Patents

Literature

202results about How to "Improve riveting quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

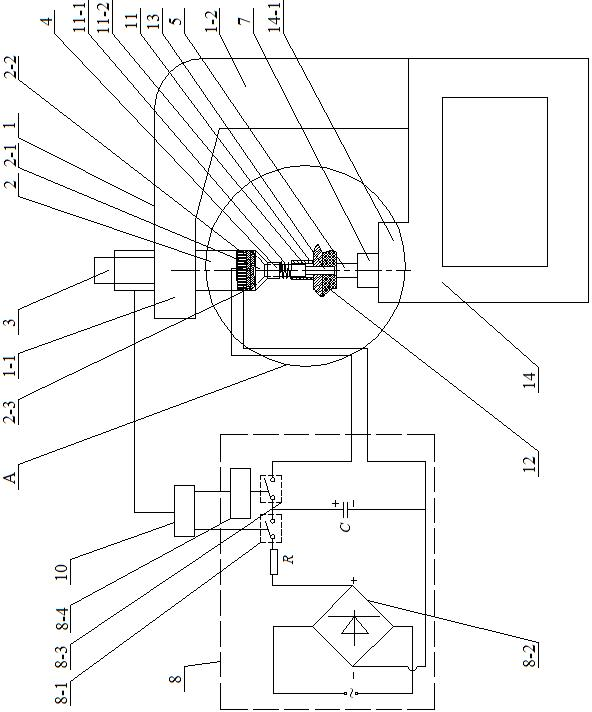

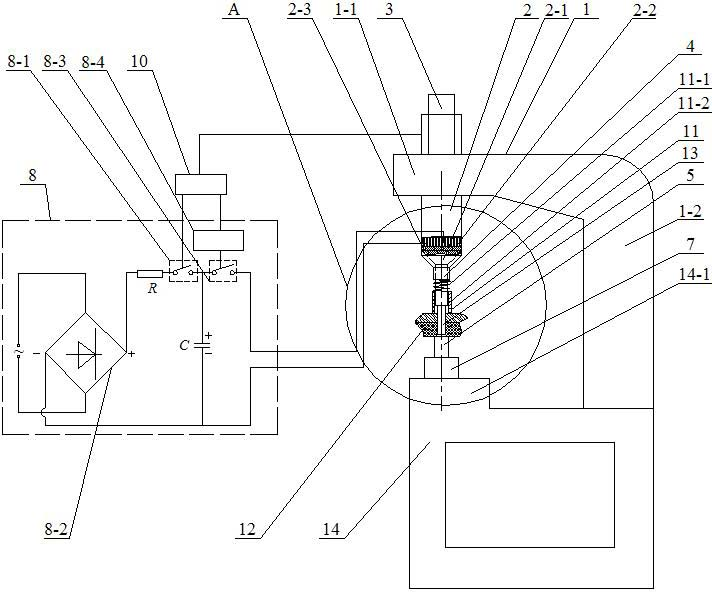

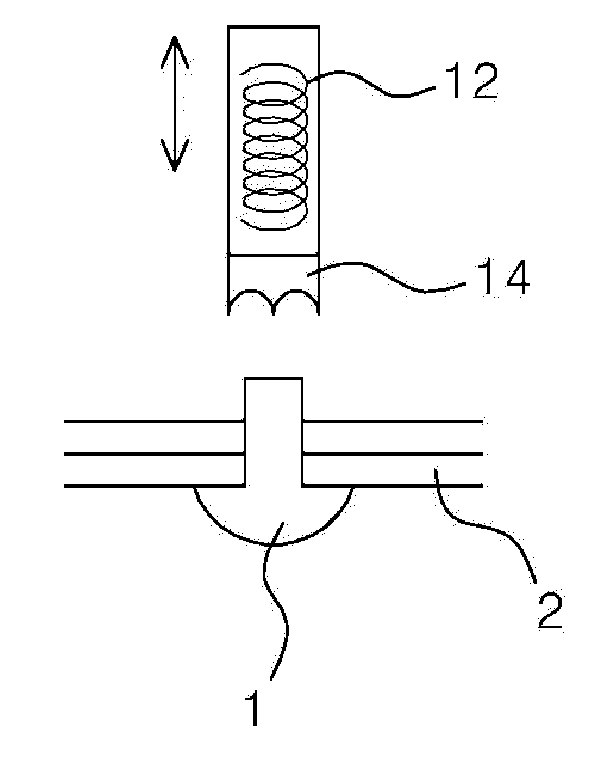

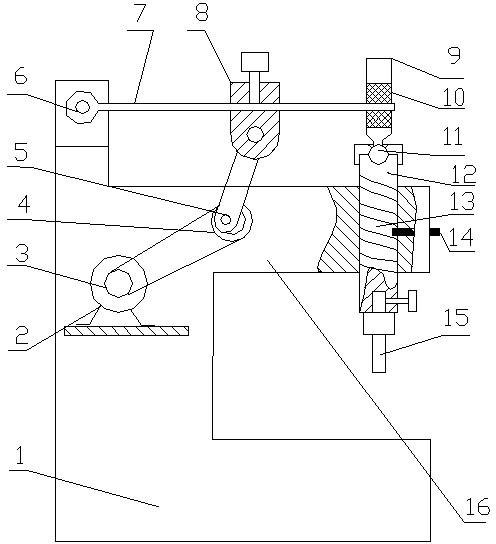

Device and method for self-piercing riveting of half-hole rivet loaded by pulse magnet field force

InactiveCN101817056ARealize stamping self-riveting rivetingIncreasing the thicknessPulse loadLow voltage

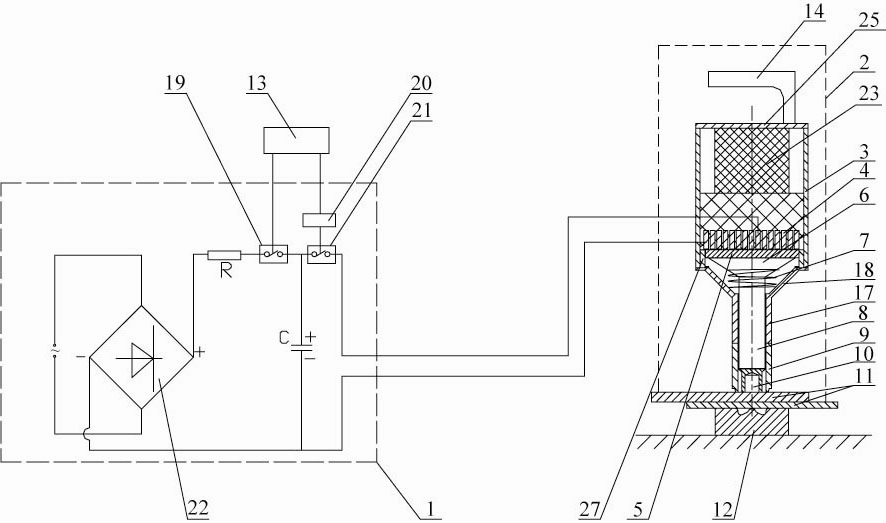

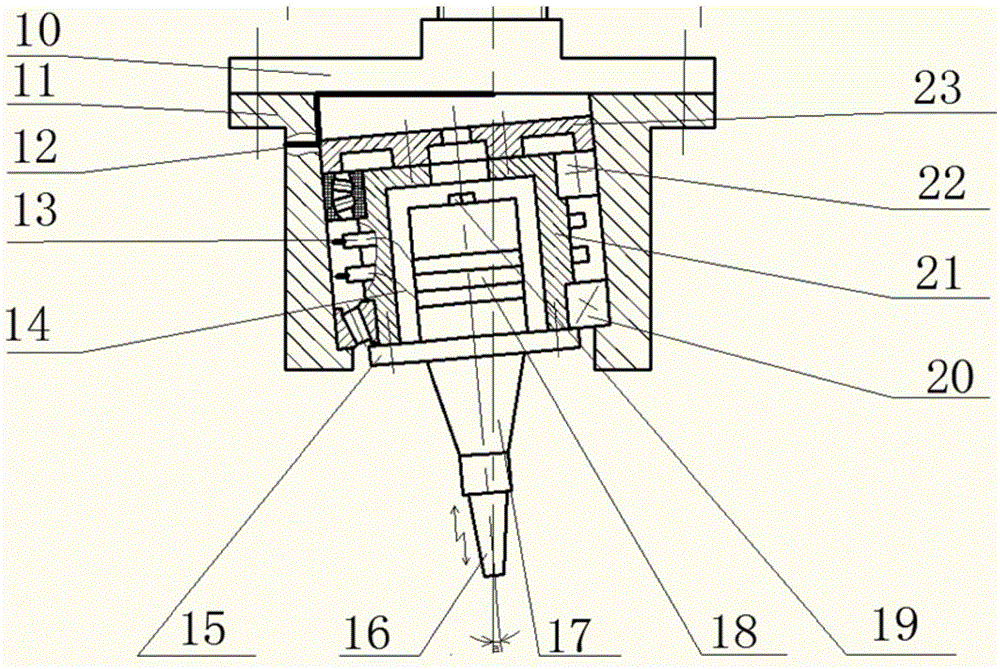

The invention discloses a device and a method for the self-piercing riveting of a half-hole rivet loaded by a pulse magnet field force, which relate to the device and the method for the self-piercing riveting of the half-hole rivet and aim to solve the problem that a conventional punching self-riveting process has the problems of complex riveting process, bad riveting quality and low efficiency in the pre-punching of a riveting component. A punch head is arranged below a stress wave modulator; a female die is arranged under an electromagnetic riveting gun; a control box controls the on / off of an electromagnetic riveting charging switch of a low-voltage electromagnetic riveting device and is connected with the signal input end of a high-voltage pulse generator of the low-voltage electromagnetic riveting device; and the signal output end of the high-voltage pulse generator is used for controlling the on / off of a high-frequency thyristor discharging switch of the low-voltage electromagnetic riveting device. The method comprises the following steps that: firstly, a capacitor bank is charged; secondly, a discharging loop is switched on and the capacitor bank is discharged to apply the action of an axially downward pulse load to a driven piece; and finally, the stress wave modulator is amplified and acts on the half-hole self-punching rivet through the punch head to realize self-punching riveting. The device and the method are used for the self-punching riveting of a connected piece.

Owner:HARBIN INST OF TECH

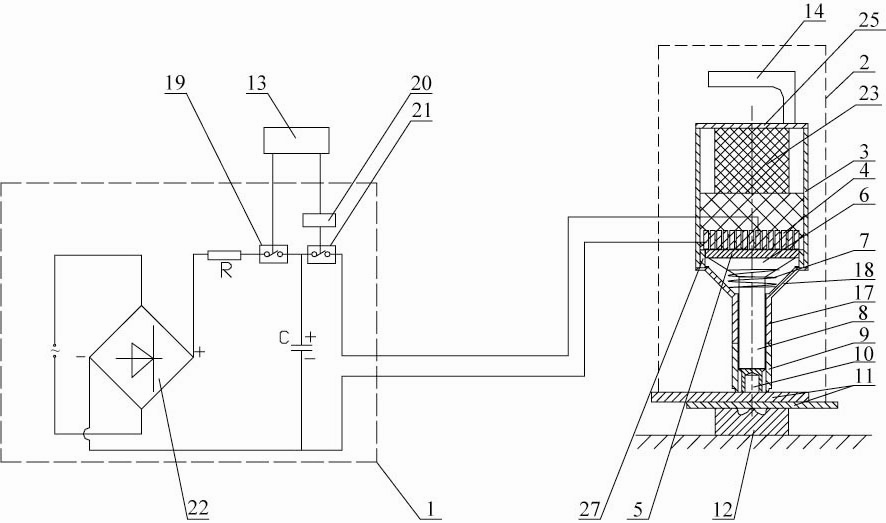

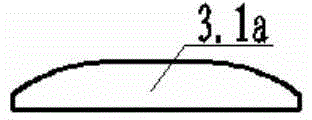

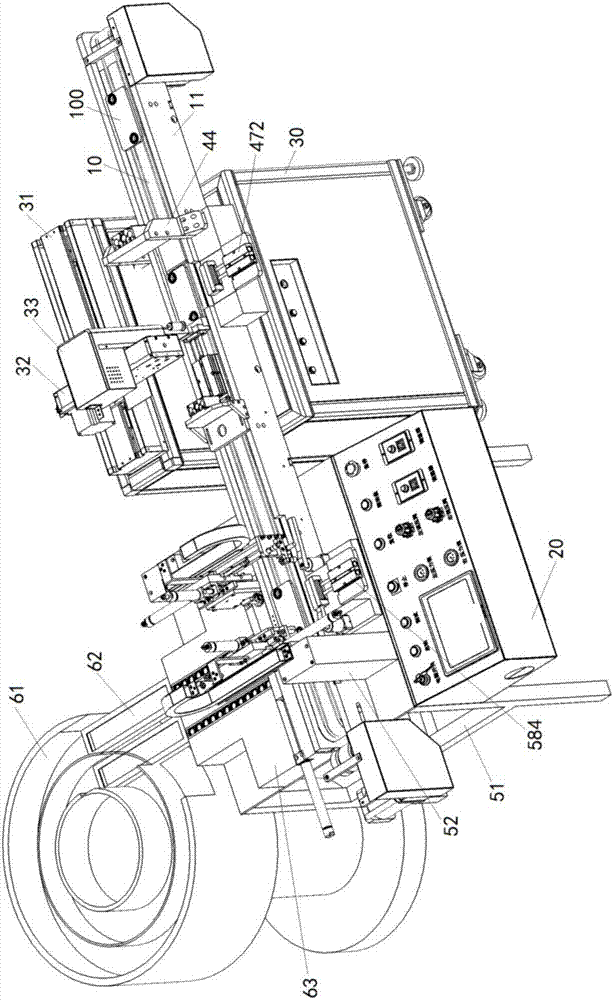

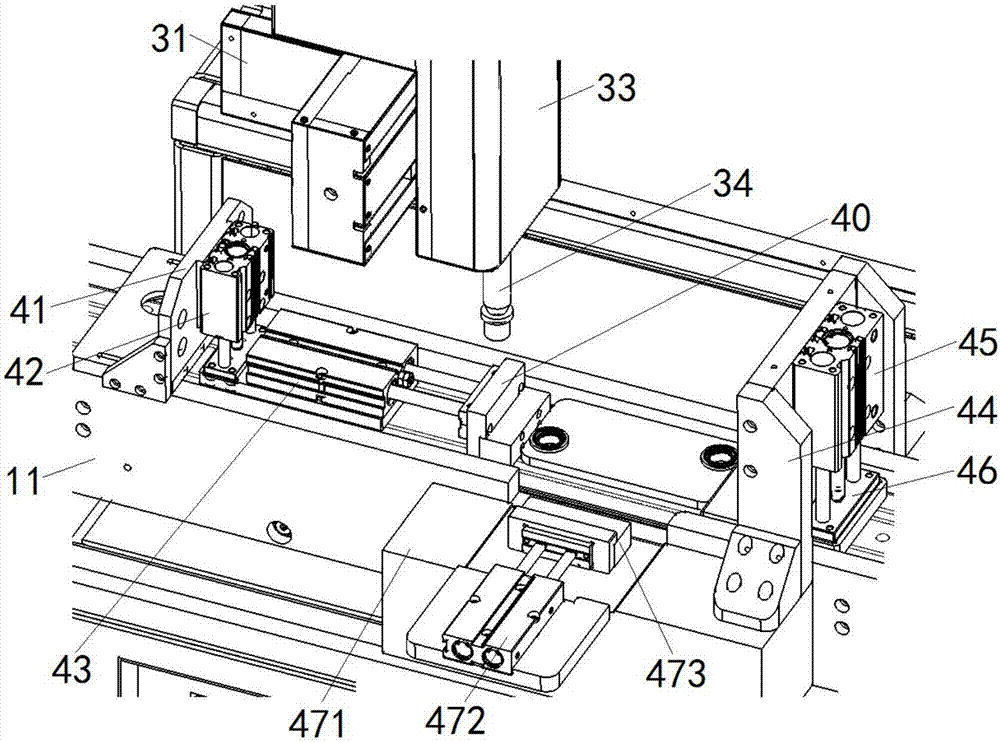

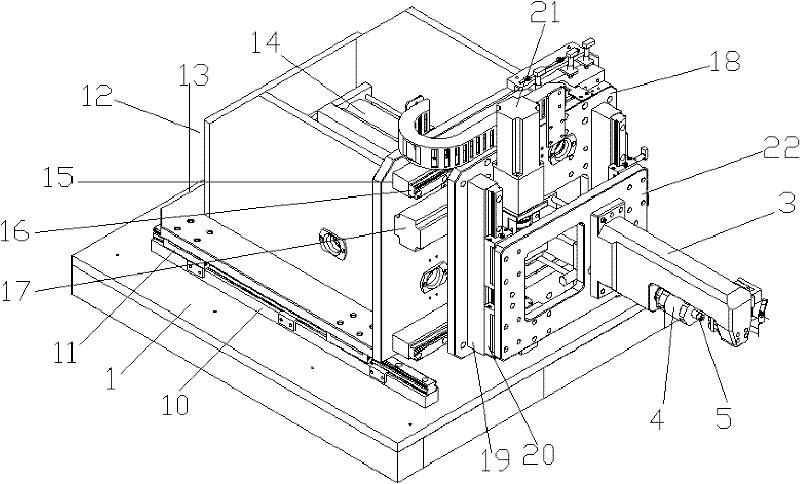

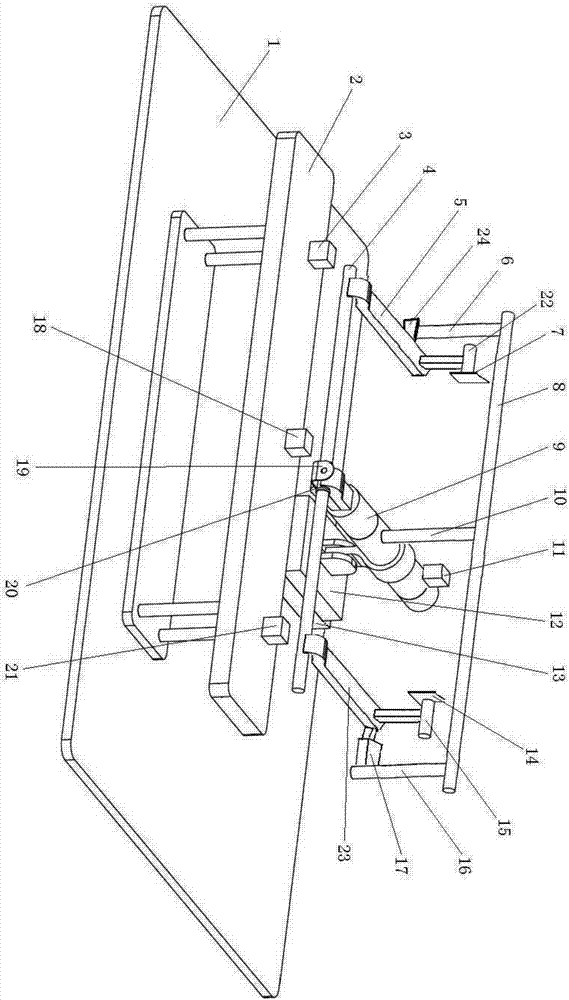

Intelligent flexible production line with double robot cooperative automatic assembling and operation method for same

The invention discloses an intelligent flexible production line with double robot cooperative automatic assembling and operation method for the same. The production line comprises an industrial control computer, a double track moving platform, double industrial robots, a control cabinet, a nail feeding system, a vacuum chip absorbing device, a knife trying station and a flexible tool. With a double-robot cooperative drilling-riveting work mode, the double-robot systems are distributed on two sides of a product, and information is detected by one-side robot to achieve robot pose correction; master-slave distribution of the robots can be dynamically realized during the work; pressure feet can be quickly exchanged upon master-slave switch; a master robot drills and conduct front compression and a slave robot compresses on the back surface of the product; and at last after drilling completion, electromagnetic riveting can be conducted to the double robots. Double-robot cooperative drilling-riveting work can be conducted with high intelligent degree; double-sized drilling and single-sided riveting operations can be completed; burrs can be prevented; and the intelligent flexible production line with double robot cooperative automatic assembling possesses high riveting quality, wide processing range, high flexibility and is suitable for various products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

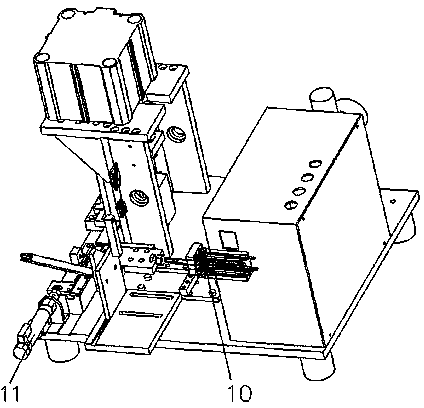

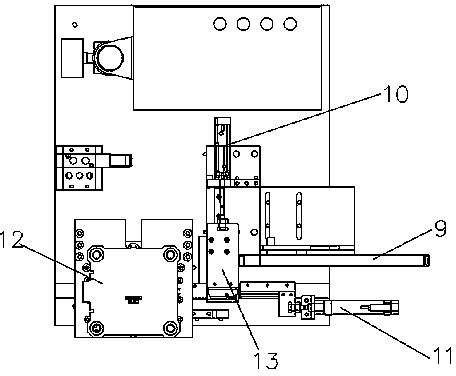

Riveting machine

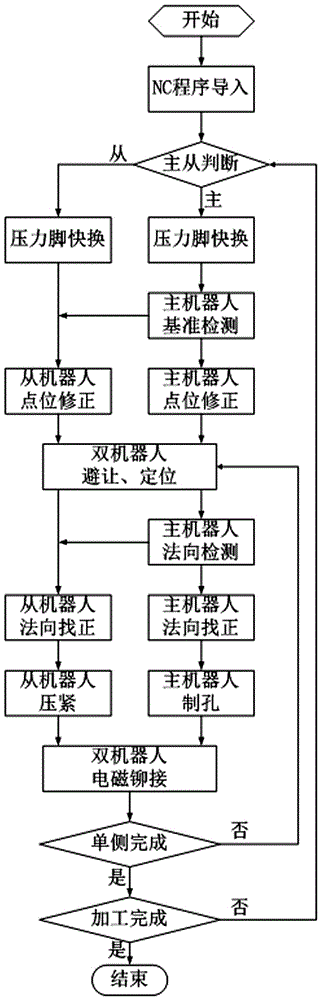

InactiveCN104785647AReduce labor intensityHigh degree of automationMetal-working feeding devicesPositioning devicesEngineeringAutomation

A riveting machine comprises a machine frame, a sheetmetal vibration disc, a sheetmetal output rail, a sheetmetal clamping and horizontally-moving mechanism, a contact vibration disc, a contact output rail, a contact horizontally-moving mechanism, a contact ejecting mechanism, a riveting punch, a riveting punch lifting control mechanism and a collection sliding groove, wherein the contact ejecting mechanism comprises a supporting cushion block and a supporting cushion block lifting control mechanism, a contact accommodating groove is formed in the top of the supporting cushion block, the riveting punch is connected with the power output end of the riveting punch lifting control mechanism, and the riveting punch is located over the contact accommodating groove; the sheetmetal clamping and horizontally-moving mechanism is used for clamping sheetmetal output through the outlet end of the sheetmetal output rail and horizontally moving the sheetmetal to the space under the riveting punch, and the contact horizontally-moving mechanism is used for horizontally moving a contact output through the outlet end of the contact output rail to the contact accommodating groove. According to the riveting machine, the contact and the sheetmetal can be riveted automatically, automation degree is high, operation is easy and safe, production efficiency is high, and riveting quality is stable.

