Patents

Literature

235 results about "Rivet gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rivet gun, also known as a pneumatic hammer, is a type of tool used to drive rivets. The rivet gun is used on rivet's factory head (the head present before riveting takes place), and a bucking bar is used to support the tail of the rivet. The energy from the hammer in the rivet gun drives the work and the rivet against the bucking bar. As a result, the tail of the rivet is compressed and work-hardened. At the same time the work is tightly drawn together and retained between the rivet head and the flattened tail (now called the shop head, or buck-tail, to distinguish it from the factory head). Nearly all rivet guns are pneumatically powered. Those rivet guns used to drive rivets in structural steel are quite large while those used in aircraft assembly are easily held in one hand. A rivet gun differs from an air hammer in the precision of the driving force.

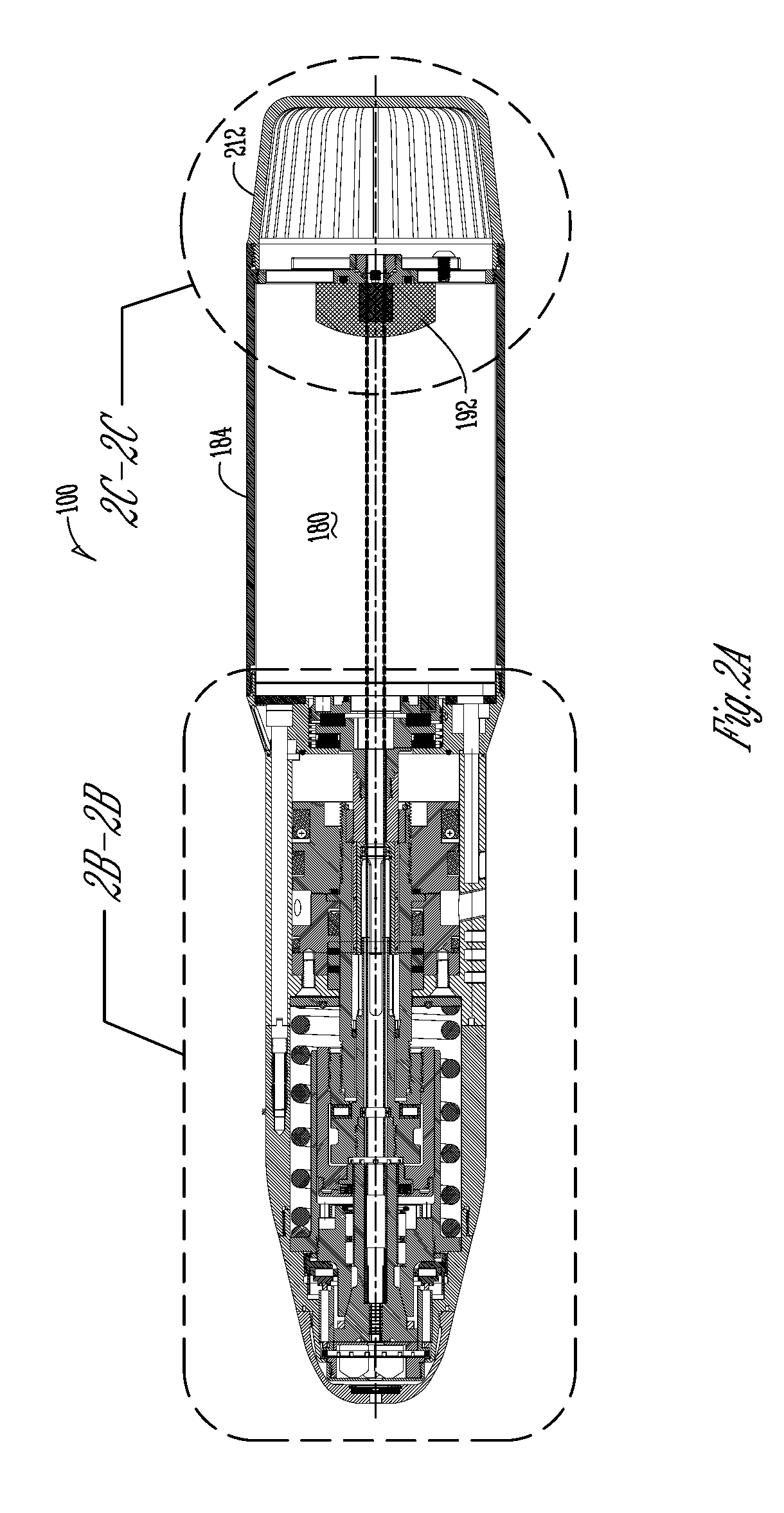

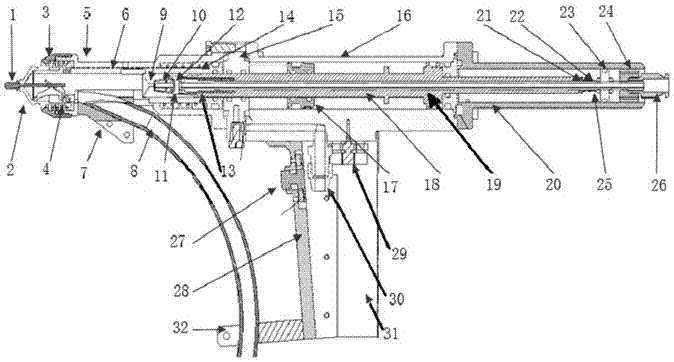

Pneumatic-hydraulic rivet gun

InactiveUS6272899B1Simple and quick controlEasy to handlePortable power-driven toolsMetal working apparatusHydraulic cylinderInlet valve

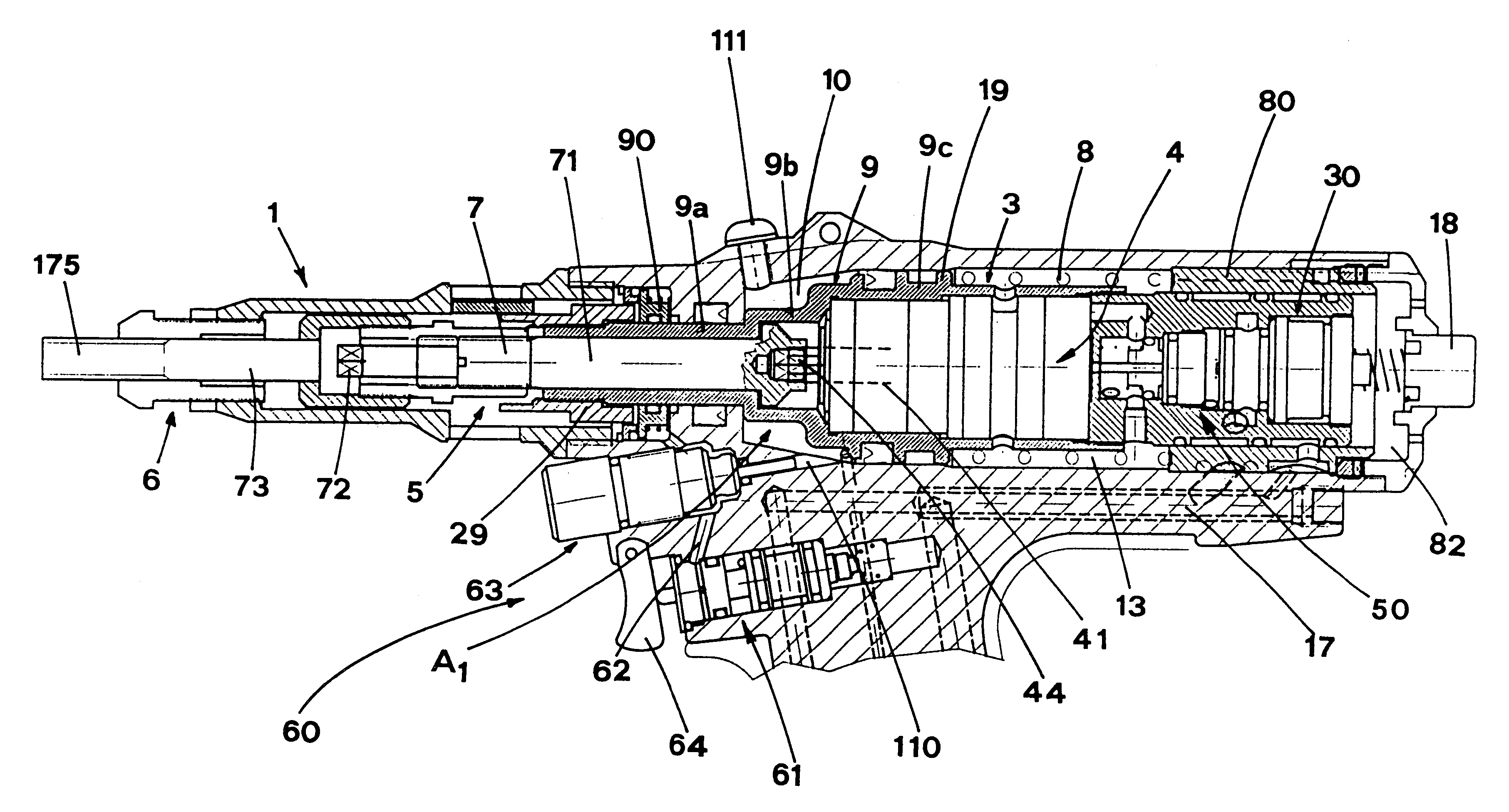

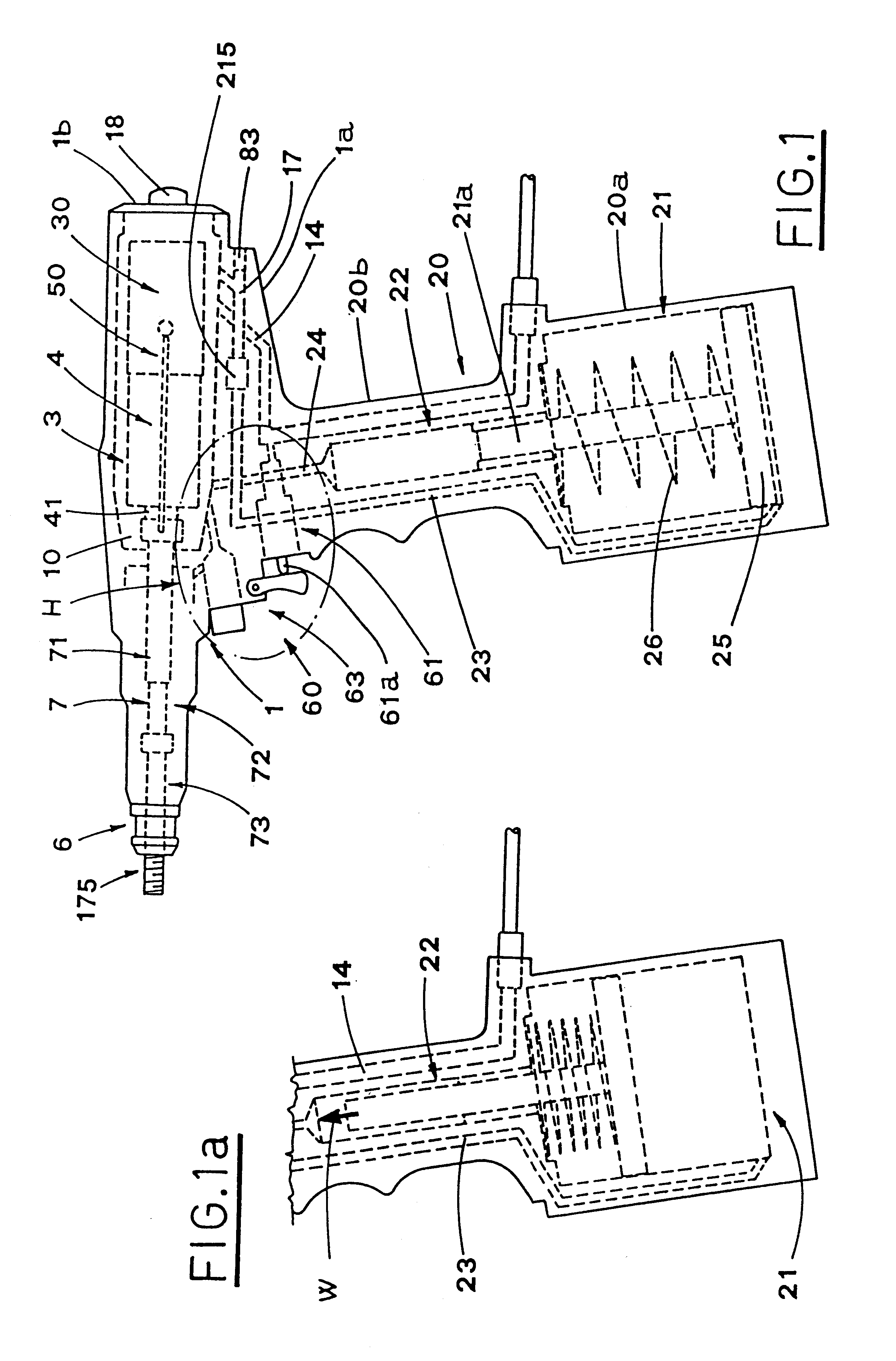

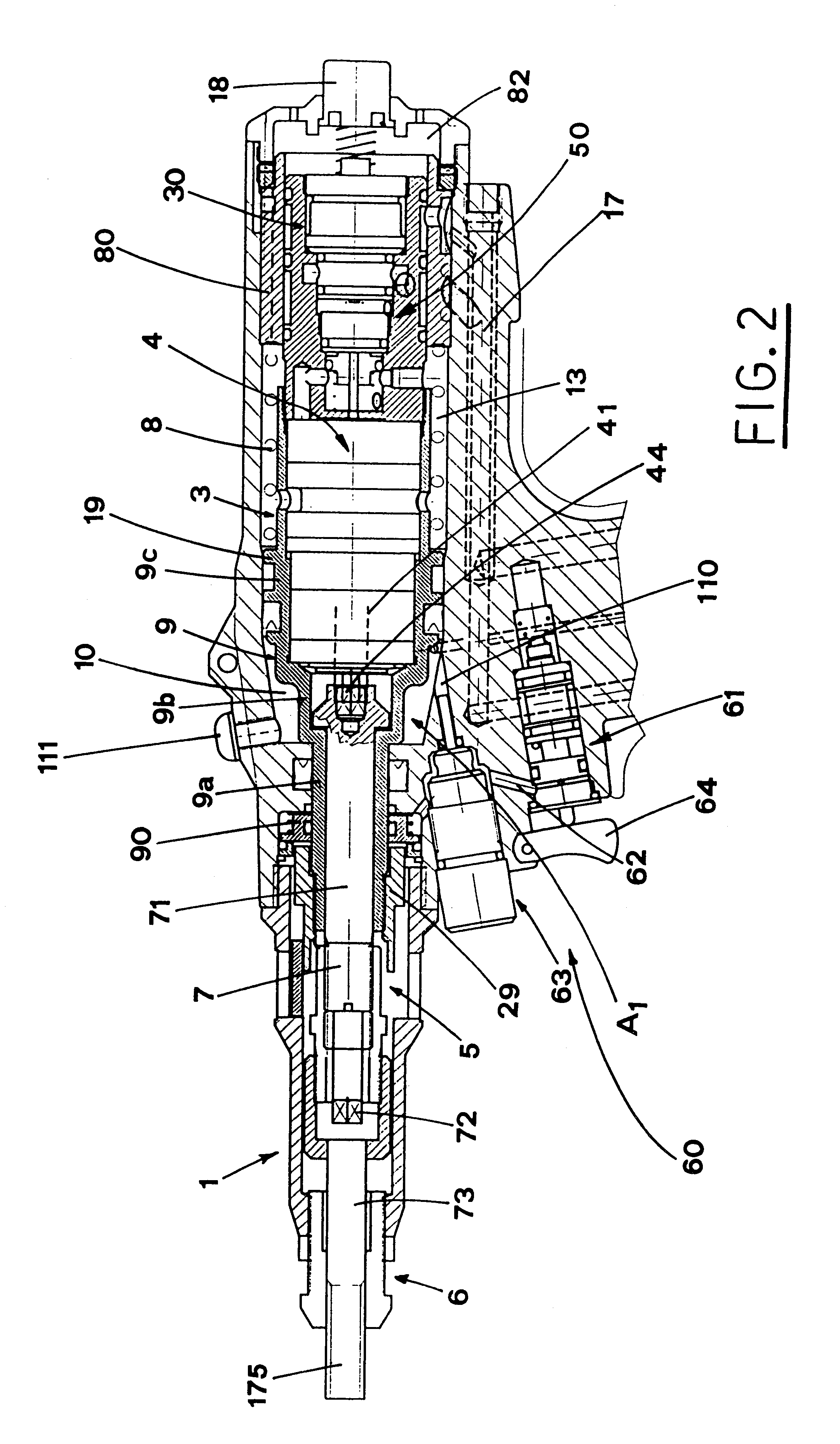

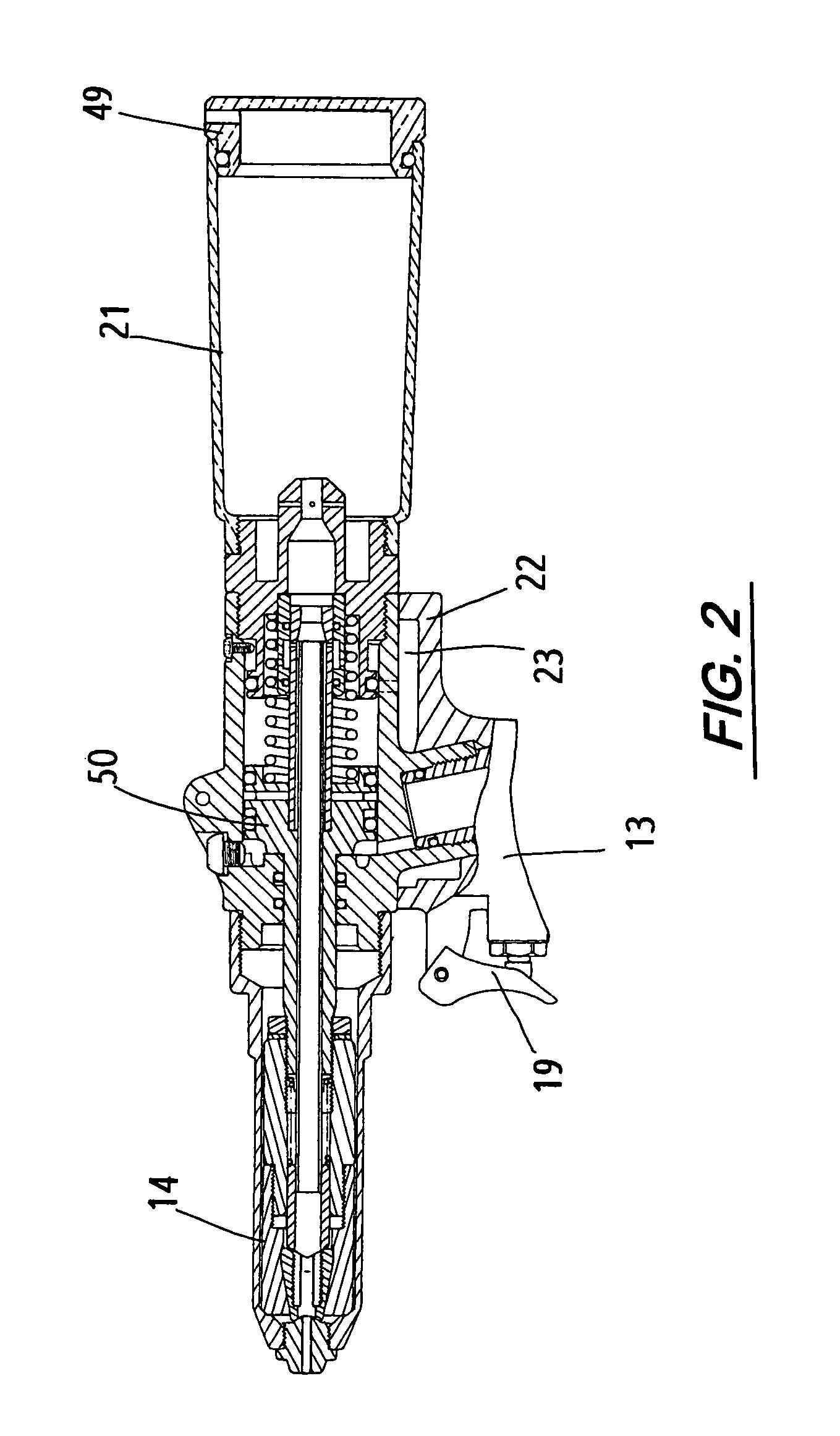

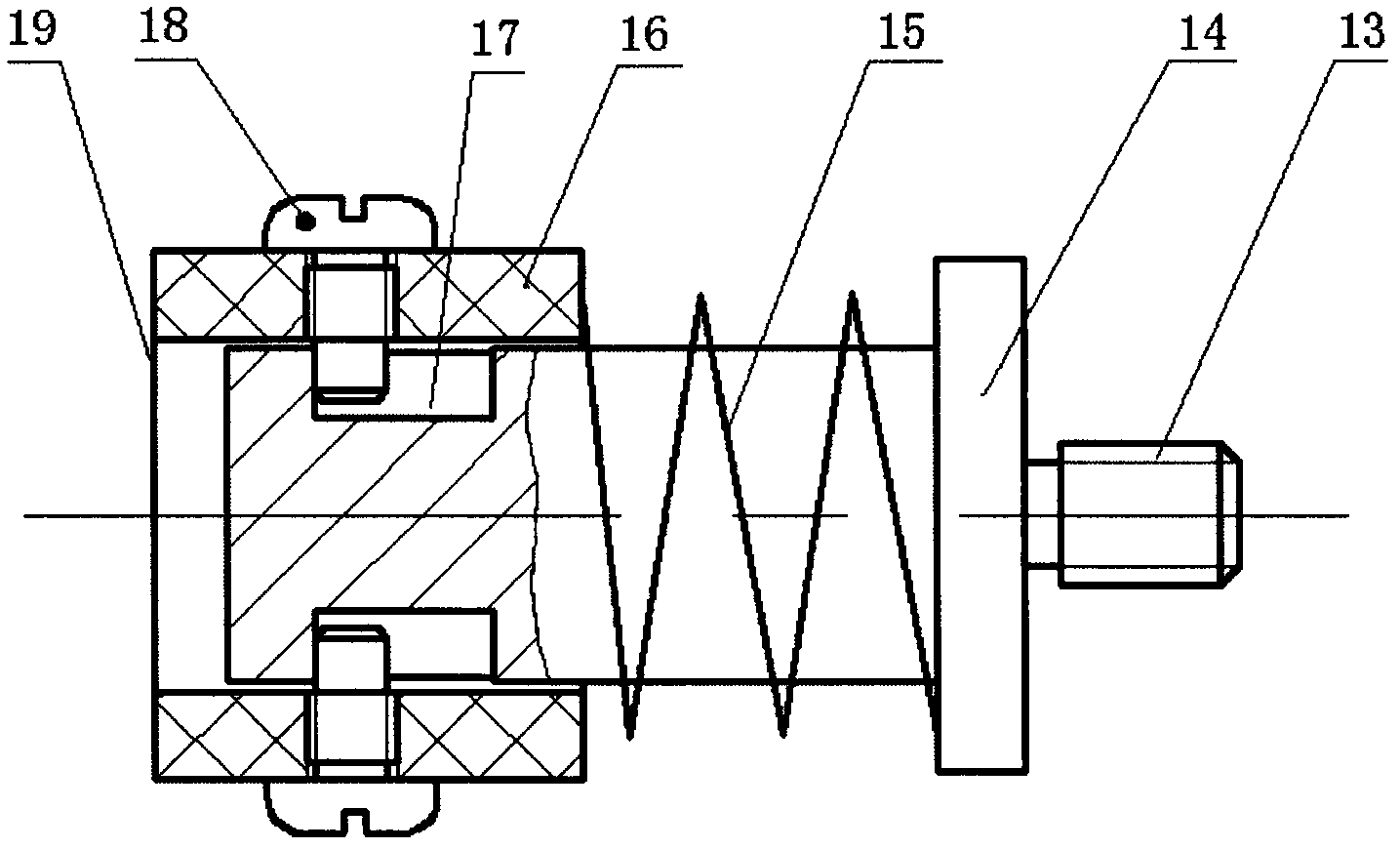

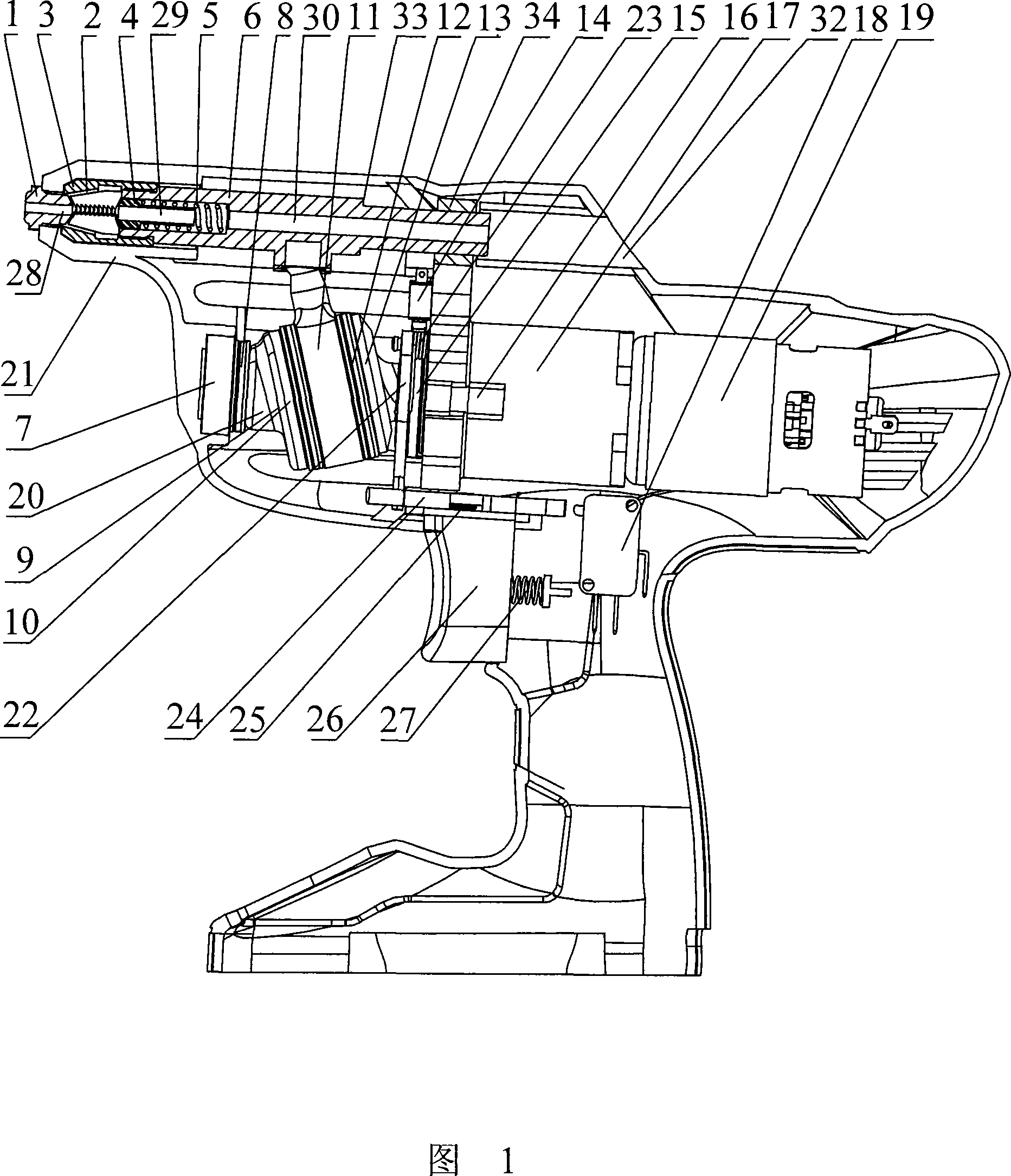

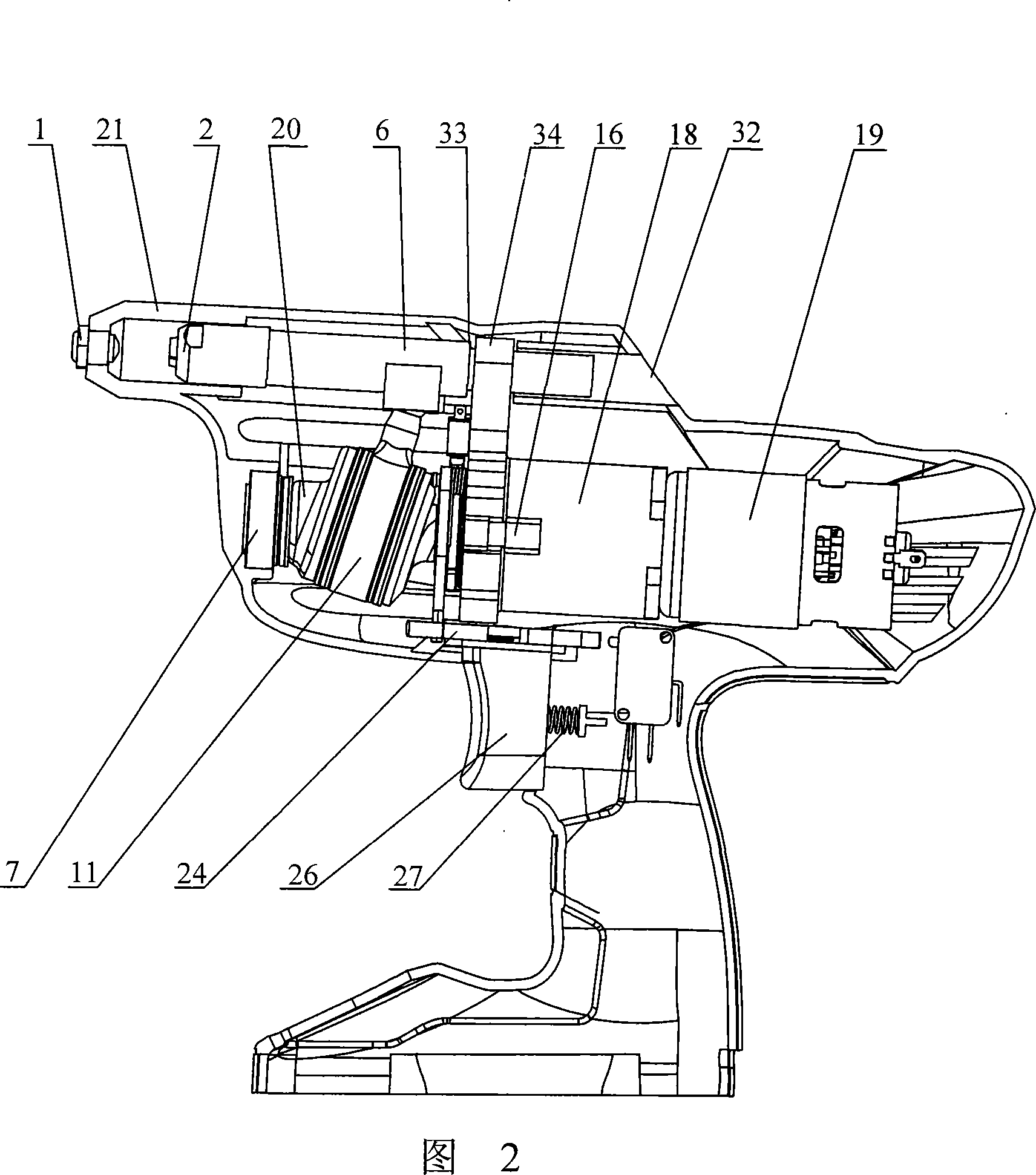

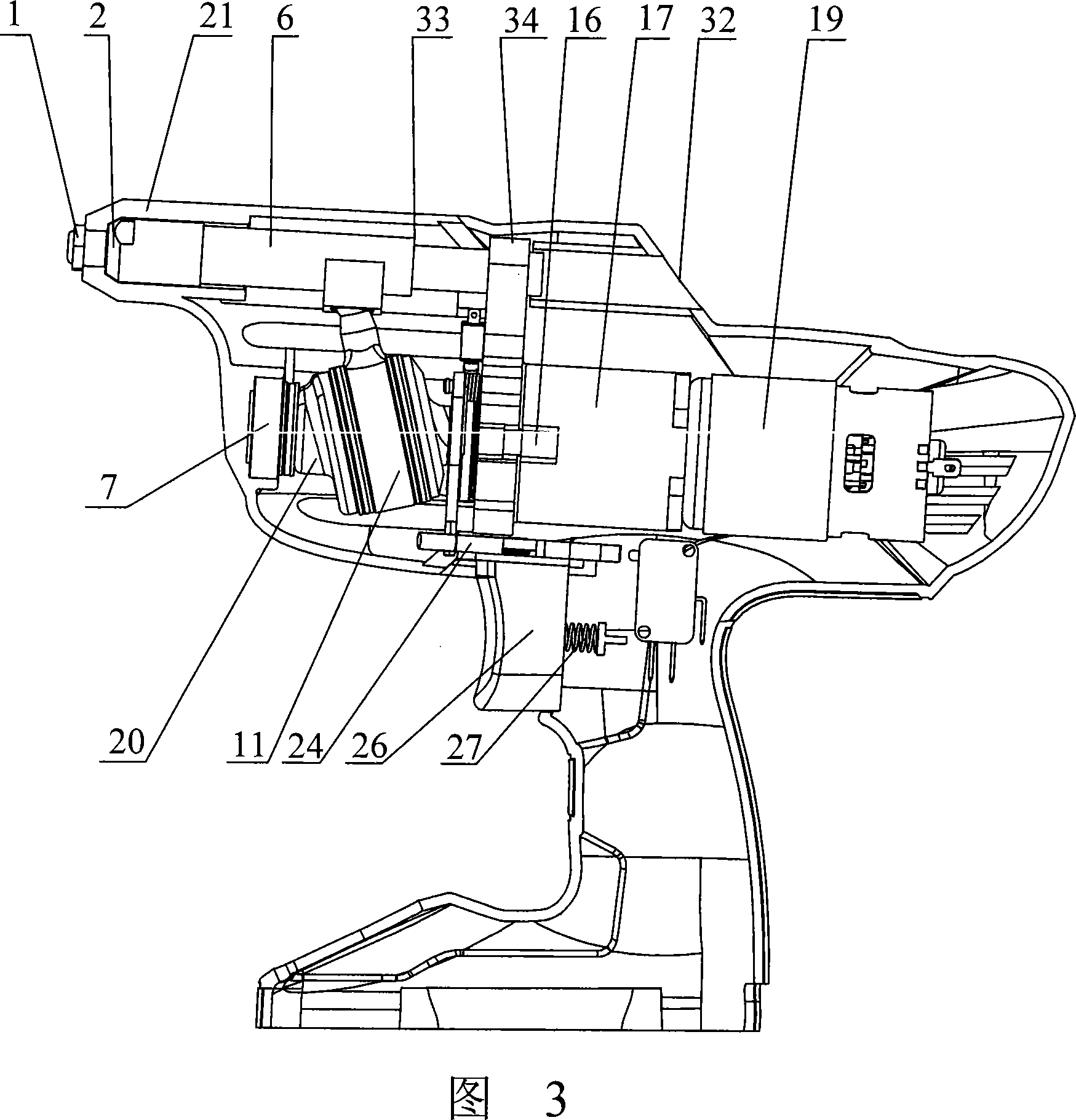

A rivet gun includes a pneumatic motor (4), that drives a segment stem 7. A pneumatic cylinder (21) actuates a hydraulic cylinder (22) which sends oil under pressure to an expansion chamber (10) provided for moving back the segment stem (7) and buckling the rivet (2) fixing it to a laminate structure (100). The rivet gun also includes a change-over switching device (30) linked to controls (50,60) for reversing rotation of the motor (4). The controls (60) include an inlet valve (61) operated by a trigger (64) for connecting a compressed air infeed duct 14 with a feed-discharge duct (23) leading to the pneumatic cylinder (21). A discharge valve (63) is disposed in series with the inlet valve (61) and has an adjustment ring (176) for adjusting of the maximum traction force. Another discharge valve (90) is disposed in series with the discharge valve (63) previously mentioned and is provided for adjustment of the stroke of the segment stem (7).

Owner:OBER UTENSILI PNEUMATICI

Structure of a rivet nut gun

A structure of rivet nut gun having a body, a handle and a pressure cylinder. The top of the handle is furnished with a mounting base having a through cylindrical hole. The lower end of the handle is furnished with a base surface for mounting the fastening disk. The body has a connector mounted with a connecting rod to penetrate through the cylindrical hole of the handle. The fastening disk is fastened to one end of the connecting rod by a nut. The fastening disk is connected with two symmetrical screw rods, which penetrate through the piston and the pressure cylinder, and are fastened to the bottom of the pressure cylinder by two nuts respectively so as to have the piston cylinder fastened in place and to prevent the pressure cylinder from deformation during the rivet nut gun operating.

Owner:LIN YU CHING

Automatic suction and repelling device for rivet gun

An automatic suction and repelling device for rivet gun, which comprises a body and a handle, and the intake passages thereof are in communication each other; the rear center of the body is furnished with a regulation ring and a used-nail cylinder; the regulation ring can be adjusted to move by means of screwing so as to adjust the volume of pressure air to enter the body, and to adjust the vacuum suction force in the used-nail pipe; during rivet-pulling work, the rivet gun can automatically suck in, and can suck a used nail into the used-nail cylinder upon the rivet-pulling work done.

