Patents

Literature

52results about How to "Increase support length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

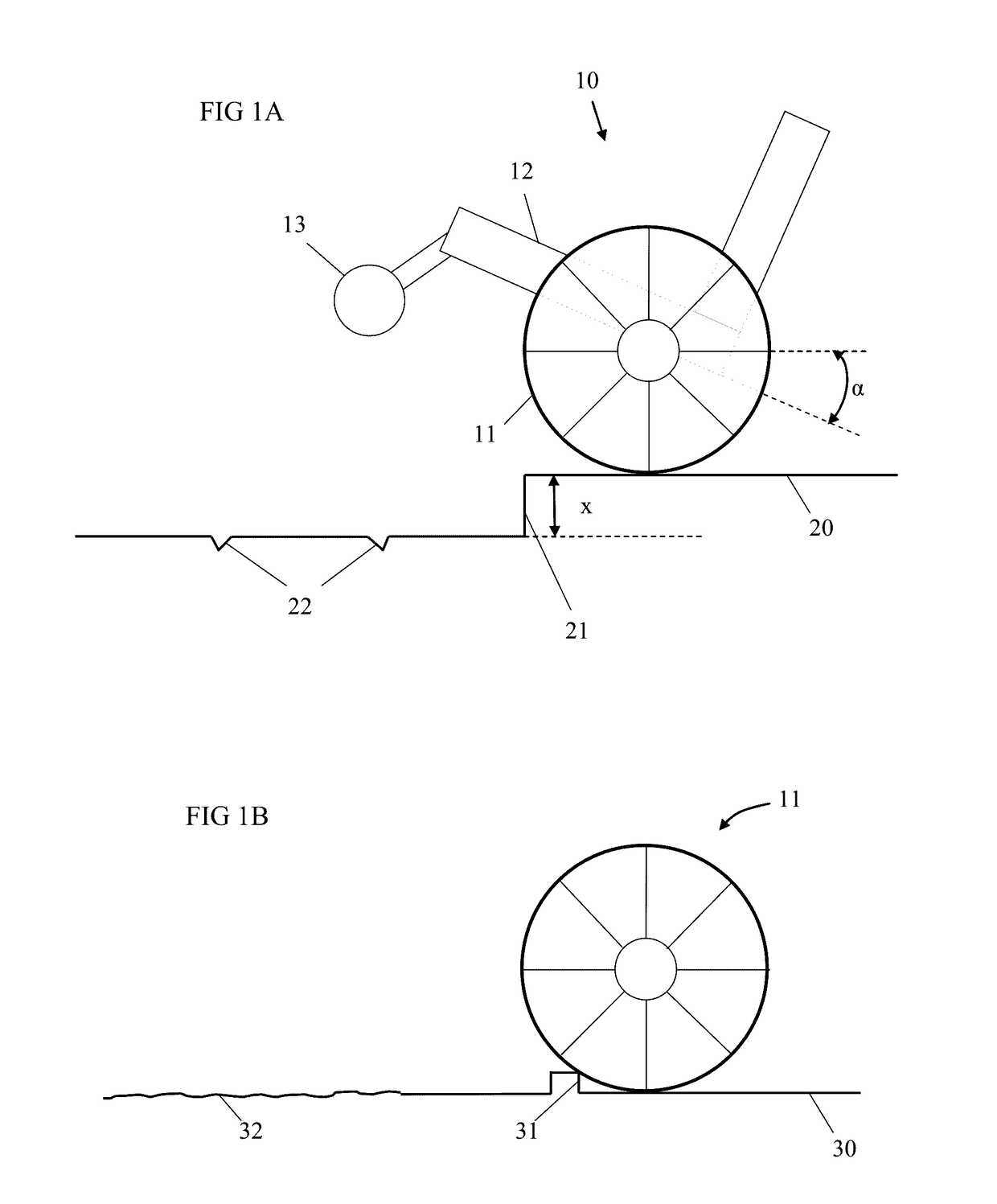

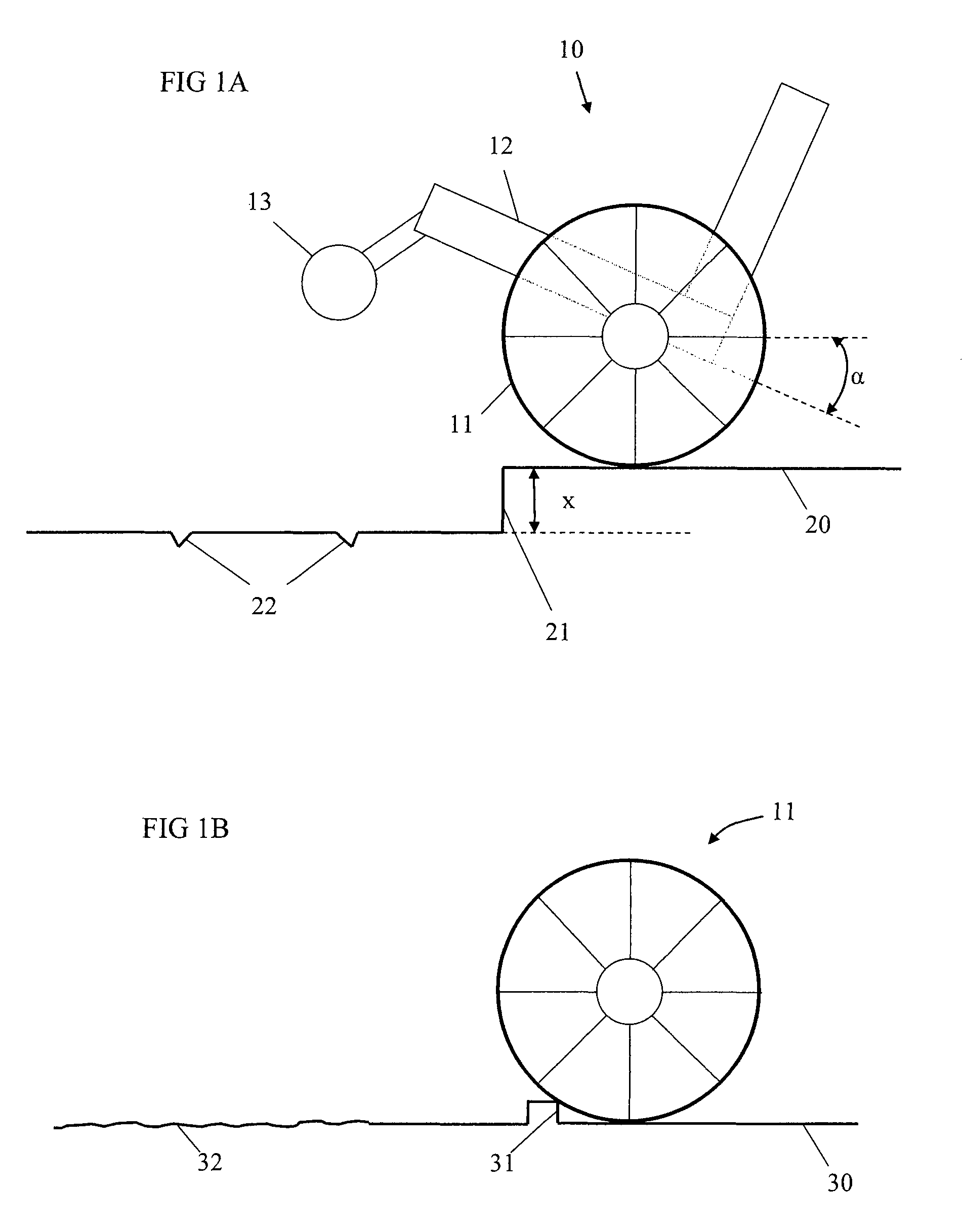

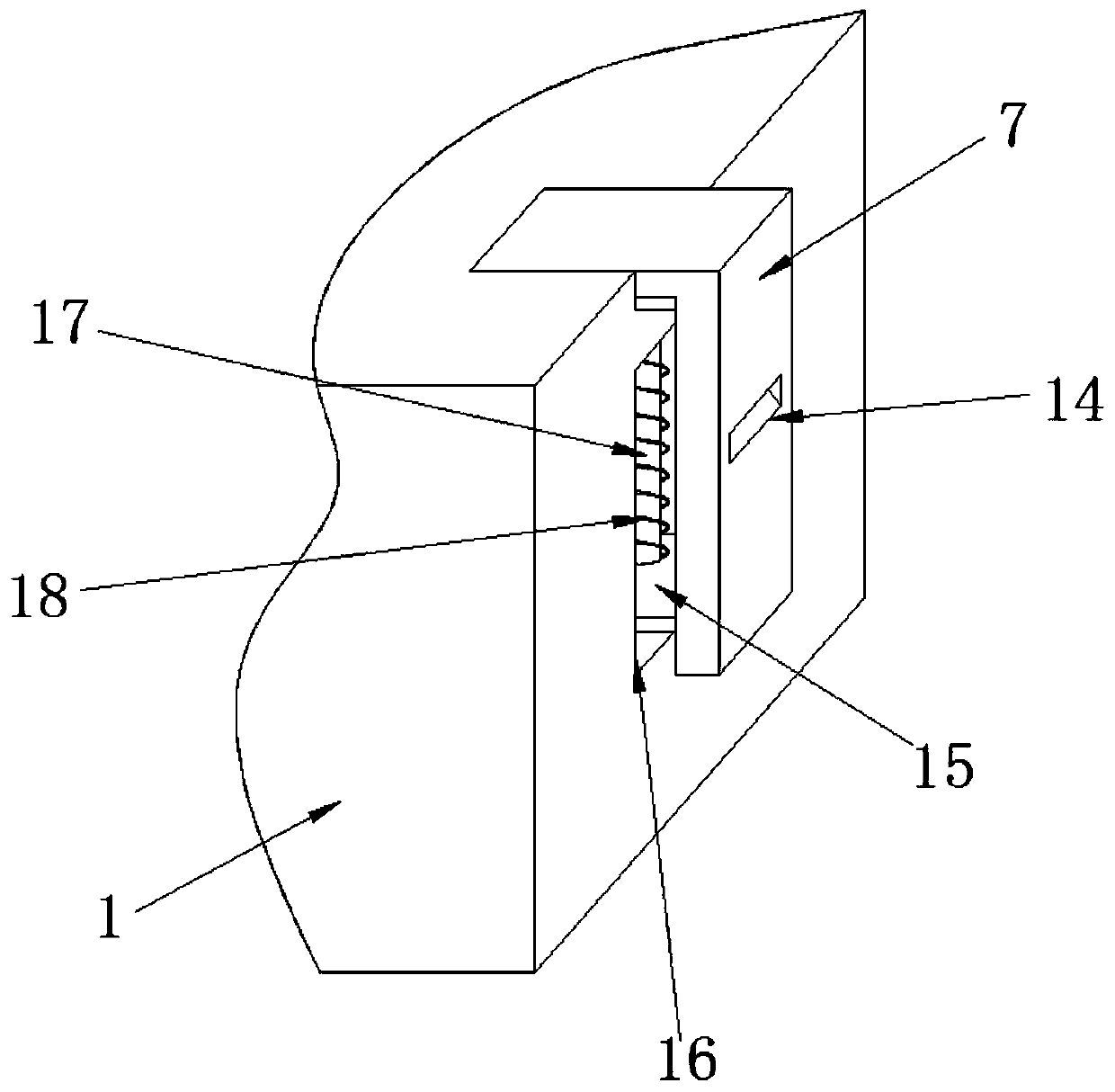

Wheel with suspension system

InactiveUS20170087932A1Moist evenlyIncrease support lengthWheelchairs/patient conveyanceCastorsRisk strokeMechanical engineering

A wheel with a suspension system being connectable to a vehicle, like a wheel chair. The wheel includes a hub and a rim rotatable about the axle of the hub. Between the hub and the rim, a number of support members is located. The support members are adapted to retain the distance when stressed up to a threshold value and recoverly alter the distanced when stressed over this threshold value. Exemplary support members are spring elements, damping strokes by compression if the support member is compressed or elongated. The spring elements may be preloaded.

Owner:SOFTWHEEL

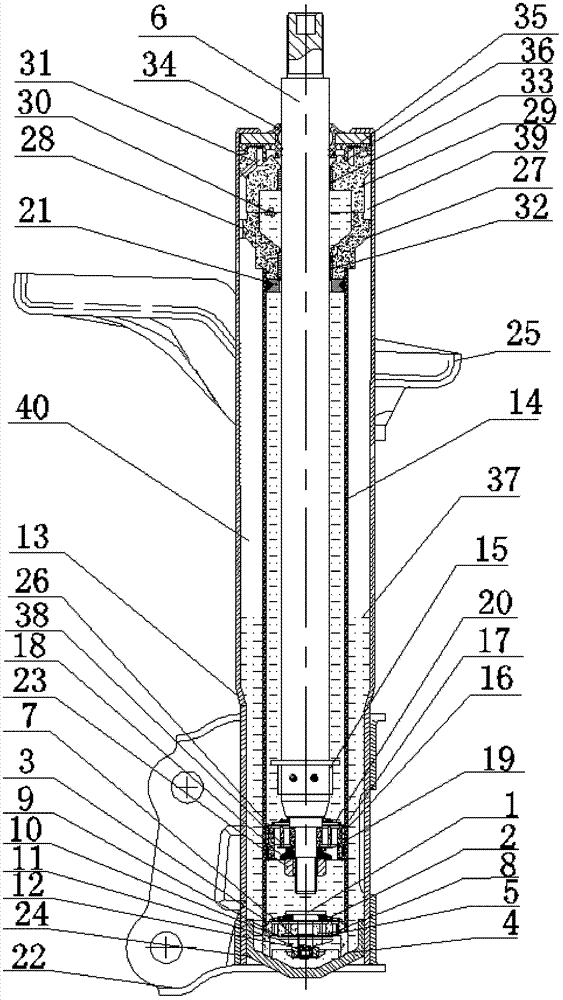

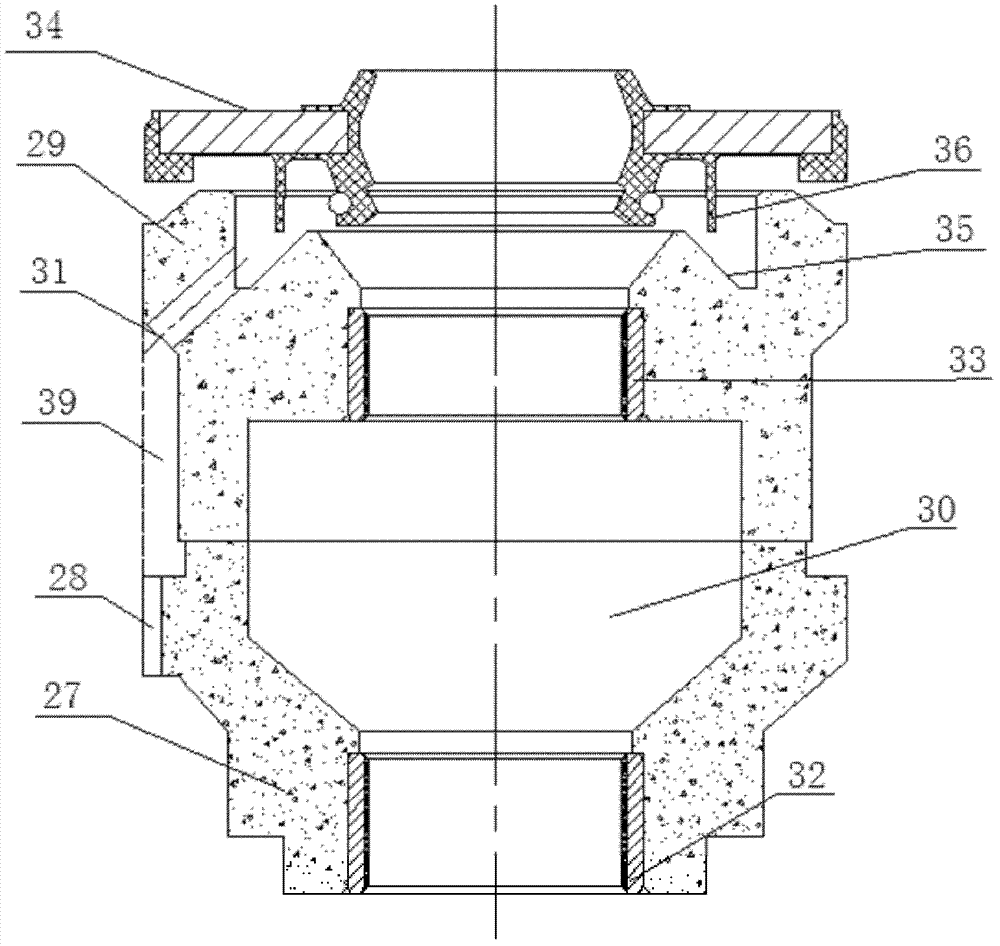

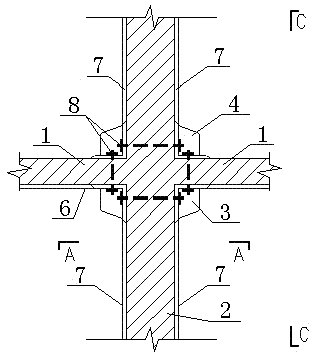

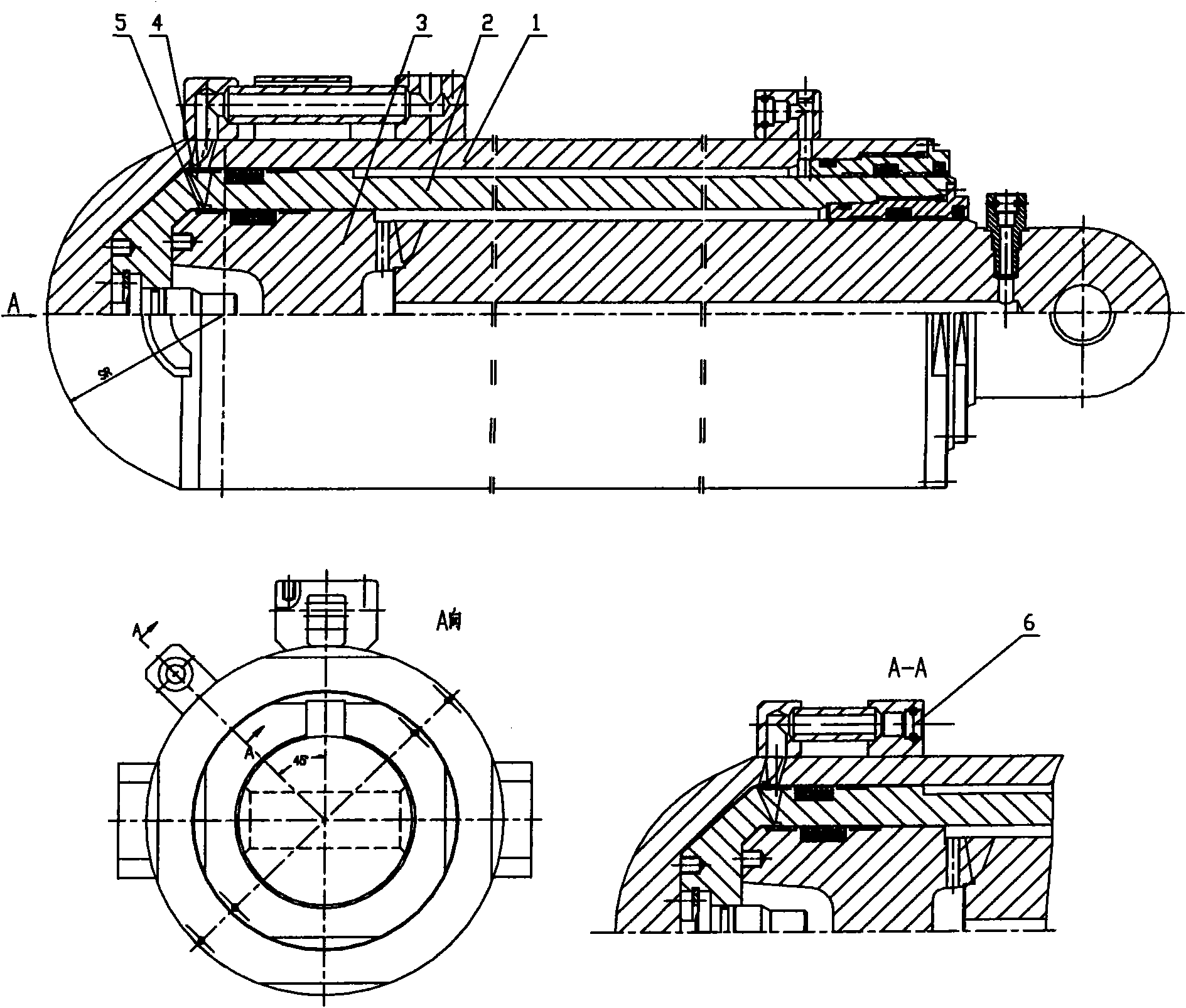

Damper, vehicle suspension system and vehicle

InactiveCN103363007AImprove vibration damping effectImprove work performanceSpringsLiquid based dampersAir separationEngineering

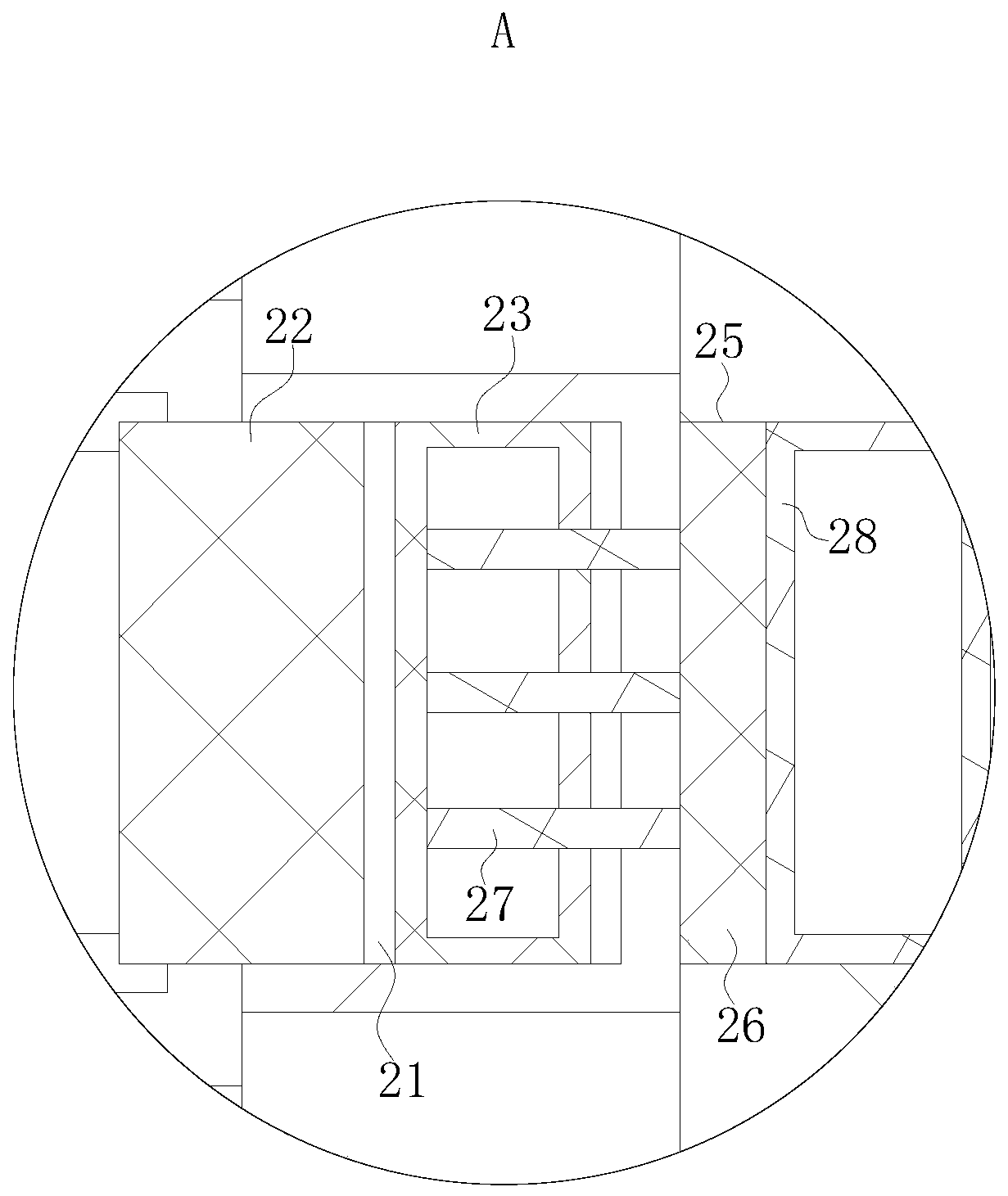

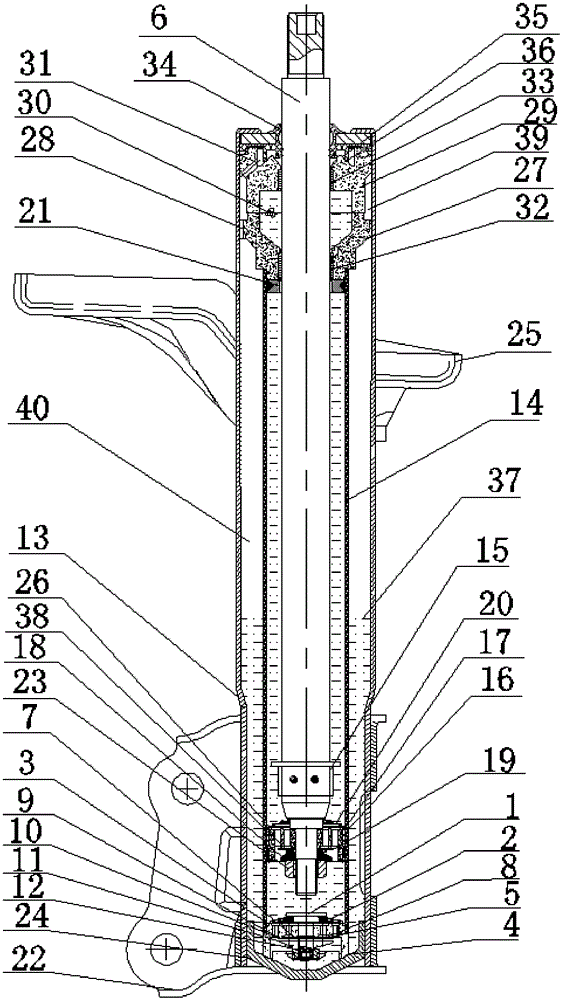

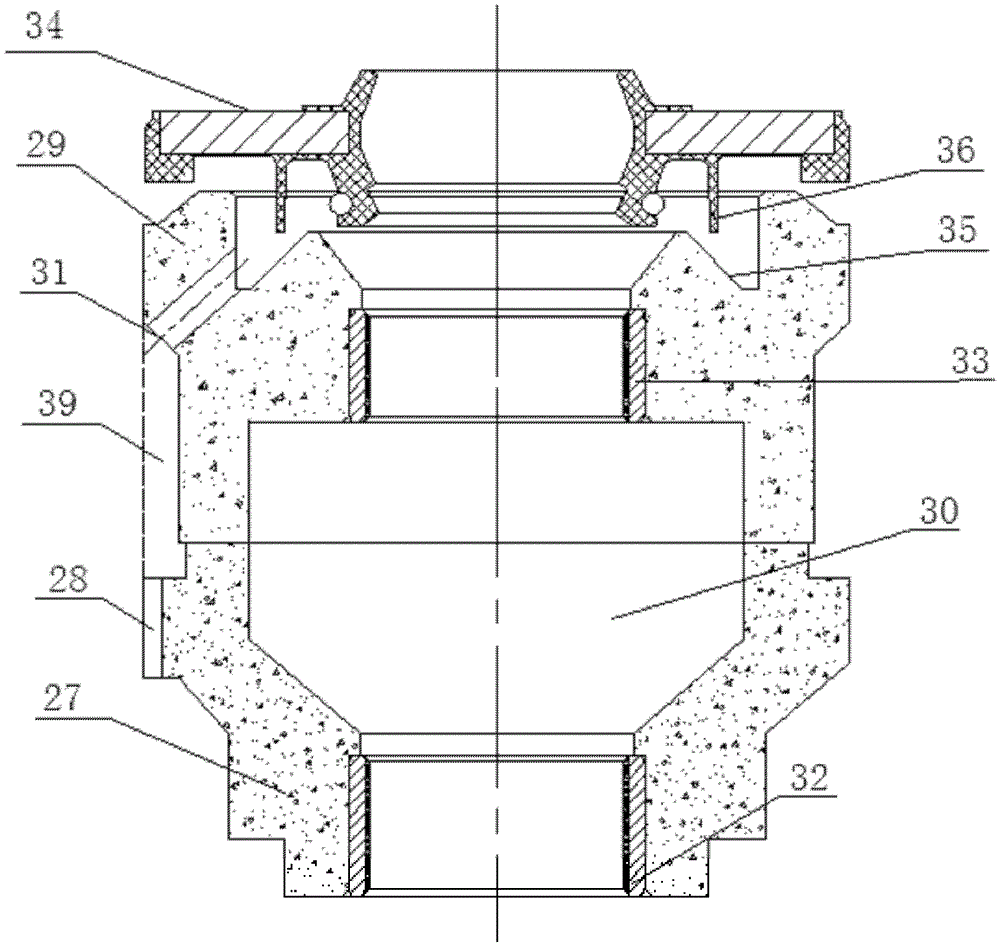

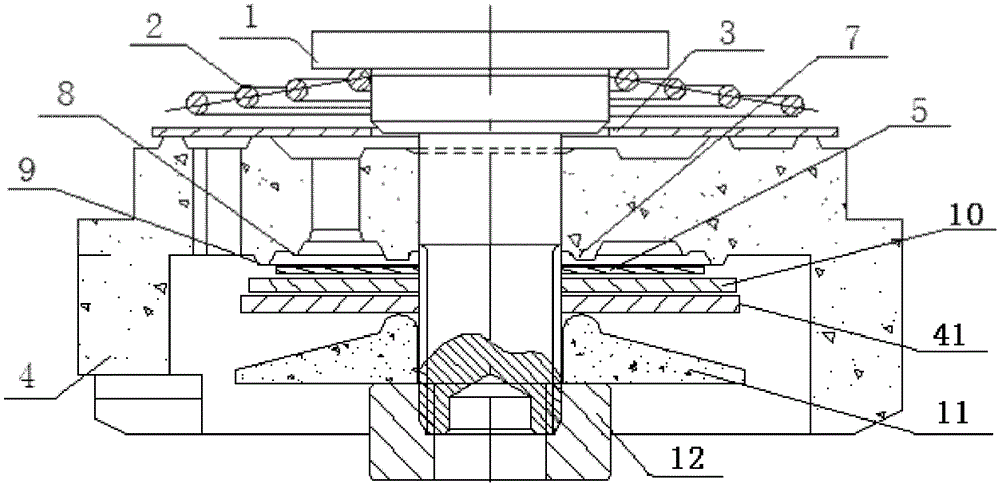

Provided is a shock absorber, comprising an oil storage cylinder (13), a working cylinder (14), a piston rod (6), a guiding and sealing assembly used to guide the movement of the piston rod (6), and an expansion and circulation valve assembly and a compression and compensation valve assembly provided on a piston (16). The guiding and sealing assembly comprises a guide seat (27, 29) and an oil seal (34) located at the upper end of the guide seat. The face of the upper end of the guide seat (27, 29) is formed with an oil storage groove, and the oil storage groove has an oil-air separation contact surface (35). An elastic separation lip (36) is formed on the oil seal (34) and the elastic separation lip (36) is in airtight contact with the oil-air separation contact surface (35) such that the oil storage groove is separated into an outside part and an inside part. Moreover, further provided are a vehicle suspension system and a vehicle comprising the shock absorber. The piston rod of the shock absorber has good movement stability, the friction between the piston and the inner wall of the working cylinder is low, and the shock absorber has a long service life and has significantly improved dampening effects.