Owner:汕头市潮阳区骏达实业有限公司

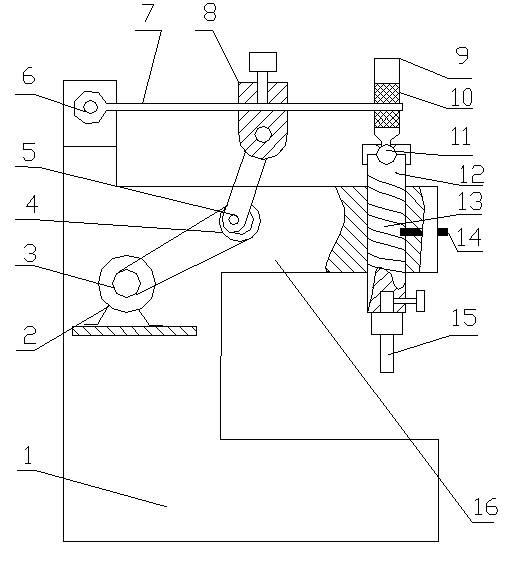

Electromagnetic riveting press suitable for large-diameter rivets and press riveting method thereof

InactiveCN101856713AImprove riveting quality stabilitySolve the strength problemVoltage pulseControl power

The invention discloses an electromagnetic riveting press suitable for large-diameter rivets and a press riveting method thereof, and relates to an electromagnetic riveting press and a press riveting method thereof. A composite structure is riveted by adopting the large-diameter rivets, and the problem of interference quantity and higher electromagnetic riveting requirement operation level are difficultly controlled by adopting hammer riveting and press riveting. An upper riveting die and a stress wave modulator of an electromagnetic riveting gun are jointed or manufactured into a whole; the electromagnetic riveting gun is arranged on a slipway on a horizontal arm; a riveting gun stroke control power source is connected with a control box; the control box is connected with a charge control signal input end of a low-voltage electromagnetic riveting device and a high-voltage pulse generator; the high-voltage pulse generator is connected with a discharge control signal input end of the low-voltage electromagnetic riveting device; positive and negative output ends of discharge signals are connected with two ends of a coil of the electromagnetic riveting gun; and the riveting gun stroke control power source drives the electromagnetic riveting gun to move downwards, a capacitor bank is charged and discharged, and a driving plate is subjected to the axial downward pulse loading effect so that an extended part of a nail bar forms an upset head. The electromagnetic riveting press is used for riveting structural members by the large-diameter rivets.

Owner:HARBIN INST OF TECH

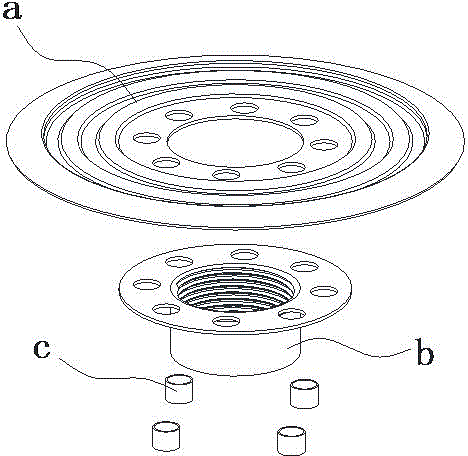

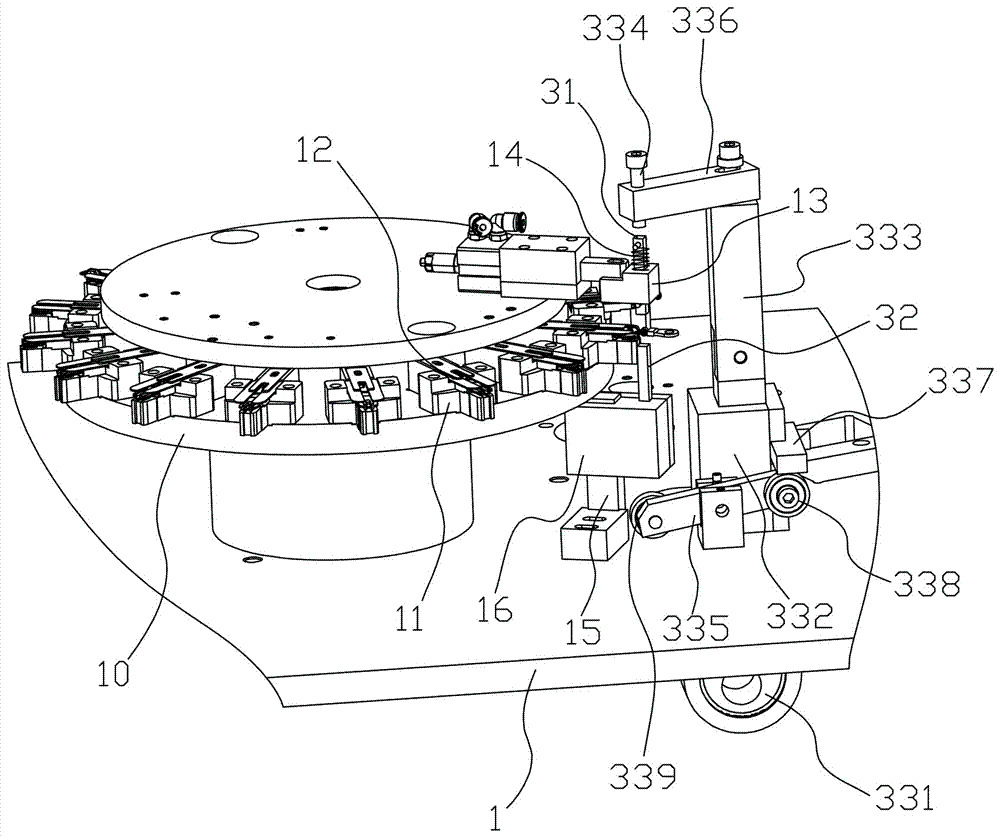

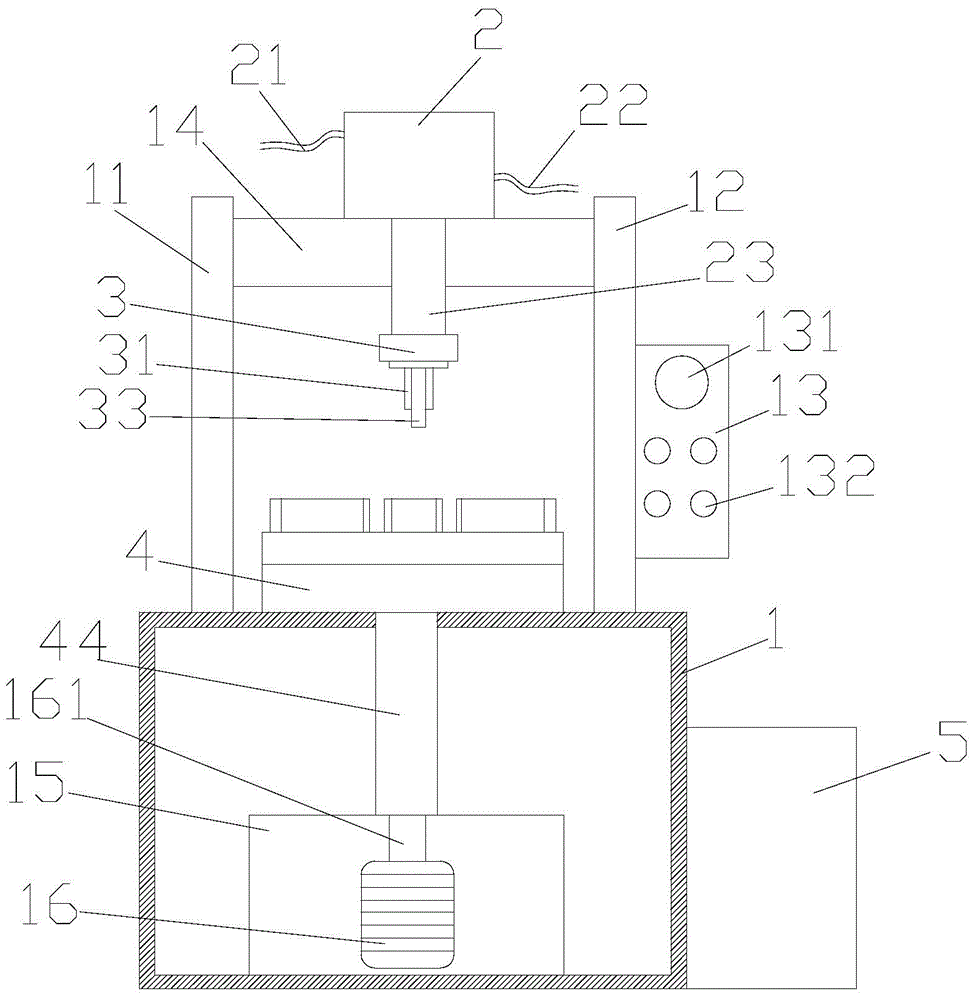

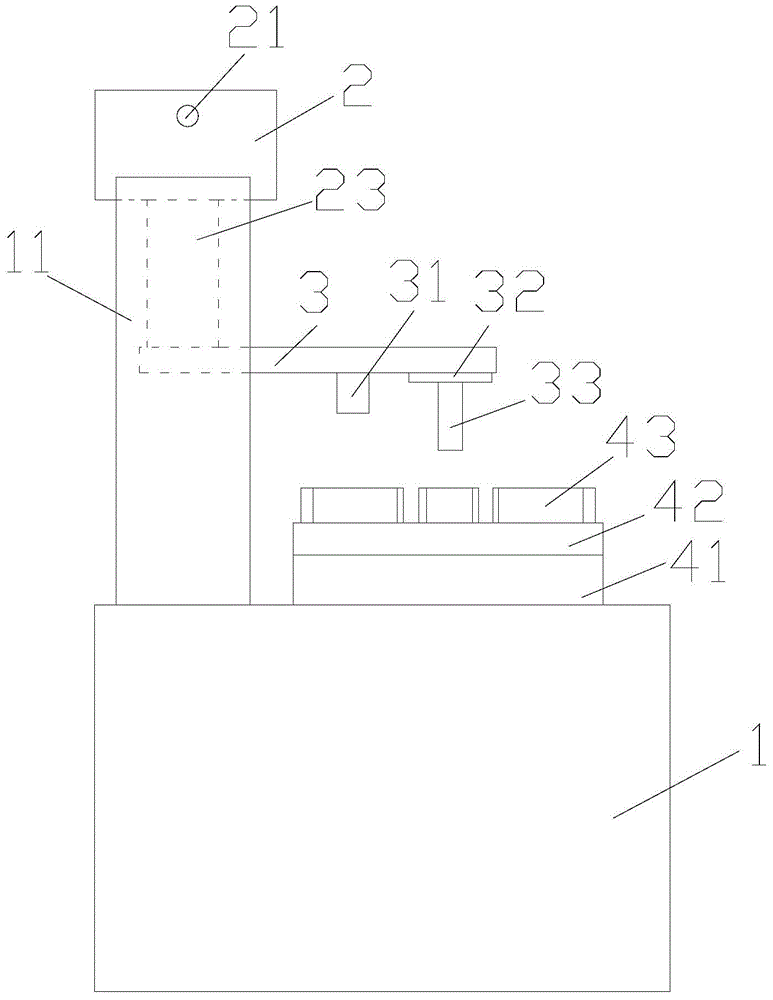

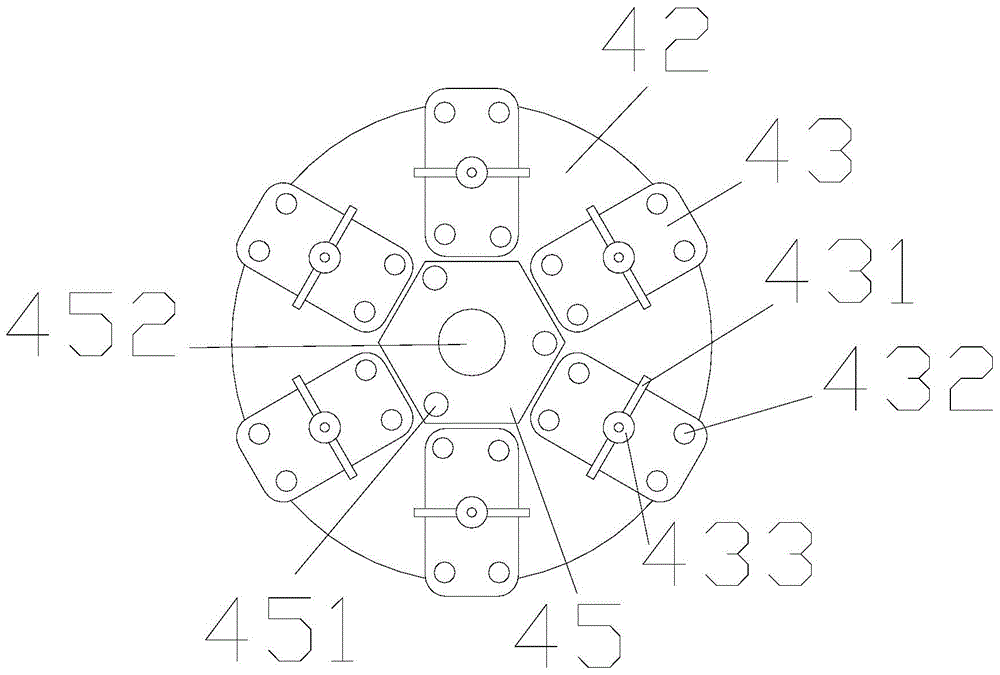

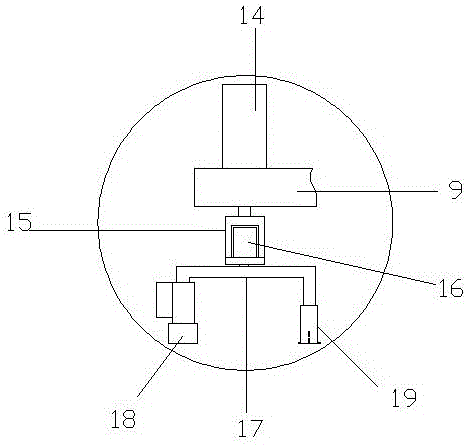

Multi-station rotary riveting machine

The invention belongs to the field of filter manufacture, and particularly relates to a multi-station rotary riveting machine. A plurality of positioning seats are arranged on a rotating plate, an operation worker can continuously perform feeding operation, and the machine is controlled through an automatic system; the positioning seats can automatically enter punching stations for riveting, and the riveting efficiency is greatly improved; meanwhile, an unloading mechanism can automatically eject out riveted end covers from the positioning seats and enables the end covers to fall into a material collecting unit, the production efficiency is greatly improved, and the labor intensity of the operator is reduced; besides, in the down pressing process of a punch, a press plate is firstly attached with one end cover and tightly presses the end cover, a mold plate and a flange on a thread tube cannot rub with each other in the riveting process, the riveting quality is good, and the rivet appearance is attractive.

