Pipe clamp

一种管夹、夹爪的技术,应用在管夹领域,能够解决会破坏、难以收紧、夹紧螺钉弯曲等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

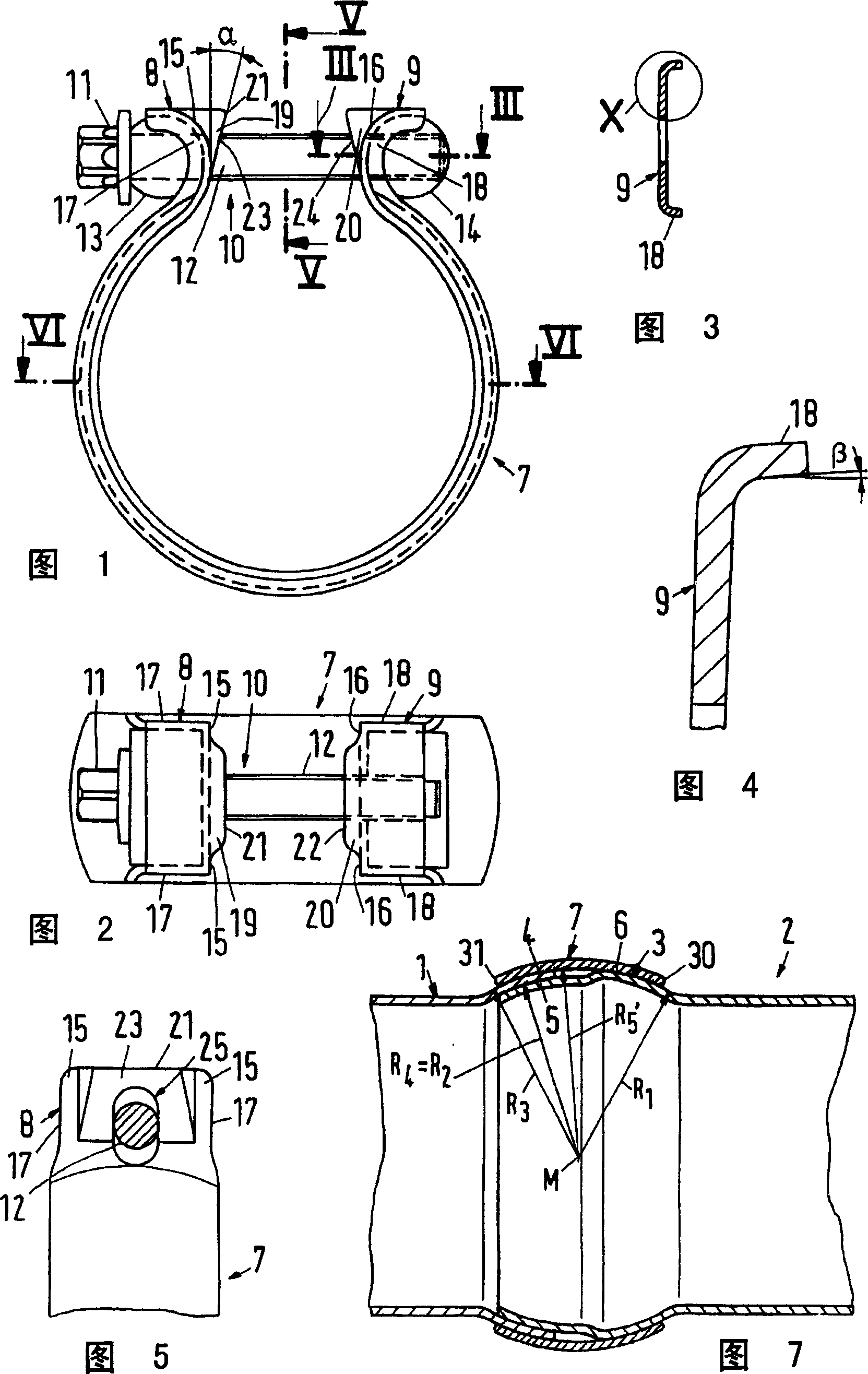

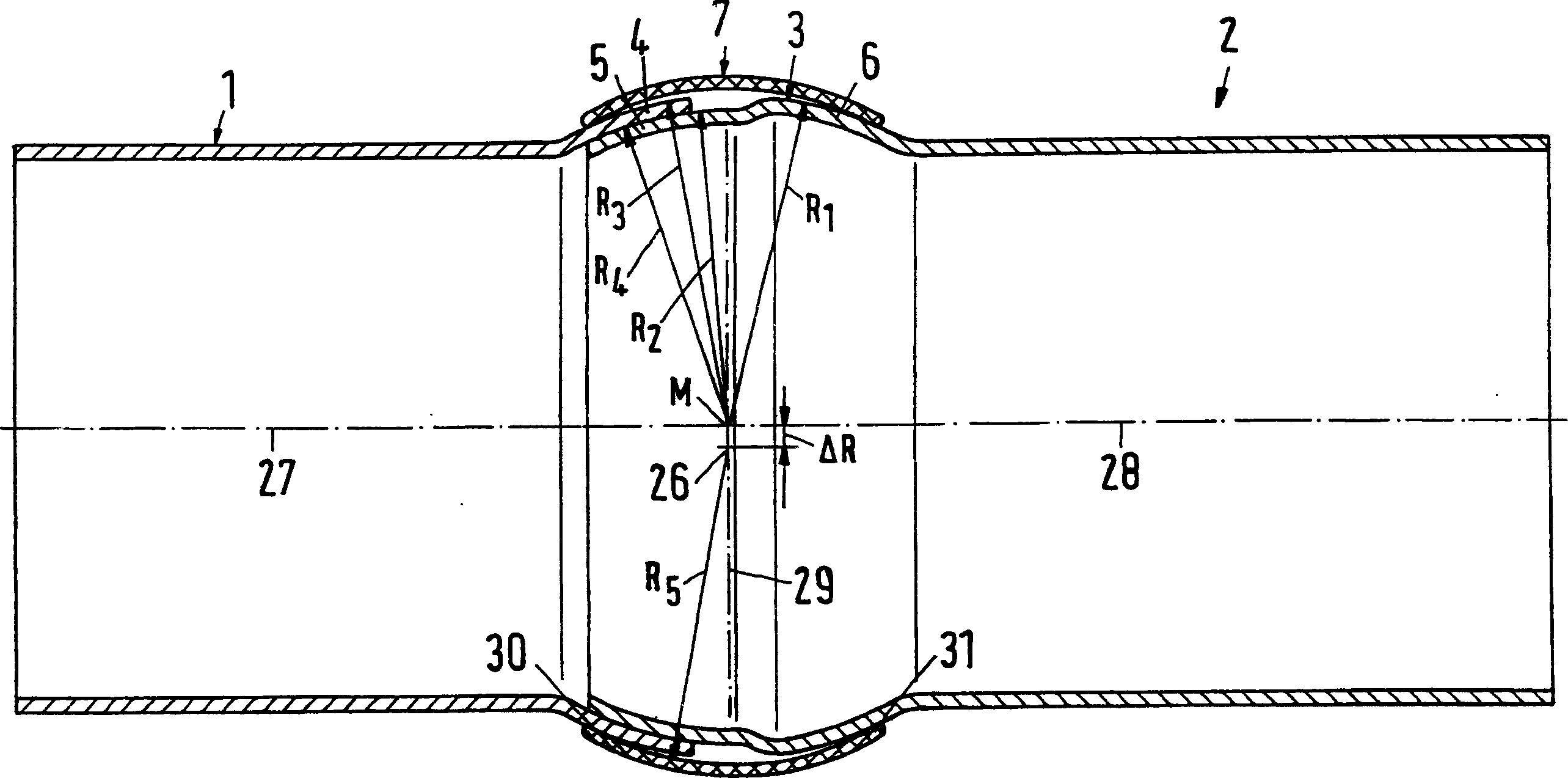

[0036] The pipe clips according to FIGS. 1 to 7 are used to connect two pipes 1 and 2 of an exhaust system of a motor vehicle. Tubes 1 and 2 have ends that can be partially plugged together: an insertion end 3 and a receiving end 4 . Insertion ends are made with different outer radii R 1 and R 2 Two spherical regions 5 and 6 are formed. The receiving end 4 is formed by only one spherical area with an outer radius R 3 with the outer radius R