Owner:浙江长进减震器有限公司

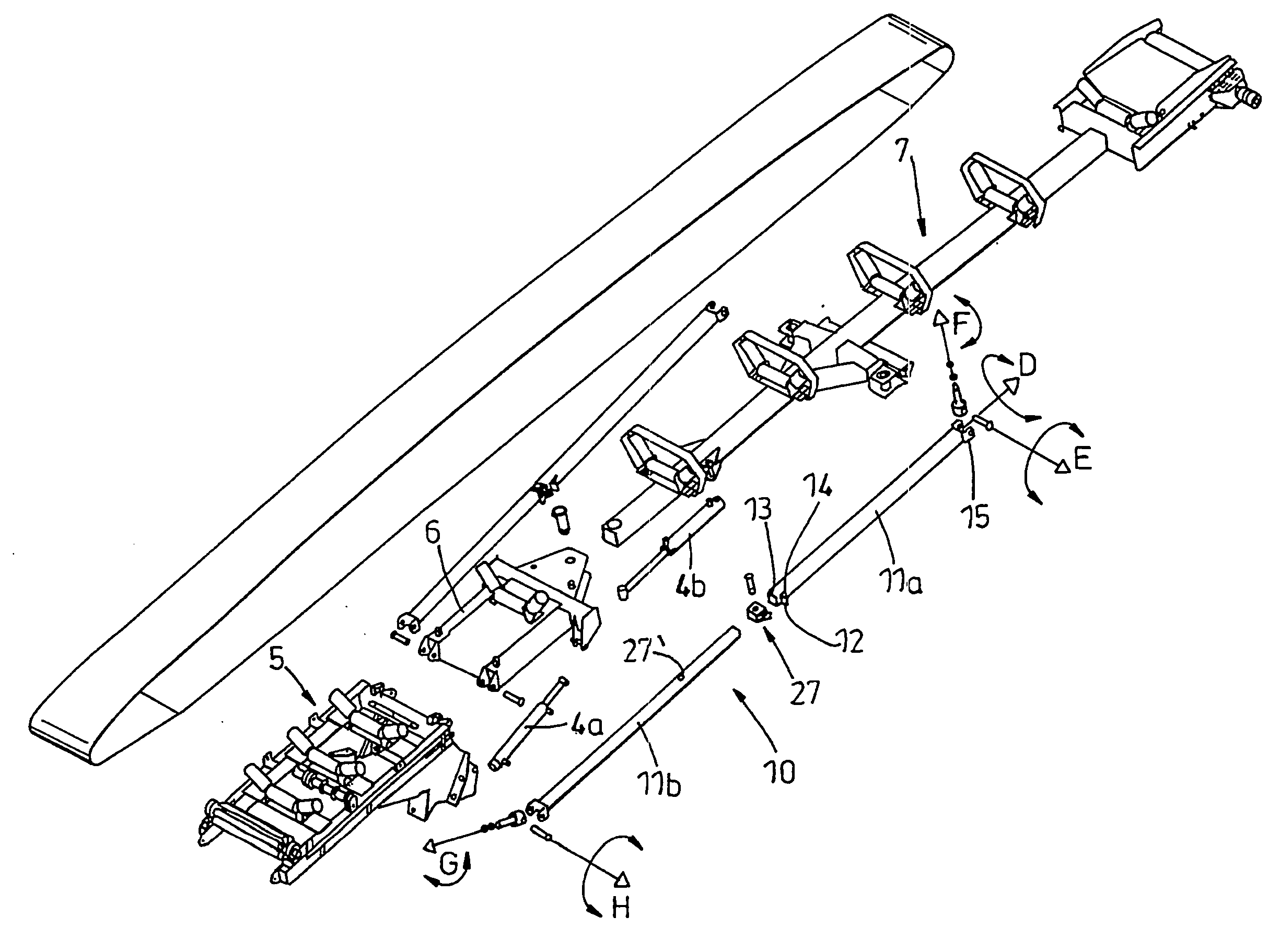

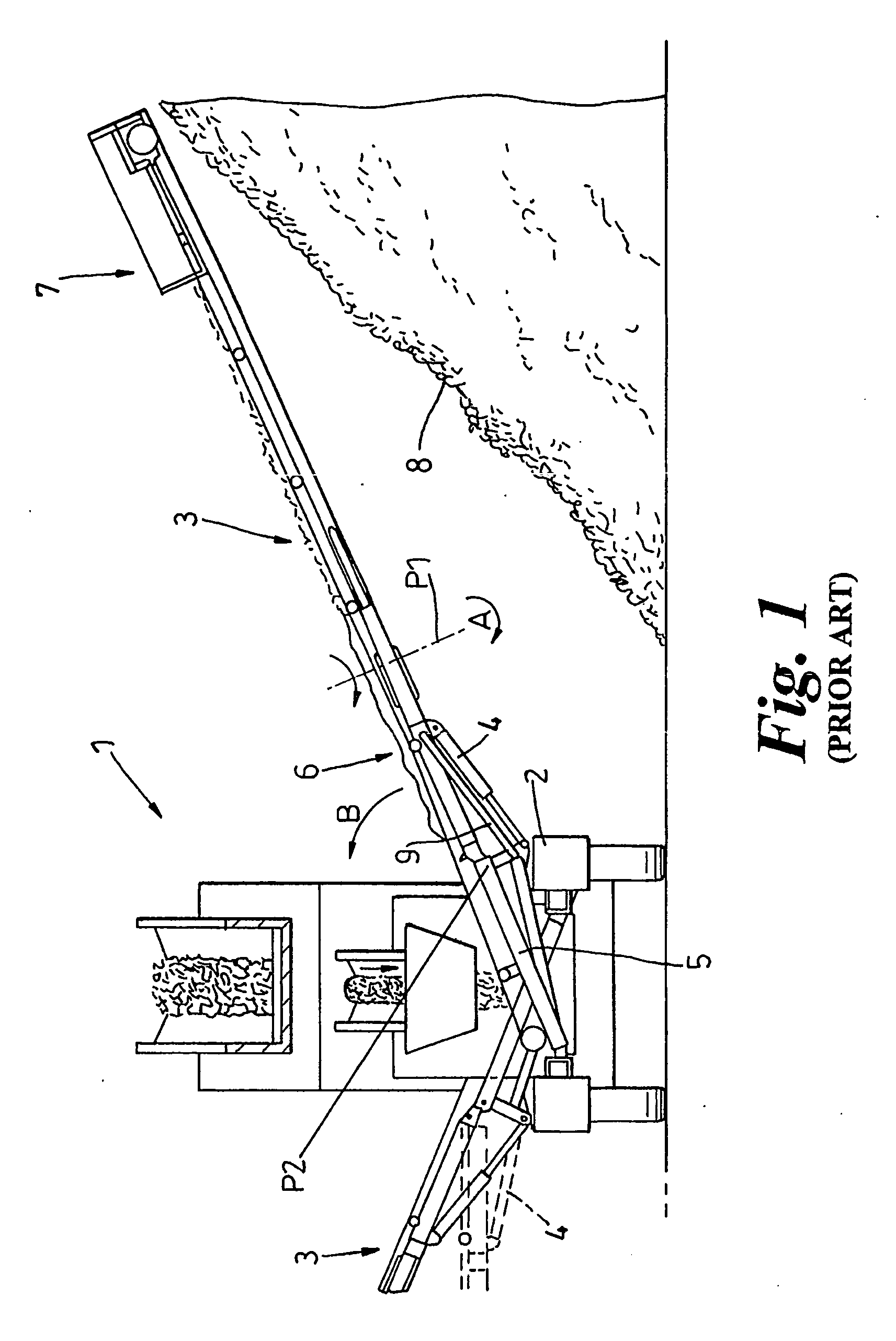

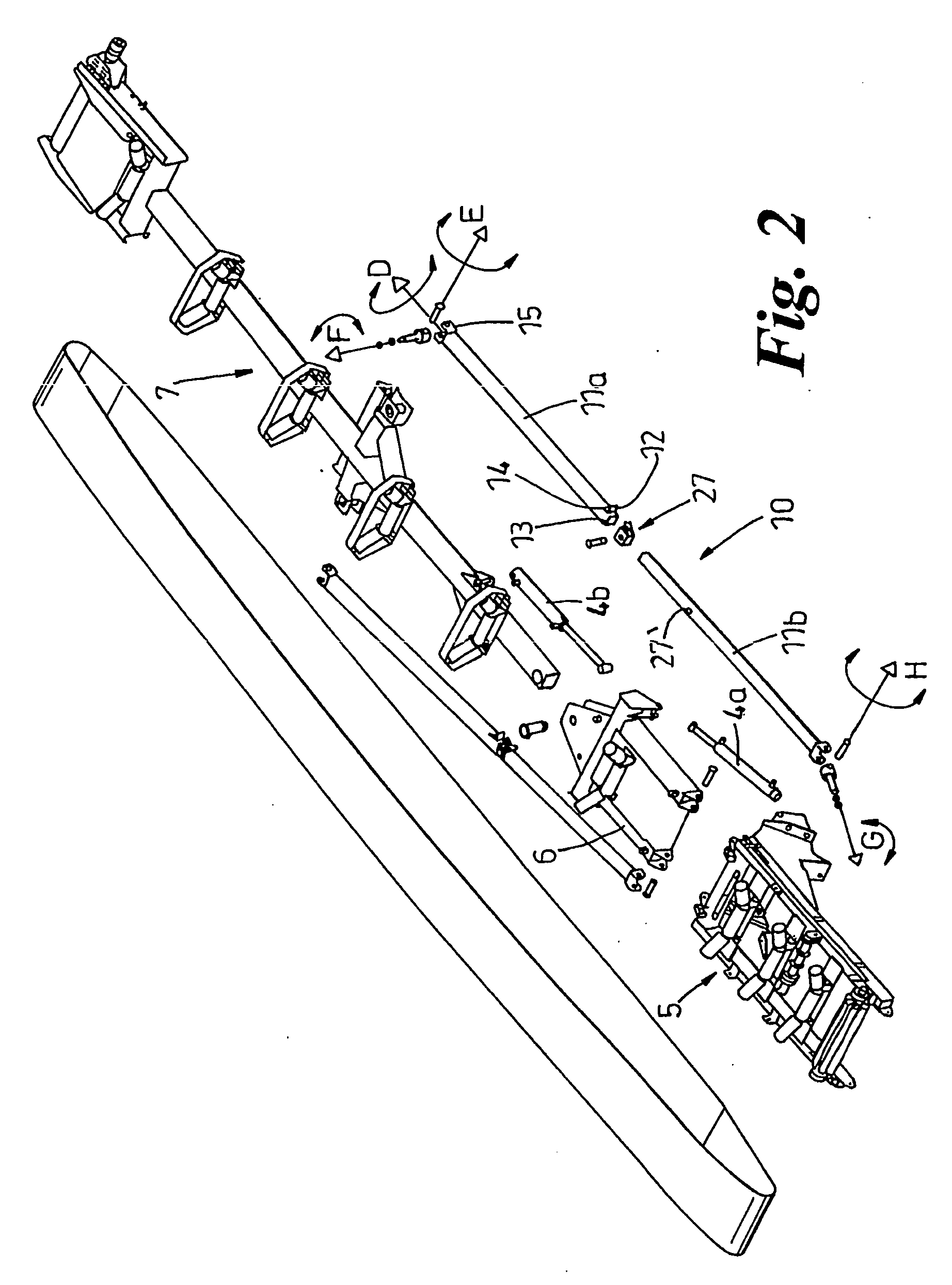

Support means

ActiveUS7552818B2Good flexibilityIncrease inventoryConveyorsSupporting framesThree degrees of freedomKinematic pair

Owner:SANDVIK INTELLECTUAL PROPERTY AB

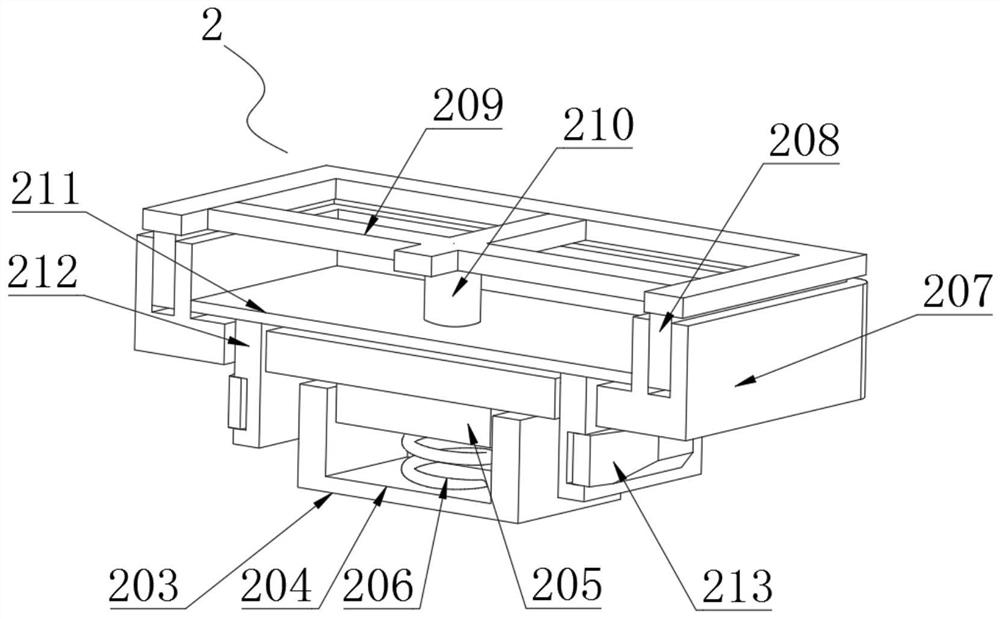

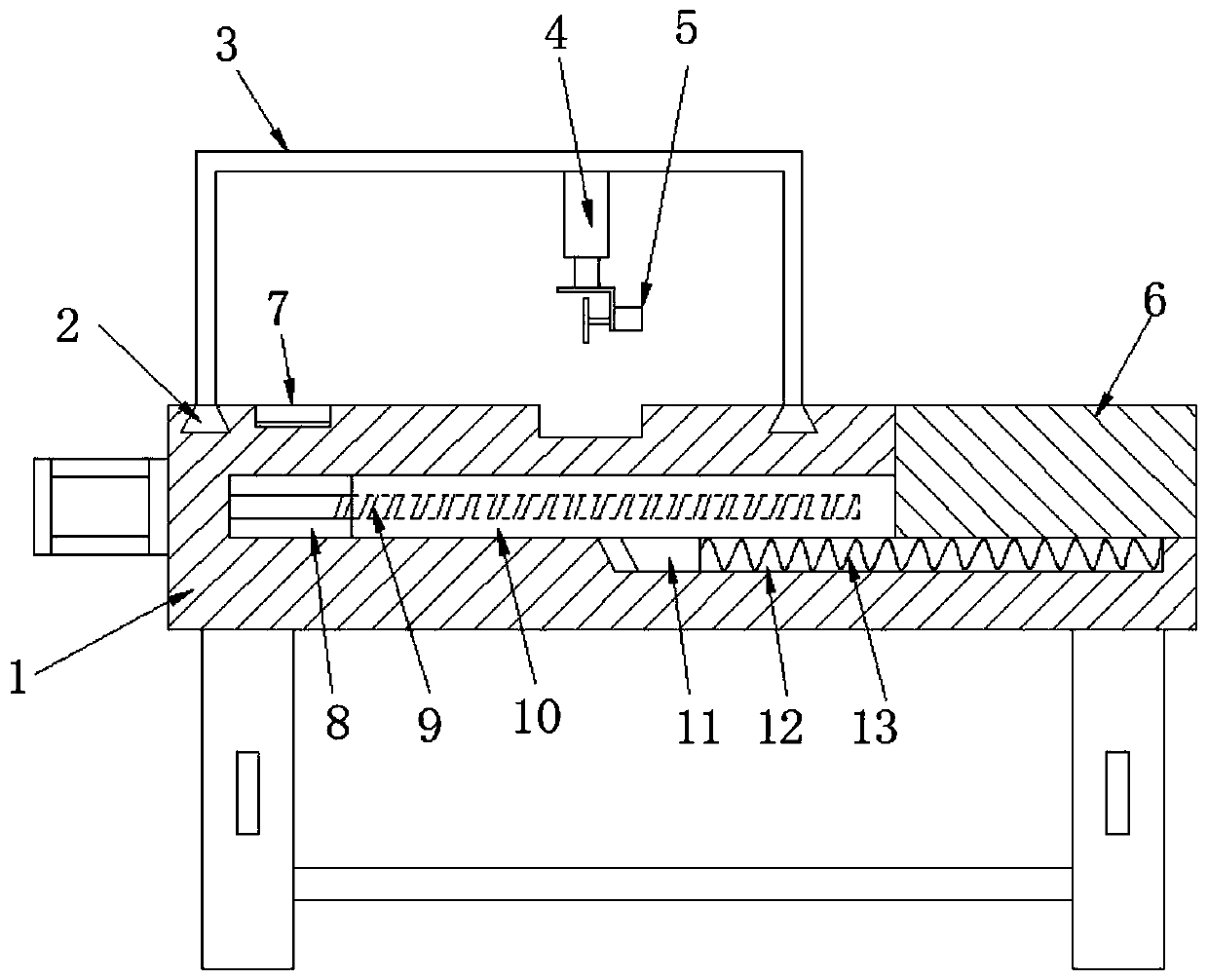

Flexible display screen and manufacturing method thereof

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

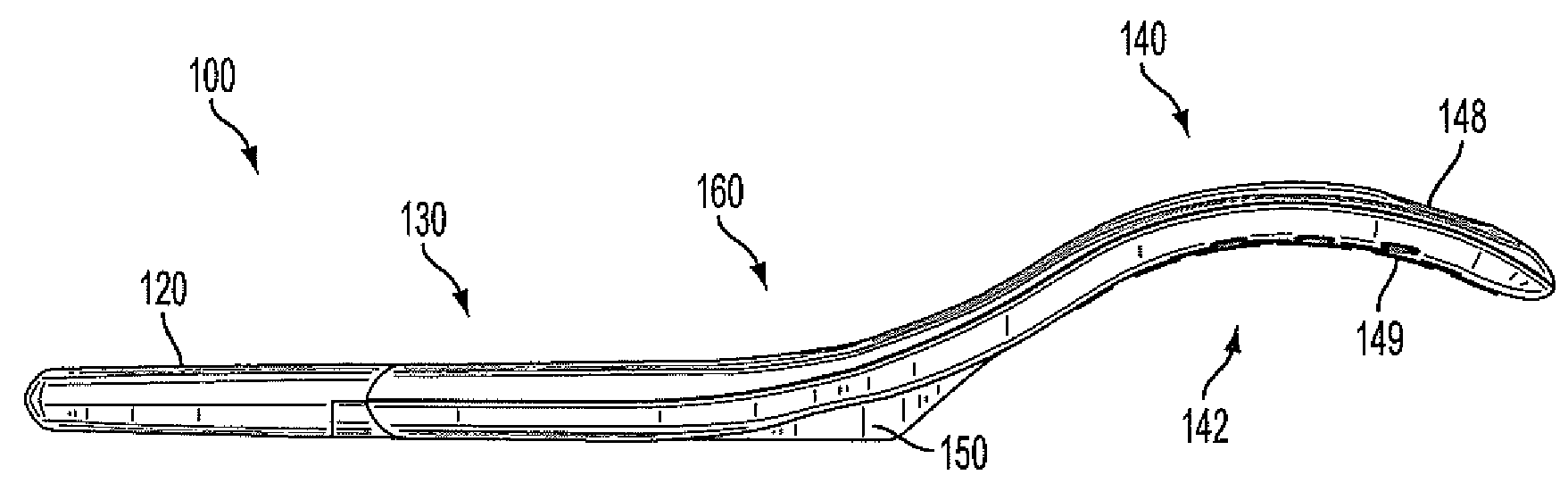

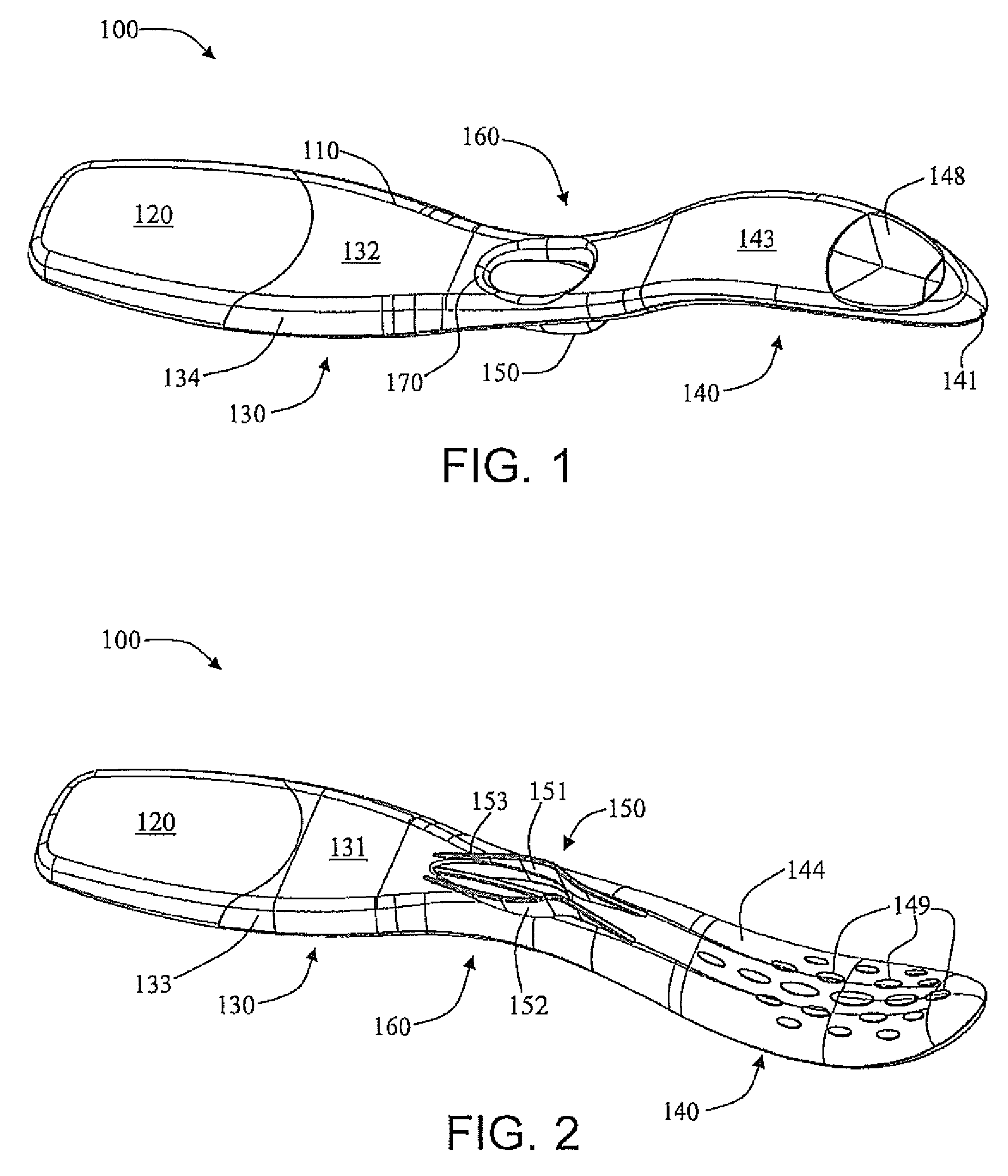

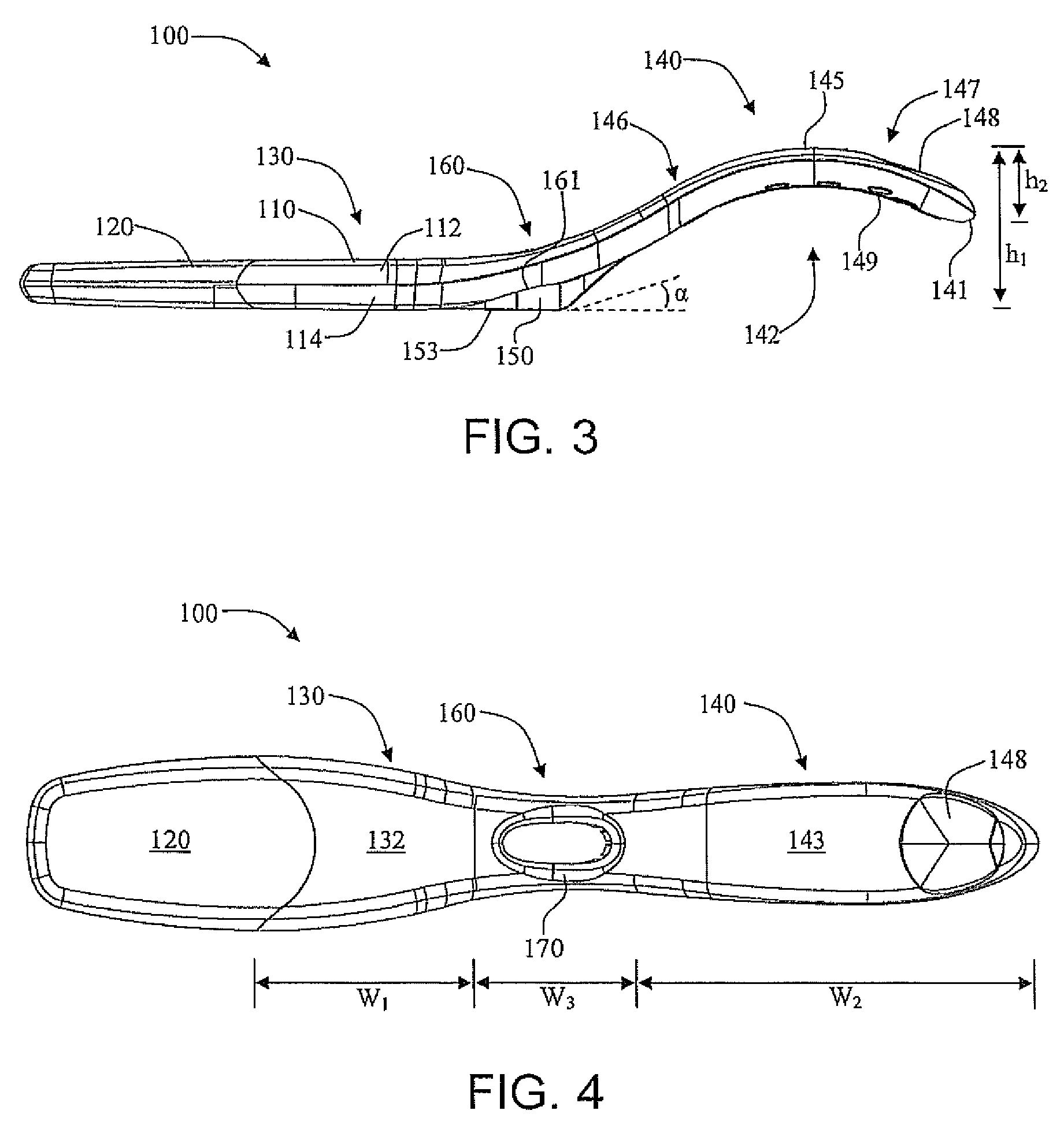

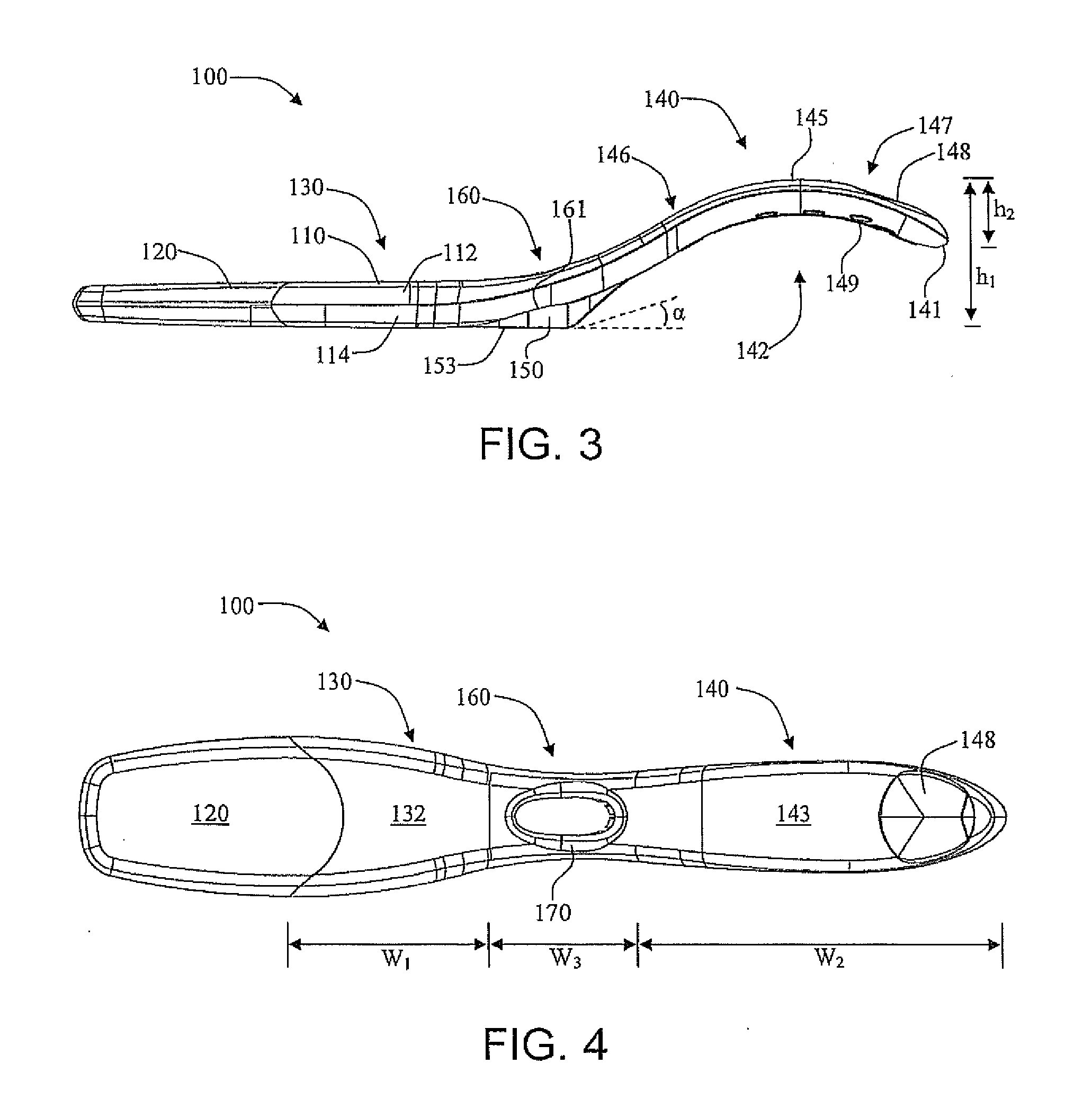

Diagnostic test device with improved structure

ActiveUS9151754B2Improved ergonomics and ease of useReduce usageSurgeryVaccination/ovulation diagnosticsAnalyteSafe operation