Owner:LIN YU CHING

Blind rivet

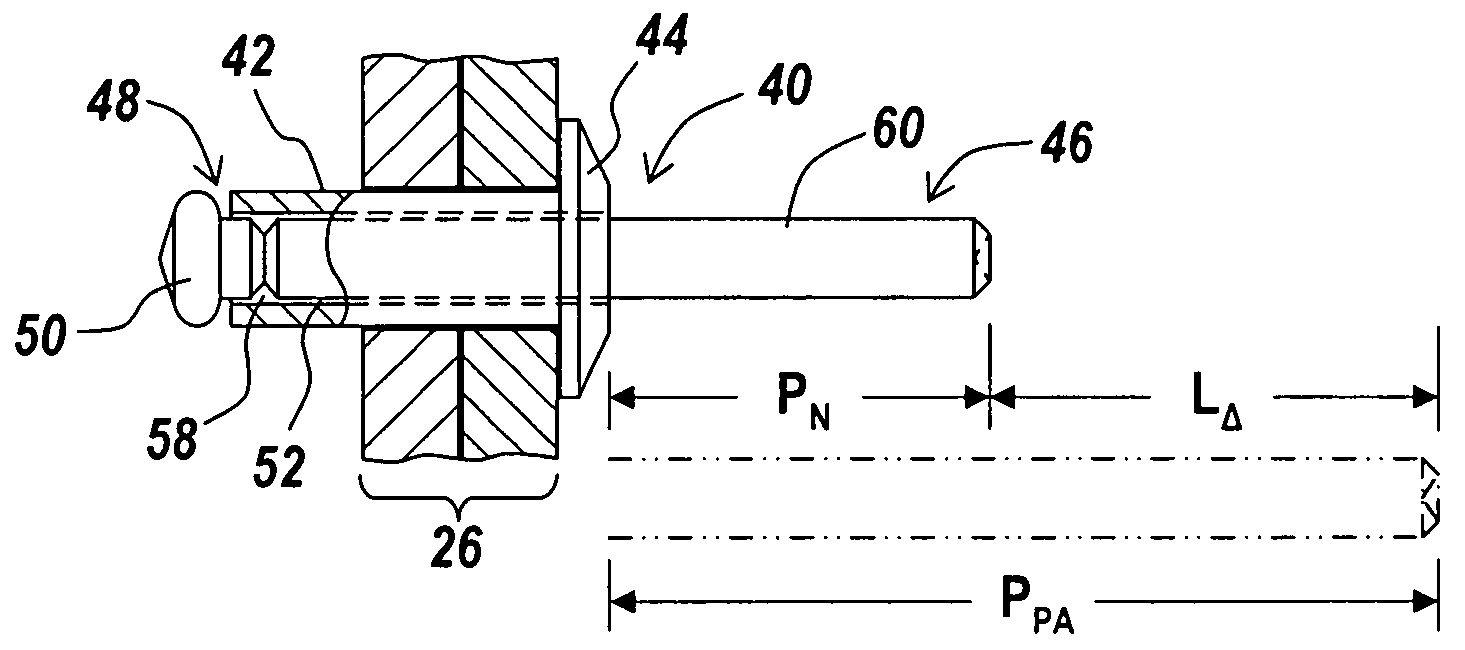

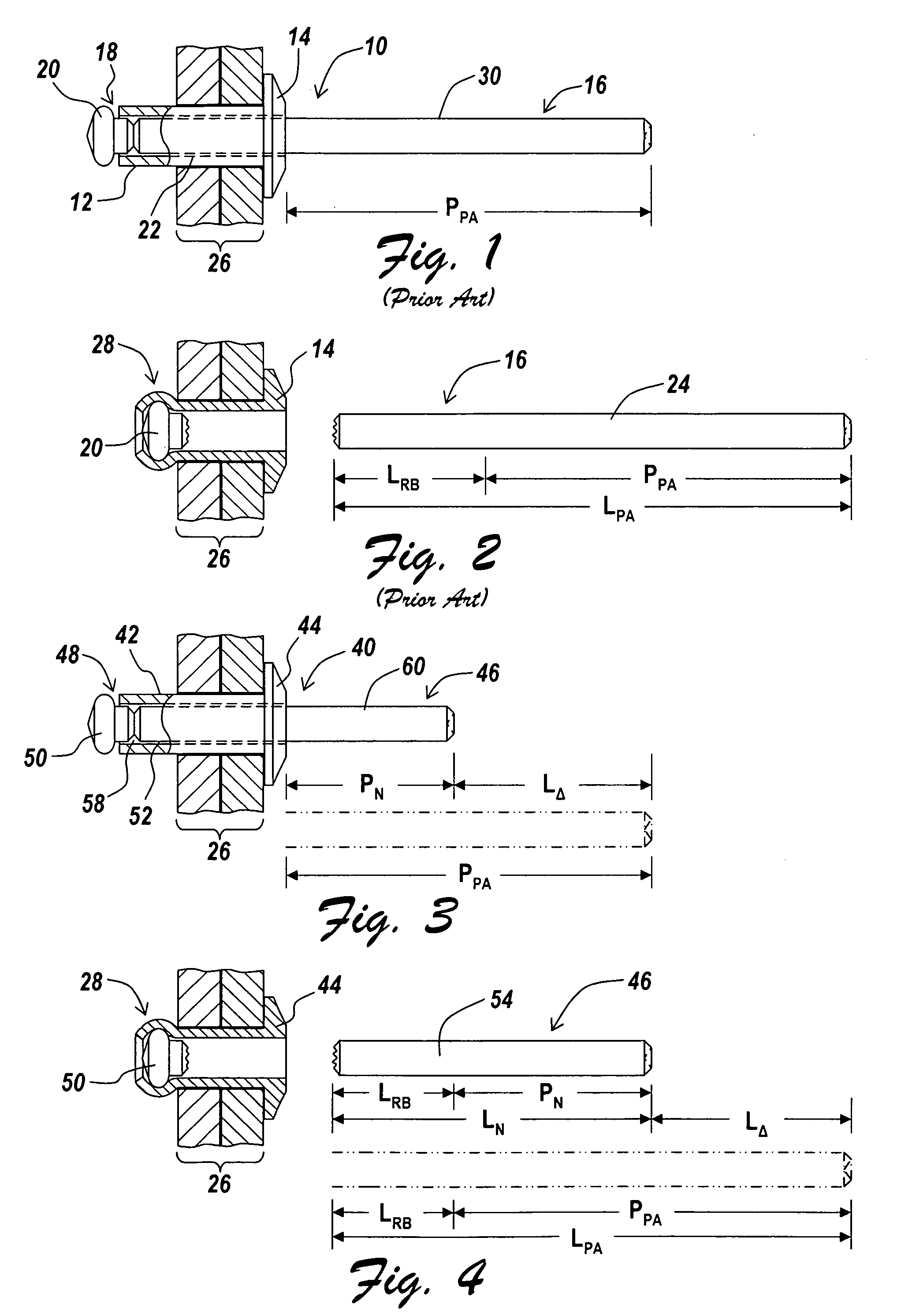

A blind rivet design has an exposed mandrel portion modified from the conventional and standardized mandrel to reduce amount and cost of materials required to produce the mandrel, while also minimizing costs related to production, use, and spent mandrel disposal, all while still making use of conventional riveting tools for rivet setting and maintaining rivet performance. To work with the inventive blind rivet design, a conventional riveting tool, i.e., a rivet gun with a replaceable nosepiece, may be utilized, with a modified nose housing attached. The replaceable nosepiece and modified nose housing on the conventional rivet setting tool enables use of a mandrel having a reduced exposed mandrel portion relative to conventional and standardized mandrels. In addition, a modified stepped approach to setting the rivet may also be utilized in conjunction with the inventive rivet design to enable use of an even further reduced exposed mandrel portion.

