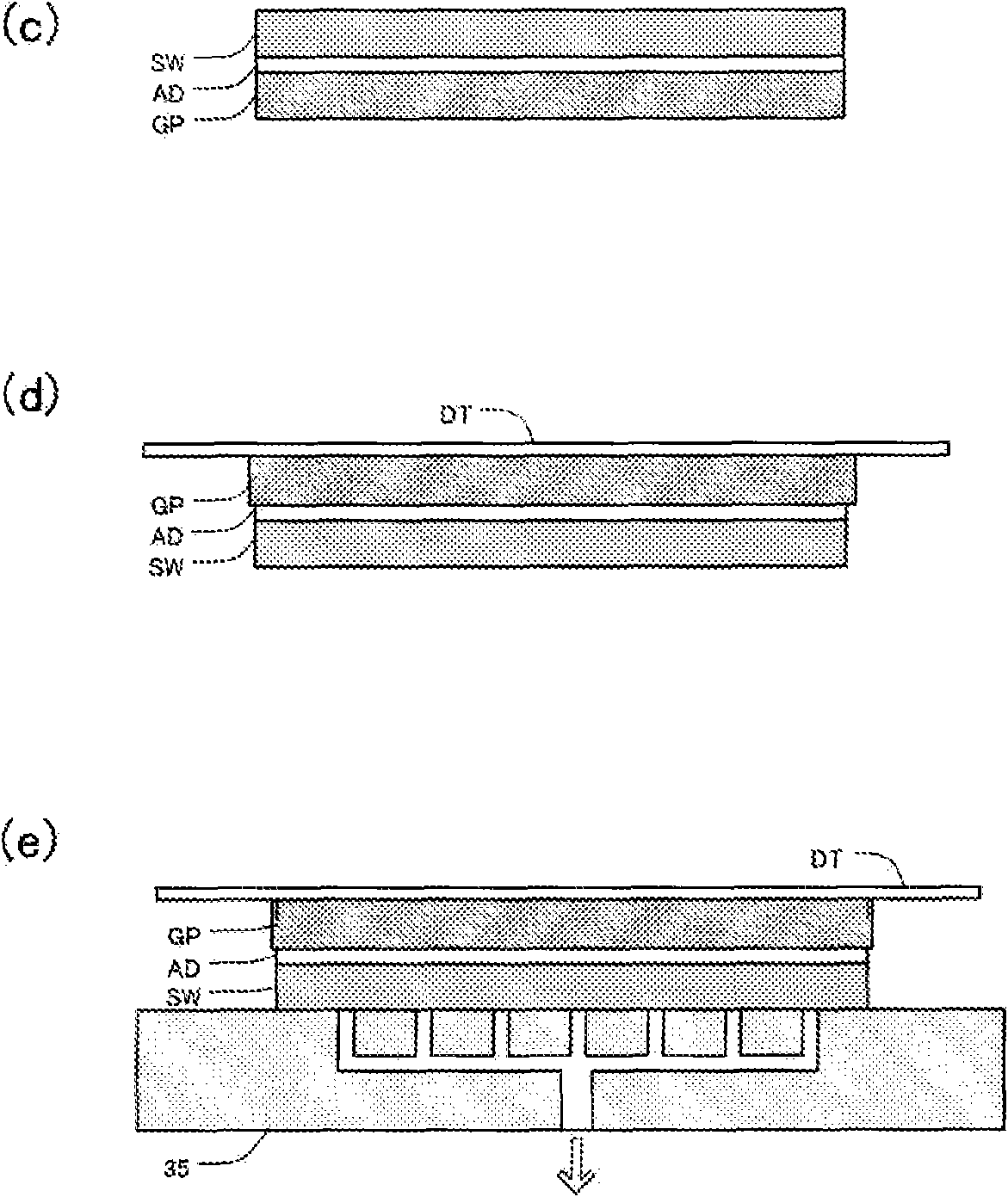

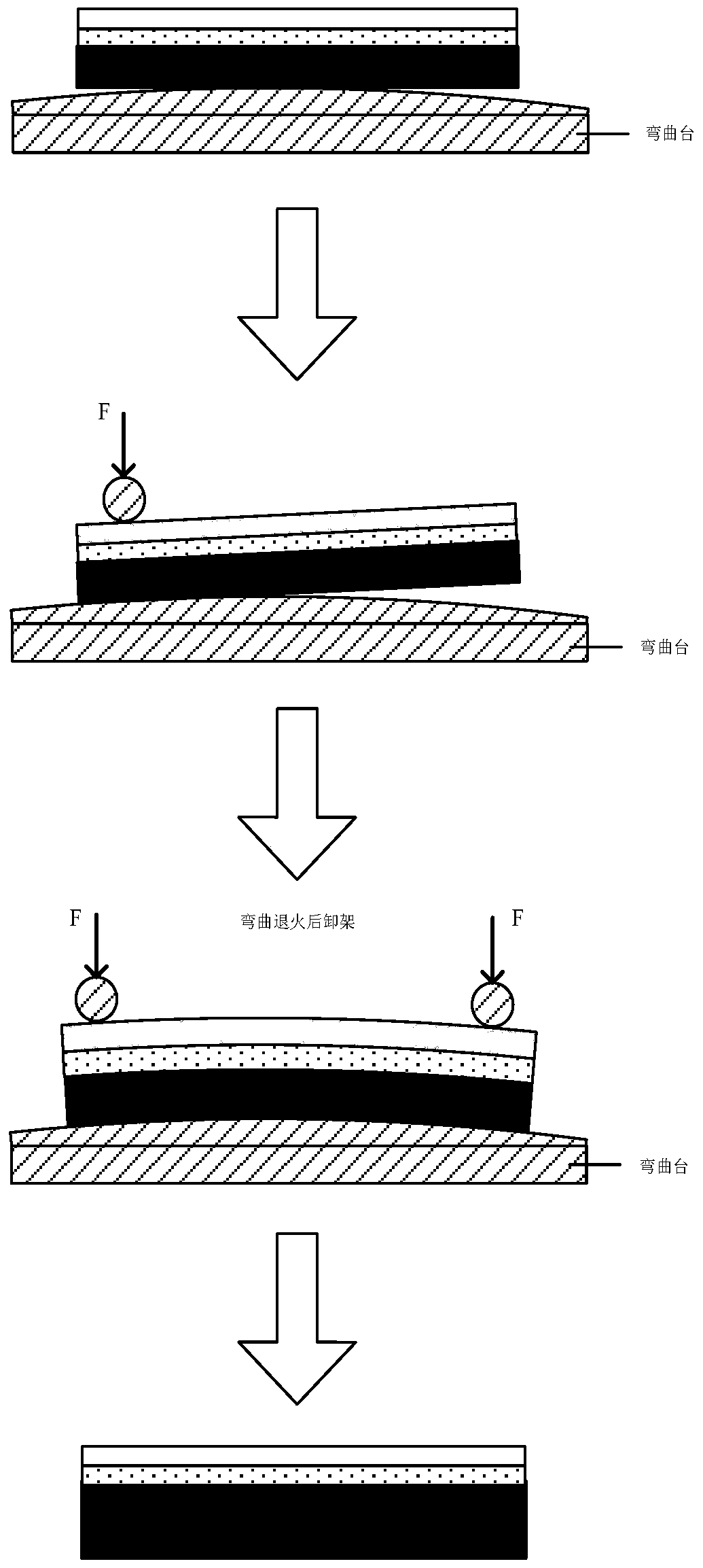

Wafer supporting glass

ActiveCN101681868AWon't breakBending will notSemiconductor/solid-state device manufacturingEngineeringGlass sheet

The invention provides a wafer supporting glass consisting of a glass plate (GP) exhibiting flexibility so that it can support a semiconductor wafer (SW) by bonding thereto and can be stripped therefrom. The glass plate (GP) is a wafer supporting glass for supporting a semiconductor wafer (SW) by bonding thereto. In order to strip the wafer supporting glass bonded to the semiconductor wafer (SW),the wafer supporting glass bends by a predetermined angle or more. When the wafer supporting glass bends 30 degrees or more, it can be stripped without applying a large force to the semiconductor wafer.

Owner:HOYA CANDEO OPTRONICS

Photographic device

ActiveCN101995737BBending will notAvoid bendingSemiconductor/solid-state device manufacturingCamera body detailsOptical axisEngineering

