Automatic loading and setting blind rivet mechanism

An automatic loading and vibrating device technology, which is applied in the field of riveting operations, can solve the problems of increasing the cost of the machine, the different weight of the rivet, and the bulky size of the machine, and achieve the effects of energy saving, space saving, and manpower simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

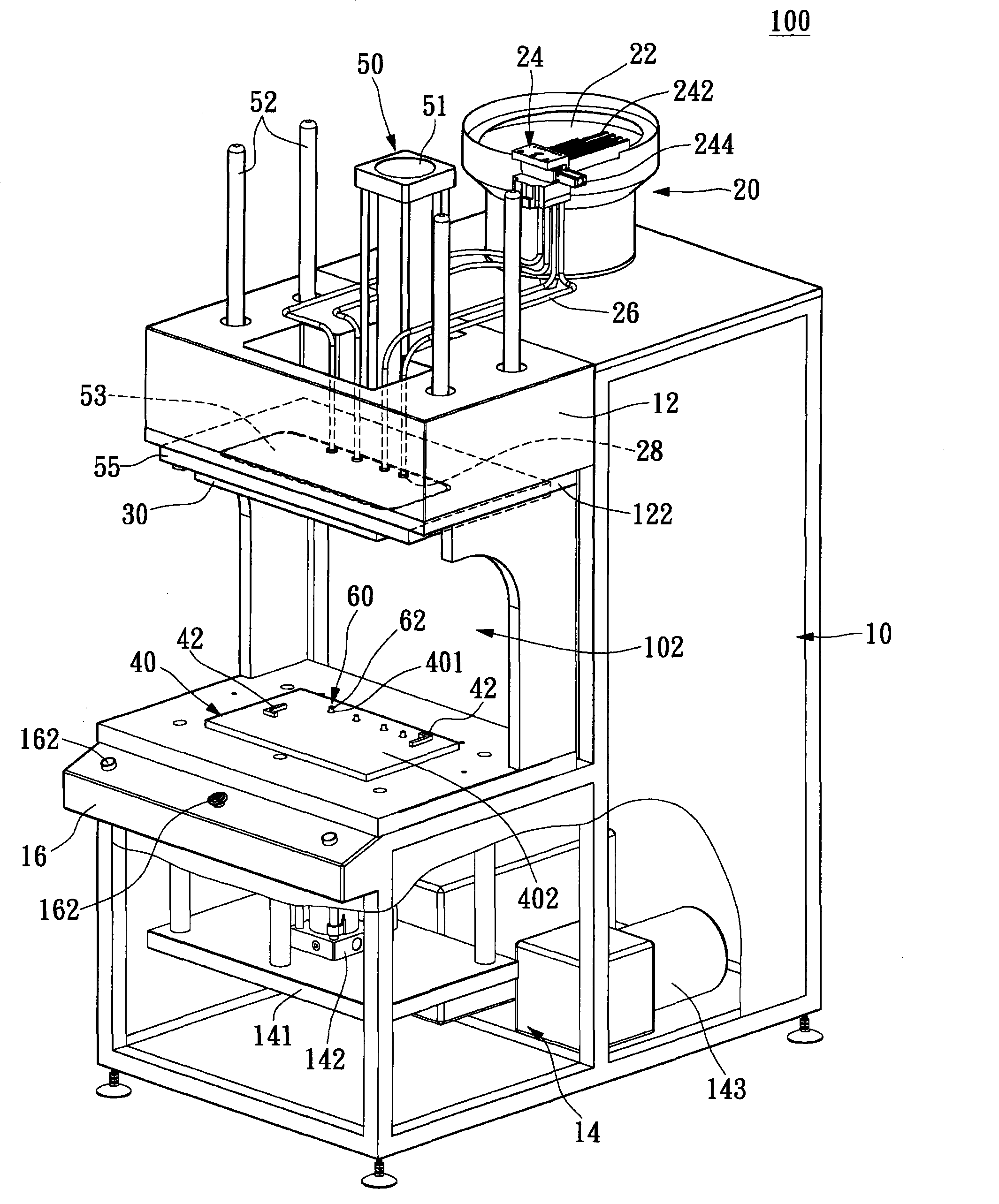

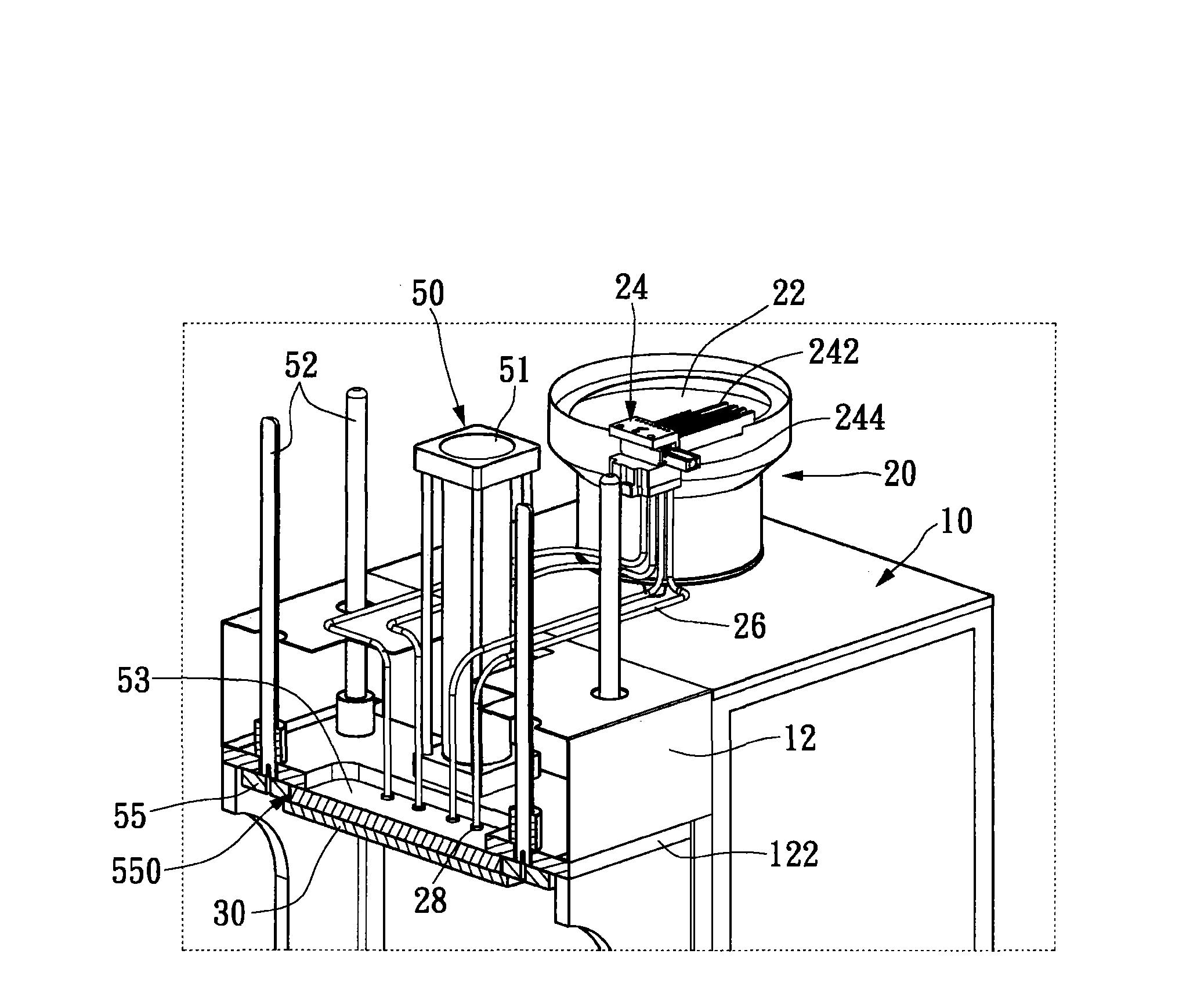

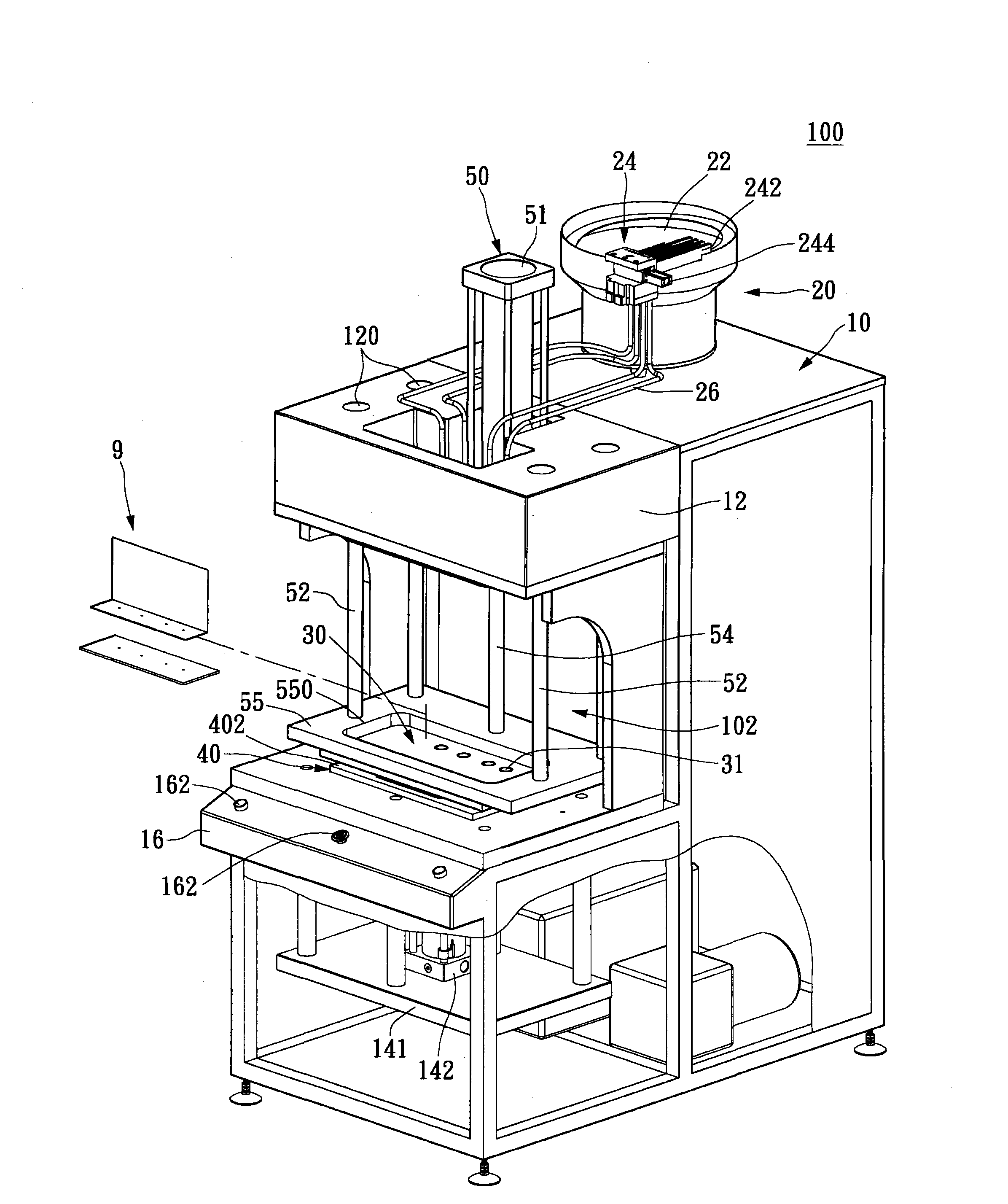

[0072] Please refer to figure 1 and figure 2 , figure 1 and figure 2 It is a three-dimensional view of the mechanism of automatic loading and performing nail pulling of the present invention. The present invention provides a mechanism 100 for automatically loading and performing nail pulling, which includes a machine base 10, a nail feeding device 20, a nail planting plate 30, a nail gun fixing part 40, a lifting device 50, and a plurality of nails Gun 60.

[0073] The base 10 is provided with a working area 102 for accommodating a workpiece 9, and the workpiece 9 includes at least two workpiece plates to be combined and pre-drilled. The machine 10 includes an upper platform 12 above the working area 102 and a lower platform 14 below the working area 102 . The lower platform 14 is provided with an operation panel 16 , and the operation panel 16 has a plurality of operation buttons 162 .

[0074] The nail feeding device 20 is arranged on the top surface of the machine bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com