Owner:TAYLOR HARRY E

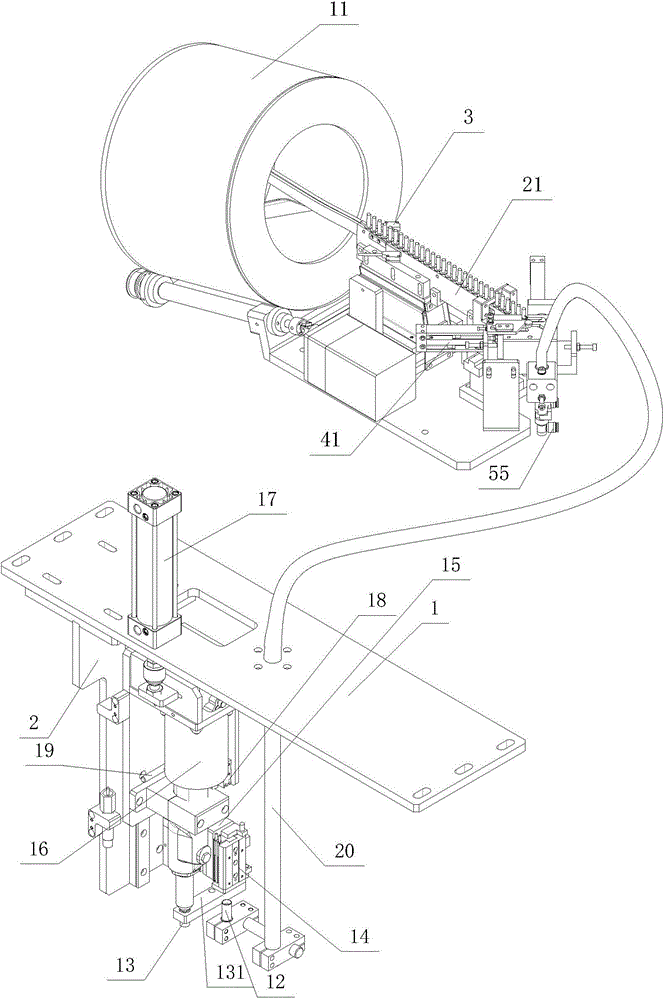

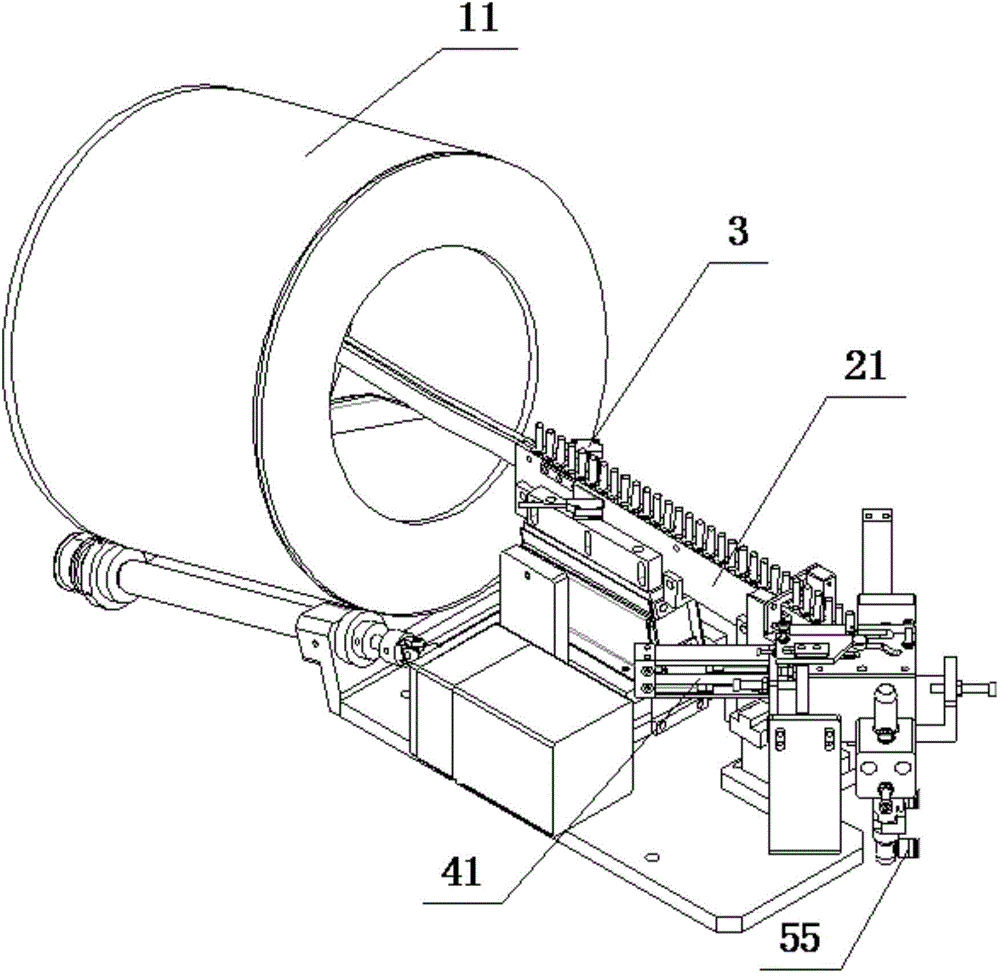

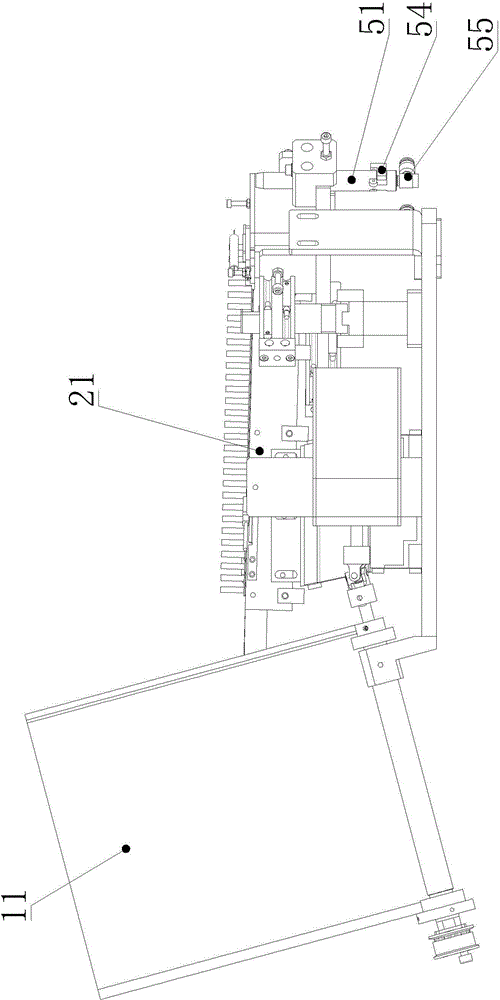

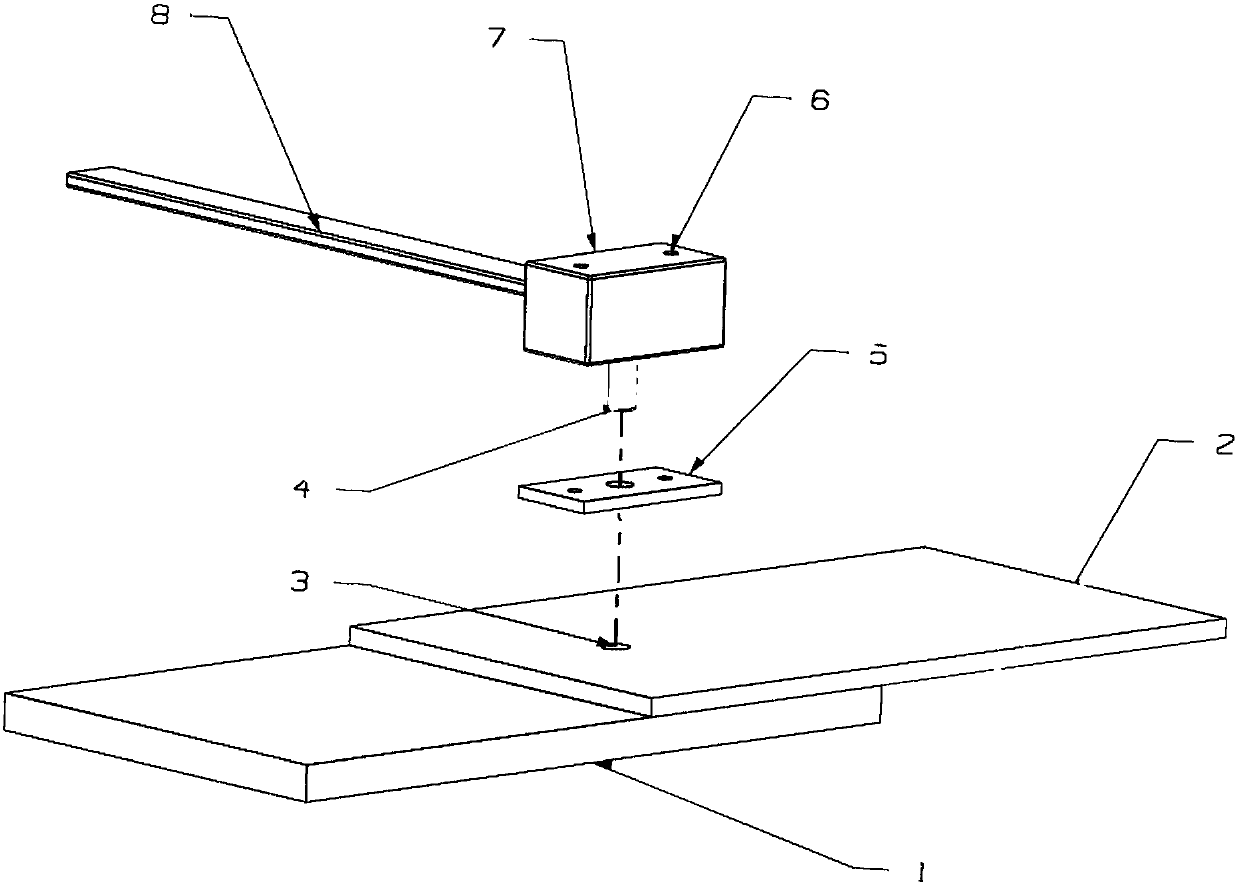

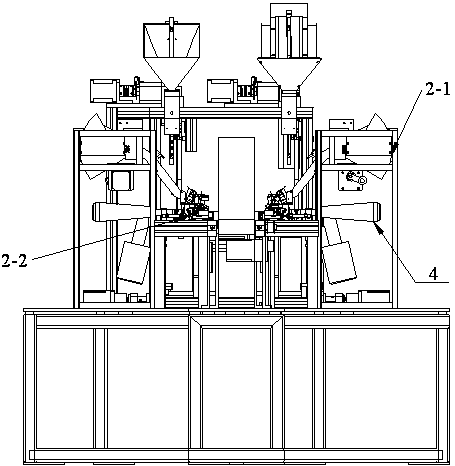

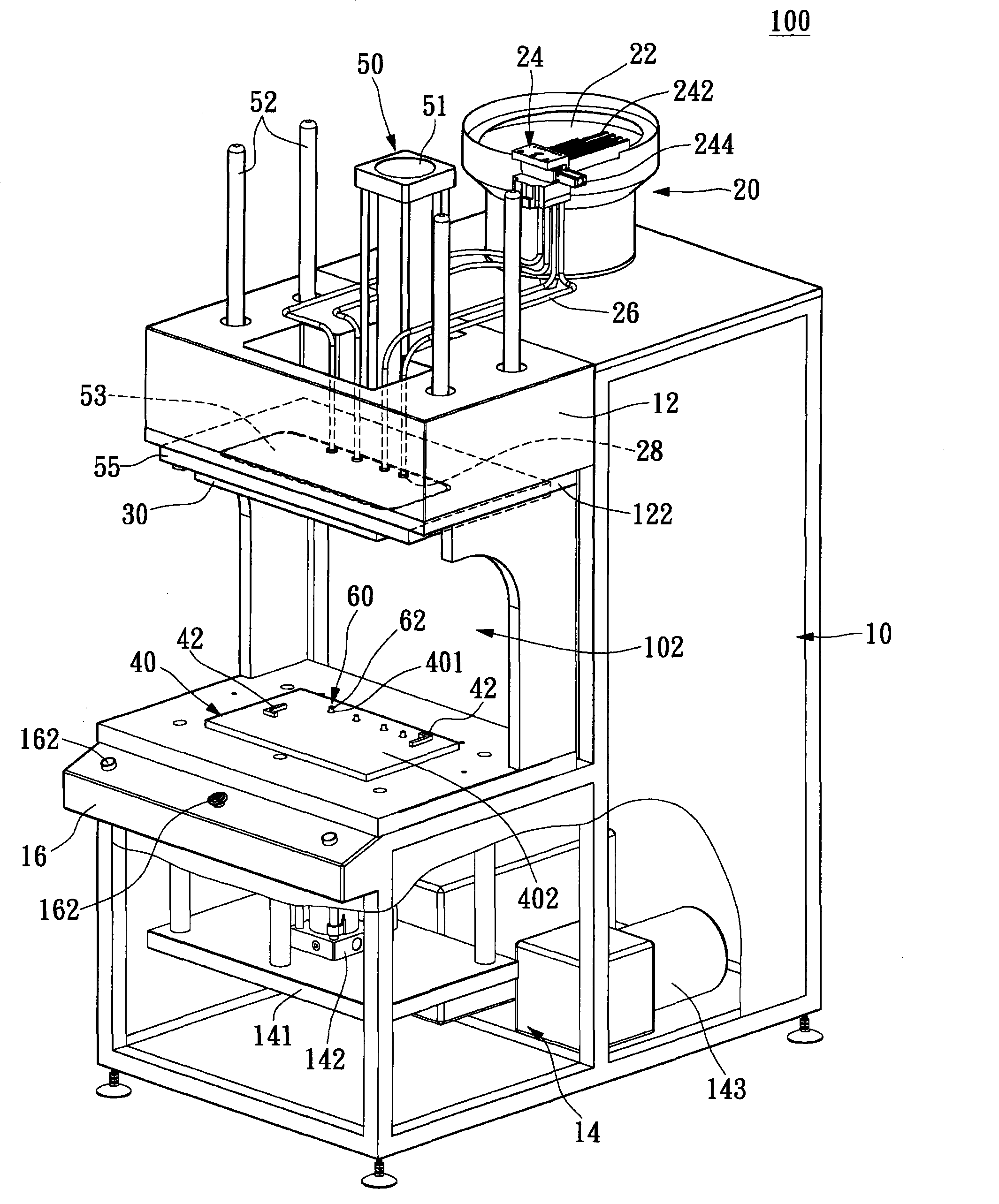

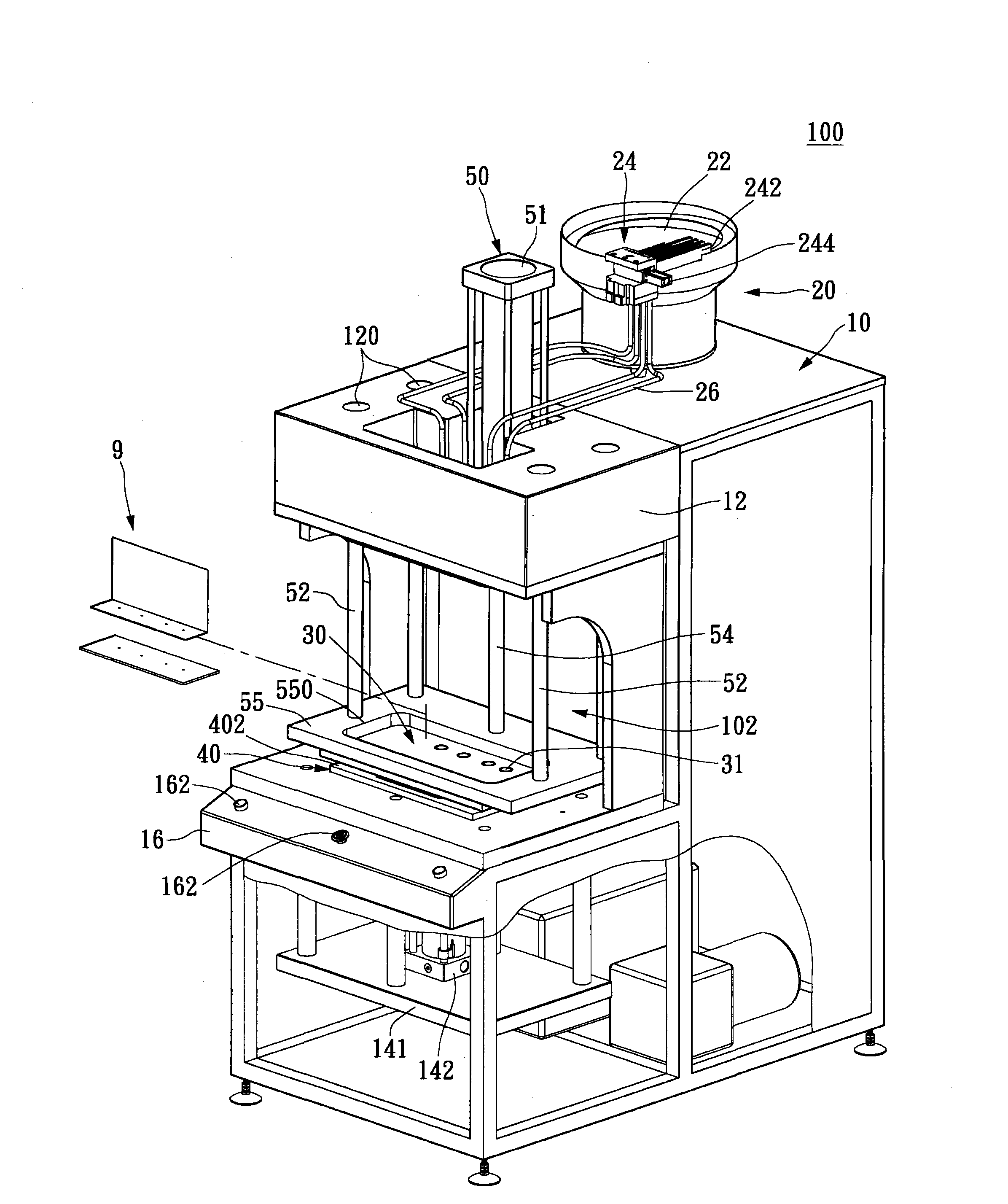

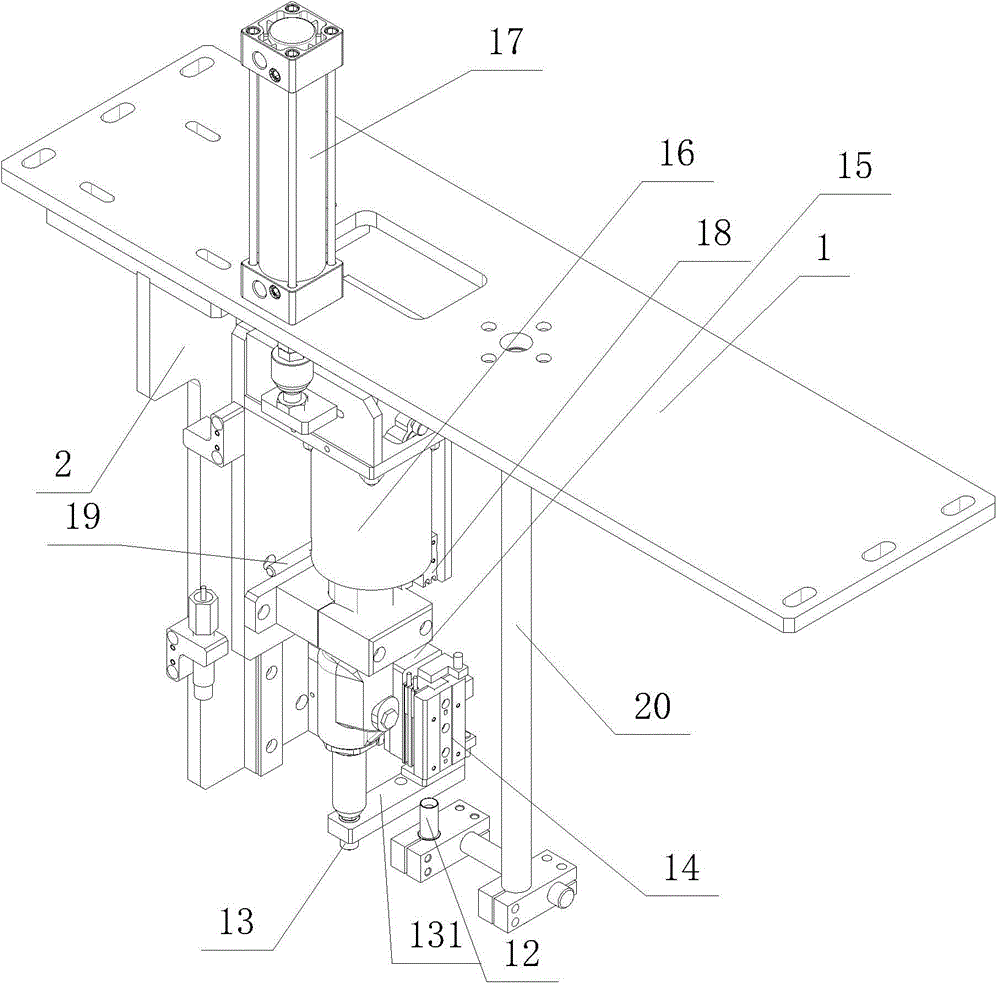

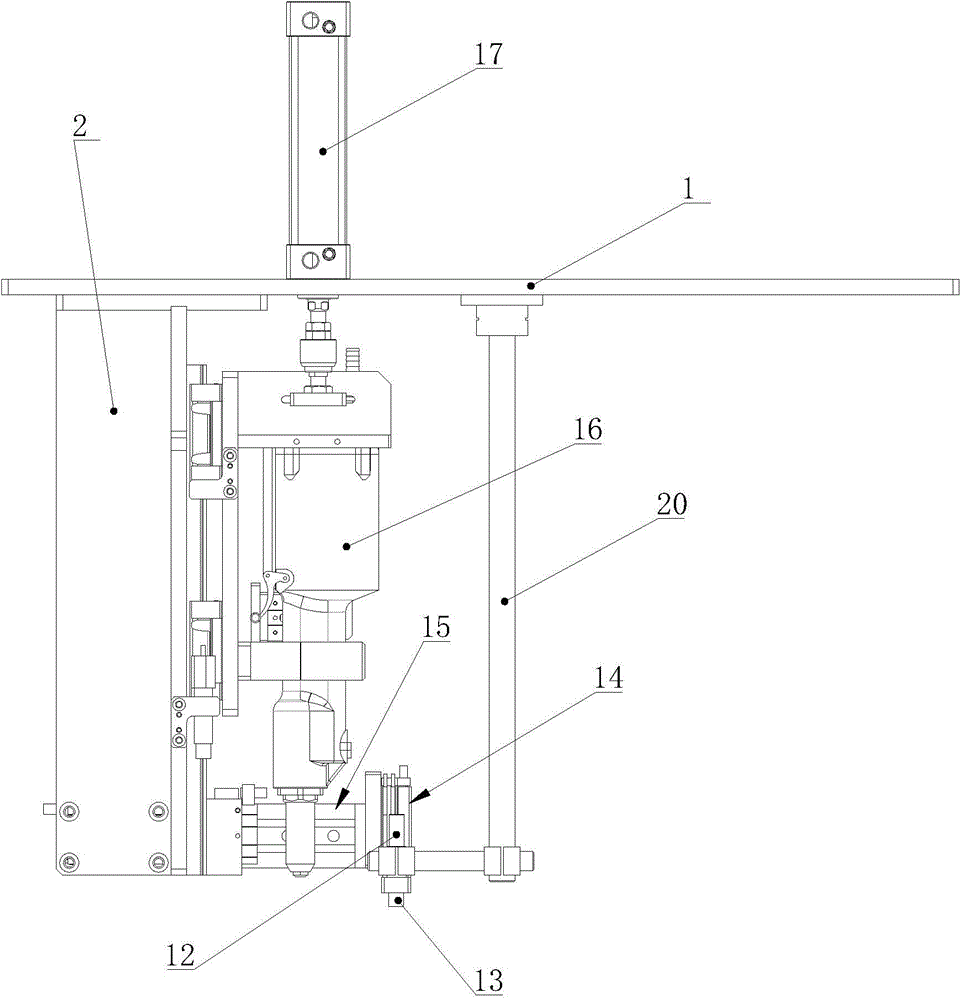

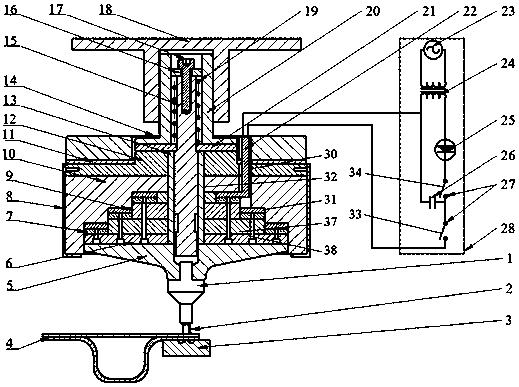

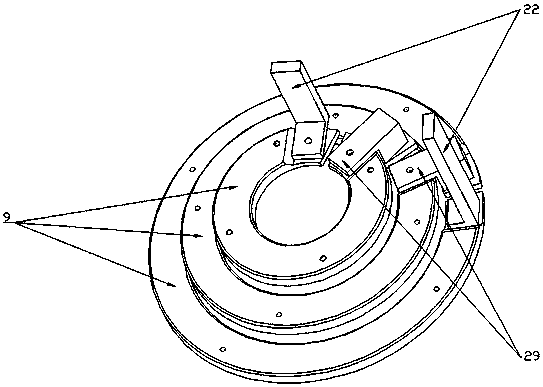

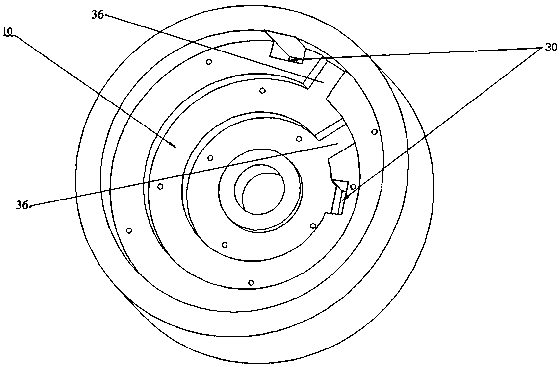

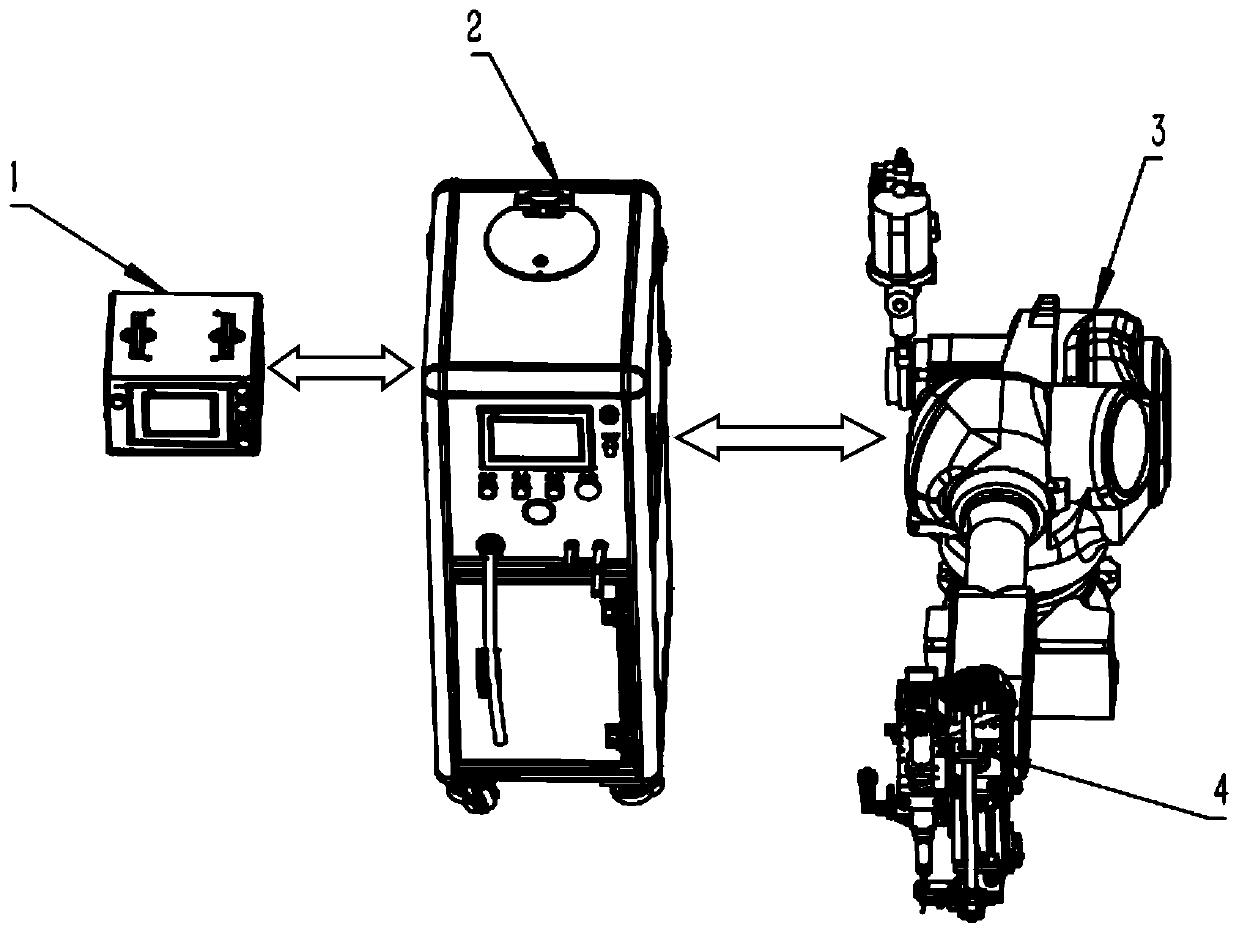

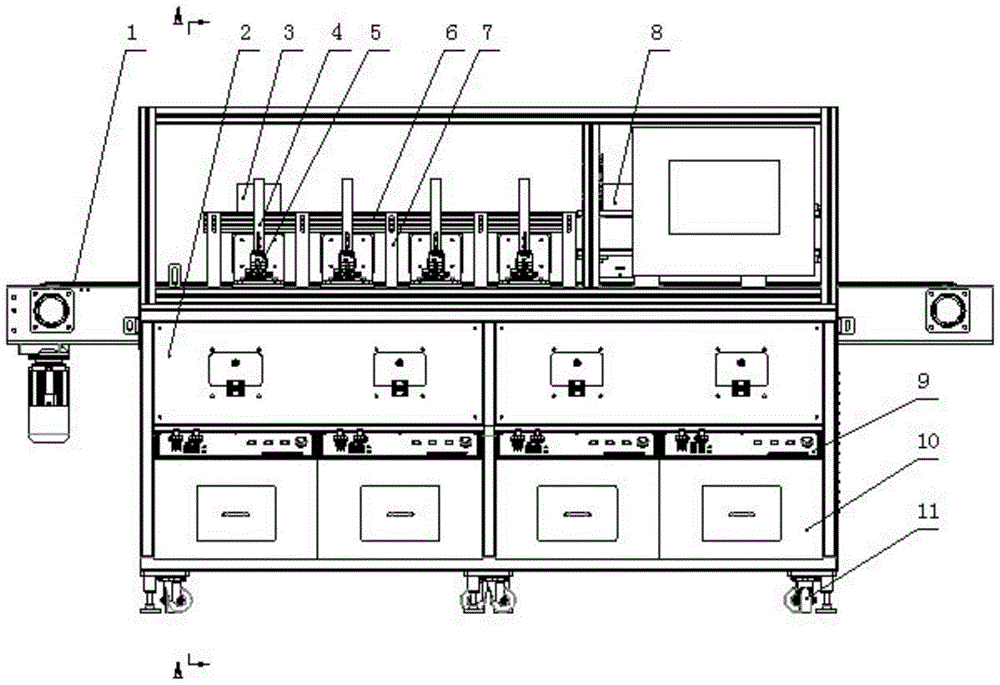

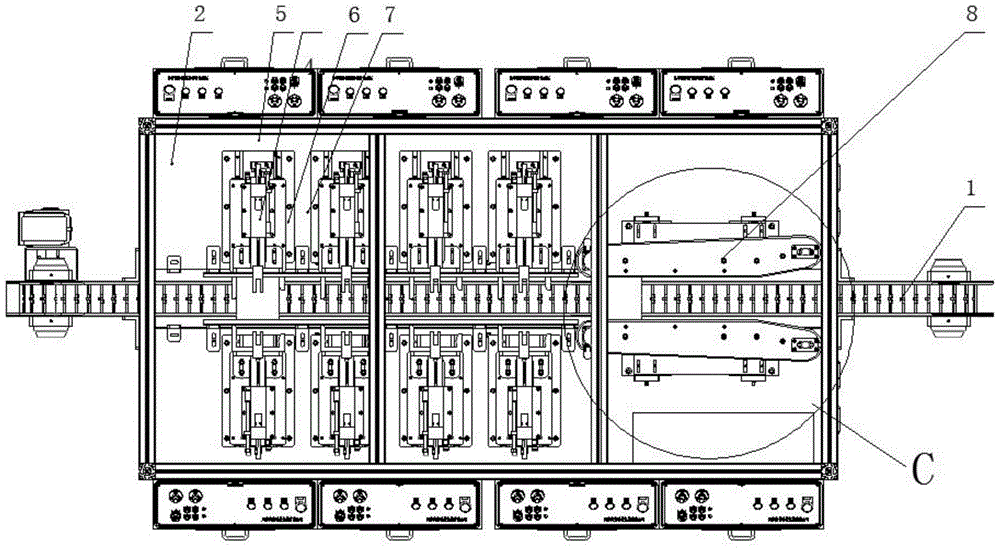

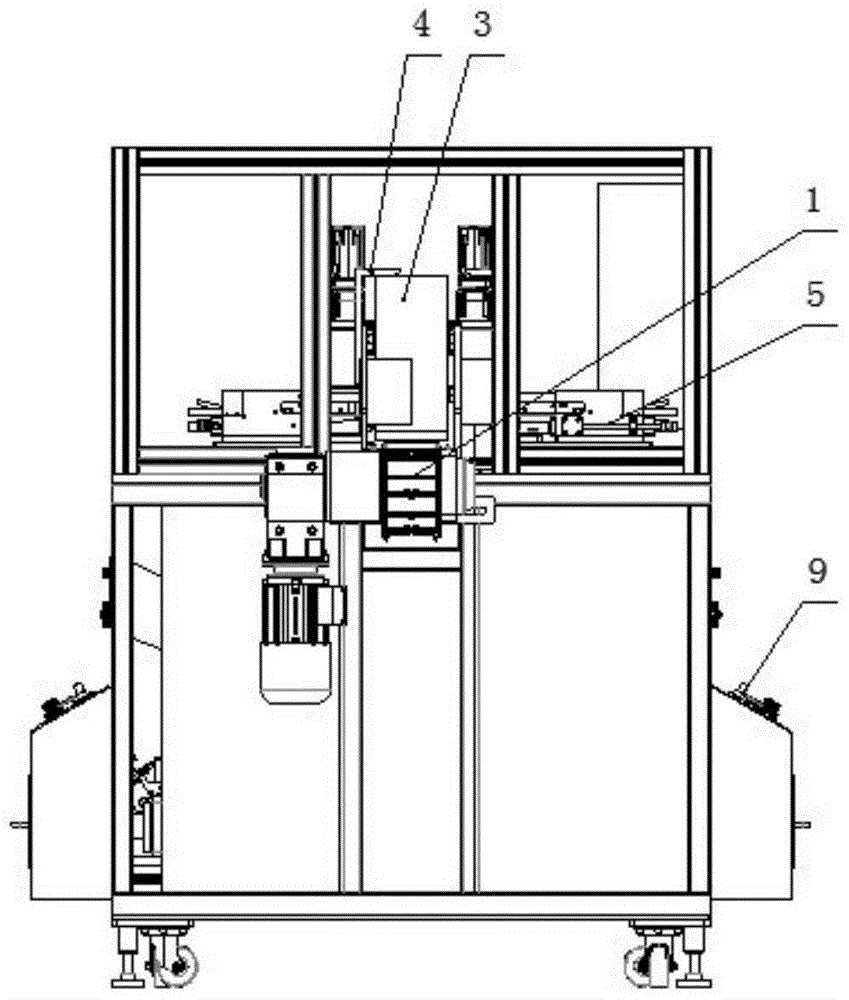

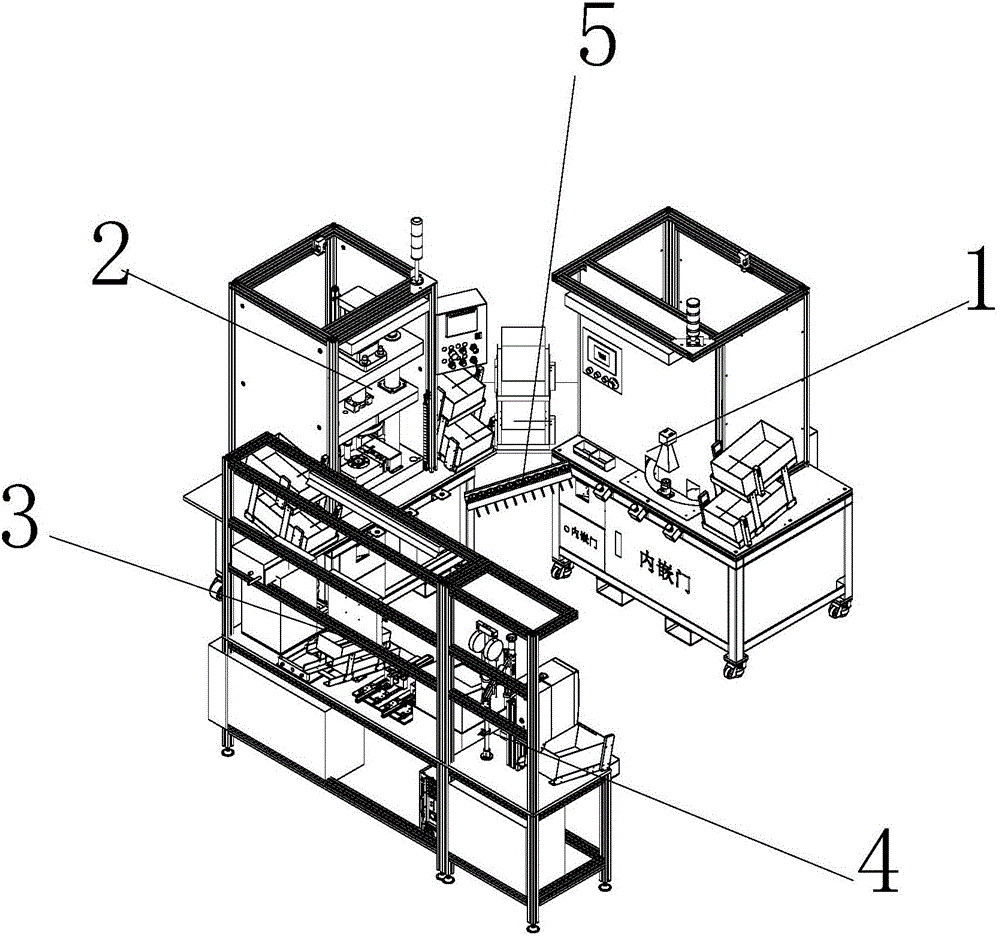

High-speed intelligent automatic rivet distributing and supplying and automatic riveting device for rivet gun

The invention provides a high-speed intelligent automatic rivet distributing and supplying and automatic riveting device for a rivet gun. The device comprises a rivet distributing and supplying device, and an automatic rivet supplying and riveting device which is connected with the rivet distributing and supplying device; the rivet distributing and supplying device comprises a supplying unit, a conveying unit, a pushing unit and a feeding unit; the automatic rivet supplying and riveting device comprises a base, a riveting mechanism, a supplying mechanism and a feeding mechanism; the rivet distributing and supplying device is used for supplying rivets; the automatic rivet supplying and riveting device is used for receiving the rivets and drilling the rivets. The high-speed intelligent automatic rivet distributing and supplying and automatic riveting device for the rivet gun is simple in structure, achieves the functions of automatically distributing the rivets, supplying the rives, feeding and riveting, is high in automation degree, greatly decreases the labor intensity of workers, and increases the production efficiency.

Owner:王承刚 +1

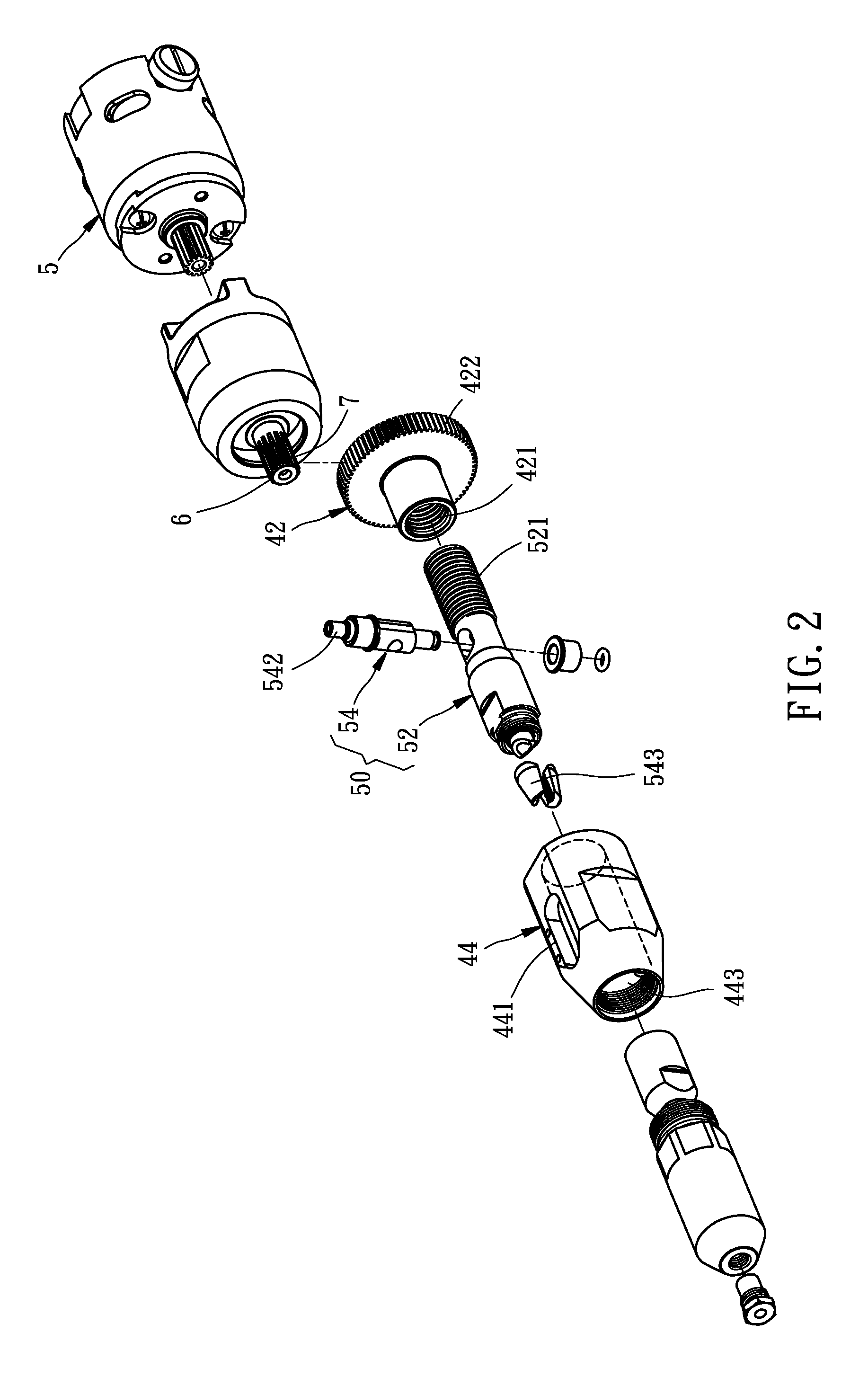

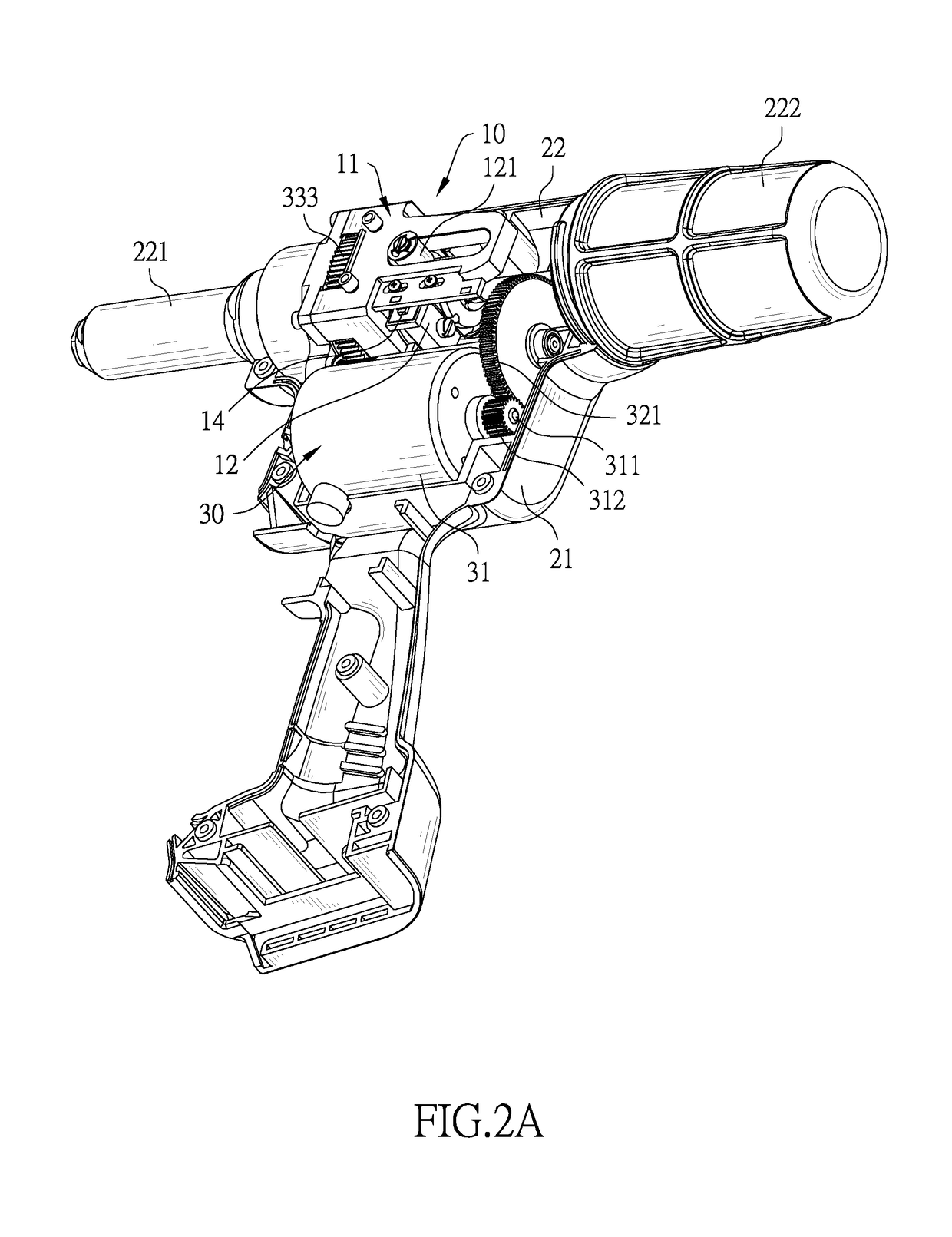

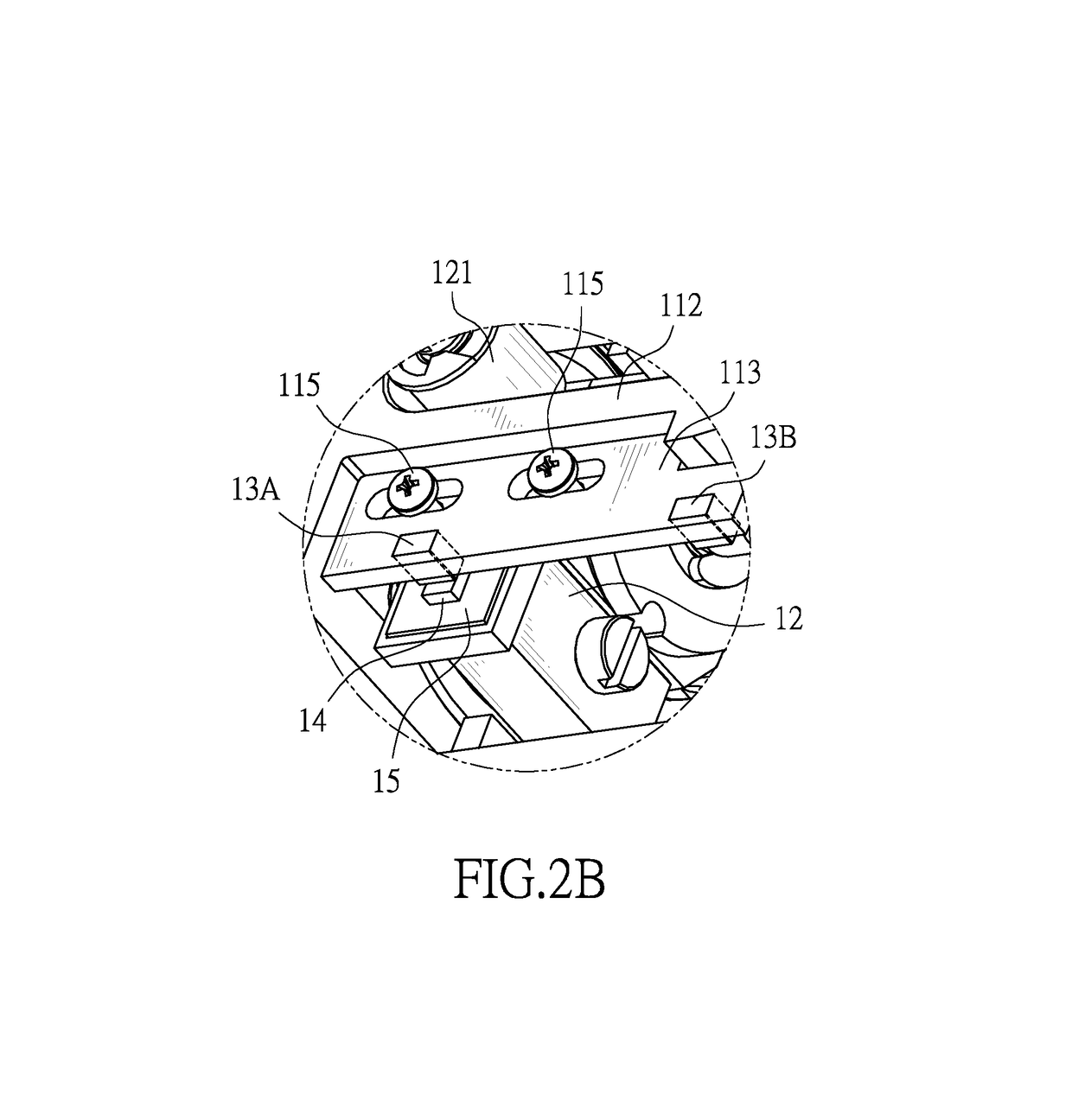

Riveting unit for electric rivet gun

ActiveUS20100139067A1Guaranteed uptimePreventing excessive backward movementShaping safety devicesMeasurement/indication equipmentsEngineeringRivet gun

A riveting unit is assembled with an electric rivet gun, including a transmission unit, a clamping jaw having a locating portion driven by the transmission unit to be moveable between a first position and a second position, a first sensor detecting whether the locating portion of the clamping jaw is located at the first position, and a second sensor detecting whether the locating portion of the clamping jaw is located at the second position. When the locating portion of the clamping jaw is located at the first position, a blind rivet can be installed in the clamping jaw, and when the locating portion of the clamping jaw is located at the second position, the blind rivet can be ejected, and meanwhile the second sensor can allow the transmission unit to stop the movement of the clamping jaw, thereby preventing the clamping jaw from moving backwards excessively.

Owner:TRANMAX MACHINERY

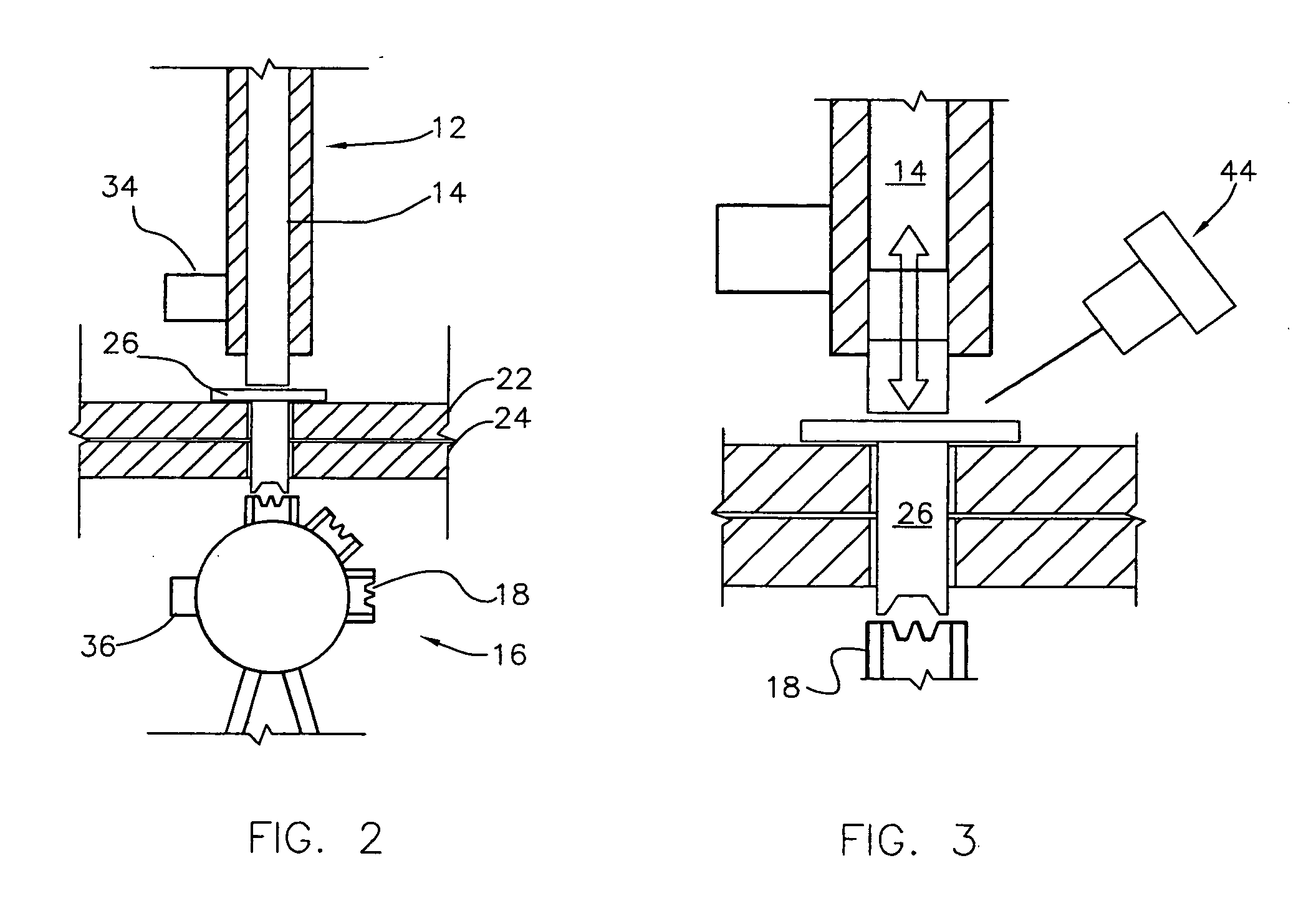

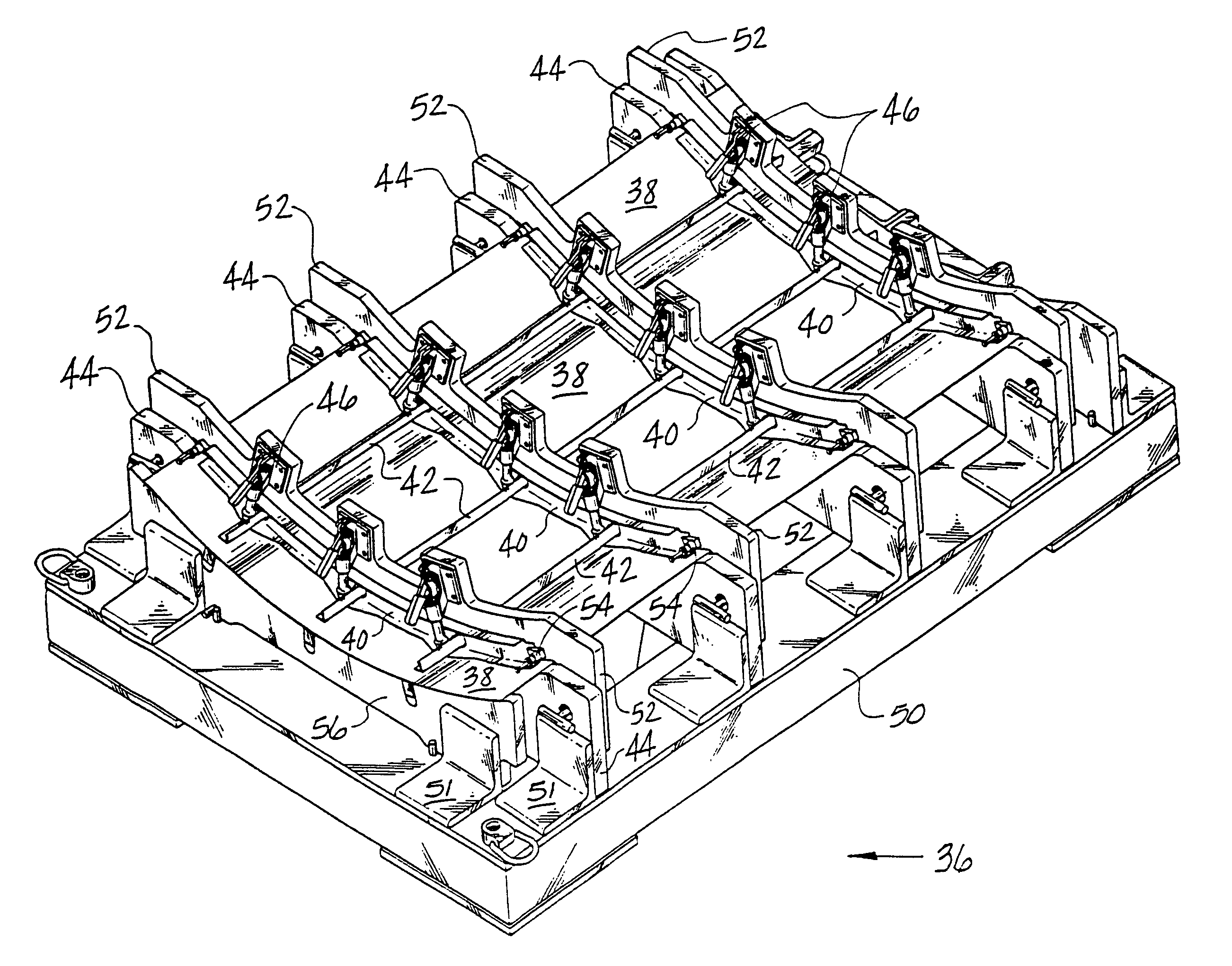

System and method for programmable pogo self-piercing riveting

ActiveUS20060230609A1Improve accessibilityImprove efficiencyAutomatic control devicesAssembly machinesEngineeringRivet gun

A system and method for self-piercing riveting including an alignment mechanism comprising laser diodes and sensors for facilitating alignment of a rivet gun and a back-up located on opposite sides of sheet metal parts to be joined, and an oscillation piercing technique for reducing force loads on structures, particularly robotic structures, carrying the rivet gun and the back-up.

Owner:GM GLOBAL TECH OPERATIONS LLC

Boeing aircraft airtight support plate nut installation process device and process

The invention discloses a Boeing aircraft airtight support plate nut installation process device and a Boeing aircraft airtight support plate nut installation process. A first process component is used for forming satellite holes; as the first process component is positioned in a screw hole through a coaxial positioning pin, the reference accuracy of the forming of the satellite holes is ensured; ejection iron and a rivet gun head are matched and are used for forming heads of two rivets simultaneously. Not only is the machining efficiency is improved, and the problem that after the first fastening rivet is installed, the head of the rivet extrudes and deforms the base of an airtight support plate nut, and further a rubber sealing ring can not be tightly fitted with a skin is thoroughly avoided, and the quality of the riveting of the airtight support plate nut is ensured. As the rivet gun head is guided by an axial positioning sleeve, the rivet gun head can only move in the axial direction; restraint and support on the rivet gun head in the radial direction during construction do not damage around structures due to shake, and the machining quality is further ensured.

Owner:SHANDONG TAIKOO AIRCRAFT ENG

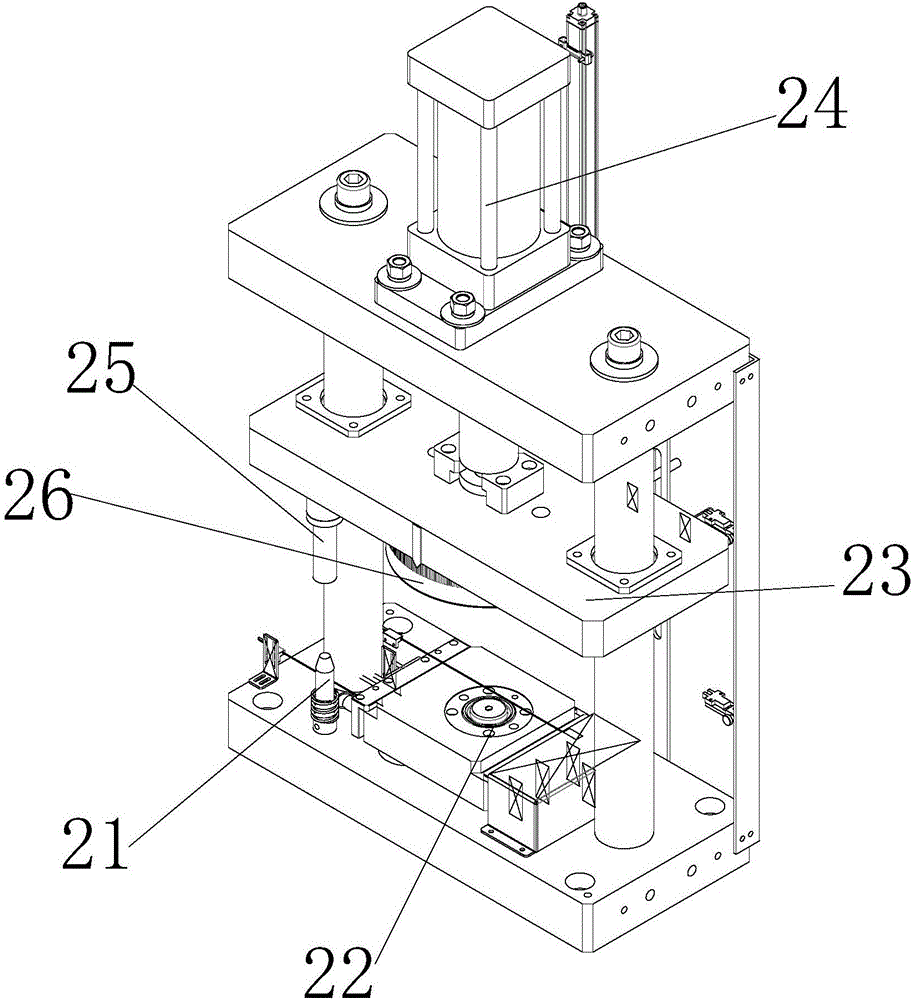

Automatic nut riveting device and automobile luggage carrier workpiece nut riveting method

ActiveCN104924059AImprove work efficiencyHigh degree of automationMetal working apparatusEngineeringRivet gun

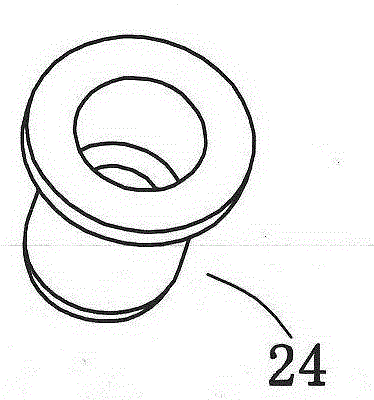

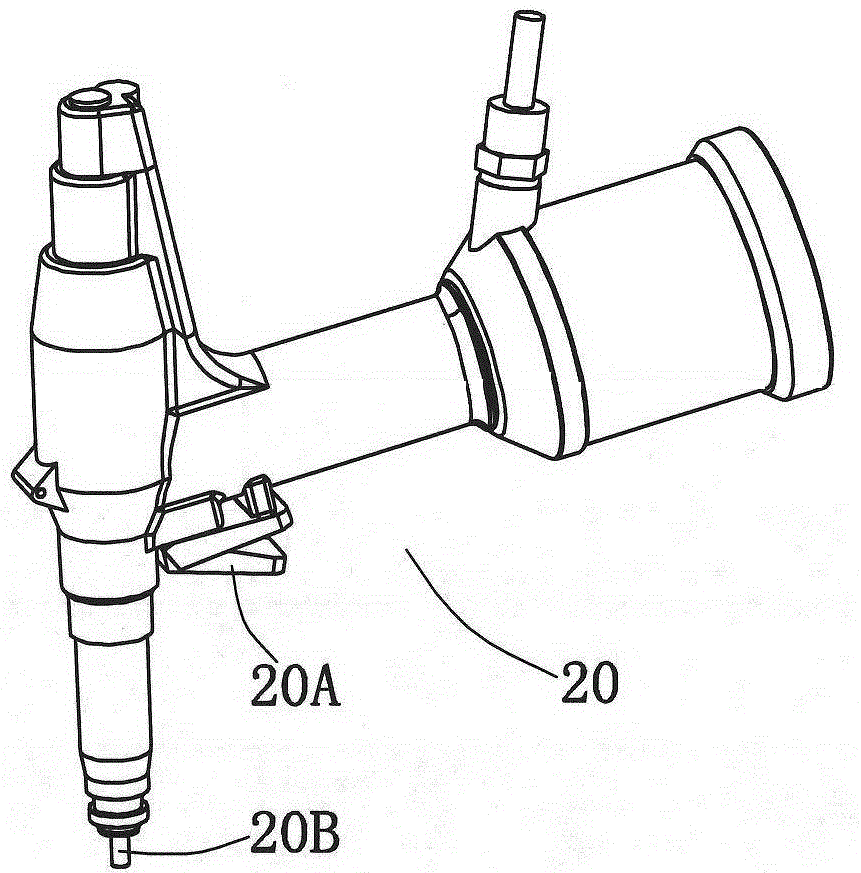

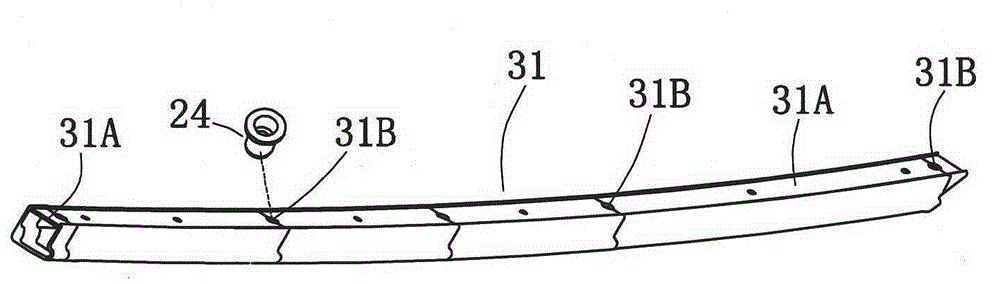

The invention provides an automatic nut riveting device and an automobile luggage carrier workpiece tube wall round hole nut riveting method. The device comprises a pneumatic nut riveting gun (20), a two-dimensional moving device, a rotating device and a second cylinder (21), the pneumatic nut riveting gun vertically and bilaterally moves by the aid of the two-dimensional moving device and rotates by the aid of the rotating device, the second cylinder (21) pushes a switch piece (20A) of the pneumatic nut riveting gun, a vibrating disk device capable of automatically supplying riveting nuts (24) is arranged beside the second cylinder, a first workpiece shelf (32) for placing a single automobile luggage carrier workpiece (31) is arranged in front of the second cylinder and can bilaterally move, the pneumatic nut riveting gun (20) sucking the riveting nuts (24) rotates along with a rotating plate (11) before the riveting nuts (24) are pulled, and the axis of an opening of the pneumatic nut riveting gun is consistent with that of a round hole (31B). The device is high in automation degree and nut riveting operation efficiency, fine in product consistency and particularly suitable for automatic nut riveting operation of the automobile luggage carrier workpiece with a bending radian.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