Owner:CHURCH & DWIGHT CO INC

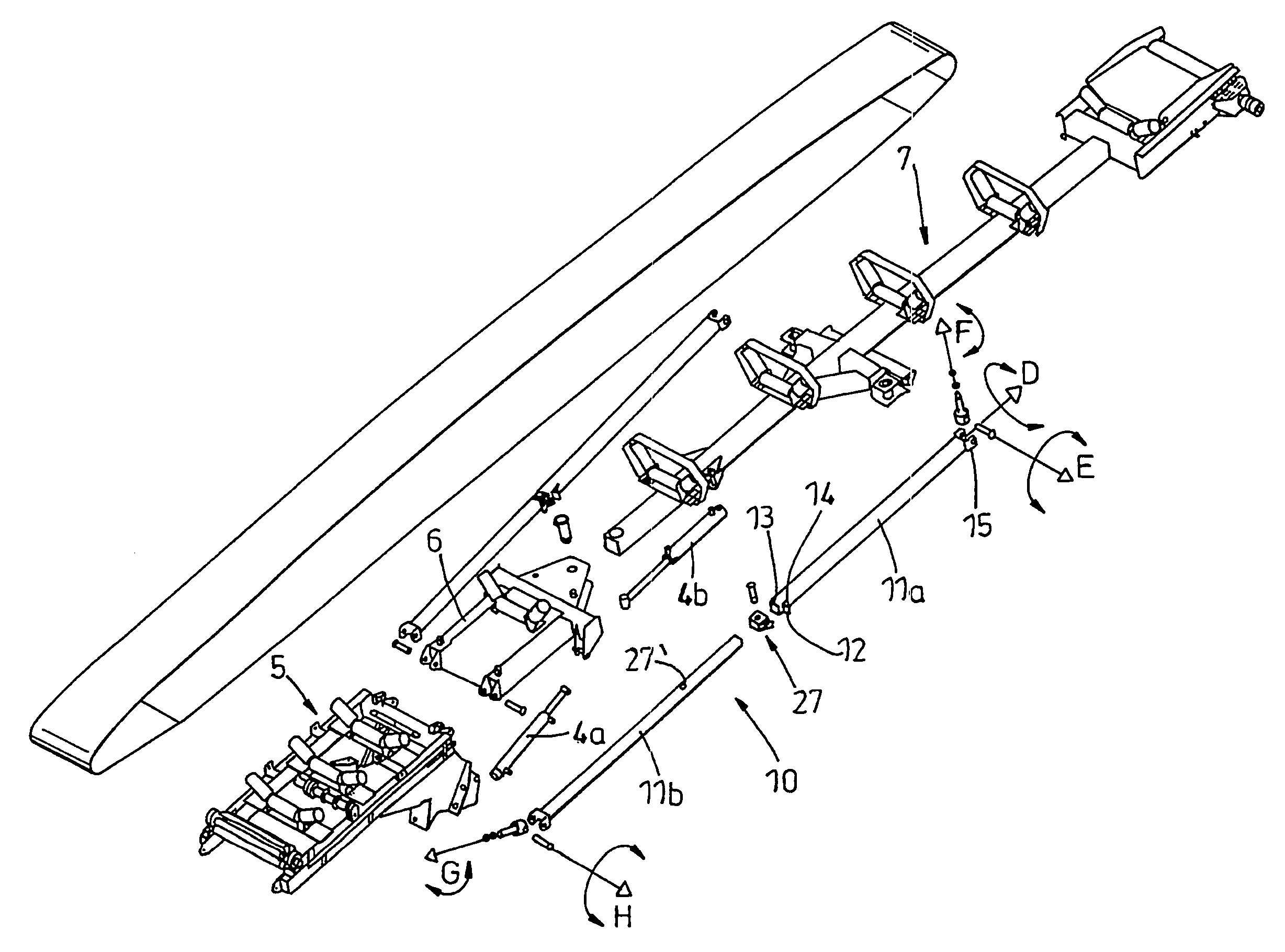

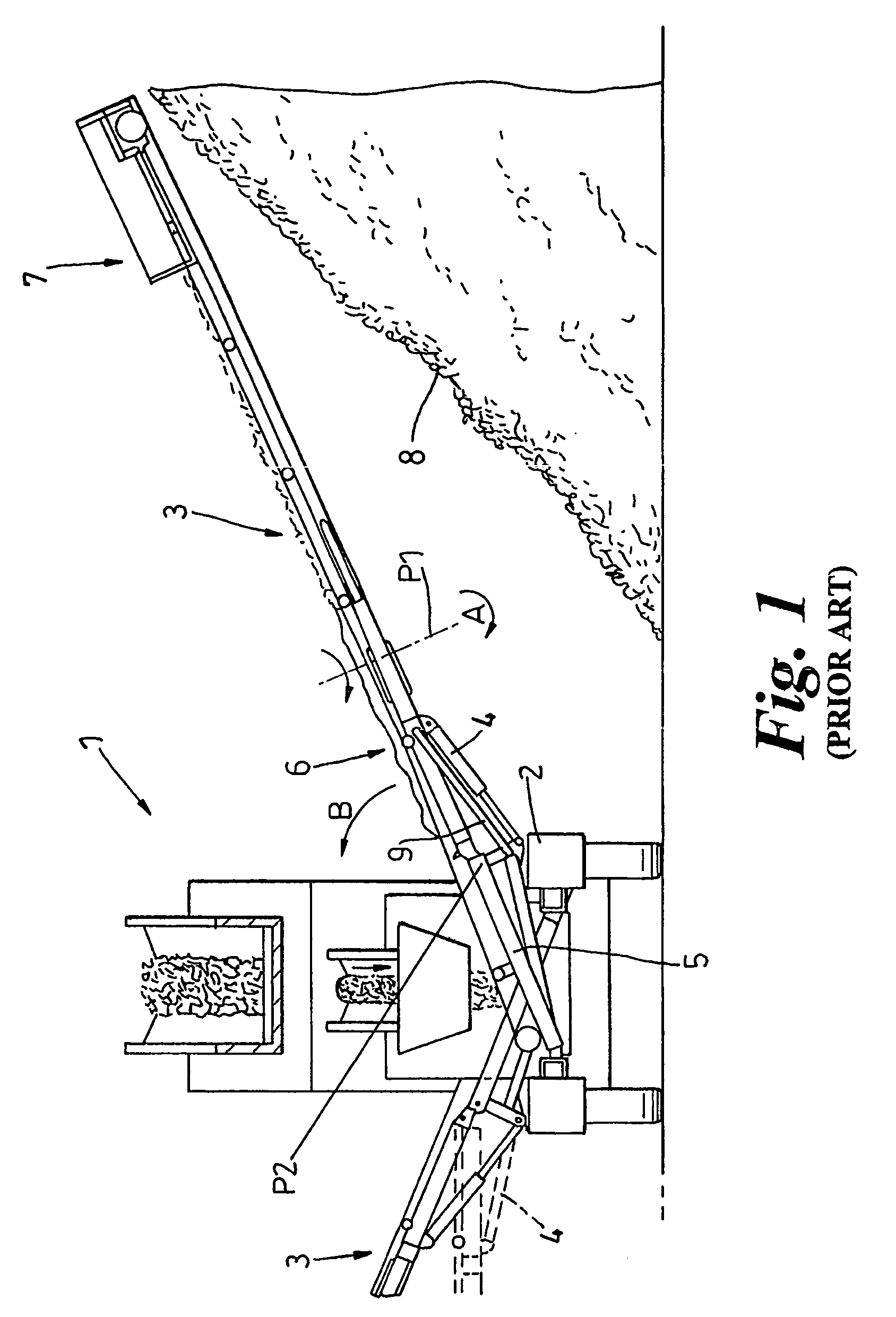

Support means

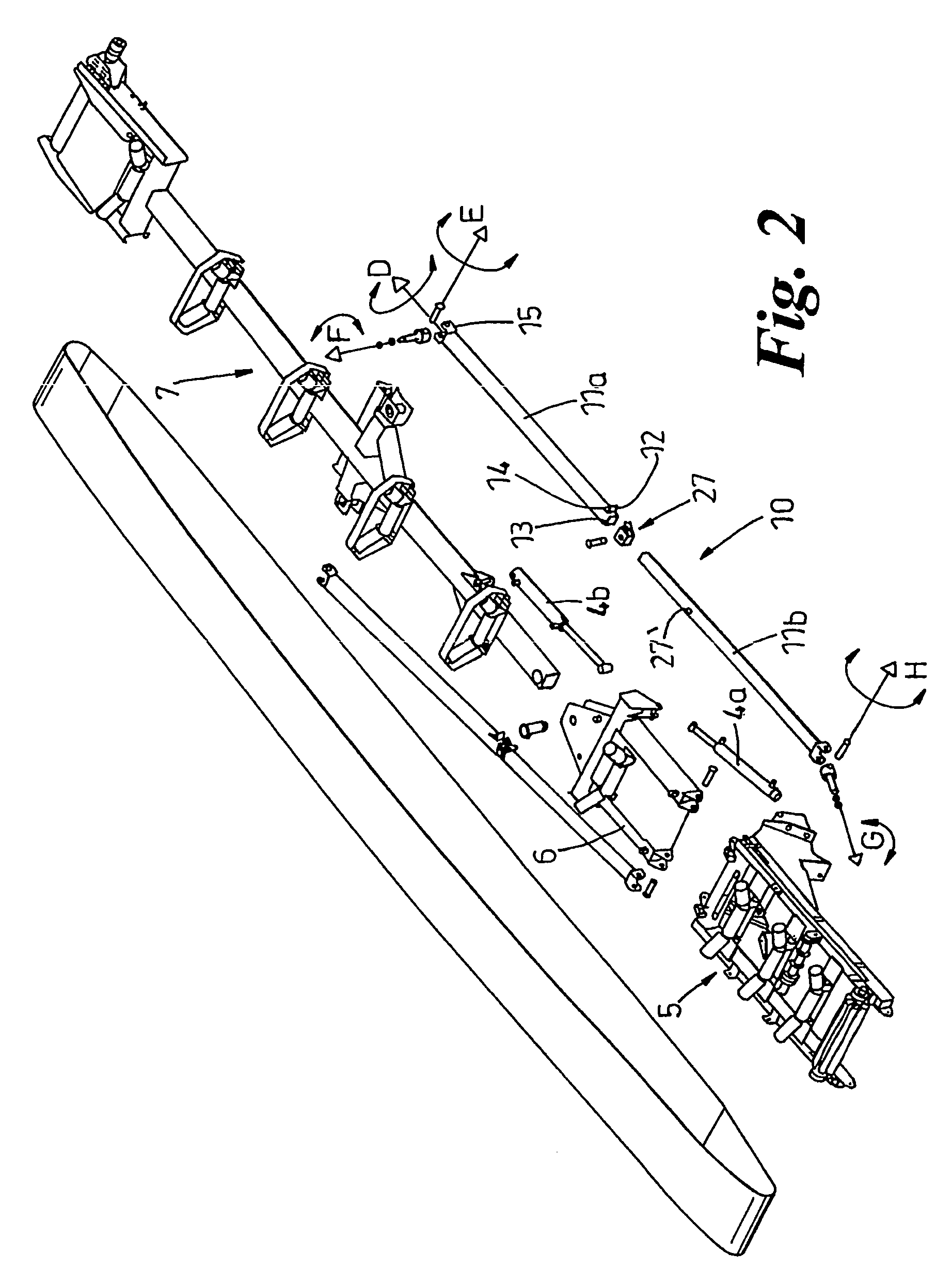

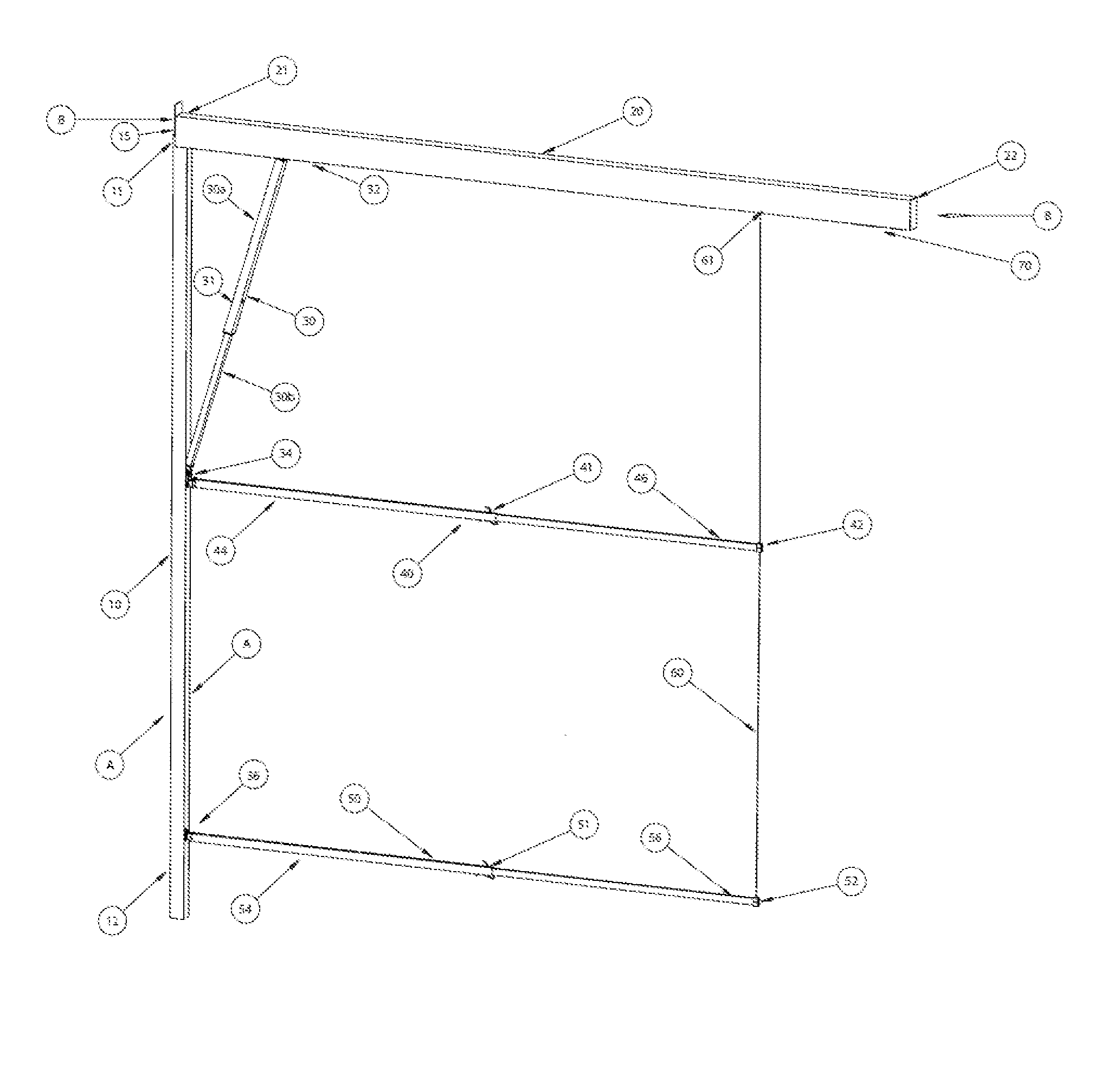

ActiveUS20070158162A1Easy to maintain and repairGood flexibilityConveyorsSupporting framesKinematic pairVariable length

The invention relates to support means, which is for supporting a lateral conveyor adapted for mounting upon a mobile chassis, including a tail section, middle section and at least one head section having pivot points related to the conveyor frame separating said sections from each other. The support means includes a variable length mounting arm comprising at least first and second sections and first and second ends, and means for locking the length of the mounting arm into at least one fixed length corresponding to the length of the conveyor in use. The first end is fixed immobile in relation to the mobile chassis and the second end is fixed immobile in relation to the head section of the conveyor. Also, the support means is configured to provide at least three kinematic pairs, a first kinematic pair being formed by the first section and the mobile chassis, a second kinematic pair is formed by the first and second sections, and the third kinematic pair is formed by the second section and the head section of the conveyor and is provided by a joint, the support means being further configured such that the first, second and third kinematic pairs respectively provide for two, one and three degrees of freedom of movement.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

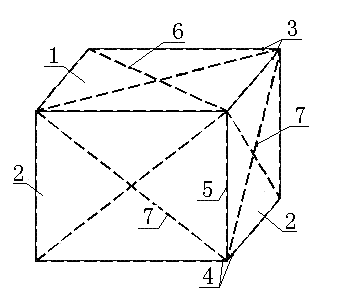

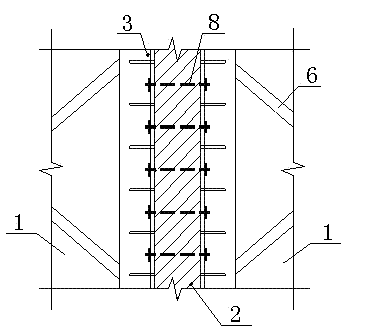

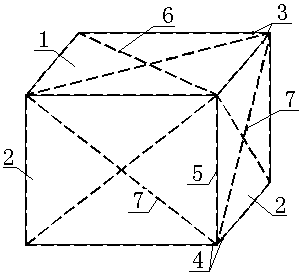

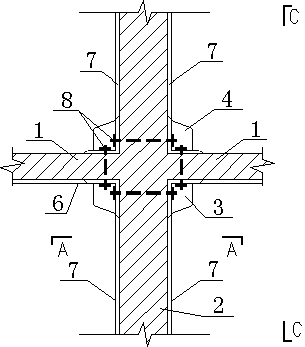

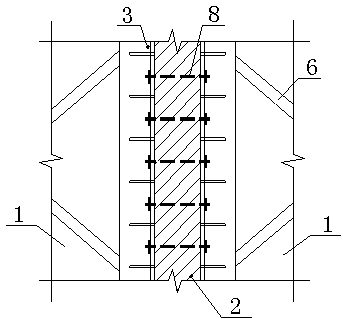

Masonry structure integrity reinforcing method

ActiveCN102477799AReduce earthquake forceProtected from vandalismBuilding repairsShock proofingCross connectionStructural integrity

The invention discloses a masonry structure integrity reinforcing method. In the method, an end reinforcing member is arranged at the junction between a floor and a wall surface; an upper end reinforcing member is arranged at the top of the wall, and a lower end reinforcing member is arranged at the bottom of the wall; when a ring beam exists, the upper end reinforcing member is not necessary, and a wall end reinforcing member is arranged at the junction of two walls; when a constructional column exists, the wall end reinforcing member is not necessary, a plate bottom reinforcing member is arranged at the bottom surface of the floor and is in cross connection with the upper end reinforcing member, and a wall surface reinforcing member is arranged on the wall surface and is in cross connection with the end reinforcing member; the upper end reinforcing member is connected with the wall surface reinforcing member, the plate bottom reinforcing member and the wall end reinforcing member; the lower end reinforcing member is connected with the wall surface reinforcing member and the wall end reinforcing member; and the upper end reinforcing member, the lower end reinforcing member, the wall end reinforcing member, the wall surface reinforcing member and the plate bottom reinforcing member are connected in a whole. Compared with the traditional reinforcement, the reinforcement of the floor and the reinforcement of the wall surface are connected with each other, the structural integrity is better, and the construction is simple and convenient and free from the influence of ambient temperature.

Owner:上海维固工程实业有限公司 +2

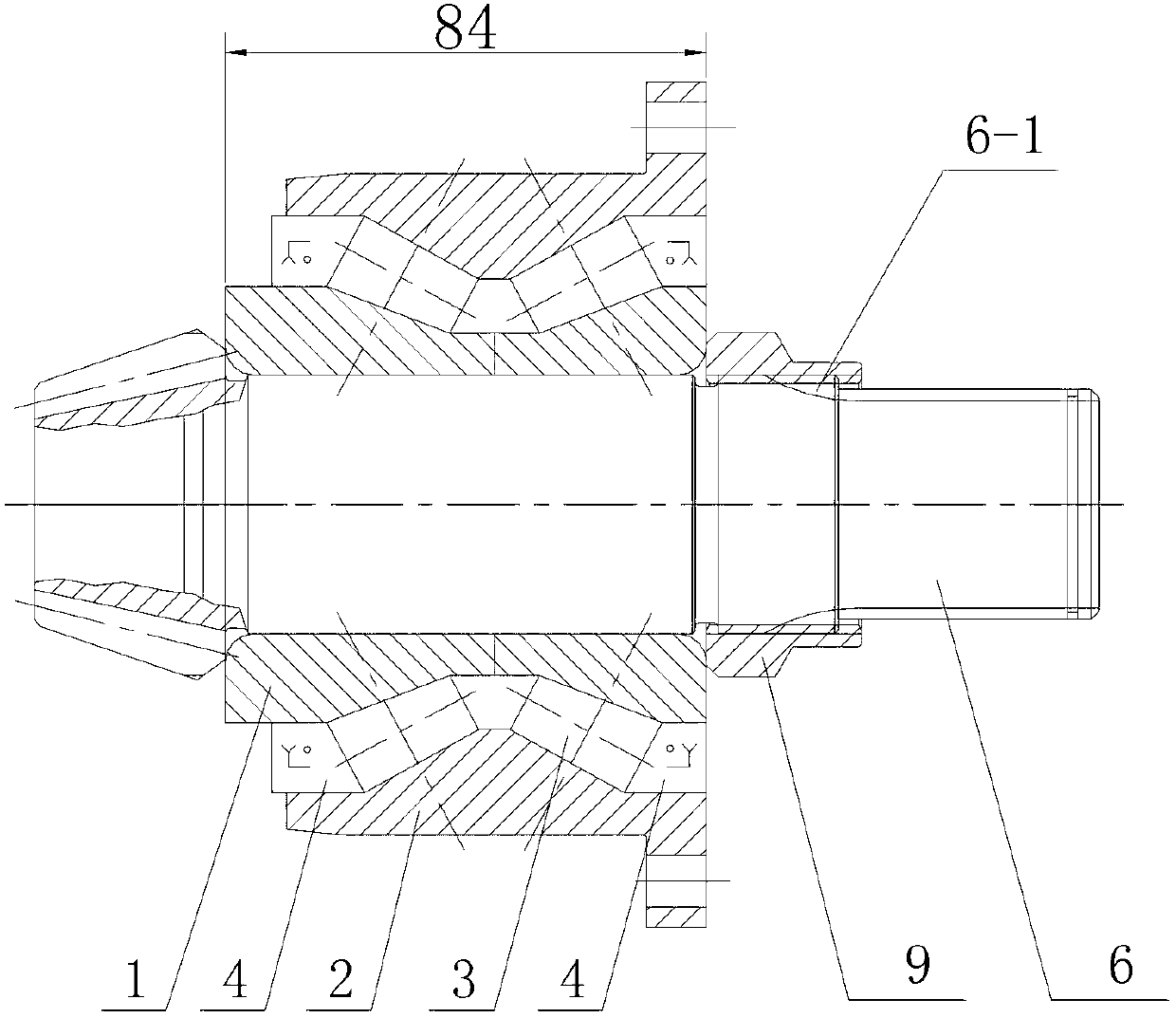

Bearing unit for supporting transmission shaft and gear reducer

InactiveCN102996630AImprove performanceClearance remains stableRoller bearingsBearing componentsDrive shaftGear wheel

The invention relates to a bearing unit for supporting a transmission shaft, which comprises an inner ring, an outer ring, a sealing member, and tapered rollers; two tapered rollers are respectively disposed between the inner ring and the outer ring; the inner ring has a fission structure; the outer ring has an integrated structure; a sealing member is disposed between the outer ring and the inner ring. The invention also relates to a gear reducer which mainly comprises a casing, a transmission shaft, a driving bevel gear, and a driven bevel gear; the transmission shaft is mounted on the casing through the bearing unit; the outer transmission shaft of the bearing unit is equipped with a retaining locking nut. The reducer improves the stability in bevel gear operation, changes traditional assembling methods for obtaining a required bearing clearance by replacing a shim and repeatedly adjusting, omits clearance adjustment, greatly improves the manufacturability and reliability of reducer assembling, reduces complicated process flow for original assembling, and improves production efficiency. In addition, the invention also has the advantages of compact structure, easy mounting and dismounting, and the like.

