Fabrication method of wafer-level uniaxial strain ge on SiN buried insulating layer based on silicon nitride stress film and scale effect

A scale effect and uniaxial strain technology, applied in the field of microelectronics, can solve the problems of wafer fragmentation, small strain, poor compatibility, etc., achieve the effect of smooth surface, large strain, and avoid wafer fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

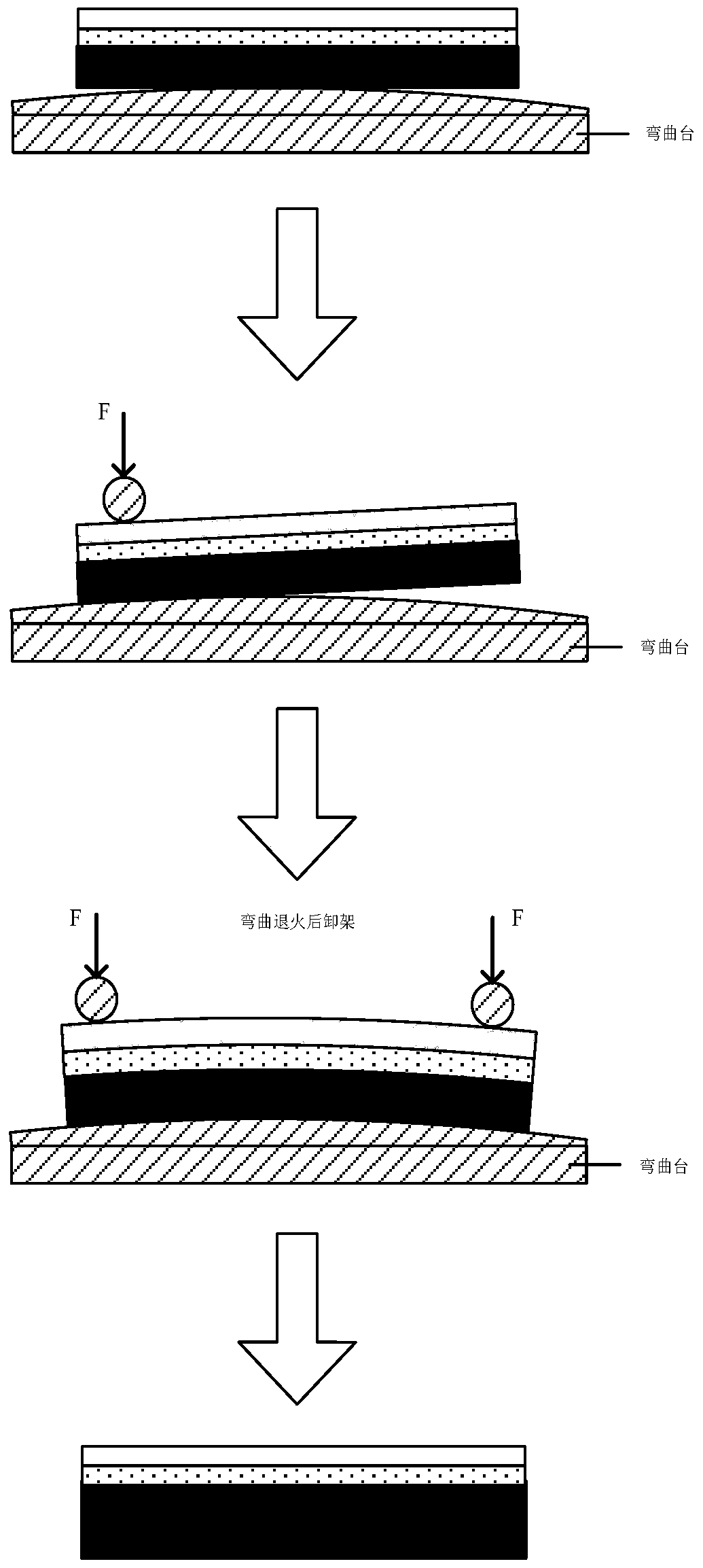

Method used

Image

Examples

Embodiment 1

[0038] Example 1, preparing a 4-inch SiN buried insulating layer uniaxial tensile strain GeOI wafer material.

[0039] Step 1: Clean the SiN buried insulating layer GeOI wafer to remove surface contaminants.

[0040] (1.1) Alternately ultrasonically clean the GeOI wafer with acetone and isopropanol to remove organic contamination on the substrate surface;

[0041] (1.2) Prepare a 1:1:3 mixed solution of ammonia water, hydrogen peroxide, and deionized water, and heat it to 120°C. Immerse the GeOI wafer in this mixed solution for 12 minutes, and rinse it with a large amount of deionized water after taking it out. To remove inorganic contaminants on the surface of GeOI wafers;

[0042] (1.3) Soak the GeOI wafer in HF acid buffer for 2 minutes to remove the oxide layer on the surface.

[0043] Step 2: Ion implantation.