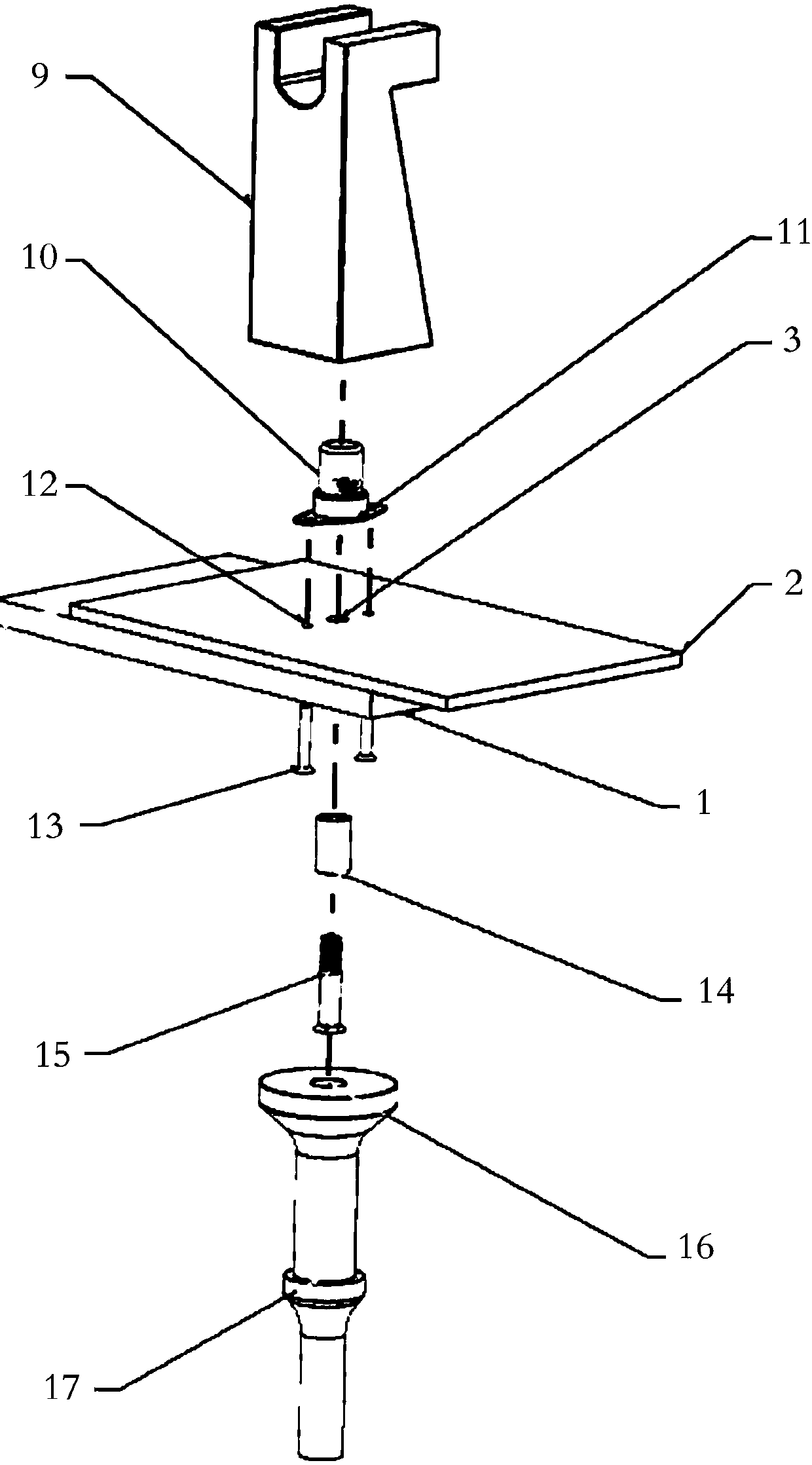

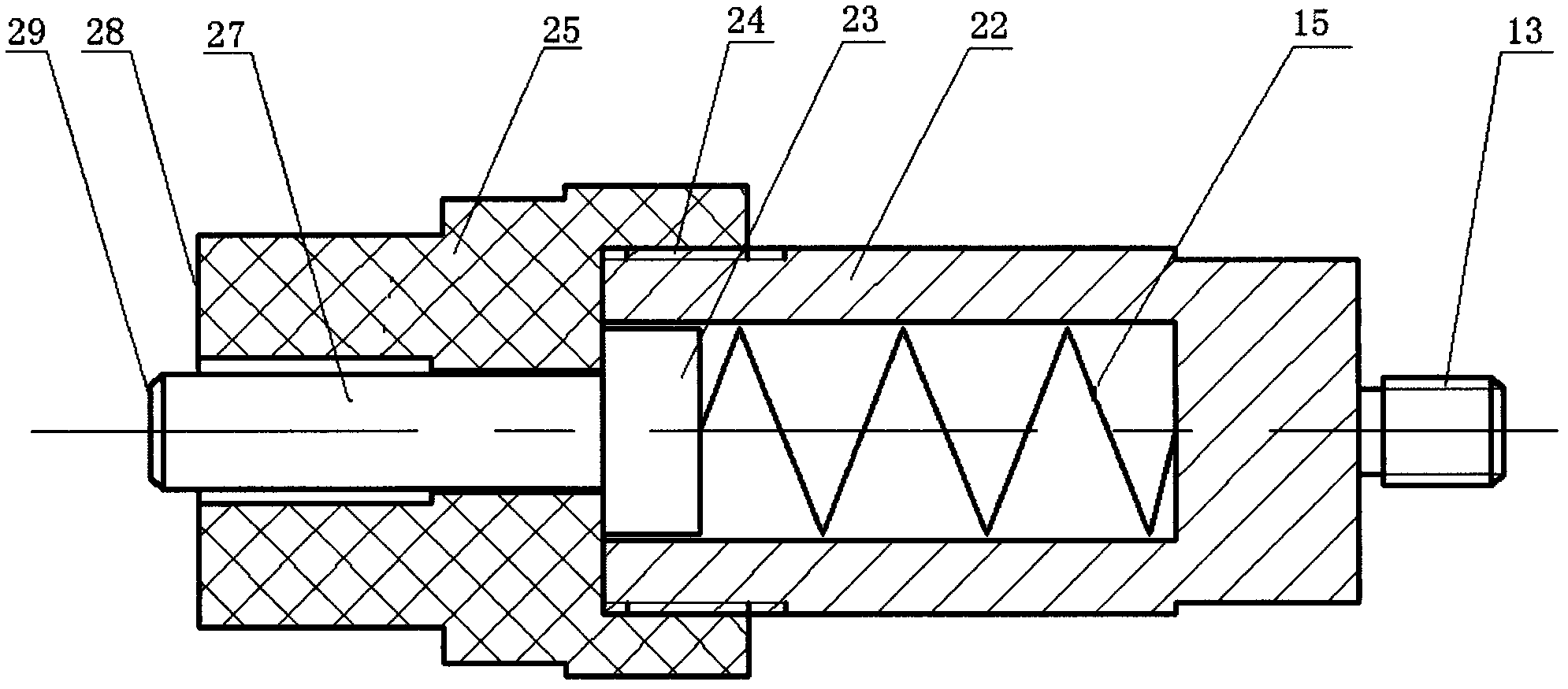

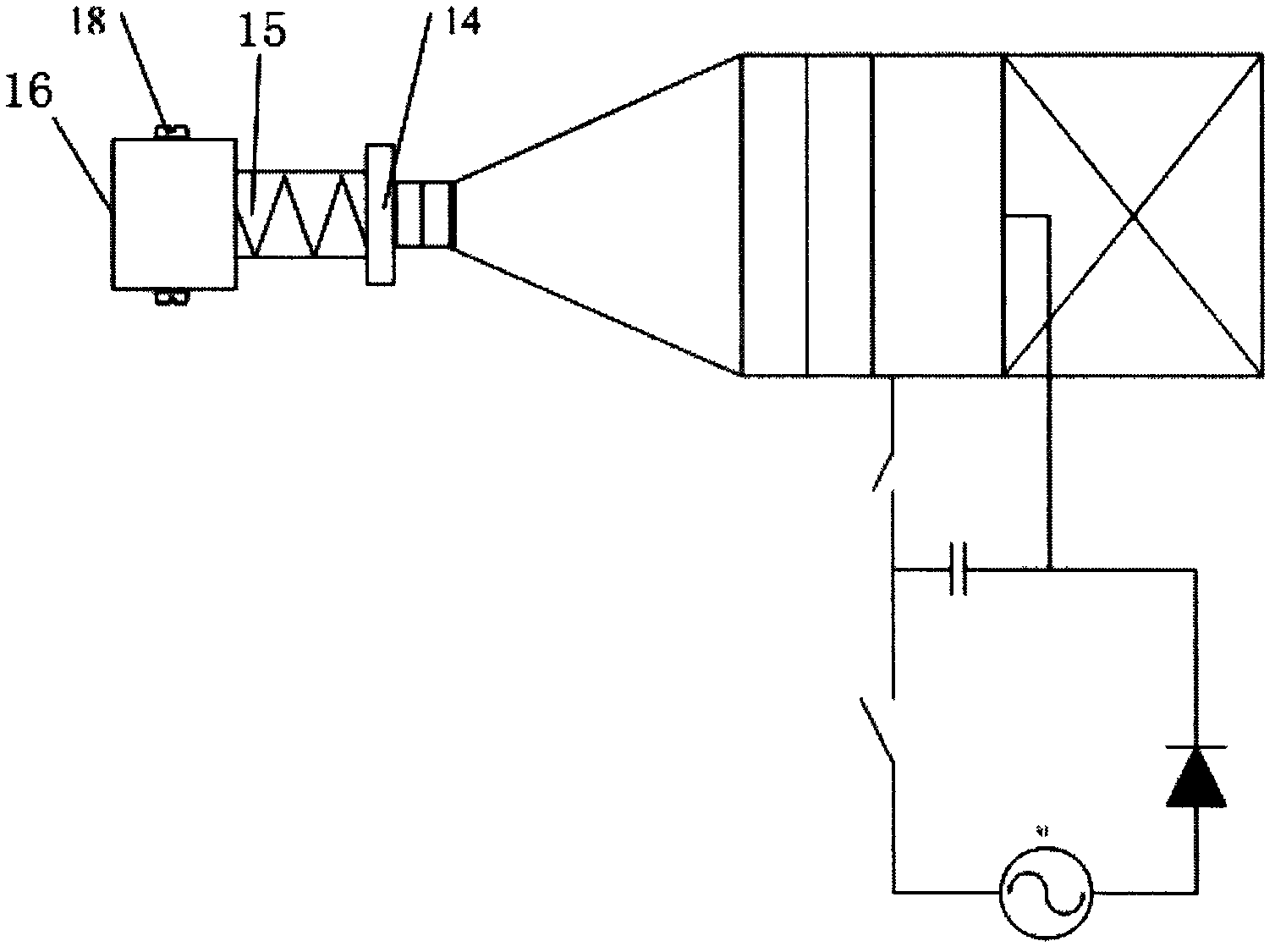

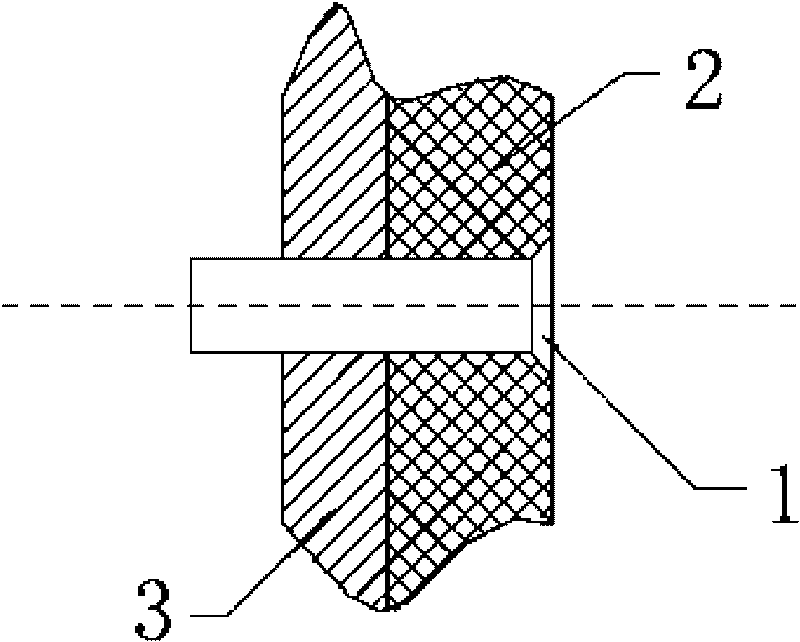

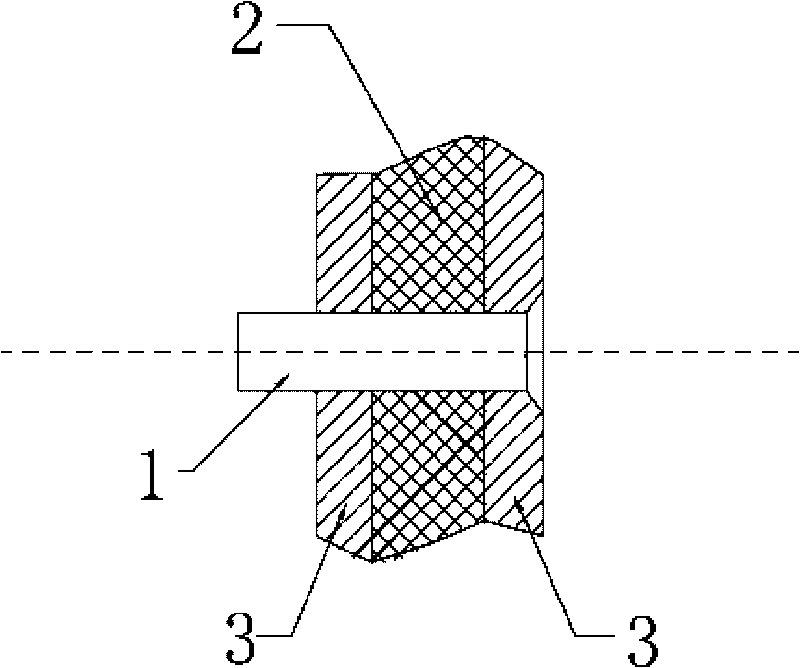

Rivet joint, auxiliary rivet joint and method for stress wave mounting of interference fit fastener

The invention discloses a rivet joint, an auxiliary rivet joint and a method for stress wave mounting of an interference fit fastener, which are used for solving the technical problem that the structure of a riveted piece is prone to deformation when an existing stress wave mounting device is used for stress wave mounting of the interference fit fastener. The technical scheme is as follows: the rivet joint and the auxiliary rivet joint are respectively mounted on two electromagnetic riveting guns through connectors 13, and position-limiting and guide structures are respectively arranged on the rivet joint and the auxiliary rivet joint, thereby ensuring the alignment between the electromagnetic rivet guns and the fastener. The rivet joint and the auxiliary rivet joint can apply force on the two surfaces of the riveted piece, thereby avoiding the deformation of the riveted piece when the single electromagnetic rivet gun is used for applying the force on the single surface of the riveted piece.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