Owner:TIANJIN HUAYE RONGCHENG PRECISION MACHINERY +1

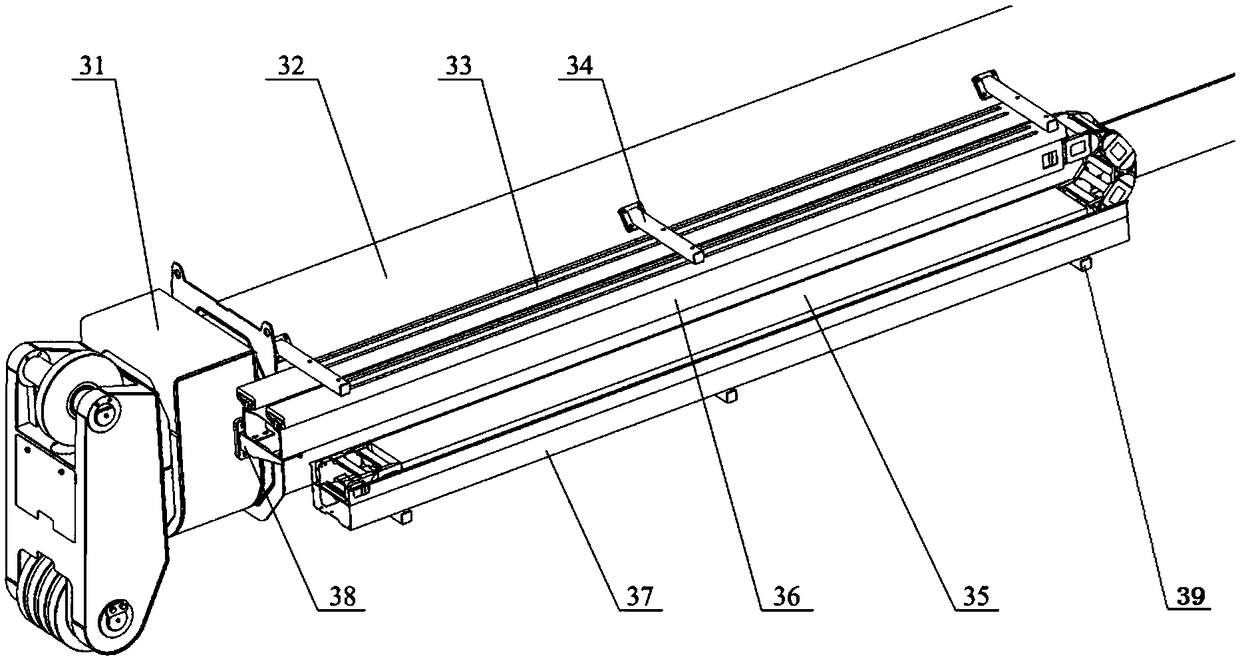

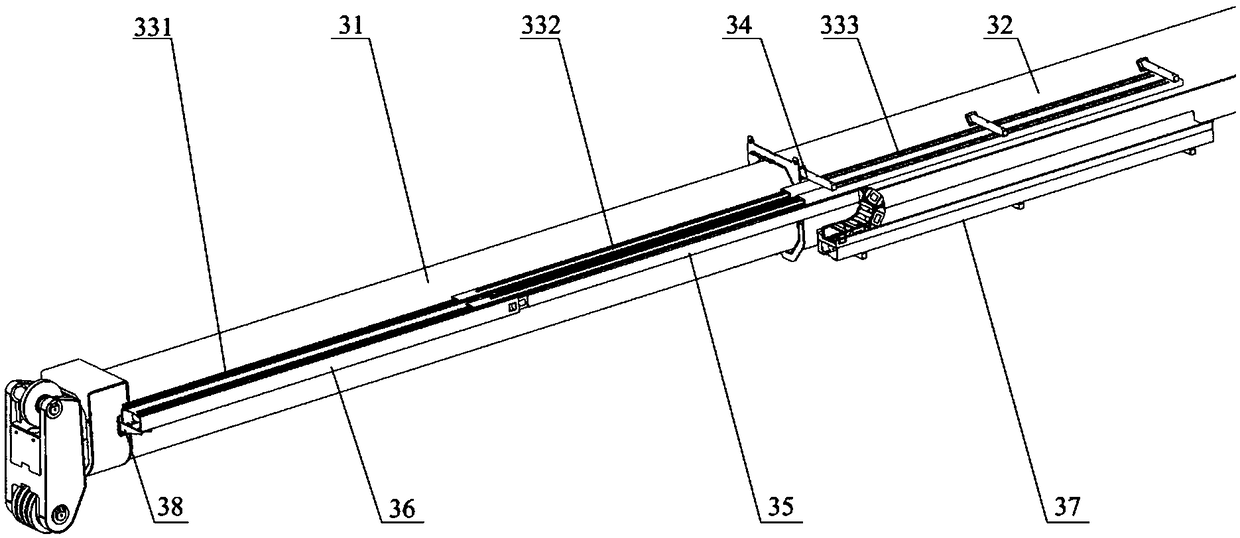

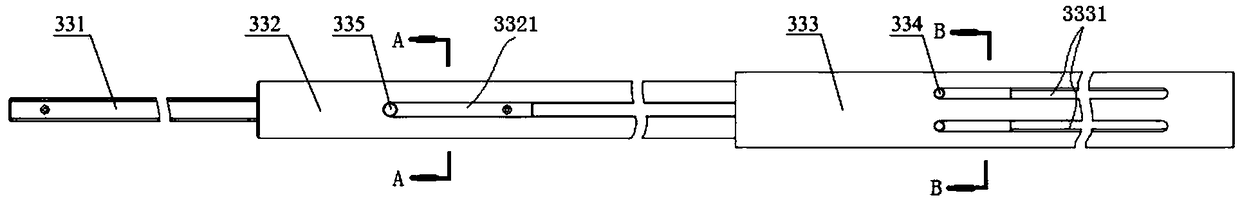

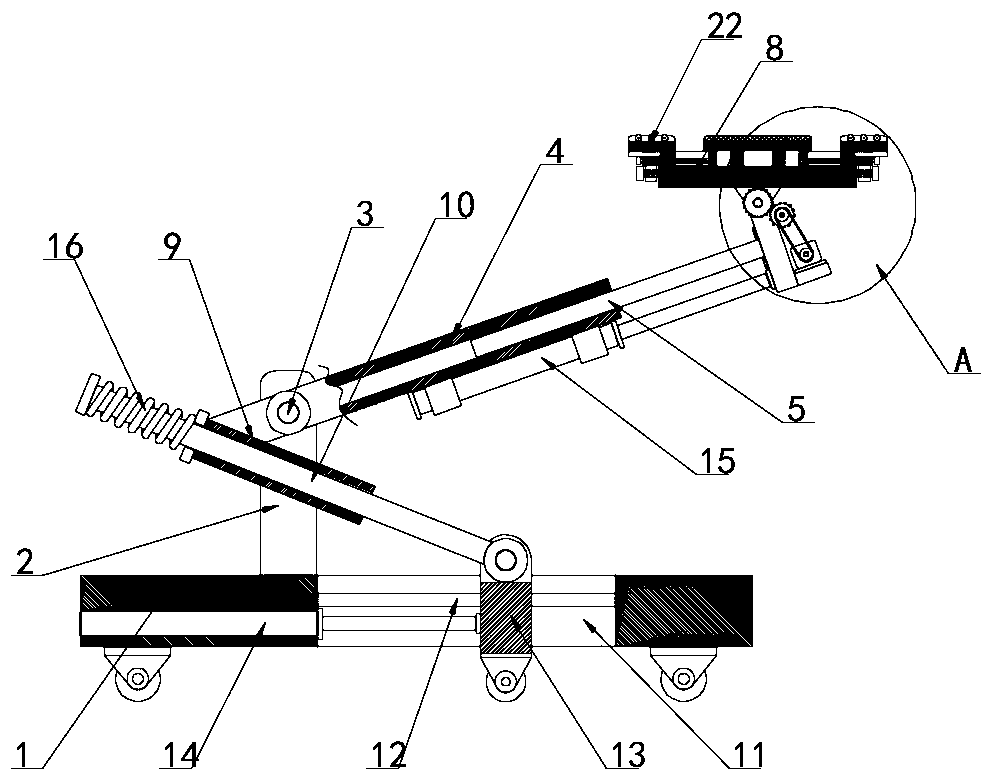

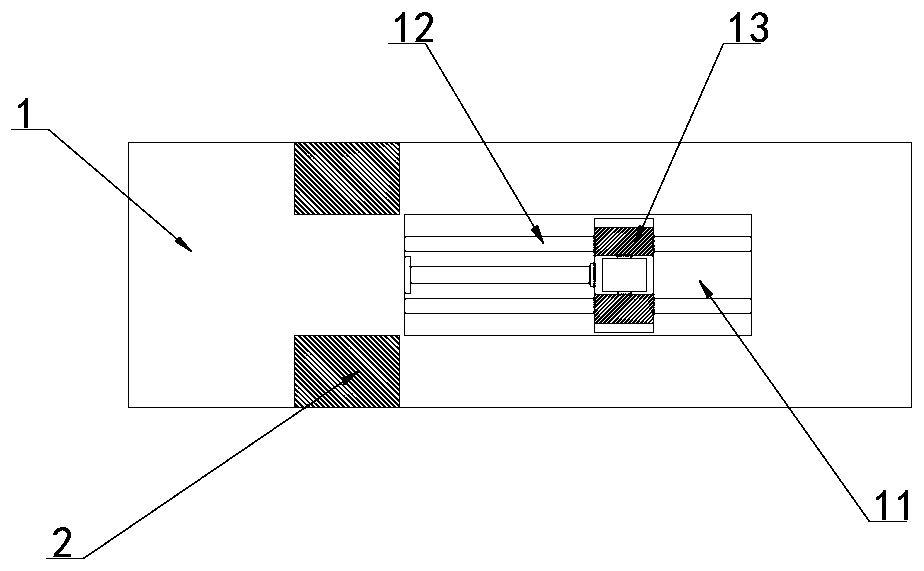

Work arm and engineering machine

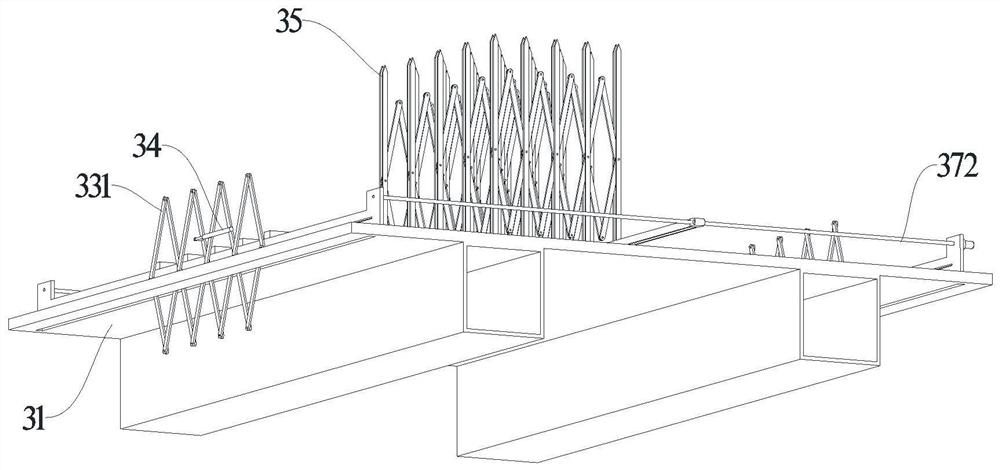

PendingCN109205470ASmall sizeIncrease support lengthRod connectionsLoad-engaging elementsLine tubingEngineering

The invention provides a work arm and an engineering machine. The work arm comprises a telescopic arm and a pipeline guiding device, wherein the pipeline guiding device comprises multistage guide rails, a pipeline box, a drag chain and a drag chain guiding groove, wherein the multistage guide rails are arranged on the telescopic arm along the extending direction of the telescopic arm and comprisemulti-section tracks which are sequentially and telescopically connected; the first-section track in the multi-section track is connected to a basic arm of the telescopic arm; the pipeline box is connected to the tail-section track of the multistage guide rails along the extending direction of the telescopic arm; the first end of the pipeline box is connected with an arm head of a tail arm sectionof the telescopic arm; the first end of the drag chain is connected to the second end of the pipeline box; the drag chain guiding groove is arranged on the basic arm along the extending direction ofthe telescopic arm and is used for bearing the drag chain; the second end of the drag chain is connected to the first end, away from the arm tail of the telescopic arm, of the drag arm guiding groove.The work arm and the engineering machine with the work arm disclosed by the invention have the advantages that the length of the pipeline box is favorably reduced, overall dimension of the pipeline guiding device is reduced, the interference risk of the pipeline guiding device and other structures is reduced and application range is wider.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

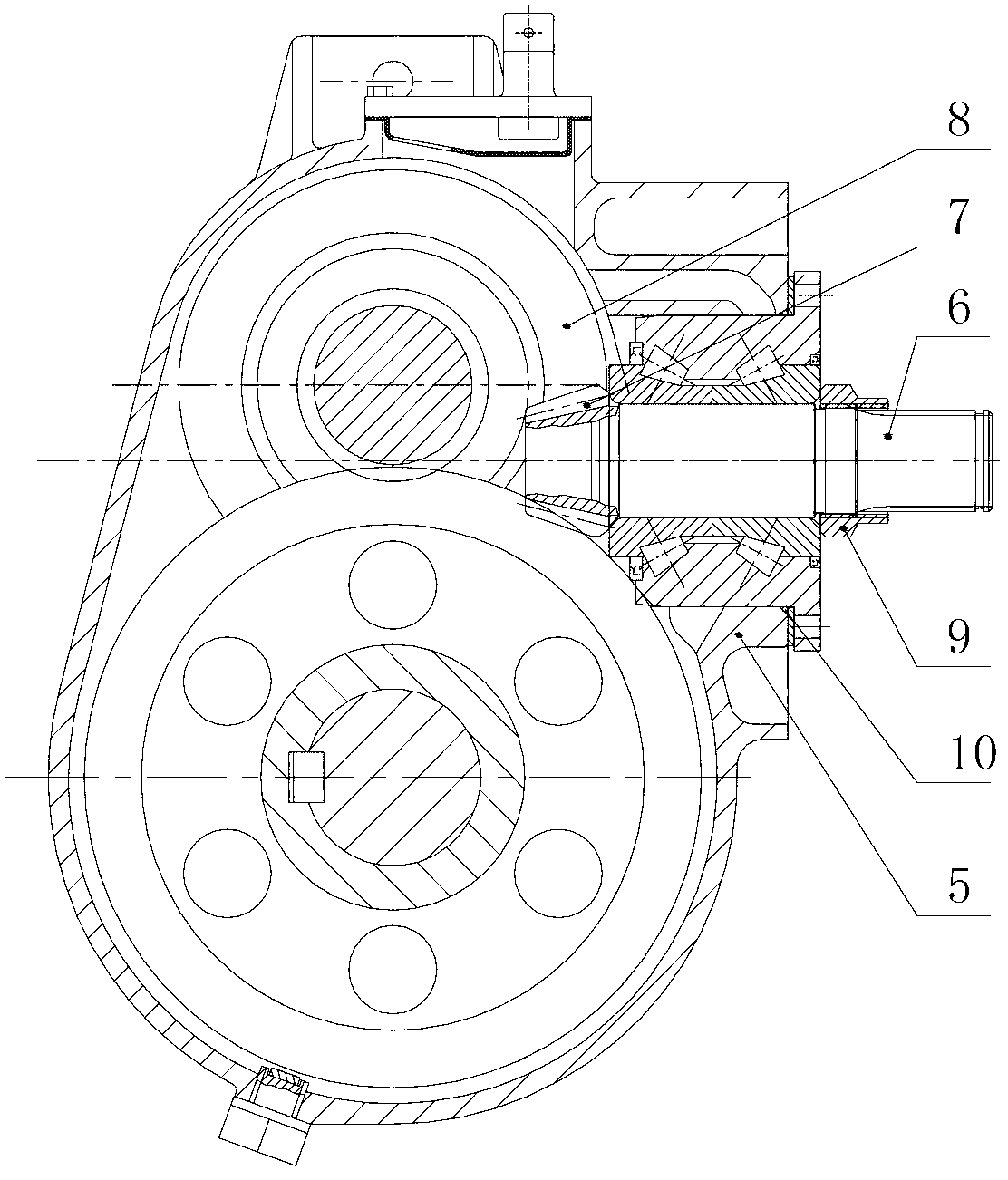

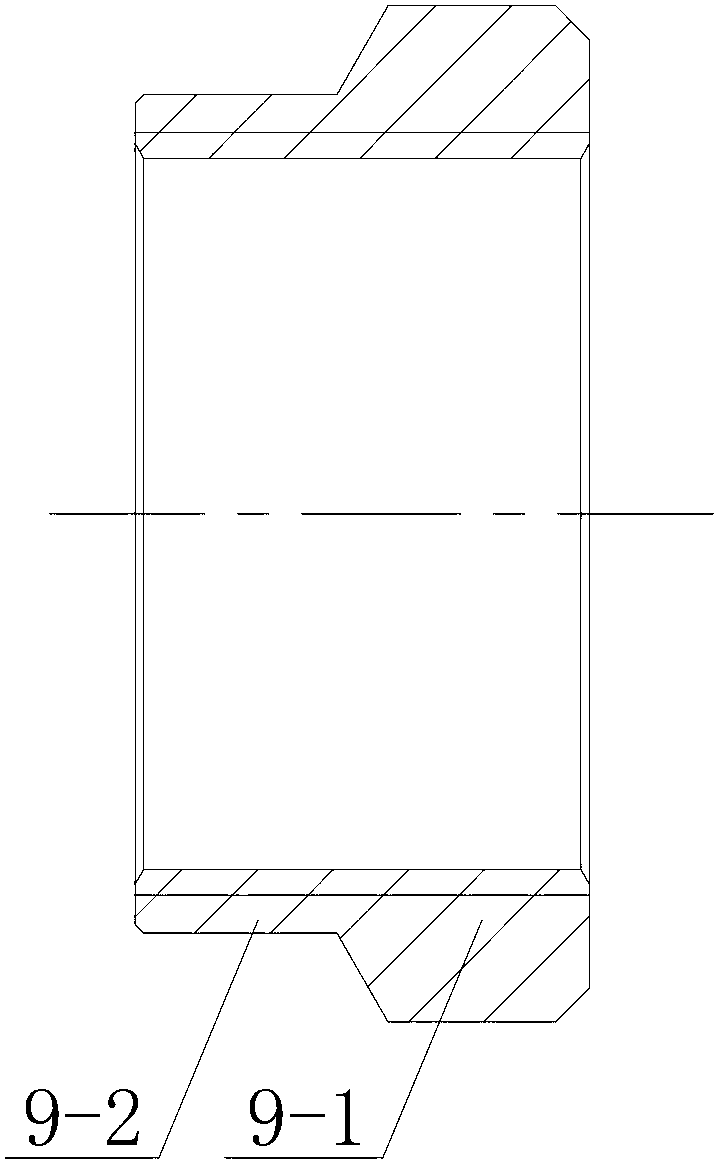

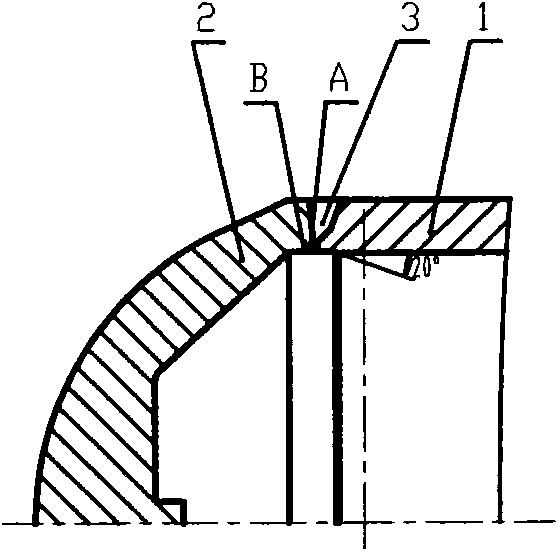

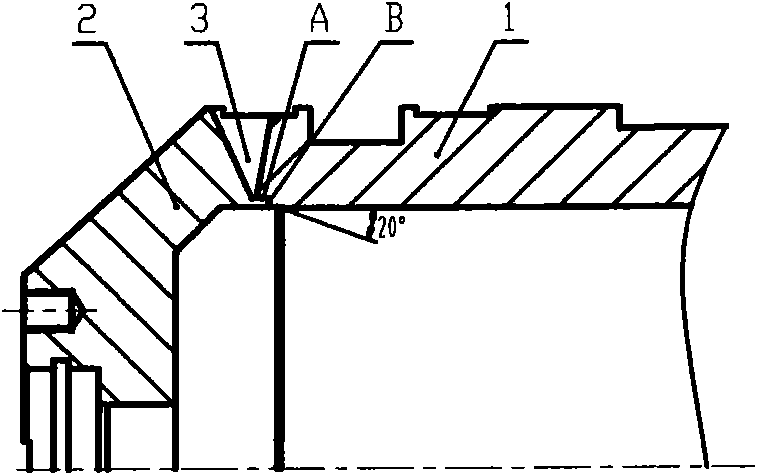

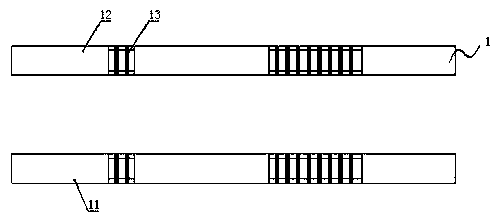

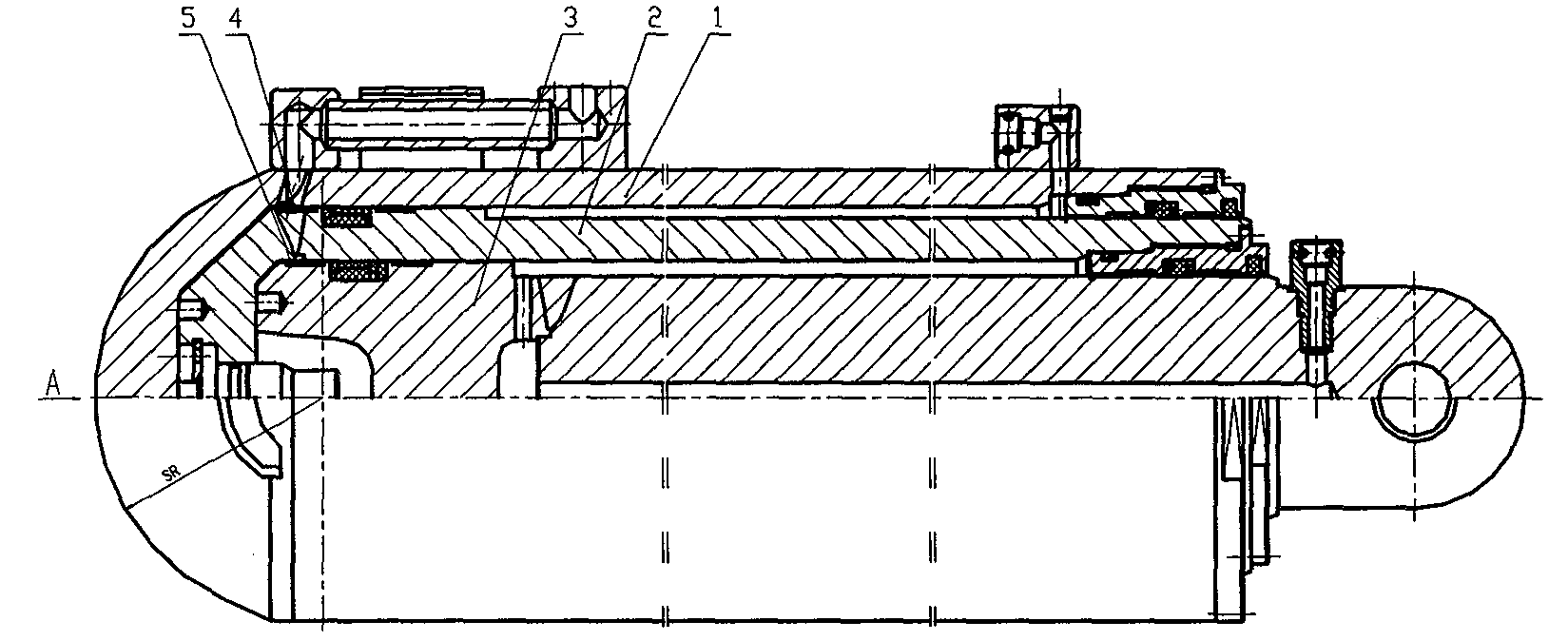

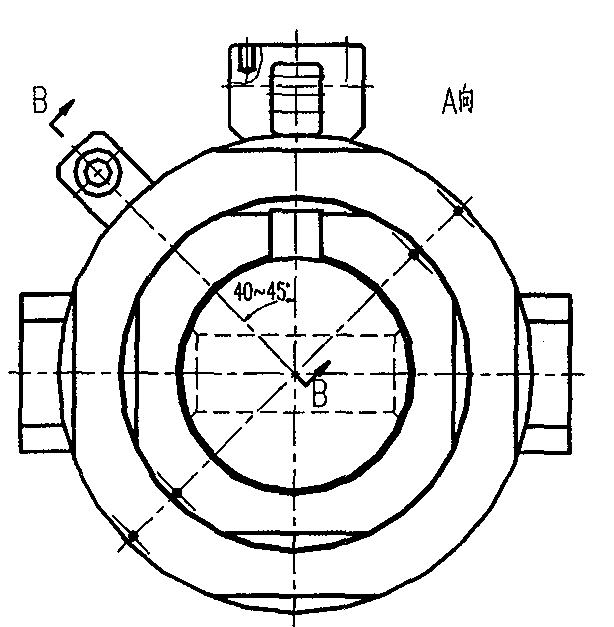

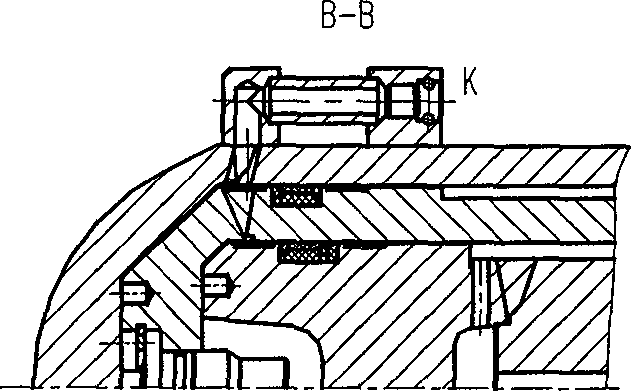

Guide ring overwelding seam large-cylinder bottom double-telescopic upright column

ActiveCN102140923AIncrease support lengthLarge expansion ratioProps/chocksPulp and paper industrySafety valve

The invention relates to a guide ring overwelding seam large-cylinder bottom double-telescopic upright column. The telescopic ratio of the double-telescopic upright column is effectively enhanced through a guide ring overwelding seam structure and a method for increasing the spheric radius of the bottom of an outer cylinder; the safety of the double-telescopic upright column is effectively enhanced by adding a bypass safety valve to the double-telescopic upright column; and the guide ring overwelding seam is realized by adopting an interference avoidance structure without processing after a cylinder bottom and a cylinder barrel are welded, thereby the processing process is simplified and the maintenance of a cylinder body is facilitated in the using process; and in addition, the invention is especially suitable for a low-coal-seam hydraulic support and a hydraulic support which has lower support efficiency caused by insufficient telescopic ratio of the double-telescopic upright column.