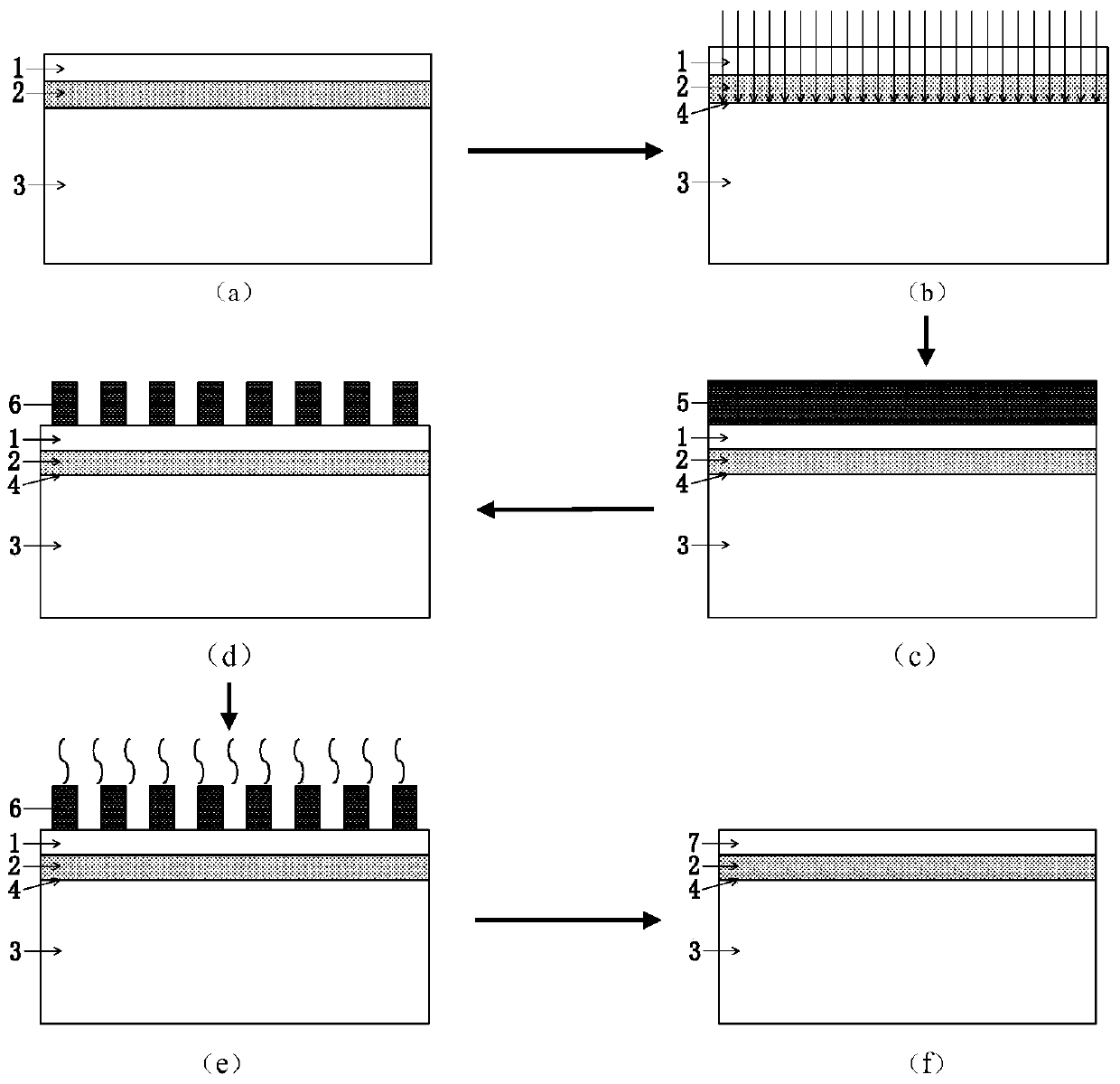

[0044] Ion implantation is performed on the cleaned GeOI wafer to loosen the interface 4 between the Si substrate 3 and the SiN buried insulating layer 2, such...

Embodiment 2

[0057] Example 2, preparation of 8-inch SiN buried insulating layer uniaxial compressive strain GeOI wafer material.

[0058] Step 1: Clean the SiN buried insulating layer GeOI wafer to remove surface contaminants.

[0059] The implementation of this step is the same as that of step 1 in Embodiment 1.

[0060] Step 2: Implant the cleaned GeOI wafer with a dose of 1.1E15cm -2 , He ions with an energy of 110Kev to loosen the interface 4 between the Si substrate 3 and the SiN buried insulating layer 2, such as figure 2 b shown.

[0061] Step 3: Using the PECVD plasma enhanced chemical vapor deposition process, a tensile stress SiN film 5 with a thickness of 1.1 μm and a stress of 1.2 GPa is deposited on the surface of the top Ge layer 1 of the GeOI wafer that has completed ion implantation, such as figure 2 c shown.

[0062] The deposition process conditions are: high-frequency HF power is 1.3KW, low-frequency LF power is 0.31KW, high-purity SiH 4 Flow rate of 0.31slm, hig...

Embodiment 3

[0070] In Example 3, a 12-inch SiN buried insulating layer uniaxial tensile strain GeOI wafer material was prepared.

[0071] Step A: Cleaning the SiN buried insulating layer GeOI wafer to remove surface contaminants.

[0072] The implementation of this step is the same as that of step 1 in Embodiment 1.

[0073] Step B: Ion implantation is performed on the cleaned GeOI wafer to loosen the interface 4 between the Si substrate 3 and the SiN buried insulating layer 2, such as figure 2 b shown.

[0074] The ion implantation process is: the implanted ions are He ions, and the implantation dose is 1.1E16cm -2 , the injection energy is 150Kev.

[0075] Step C: depositing a high pressure stress SiN film.

[0076] Using PECVD plasma enhanced chemical vapor deposition process, the high-frequency HF power is 0.41KW, the low-frequency LF power is 0.61KW, and the high-purity SiH 4 Flow rate of 0.21slm, high purity NH 3 The flow rate is 2.4slm, the flow rate of high-purity nitrogen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com