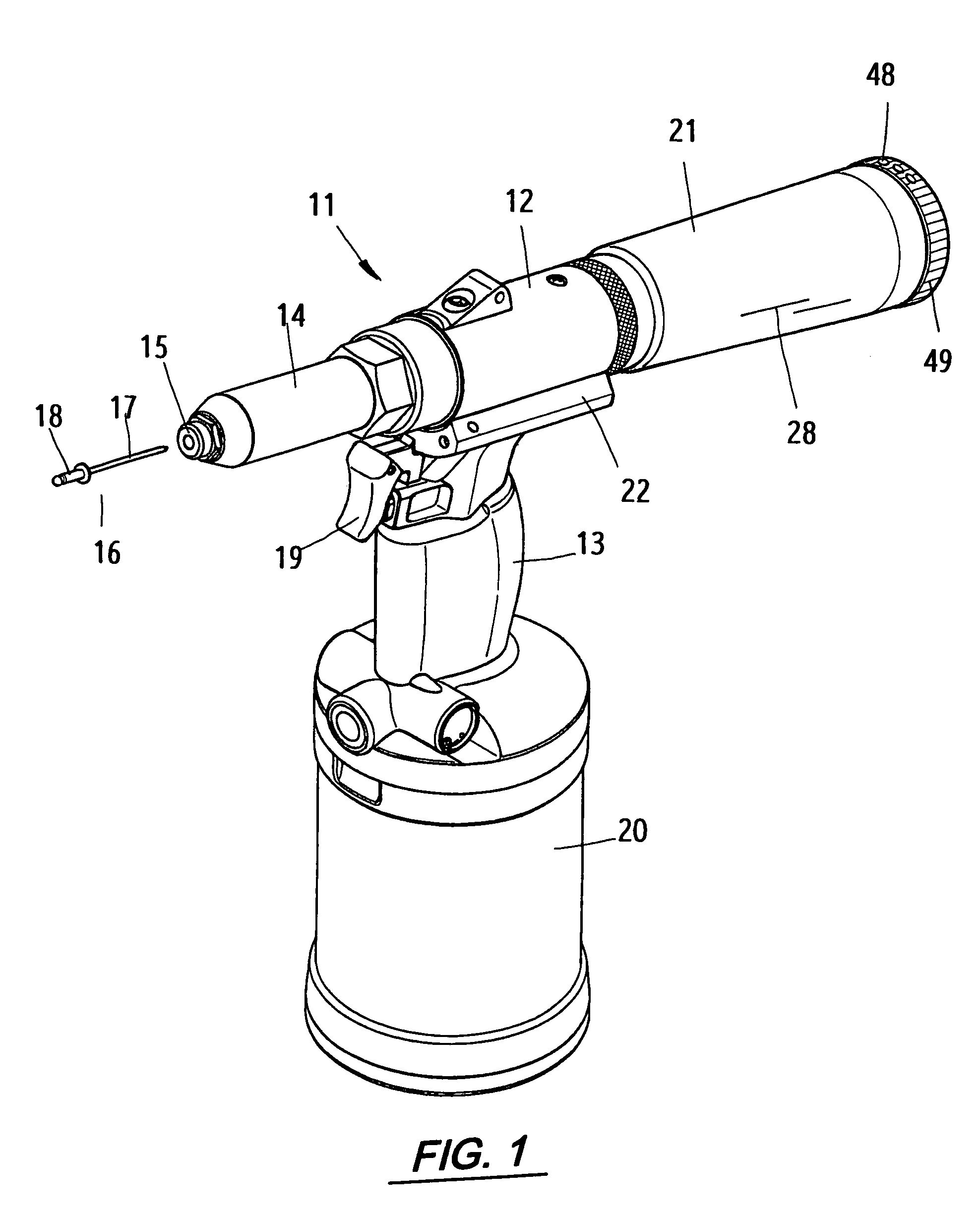

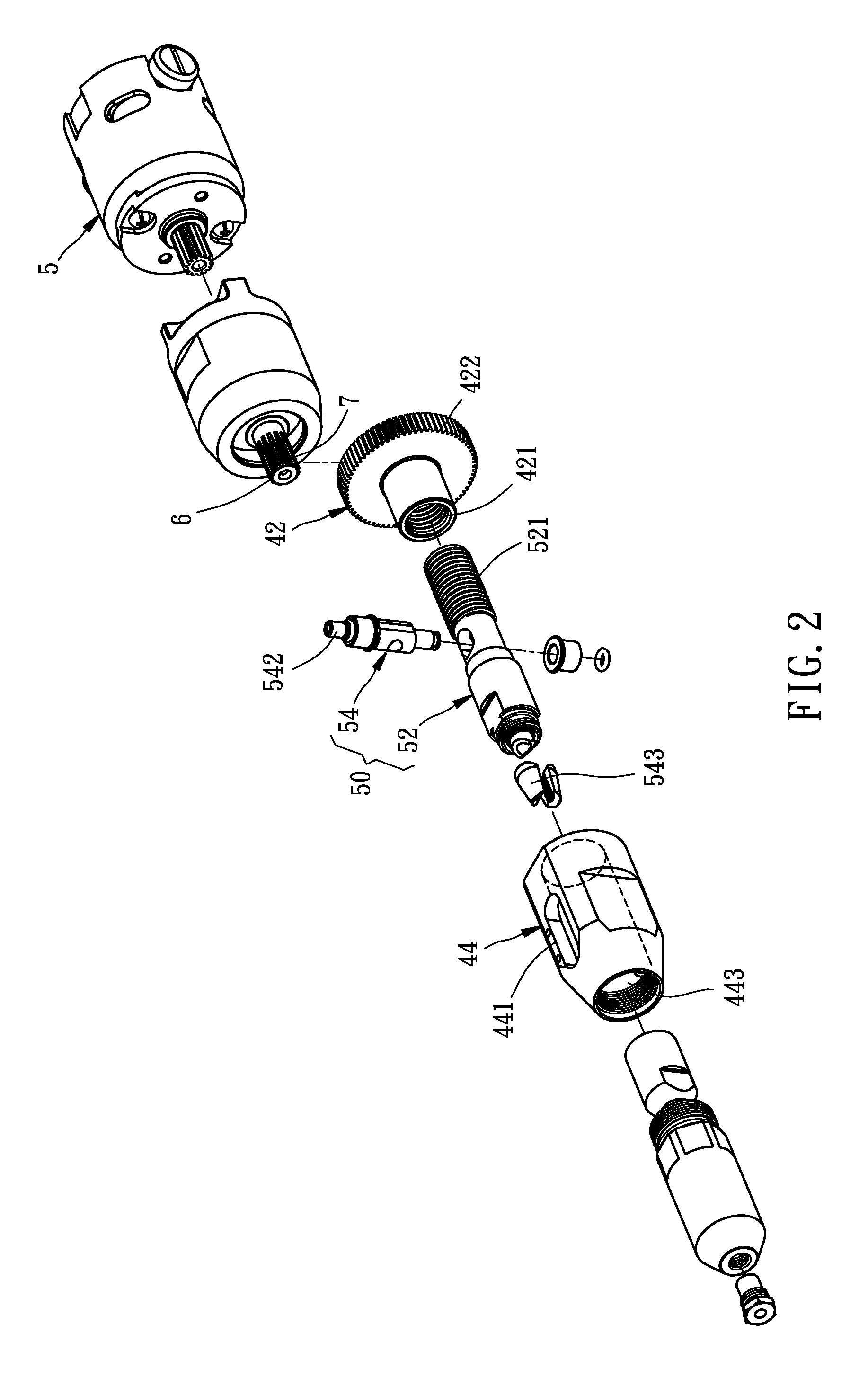

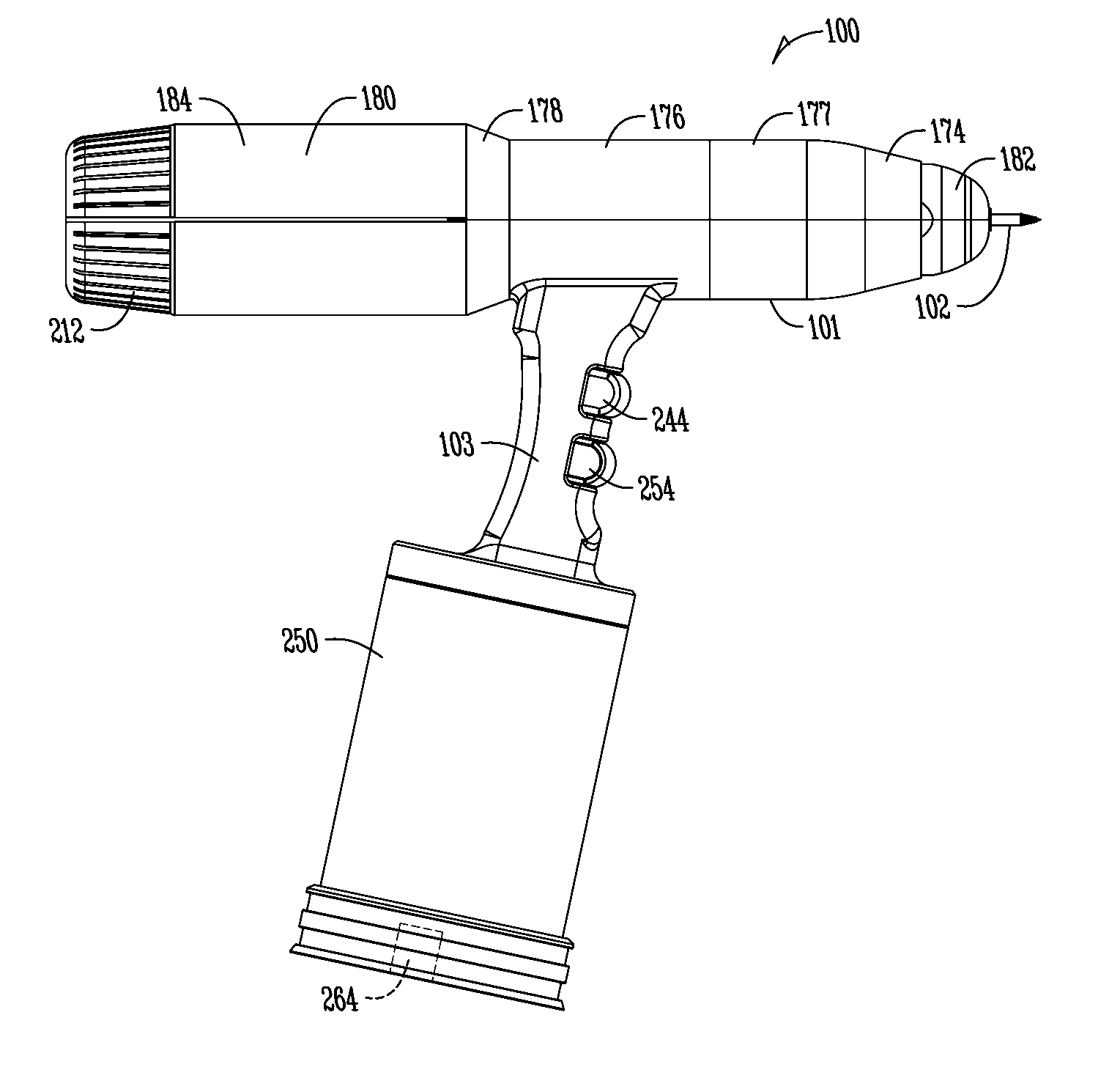

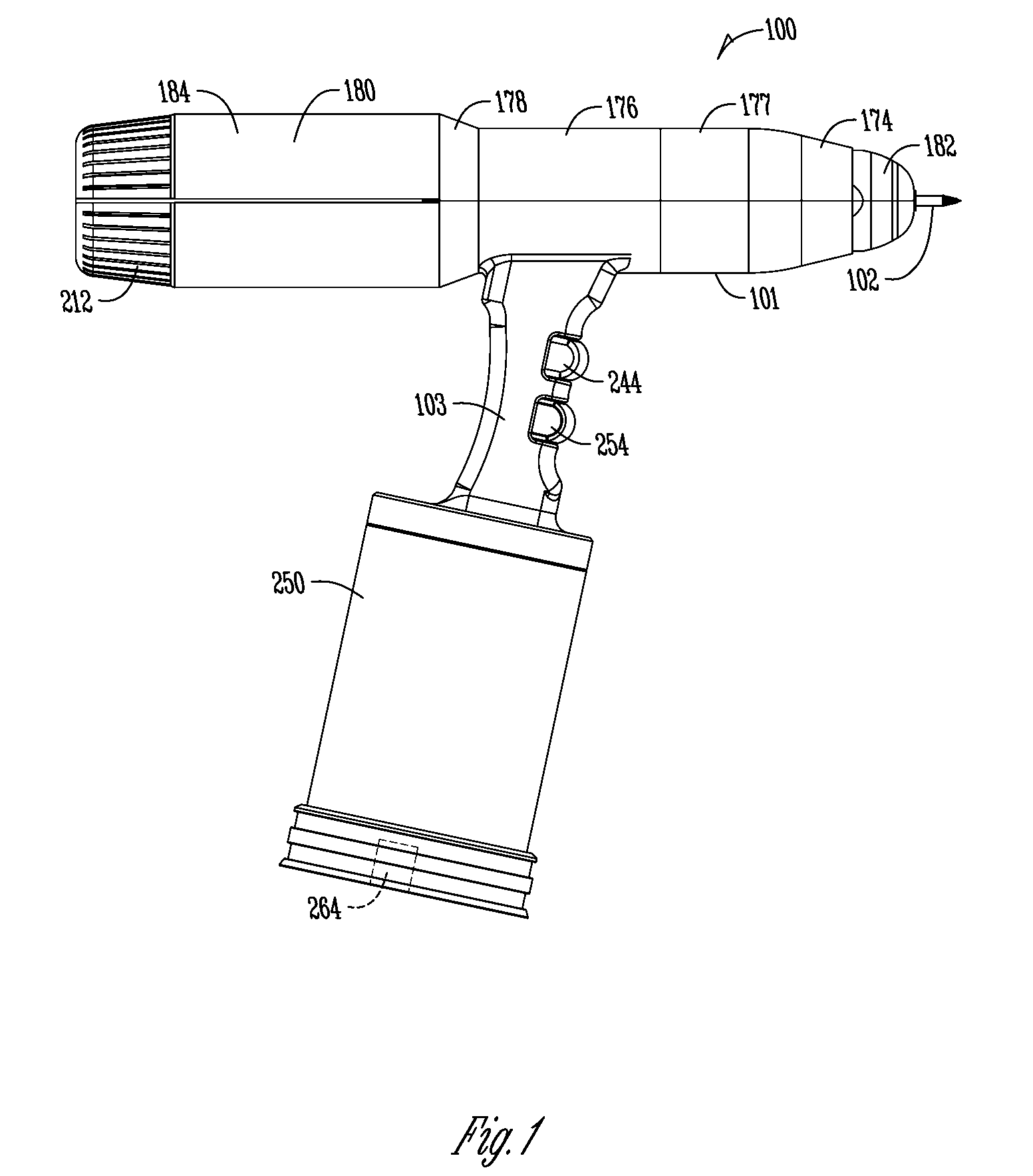

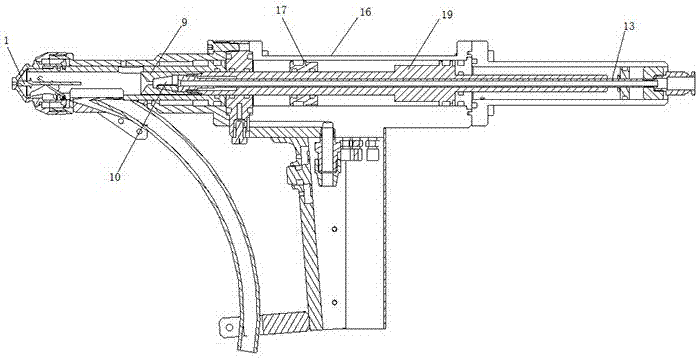

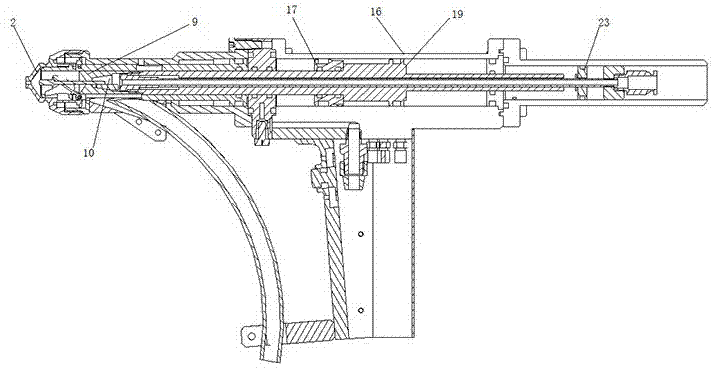

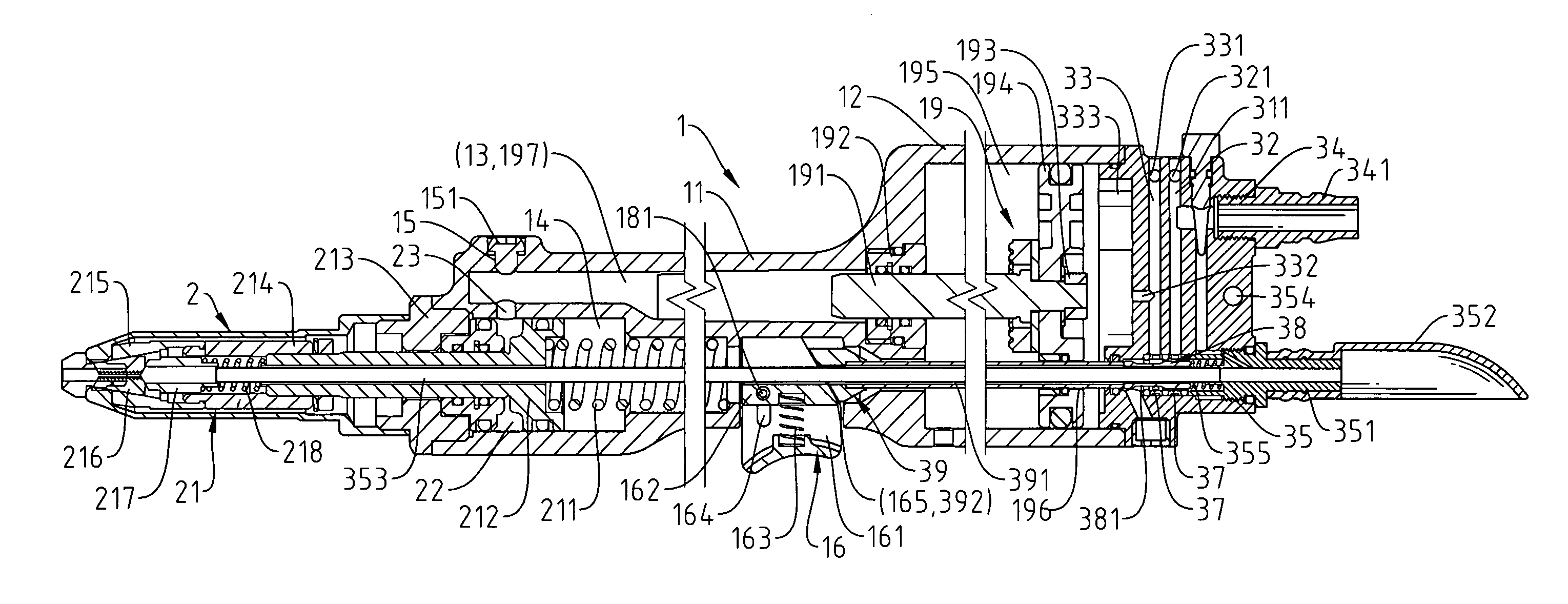

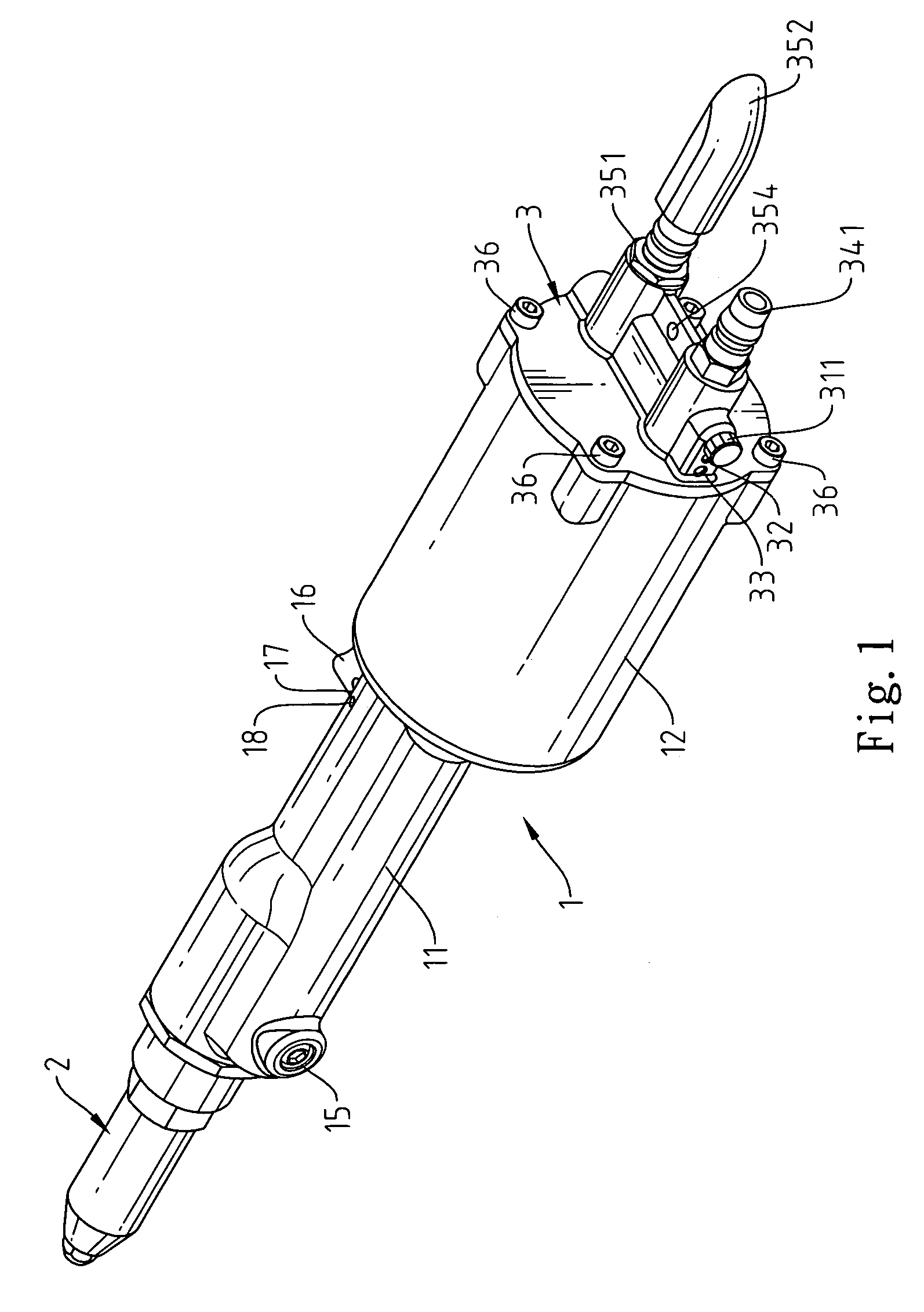

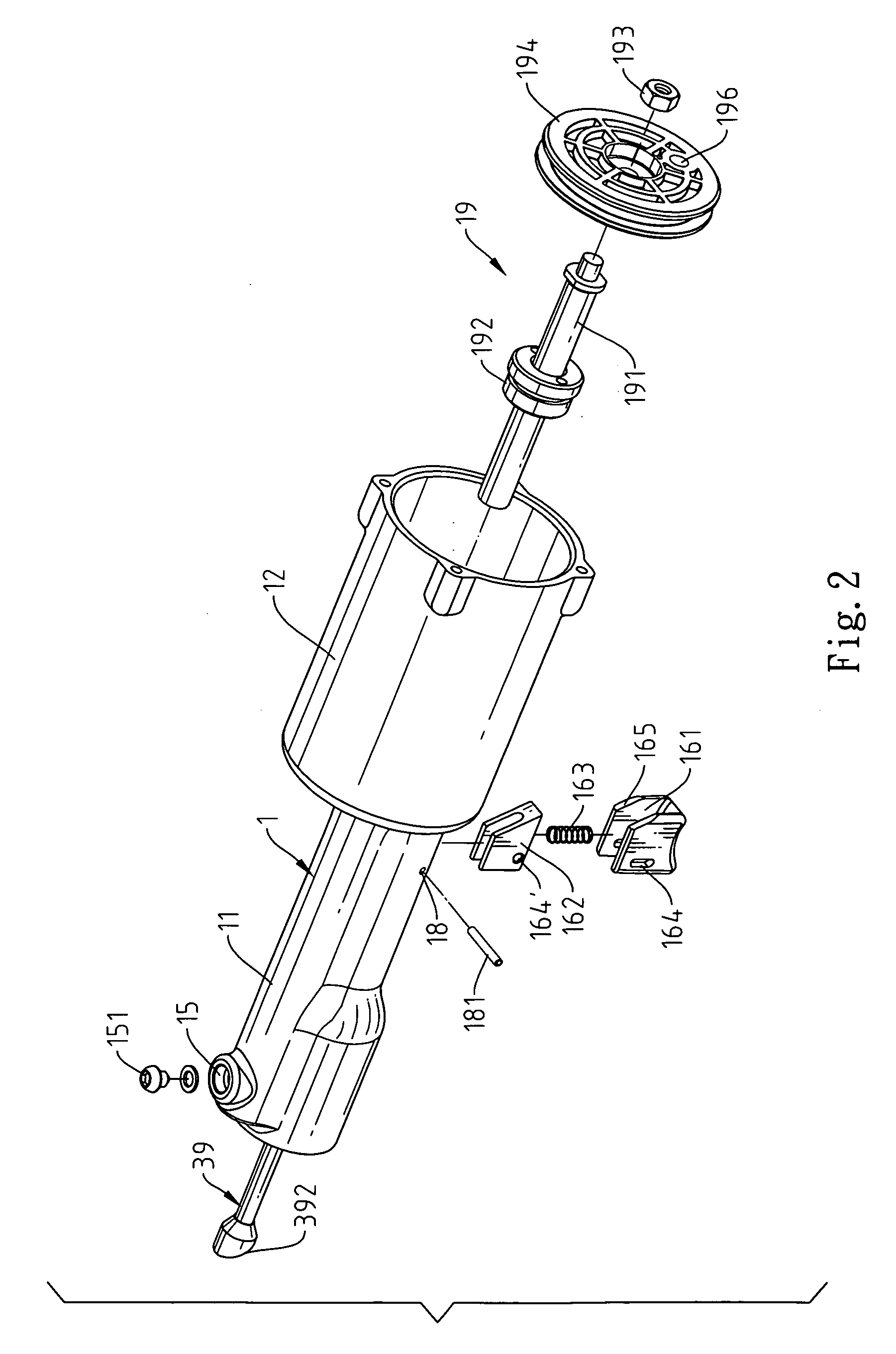

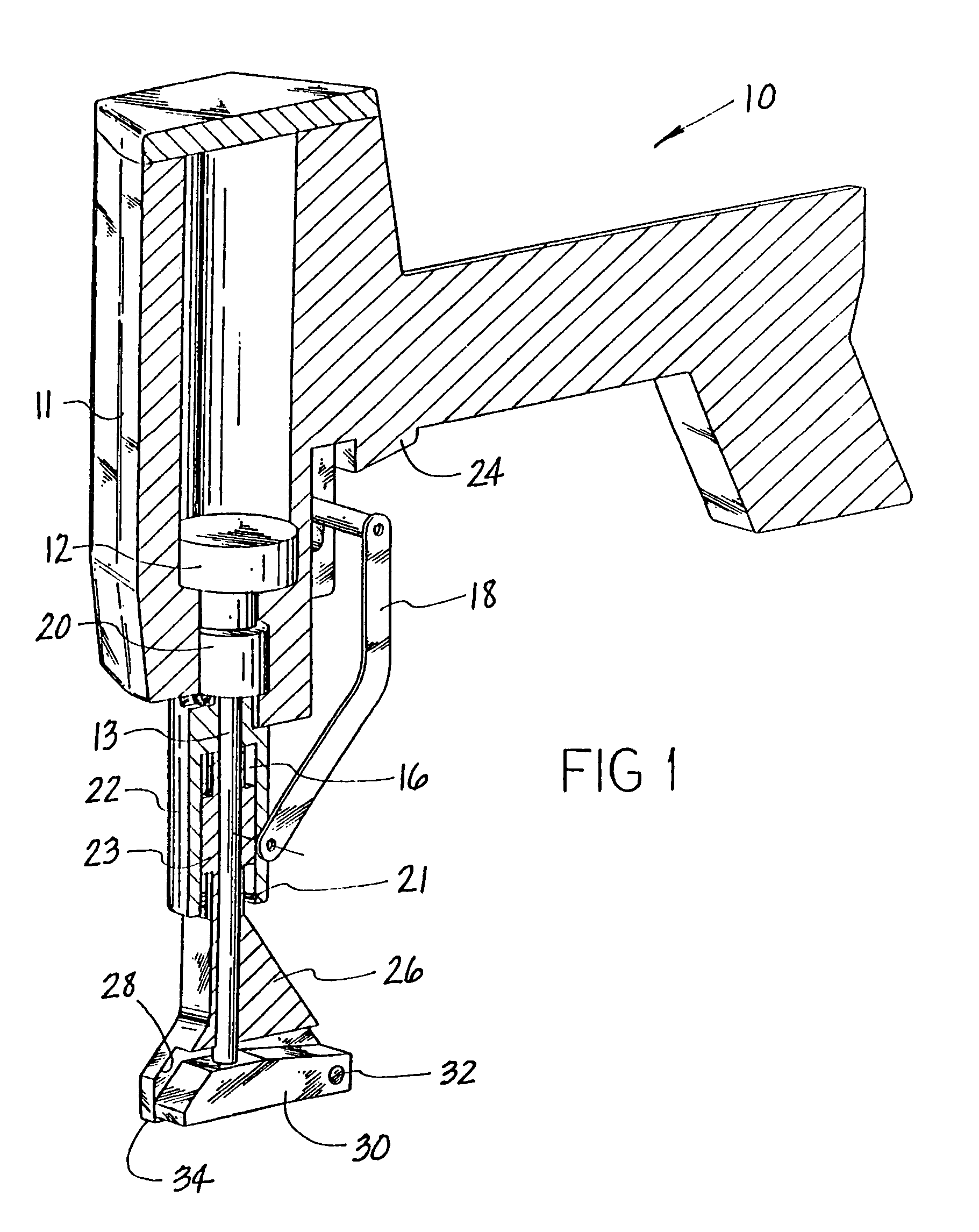

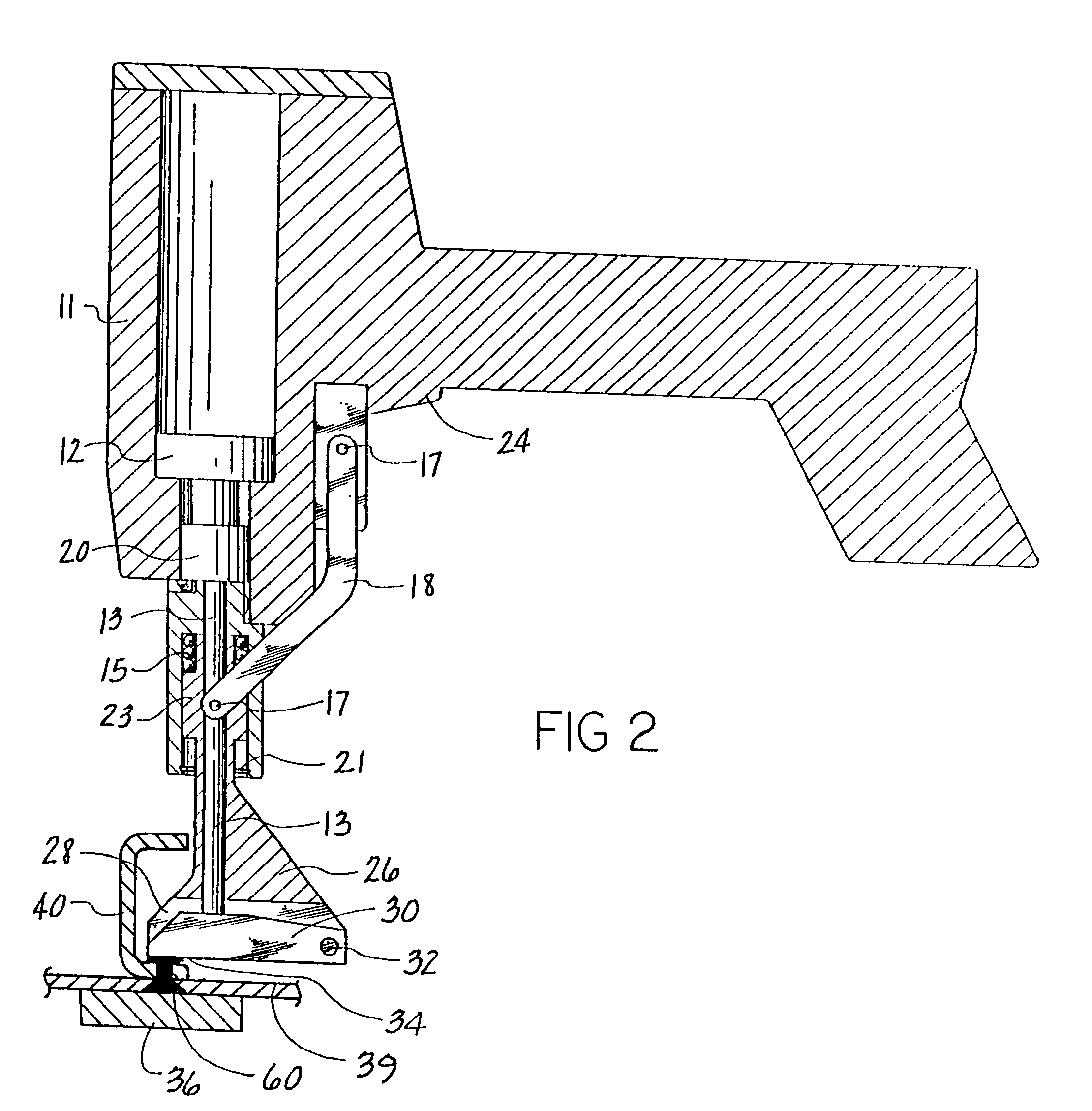

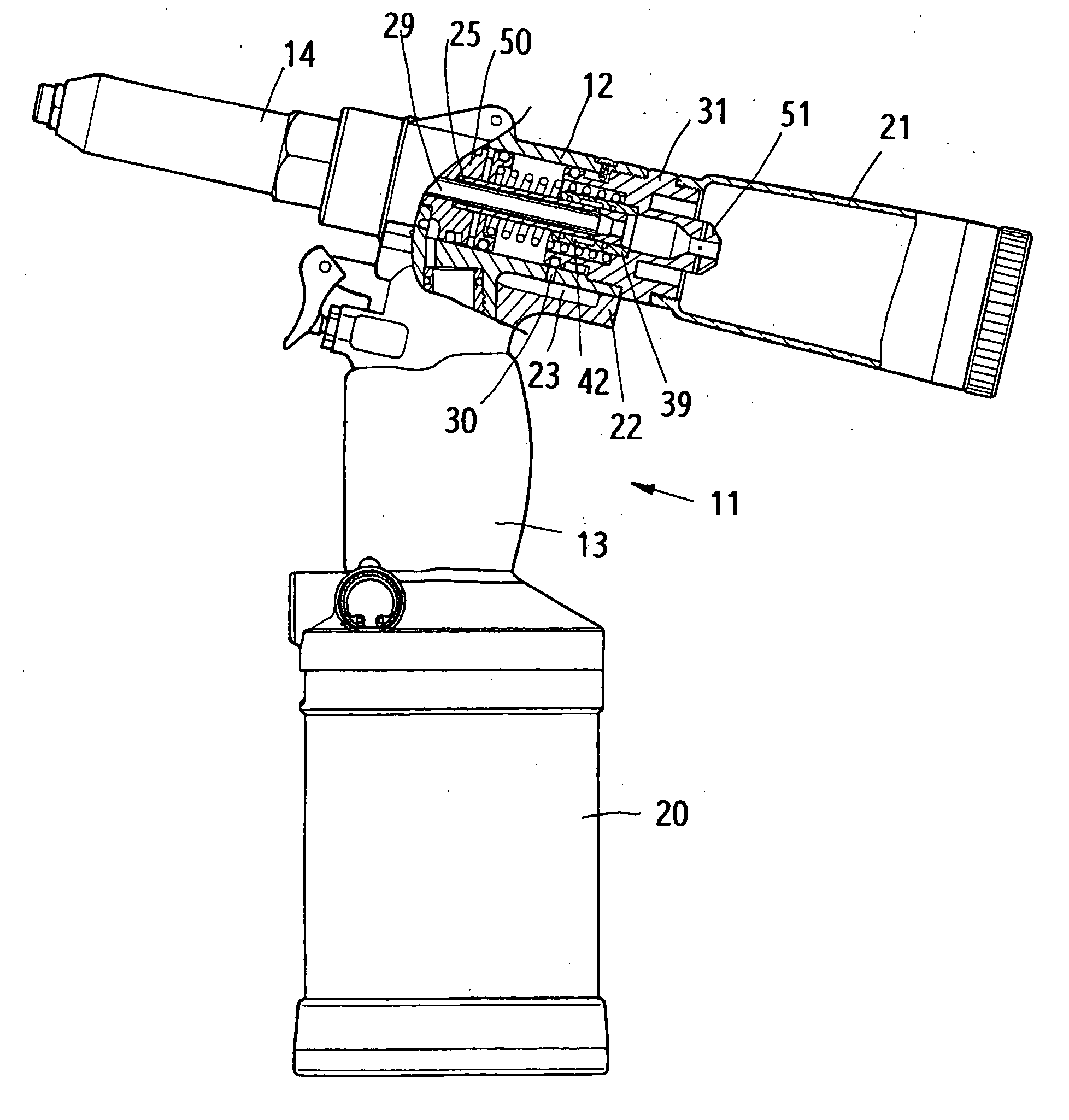

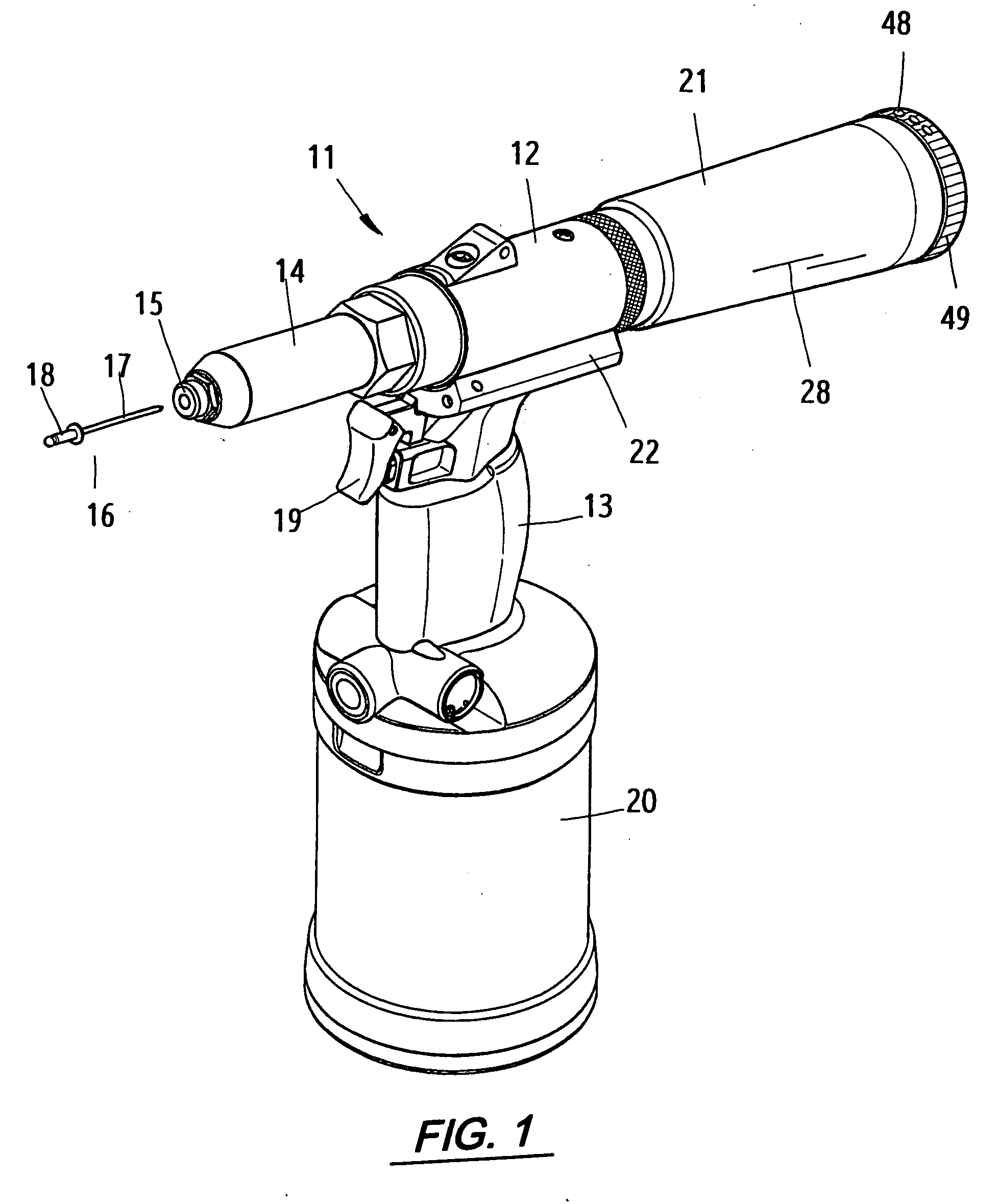

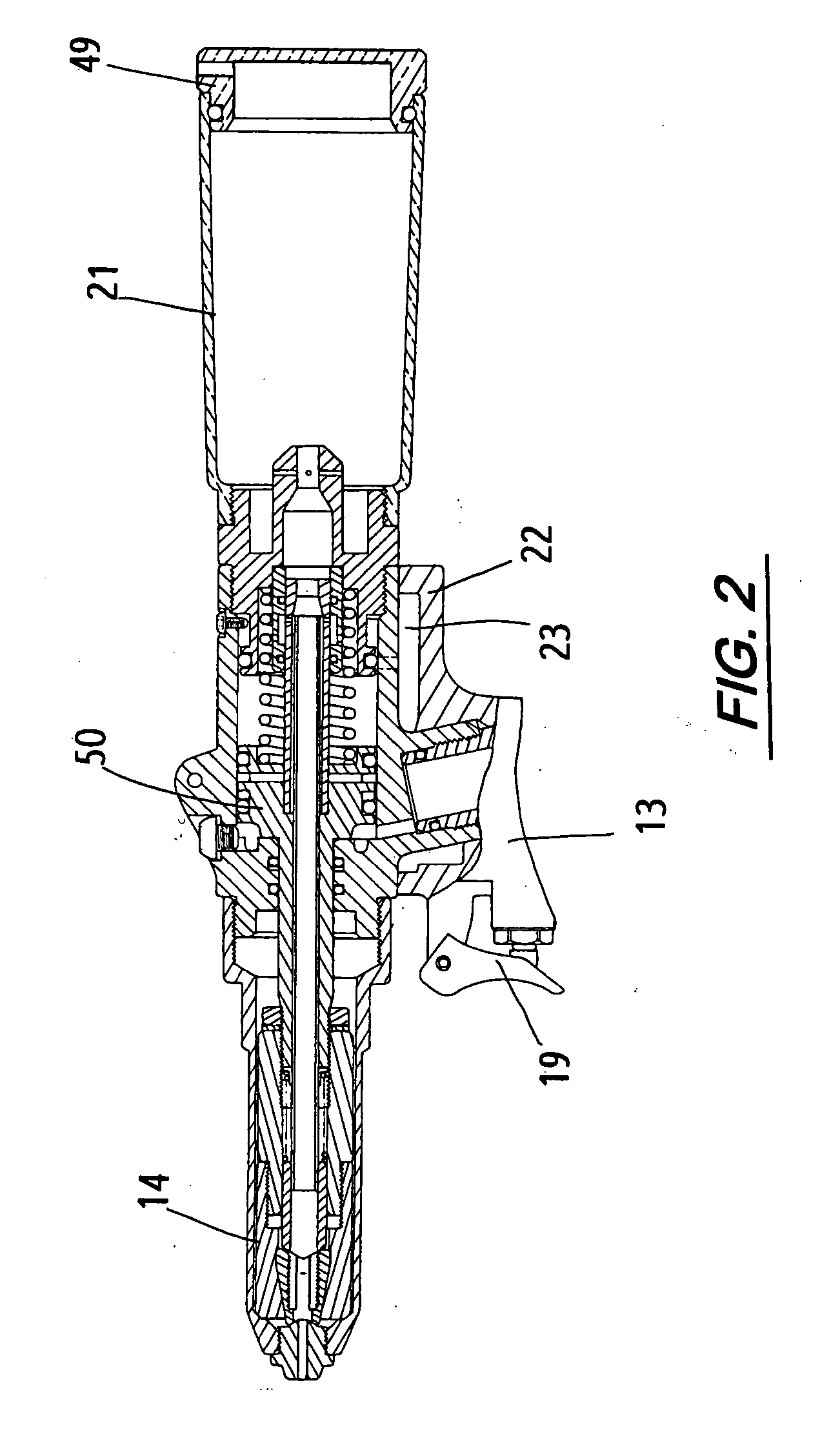

Rivet gun

InactiveUS20090031545A1Reduce the overall diameterAvoid simultaneous operationForging press detailsForging press drivesRivet gunEngineering

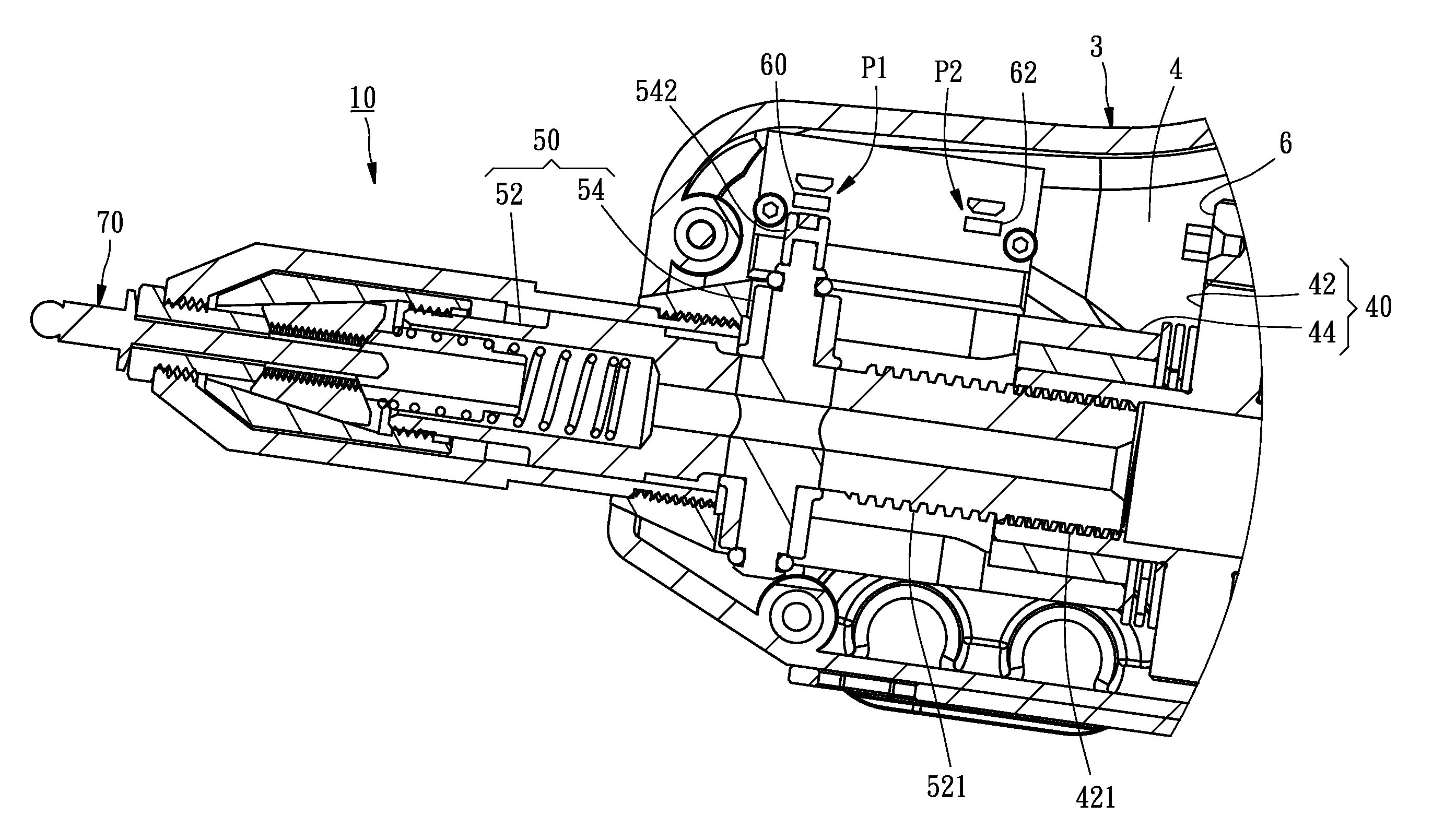

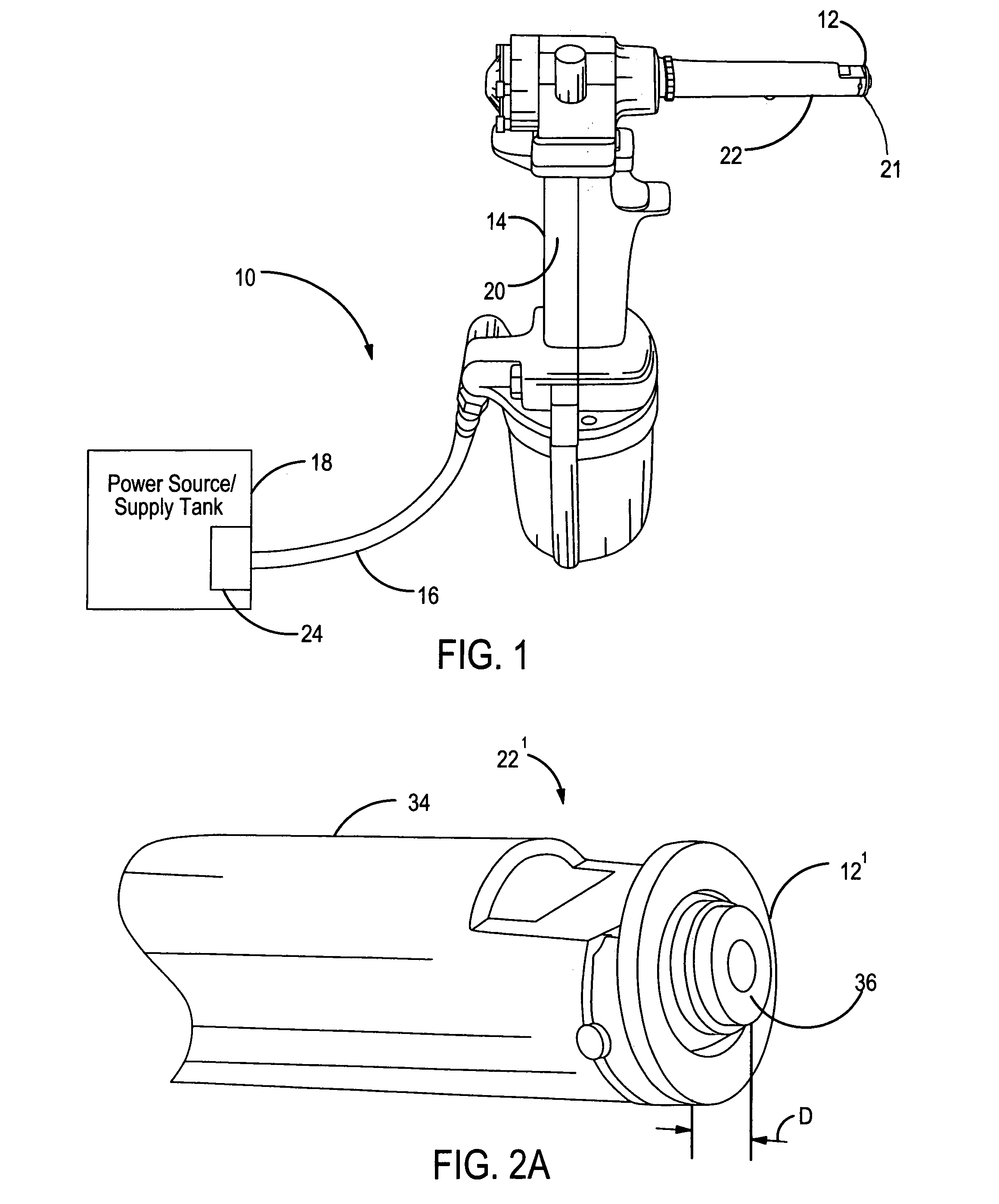

A rivet gun for setting a self-tapping rivet in one or more work pieces has a tool body having a handle for gripping, a rotation assembly having a motor attached to an axially adjustable shaft and a chuck to thereby impart rotation to the chuck adapted to grip and rotate the shank of the self-tapping rivet. A hydraulic assembly having a pull bushing is connected to a piston rod attached to a piston and a retraction assembly having a mandrel clamp and a mandrel clamp ring is connected to a spring guide biased toward the mandrel clamp by a spring to thereby compress the mandrel clamp to grip and retract the shank, set the self-tapping rivet in the work pieces and detach the shank from the self-tapping rivet.

Owner:ABEO

Automatic riveting machine for wine box package

The invention discloses an automatic riveting machine for wine box package. The automatic riveting machine comprises a working table, an automatic riveting device and a wine box conveying, positioning and clamping mechanism, wherein the wine box conveying, positioning and clamping mechanism is arranged on the working table; the automatic riveting device is symmetrically and fixedly arranged on the working table on the two sides of the wine box conveying, positioning and clamping mechanism; the automatic riveting device comprises a rivet sorting mechanism, a rivet conveying mechanism, a petal sorting mechanism, a petal conveying mechanism and a rivet gun; the rivet conveying mechanism is positioned at a central position of the working table; the upper side of the rivet conveying mechanism is connected with the rivet sorting mechanism through a rivet flow passage; the rivet gun is arranged below the rivet conveying mechanism; the petal sorting mechanism is connected with the petal conveying mechanism through a petal flow passage; the petal conveying mechanism is positioned on one side of the rivet conveying mechanism and pushes a petal receiving seat to be connected with the rivet conveying mechanism through a rodless cylinder. The automatic riveting machine has the advantages of high degree of automation, stable work, high reliability and capabilities of reducing the labor cost and improving the economic benefit of enterprises.