Owner:蚌埠威诺过滤器有限公司

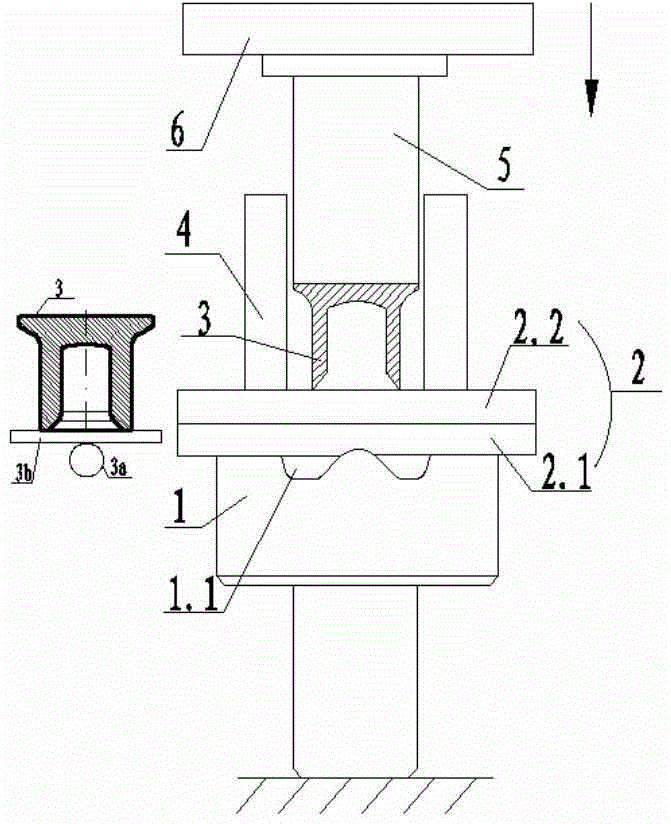

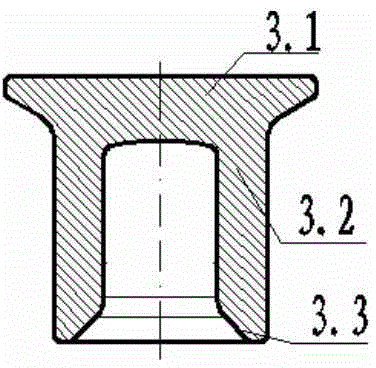

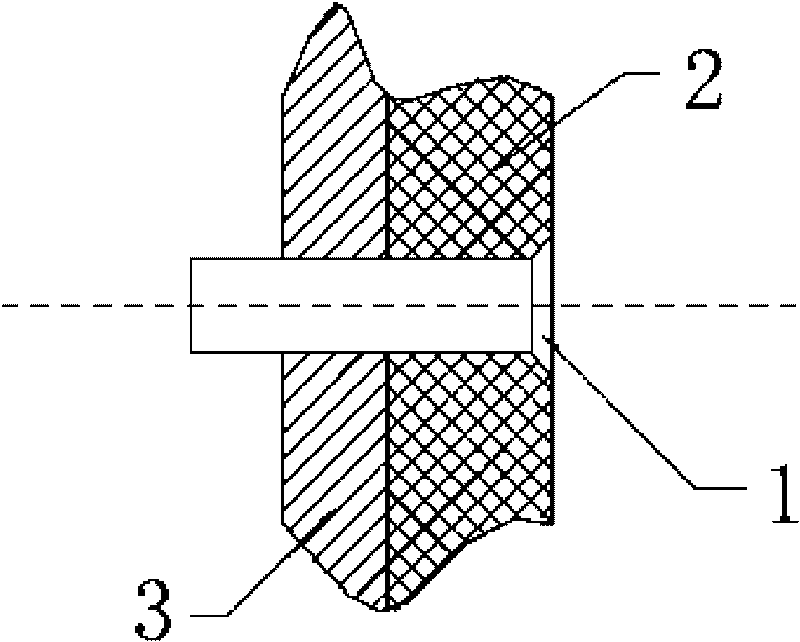

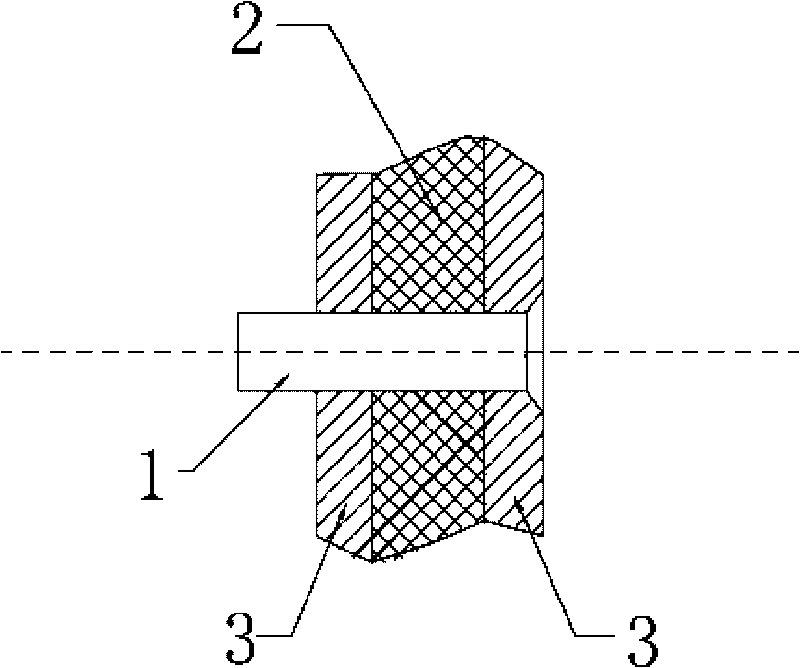

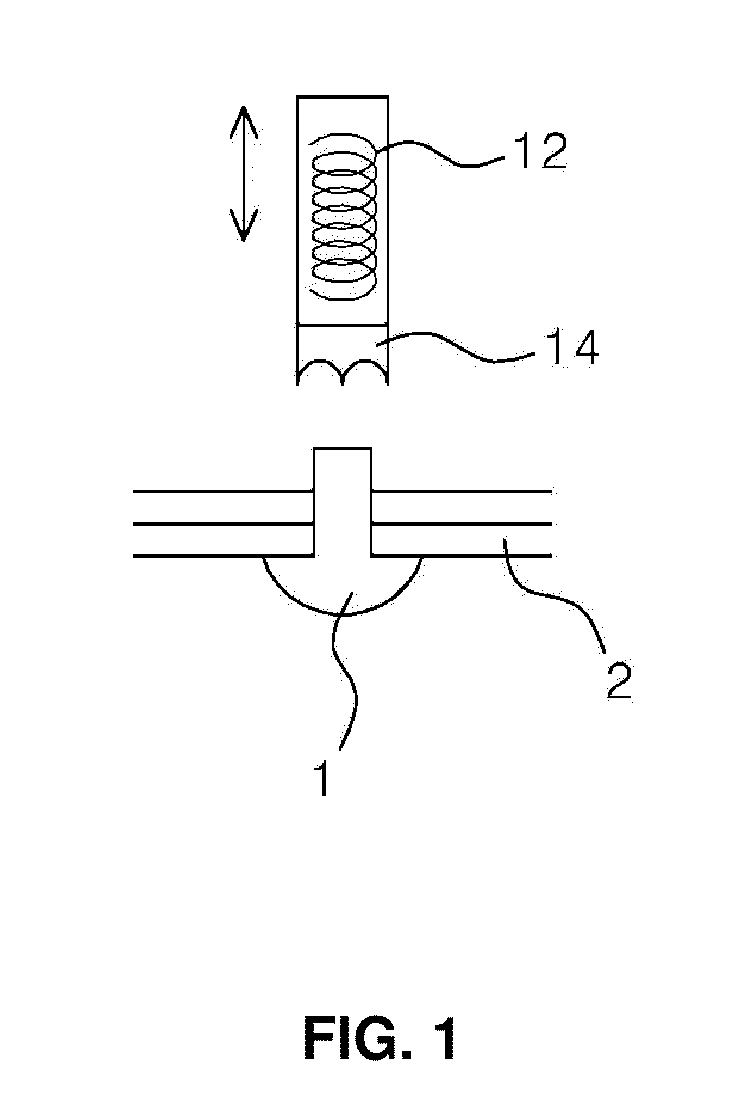

Method and system for self-locking and fixedly connecting thin plate

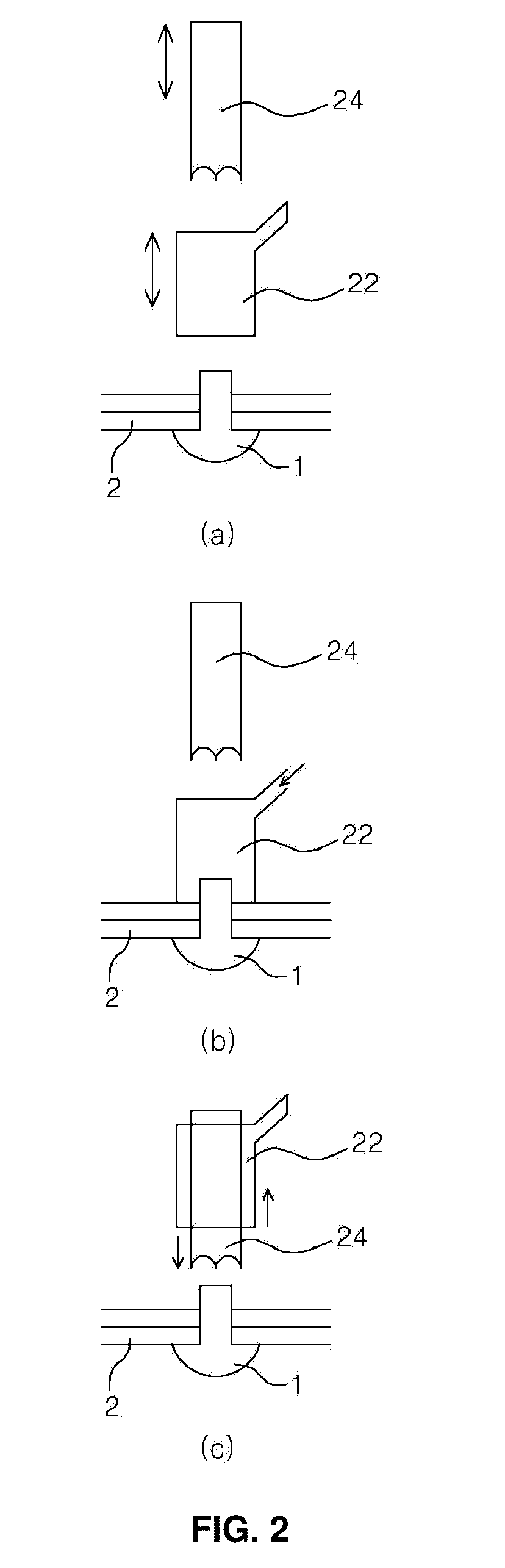

The invention relates to a method and a system for self-locking and fixedly connecting a thin plate. The connecting system is provided with a self-locking rivet with a cylinder rod part with a pointed circular ring at the lower end of the cylinder rod part, a blank holder outside the rivet, the thin plate to be connected, and a female die with an annular groove in the lower part of the female die; the thin plate to be connected has two to three layers, and the elongation rate of the lowest layer is more than or equal to 12 percent; the thickness and the strength from the lowest layer to the top layer are gradually reduced; and the thickness of the lowest layer is more than 1 / 3 of the tot l thickness. When a self-locking riveting tool is used, a drive punch hammer and the blank holder pre-press the thin plate, and the self-locking rivet stabs the thin plate after pressurization, so that the lower part of the thin plate is subject to plastic deformation towards the inner part of the annular groove; and a mechanical self-locking structure is formed after expansion. According to the method and the system for self-locking and fixedly connecting the thin plate, a problem that the thin plate cannot be subject to spot welding can be solved; punching and riveting can be achieved at one time, the efficiency is high, and a time cycle for connecting one rivet is three seconds; products can be manufactured without smoke, gas, spark, dust, scraps and noise, and requirements on connection, automatic mass production and environmental protection of automobile light materials; and the connecting method and the system can be used for the fixed connection of thin aluminum plates, metal and non-metal, painted or cladded ferrous metal and the like.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

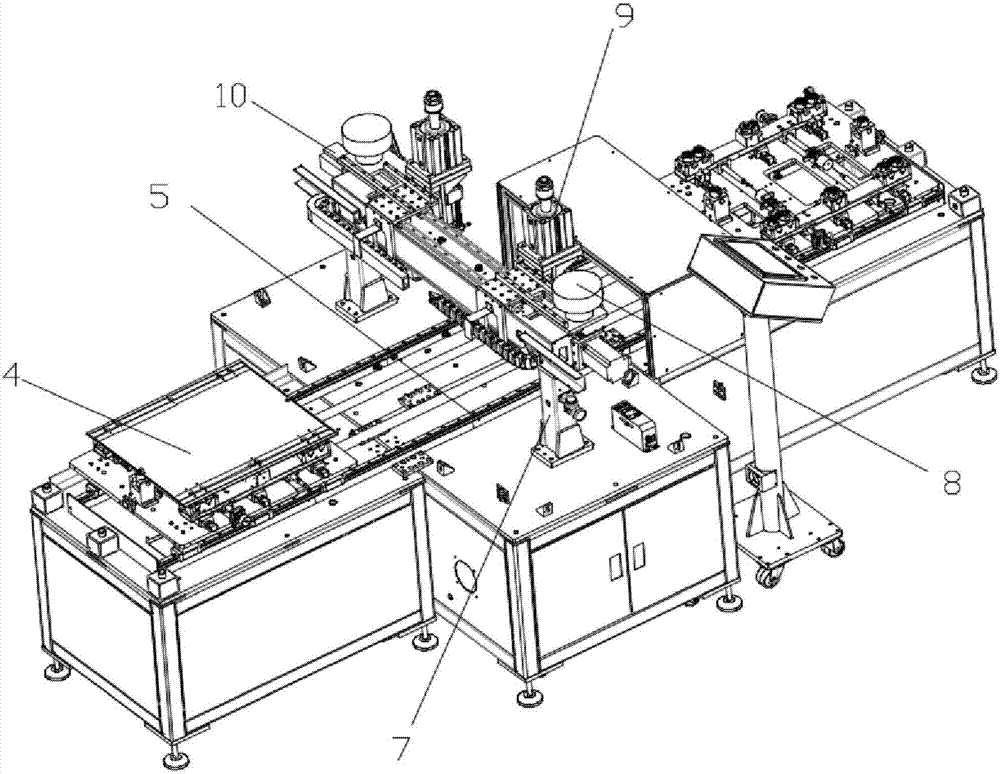

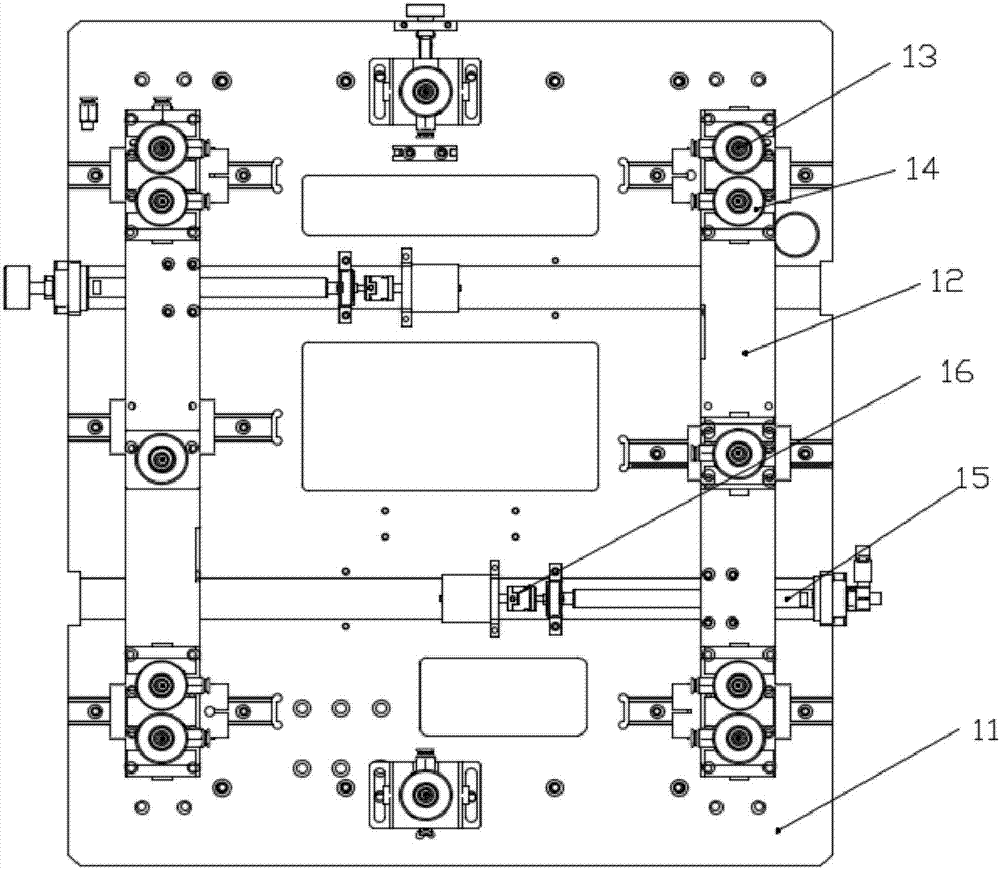

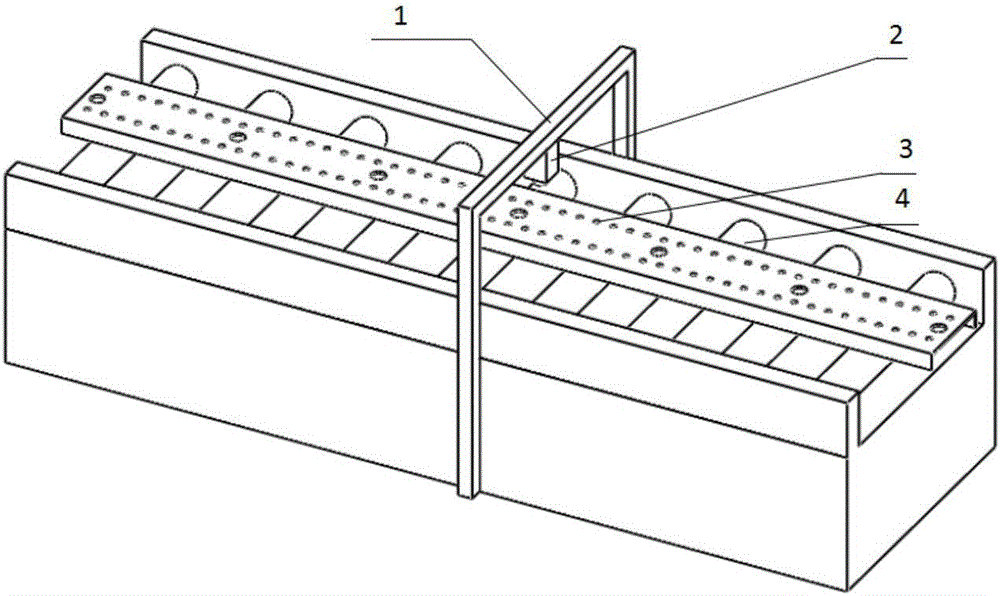

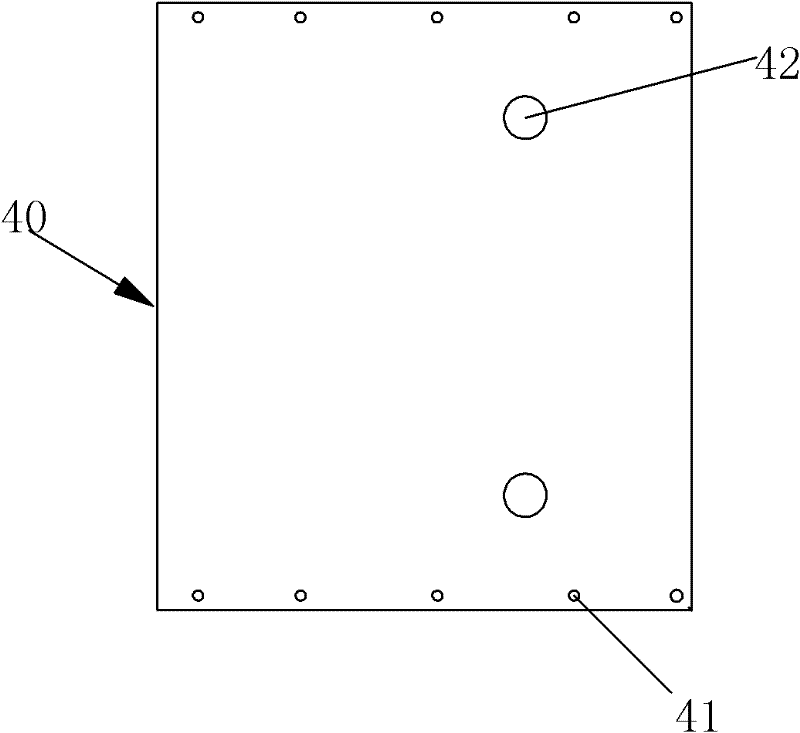

Brand new PCB automatic riveting machine

The invention relates to a brand new PCB automatic riveting machine which comprises a rack, a feed mechanism, a protective cover and two riveting mechanisms. The rack is formed by sequentially connecting a first rack body, a second rack body and a third rack body from left to right. The feed mechanism comprises two feed jigs and a feed guide rail which is arranged on the first rack body, the second rack body and the third rack body. The two feed jigs are movably connected with the portions, above the first rack body and the third rack body, of the feed guide rail correspondingly. The protective cover is arranged on the second rack body. The feed guide rail penetrates through the protective cover. The two riveting mechanism are arranged on the second rack body which is connected with a riveting bracket. The two riveting mechanisms are mounted on the riveting bracket. According to the brand new PCB automatic riveting machine, by adoption of the design, the problems that riveting is slow and scrappage is high during circuit board riveting are solved, and machining time and manufacturing cost are greatly saved.

Owner:昆山敏欣电子有限公司

Automatic frame riveting machine

The invention discloses an automatic frame riveting machine. The automatic frame riveting machine comprises a rotary workbench, a lower frame body feeder, a coil feeder, an upper frame body feeder and a position change riveting device, wherein a lower frame body station, a coil station, an upper frame body station and a riveting station are at least arranged on the outer circumference of the rotary workbench, a workpiece fixing device is installed on each station, the workpiece fixing devices and the rotary workbench rotate at the same time to carry out assembly and riveting operation of solenoid valves, the position change riveting device is composed of a position change mechanism and a double-side riveting mechanism in a combination mode, and the position change mechanism is used for carrying out position change and transfer on a workpiece on the rotary workbench and a riveted workpiece on the double-side riveting mechanism. The automatic frame riveting machine is completely automatic in the whole process, good in riveting quality, high in working efficiency, and suitable for batch production on a large scale.

Owner:XIAMEN METEOR WINDING TECH

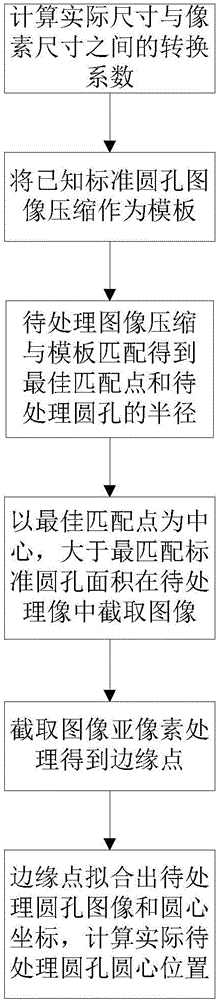

Vision-based identification and locating method for outer beam holes in multilayer beam

ActiveCN106778541AImprove machining accuracyImprove riveting qualityCharacter and pattern recognitionMachine visionConversion coefficients

The invention belongs to the field of machine vision and detection, and discloses a vision-based identification and locating method for outer beam holes in a multilayer beam. The method comprises the steps of (a) calculating a conversion coefficient for converting an actual size into a pixel size; (b) selecting a generation template in a to-be-identified outer beam hole of the multilayer beam, performing template matching on a to-be-identified image, obtaining a size type of the hole, intercepting a new local image by taking an optimal matching point as a center, and performing sub-pixel precision-level edge detection on the new image; and (c) fitting central coordinates of the hole by using edge point data, and performing multiplication by the conversion coefficient to obtain the central coordinates of the to-be-identified outer beam hole of the multilayer beam, thereby realizing the identification and locating of the hole. Through the method, automatic blind hole identification and locating of the outer beam holes in the multilayer beam are realized, the labor intensity of workers is reduced, the machining precision of the outer beam holes and the riveting quality of the multilayer beam are improved, and the production efficiency is improved by multiple times.

Owner:HUAZHONG UNIV OF SCI & TECH

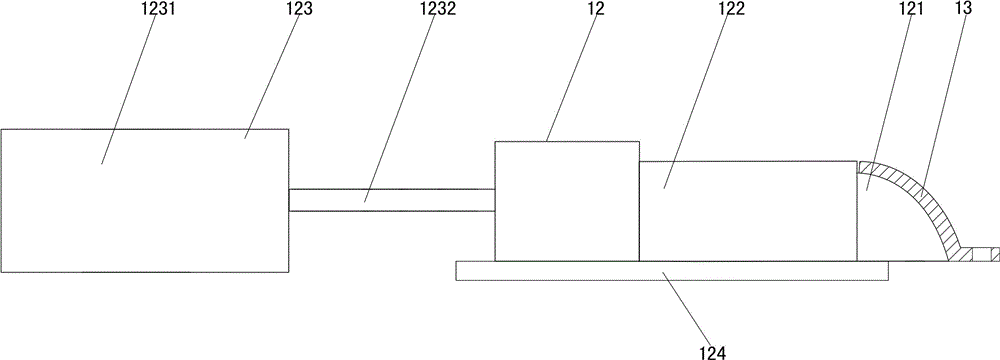

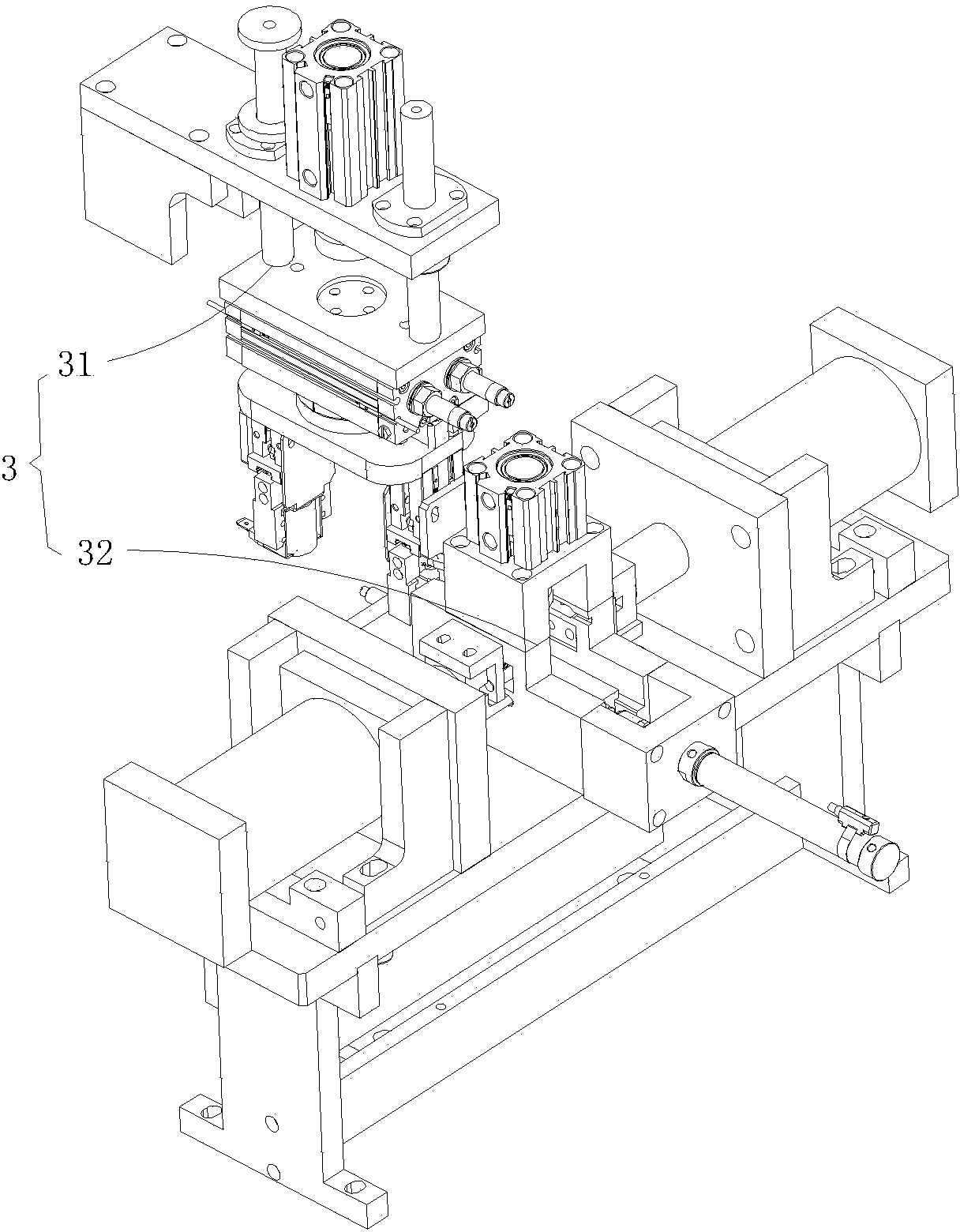

Automated riveting device

ActiveCN107297609AImprove riveting qualityImprove riveting efficiencyPolishing machinesMetal working apparatusEngineeringMachining

The invention discloses an automated riveting device. The automated riveting device comprises a delivering belt, a polishing mechanism, a riveting mechanism, a feeding mechanism and a controlling mechanism, the polishing mechanism comprises a polishing table, an X-axis slide rail, a Y-axis slide rail, a lifting slide rail, a motor mounting plate, a polishing motor and a positioning component; the riveting mechanism comprises a riveting table, a riveting frame, a riveting motor, a horizontal slide rail, a longitudinal slide rail and a rotary pressing strip, the riveting motor is installed on a riveting bottom plate, and the riveting bottom plate is longitudinally and slidably arranged on the longitudinal slide rail; the feeding mechanism comprises a feeding disc, a connecting groove, a feed guiding plate and a feeding arm, and the feed guiding plate is provided with a feed guiding groove and a feeding groove which are horizontally formed and mutually vertically formed; the feeding groove is internally provided with a feeding strip, and the feeding strip is provided with a feed storage hole. The automated riveting device is compact in structure, can automatically load feed and unload feed, automatically conduct polishing and riveting, drastically lower the labor intensity of workers, and simplify the machining procedure, the riveting quality of an end plate is good, and the riveting efficiency is high.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

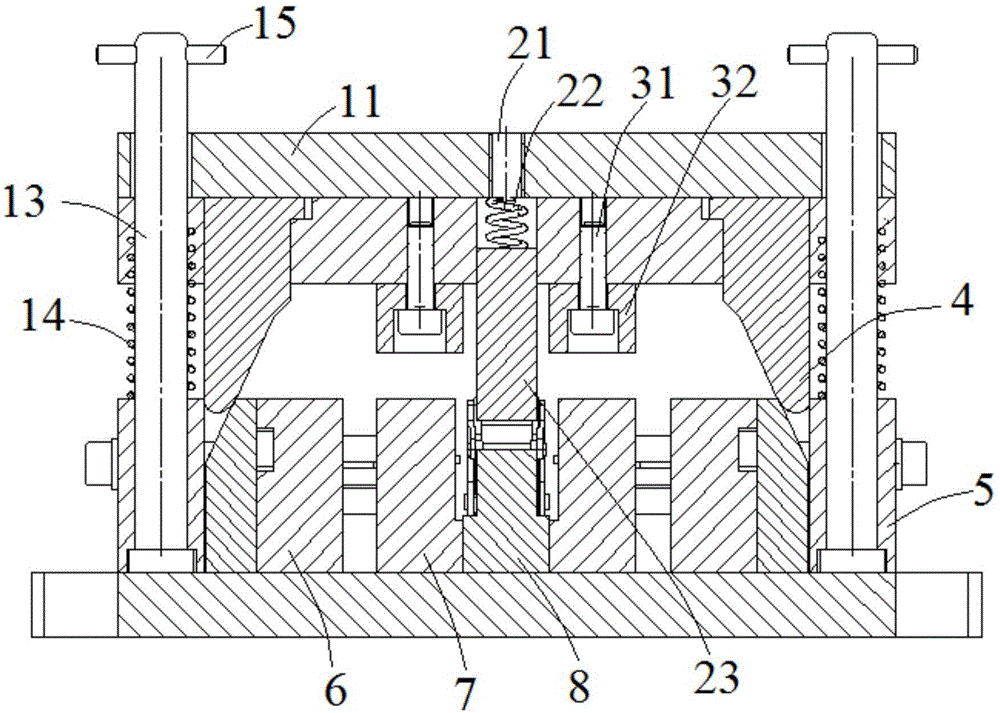

Jump catch clamp, integrated tool for jump catch riveting and flanging and machining method thereof

ActiveCN106653495AEasy to placeNot easy to scatterEmergency protective device manufactureEngineeringMechanical engineering

The invention discloses a jump catch clamp, an integrated tool for jump catch riveting and flanging and a machining method thereof, and the jump catch clamp is a special clamp. The tool disclosed by the invention comprises an upper die, a guide post, a guide post spring, a base plate, sliding block assemblies, a first lower die upright post plate and the jump catch clamp, wherein the guide post is serially connected to the upper die, the first lower die upright post plate and the base plate; the guide post spring is arranged on the guide post in a penetrating manner; the jump catch clamp can be inserted in a drawer groove in the middle part of the base plate; the sliding block assemblies capable of moving horizontally are arranged on the left side and the right side of the jump catch clamp; a riveting punch is arranged on the side, close to the jump catch clamp, of each sliding clock assembly, and an inclined wedge surface is arranged on the other side of each sliding block assembly; an inclined pressing block is arranged above each inclined wedge surface; the inclined pressing blocks are connected with the upper die; and the inclined pressing blocks are provided with inclined wedge surfaces matched with the inclined wedge surfaces of the sliding block assemblies. The jump catch can be assembled at a time, the riveting and flanging quality is reliable, and the production efficiency is improved.

