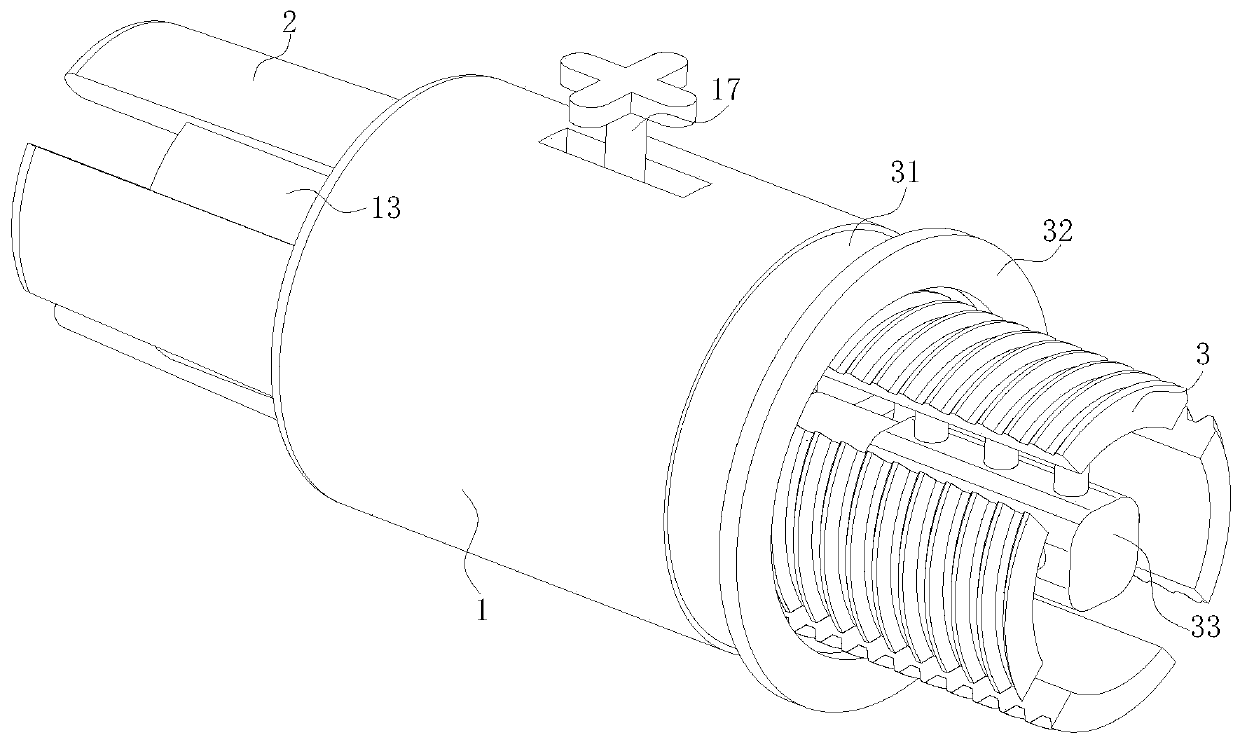

Gun head of pneumatic hot riveting gun

A technology for pneumatic heat and riveting guns, applied in the field of heat riveting gun heads, can solve the problems of reducing installation efficiency, waste of resources, etc., and achieve the effects of improving support force, prolonging service life, and increasing support length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