of the spherical area 6 1 same, its inner radius R 4 with the outer radius R of the spherical area 5 2 same. The purpose of these spherical areas is to position the tubes 1 and 2 in position before tightening the tube clamps, where the two tubes are at a slight angle to each other.

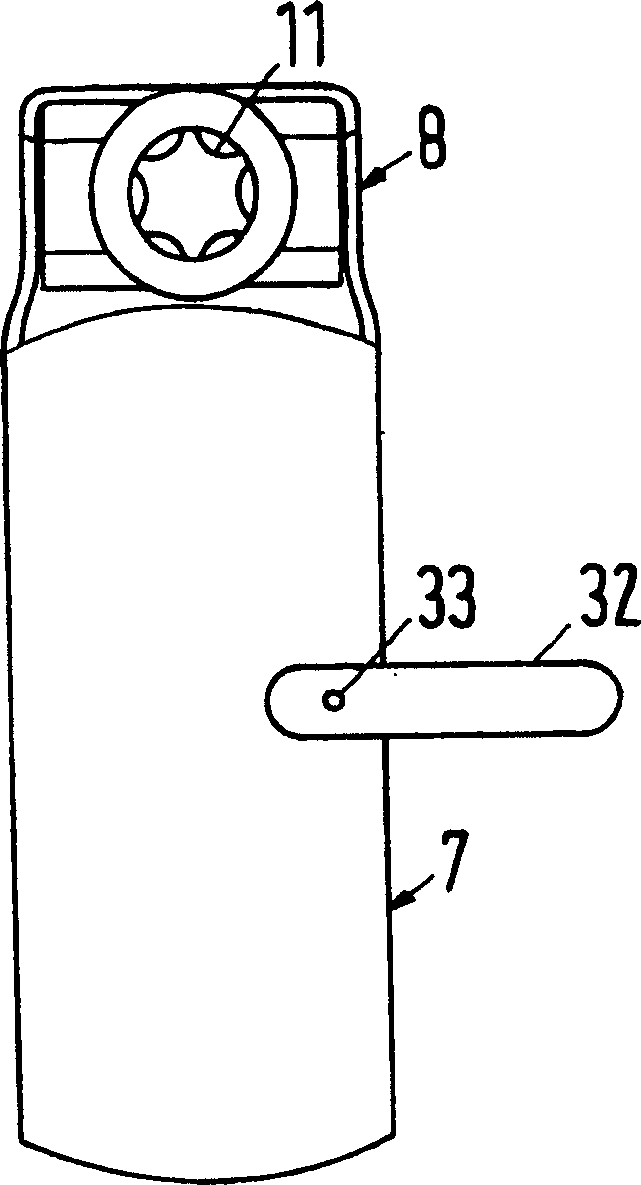

[0037]The pipe clamp according to FIGS. 1 to 7 has a clamping strip 7 which has an outwardly bent barrel shape in the axial direction, the ends of which are formed as clamping jaws 8 and 9 . Thus, jaws 8 and 9 are integrally formed with entrainment stri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com