Owner:CCTEG COAL MINING RES INST

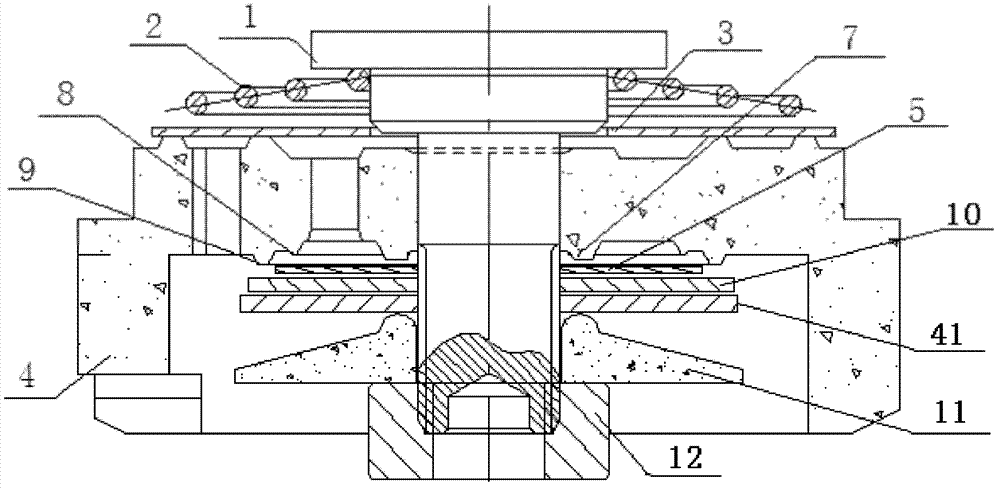

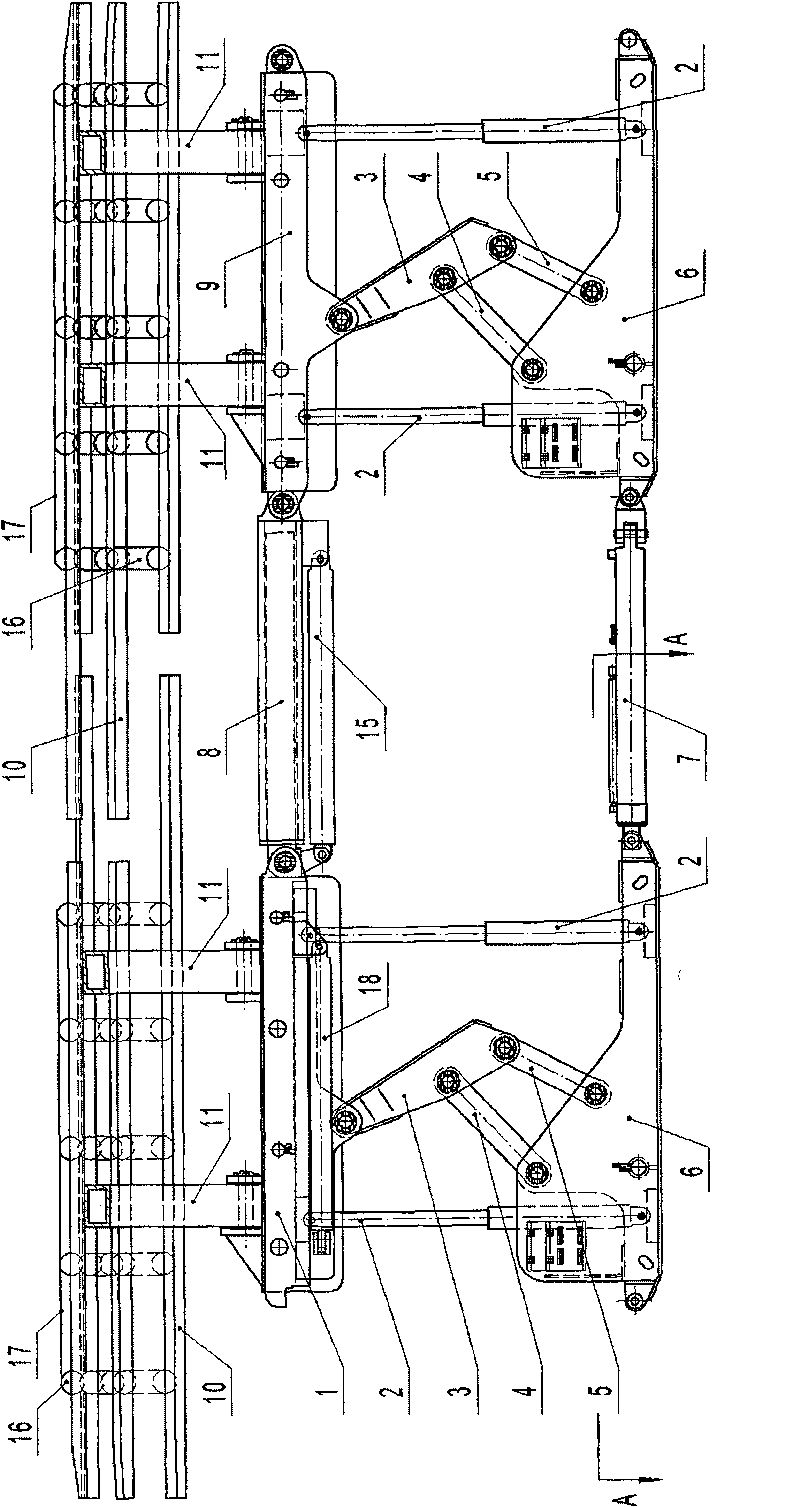

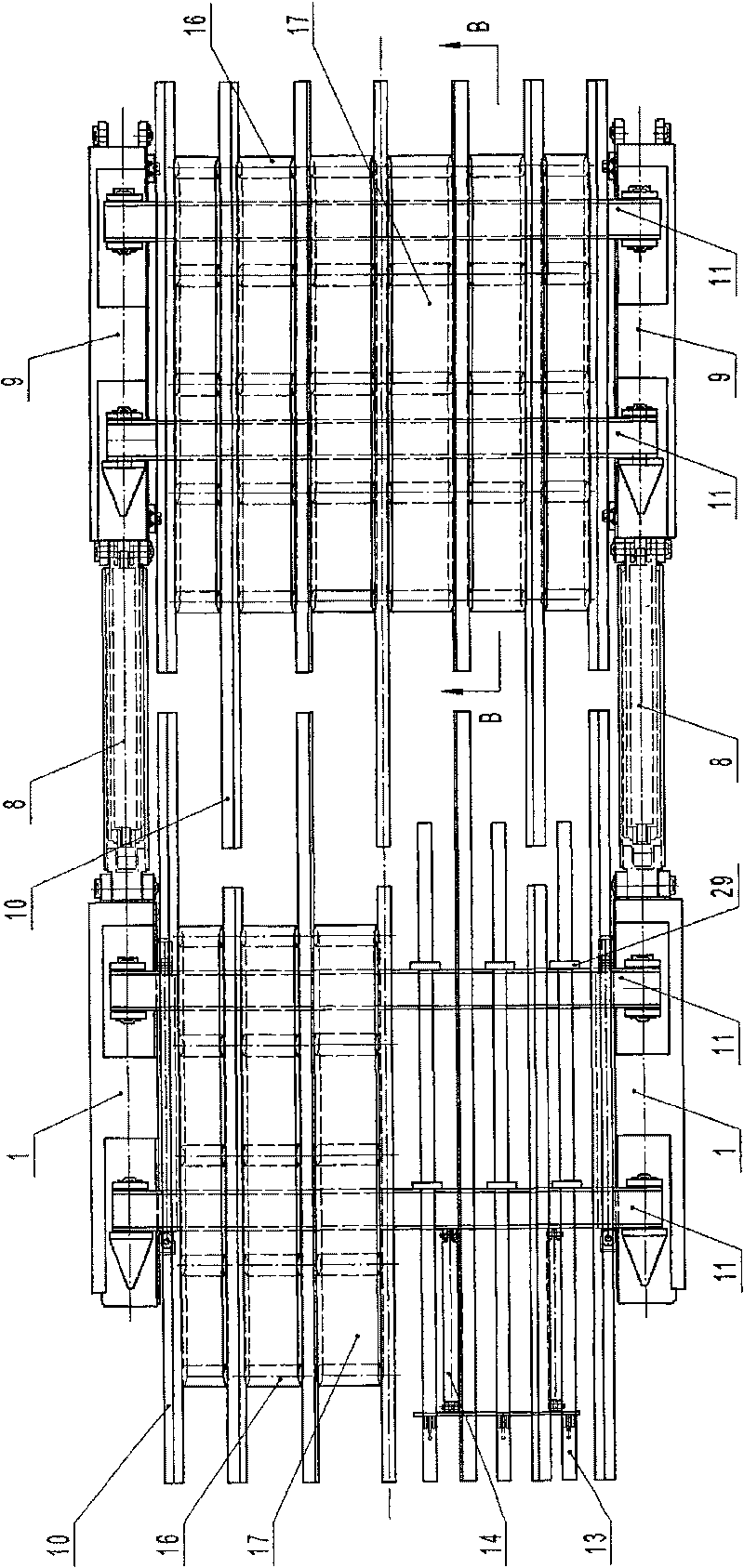

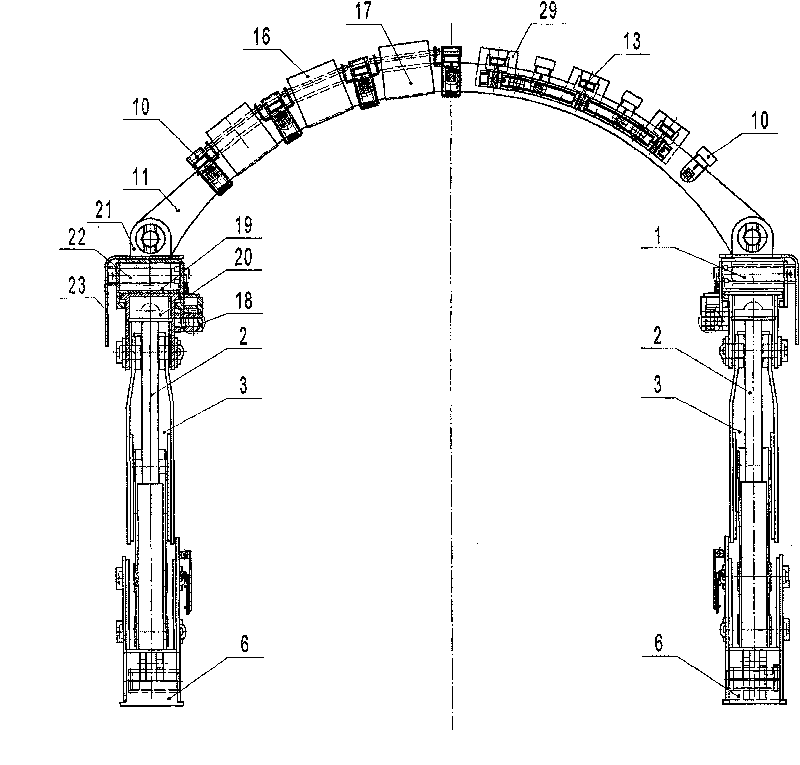

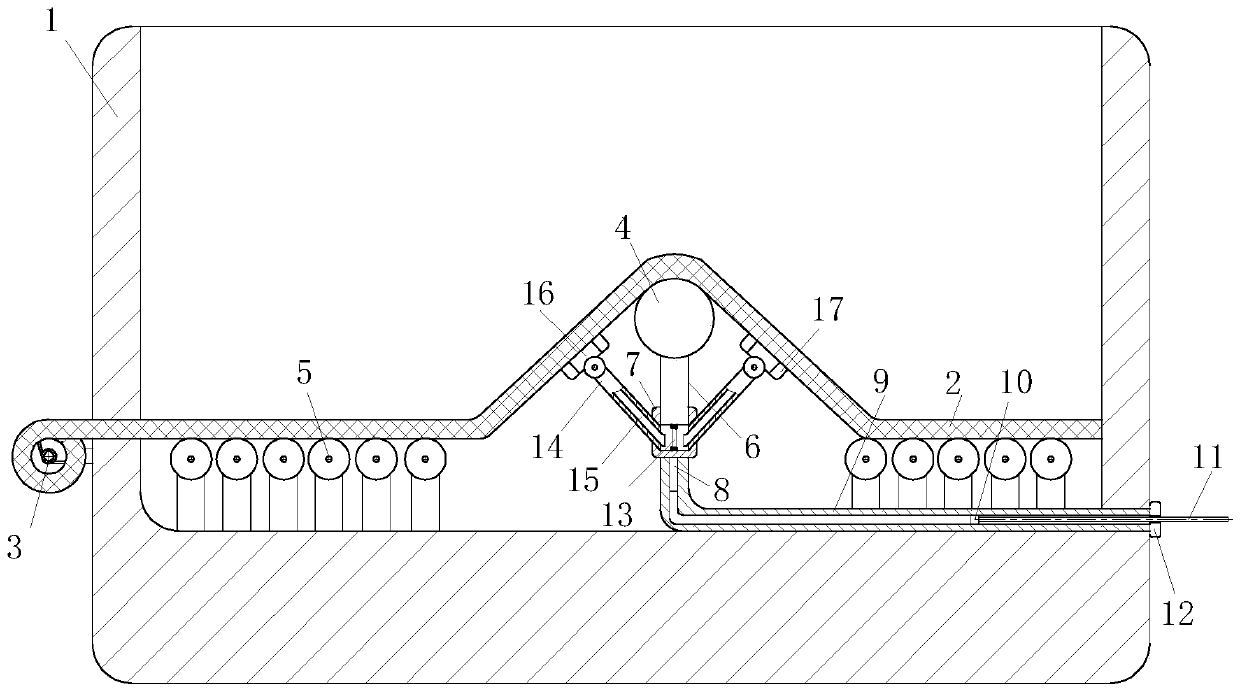

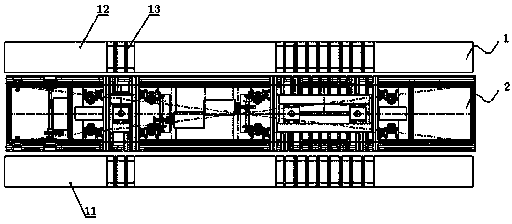

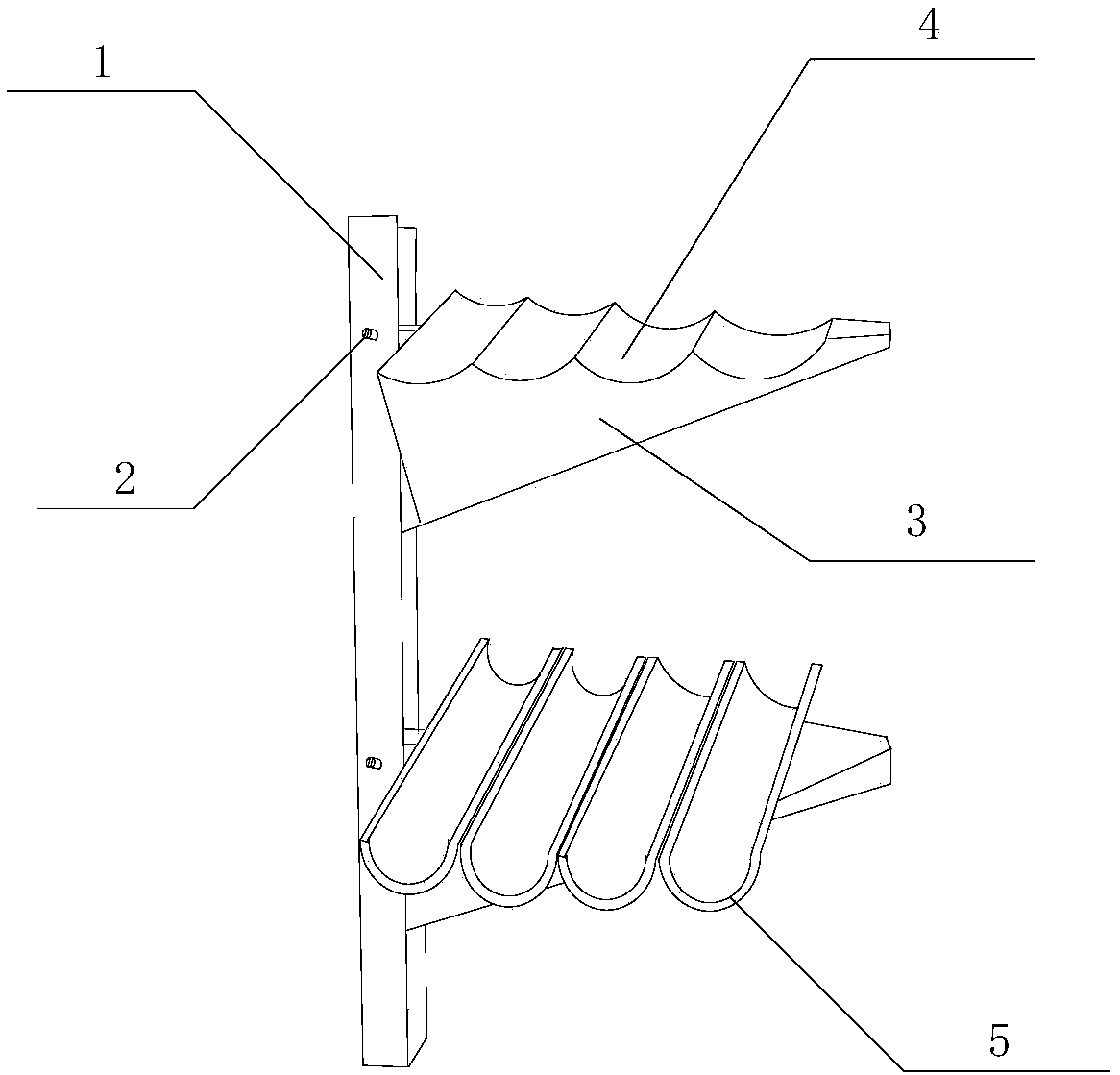

Immediate support device for digging machine

ActiveCN101251022BAvoid distortionIncrease support lengthMine roof supportsHydraulic cylinderContinuous operation

The invention relates to an in-time supporting device for a fully-mechanized coal mining machine, comprising a pedestal, a top beam, a hydraulic upright post which connects the pedestal and the top beam, side frames which consist of four link mechanisms, and a telescopic connecting beam and a hydraulic cylinder which are hinged between two side frames. The invention adopts the technical key pointsthat: top beams of the side frames adopt front top beams or continuous top beams; the side frames which are arranged in parallel and provided with the front top beams or the continuous top beams arehinged into a front support or a continuous support through an arched beam or a horizontal beam; shun beams are arranged on the arched beam or the horizontal beam at intervals; belt guard beams or telescopic shun beams are arranged between adjacent shun beams. The in-time supporting device for the fully-mechanized coal mining machine effectively solves the problems in the prior art of lagged supporting means, difficult frame movement, requirement of stop operation, low efficiency and so on, is reasonable in structural design, stable in supporting operation, convenient in assembly and disassembly and maintenance, and safe and reliable in use, preferably meets the requirements of matched operation of underworkings and the fully-mechanized coal mining machine, realizes in-time mechanical support of a just exposed roof of a tunneling work surface of a laneway, and shields the fully-mechanized coal mining machine to realize continuous operation.

Owner:SHENYANG TIAN AN TECH CO LTD

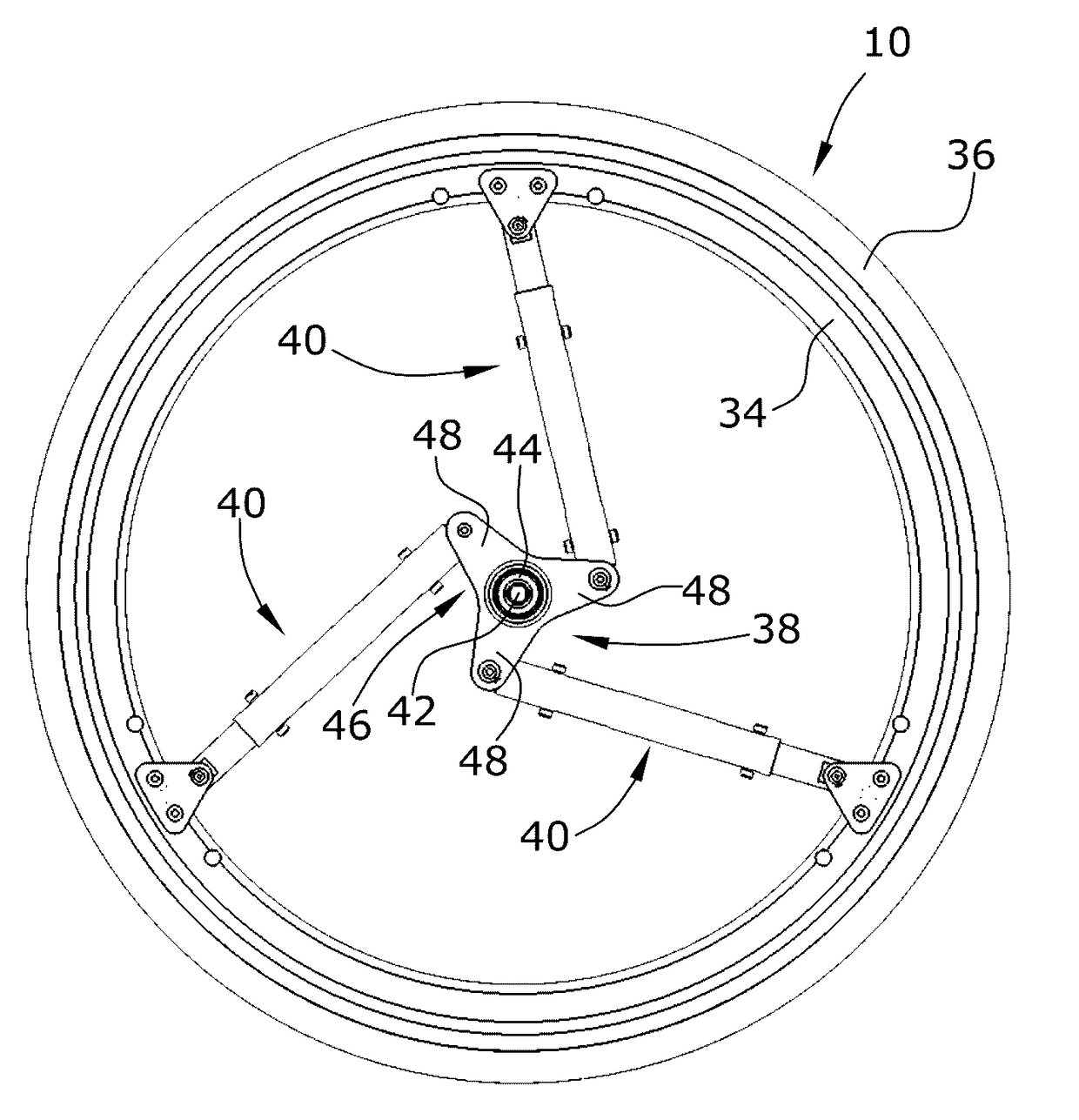

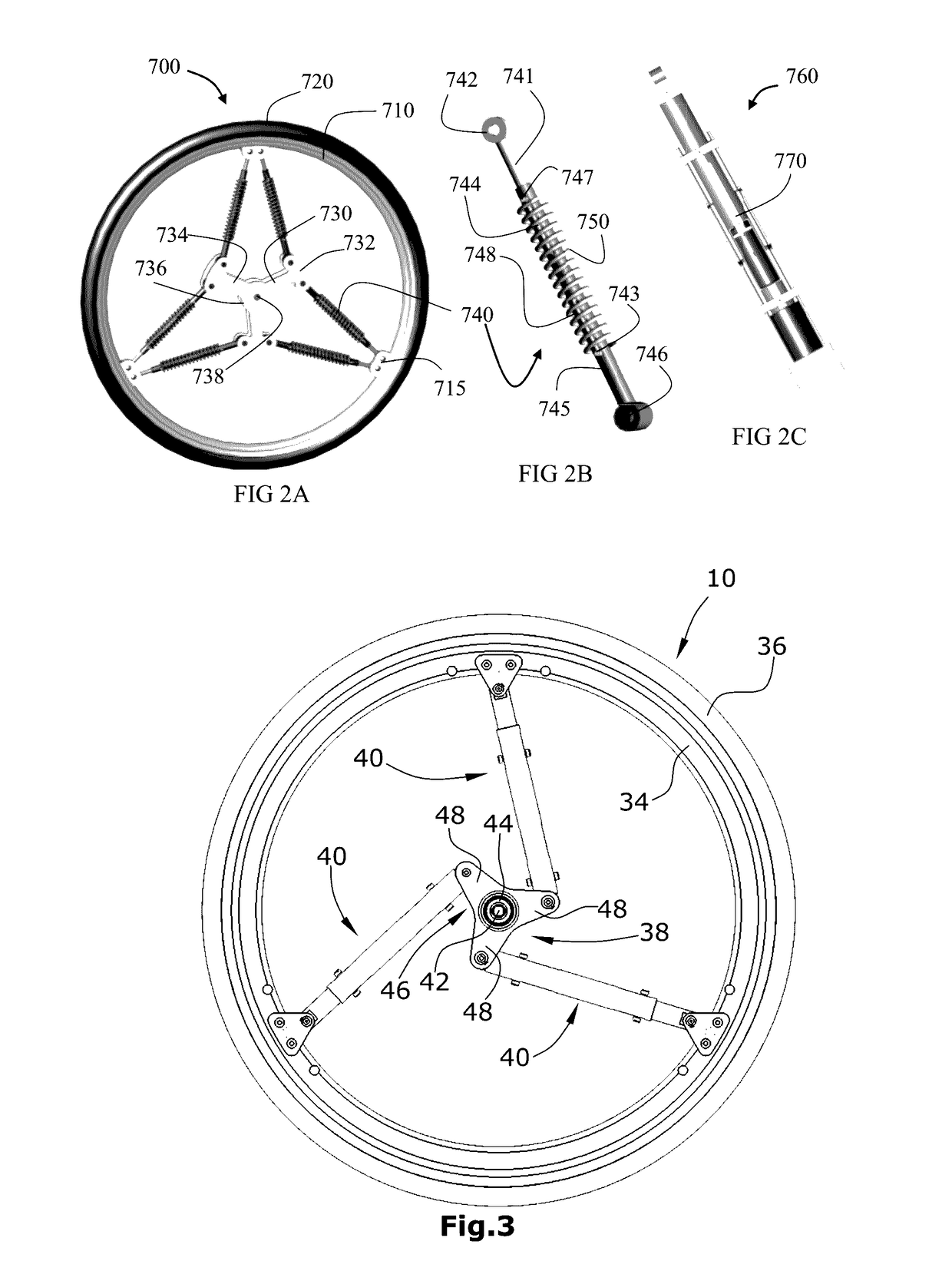

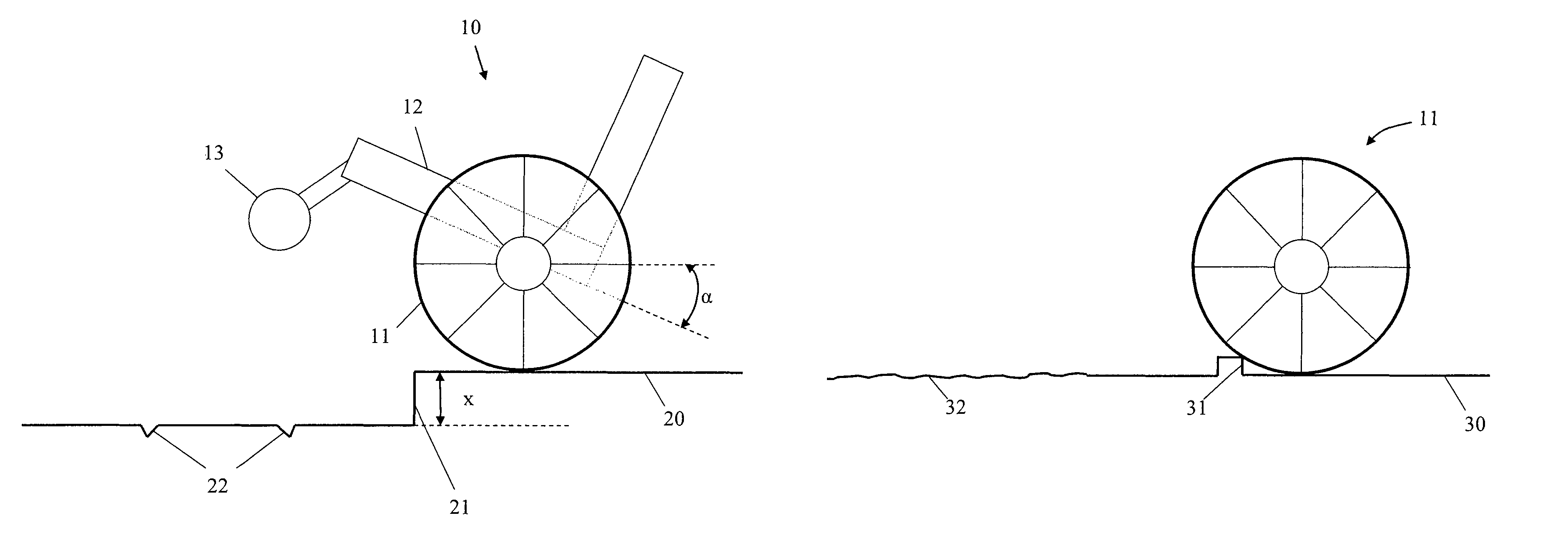

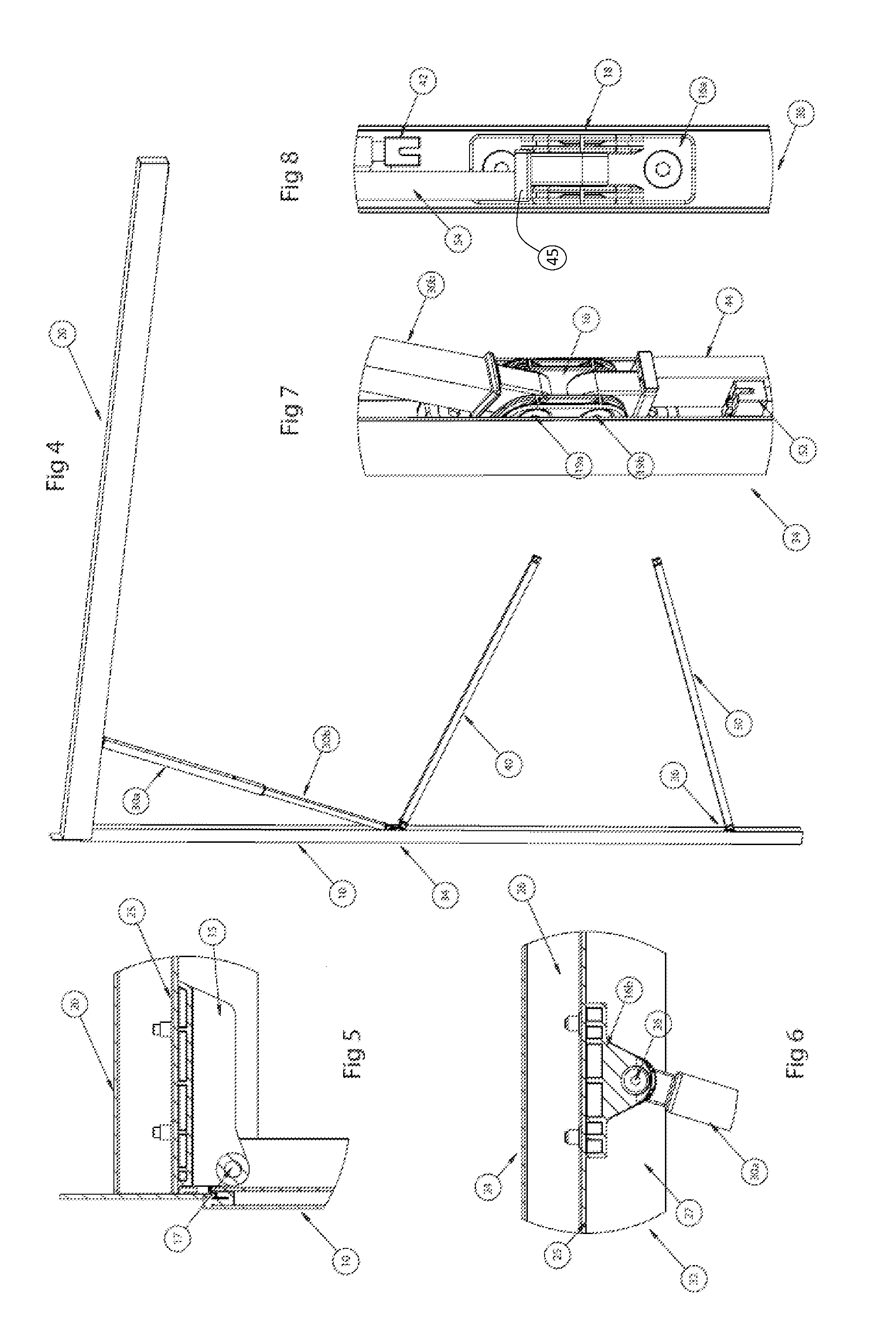

Wheel with suspension system and centralizing unit with suspension system

ActiveUS9539876B2Increase stroke lengthImprove stabilityNon-rotating vibration suppressionWheelchairs/patient conveyanceMechanical engineeringEngineering

A wheel with a suspension system being connectable to a vehicle, like a wheel chair, comprises a hub (38) and a rim (34) rotatable about the axle (42) of the hub (38). Between the hub (38) and the rim (34), a number of support members (40) is located. The support members (40) are adapted to retain the distance when stressed up to a threshold value and recoverly alter the distanced when stressed over this threshold value. According to the invention, the support members (40) are comprising spring elements (50), damping strokes by compression if the support member (40) is compressed or elongated. The spring elements (50) are preferably preloaded.

Owner:REE AUTOMOTIVE LTD

Production method of customized insole based on three-dimensional scanning technology

InactiveCN110279192ALow costImprove accuracyFoot measurement devicesInsolesFoot typeManufacturing engineering

The invention belongs to the technical field of insole production equipment, and particularly relates to a production method of a customized insole based on a three-dimensional scanning technology. The production method of the customized insole based on the three-dimensional scanning technology comprises the steps that firstly, a foot shape of a user is scanned by three-dimensional scanning, and a customized insole production device is produced according to obtained data; secondly, the feet of the user are placed in the customized insole production device, adjustment is carried out to adapt to a sole of the current period; and finally, raw materials are placed in the adjusted customized insole production device for design finalizing, and can be taken out after completion. A rotating rod and an adjusting roller are arranged, and the rotating rod is adjusted to lower the adjusting roller, and the highest point of a supporting mat can be lowered, the customized insole is more suitable for arched and flattened feet after correction and can better adapt to the sole of the feet in the current period of the correction process. A set of devices can be adjusted to meet the needs of different types of foot in the correction process, and the cost of customized insole production is reduced.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

Conveniently moved and stored supporting device for building engineering

ActiveCN110295766AIncrease support lengthIncreased lateral support lengthShoresFixed frameEngineering

The invention discloses a conveniently moved and stored supporting device for building engineering, and particularly relates to the technical field of building supporting equipment. The conveniently moved and stored supporting device comprises a device base, the top of one end of the device base is provided with a rack, the top of the rack is provided with a fixed shaft, a rotating support upper cylinder is arranged on the outer side of the fixed shaft, one end of the rotating support upper cylinder is provided with a telescopic support rod, and one end of the telescopic support rod is provided with a fixed frame; and the two sides of the top of the fixed frame are provided with rotating installation seats, a support frame is arranged between the tops of the two rotating installation seats, and a lifting adjustment mechanism is arranged between the other end of the rotating support upper cylinder and the device base. According to the supporting device, a movable base is pushed by a first hydraulic cylinder to move on a sliding rod, the rotating support upper cylinder is driven to rotate with the fixed shaft as the center, and the support height of the device is adjusted; and a second hydraulic cylinder pushes the fixed frame, the lateral support length of the device is increased, the use function of the device is increased, and use of the device is facilitated.

Owner:XUZHOU COLLEGE OF INDAL TECH

Forward pushing mechanism for annular stacking three-dimensional garage parking and picking trolley

ActiveCN104314344AAutomatic and accurate positioningReduced proficiency requirements for moving carsParkingsDriver/operatorParking space

The invention relates to a forward pushing mechanism for an annular stacking three-dimensional garage parking and picking trolley. The system is characterized by comprising a plurality of parking platforms and at least one pair of jacking platforms, wherein the parking platforms are arranged on parking spaces, an entrance parking space or an exit parking space; supporting platforms of the parking platforms are provided with comb-like supporting components A for supporting front and rear wheels of an automobile respectively; the jacking platforms are arranged on the three-dimensional garage parking and picking trolley and are both provided with a pair of comb-like supporting components B capable of being matched with the comb-like supporting components A and a forward push driving mechanism for driving the comb-like supporting components B to move. The mechanism has the advantages that the automobile is pushed to move transversely under the driving of the forward push driving mechanism on the jacking platforms when the automobile is stopped and positioned in the three-dimensional garage, so that the automobile can be automatically and accurately positioned, and a driver does not need to repeatedly adjust the automobile to a central position of the parking platform; the requirements on automobile movement proficiency of drivers are reduced and the average consumed time for parking is shortened.