Owner:DISCO CORP

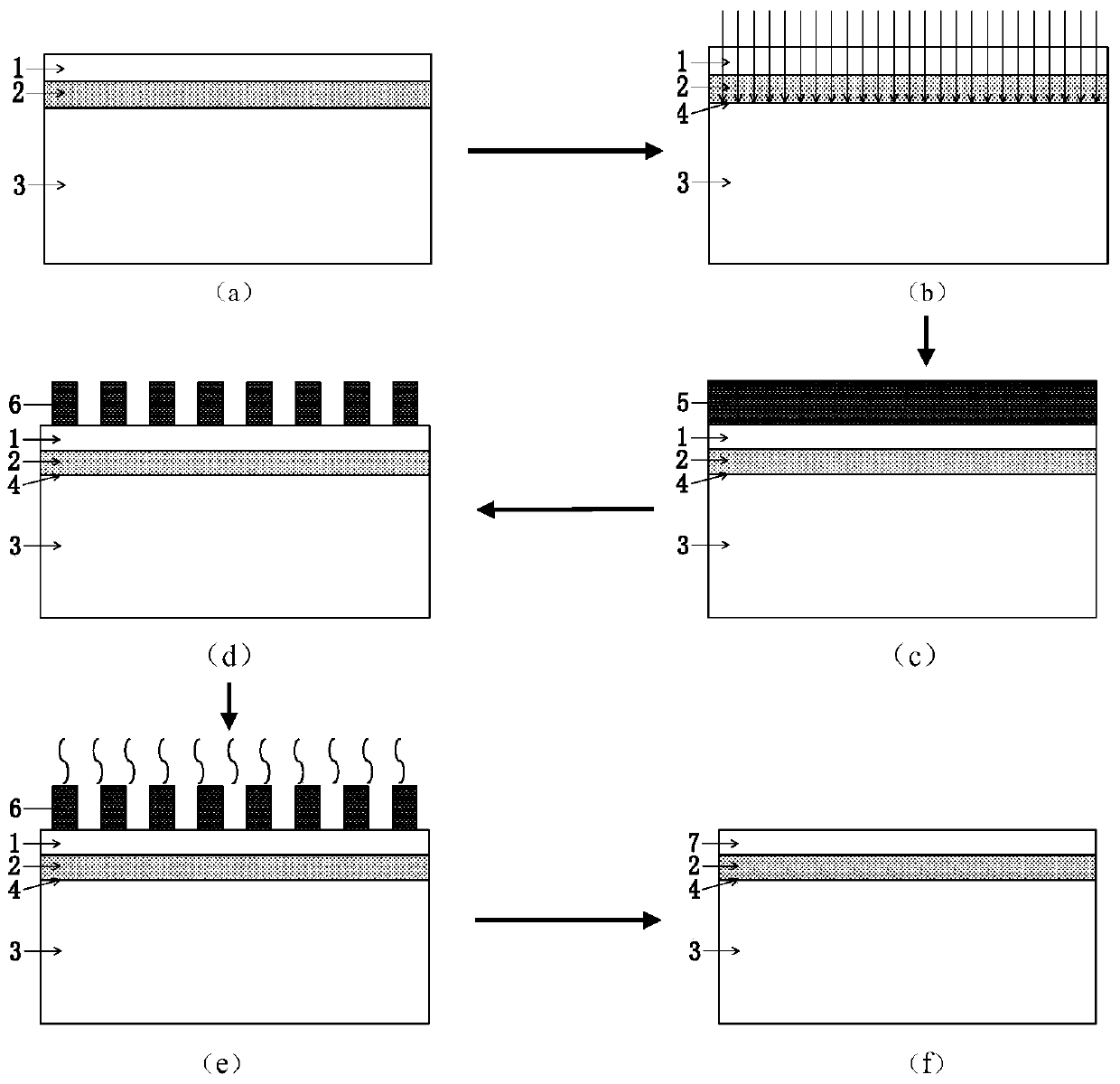

Fabrication method of wafer-level uniaxial strain ge on SiN buried insulating layer based on silicon nitride stress film and scale effect

ActiveCN106098612BSimple processAvoid bendingSemiconductor/solid-state device manufacturingUltra high speedWafer

Owner:XIDIAN UNIV

Machining method for valve rod

InactiveCN109986292ALess materialNo burr edges and cornersValve arrangementsScrew threadWear resistance

The invention discloses a machining method, and particularly discloses a machining method for a valve rod. The machining method for the valve rod comprises the following steps: blanking a round steelblank of the valve rod at first; carrying out rough machining on a tail end head, a polished rod part, back seal, and a groove buffer area between the back seal and the polished rod part, of the valverod; carrying out rough turning on a thread rod; rolling a trapezoidal thread which is formed through the rough turning on a thread rolling machine by virtue of a die, and correcting the redundant parts and nonstandard parts of the trapezoidal thread through cold rolling; carrying out finish turning on the back seal, and a groove between the back seal and the polished rod part to form the groovebuffer area; and carrying out finish turning on a polished rod of the valve rod. The machining method for the valve rod has the following beneficial effects: less material waste, no burrs, edges and corners, and high smoothness and concentricity are achieved; the valve rod is flexibly and easily opened and closed while being cooperatively used with a valve; high sealing performance is achieved; the valve rod is highly light and not liable to be damaged and bent, and high in tensile resistance and wear resistance; and the service life of the valve is prolonged.

Owner:王刚

A mobile windproof sightseeing platform used in municipal engineering

ActiveCN106930565BWith wind resistanceTo achieve the purpose of windproofBenchesSpecial buildingEngineering

The invention belongs to the field of a windproof observation deck for municipal engineering, and particularly relates to the windproof observation deck for municipal engineering. The windproof observation deck comprises windproof observation deck unit which are successively arranged. The windproof observation deck unit comprises a seat mechanism, a windproof moving mechanism and a windproof action mechanism. The seat mechanism is mounted above the windproof action mechanism. The windproof moving mechanism is mounted on the windproof action mechanism. The seat mechanism realizes functions of resting of sightseeing visitors and landscape observing. Furthermore the seat mechanism can trigger motion of the windproof action mechanism, thereby driving action of the windproof moving mechanism sothat a wind shield mounted on the windproof moving mechanism prevents harm of blown wind to visitors, thereby performing a windproof function.