Owner:JIANGSU DAQO KFINE ELECTRIC

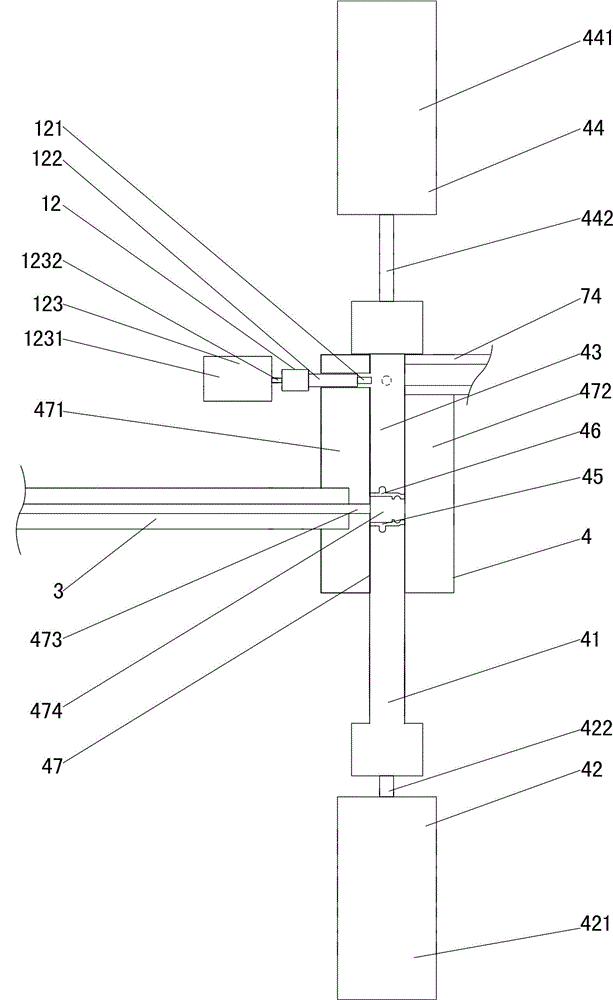

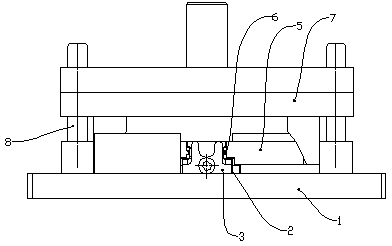

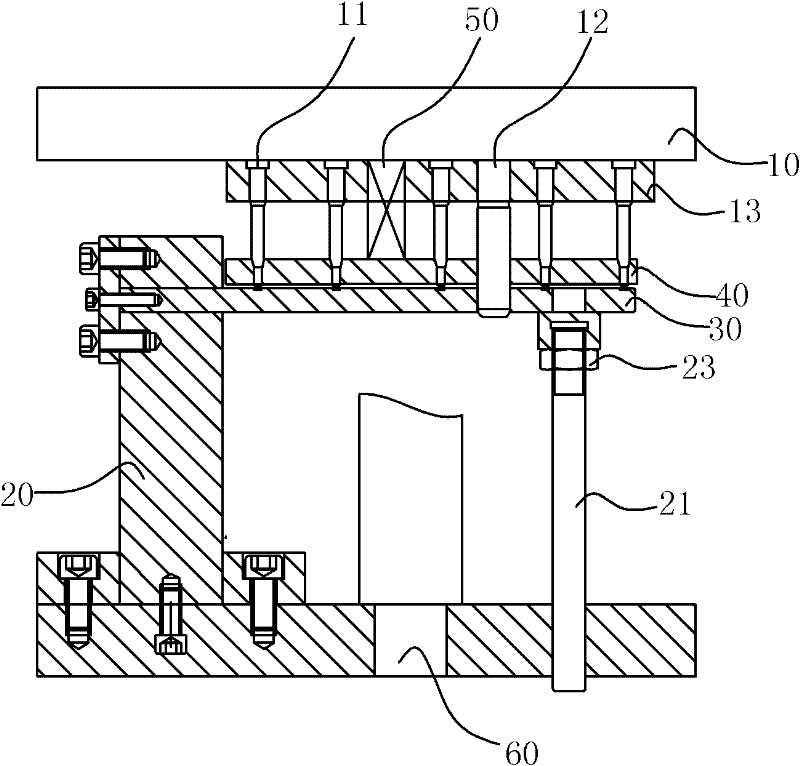

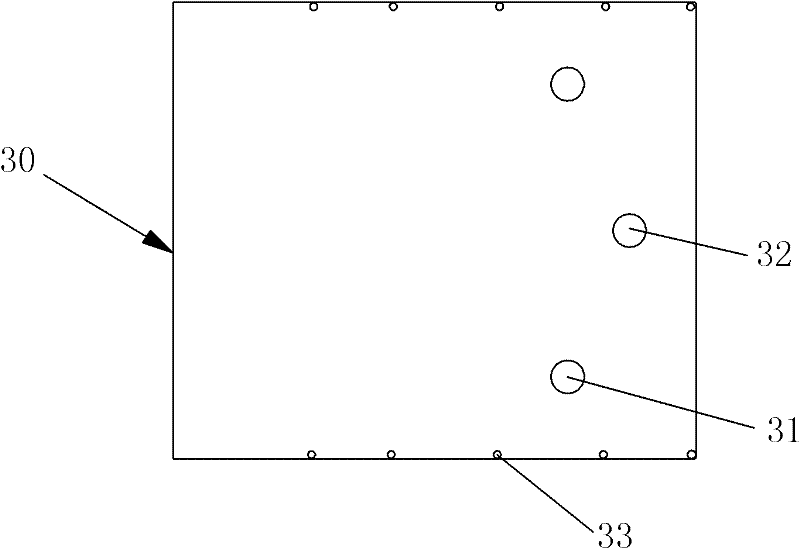

Riveting pressing forming device for cover plate of automobile clutch booster

The invention discloses a riveting pressing forming device for a cover plate of an automobile clutch booster. The riveting pressing forming device for the cover plate of the automobile clutch booster comprises a base plate, wherein a positioning base is arranged on the base plate; a positioning cylinder is arranged rightly opposite to the positioning base; a pressing block is arranged on the positioning cylinder; a riveting cylinder is arranged on the base plate; the output end of the riveting cylinder is connected with the riveting assembly; a pressing cylinder is arranged below the base plate of the corresponding riveting cylinder; the output end of the pressing cylinder is connected with the pressing assembly; the riveting assembly comprises an installing base and a hinging pressing head; the installing base is fixedly installed on the base plate; the hinging pressing head are hinged with the installing base and the output end of the riveting cylinder; an installing plate is fixedly arranged on the base plate; the end part of the riveting cylinder is hinged with the installing plate; the pressing assembly comprises a pressing plate; the pressing plate is fixedly connected with the output end of the pressing cylinder vertically; and the pressing cylinder is fixed below the base plate through a fixing plate. The riveting pressing forming device for the cover plate of the automobile clutch booster has good riveting quality; in the riveting process, the damage to an electrophoretic paint layer at a cover plate forming position is avoided; the consistency of products is good; and the production efficiency is high.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