Owner:JIANGSU SHUNDA ENG TECH

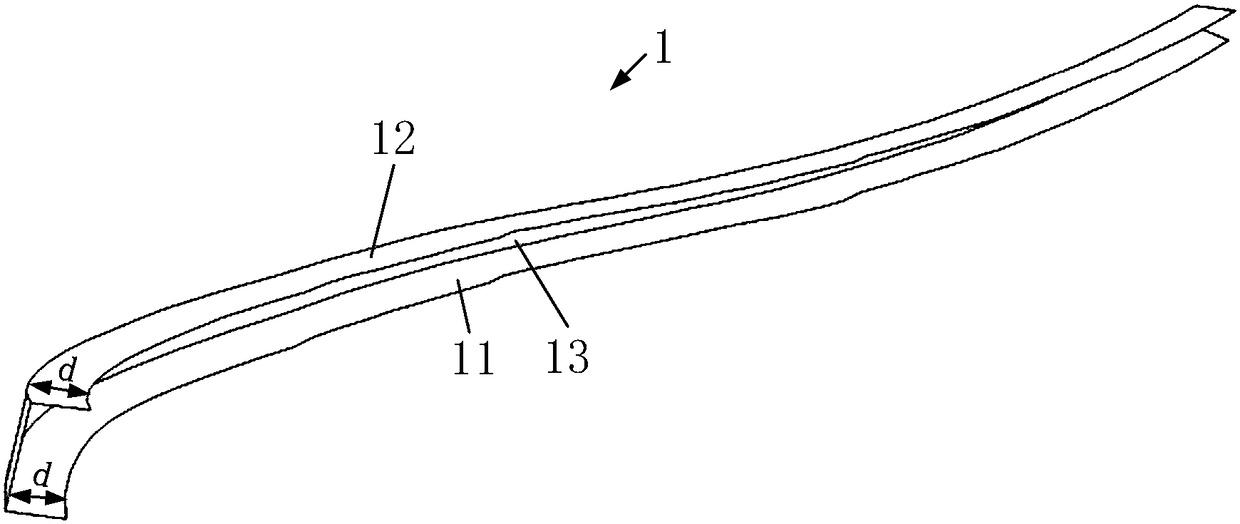

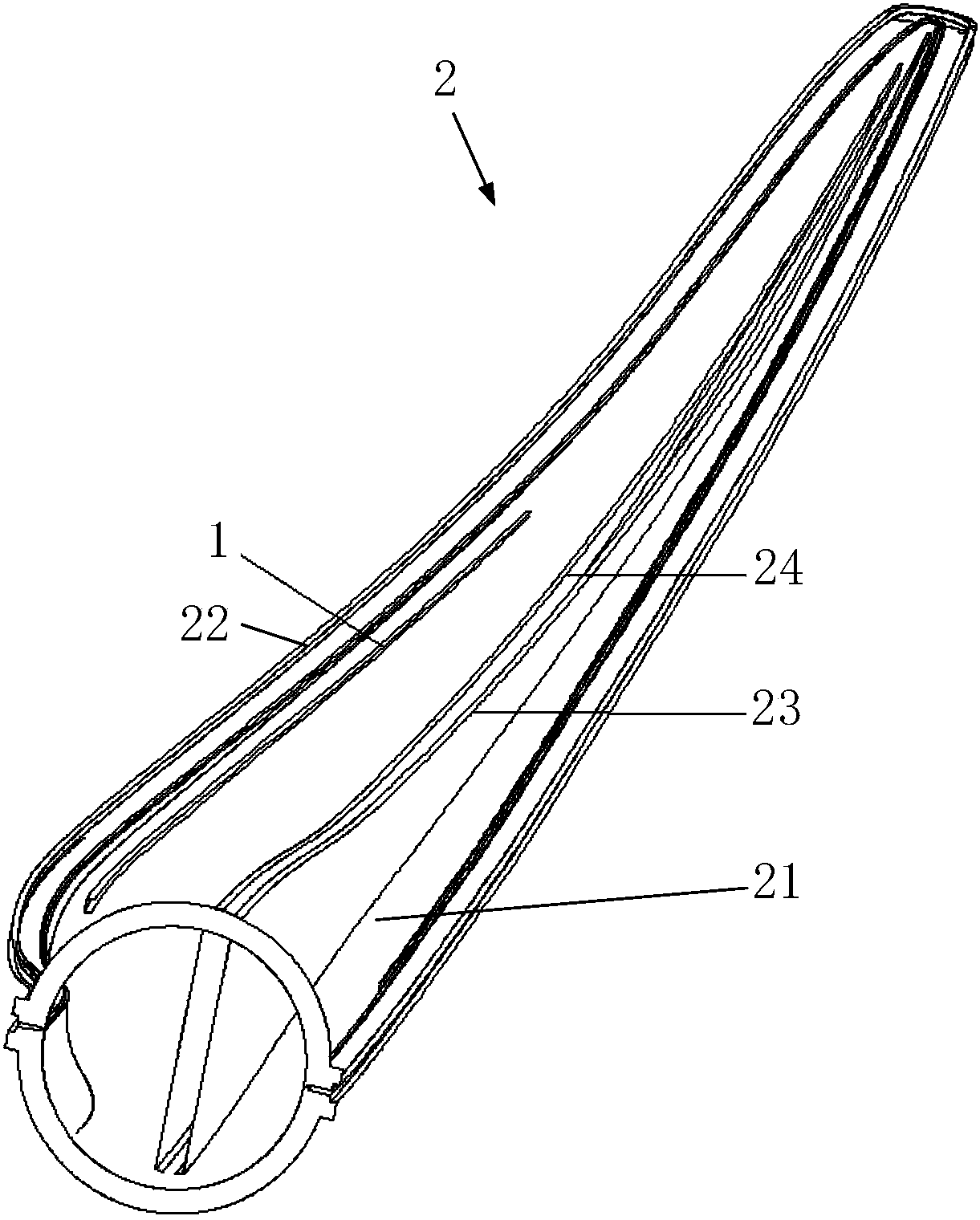

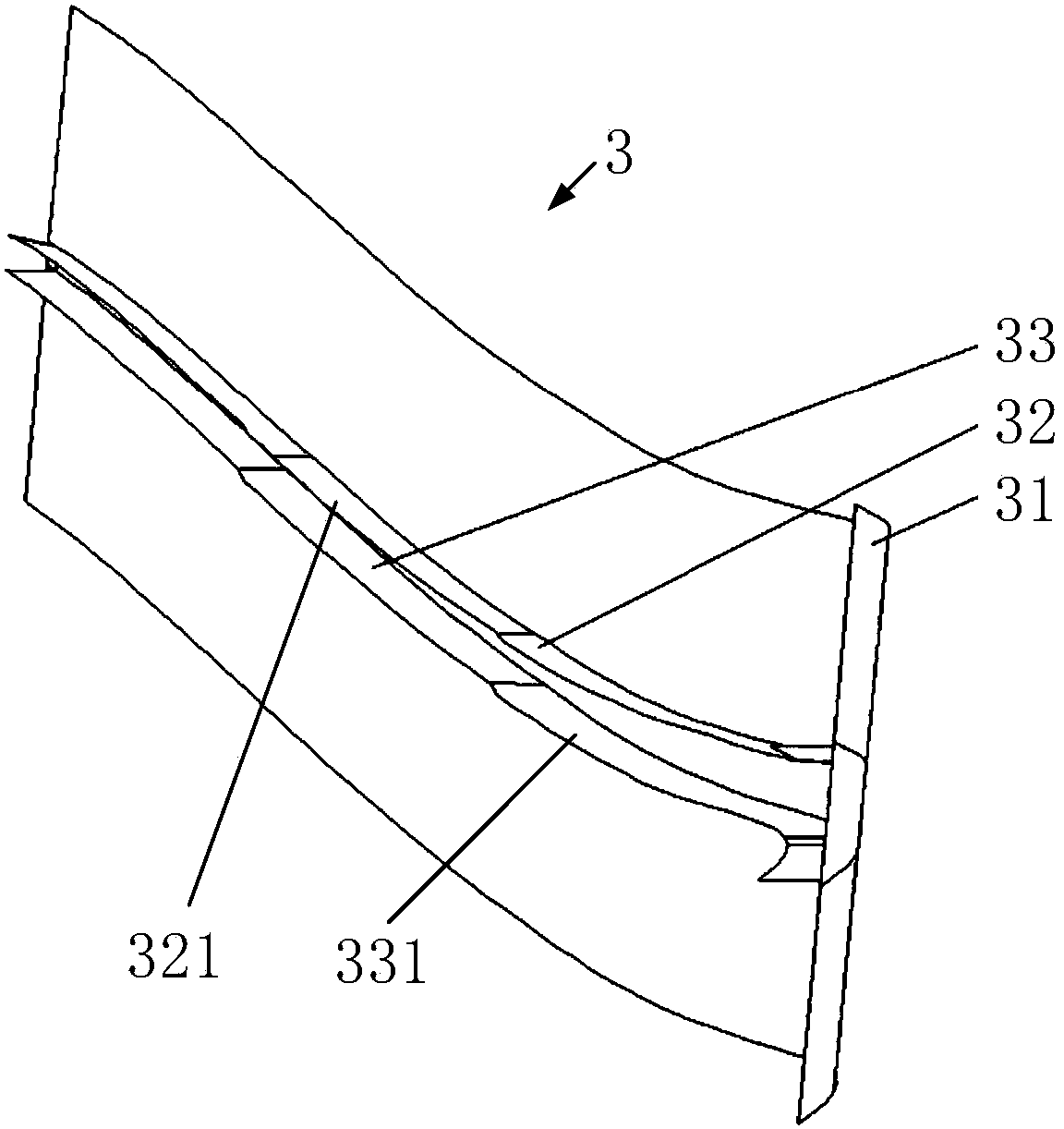

Wind power blade web plate, wind power blade and a die for preparing wind power blade web plate

ActiveCN108481628AAvoid problems with small support rangesIncrease support lengthMachines/enginesWind energy generationElectricityEngineering

The invention provides a wind power blade web plate, a wind power blade and a die for preparing the wind power blade web plate. The wind power blade web plate comprises a suction face adhesion sectionadhering to a blade suction face, a pressure face adhesion section adhering to a blade pressure face, and a connection hook face section arranged between the suction face adhesion section and the pressure face adhesion section, and the hook face of the connection hook face section is arranged along the bending trajectory of the rear edge of the blade. The wind power blade comprises a blade shelland the wind power blade web plate, the wind power blade web plate is supported in an area on the rear edge inside the blade shell, and the connection hook face section of the wind power blade web plate is parallel to the rear edge of the blade shell. The die for preparing the wind power blade web plate comprises a bent bottom plate, a suction face baffle and a pressure face baffle, the hook faceof the bent bottom plate is arranged along the bending trajectory of the rear edge of the blade, and the suction face baffle and the pressure face baffle are oppositely arranged on the upper surface of the bent bottom plate. The advantages that the blade baring capacity is high, and safety and reliability are high are achieved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

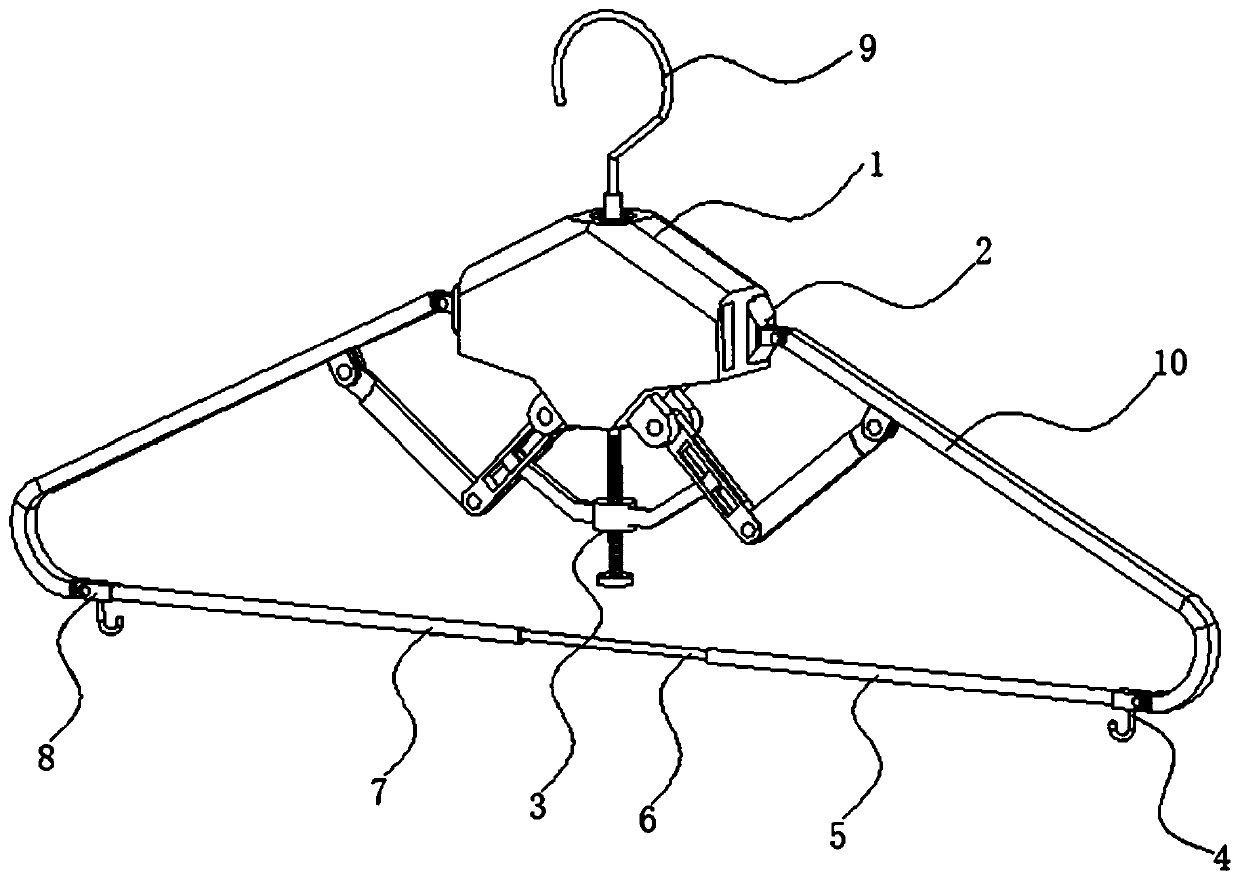

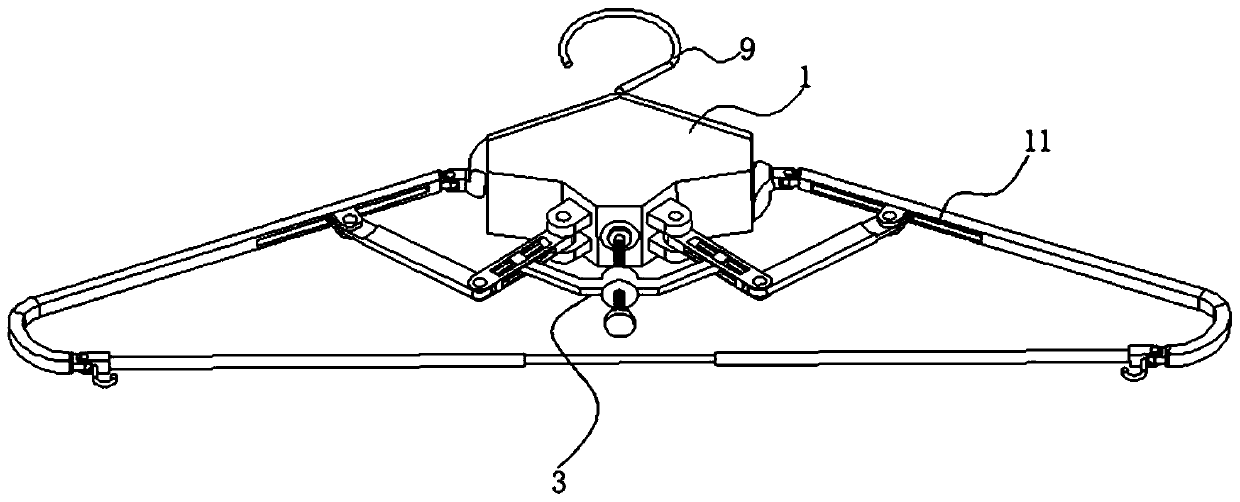

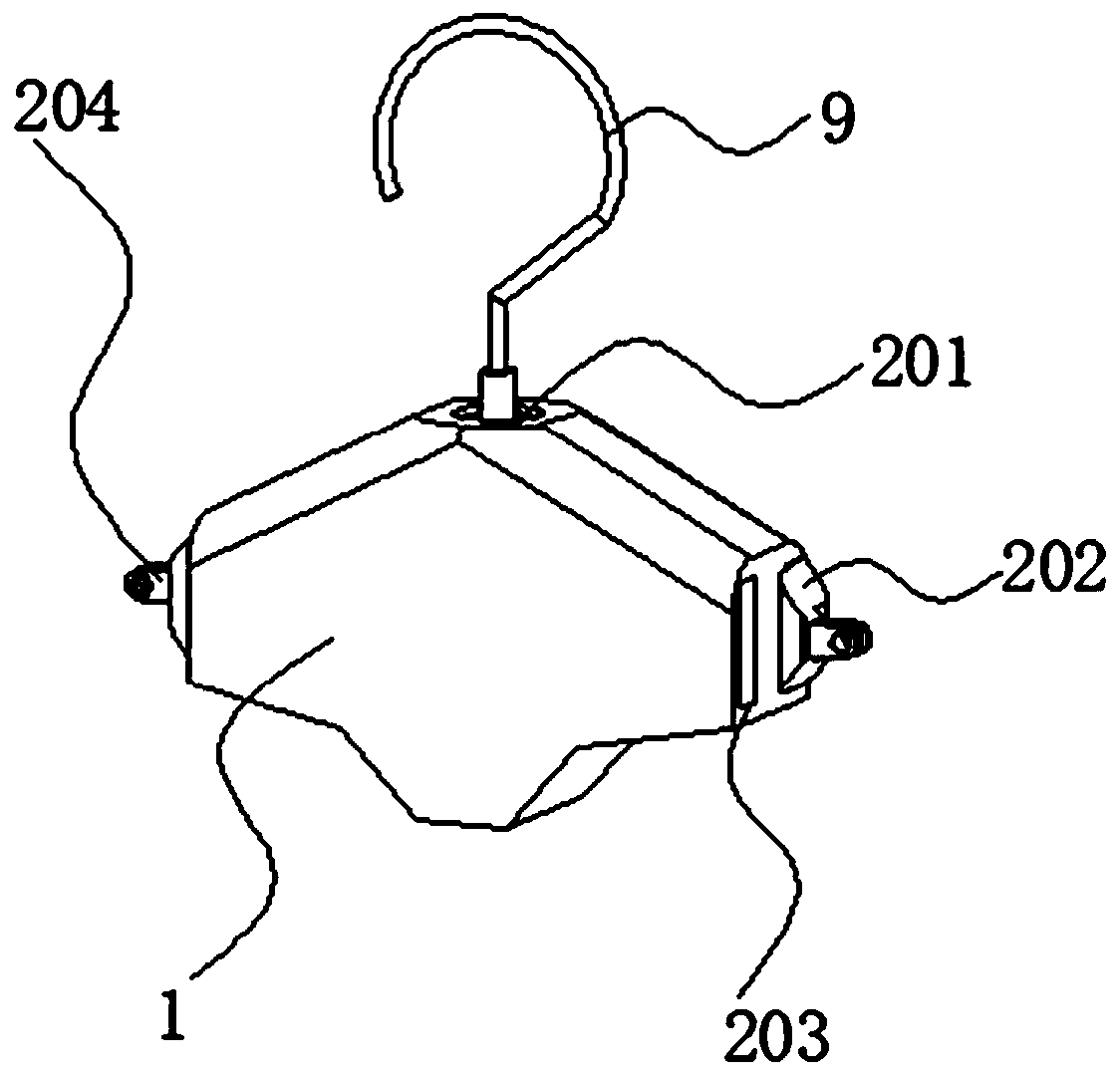

Adjustable clothes hanger

InactiveCN111588256AReduce spacingIncrease support lengthApparel holdersOther drying apparatusClothes hangerStructural engineering

The invention discloses an adjustable clothes hanger and relates to the technical field of clothes hangers. The adjustable clothes hanger comprises a fixing box, a transverse adjusting mechanism is fixedly mounted in the fixing box, a supporting arm adjusting mechanism is fixedly mounted at the bottom of the fixing box, swing arm rods are fixedly hinged to the left end and the right end of the transverse adjusting mechanism, and a first hinge seat is fixedly hinged to the bottom end of each swing arm rod. According to the adjustable clothes hanger, a hook is rotated clockwise, the distance between the lower ends of the two swing arm rods is shortened, therefore, the clothes hanger is better suitable for supporting clothes with smaller shoulder breadth, a screw rod is driven to rotate clockwise by rotating a rotary plate clockwise, the distance between the bottom ends of the two swing arm rods is increased, the supporting length of the support is increased, clothes with large shoulder breadth can be better used, the swing arm rods at different positions are adjusted in length and inclination angle through a swing arm adjusting mechanism, the clothes hanger is better suitable for different clothes, and the adaptability of the clothes hanger is improved.

Owner:黄利杰

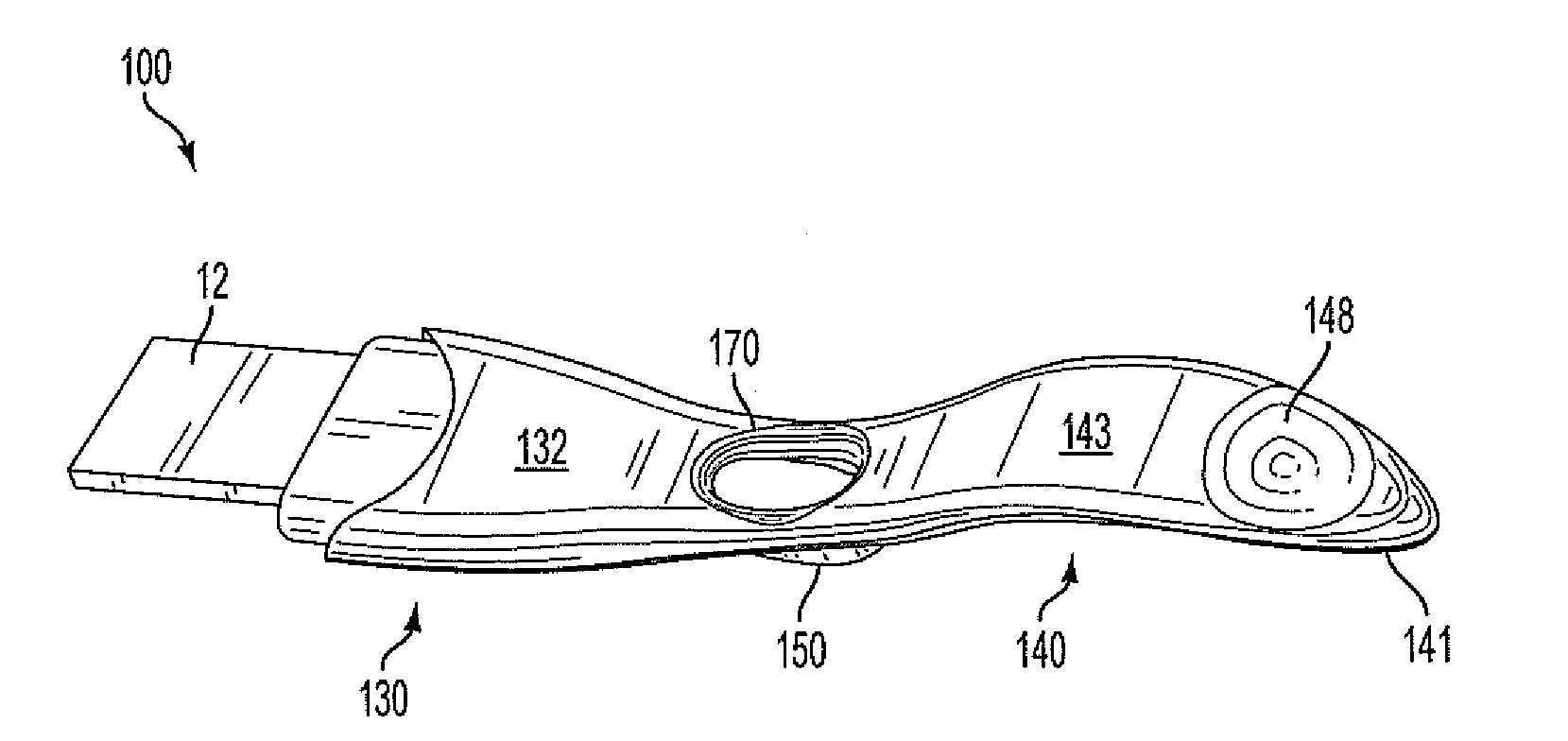

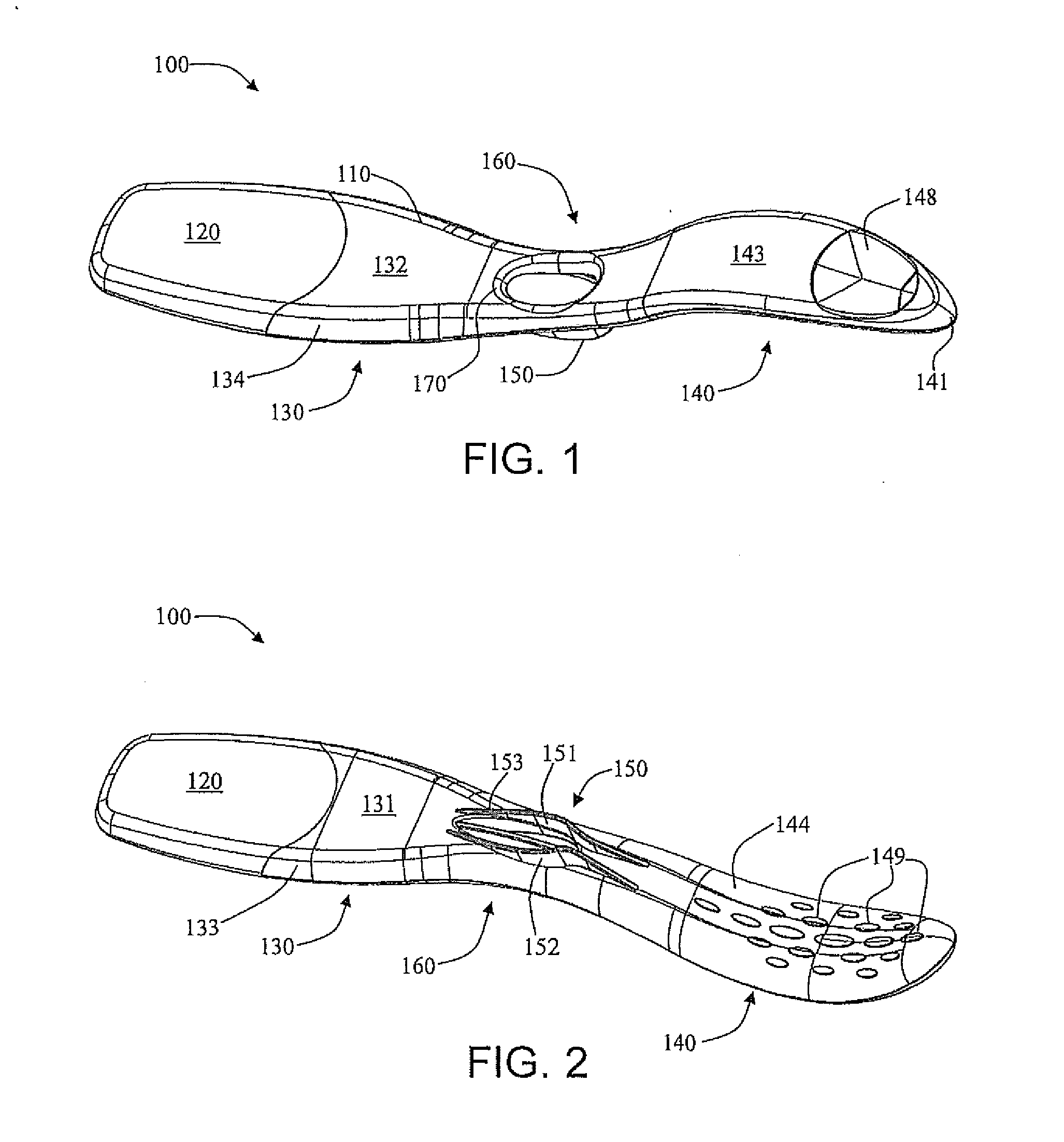

Diagnostic test device with improved structure

ActiveUS20140273012A1Improve ergonomicsImprove ease of useBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteEngineering

The present disclosure relates to diagnostic test devices that provide increased comfort and ease of use. The diagnostic test device can include a test member, such as a lateral flow assay test strip. The test device can further comprise a housing that comprises a substantially arch shaped handle. The housing of the test device can comprise a base member that is attached to a curved lower surface of the housing and that can improve stability of the device in an upward facing position as well as enable angled positioning of the device relative to a flat, horizontal surface. The curvature of the test device in particular can provide secure handling of the device while also improving ease and comfort of use thereof. The disclosure further relates to methods of determining the presence of an analyte in a fluid sample and methods for evaluating a test result of a personal use diagnostic test device.