Owner:平邑经济开发区投资发展有限公司

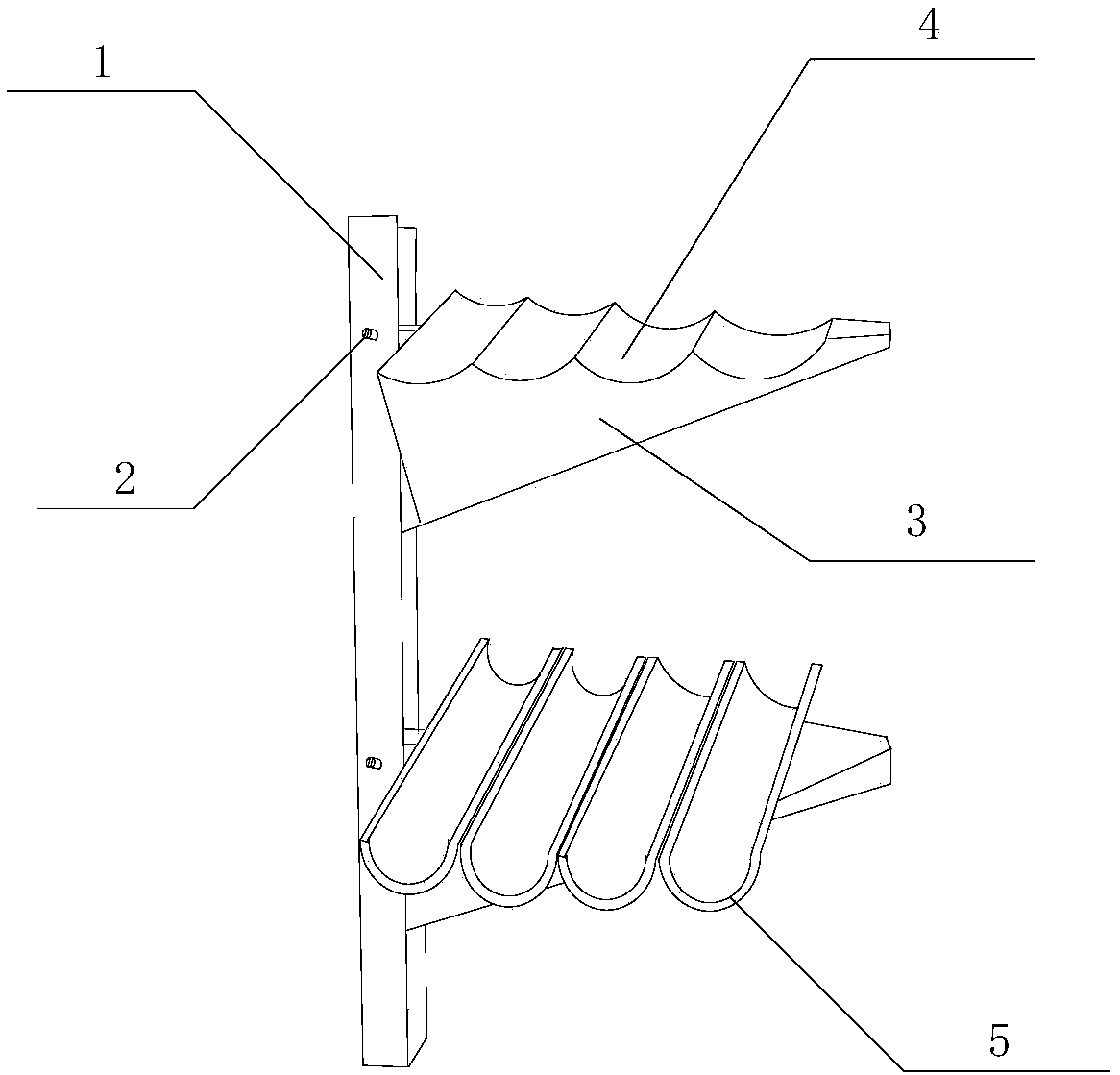

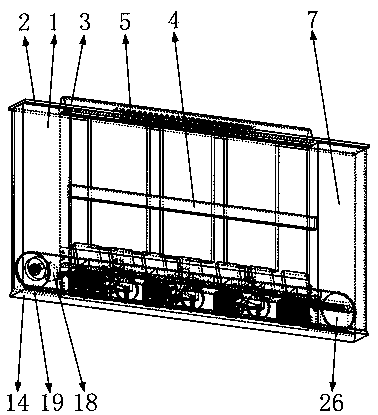

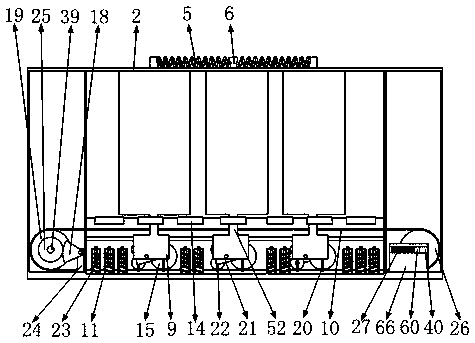

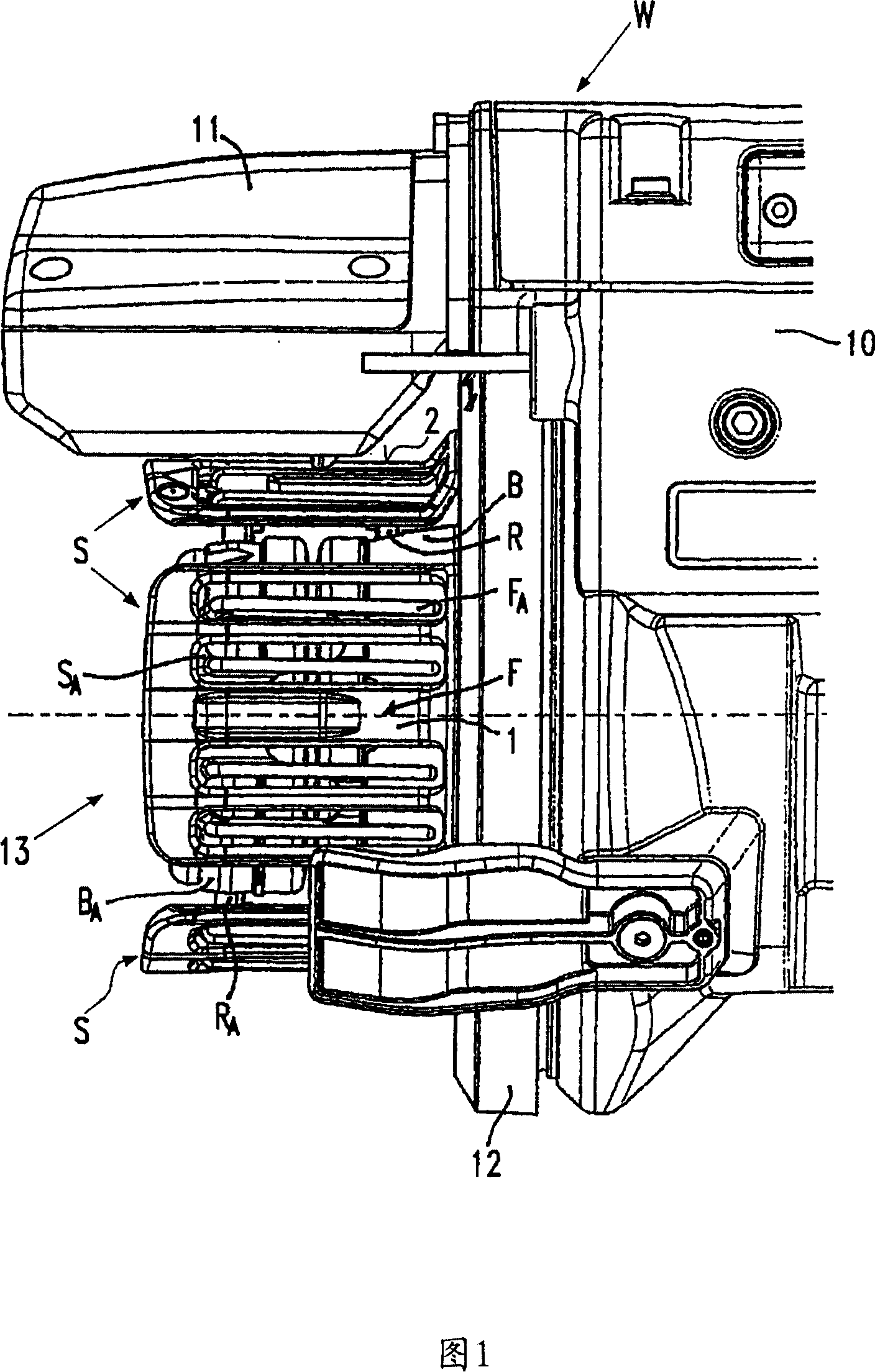

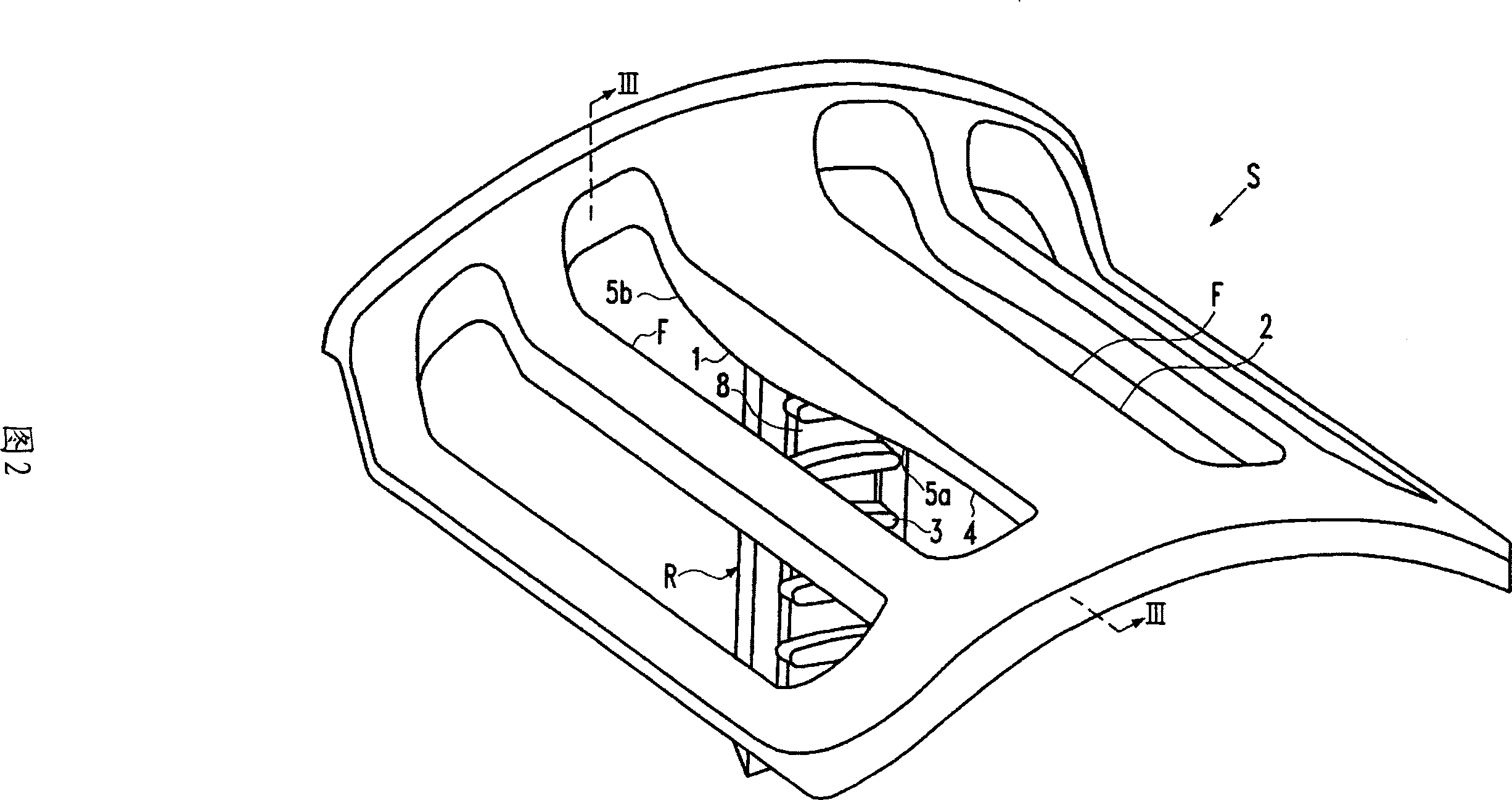

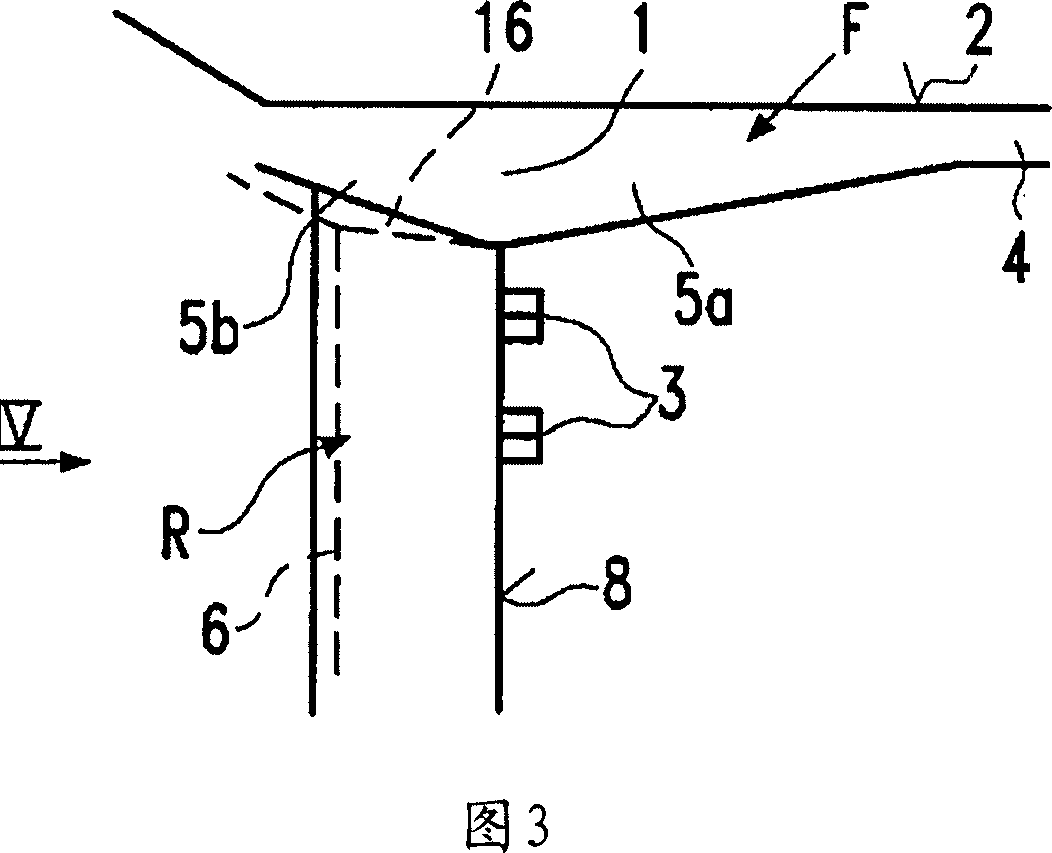

Yarn feeder