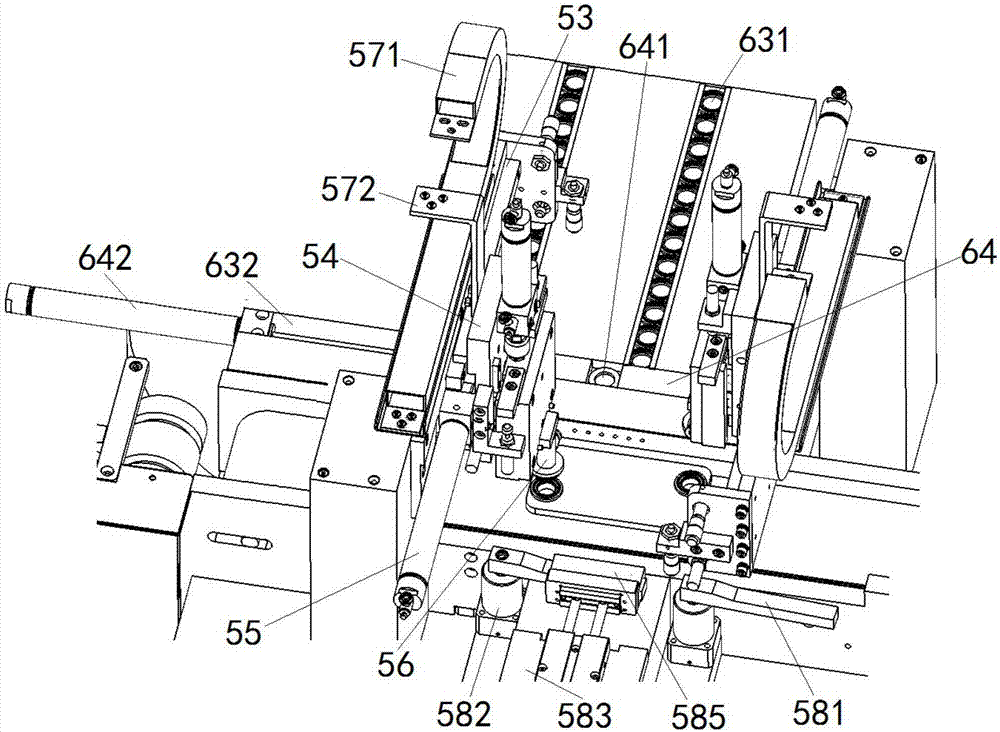

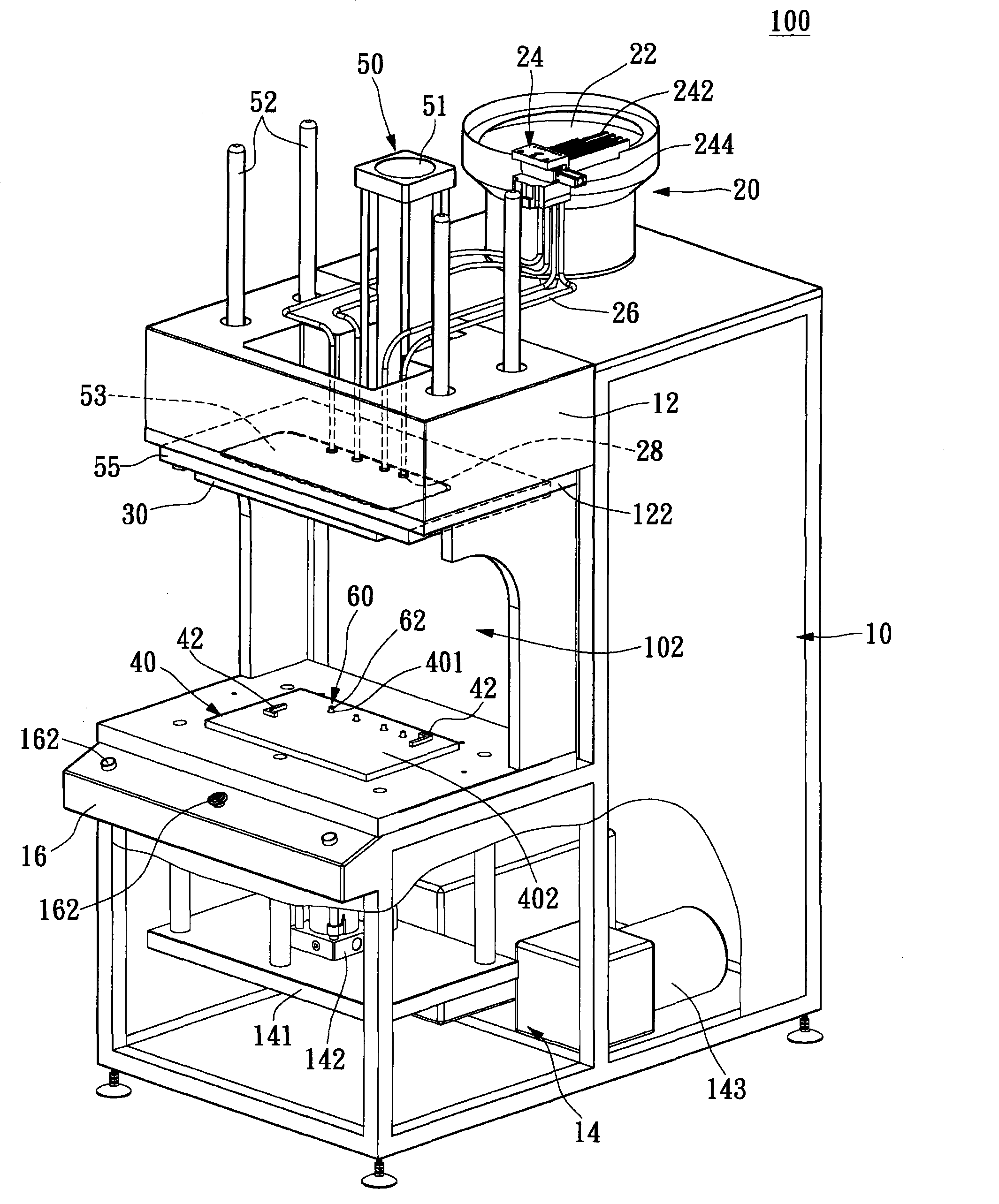

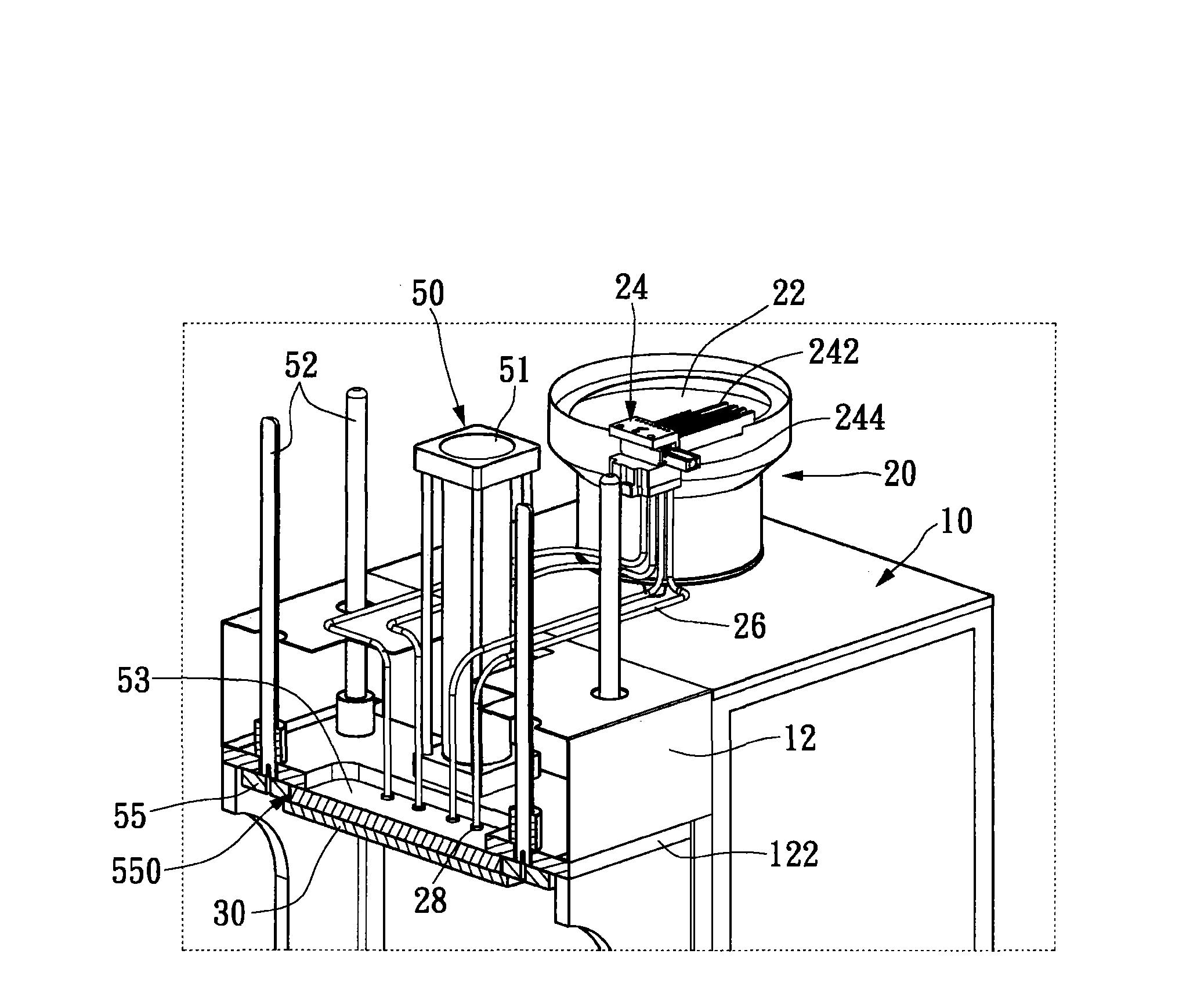

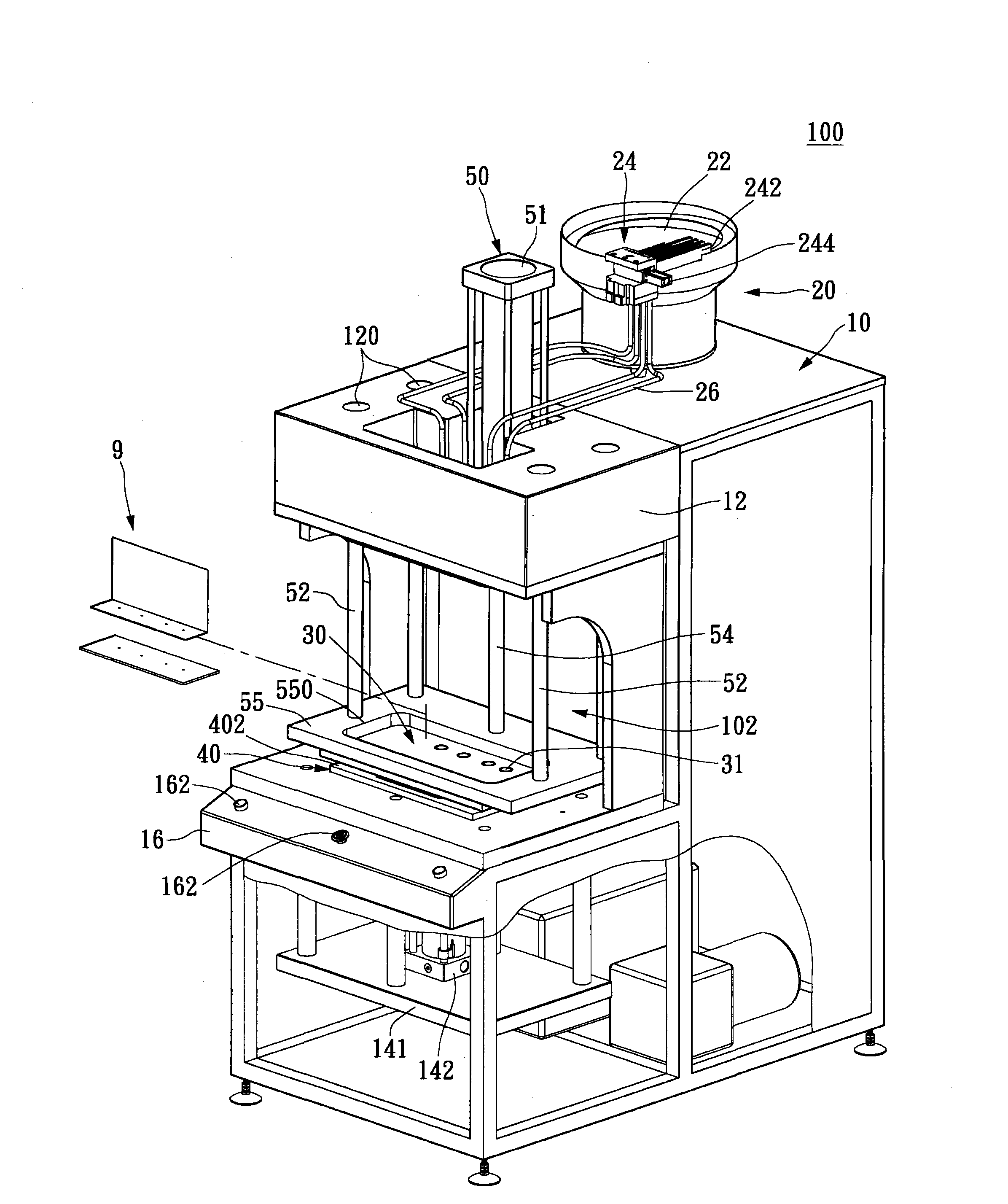

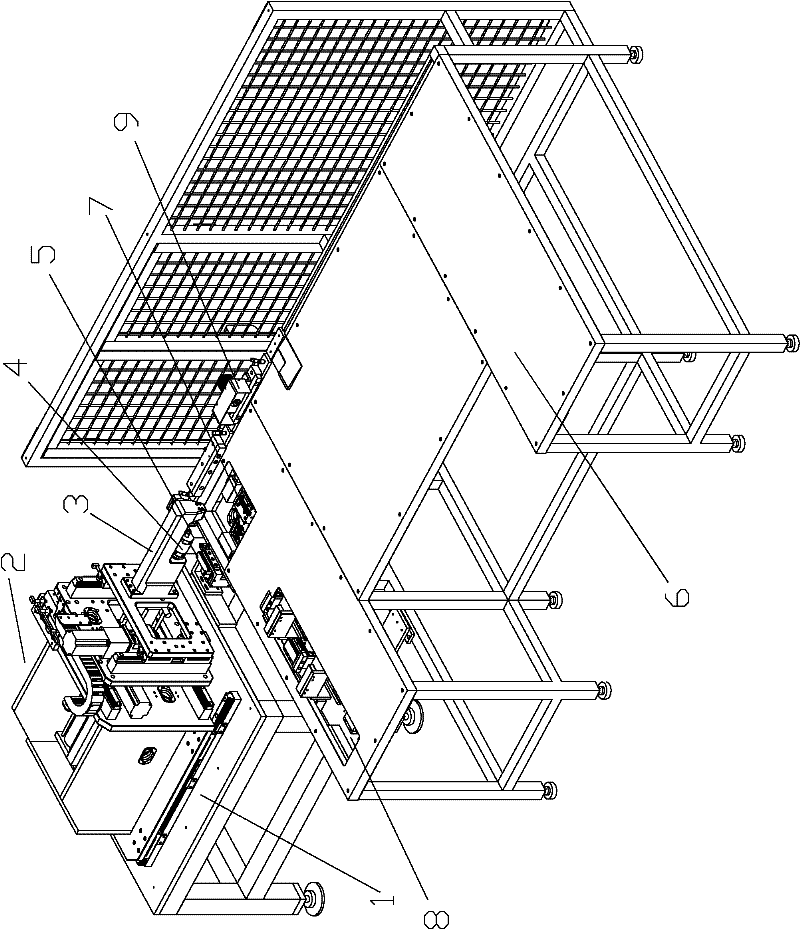

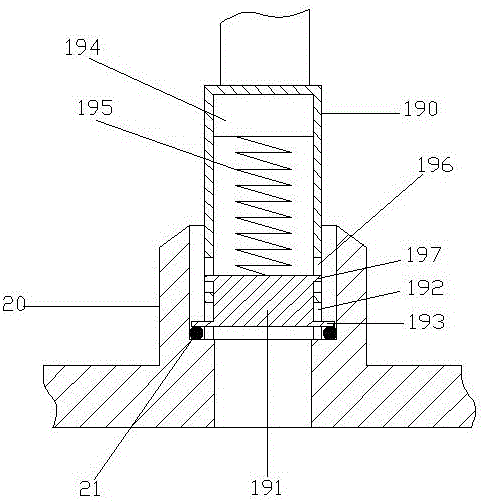

Automatic loading and setting blind rivet mechanism

The invention provides an automatic loading and and setting blind rivet mechanism, comprising one machine base provided with a working area, a rivet-supplying device disposed on the top surface of the machine base, a rivet-setting plate provided with a plurality of rivet-setting devices, a rivet gun fixing member and a lifting device. The rivet-supplying device comprises a shock device, a rivet-distributing device abutting against the shock device and a plurality of rivet-guiding pipes connected with the rivet-distributing device. The rivet-setting plate is disposed in a working area and provided with the plurality of rivet-setting devices; bottom outlets of the rivet-guiding pipes correspond to the plurality of rivet-setting devices to guide the blind rivets into the plurality of rivet-setting devices; the rivet gun fixing member is disposed below the rivet-setting plate and fixedly provided with a plurality of rivet guns thereblow, each rivet gun being provided with a gun tips; the lifting device moves the rivet-setting plate to be close or far from the rivet gun fixing member, so that a plurality of rivet guns enter the rivet-setting devices of the rivet-setting plate to insert the blind rivets on a plurality of gun tips. The automatic loading and setting blind rivet mechanism can automatically filling the blind rivet, so as to save manpower for filling the blind rivet.

Owner:LITE ON TECH CORP

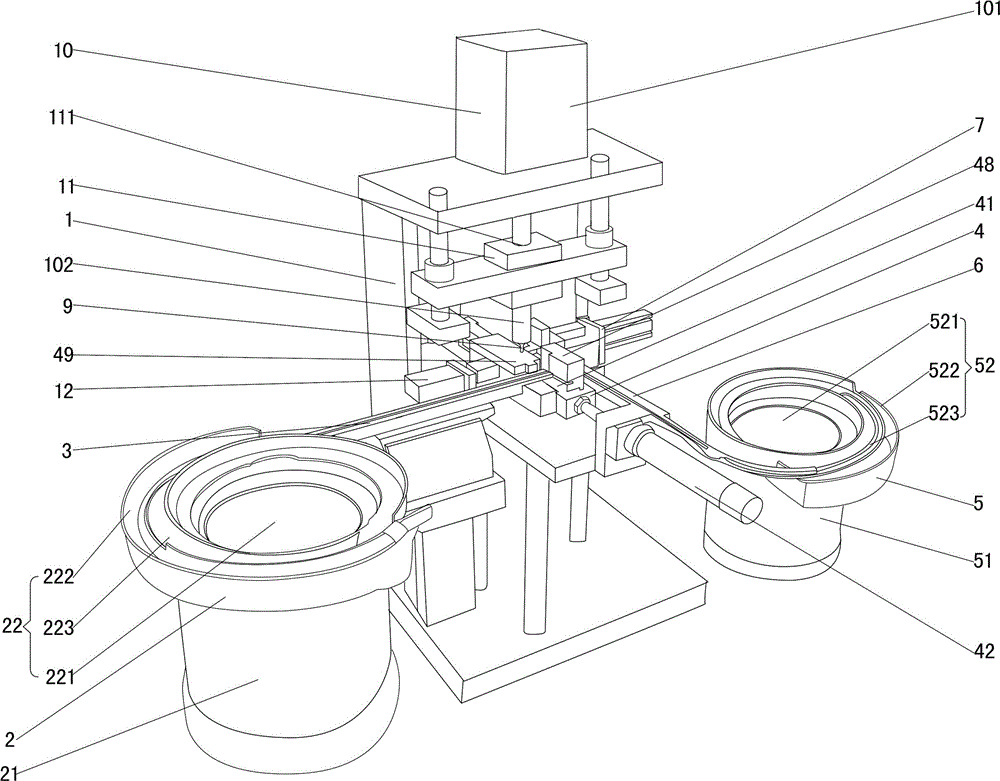

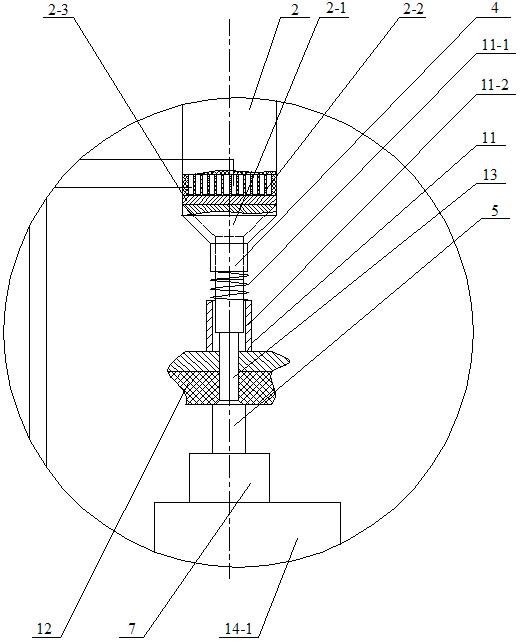

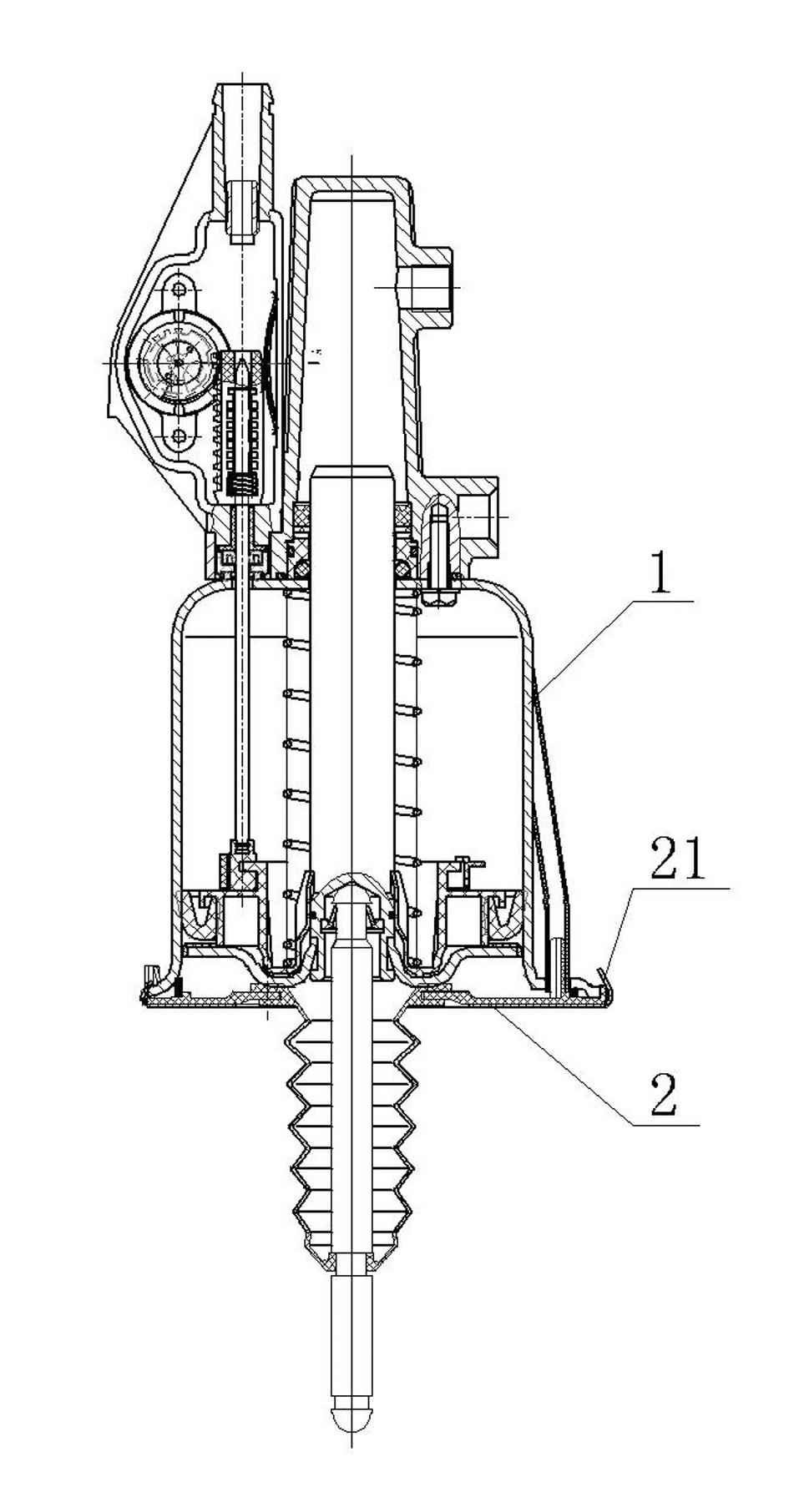

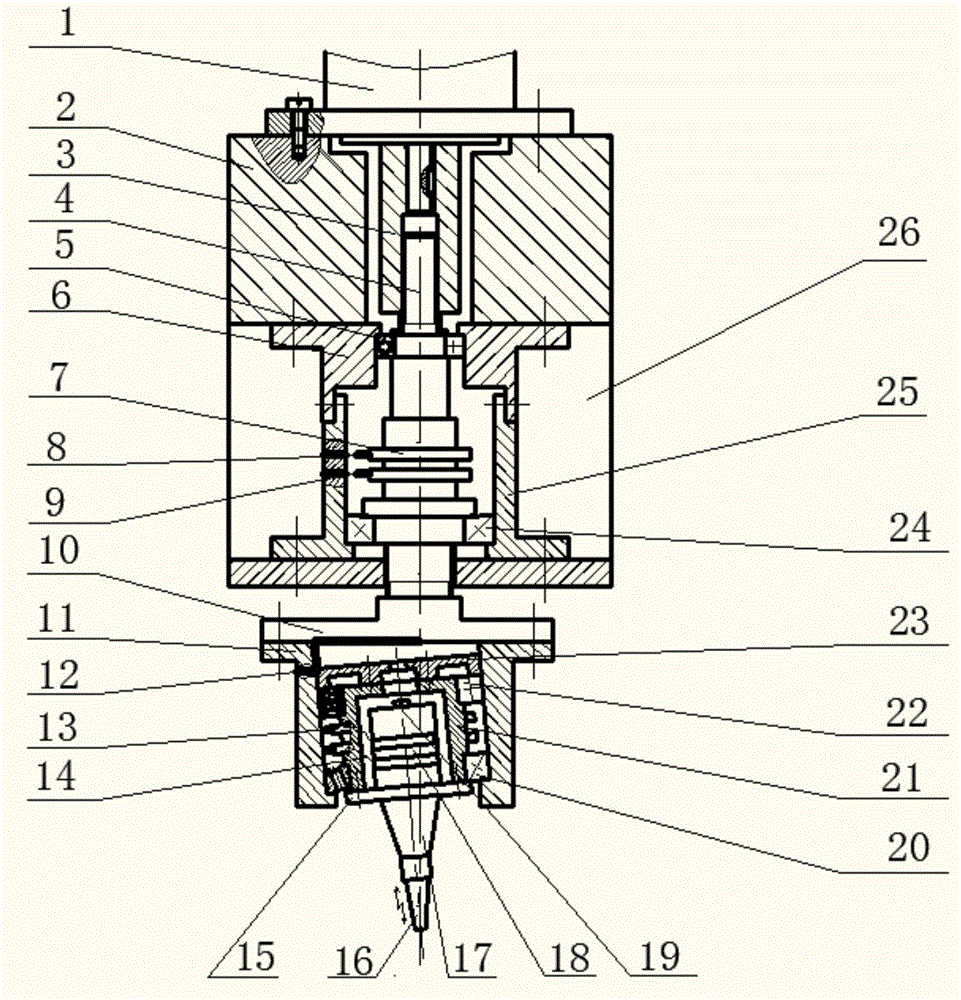

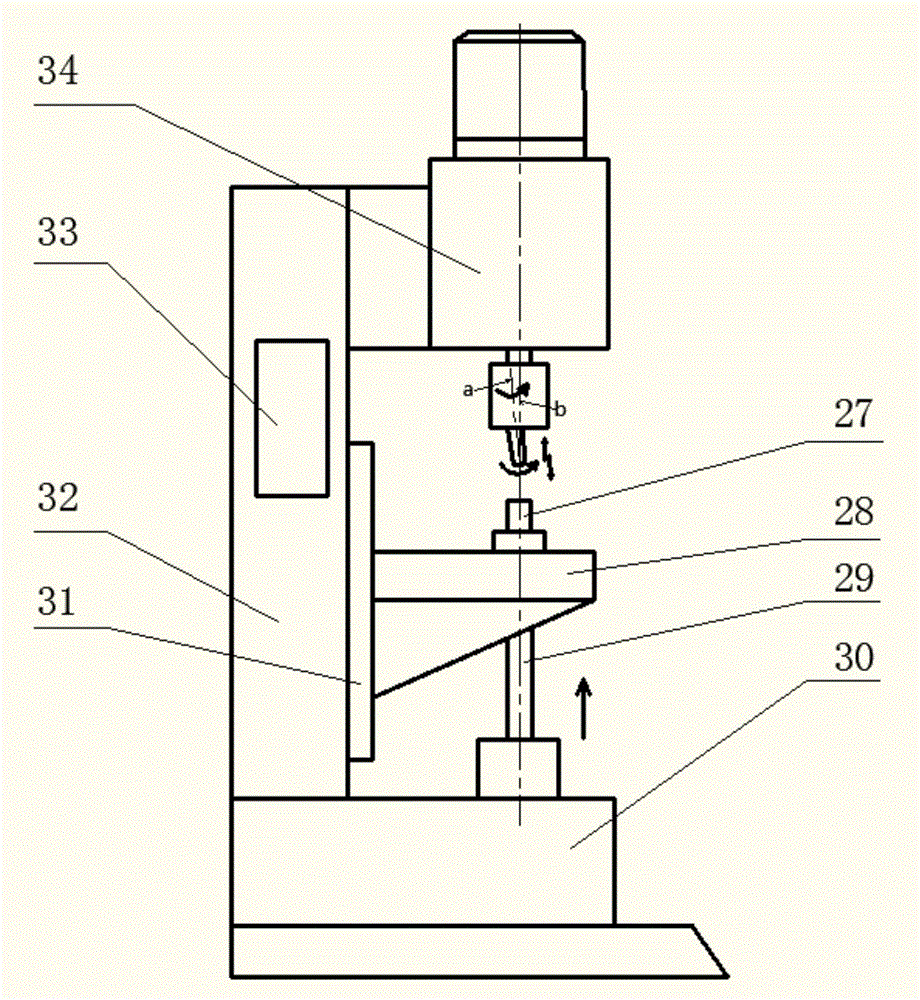

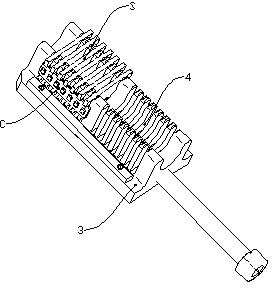

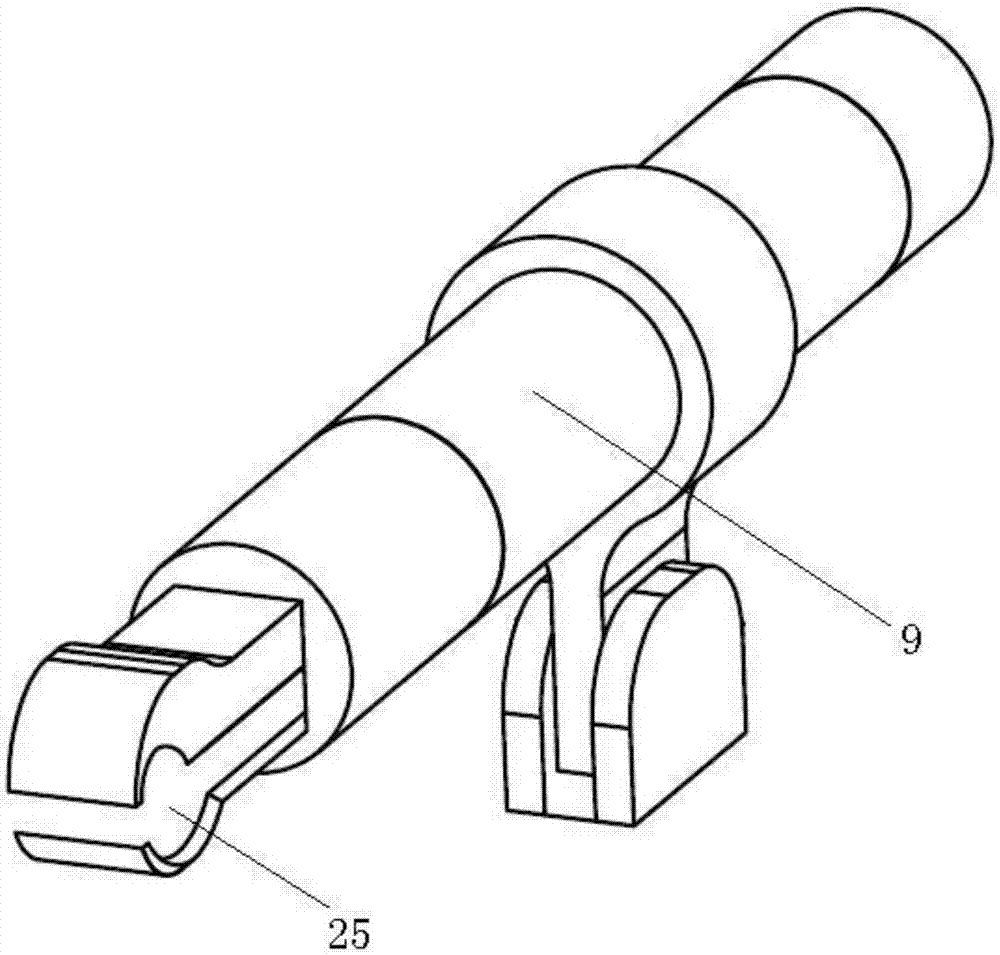

Supersonic vibration spin riveting machine

The invention discloses a supersonic vibration spin riveting machine. The supersonic vibration spin riveting machine comprises an upper riveting head (16) which is connected with an amplitude transformer (17). The supersonic vibration spin riveting machine is characterized in that the amplitude transformer (17) is connected with a high frequency transducer (18), and the high frequency transducer (18) is installed in an inner sleeve (21); the inner sleeve (21) is installed in a cylindrical lower bearing pedestal (11) and connected with a connecting end base (10), the connecting end base (10) is connected with the lower end of a main shaft (4), and the upper end of the main shaft (4) is connected with a motor (1); a first electricity collecting ring (7) is installed in the middle of the main shaft (4) and connected with a first wire (9) and an outer guide line through a carbon brush (8) and transmits high frequency electrical signals obtained from an ultrasonic generator; and a second electricity collecting ring (13) transmits the high frequency electrical signals of the first electricity collecting ring (7) to the transducer (18) through a second wire (12), so that the transducer (18) generates high frequency mechanical vibration to drive the amplitude transformer (17) to do high-frequency vibration. By means of the supersonic vibration spin riveting machine, the riveting force can be reduced, and the riveting efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