Owner:CHURCH & DWIGHT CO INC

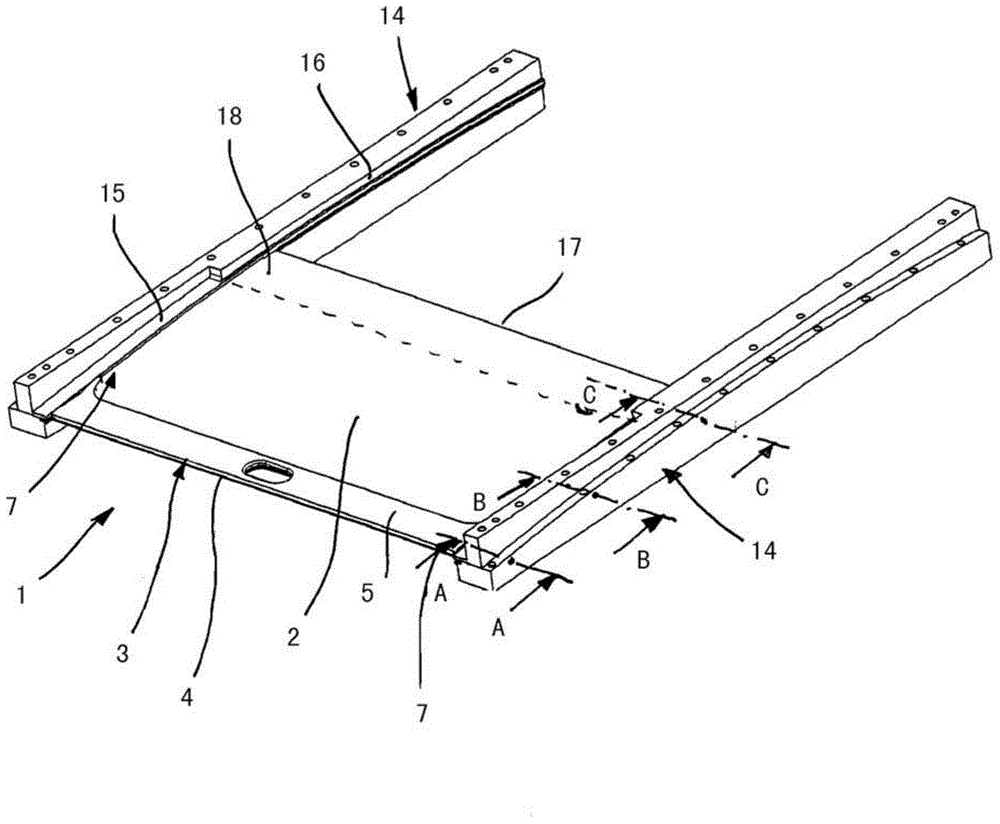

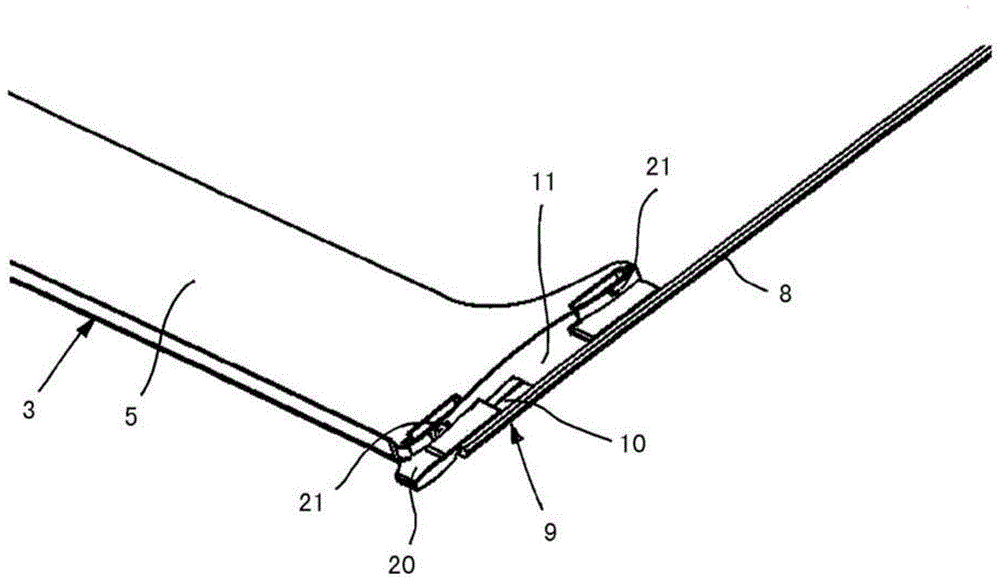

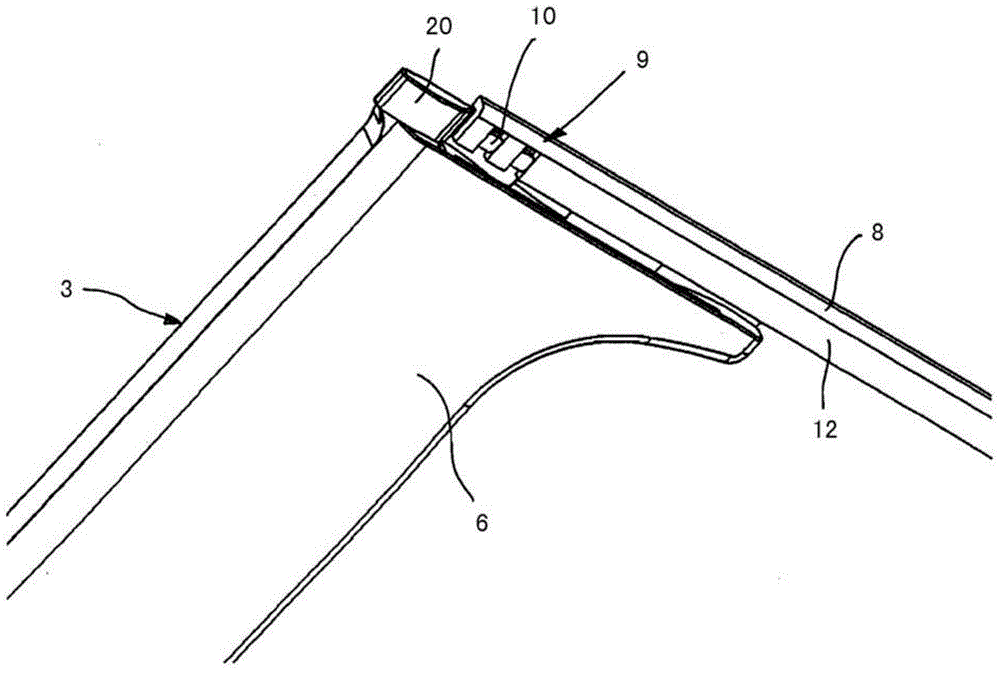

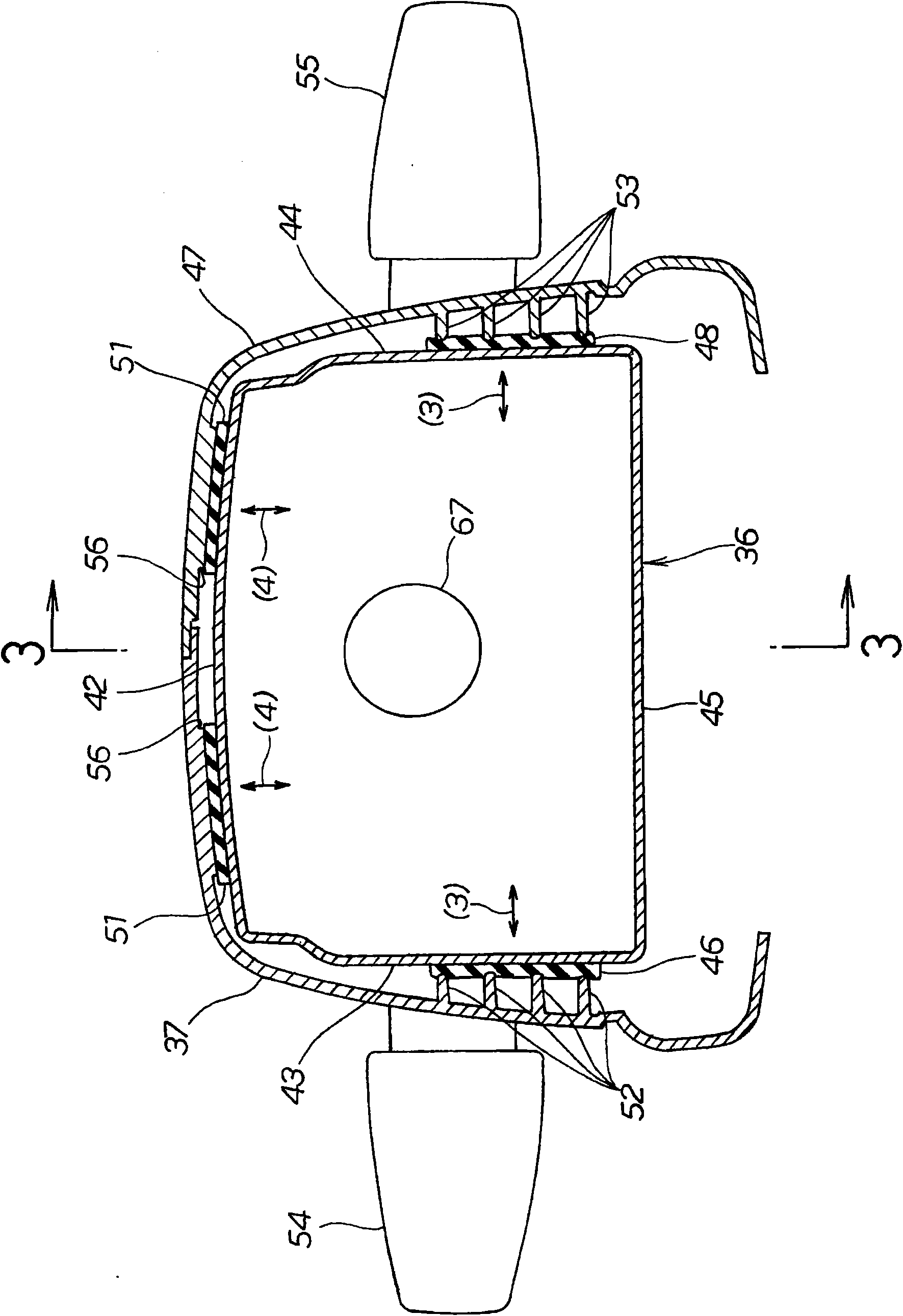

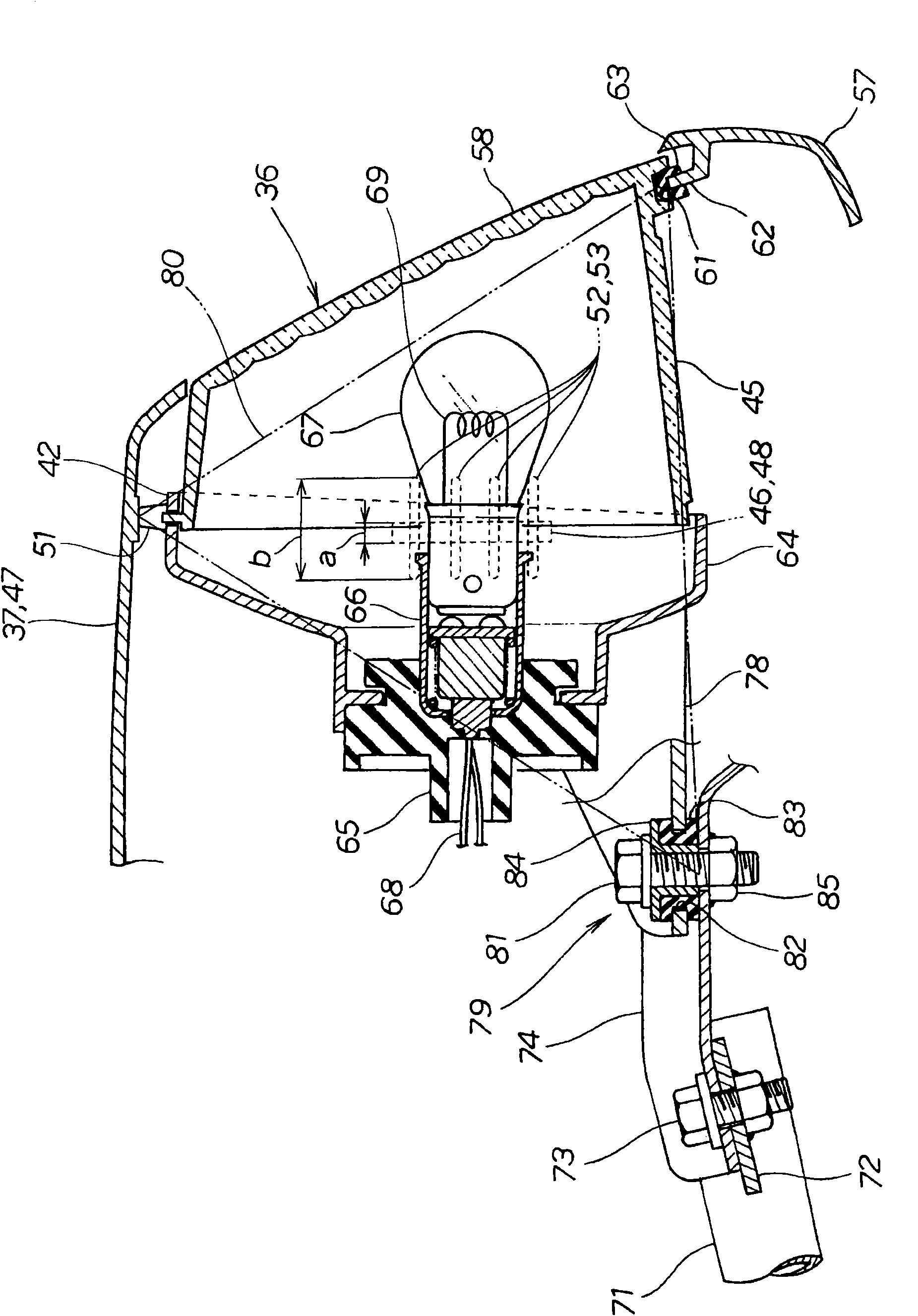

Sliding roof panel for a motor vehicle

A sliding headliner for a motor vehicle that is movably guided on guides on both sides and that comprises a flexible shading element, whereby the invention provides that the shading element is tightened by two side profile strips of the sliding headliner, which strips are movably guided on the two guides, that each guide has a front guide section and a rear guide section, that the two side profile strips are held at a distance from one another by the rear guide sections under tightening of the shading element in the transverse direction and are guided in a non-tightened manner in the transverse direction by the front guide sections, and that the side profile strips are held at a distance from one another in the transverse direction on the front guide sections by their own bending stiffness and / or by a cross bow.

Owner:WEBASTO AG

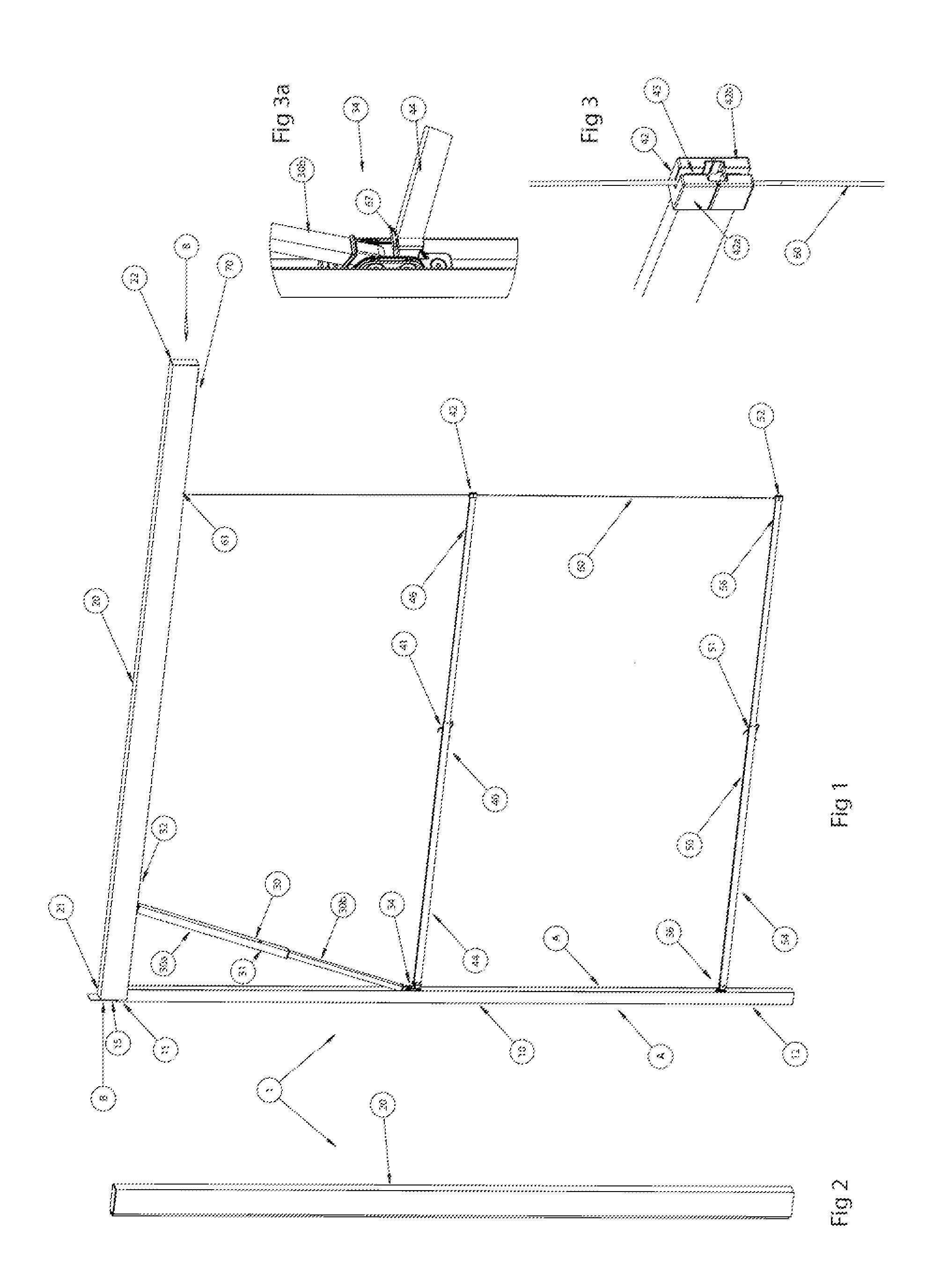

Drying assembly

InactiveUS20160348300A1Easy to useShorten drying timeOther drying apparatusTextiles and paperMechanical engineeringEngineering

A drying assembly for mounting to a wall, the assembly comprising: (a) an elongate mounting member; (b) an elongate support member hingeably coupled to an upper end of the mounting member for disposition between a storage position in which the mounting member and the support member are aligned parallel and an open position in which the support member extends outwardly from the mounting member to provide a continuous length for supporting clothes; and (c) a brace that is operable to retain the members in the open position; and wherein the support member has a profile that defines a volume that conceals the brace and the mounting member in the storage position and that includes a reinforcing web enabling connections with the brace and the mounting member to be concealed.

Owner:THE ASSASSIN GRP LTD

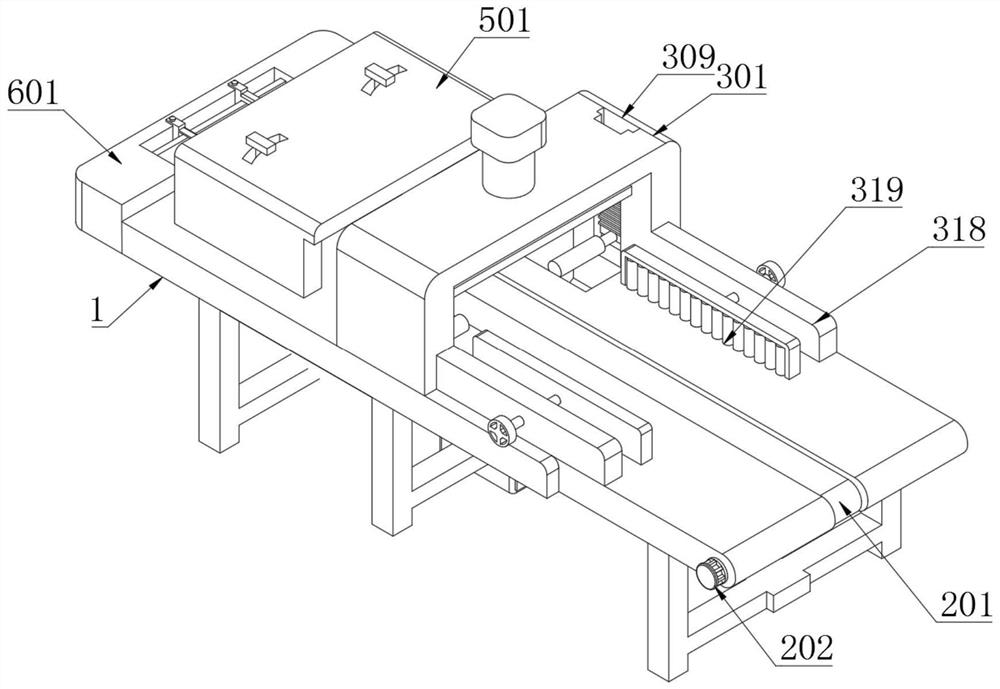

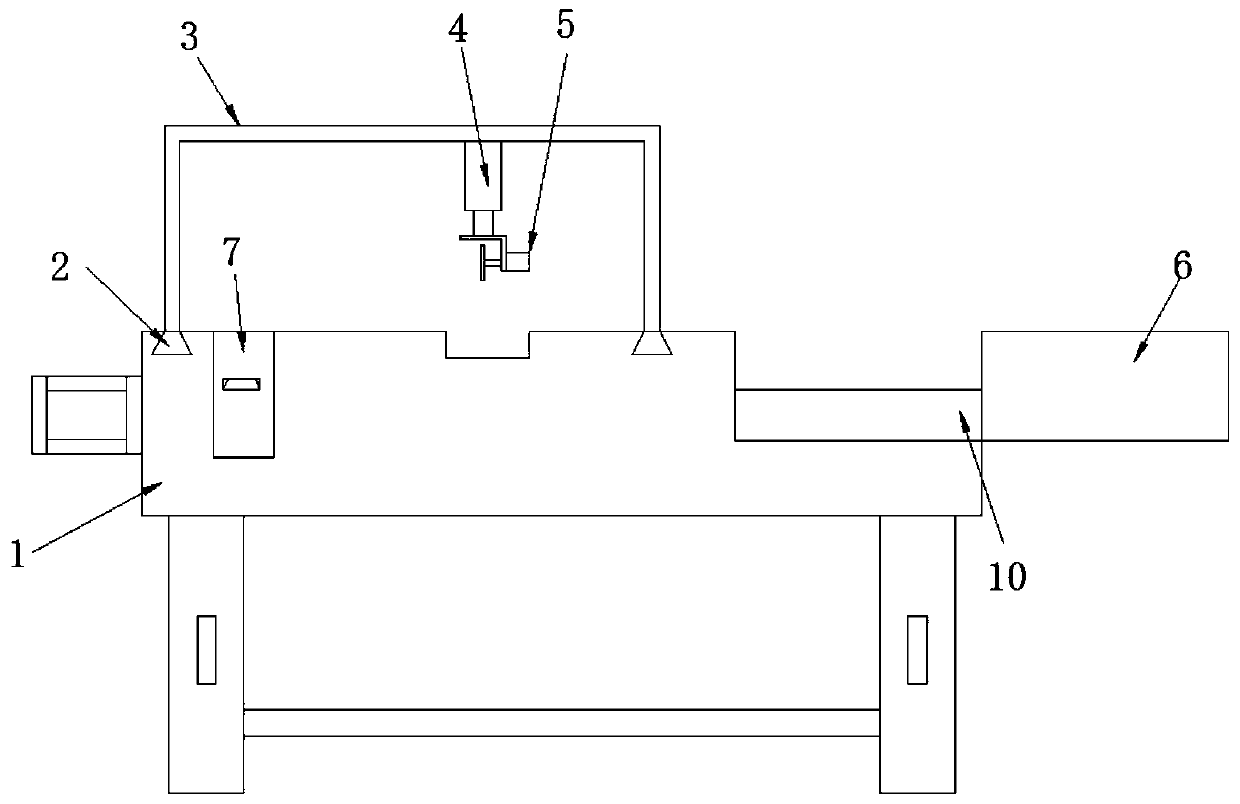

Cutting device for door and window production

ActiveCN111545834AImprove stabilityIncrease support lengthLarge fixed membersPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a cutting device for door and window production. The cutting device comprises a base table. A cutting mechanism is arranged above the top of the base table. A cutting slot is formed at the position, located below the cutting mechanism, of the outer wall of the top of the base table. Mounting slots are formed on the outer walls of the two sides of the base table. A clampingmechanism is arranged in each mounting slot. An embedded supporting table is arranged on the right side of the base table, and an extending plate is fixed to the bottom end of the outer wall of the left side of the supporting table. The extending plate is movably connected in a storage slot formed in the base table in an inserted manner. The end, away from the supporting table, of the extending plate is in transmission connection with a transverse drive mechanism. A guide block is fixed to the bottom of the extending plate and is movably connected in a guide slot formed on the right side of the base table in an inserted manner. According to the cutting device, the overall supporting length of the base table can be increased, placement and supporting work can be carried out on some long profiles conveniently, then the stability of profile cutting work can be improved, and the situation that profiles fall off can be avoided.

Owner:烟台红旗瑞景门窗有限公司

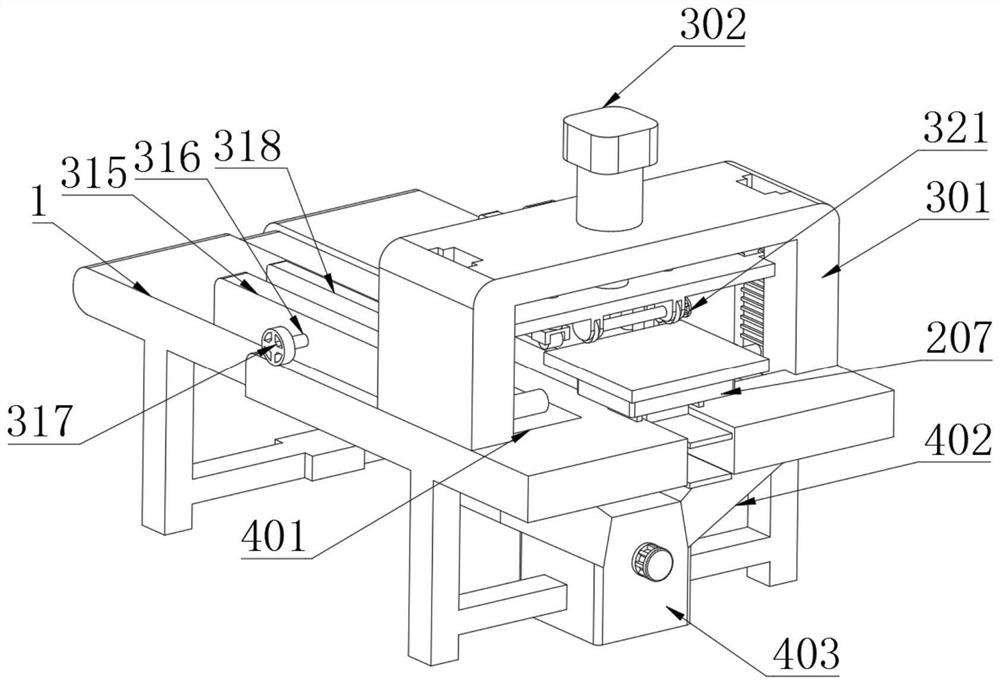

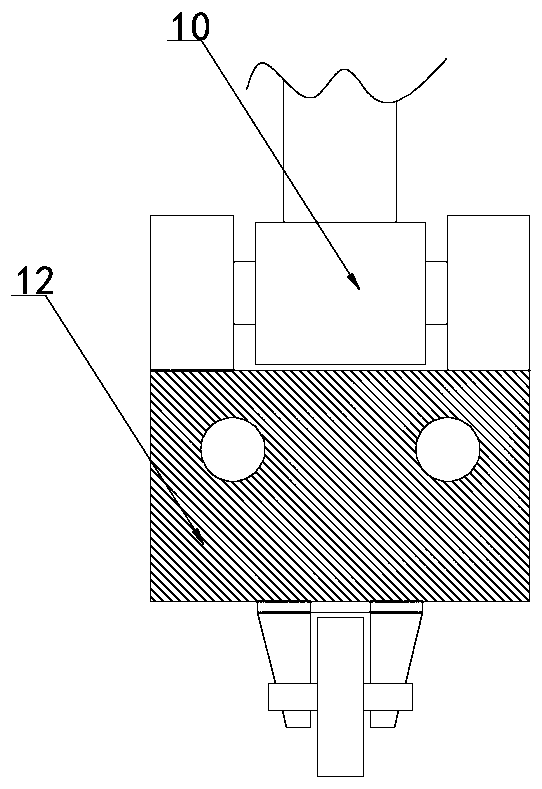

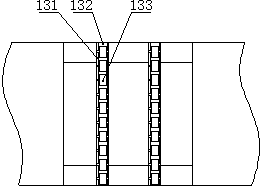

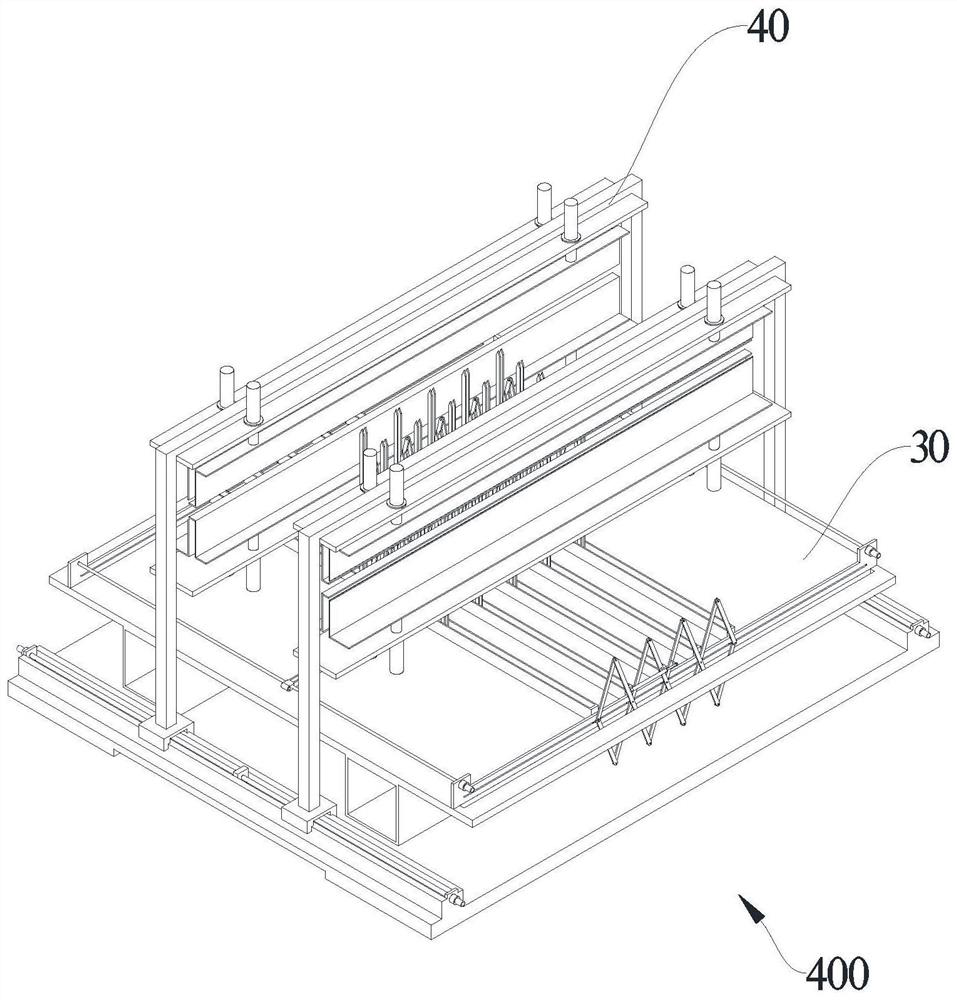

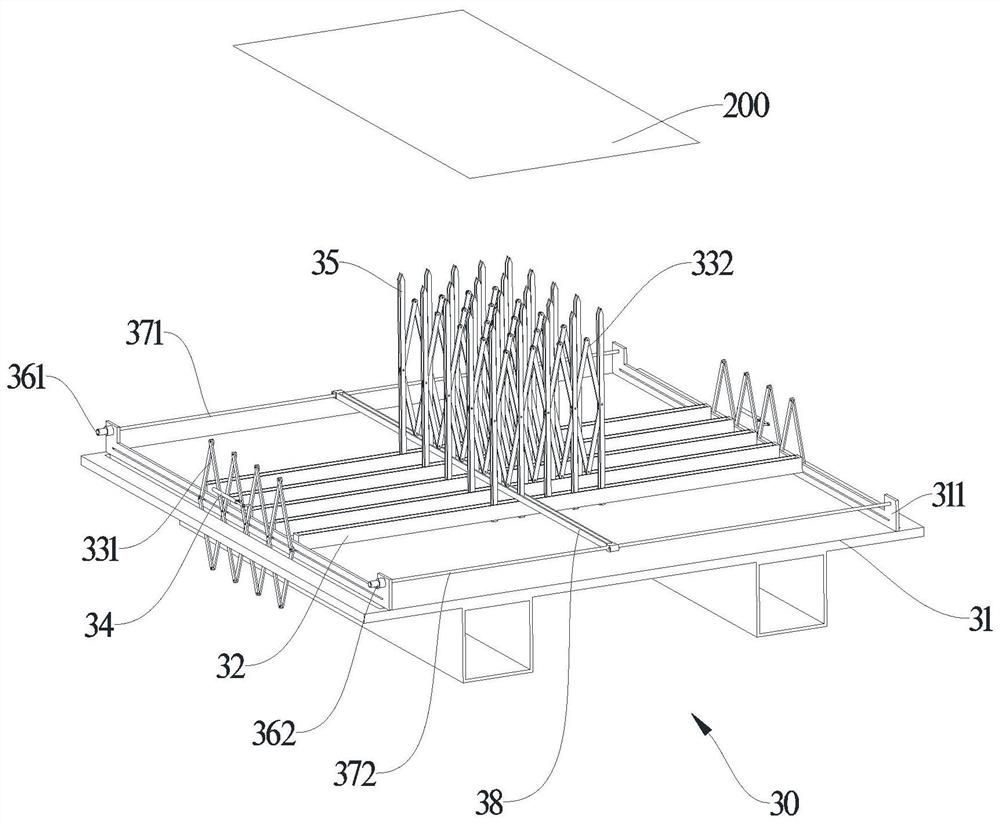

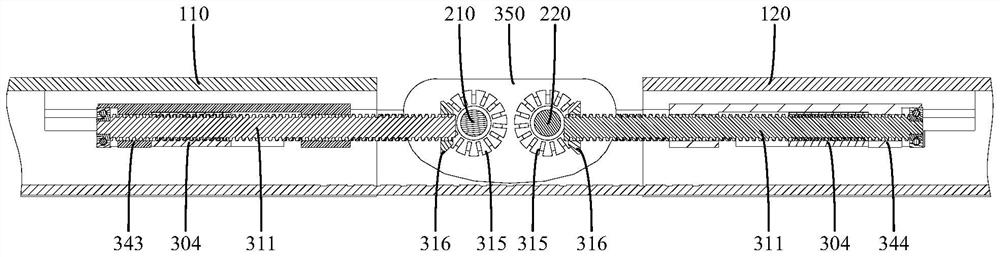

Plate supporting mechanism and metal plate bending machine

PendingCN111702037AIncrease support widthIncrease support lengthMetal-working feeding devicesPositioning devicesMachineSupport surface