Owner:张瑞

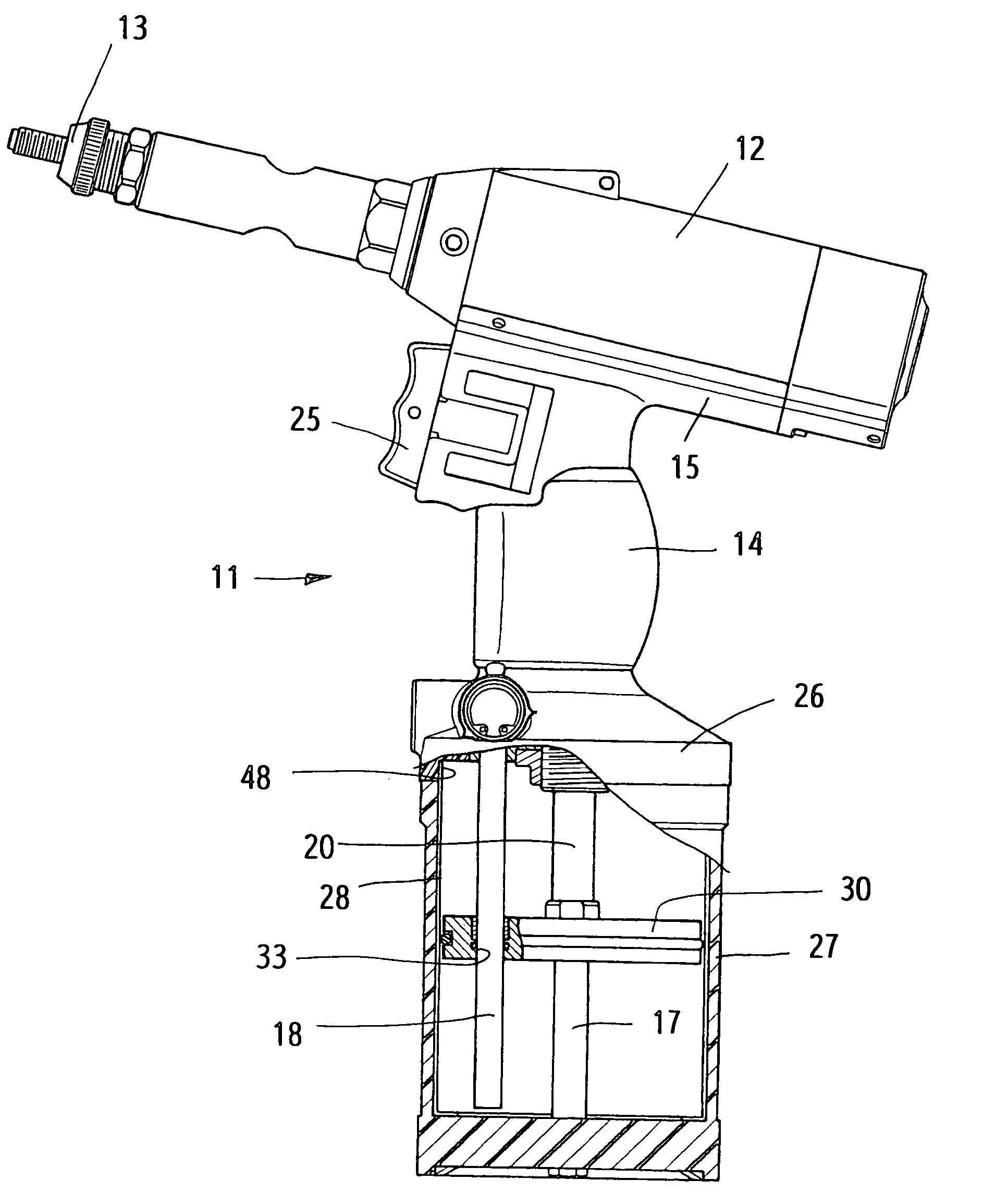

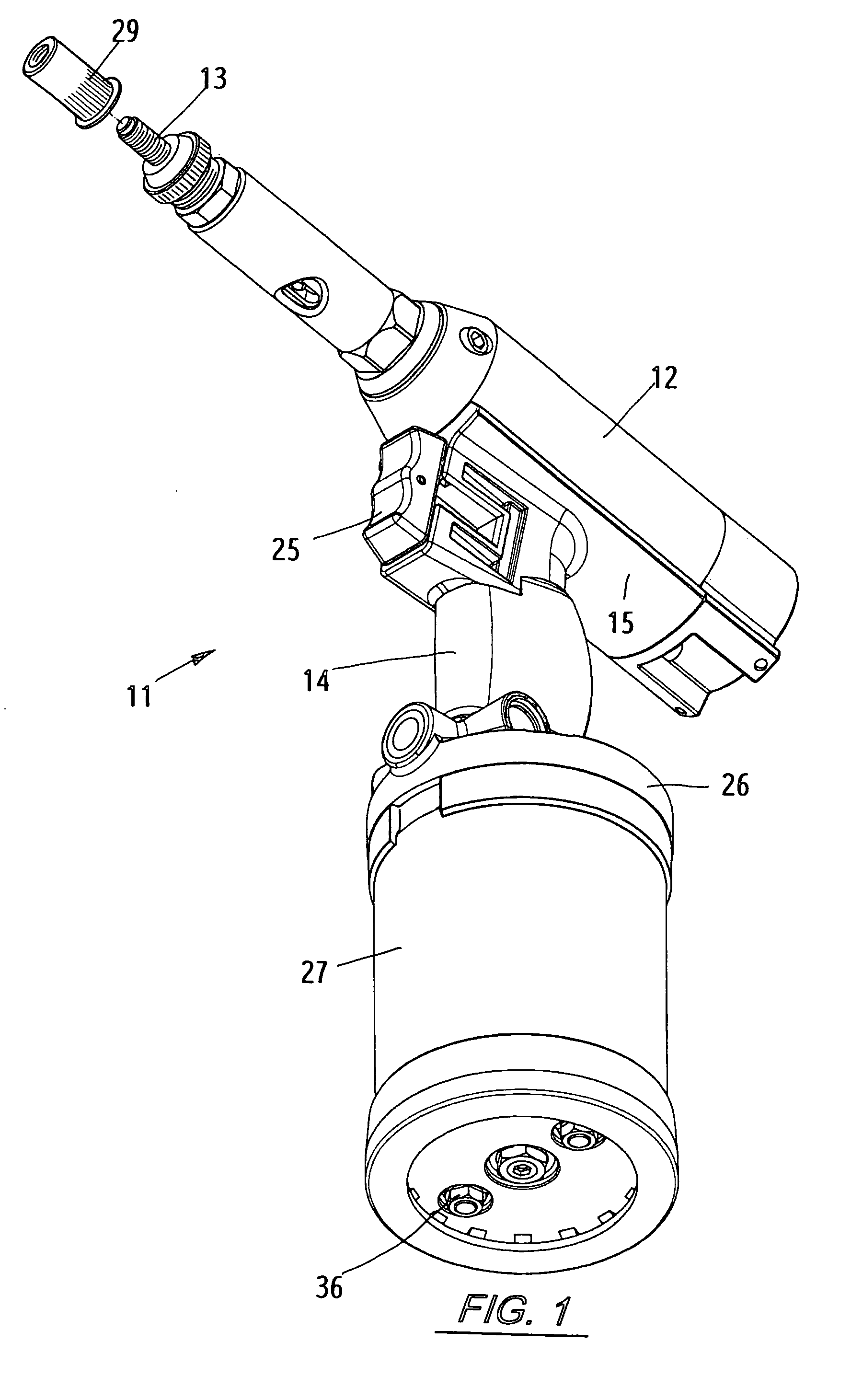

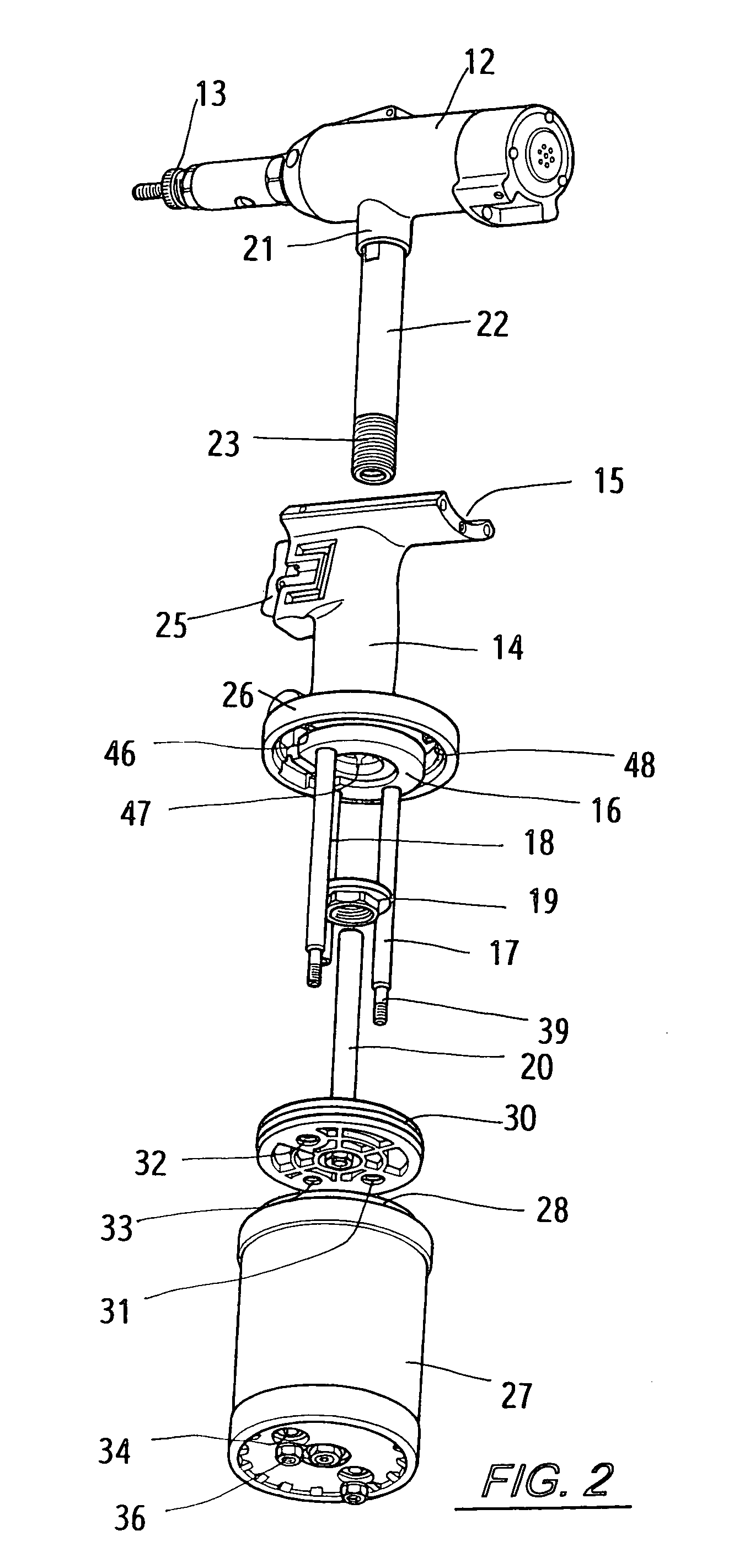

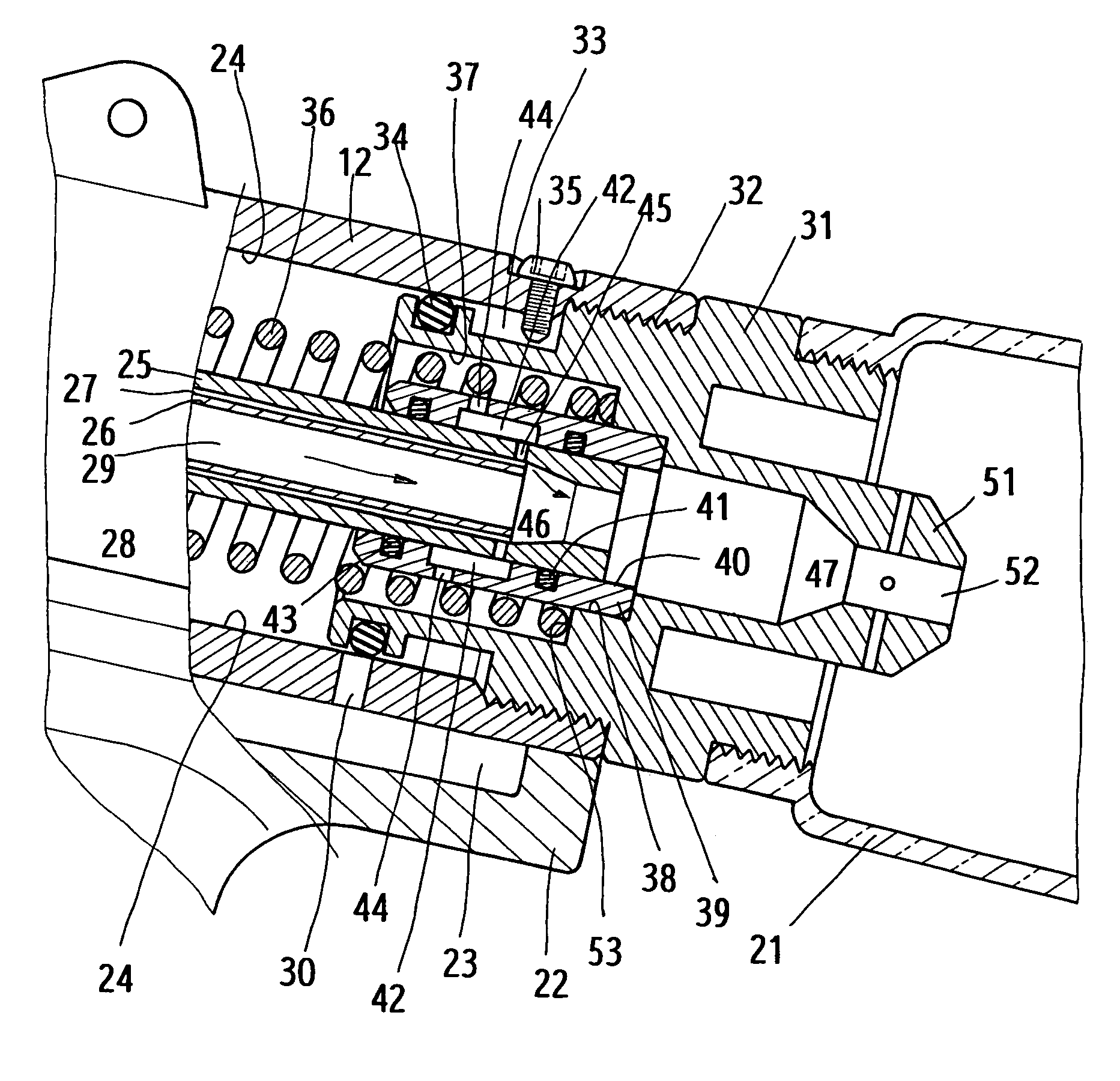

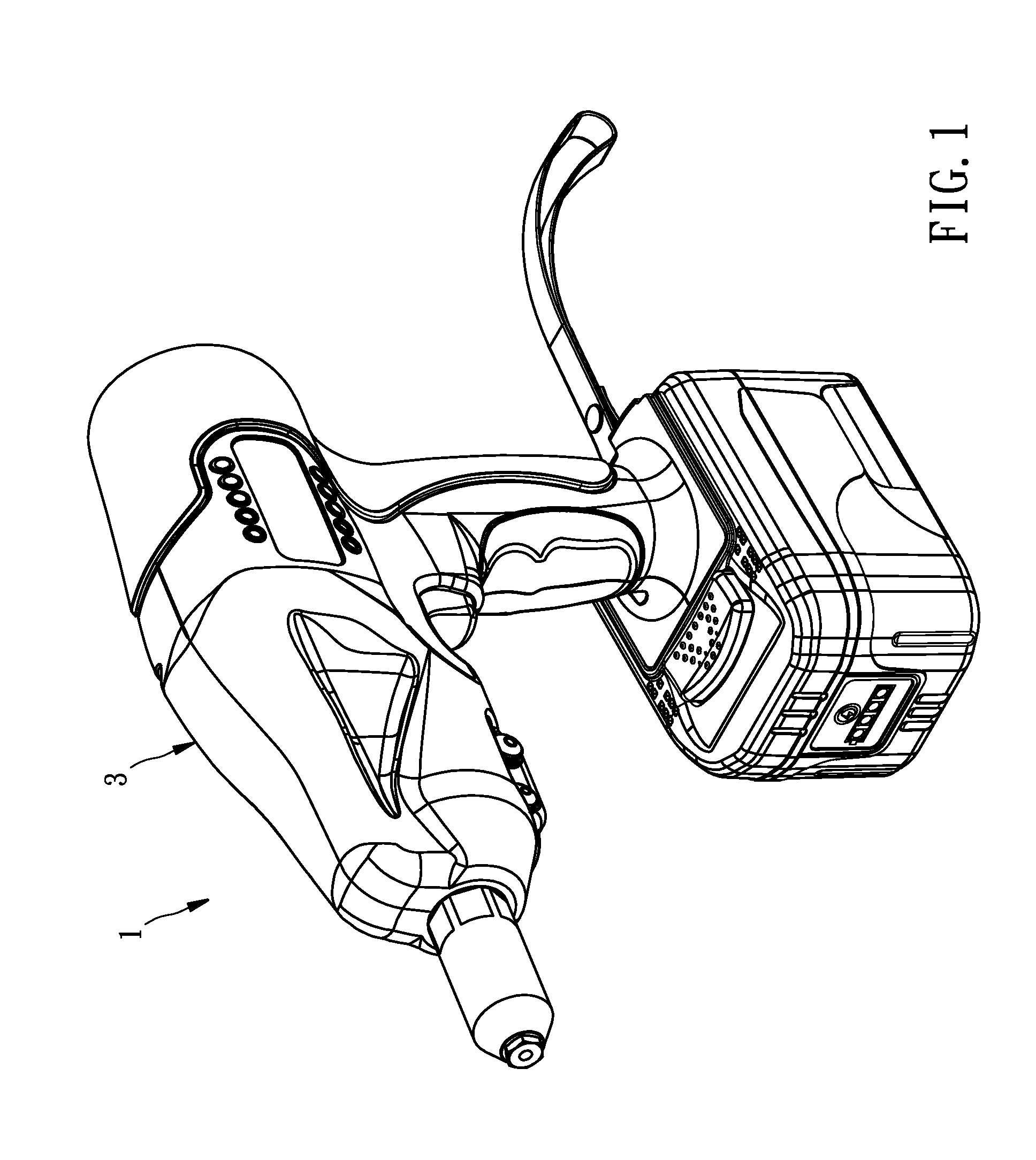

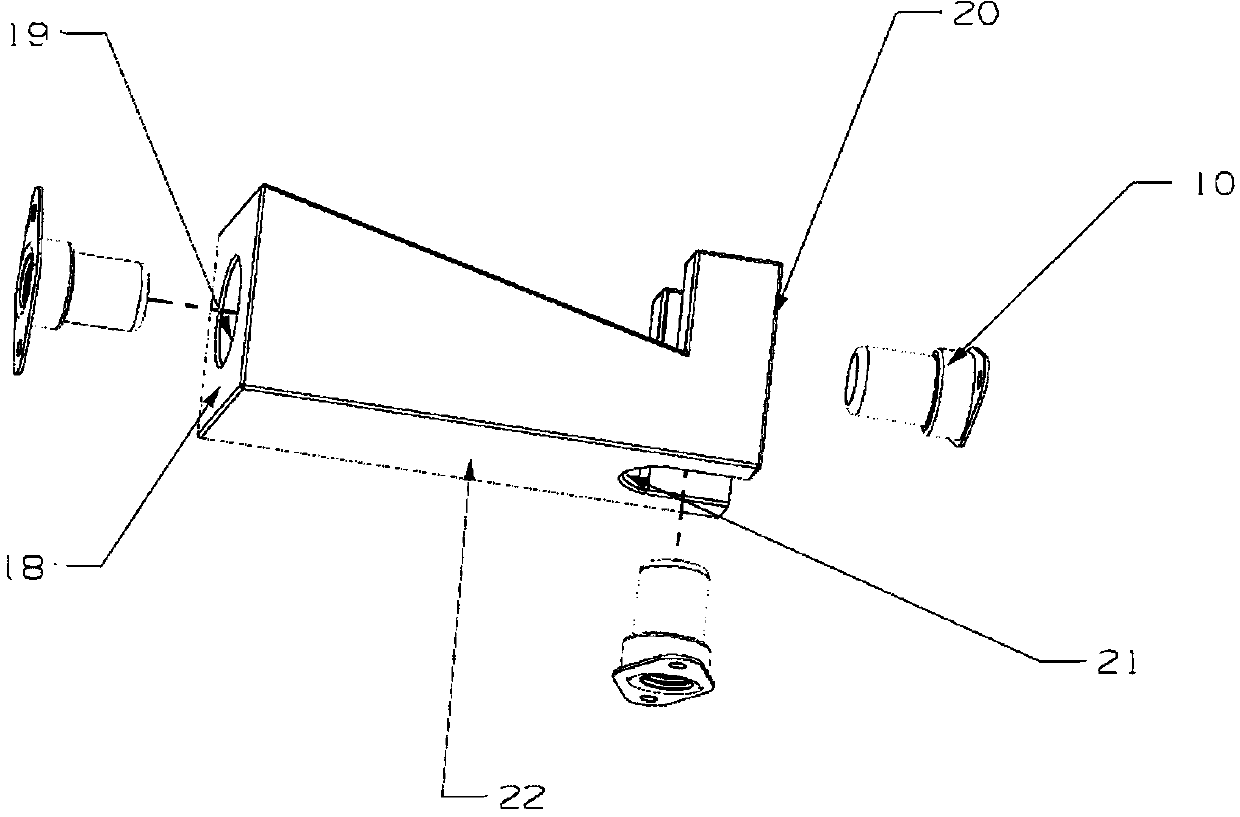

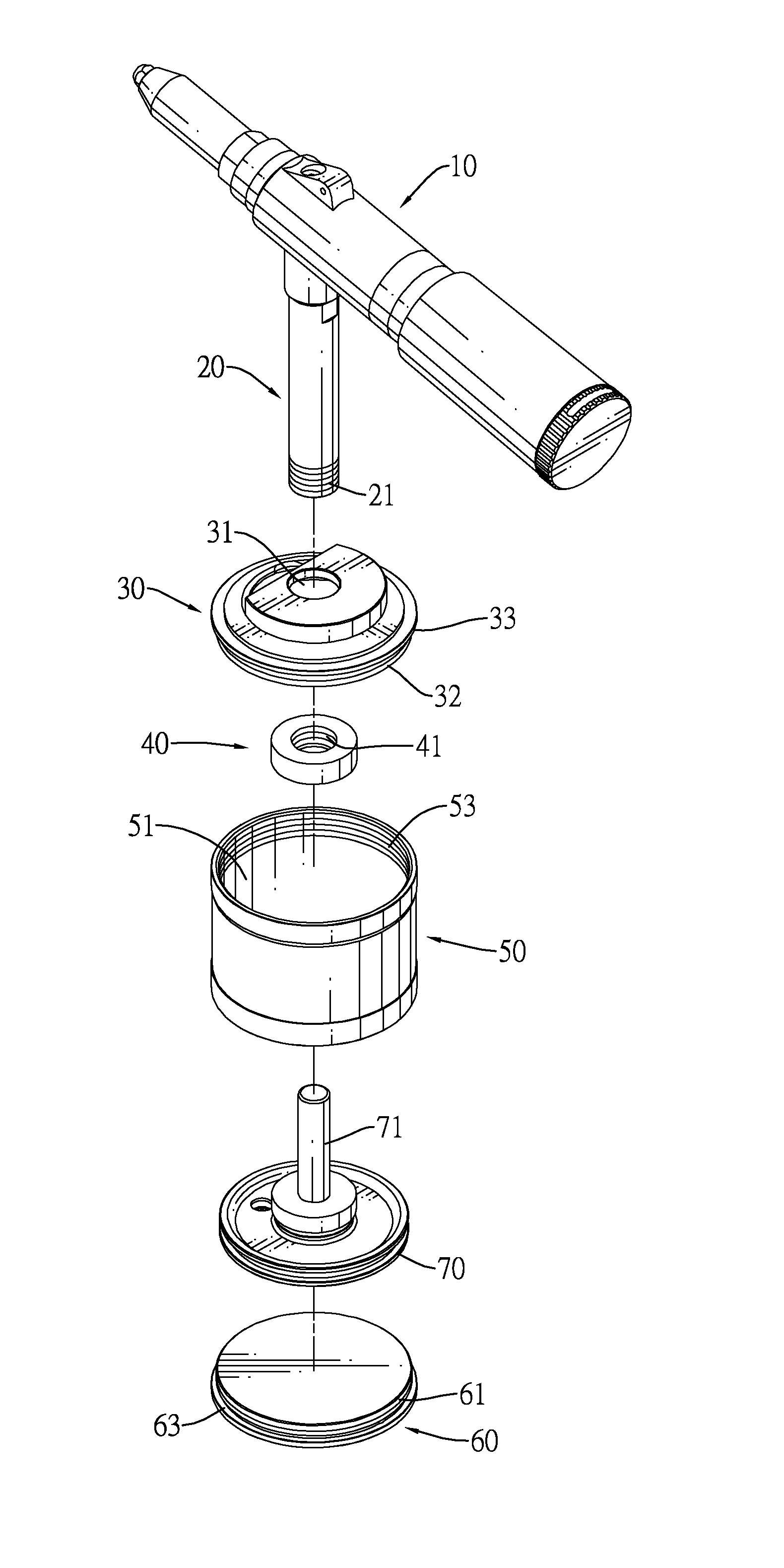

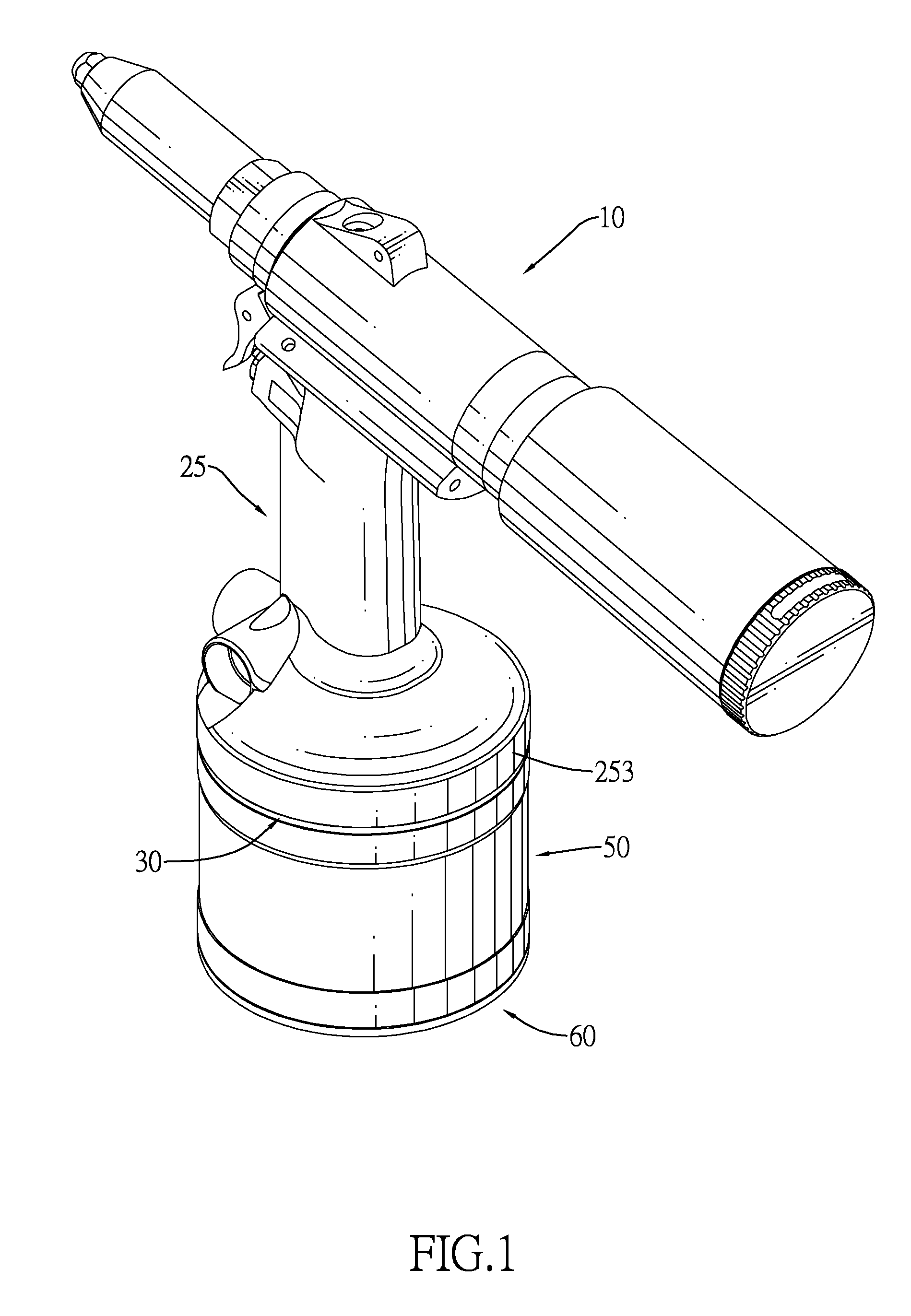

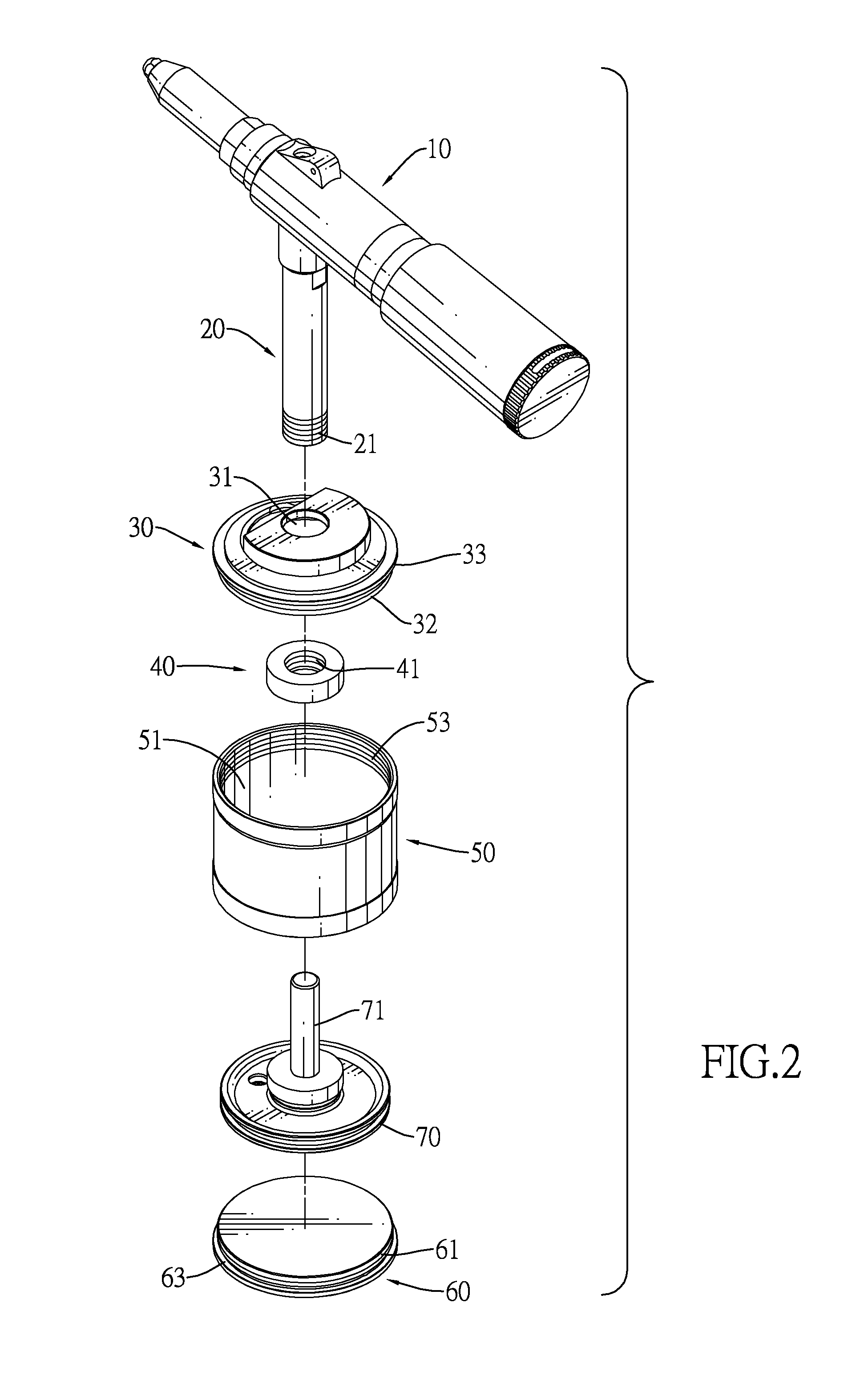

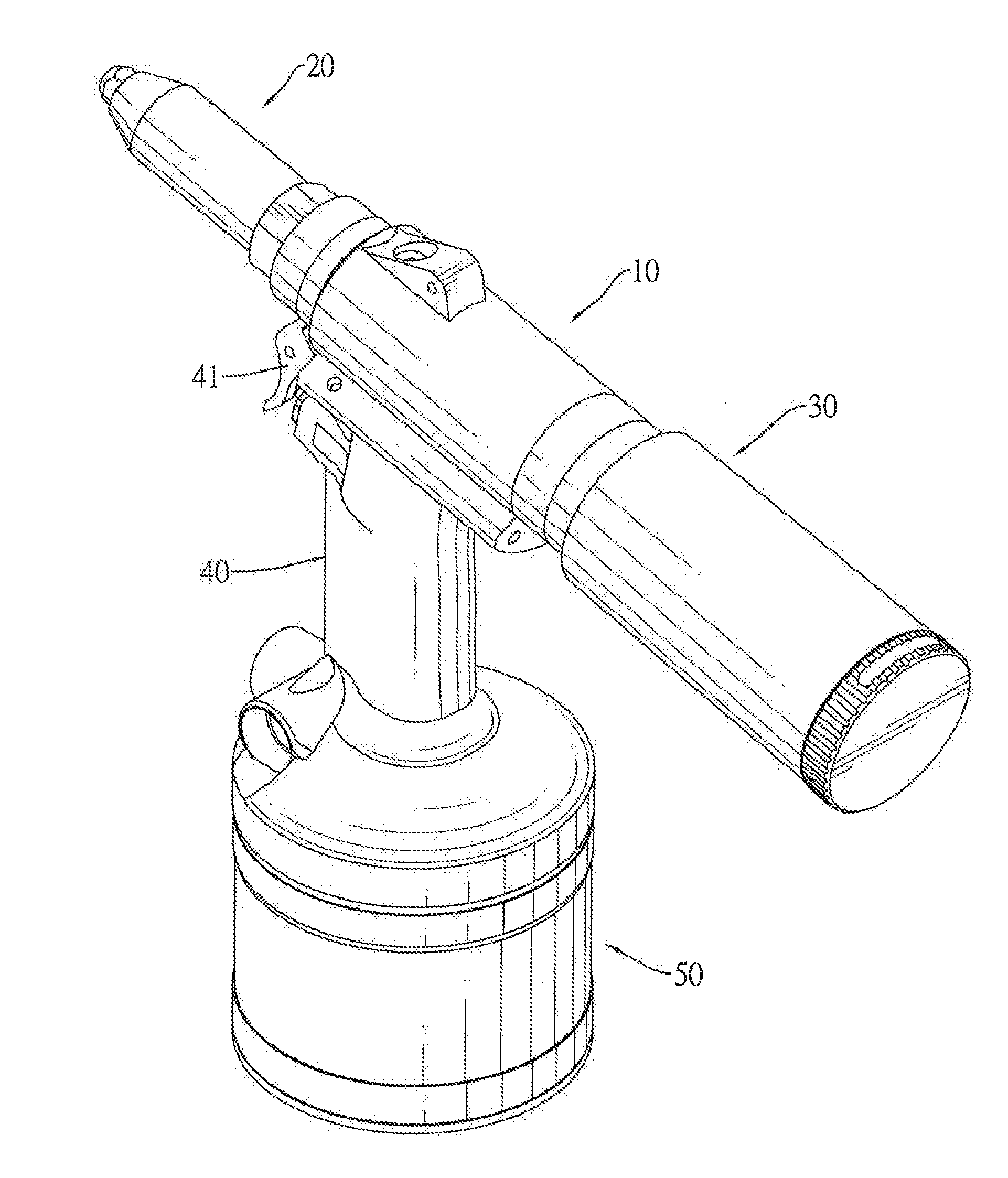

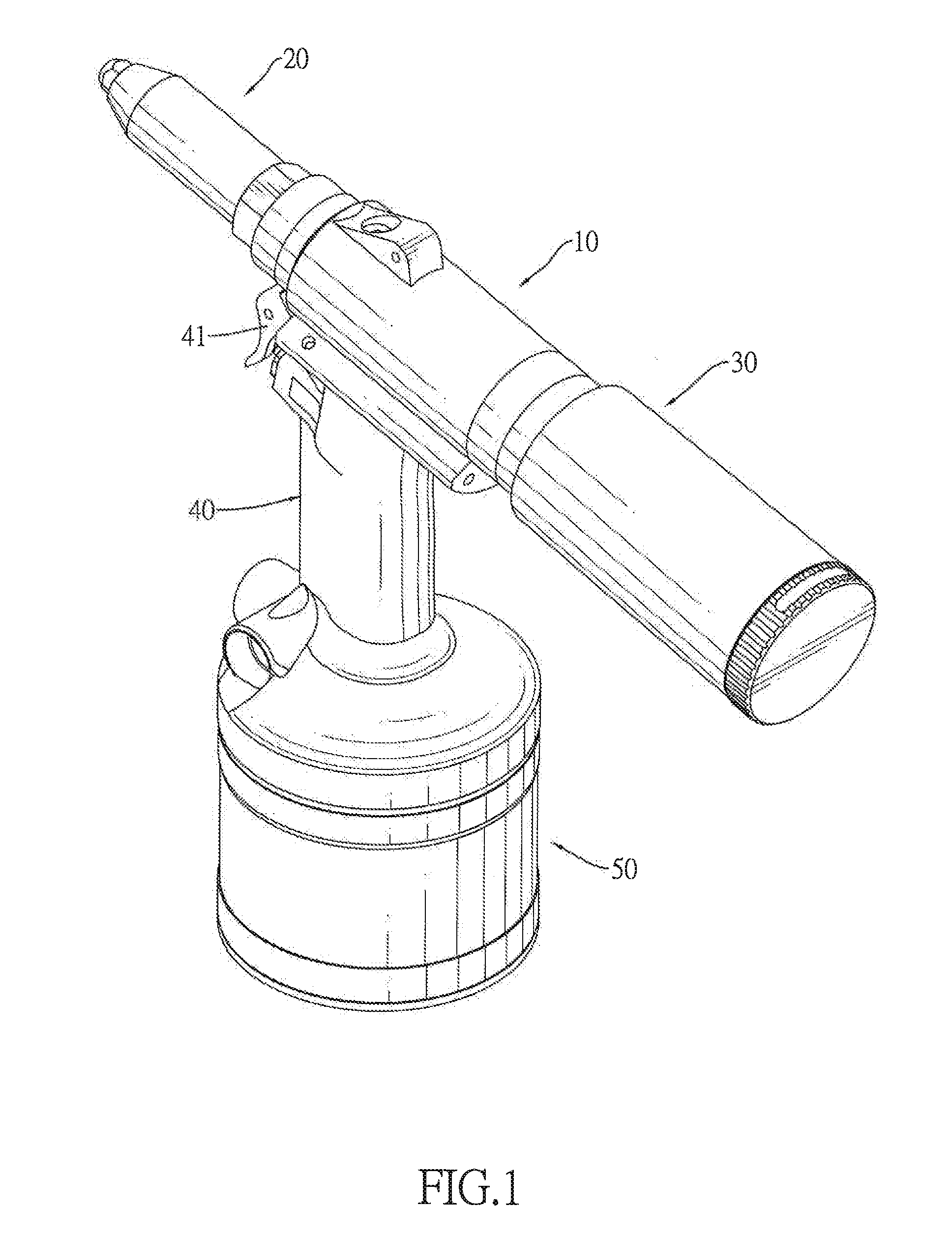

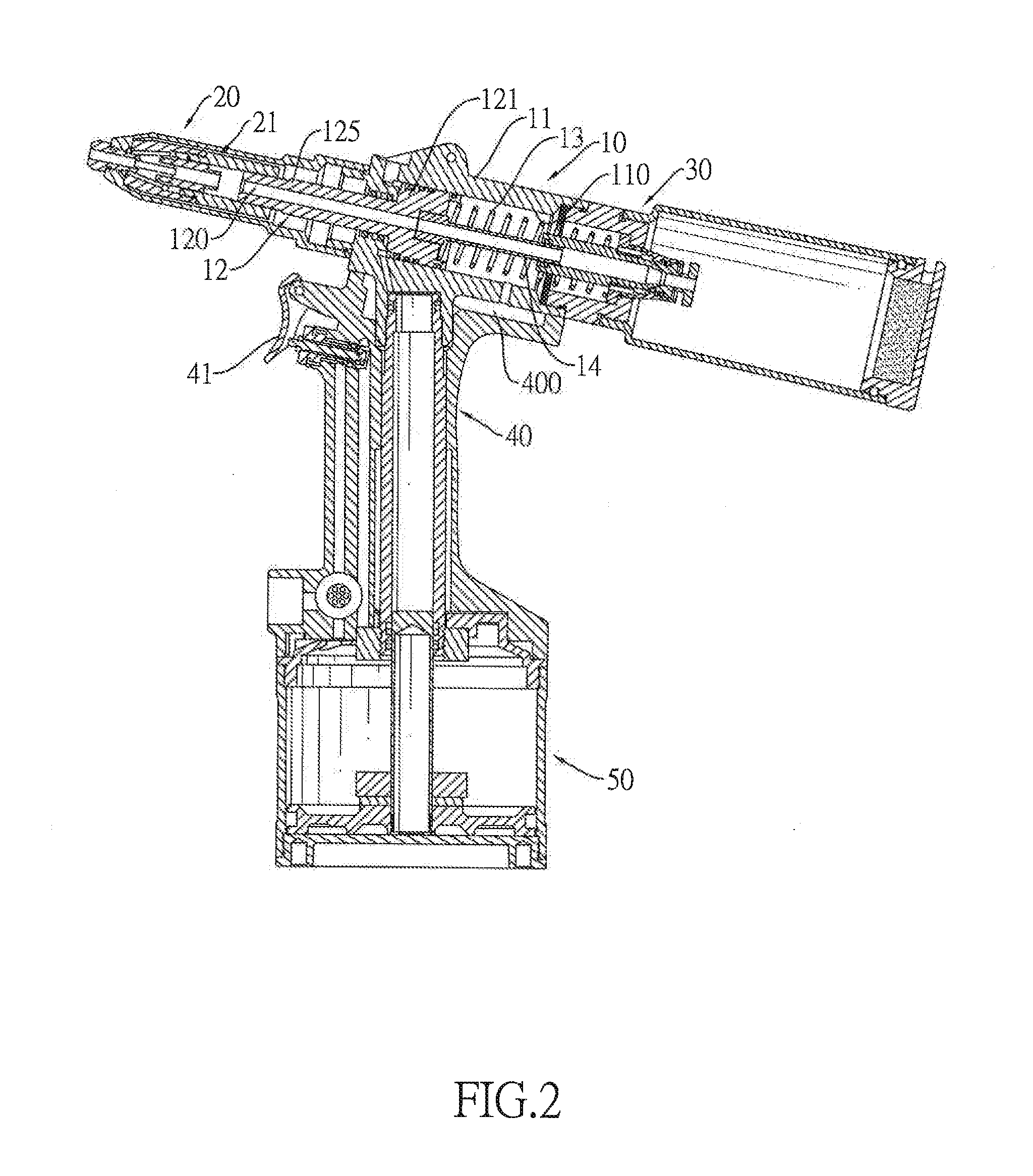

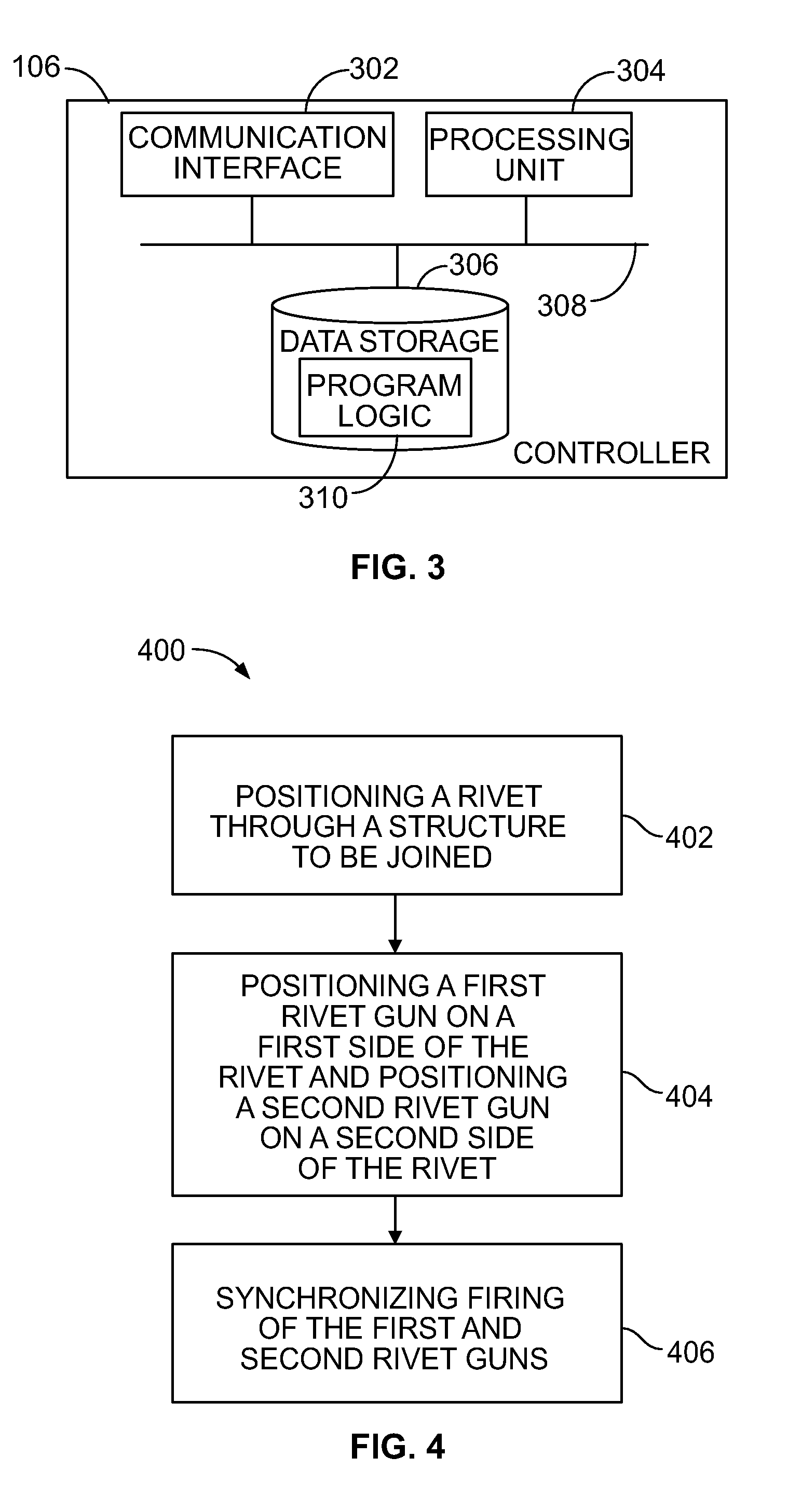

Rivet gun with detachable pneumatic cylinder assembly

ActiveUS8365375B2Easy to replaceReduce maintenance costsMetal working apparatusRivet gunPneumatic cylinder

A rivet gun has a barrel, a shaft, a handle and a pneumatic cylinder assembly. The shaft is mounted under the barrel. The handle is mounted around the shaft. The pneumatic cylinder assembly is mounted under the handle and has a top cover, a fastener, an annular cylinder and a bottom base. The top cover, fastener, annular cylinder and bottom base are detachably assembled so can be replaced easily without changing the whole pneumatic cylinder assembly. The maintenance costs of the rivet gun are reduced.