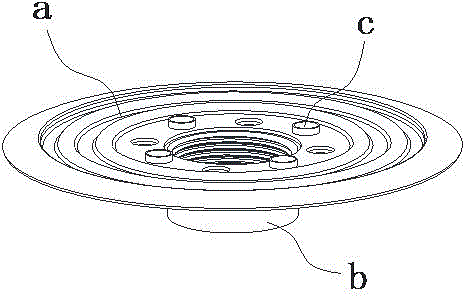

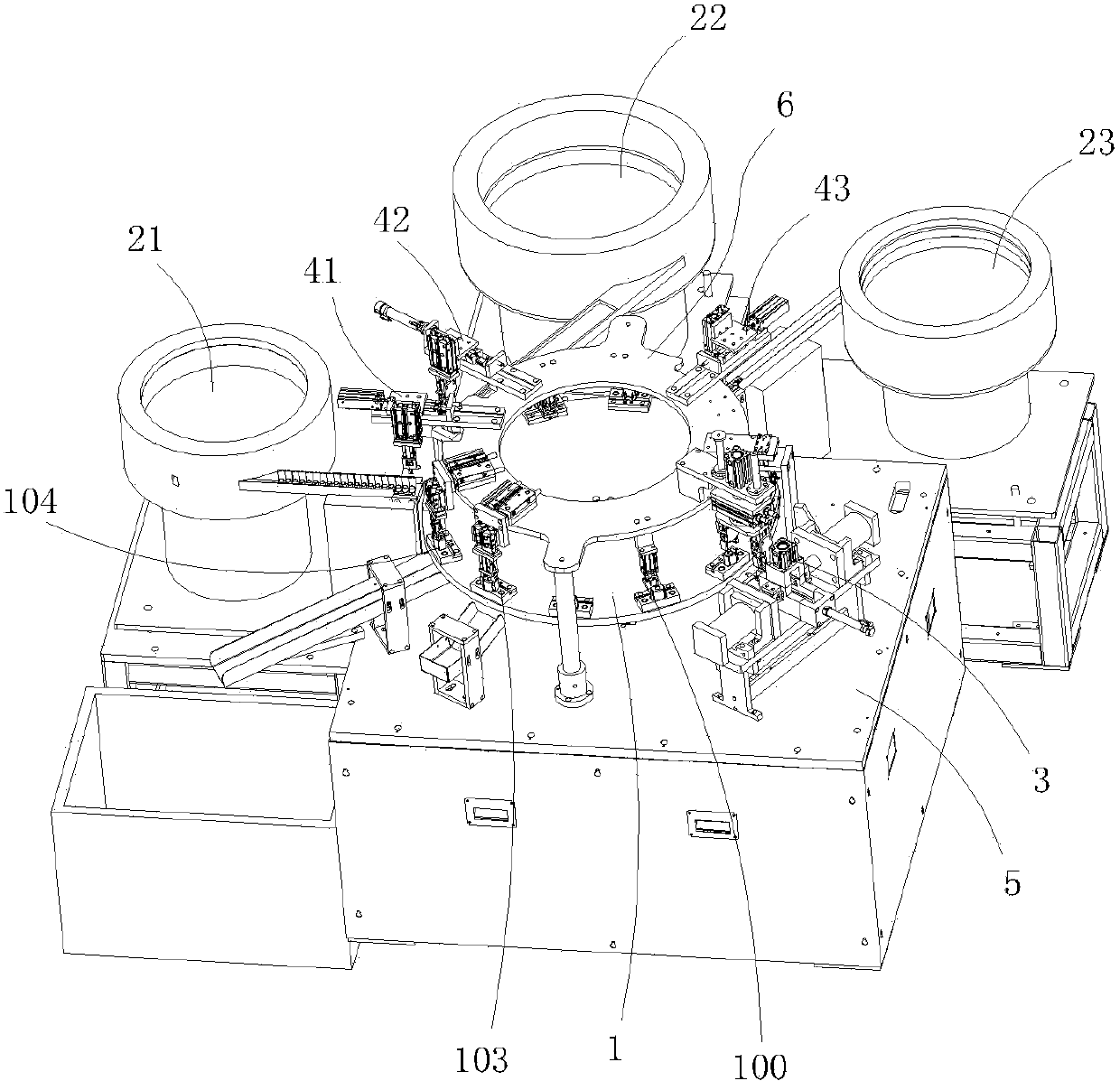

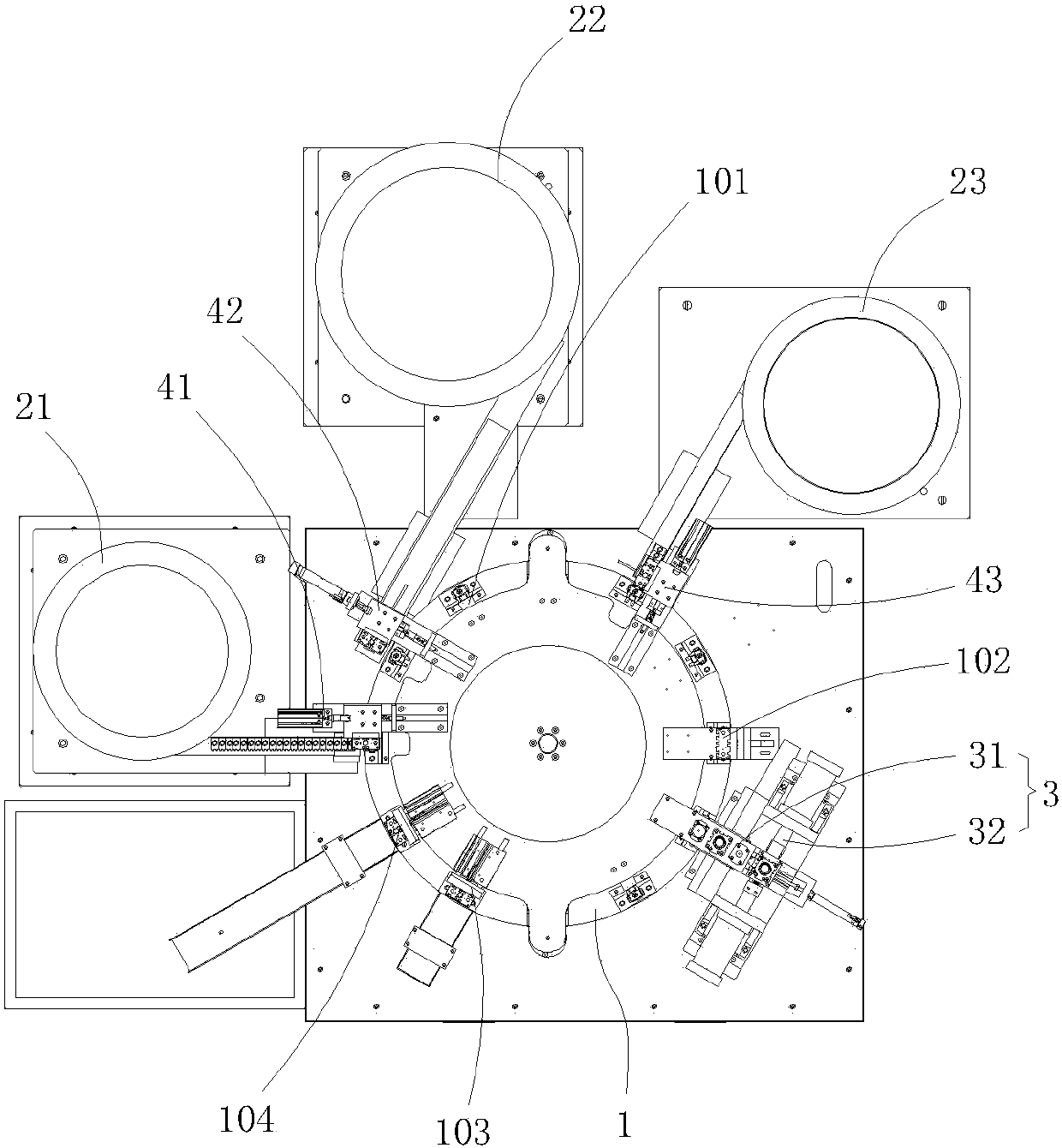

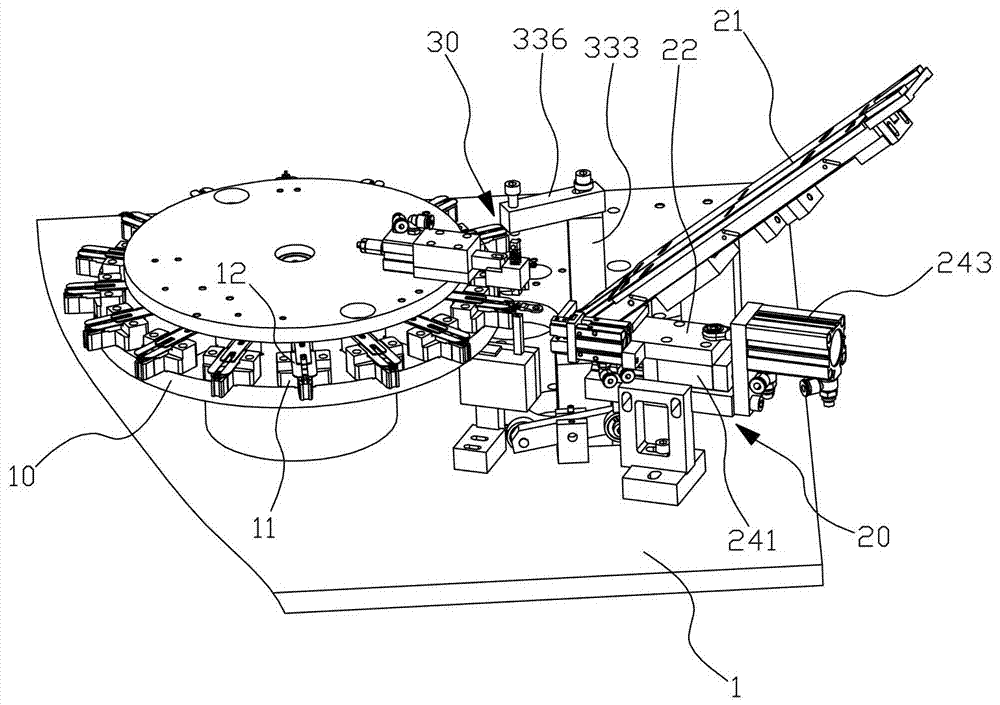

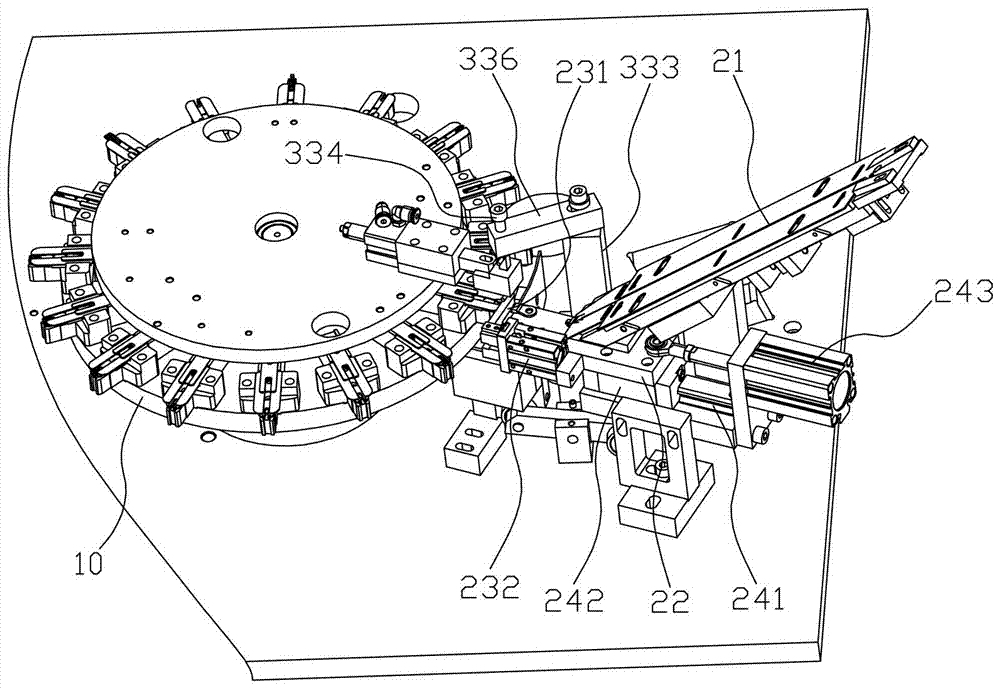

Automatic core drawing piece feeding assembling machine for pullers with rings in shape like Chinese character 'ri'

ActiveCN107052174AImprove riveting qualityImprove assembly efficiencySlide fastenersMetal-working feeding devicesEngineeringChinese characters

An automatic core drawing piece feeding assembling machine for pullers with rings in the shape like the Chinese character 'ri' comprises a rack and a circular rotary disc. A plurality of puller die cores are arranged on the circumferential face of the rotary disc. Each puller die core is provided with a U-shaped pressing sheet. A core drawing piece conveying device and a riveting device are arranged on the rack around the circular rotary disc. The core drawing piece conveying device comprises a pull piece track, a material distributing plate, a core drawing piece clamping mechanism and a core drawing piece pushing mechanism, wherein the pull piece track is obliquely and fixedly supported on the rack, the material distributing plate is arranged at the bottom of the discharging end of the puller track in a sliding manner, the core drawing piece clamping mechanism comprises a pair of clamping arms and a finger air cylinder, the clamping arms are arranged in front of the material distributing plate, the finger air cylinder is fixed to the side face of the material distributing plate, the clamping arms are fixed to the front end of the finger air cylinder, and the core drawing piece pushing mechanism comprises a sliding rail, a sliding block and an air cylinder. The assembling machine is simple in structure, core drawing pieces can be accurately clamped and conveyed to the corresponding positions of the rings in the shape like the Chinese character 'ri', and the assembling efficiency of the core drawing pieces and the rings in the shape like the Chinese character 'ri' and the quality and the qualification rate of puller products are greatly improved.

Owner:QUANZHOU LICHENG DISTRICT ZHAN AUTOMATION EQUIP

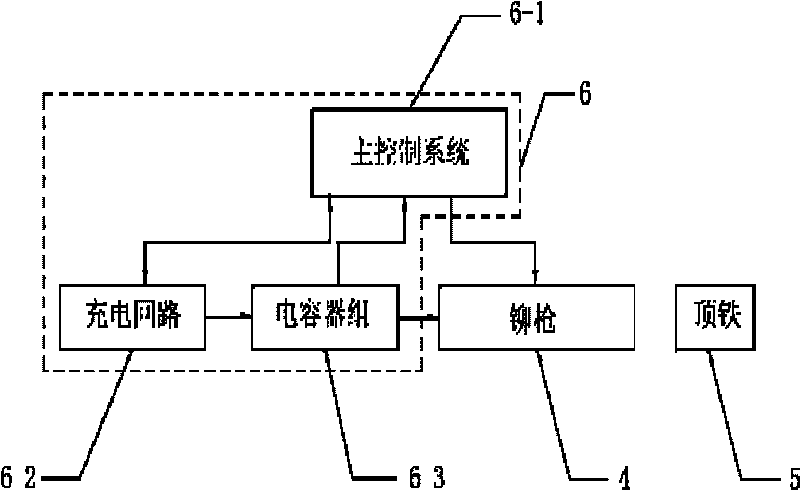

Low-voltage electromagnet riveting method of metal-composite material combined structure

The invention relates to a low-voltage electromagnet riveting method of a metal-composite material combined structure, belonging to the manufacture filed of aviation and space engineering and solving the problems that the traditional riveting technology is difficult to realize the riveting of rivets with high strength, large diameter and large length on the metal-composite material, the metal-composite material combined structure has unstable riveting quality, the riveted structure has short life and the uniform interference riveting forming of rivets with large length cannot be ensured. The low-voltage electromagnet riveting method of the metal-composite material combined structure comprises the following steps: firstly, fixing metals and composite materials on which through holes are drilled; secondly, leading the rivets to pass through the through holes of the metals and the composite materials; thirdly, contacting a rivet head of a rivet gun with one side of a rivet tail and contacting one side of the rivet tail with top iron; and fourthly, giving out a processing signal to the rivet gun by a low-voltage electromagnetic riveting system and finishing the riveting. The invention is applied in the riveting process of the metal-composite material combined structures of large-sized cylinders of large-sized planes and rocket projectile bodies.

Owner:HARBIN INST OF TECH

Riveting device for nail and iron sheet

InactiveCN105014358ASimple riveting principleGood riveting qualityMetal working apparatusEngineeringHydraulic pump

The invention provides a riveting device for a nail and an iron sheet. The riveting device for the nail and the iron sheet comprises a box body, a hydraulic cylinder, a pressing device, a workbench and a hydraulic pump. The box body is hollow and is located at the bottom of the device. The box body further comprises a first supporting plate, a second supporting plate, a controller and a cross beam. The controller further comprises a scram button and a control button. The scram button is located above the controller. The control button is located below the scram button. The hydraulic cylinder is fixed above the cross beam. The hydraulic cylinder further comprises an oil inlet pipe, an oil outlet pipe and a hydraulic shaft. The hydraulic shaft is located at the lower end of the hydraulic cylinder. The lower end of the hydraulic shaft is connected with the pressing device. The workbench is arranged on the upper surface of the box body. The hydraulic pump is located on the right side of the box body. The oil inlet pipe and the oil outlet pipe are connected with the hydraulic pump. The riveting device for the nail and the iron sheet is simple in riveting principle, good in riveting quality, simple in structure, convenient to operate and good in safety performance.

