Support rack for power transmission line of power system

A technology for power systems and transmission lines, applied in the direction of electrical components, etc., can solve the problems of wasteful cable length, time-consuming and labor-intensive use, cable bending, etc., and achieve the effects of avoiding short circuits, reducing load loads, and increasing support lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

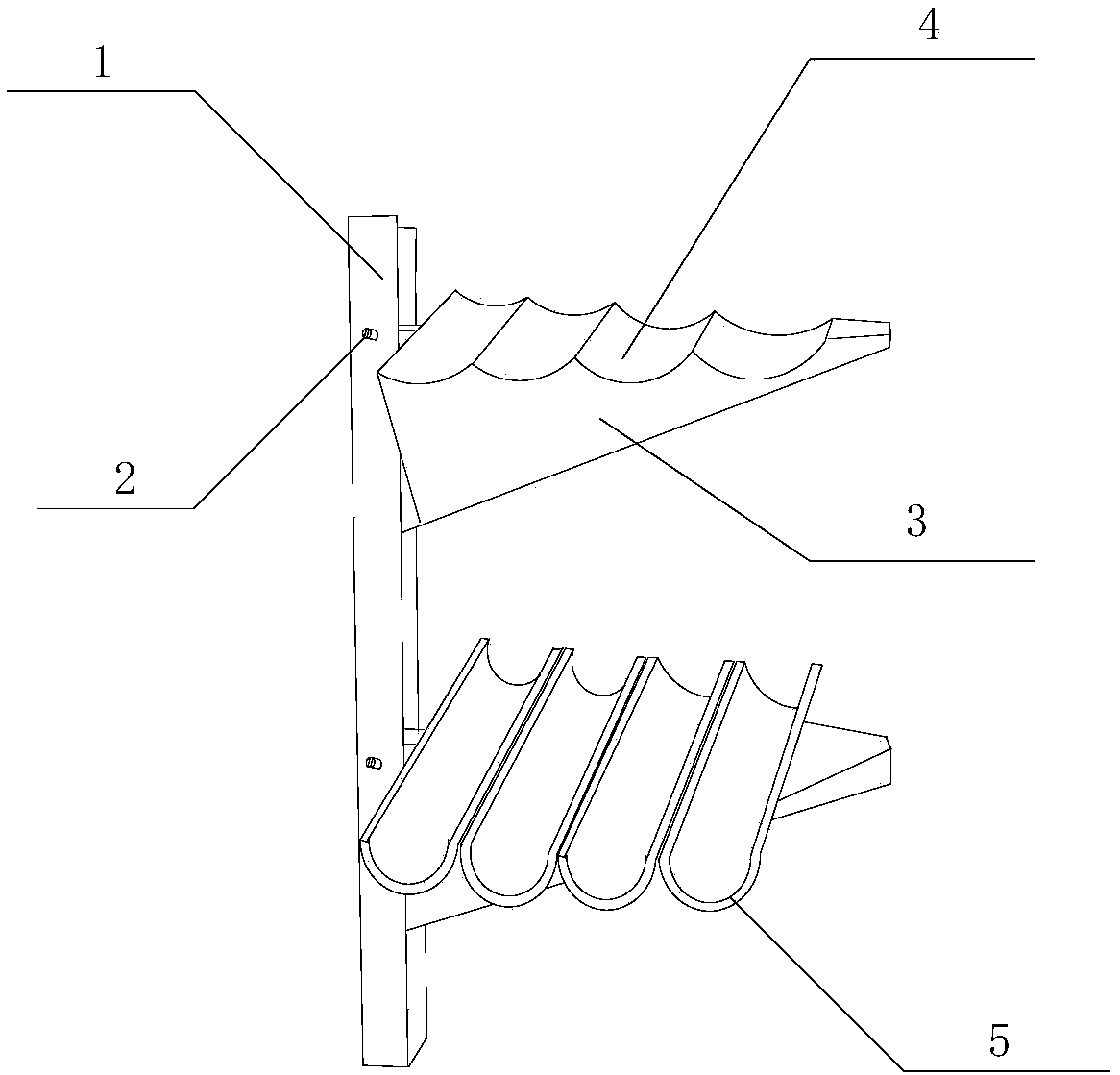

[0018] Such as figure 1 As shown, the support frame of the power system power transmission line of the present invention includes an arm frame 1, and the arm frame 1 is a U-shaped groove, and the arm frame 1 is fixed on the wall. Bolt holes are provided on both sides of the arm frame 1. By fixing The bolt 2 fixes the support seat 3 on the arm frame 1, and the support seat 3 is a triangle; the lower end of the support seat 3 is an edge of the triangle, and the upper end is a surface; the upper end surface of the support seat 3 is provided with an arc-shaped wire groove guide rail 4. The wire groove guide rail 4 is provided with a wire groove 5, the length of the wire groove 5 is 0.5-1m, and the wire groove 5 is made of plastic. When in use, the ledge is installed on the wall, the cable can be laid after the supporting frame is installed, and the cable can be placed in the wire groove after the cable is laid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com