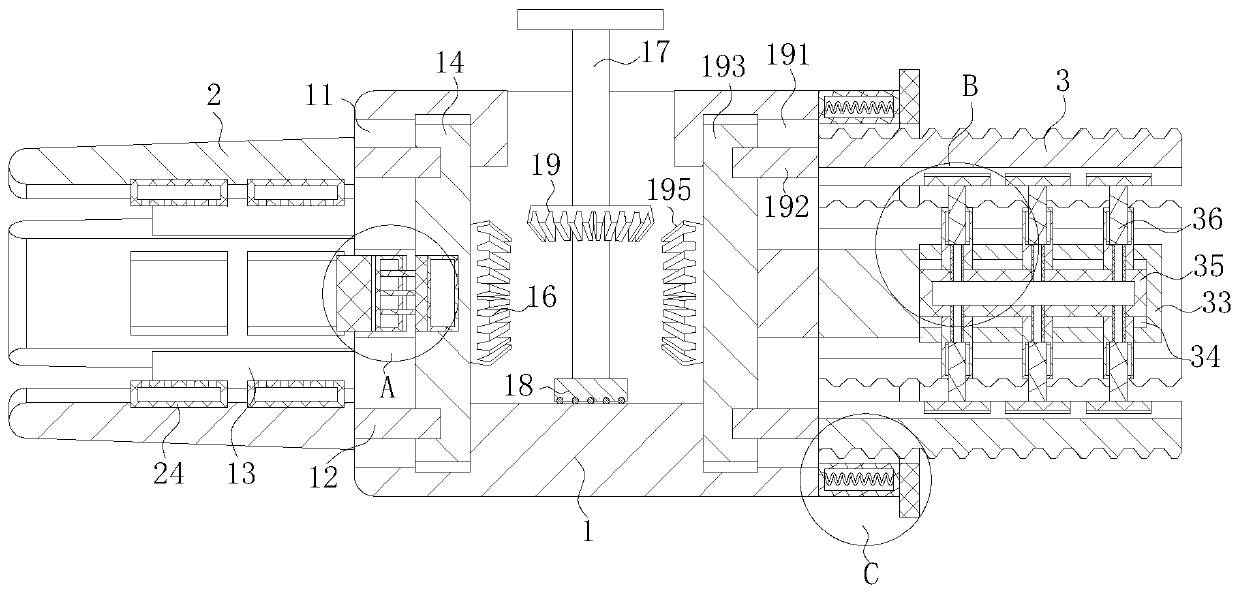

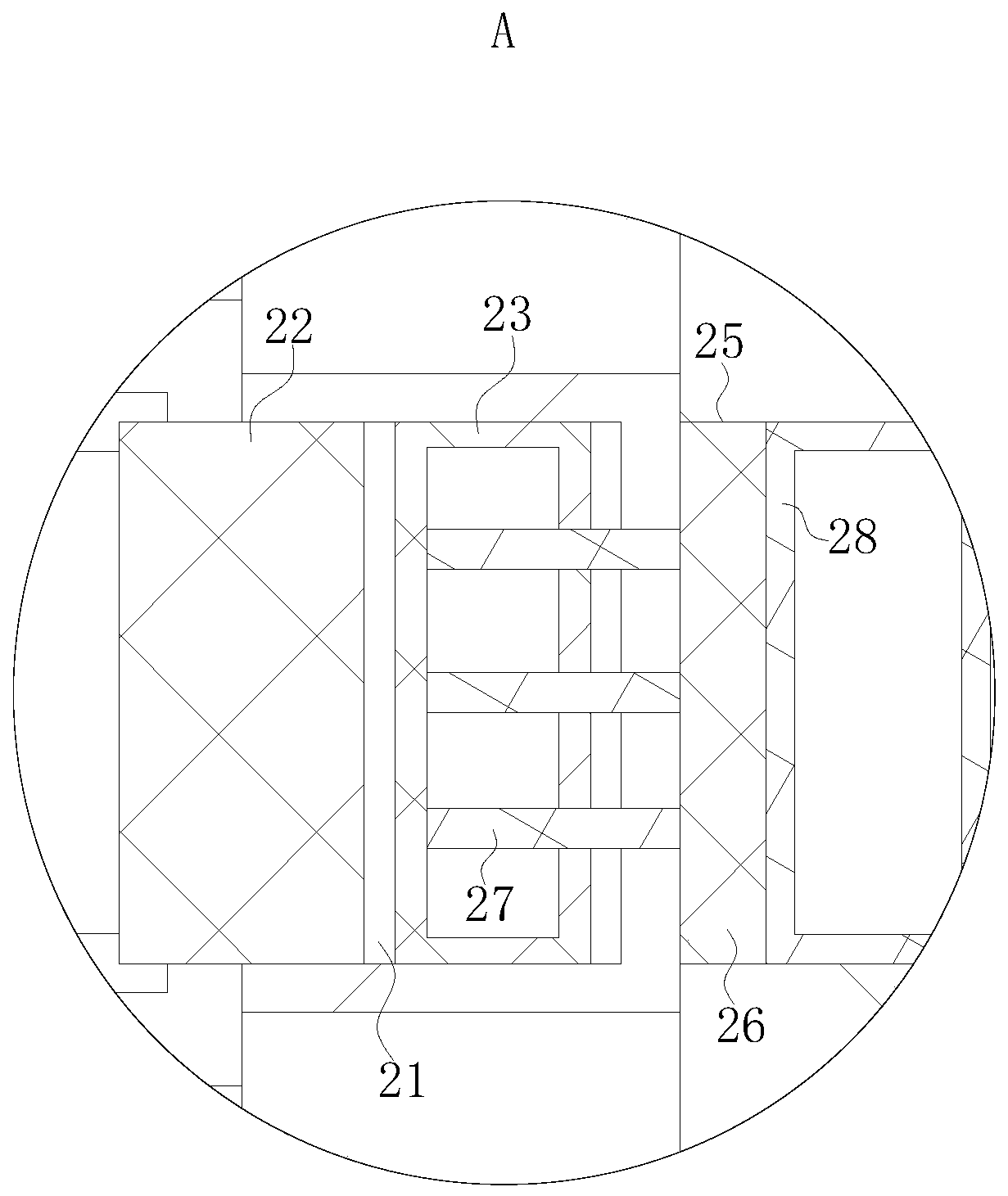

[0025] As an embodiment of the present invention, the left end surface of the connecting block 1 is provided with a first round groove 21 at the centerline position, and a first round block 22 is slidably connected in the first round groove 21; The right side of the block 22 is fixedly connected with a first airbag 23 in the inner wall of the first circular groove 21; the opposite side of each of the chucking heads 2 is fixedly connected with a second airbag 24 evenly arranged in the inner wall of the chucking head 2, and The second air bag 24 communicates with the first air bag 23 through the trachea; during work, when the bolts are put between the clamping heads 2 and the bolts continue to be pressed, the first round block 22 starts to move toward the first round due to the pressure of the bolts. Sliding in the groove 21, the first airbag 23 in the first circular groove 21 can be squeezed during the sliding process of the first round block 22. When the first airbag 23 is sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com