Owner:HAIYAN HONGQIANG HARDWARE MFG CO LTD

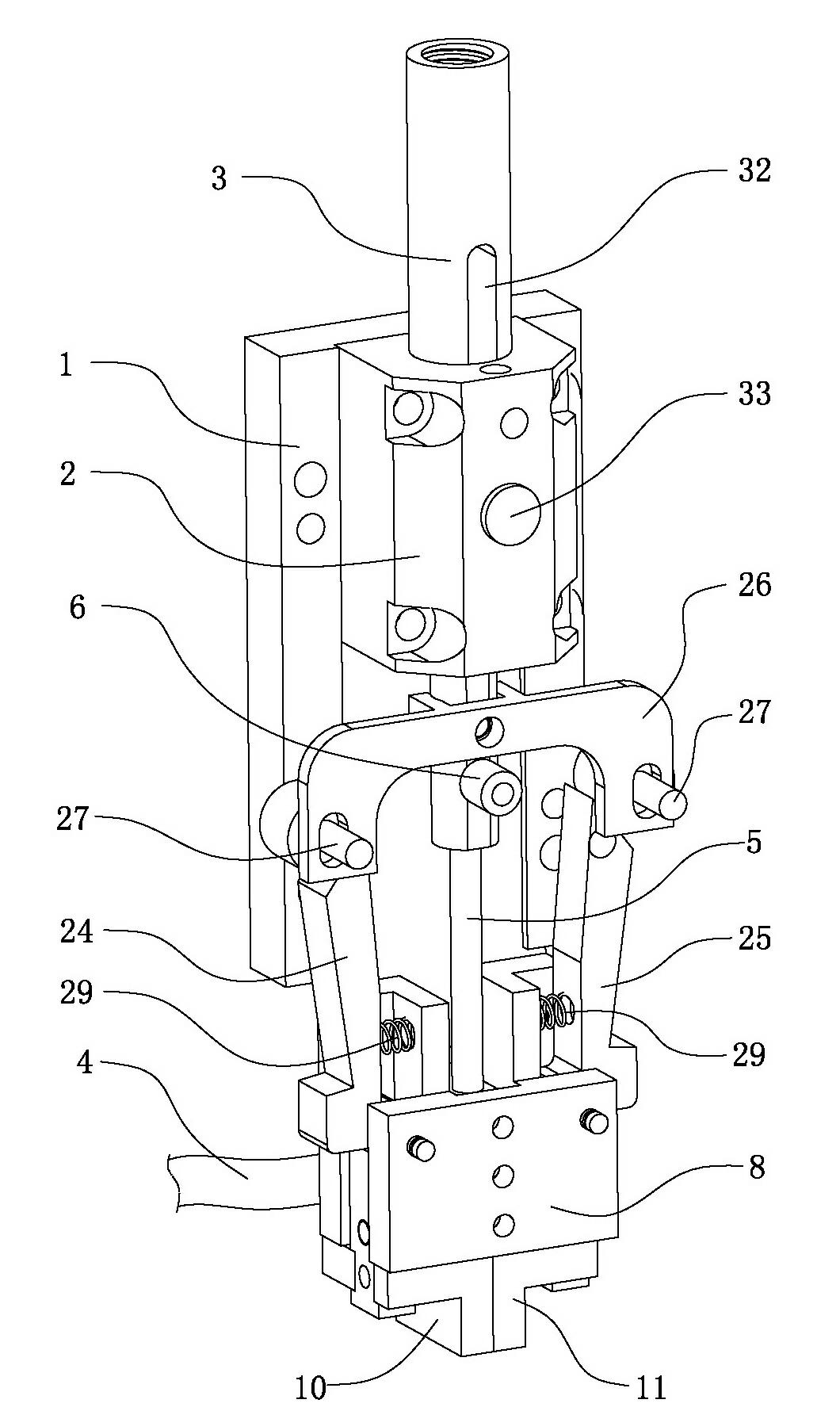

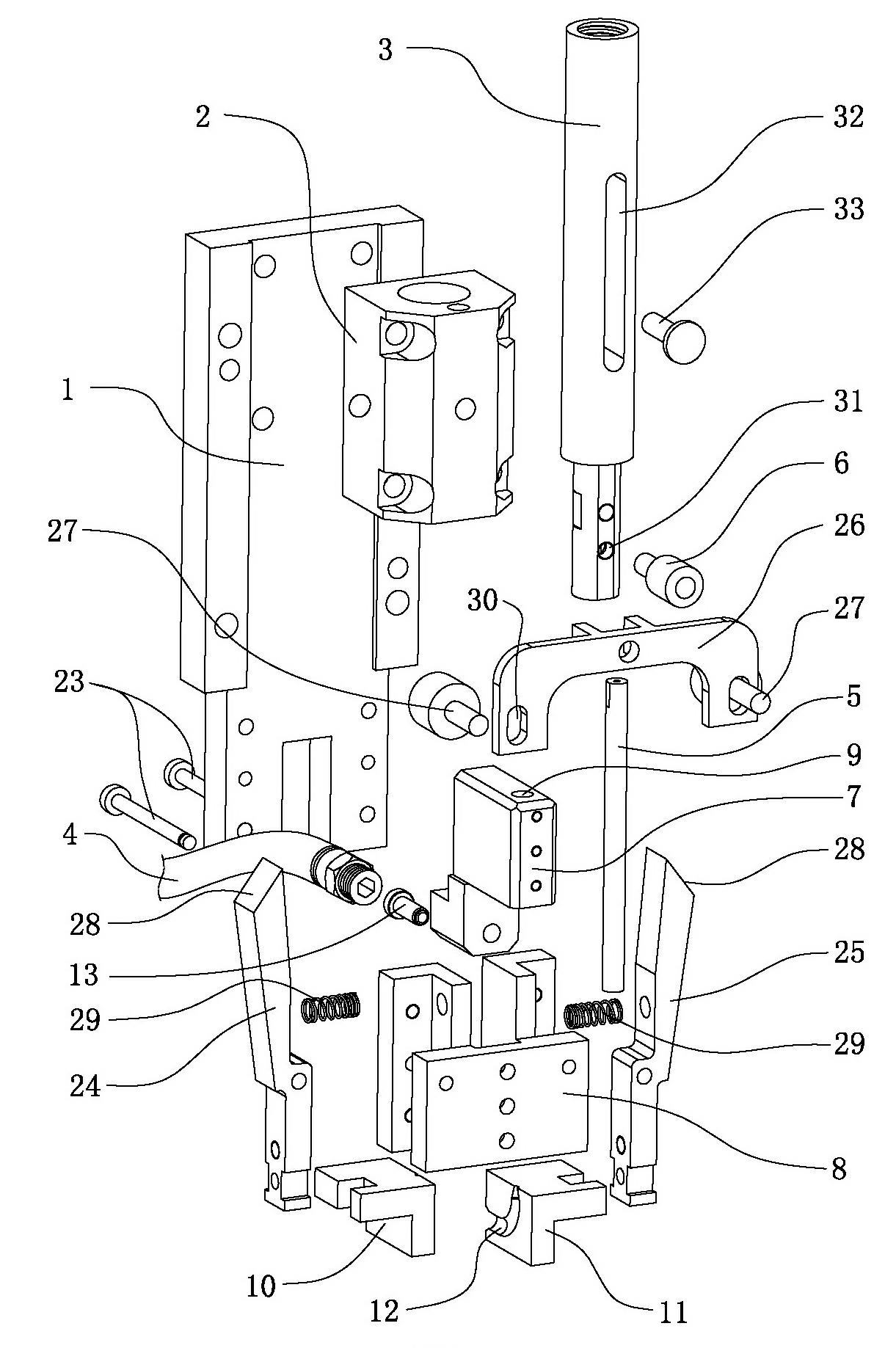

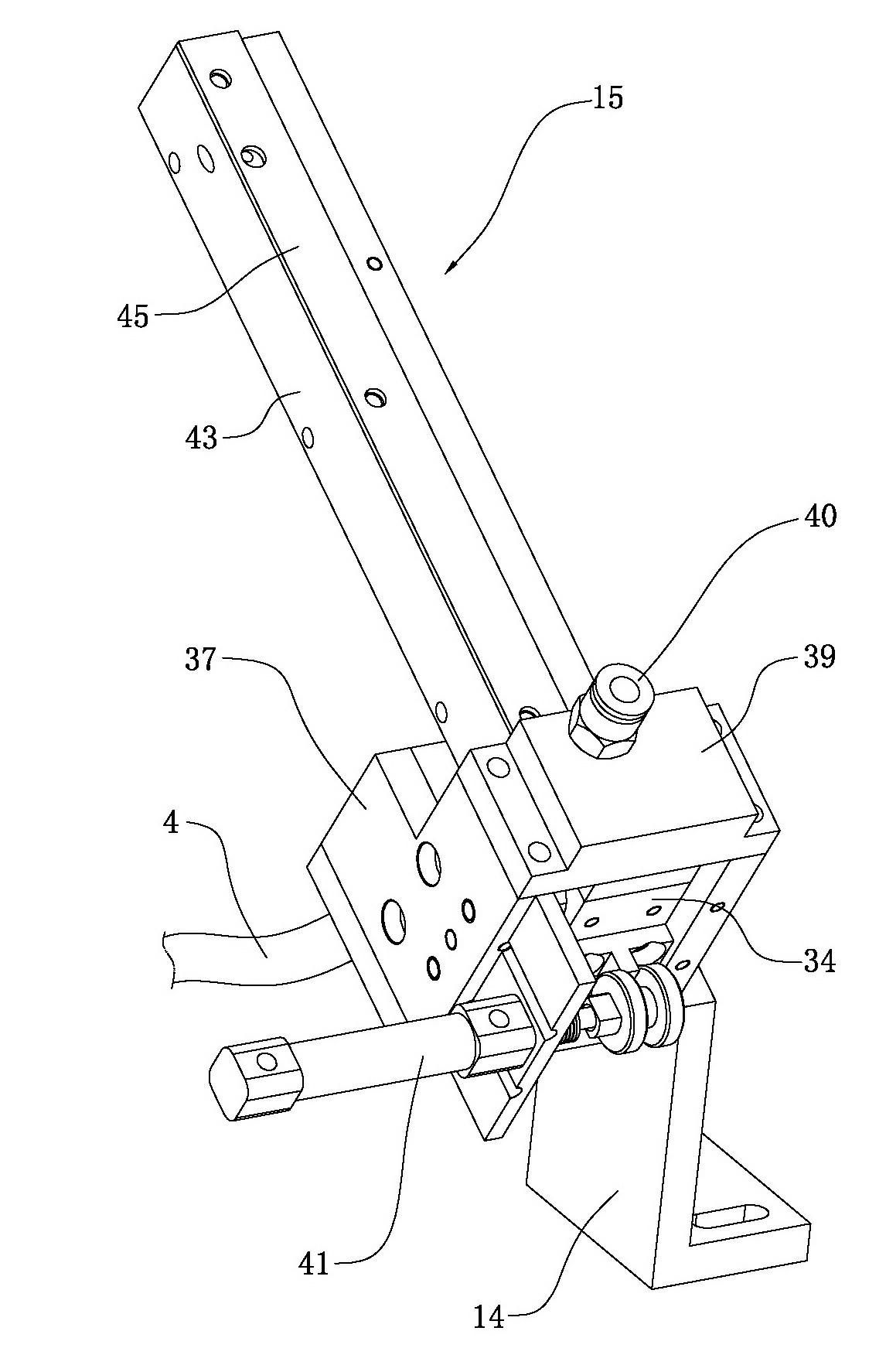

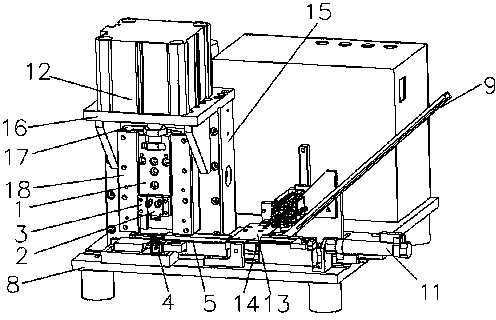

Riveting fixture for low voltage circuit-breaker arc extinguishing chambers

InactiveCN103681121ASimple structureReliable actionEmergency protective device manufactureLow voltage circuitsEngineering

Owner:JIANGSU KAIFAN ELECTRICAL APPLIANCES

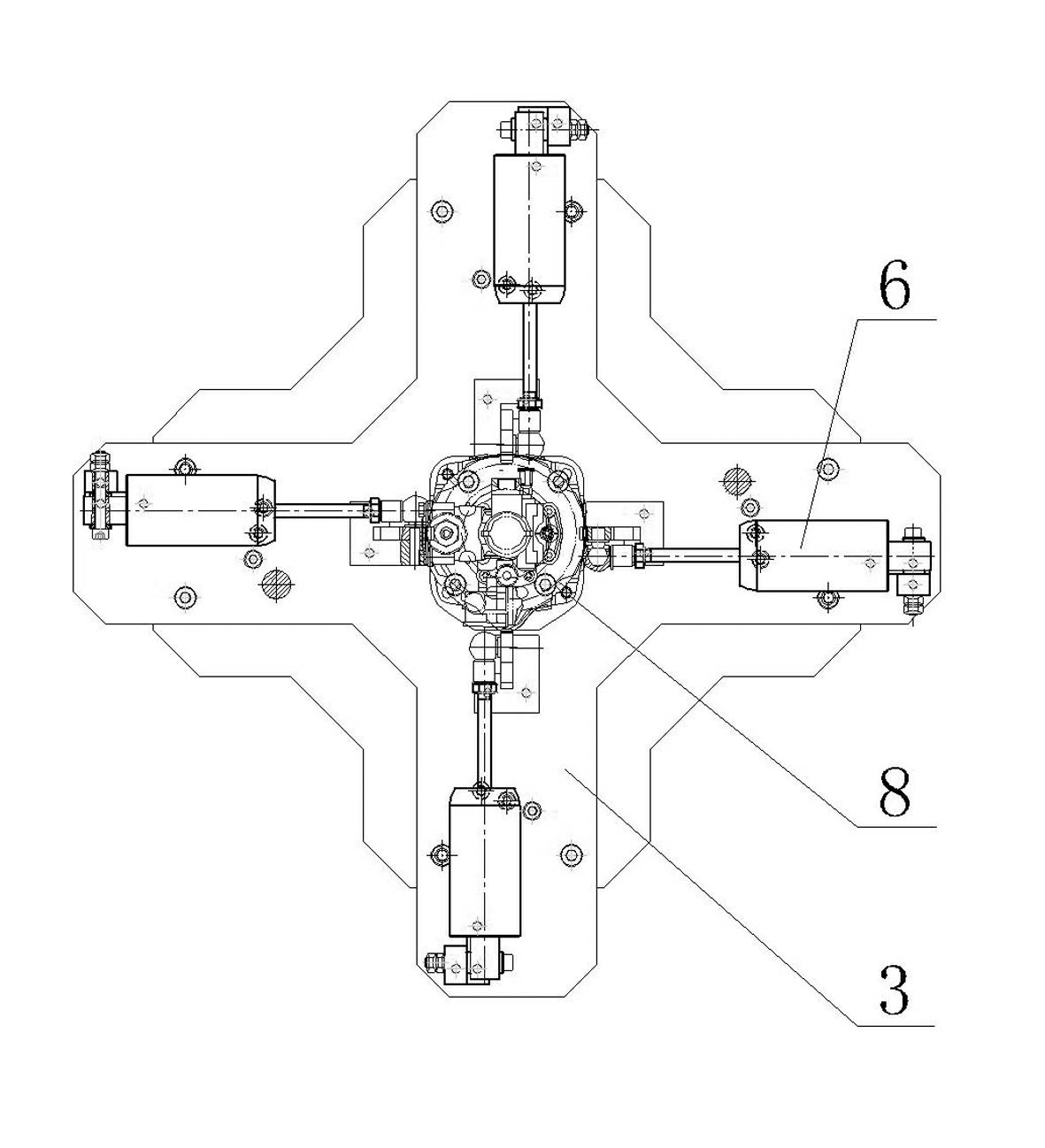

Multipoint rivet-free automatic riveting machine

InactiveCN102240746ARealize riveting automationNo manual operationMetal-working feeding devicesPositioning devicesPulp and paper industryAutomation

The invention provides a multipoint rivet-free automatic riveting machine, comprising an automatic riveting device, a machine frame and a positioning operating platform, wherein the automatic riveting device comprises a push device, a riveting convex-concave mould base, a demoulding device and a riveting convex-concave mould; the riveting convex-concave mould base is fixedly arranged on the push device; the riveting convex-concave mould is fixed on the riveting convex-concave mould base through the demoulding device; the automatic riveting device is arranged on the machine frame; the positioning operating platform comprises an operating platform, a servo positioning device, a pneumatic rotating positioning device and a pneumatic positioning device; the servo positioning device and the pneumatic positioning device are sequentially arranged at one side of the operating platform connected with the machine frame; and the pneumatic rotating positioning device is arranged at the side of theoperating platform and is next to the pneumatic positioning device. By adopting the multipoint rivet-free automatic riveting machine provided by the invention, multipoint riveting automation on a framework sectional bar is realized, and production efficiency is improved; riveting pressure consistency is realized, and product riveting quality is stabilized; and automatic riveting of framework sectional bars with different specifications is realized by adopting one riveting machine.

Owner:TIANJIN RENYIHE AUTOMATION TECH

Riveting mechanism of automatic riveting machine

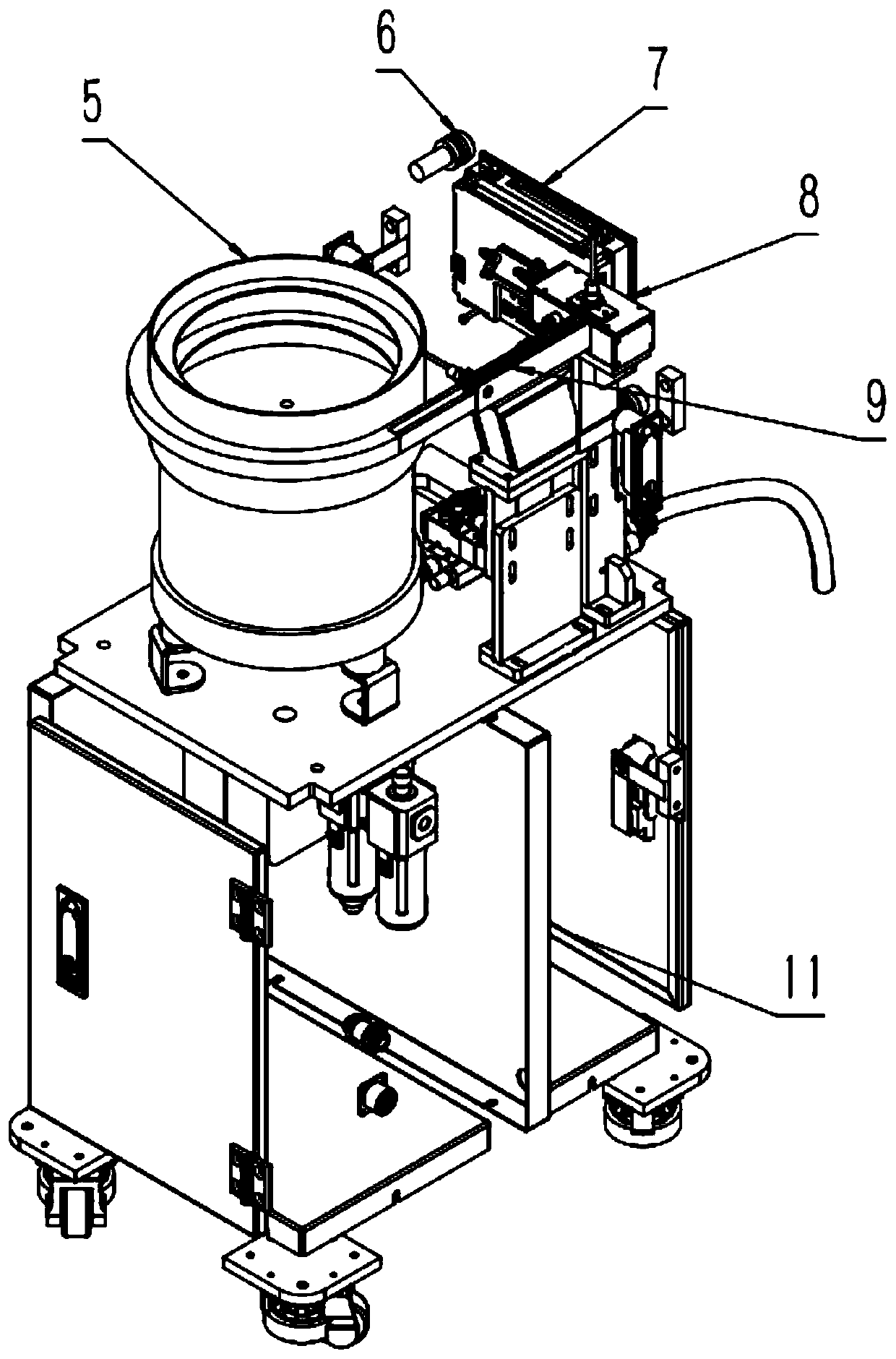

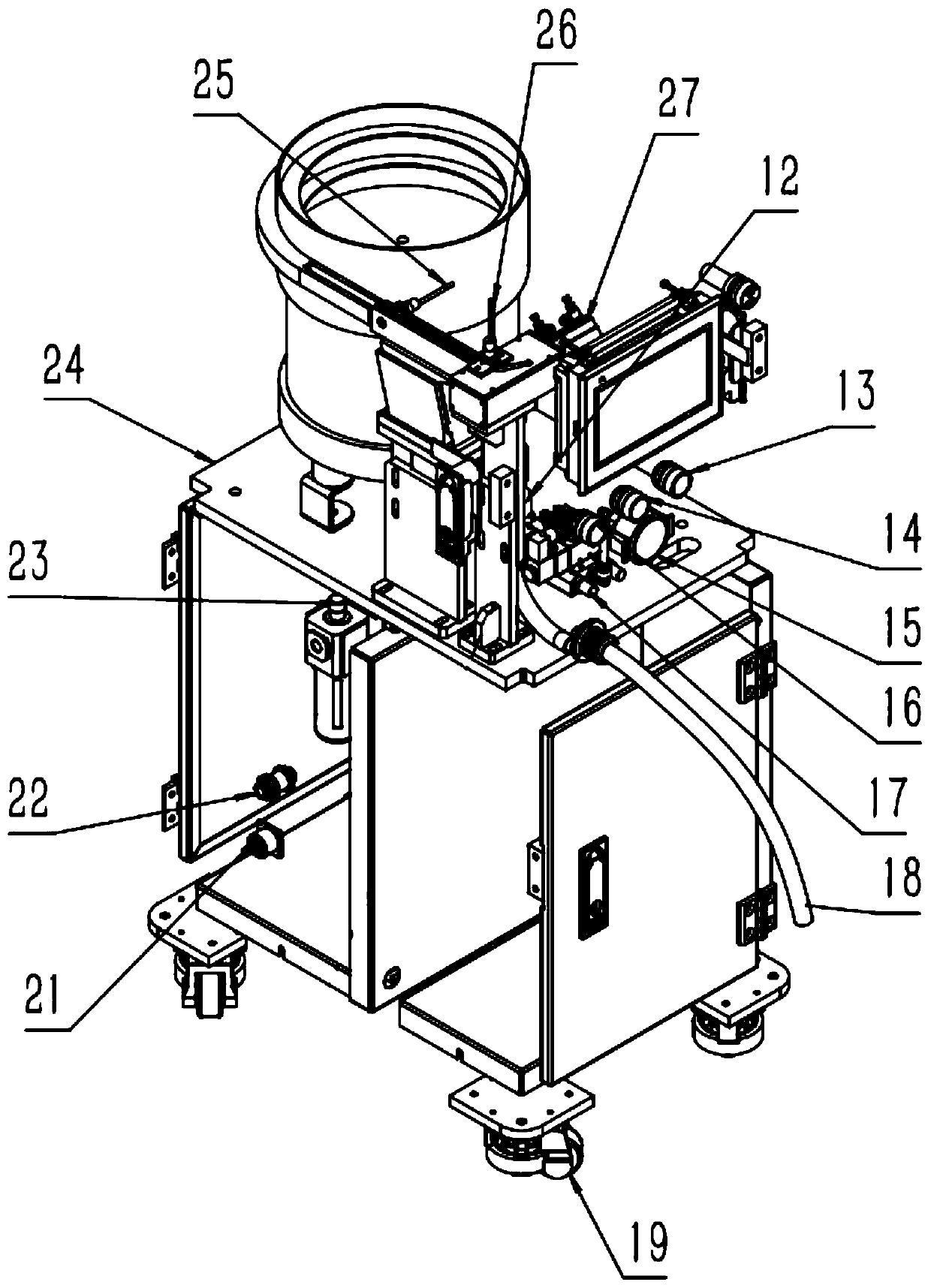

InactiveCN106964742AImprove riveting qualityIncrease productivityMultilayer circuit manufactureEngineeringMaterial distribution

The invention discloses a riveting mechanism of an automatic riveting machine. The riveting mechanism comprises a vibrating plate, a riveting handpiece, a riveting driving device and an upper jacking and supporting device. The riveting handpiece comprises a material distribution dop, a prepressing device, a riveting pressure air cylinder, a mounting frame and a riveting pressure rod. The material distribution dop, the prepressing device, the riveting pressure air cylinder and the riveting pressure rod are mounted on the mounting frame. The mounting frame is mounted to the riveting driving device. The riveting handpiece and the upper jacking and supporting device move in the feeding direction of the riveting machine through the riveting driving device. The vibrating plate is connected with the material distribution dop. The riveting pressure air cylinder drives the riveting pressure rod and the prepressing device to go up and down. The riveting mechanism of the automatic riveting machine is high in riveting quality and production efficiency and low in cost, the defects that in the prior art, the manual labor amount is high, and the working efficiency and the reliability are low are overcome, and thus the low manual labor amount and high working efficiency and reliability are achieved.