Owner:LIN YU CHING

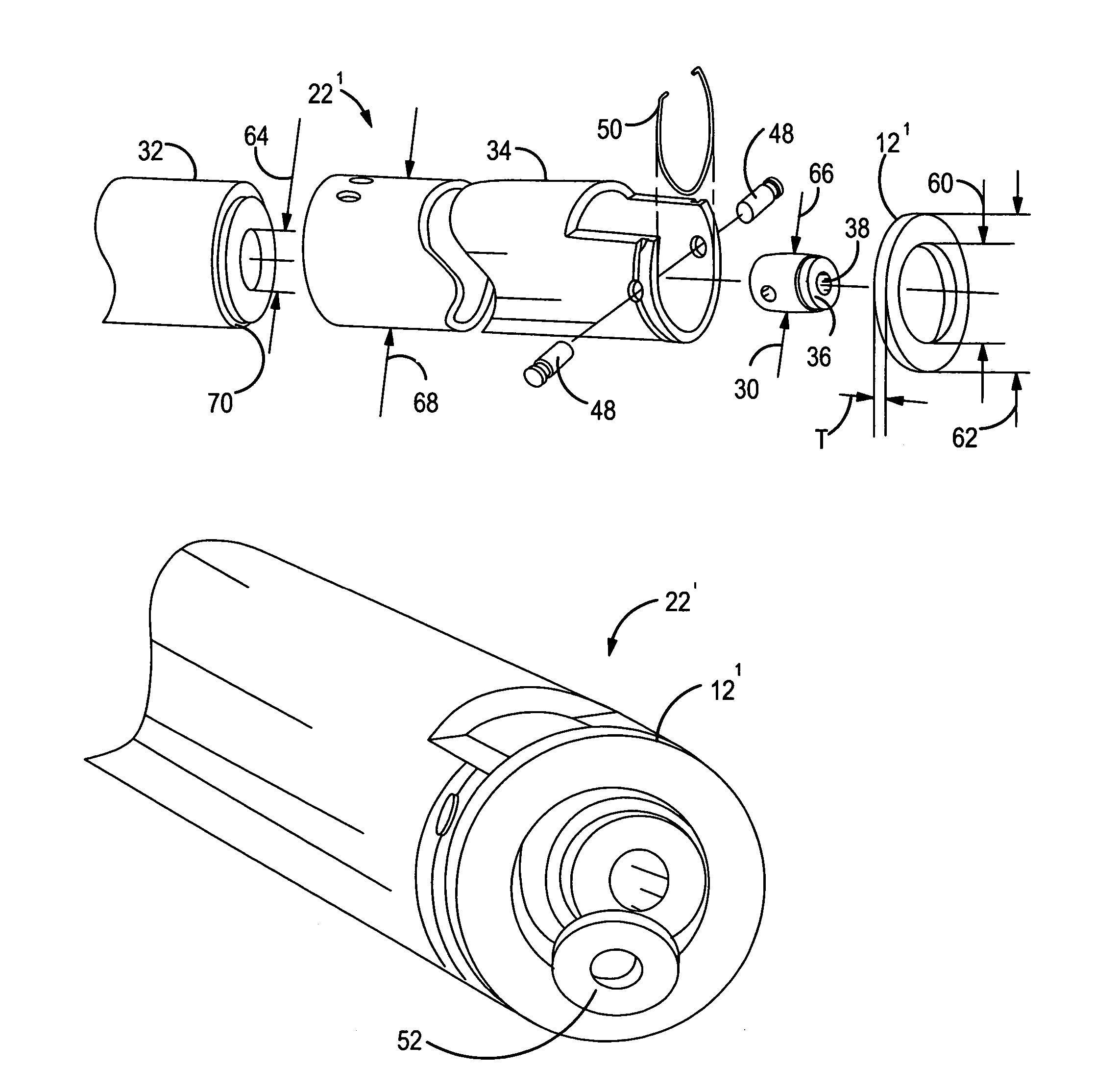

Rivet driving anvil retention system and method

ActiveUS7178213B2Prevents and minimizes creationEasy and quick and inexpensiveSecuring devicesMetal working apparatusEngineeringRivet gun

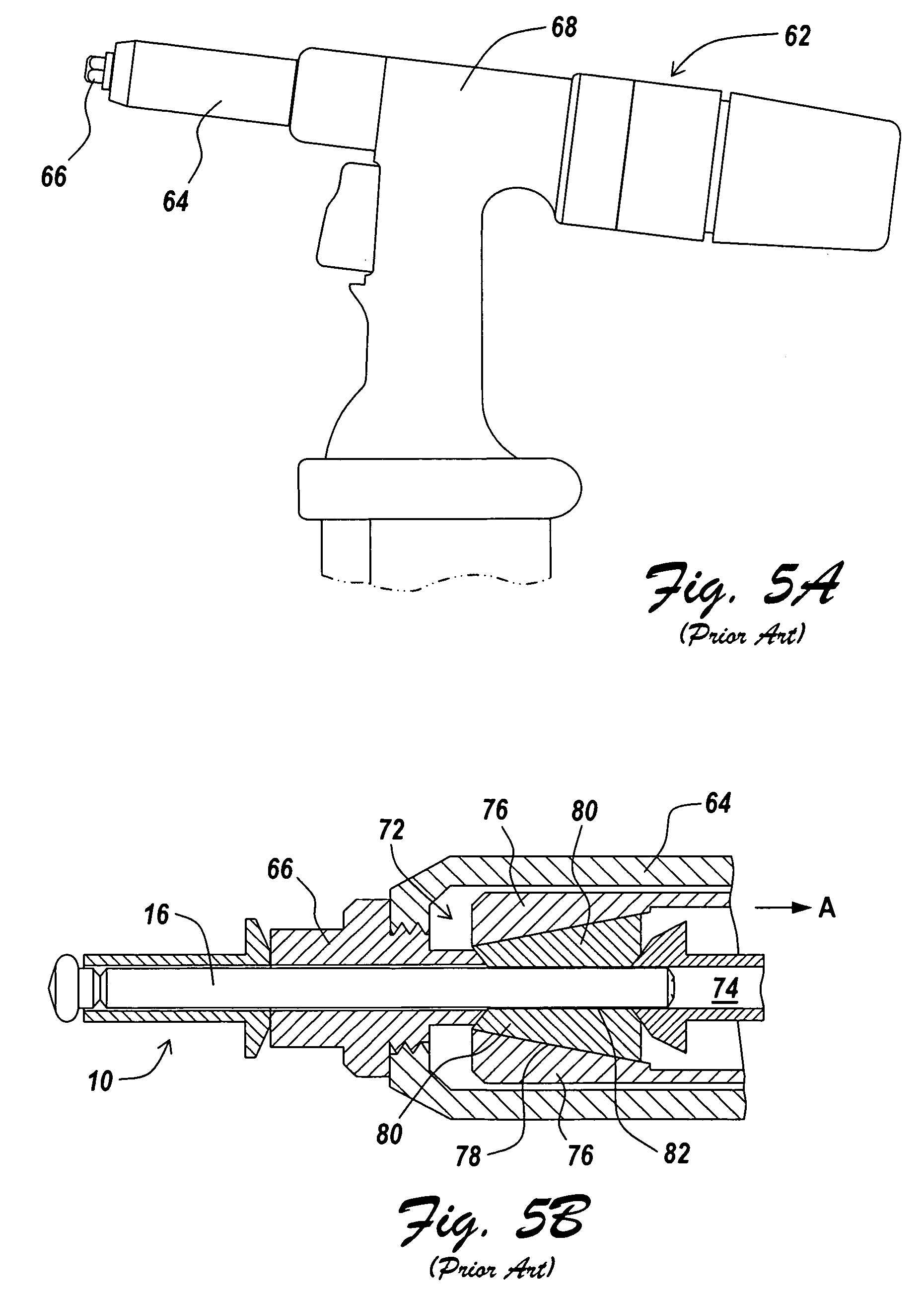

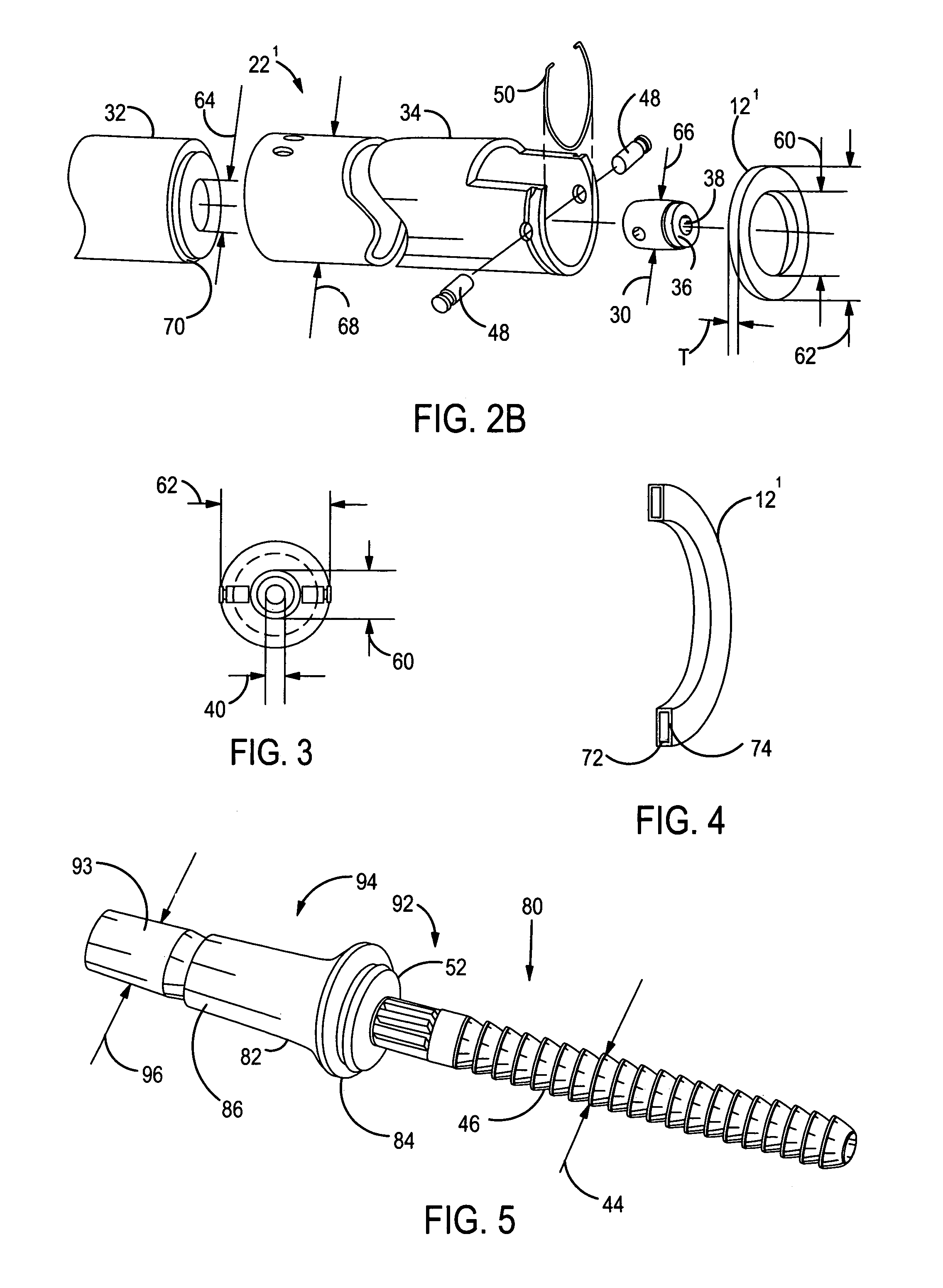

A driving anvil washer retaining apparatus (12) for a rivet gun (14) includes a magnetized element (21). The magnetized element (21) is coupled to the rivet gun (14) and retains an anvil washer (52) during installation of a rivet (82). A method of installing a rivet (82) includes inserting a stem (46) of a rivet assembly (80) into a rivet gun nose (22) having at least one magnetized portion (21). A rivet (82) of the rivet assembly (80) is inserted into at least one object. The stem (46) is removed from the rivet assembly (80). A driving anvil washer (52) is retained via the magnetized portion (21).

Owner:THE BOEING CO

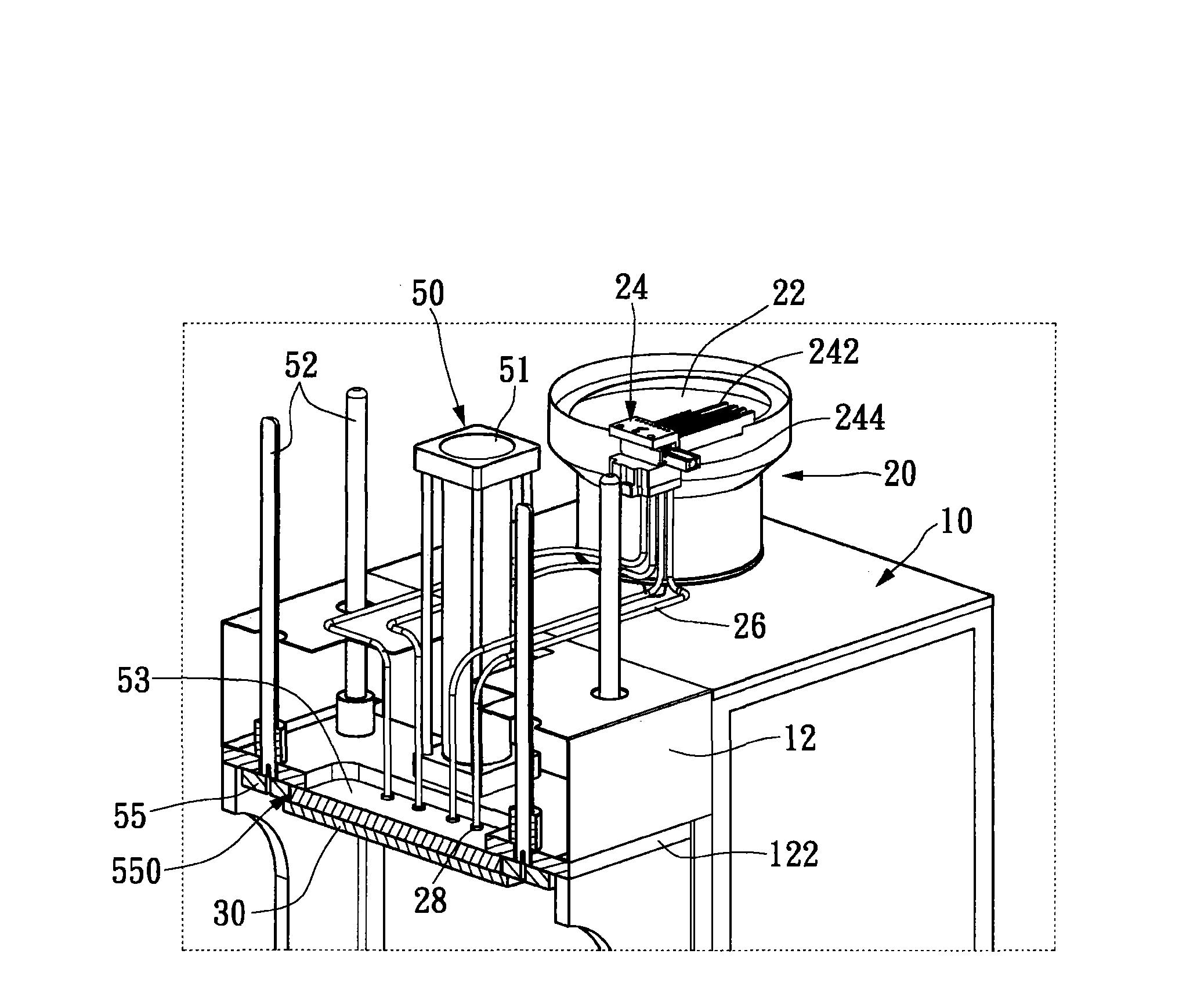

Automatic loading and setting blind rivet mechanism

The invention provides an automatic loading and and setting blind rivet mechanism, comprising one machine base provided with a working area, a rivet-supplying device disposed on the top surface of the machine base, a rivet-setting plate provided with a plurality of rivet-setting devices, a rivet gun fixing member and a lifting device. The rivet-supplying device comprises a shock device, a rivet-distributing device abutting against the shock device and a plurality of rivet-guiding pipes connected with the rivet-distributing device. The rivet-setting plate is disposed in a working area and provided with the plurality of rivet-setting devices; bottom outlets of the rivet-guiding pipes correspond to the plurality of rivet-setting devices to guide the blind rivets into the plurality of rivet-setting devices; the rivet gun fixing member is disposed below the rivet-setting plate and fixedly provided with a plurality of rivet guns thereblow, each rivet gun being provided with a gun tips; the lifting device moves the rivet-setting plate to be close or far from the rivet gun fixing member, so that a plurality of rivet guns enter the rivet-setting devices of the rivet-setting plate to insert the blind rivets on a plurality of gun tips. The automatic loading and setting blind rivet mechanism can automatically filling the blind rivet, so as to save manpower for filling the blind rivet.

Owner:LITE ON TECH CORP

Full-automatic rivet gun

The invention discloses a fully automatic rivet gun, which comprises a rivet gun body. The front part of the rivet gun body is provided with an automatic feeding mechanism, the middle part is provided with an automatic riveting mechanism, and the rear part is provided with an automatic material receiving mechanism. Feeding mechanism, automatic riveting mechanism and automatic receiving mechanism, and can be installed on the robot arm or other mechanisms, controlled by PLC signal, complete automatic operation instead of manual operation, reduce the labor intensity of operators, and occupy space It is small and convenient for operation. In addition, since the rivet guide block and the clip are provided, the position of the rivet is consistent each time. During operation, the rivet gun can be positioned accurately, which improves the stability of product quality. There is no restriction on the direction of operation, and it is not affected by the direction of gravity, which greatly improves the production efficiency of continuous operation.

Owner:广州市创效电子设备有限公司

Straight type riveting gun

InactiveUS7062843B1Easy to operateBeautify the appearanceAutomatic control devicesAssembly machinesPull forceEngineering

The present invention relates to a straight type riveting gun, which comprises a gun body having a pipe body and a tube body, a front gun pipe, and a back cover, wherein the front gun pipe is locked to front end of the pipe body and the back cover is locked to the tail end of the tube body. The tube body is provided for receiving a rivet-ejecting adaptor of an oil pressure rod. A trigger is mounted at the tail end of the pipe body for pushing a trigger ejector rod. The trigger ejector rod moves a valve to allow the exterior gas to enter a gas-collecting room for forcing a pneumatic piston to perform movement by use of air pressure. The oil pressure rod pushes the oil liquid to allow the riveting rod to generate powerful pulling force instantaneously thereby completing the riveting operation.

Owner:LIN YU CHING

Low-voltage electromagnet riveting method of metal-composite material combined structure

The invention relates to a low-voltage electromagnet riveting method of a metal-composite material combined structure, belonging to the manufacture filed of aviation and space engineering and solving the problems that the traditional riveting technology is difficult to realize the riveting of rivets with high strength, large diameter and large length on the metal-composite material, the metal-composite material combined structure has unstable riveting quality, the riveted structure has short life and the uniform interference riveting forming of rivets with large length cannot be ensured. The low-voltage electromagnet riveting method of the metal-composite material combined structure comprises the following steps: firstly, fixing metals and composite materials on which through holes are drilled; secondly, leading the rivets to pass through the through holes of the metals and the composite materials; thirdly, contacting a rivet head of a rivet gun with one side of a rivet tail and contacting one side of the rivet tail with top iron; and fourthly, giving out a processing signal to the rivet gun by a low-voltage electromagnetic riveting system and finishing the riveting. The invention is applied in the riveting process of the metal-composite material combined structures of large-sized cylinders of large-sized planes and rocket projectile bodies.

Owner:HARBIN INST OF TECH

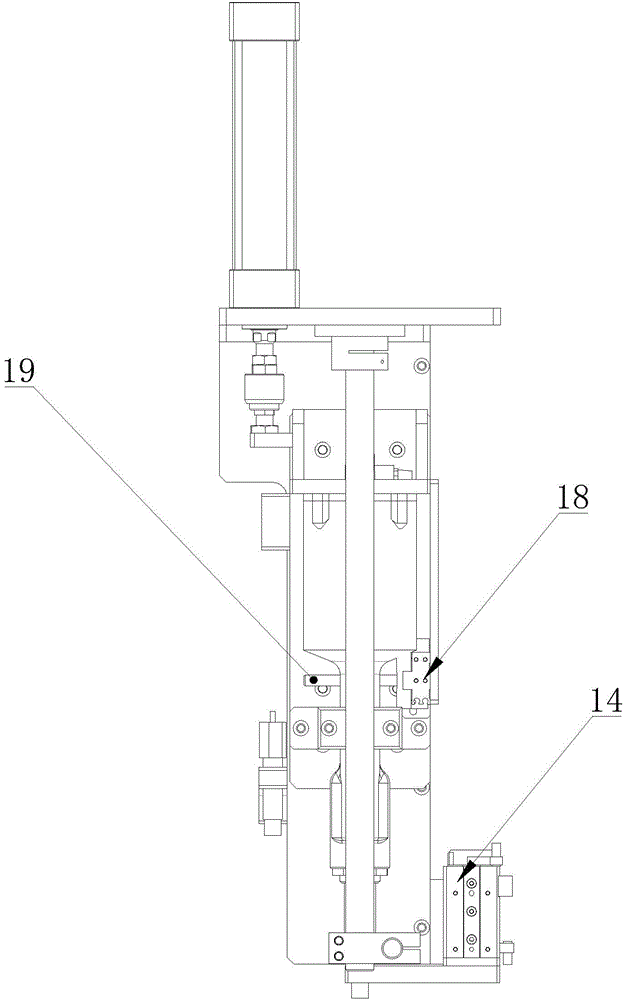

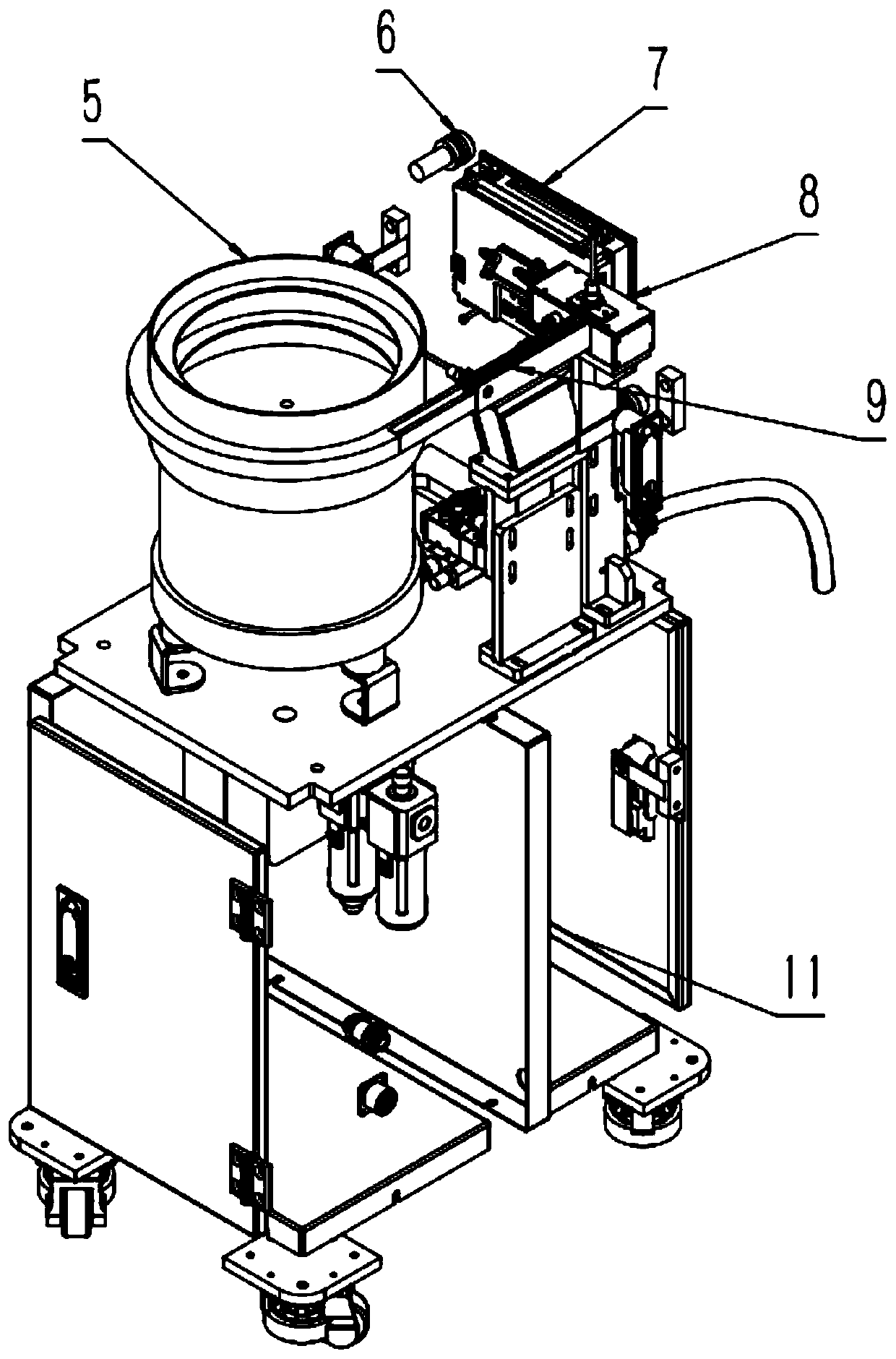

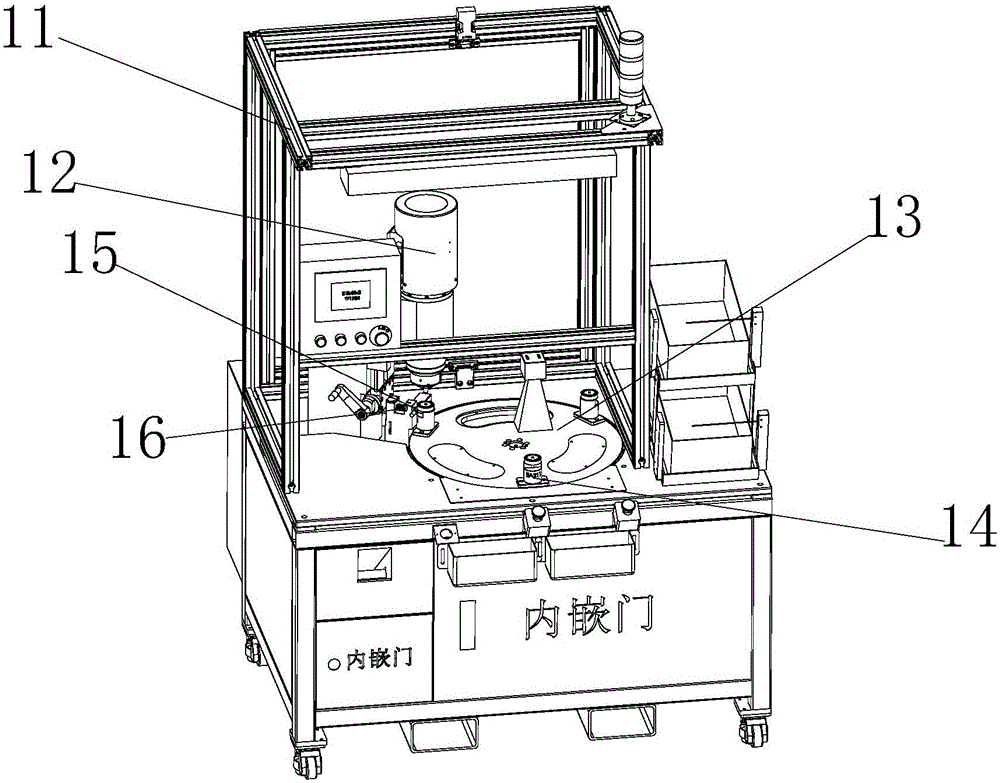

Automatic rivet supplying and automatic rivet pulling device for intelligent high-speed riveting gun

The invention provides an automatic rivet supplying and automatic rivet pulling device for an intelligent high-speed riveting gun. The automatic rivet supplying and automatic rivet pulling device comprises a base, a riveting mechanism, a material supplying mechanism and a feeding mechanism. The riveting mechanism comprises a riveting cylinder, a riveting gun body and a switch cylinder. The material supplying mechanism comprises a material supplying tube which is vertically fixed on a mounting support plate, and a rivet receiving tube is arranged at the lower end of the material supplying tube. The feeding mechanism comprises a horizontal cylinder, a vertical cylinder and a rivet head, wherein the horizontal cylinder is horizontally fixed on the side wall of a mounting base, the vertical cylinder is vertically fixed at the output end of the horizontal cylinder, and the rivet head is fixed at the end of an output shaft of the vertical cylinder through a connecting plate. A gun nozzle of the riveting gun body and the rivet receiving tube are placed on the movement path of the rivet head. The automatic rivet supplying and automatic rivet pulling device for the intelligent high-speed riveting gun is simple in structure, convenient to operate, high in working efficiency and good in stability, greatly lowers the labor intensity of workers and improves the production efficiency.

Owner:DALIAN YUN MING AUTOMATION TECH

Novel lightweight electromagnetic self-piercing riveting gun

The invention discloses a novel lightweight electromagnetic self-piercing riveting gun. According to the riveting gun, a coil carrier is fixedly arranged at the bottom of a fixing plate; a rubber cushion pad is fixedly arranged on the fixing plate; a buffer block is fixedly arranged on the rubber cushion pad; a spring pressing block is fixedly arranged on the fixing plate; a guide cylinder is fixedly arranged on the spring pressing block; a connecting seat is fixedly arranged on the upper part of the guide cylinder; ring grooves are distributed in the lower part of the coil carrier in a ladderform; electrically-connected coils are shaped like rings corresponding to the ring grooves and are respectively fixedly arranged in the ring grooves; and guiding holes are formed in the fixing plateand the coil carrier. The riveting gun disclosed by the invention has that advantages that the structure is simplified; the manufacturing cost is reduced; the frequency and the magnitude of currents are increased; the forming force is increased; the shock absorption effect is obvious; the recoil force is remarkably reduced; the consistency of workpiece riveting is well guaranteed; and the rivetinggun is suitable for production lines for automatically connecting workpieces.