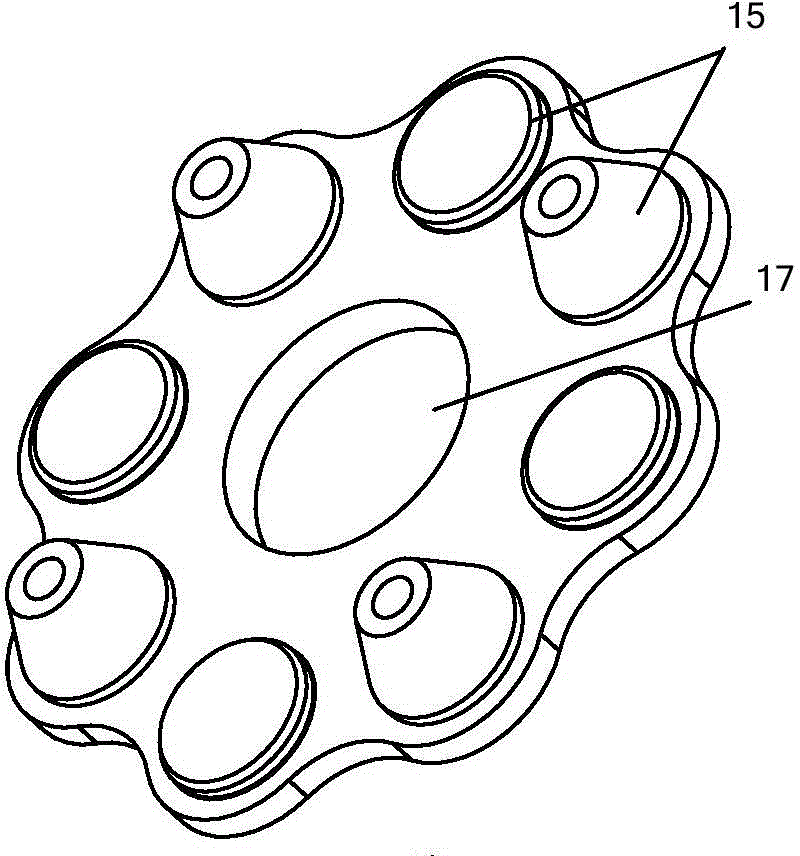

A yarn feeder (W) comprising a variable diameter stationary storage body (13) consisting of separated segments (S, SA) received in radial guidances (7) of a support structure (B), each segment comprising at least one finger (F) and a rod (R) unitarily formed with the finger (F), the rod (R) being connected to the lower side of the finger in a junction region, the rod carrying engagement elements (3) at a front side (8) and defining longitudinal guiding surfaces (G) at other sides of the rod, the junction region (1) having at least a gusset (5a) at the transition between the front side (8) and the lower side of the finger, the junction region (1), furthermore, comprising an additional gusset (5b) at a transition from the rear side of the rod into the lower side of the finger. The guiding surfaces (G)- in a crosssection of the rod (R)- being arranged pairwise and with a V-shape.