The invention relates to a plate supporting mechanism and a metal plate bending machine. The metal plate bending machine comprises the plate supporting mechanism and a bending mechanism. The plate supporting mechanism is used for supporting a plate and can adjust the size of a supporting surface. The bending machine can conduct bending on the two sides of the plate synchronously. The plate supporting mechanism and the metal plate bending machine have the advantages that the spacing between supporting vertical rods is adjusted by moving a shifting rod, and the supporting width of the supportingvertical rods can be increased; the spacing between the supporting vertical rods is adjusted through telescopic cylinders, and the supporting length of the supporting vertical rods can be increased;and through bending assemblies arranged symmetrically, the metal plate bending machine can conduct bending on the two sides of the plate simultaneously, and the machining efficiency is improved.

Owner:宁波源码智能机械科技有限公司

Support rack for power transmission line of power system

The invention discloses a support frame for a transmission line of an electric power system, which includes an arm frame, the arm frame is a U-shaped groove, the arm frame is fixed on the wall, bolt holes are arranged on both sides of the arm frame, and the support seat is fixed by fixing bolts On the arm frame, the support seat is a triangle; the lower end of the support seat is a rib of the triangle, and the upper end is a surface; the upper end surface of the support seat is provided with an arc-shaped wire groove guide rail, and the wire groove guide rail is provided with a wire groove. The length of the trunking is 0.5-1m, and the trunking is made of plastic. When in use, the ledge is installed on the wall, the cable can be laid after the supporting frame is installed, and the cable can be placed in the wire groove after the cable is laid. The support length is increased, and the use of the support frame of the present invention can prevent the cable from bending without increasing the installation support point, which solves the problem of cable bending caused by point support when the cable is laid in the tunnel, and the increase in the use length wastes the cable. If support points are added, it will be time-consuming and labor-intensive.

Owner:田喜桂

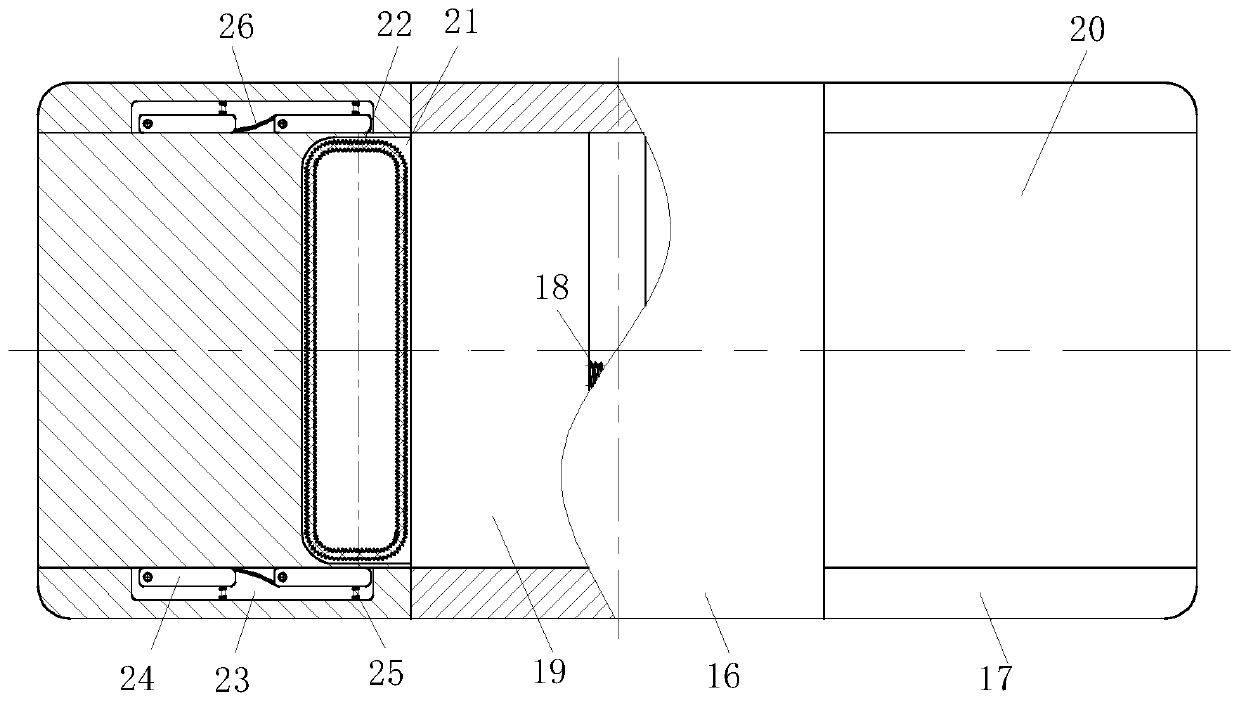

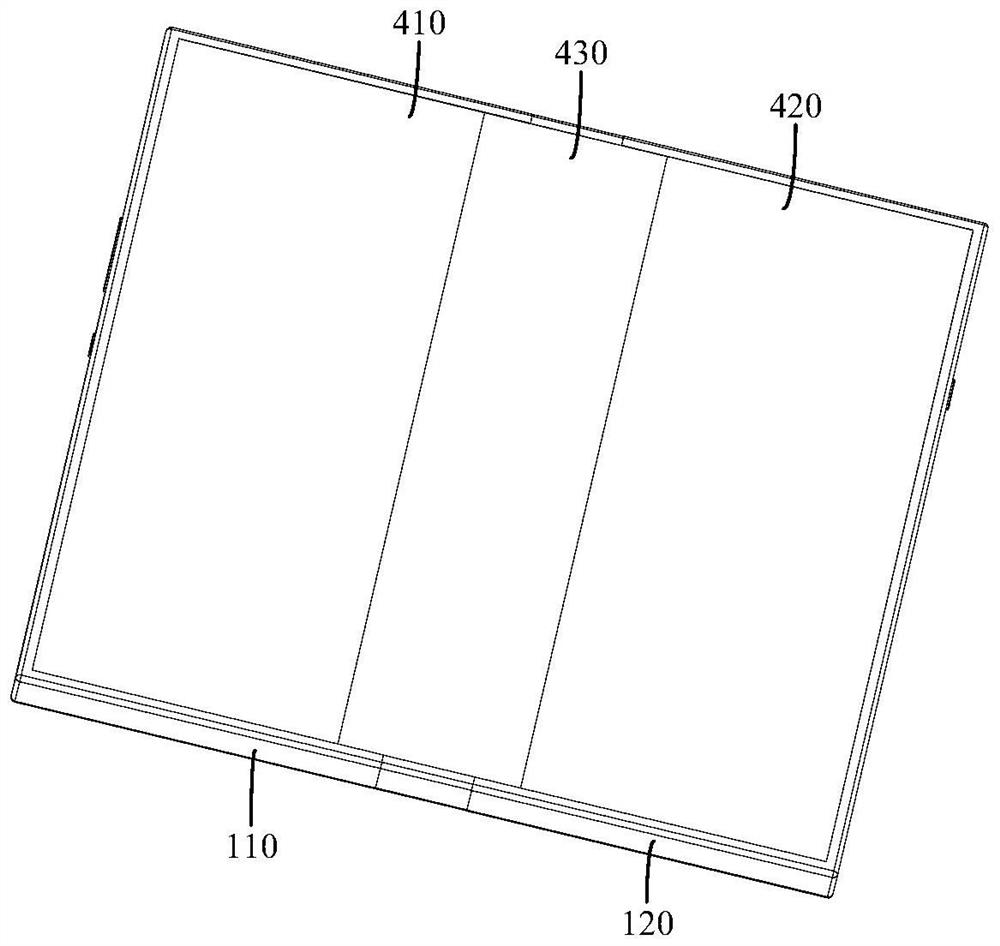

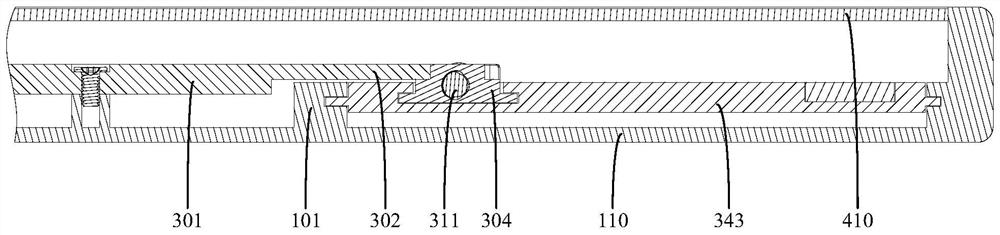

Electronic device

PendingCN114244934AIncrease support lengthSmall support lengthDigital data processing detailsTelephone set constructionsEngineeringFlexible display

The invention discloses electronic equipment, which comprises a first equipment main body, a second equipment main body, a rotating mechanism and a flexible display screen, and is characterized in that the flexible display screen comprises a first display screen, a second display screen and a third display screen; the first equipment main body is rotationally connected with the second equipment main body through the rotating mechanism; the first display screen is connected with the second display screen through the third display screen; the first equipment main body is connected with the first display screen, and the second equipment main body is connected with the second display screen; the rotating mechanism comprises a rotating shaft and a transmission device; the rotating shaft is connected with at least one of the first equipment main body and the second equipment main body through the transmission device; under the condition that the electronic equipment is switched from the folding state to the unfolding state, the rotating shaft drives at least one of the first equipment main body and the second equipment main body to be far away from the rotating shaft through the transmission device; when the electronic device is switched from the unfolding state to the folding state, the rotating shaft drives at least one of the first device body and the second device body to be close to the rotating shaft through the transmission device.

Owner:VIVO MOBILE COMM CO LTD

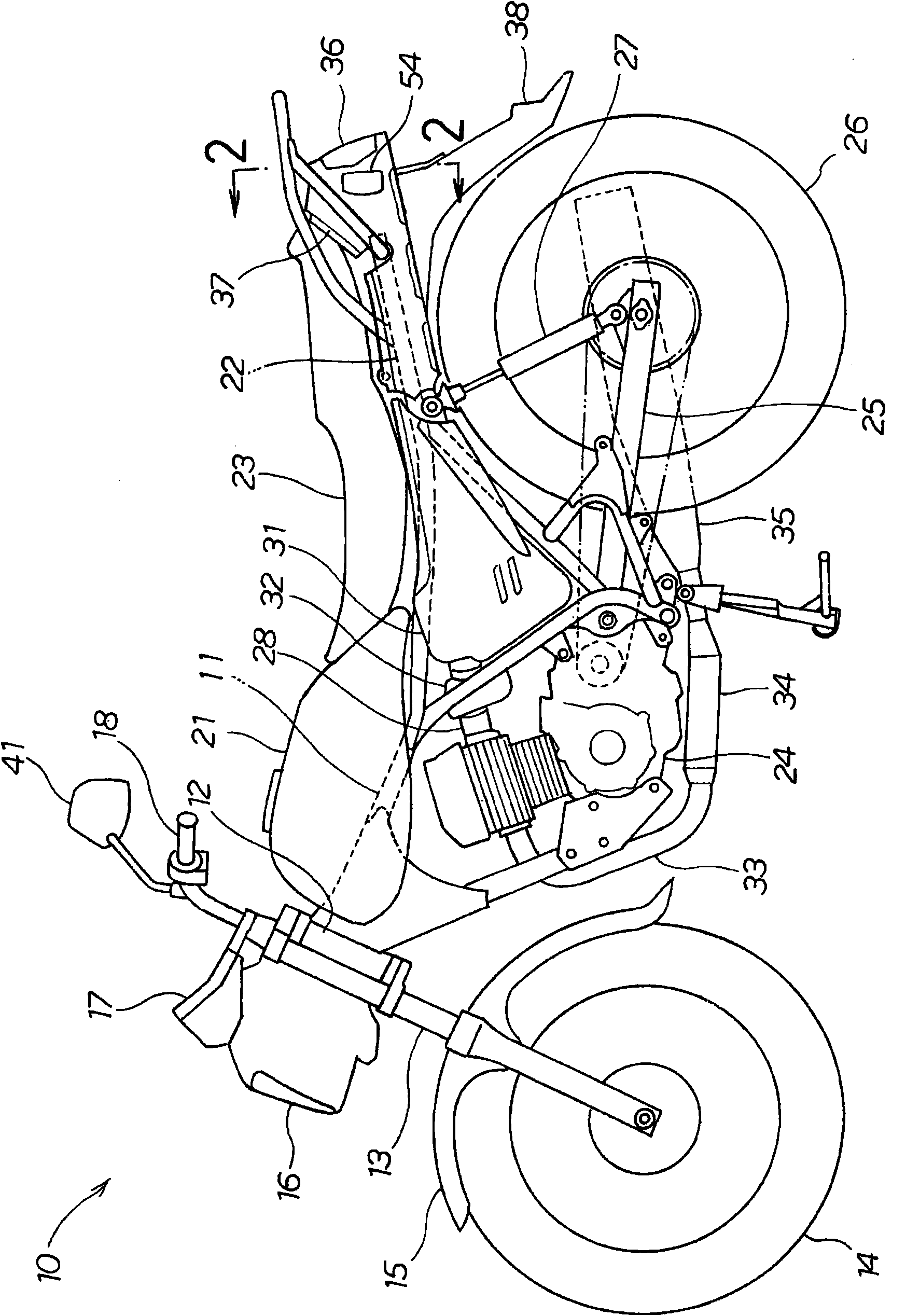

Two-wheeled motor vehicle

ActiveCN101954939ASuppress left and right vibrationAvoid vibration up and downOptical signalWeather guardsAerospace engineering

The invention aims to provide a two-wheeled motor vehicle capable of inhibiting up and down, left and right vibration of a tail lamp with low cost. The tail lamp (36) is provided with an upper surface (42), left and right lateral surfaces (43, 44) and a bottom surface (45). A left elastic body (46) butted with a rear cover (37) on the left side to prevent the vibration of the vehicle width direction (left and right) is preassembled on the left lateral surface (43). A right elastic body (48) butted with a rear cover (47) on the right side to prevent the vibration of the vehicle width directionis preassembled on the right lateral surface (44). Because the elastic bodies are preassembled on the tail lamp, the assembly cost for separately assembling the elastic bodies is not produced. Therefore, the invention provides the two-wheeled motor vehicle capable of inhibiting the up and down, left and right vibration of the tail lamp with low cost.

Owner:HONDA MOTOR CO LTD

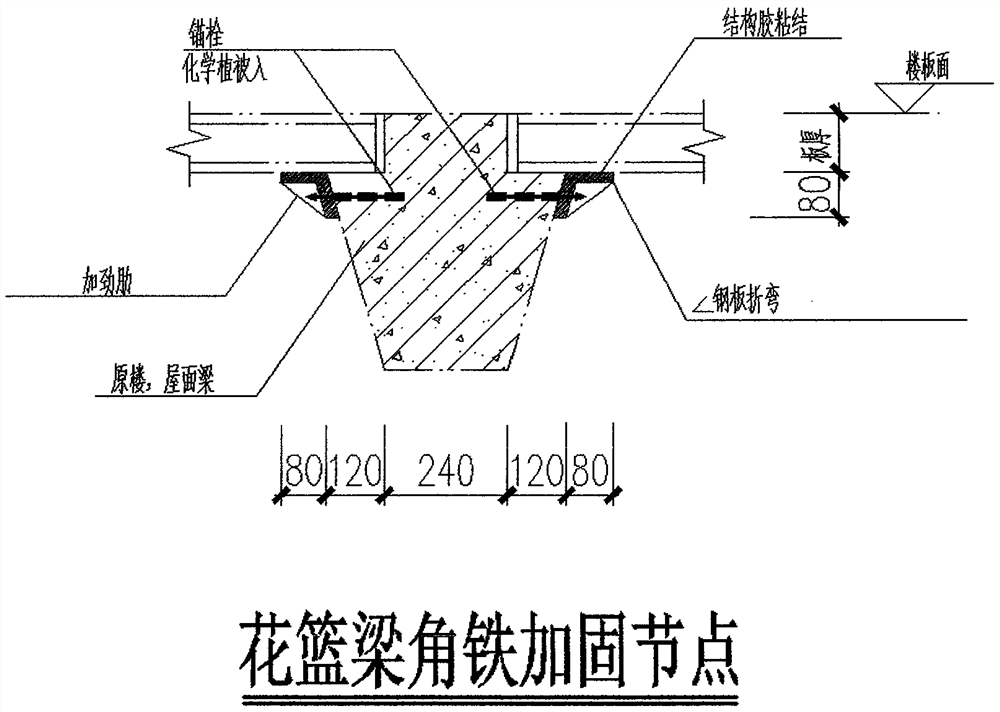

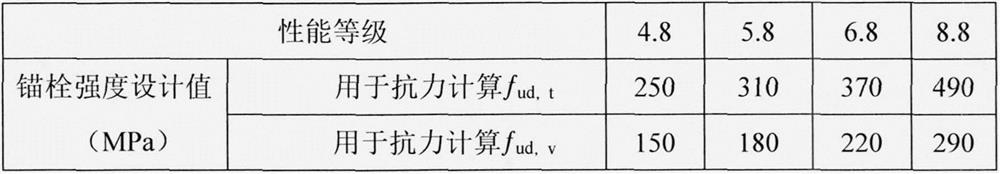

Angle iron reinforcing method for concrete ledger beam

Owner:青海恒固建筑工程有限公司

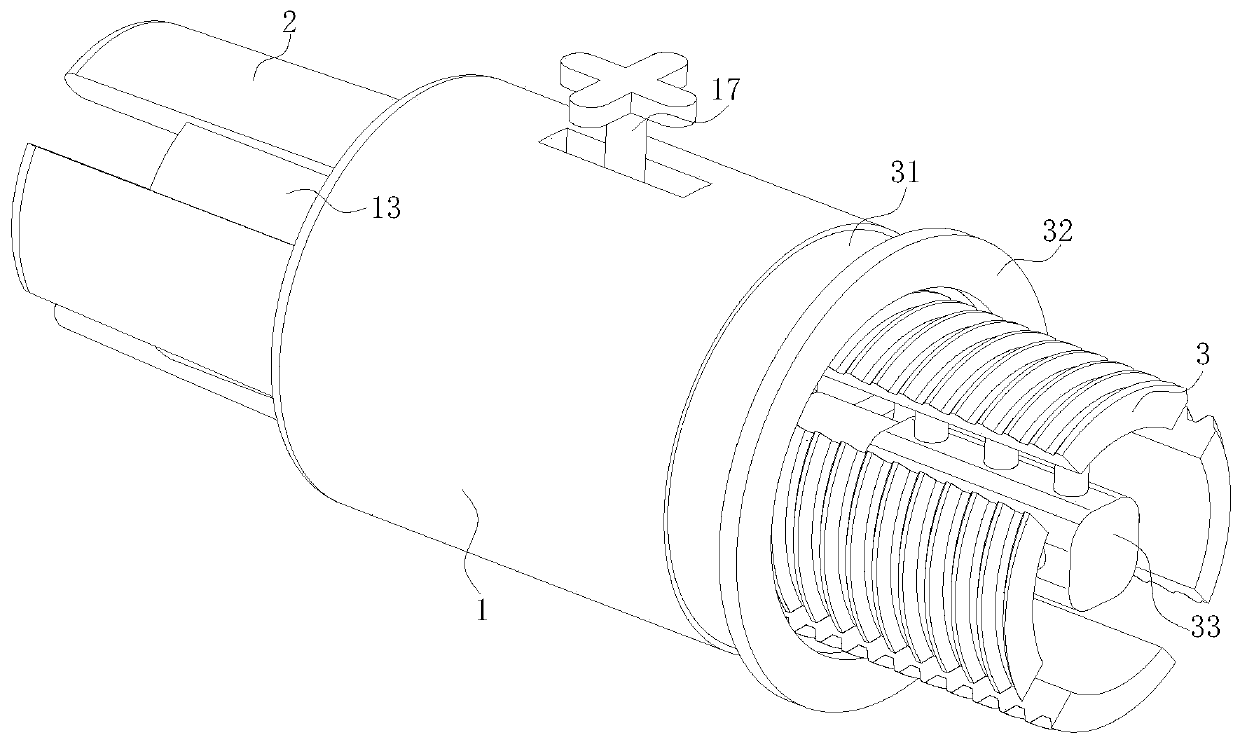

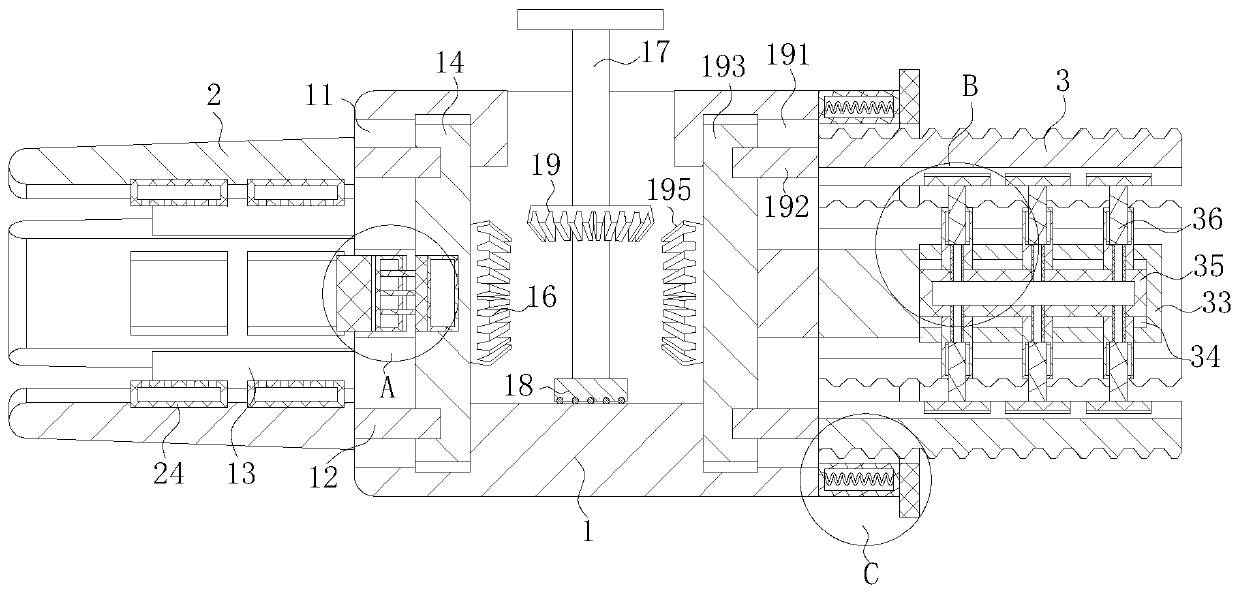

Gun head of pneumatic hot riveting gun

Owner:淮南巧天机械设备技术有限公司

Shock absorber, vehicle suspension system and vehicle

InactiveCN103363007BImprove vibration damping effectImprove work performanceSpringsLiquid based dampersEngineeringAir separation

Provided is a shock absorber, comprising an oil storage cylinder (13), a working cylinder (14), a piston rod (6), a guiding and sealing assembly used to guide the movement of the piston rod (6), and an expansion and circulation valve assembly and a compression and compensation valve assembly provided on a piston (16). The guiding and sealing assembly comprises a guide seat (27, 29) and an oil seal (34) located at the upper end of the guide seat. The face of the upper end of the guide seat (27, 29) is formed with an oil storage groove, and the oil storage groove has an oil-air separation contact surface (35). An elastic separation lip (36) is formed on the oil seal (34) and the elastic separation lip (36) is in airtight contact with the oil-air separation contact surface (35) such that the oil storage groove is separated into an outside part and an inside part. Moreover, further provided are a vehicle suspension system and a vehicle comprising the shock absorber. The piston rod of the shock absorber has good movement stability, the friction between the piston and the inner wall of the working cylinder is low, and the shock absorber has a long service life and has significantly improved dampening effects.

Owner:浙江长进减震器有限公司

Masonry structure integrity reinforcing method

ActiveCN102477799BReduce earthquake forceProtected from vandalismBuilding repairsShock proofingCross connectionStructural integrity

The invention discloses a masonry structure integrity reinforcing method. In the method, an end reinforcing member is arranged at the junction between a floor and a wall surface; an upper end reinforcing member is arranged at the top of the wall, and a lower end reinforcing member is arranged at the bottom of the wall; when a ring beam exists, the upper end reinforcing member is not necessary, and a wall end reinforcing member is arranged at the junction of two walls; when a constructional column exists, the wall end reinforcing member is not necessary, a plate bottom reinforcing member is arranged at the bottom surface of the floor and is in cross connection with the upper end reinforcing member, and a wall surface reinforcing member is arranged on the wall surface and is in cross connection with the end reinforcing member; the upper end reinforcing member is connected with the wall surface reinforcing member, the plate bottom reinforcing member and the wall end reinforcing member; the lower end reinforcing member is connected with the wall surface reinforcing member and the wall end reinforcing member; and the upper end reinforcing member, the lower end reinforcing member, the wall end reinforcing member, the wall surface reinforcing member and the plate bottom reinforcing member are connected in a whole. Compared with the traditional reinforcement, the reinforcement of the floor and the reinforcement of the wall surface are connected with each other, the structural integrity is better, and the construction is simple and convenient and free from the influence of ambient temperature.

Owner:上海维固工程实业有限公司 +2

Guide ring overwelding seam large-cylinder bottom double-telescopic upright column

ActiveCN102140923BIncrease support lengthImprove impact resistanceProps/chocksPulp and paper industrySafety valve

The invention relates to a guide ring overwelding seam large-cylinder bottom double-telescopic upright column. The telescopic ratio of the double-telescopic upright column is effectively enhanced through a guide ring overwelding seam structure and a method for increasing the spheric radius of the bottom of an outer cylinder; the safety of the double-telescopic upright column is effectively enhanced by adding a bypass safety valve to the double-telescopic upright column; and the guide ring overwelding seam is realized by adopting an interference avoidance structure without processing after a cylinder bottom and a cylinder barrel are welded, thereby the processing process is simplified and the maintenance of a cylinder body is facilitated in the using process; and in addition, the invention is especially suitable for a low-coal-seam hydraulic support and a hydraulic support which has lower support efficiency caused by insufficient telescopic ratio of the double-telescopic upright column.

Owner:CCTEG COAL MINING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com