Owner:HUBEI BOSHILONG TECH

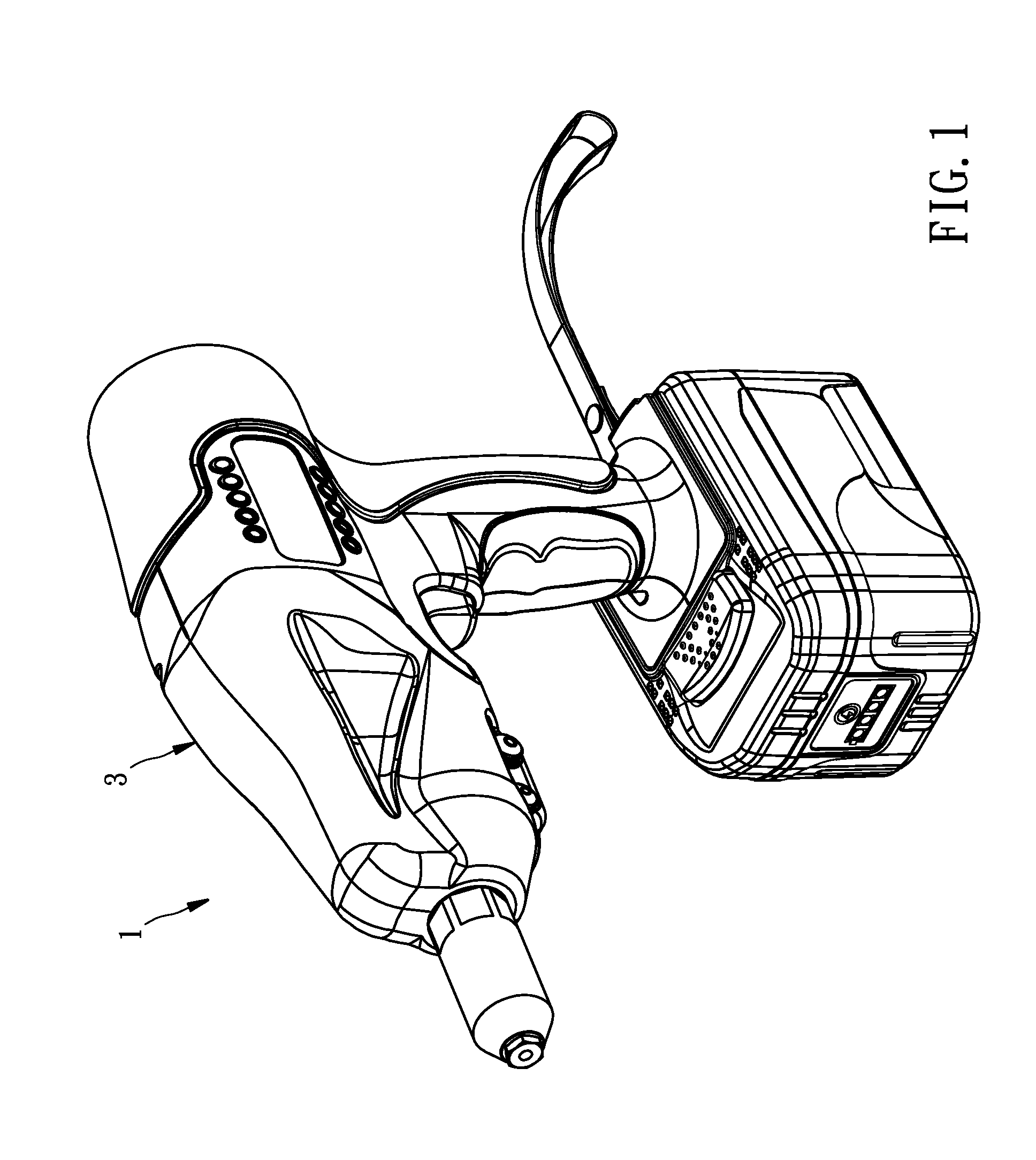

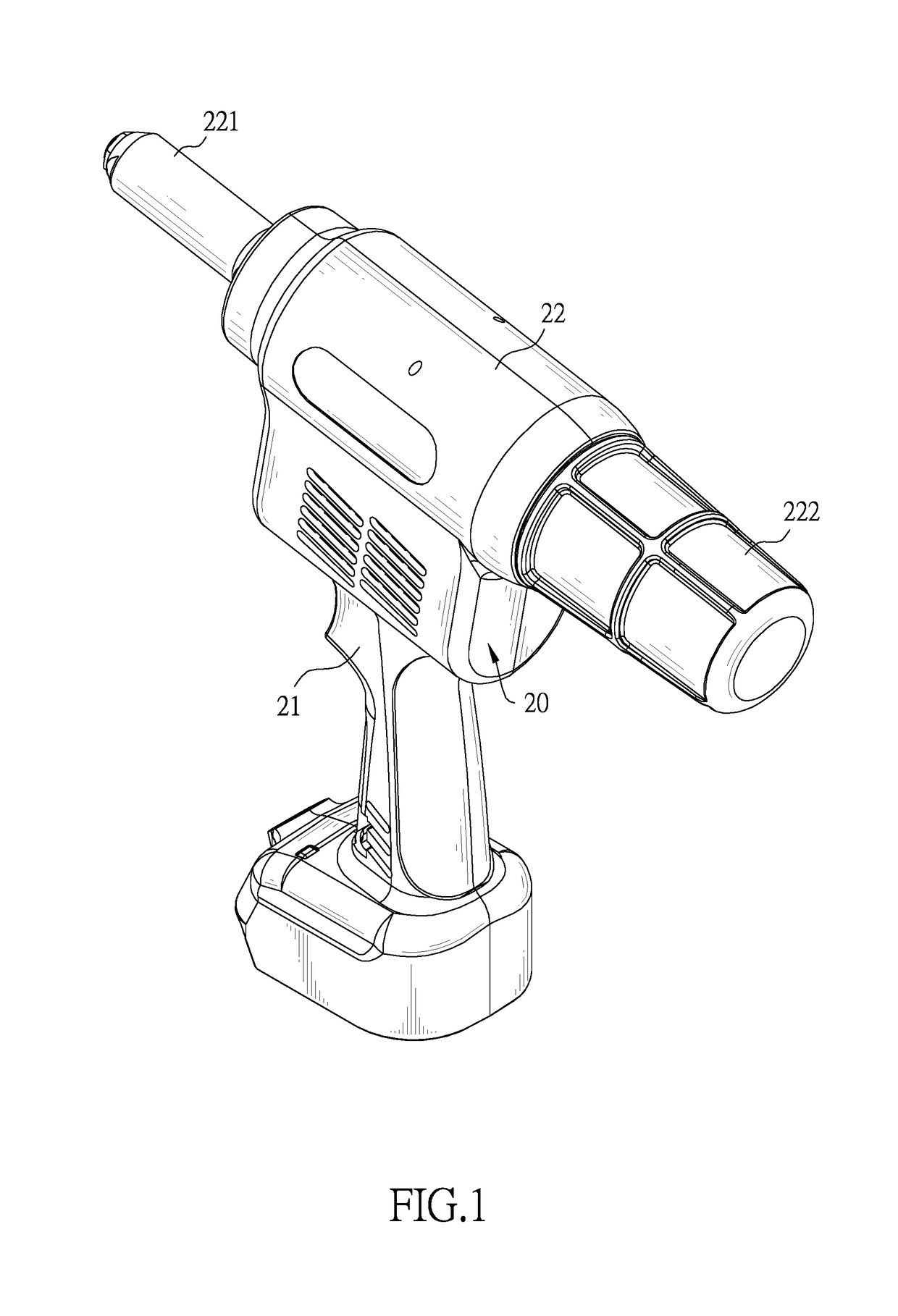

Easy squeeze blind rivet gun

The invention relates to a device which uses a rivet, in particular to a hand riveter which is driven to achieve the riveting operation by a motor. According to the technical proposal which is provided by the invention, a rivet nozzle is fixedly arranged in a shell; the rivet nozzle is provided with a through hole where the rivet can be inserted; a hand riveting device is connected in the shell at one side of the rivet nozzle in a sliding way; the sliding direction of the hand riveting device is consistent to the axis line of the through hole; the shell is internally provided with a driving device and a control device thereof which drive the hand riveting device to slide forwards and backwards corresponding to the rivet nozzle. The invention has the advantages of compact structure, convenient application, strong force, and avoiding the hidden trouble which is possible to be brought by error operations.

Owner:孙延新

Barrel assembly for a rivet gun

InactiveUS20150273569A1Reduces high pressure air consumptionIncrease consumptionMetal working apparatusEngineeringRivet gun

A barrel assembly for a rivet gun has a tube body, a vising piston and a rear valve. The tube body has an assembling hole and a bypass hole. The vising piston is mounted slidably in the assembling hole of the tube body and has a piston head mounted slidably in the assembling hole of the tube body and having two O-rings mounted around the piston head at an interval, and a shaft formed on the piston head. The rear valve mounted on the rear opening of the assembling hole of the tube body. When the vi sing piston moves backward adjacent to the rear opening of the assembling hole of the tube body, the bypass hole of the tube body is located at the interval between the O-rings and is sealed by the 0-rings without consuming high pressure air from a pneumatic cylinder.

Owner:LIN YU TANG

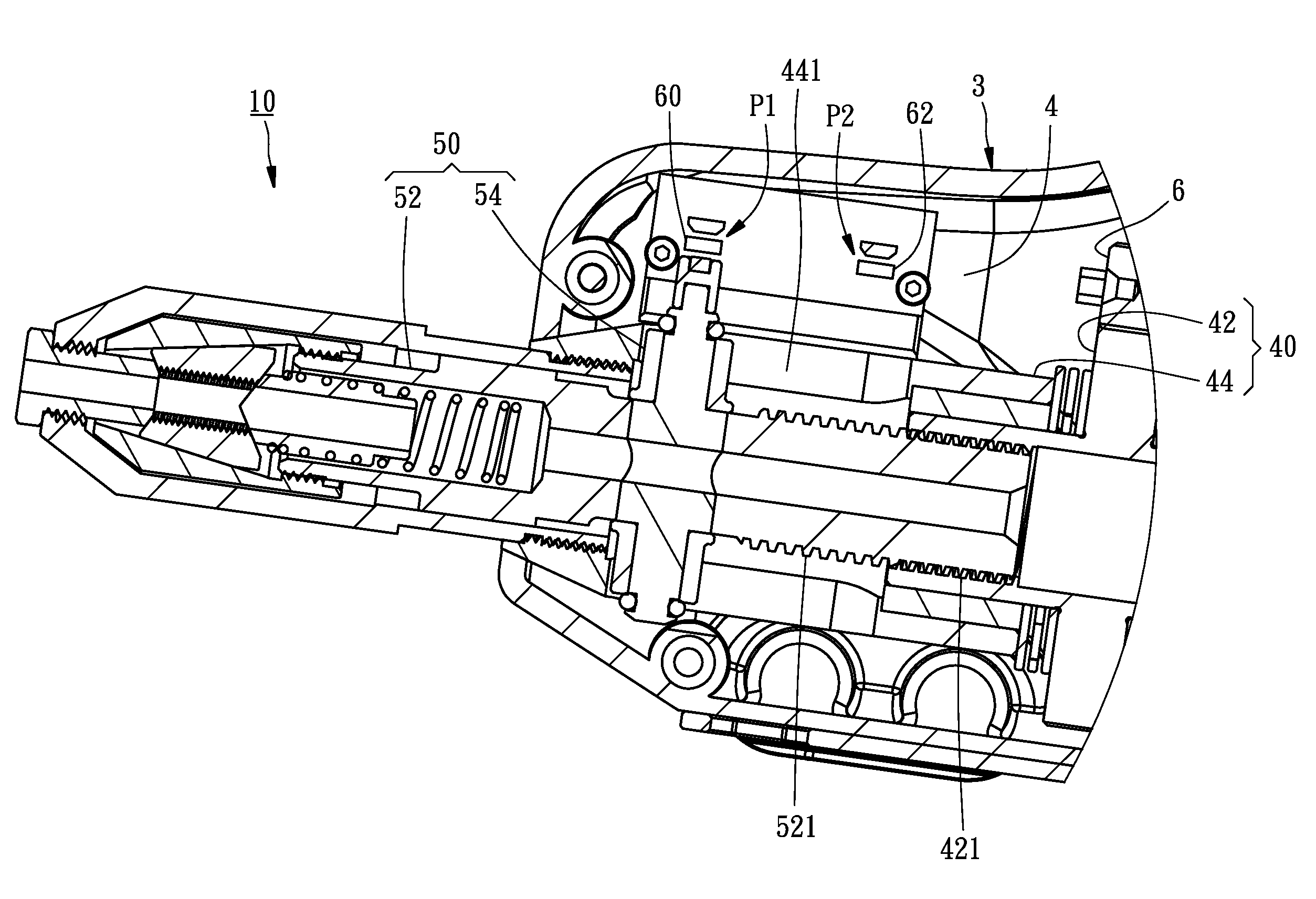

Riveting unit for electric rivet gun

ActiveUS8109123B2Guaranteed uptimePreventing excessive backward movementShaping safety devicesMeasurement/indication equipmentsRivet gunEngineering

A riveting unit is assembled with an electric rivet gun, including a transmission unit, a clamping jaw having a locating portion driven by the transmission unit to be moveable between a first position and a second position, a first sensor detecting whether the locating portion of the clamping jaw is located at the first position, and a second sensor detecting whether the locating portion of the clamping jaw is located at the second position. When the locating portion of the clamping jaw is located at the first position, a blind rivet can be installed in the clamping jaw, and when the locating portion of the clamping jaw is located at the second position, the blind rivet can be ejected, and meanwhile the second sensor can allow the transmission unit to stop the movement of the clamping jaw, thereby preventing the clamping jaw from moving backwards excessively.

Owner:TRANMAX MACHINERY

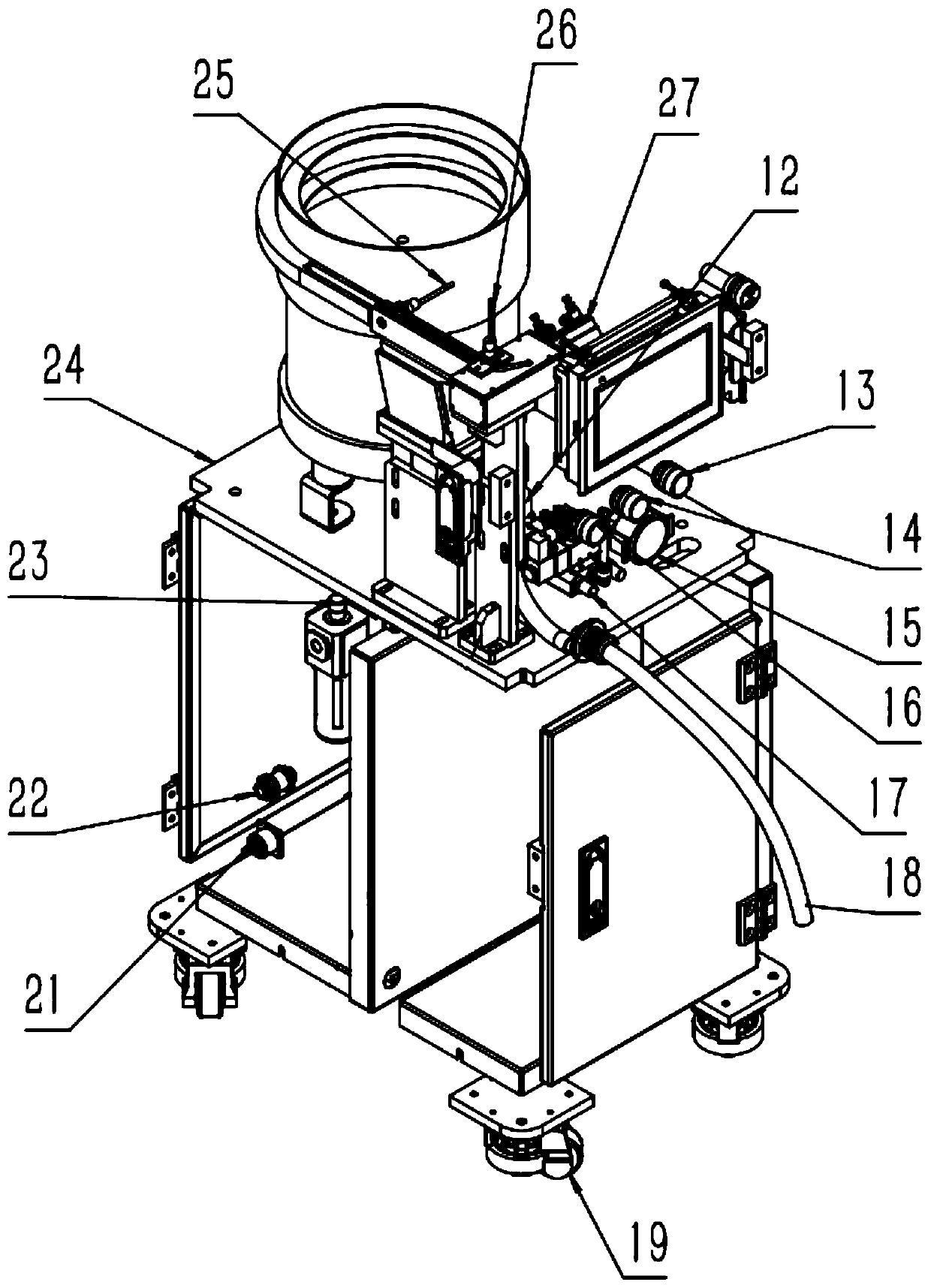

Full-automatic rivet nut feeding and riveting monitoring system

InactiveCN110170580AEasy maintenanceEasy to troubleshootMetal-working feeding devicesPositioning devicesMonitoring systemRivet gun

The invention discloses a full-automatic rivet nut feeding and riveting monitoring system which comprises a rivet nut feeder, a rivet nut receiving mechanism, riveting moving equipment and a rivetingmonitoring meter. The rivet nut feeder arranges and separates rivet nuts and conveys the rivet nuts to the rivet nut receiving mechanism through a nail feeding pipe, a rivet nut gun is arranged on therivet nut receiving mechanism, the rivet nut receiving mechanism conveys the received rivet nuts to a rivet rod of the rivet nut gun, and the riveting monitoring meter detects riveting tension and displacement through a riveting sensor connected to the rivet nut gun and displays riveting information. The full-automatic rivet nut feeding and riveting monitoring system is modular in design and convenient to maintain and troubleshoot, loads the rivet nuts automatically to the rivet gun of the rivet nut gun to improve the riveting efficiency, judges the riveting quality in real time to improve the riveting quality, and is connected to and combined with the rivet nut moving equipment in use to achieve a full-automatic riveting process.

Owner:铁藤机电技术(上海)有限公司

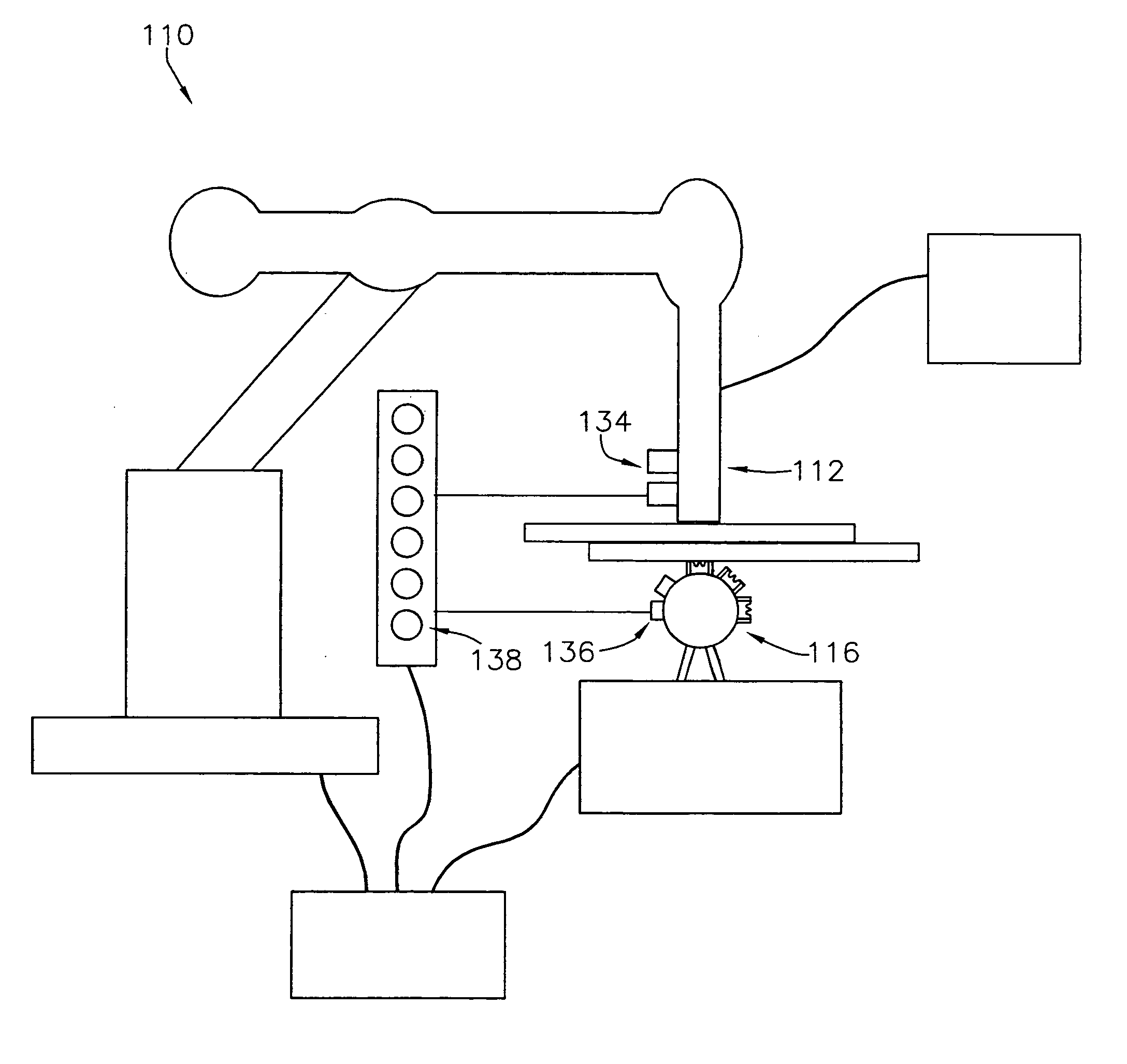

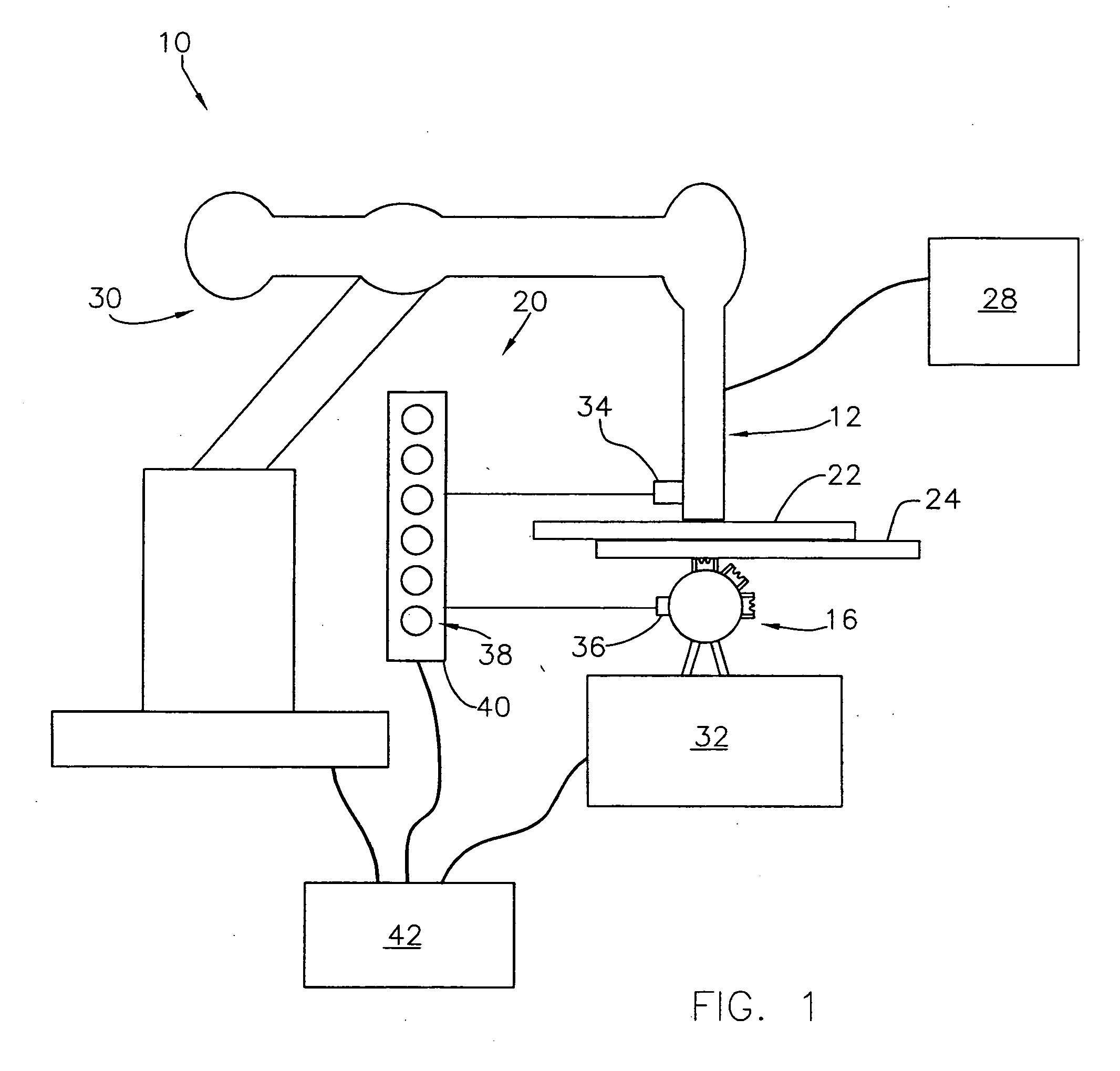

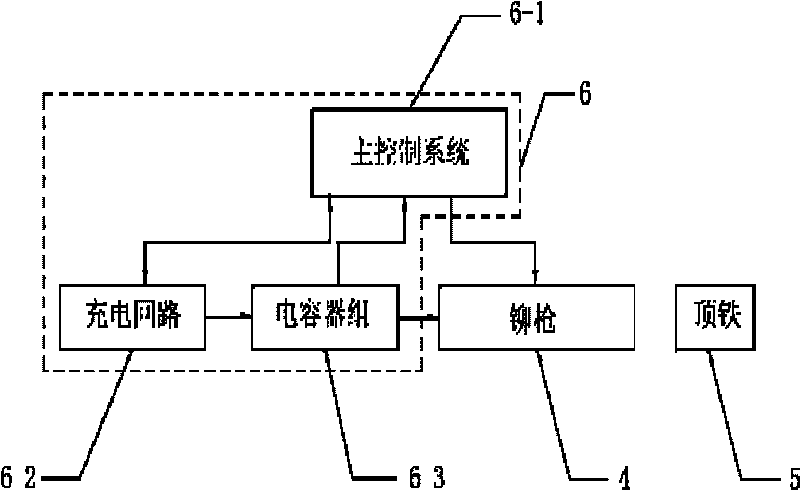

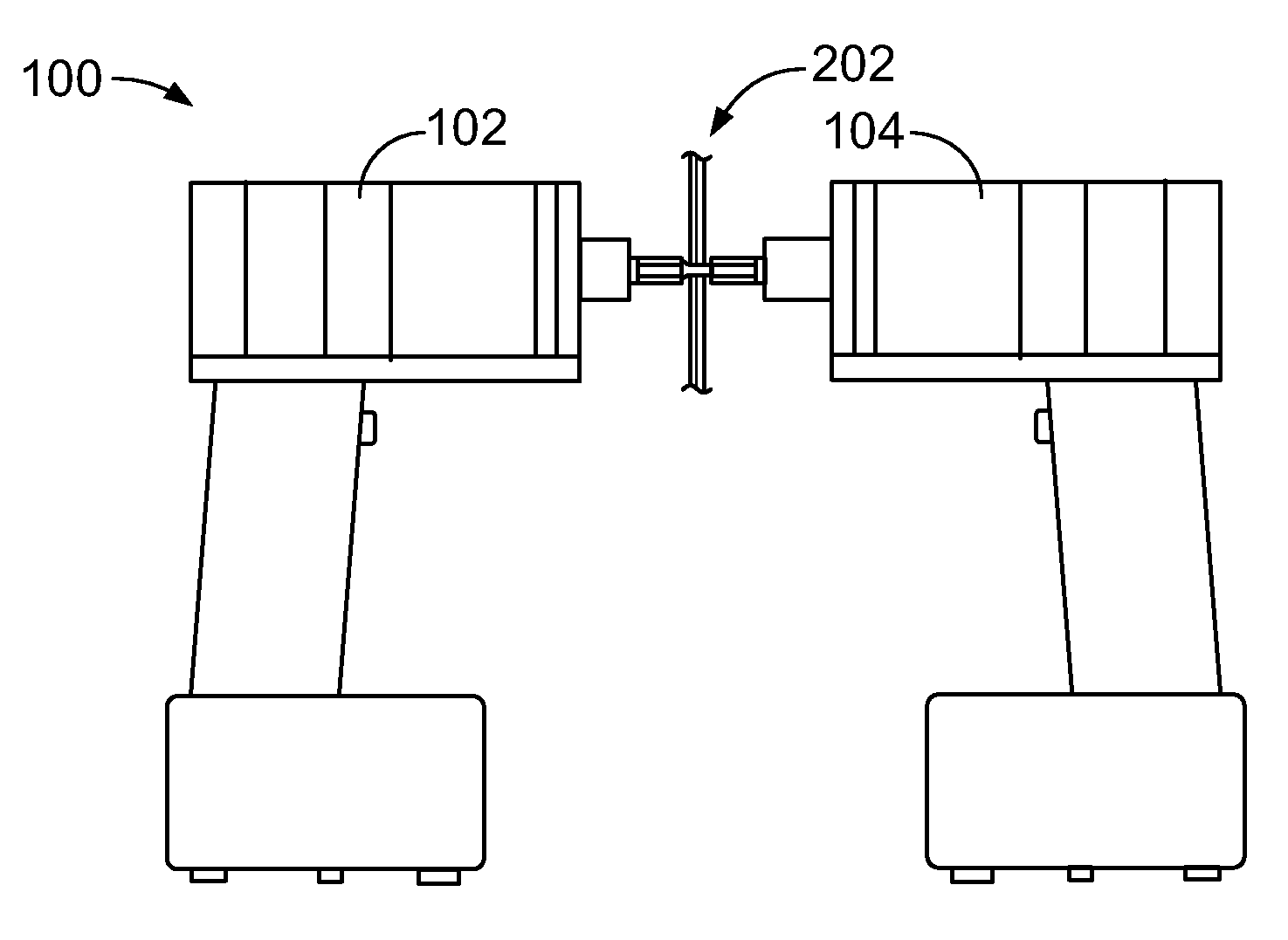

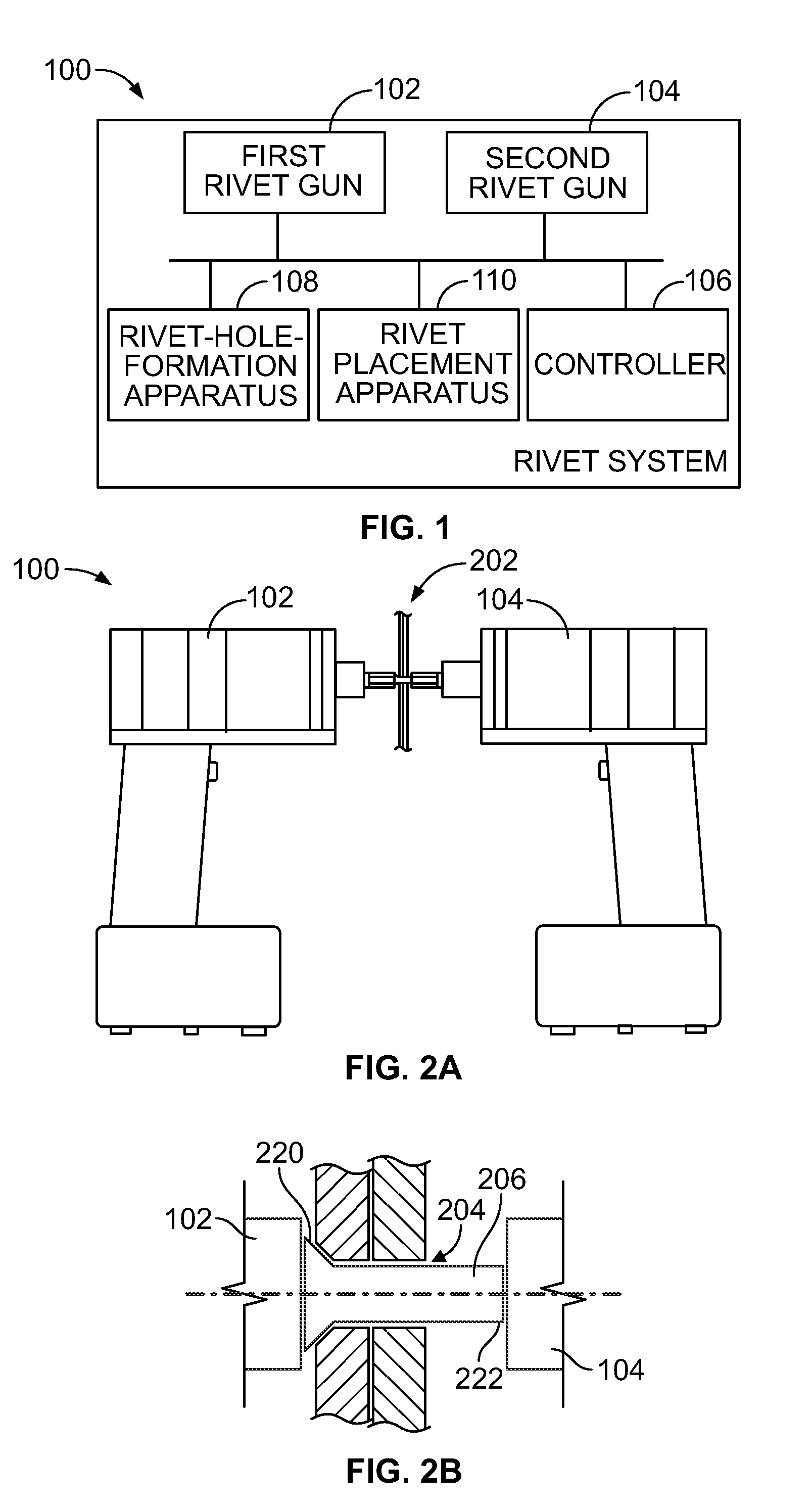

Apparatus and method for synchronized multi-stage electromagnetic rivet guns

A method and system for installing rivets is disclosed. The method involves positioning a rivet through a structure to be joined. The method further involves positioning a first rivet gun on a first side of the rivet and positioning a second rivet gun on a second side of the rivet. The method also involves synchronizing firing of the first and second rivet guns, so as to cancel forces that otherwise would propagate into the structure during installation of the rivet.

Owner:THE BOEING CO

Mandrel-pulling distance sensing assembly of an electric rivet gun

A mandrel-pulling distance sensing assembly of an electric rivet gun is mounted in a barrel of a housing and has a stationary seat, a moving seat, two magnetic elements separately fixed on the stationary seat, and a Hall effect sensor fixed on the moving seat. The moving seat is driven by a driving assembly of the electric rivet gun and is movable relative to the stationary seat. While the Hall effect sensor moves along with the moving seat between the two magnetic elements, the Hall effect sensor detects a changing magnetic field and produces and outputs a changing voltages to a control unit to allow the control unit to operate the driving assembly according to the changing voltages. Thus, the moving seat can be accurately positioned and moving ranges of a snapping device that is driven by the driving assembly can be accurately controlled.

Owner:LIN YU TANG

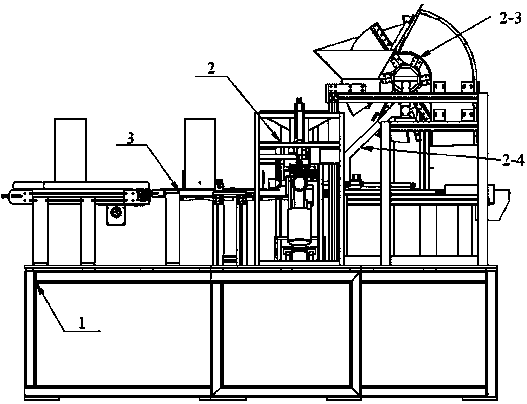

Automatic nailing system for anti-fake rivet of baijiu gift box and working method for automatic nailing system

ActiveCN105173233APrecise positioningRapid positioningWrapper twisting/gatheringEngineeringRivet gun

The invention relates to an automatic nailing system for an anti-fake rivet of a baijiu gift box and a working method for the automatic nailing system. The automatic nailing system comprises a rack, a conveying belt, a limiting conveying device, positioning clamps, automatic blind-riveting guns and automatic rivet feeding devices; the conveying belt used for conveying the gift box is transversely arranged in the middle portion of the upper end of the rack horizontally, and the limiting conveying device is installed at the position, at the input end of the conveying belt, of the rack; and the multiple positioning clamps are evenly and transversely distributed at the positions, on the horizontally-longitudinal two sides of the middle of the conveying belt, of the rack at intervals, and the automatic blind-riveting guns are installed at the lower portions of the positioning clamps and are connected with the automatic rivet feeding devices correspondingly installed at the lower portion of the rack respectively. The automatic nailing system is used for finishing work of automatically installing the anti-fake rivet on the gift box needing packing machining, positioning is accurate and rapid, the packaging efficiency is effectively improved, and the packaging quality of a product is guaranteed.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

Tooling for rivet gun

InactiveUS6961983B1Maximum strength connectionReduce the possibilityWorkpiece holdersPositioning apparatusRivet gunEngineering

Method and apparatus of back riveting construction for sections of aircraft structure utilizing the flush riveting wherein the back bar tooling for all the rivets in the entire section is a single piece of stationary tooling which conforms to the exterior shape of the aircraft section. The rivet gun is a single impact pneumatic gun with a rivet driving hammer which is offset from the axis of the gun's piston and impact pin to upset rivet under C-channel flanges.

Owner:TEXTRON INNOVATIONS

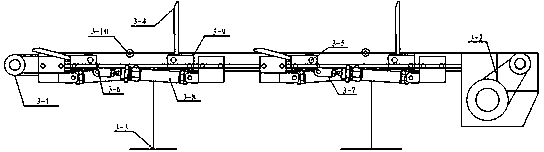

Actuator assembly line and assembly method

ActiveCN106271610ARealize the assemblyImprove assembly efficiencyAssembly machinesVehicle componentsAssembly lineEngineering

The invention discloses an actuator assembly line and an assembly method. The actuator assembly line mainly comprises a spin-riveting device, a hemming device, a detecting device and a tightening device which are arranged in sequence, wherein the spin-riveting device comprises a first machine frame, a spin-riveting gun is arranged in the first machine frame, a product turnplate and a turnplate driving mechanism driving the product turnplate to rotate are arranged below the spin-riveting gun, multiple first product accommodating tools are arranged in the peripheral direction of the product turnplate, and a clamping device is arranged below the spin-riveting gun. According to the assembly line, an actuator is assembled through combination of mechanical structures, actuator assembly efficiency is improved, and physical strength of workers is saved; a spring in the actuator is subjected to elasticity testing in advance, so that the quality of the spring is guaranteed; furthermore, hemming is also conducted during elasticity testing, operation is convenient and quick, and energy consumption is reduced.

Owner:YANGZHOU CHAONENG ELECTRIC VALVE CO LTD

Automatic suction and repelling device for rivet gun

An automatic suction and repelling device for rivet gun, which comprises a body and a handle, and the intake passages thereof are in communication each other; the rear center of the body is furnished with a regulation ring and a used-nail cylinder; the regulation ring can be adjusted to move by means of screwing so as to adjust the volume of pressure air to enter the body, and to adjust the vacuum suction force in the used-nail pipe; during rivet-pulling work, the rivet gun can automatically suck in, and can suck a used nail into the used-nail cylinder upon the rivet-pulling work done.

Owner:LIN YU CHING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com