Owner:VANDEWIELE SWEDEN AB

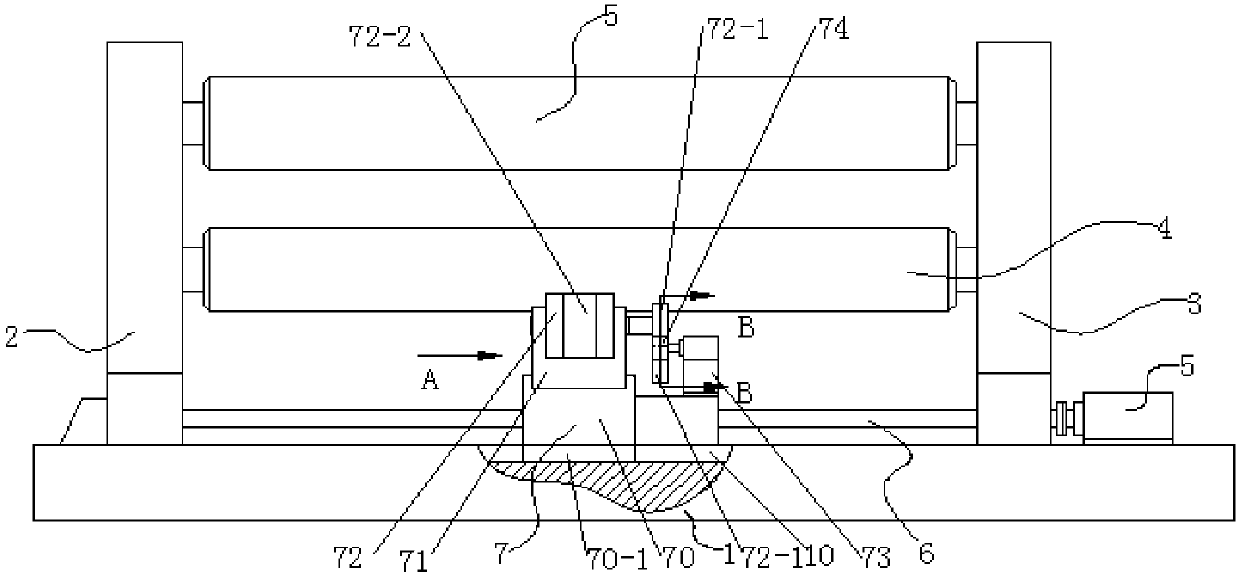

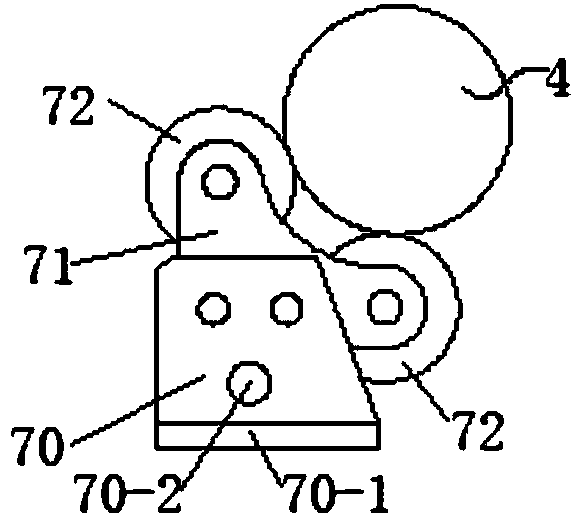

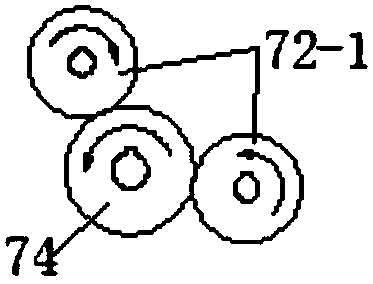

Support device for driving roller of plate rolling machine

The invention discloses a support device for the driving roller of a plate rolling machine. The support device comprises a base, a side frame I, a side frame II, driving rollers, a servo motor, a leadscrew, and a support device body, wherein a rectangular groove is formed in the base; the lower end of the side frame I is connected to one end of the base through a bolt; the lower end of the side frame II is connected to the other end of the base through a bolt; one ends of the driving rollers are rotatably connected with the side frame I, and the other ends of the driving rollers are rotatablyconnected with the side frame II; the servo motor is connected with the base through a bolt; one end of the lead screw is rotatably connected with the side frame I, and the other end of the lead screw is rotatably connected with the side frame II; the output shaft of the servo motor is connected to one end of the lead screw through a coupling; and the support device body comprises a support seat,a roller stand, a roller, a motor, and a gear II, the bending deformation of the driving rollers during the barrel roll-forming operation of the plate rolling machine is effectively avoided, the rollforming operation circular degree of the plate rolling plate is ensured, and the dynamic balance fluctuation quantity of a circular barrel after roll forming is small.

Owner:MAANSHAN FEIDA BELLOWS MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com