Owner:庄召国

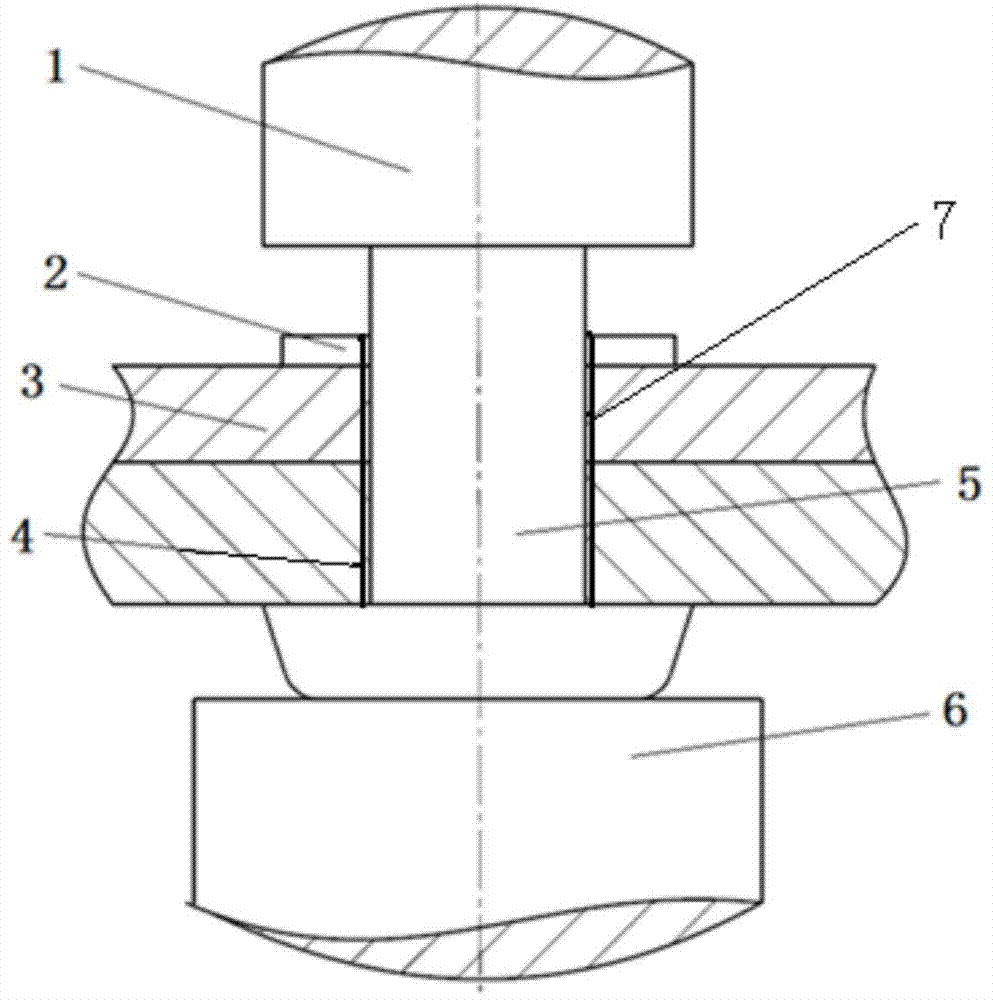

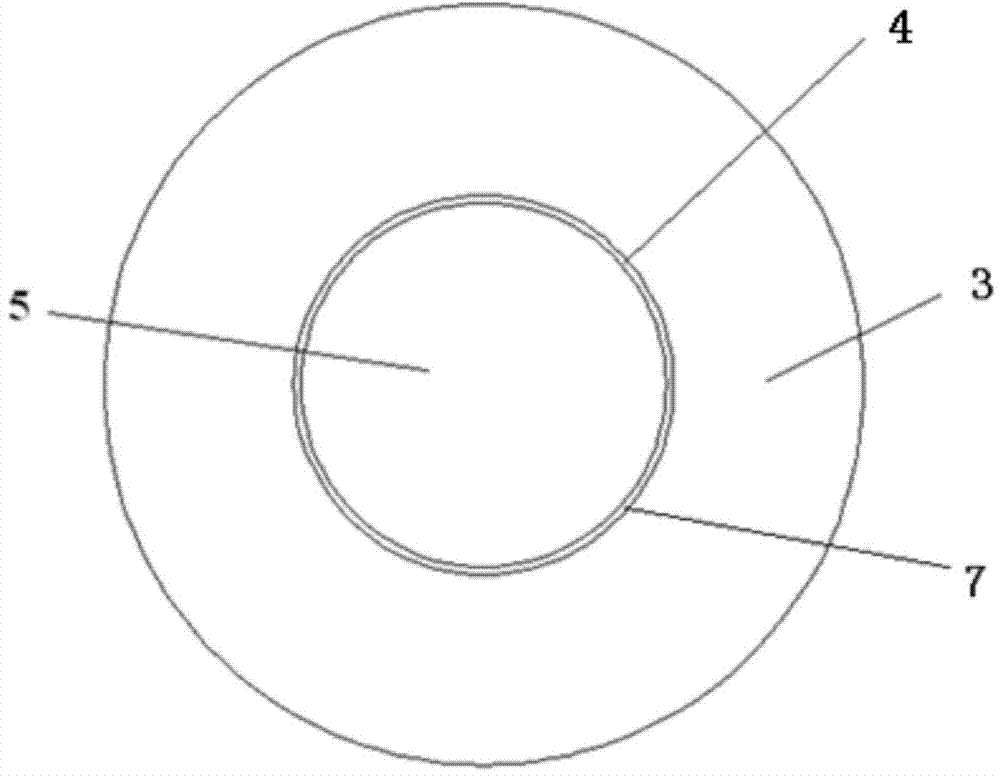

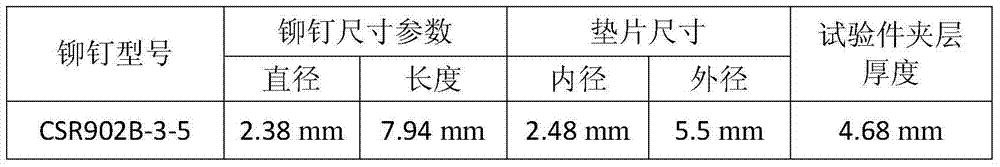

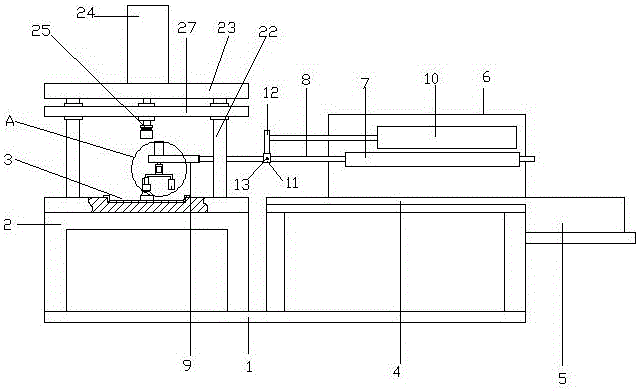

Process method of electromagnetic riveting composite material

The invention discloses a process method for achieving an electromagnetic riveting composite material. The method mainly resolves the problem that when riveting is carried out through a traditional riveting method at preset, the composite material is damaged easily. The process method for achieving the electromagnetic riveting composite material adopts the electromagnetic riveting technology, and largely reduces the installation damage to the structure of the composite material in the riveting process through a specially designed gasket and an appropriate tack hole interval and rivet overhang, thereby improving the quality of connectors.

Owner:XIAN AIRCRAFT BRANCH OF XIAN AIRCRAFT INT

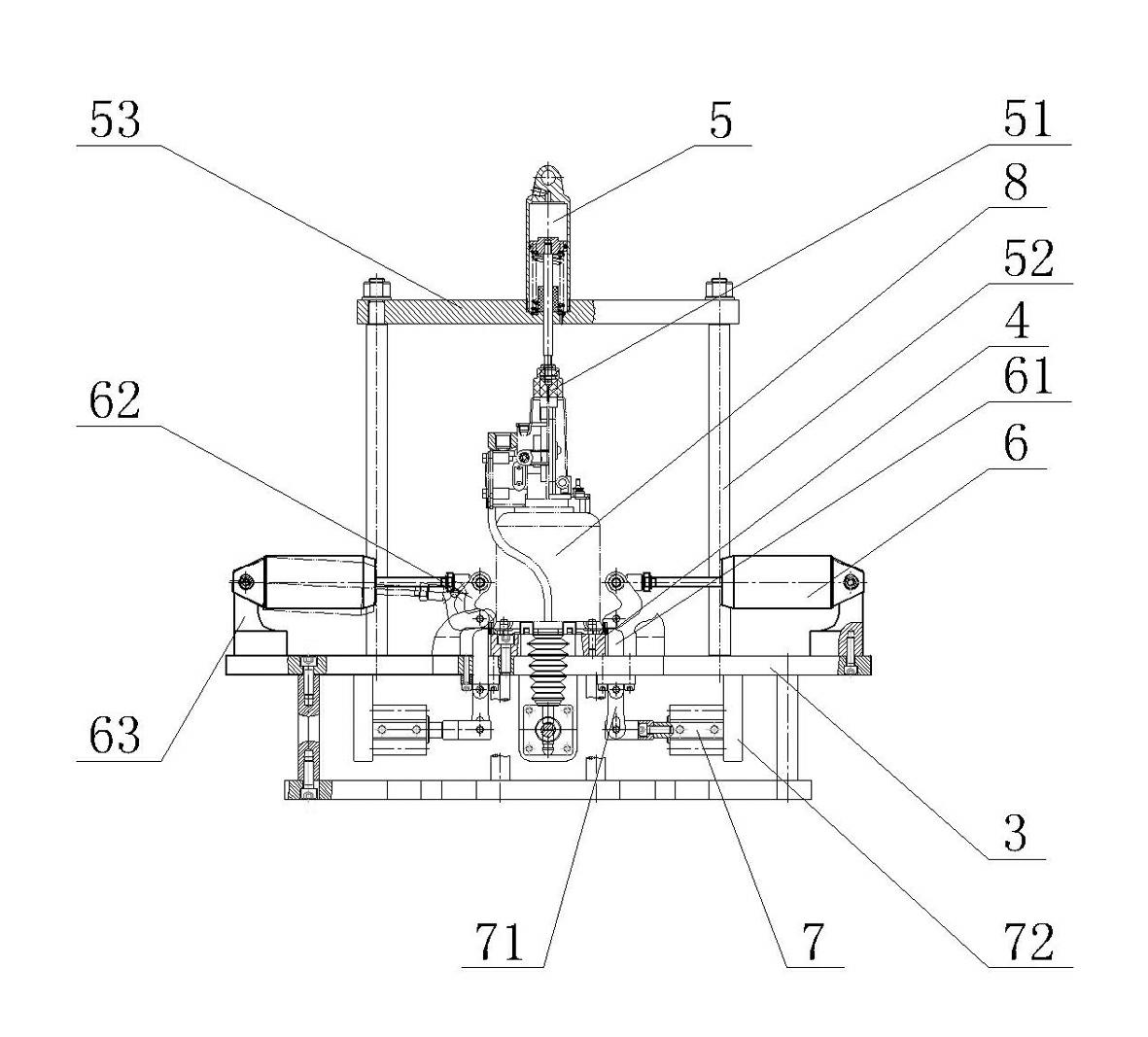

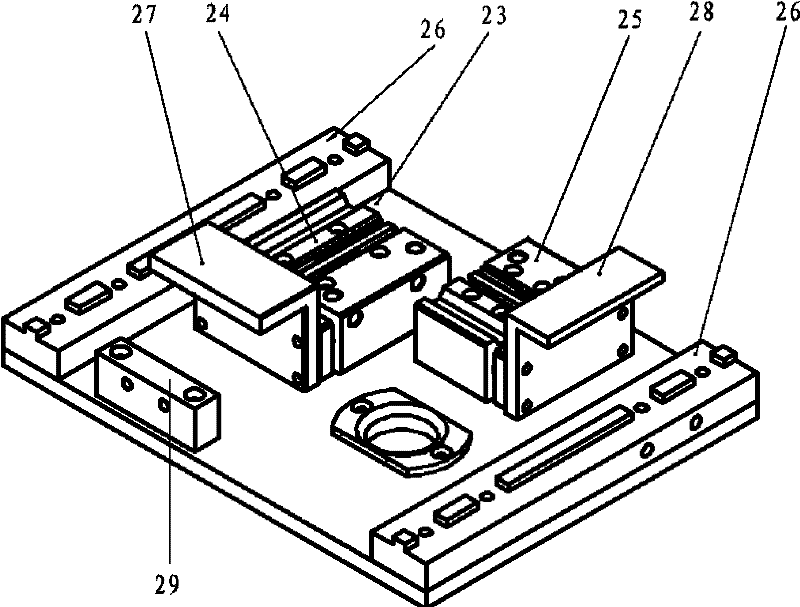

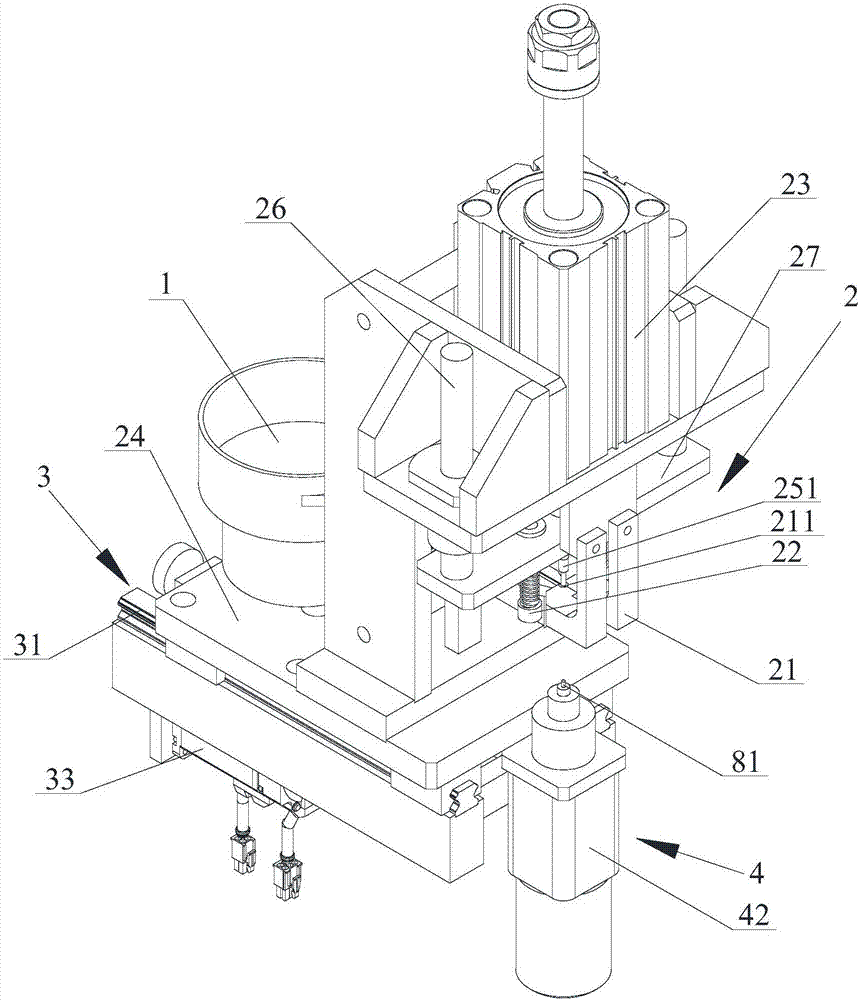

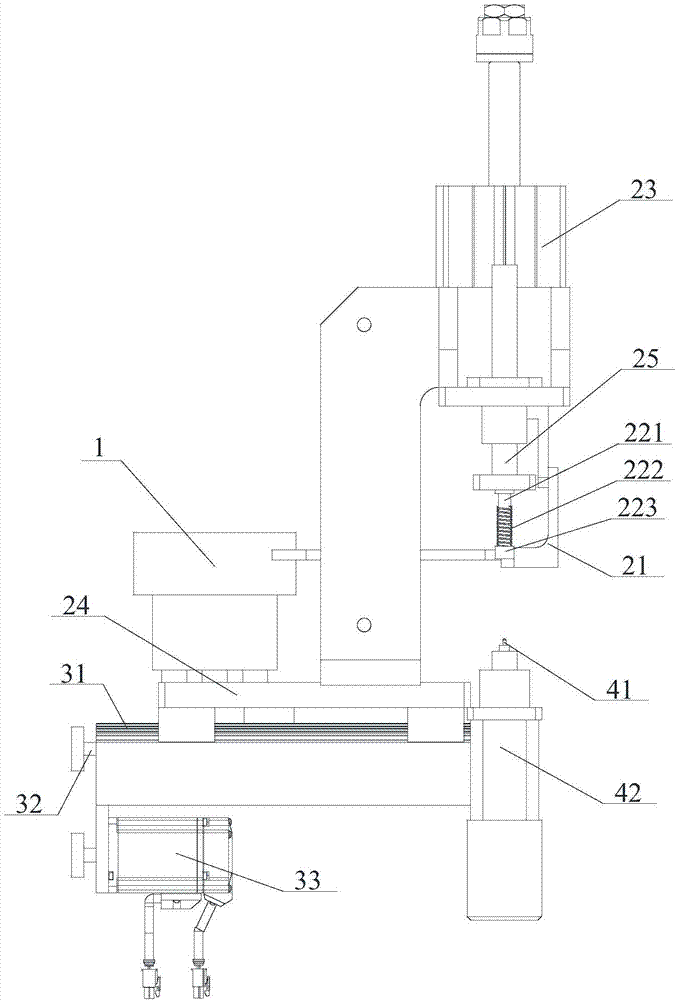

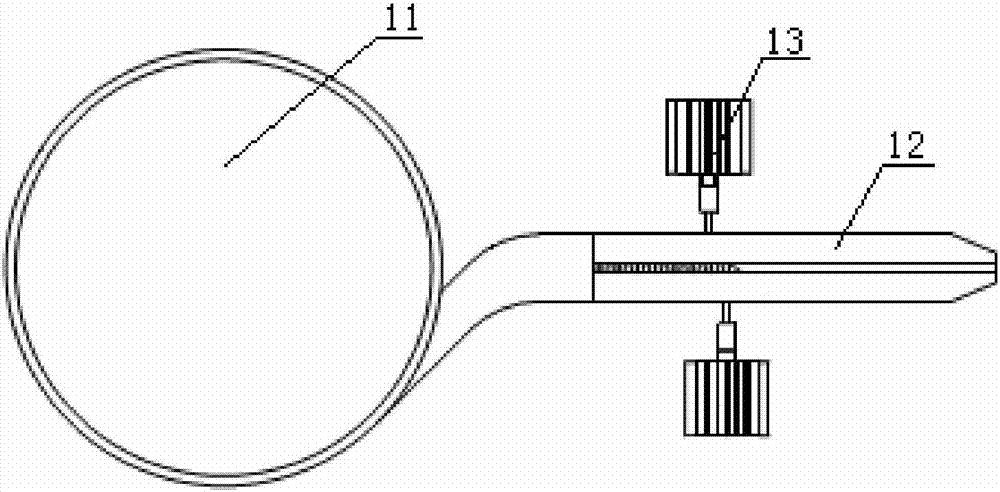

Assembling mechanism for sealing ring of igniter base of gas generator

ActiveCN106239120AFeed stabilityImprove assembly efficiencyMetal working apparatusGas generatorSignal generator

The invention relates to the technical field of assembling of gas generators, and discloses an assembling mechanism for a sealing ring of an igniter base of a gas generator. The assembling mechanism for the sealing ring of the igniter base of the gas generator comprises a base plate. A positioning base is arranged at one end of the base plate. A positioning cavity is formed in the center of the top surface of the positioning base. A sealing ring feeding guide rail is arranged at the other end of the base plate. A vibrating tray is arranged at the outer end of the sealing ring feeding guide rail. A horizontal movement mechanism is arranged above the sealing ring feeding guide rail. A horizontal connecting plate is arranged at the head of the horizontal movement mechanism. A lifting air cylinder is arranged on the upper side of the connecting plate. A connecting base is arranged at the shaft end of the lifting air cylinder. A rotary air cylinder is arranged in the connecting base. A U-shaped support which is open downwards is connected to the shaft end of the rotary air cylinder. The center of the upper end of the U-shaped support is connected with the rotary air cylinder. A sealing ring suction cup is arranged at one end of the U-shaped support. A sealing ring detection head is arranged at the other end of the U-shaped support. According to the assembling mechanism for the sealing ring of the igniter base of the gas generator, the sealing ring in the igniter base can be detected, so that mounting omission of the sealing ring or mounting of redundant sealing rings is effectively prevented, and defective products are prevented in the later stage.

Owner:均胜汽车安全系统(长兴)有限公司

Apparatus for Rivetting

A riveting apparatus includes a hot air pipe; a connection pipe coupled to the hot air pipe; a forming tool having a configuration in which peripheral and center portions project downward and portions existing therebetween are curved upward, defined with discharge holes which extend in axial and radial directions, and coupled to a lower end of the connection pipe so that hot air having passed through the connection pipe can be discharged through the discharge holes to heat an end of a rivet to thereby allow the forming tool to form the end of the rivet into the shape of a head; a moving unit coupled to the hot air pipe or the connection pipe to move the forming tool upward and downward; and a guide surrounding the forming tool so that hot air discharged through the discharge holes can be directed toward the end of the rivet.

Owner:GUNYANG ITT

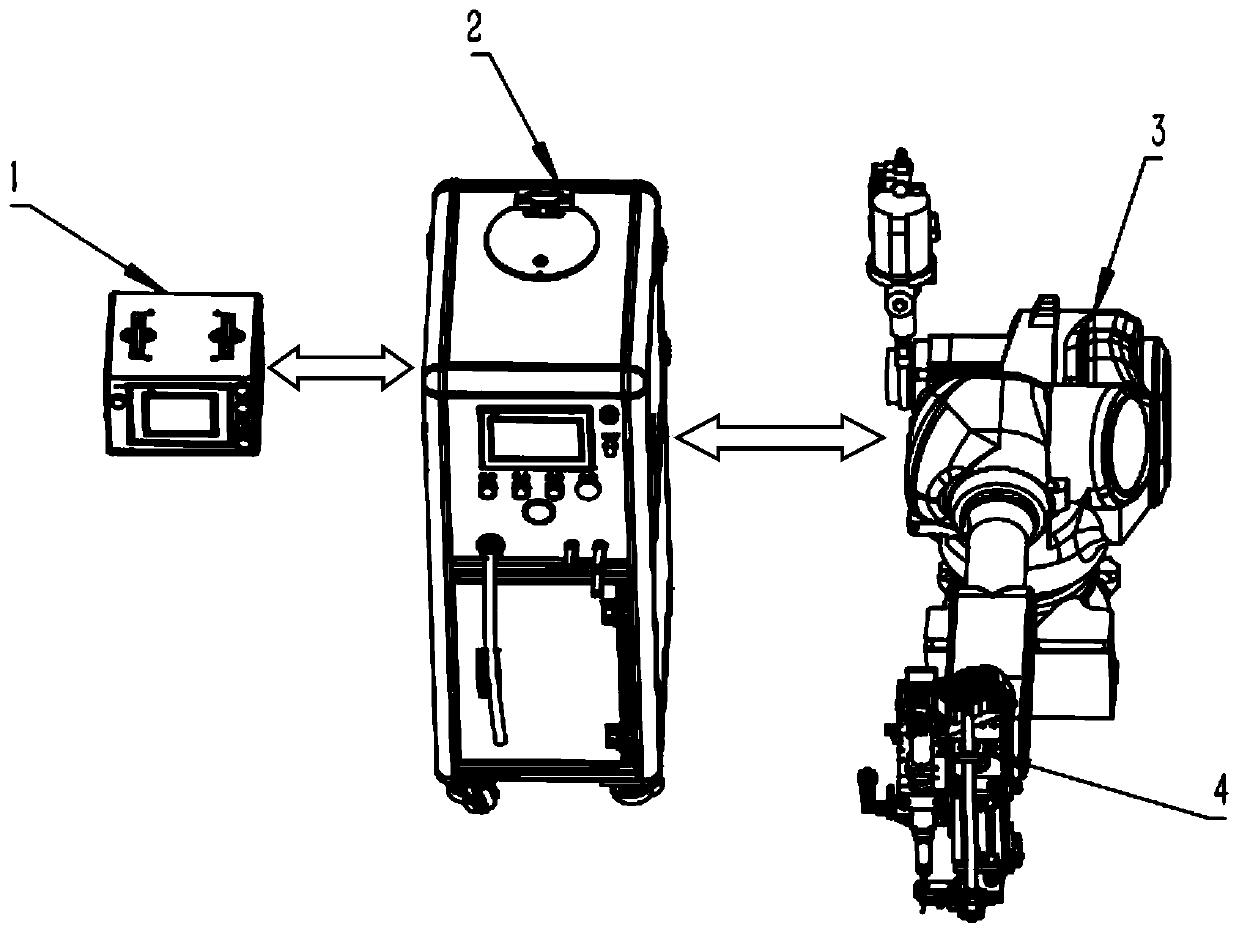

Full-automatic rivet nut feeding and riveting monitoring system

InactiveCN110170580AEasy maintenanceEasy to troubleshootMetal-working feeding devicesPositioning devicesMonitoring systemRivet gun

The invention discloses a full-automatic rivet nut feeding and riveting monitoring system which comprises a rivet nut feeder, a rivet nut receiving mechanism, riveting moving equipment and a rivetingmonitoring meter. The rivet nut feeder arranges and separates rivet nuts and conveys the rivet nuts to the rivet nut receiving mechanism through a nail feeding pipe, a rivet nut gun is arranged on therivet nut receiving mechanism, the rivet nut receiving mechanism conveys the received rivet nuts to a rivet rod of the rivet nut gun, and the riveting monitoring meter detects riveting tension and displacement through a riveting sensor connected to the rivet nut gun and displays riveting information. The full-automatic rivet nut feeding and riveting monitoring system is modular in design and convenient to maintain and troubleshoot, loads the rivet nuts automatically to the rivet gun of the rivet nut gun to improve the riveting efficiency, judges the riveting quality in real time to improve the riveting quality, and is connected to and combined with the rivet nut moving equipment in use to achieve a full-automatic riveting process.

Owner:铁藤机电技术(上海)有限公司

Riveting machine for rivets

A riveting machine for rivets mainly comprises a body, a motor, a motor wheel, an eccentric wheel, a connecting rod, a rotating shaft, an elastic plate, an adjusting seat, a ball connecting rod, a rubber pad, a guide rod and a riveting head. An eccentric disk is driven by the motor to drive the connecting rod, the connecting rod drives the elastic plate to rotate around the rotating shaft, the elastic plate drives the guide rod to move vertically, a cam slot is arranged on the guide rod, a pin is mounted on the body, and the inner end of the pin is clamped in the cam slot. Therefore, the guide rod rotates to a certain degree while moving vertically, and then drives the riveting head to spin the rivets. The riveting machine has the advantages of simple structure, lower cost and higher quality of riveting for the rivets.

Owner:徐州宇家化工科技有限公司

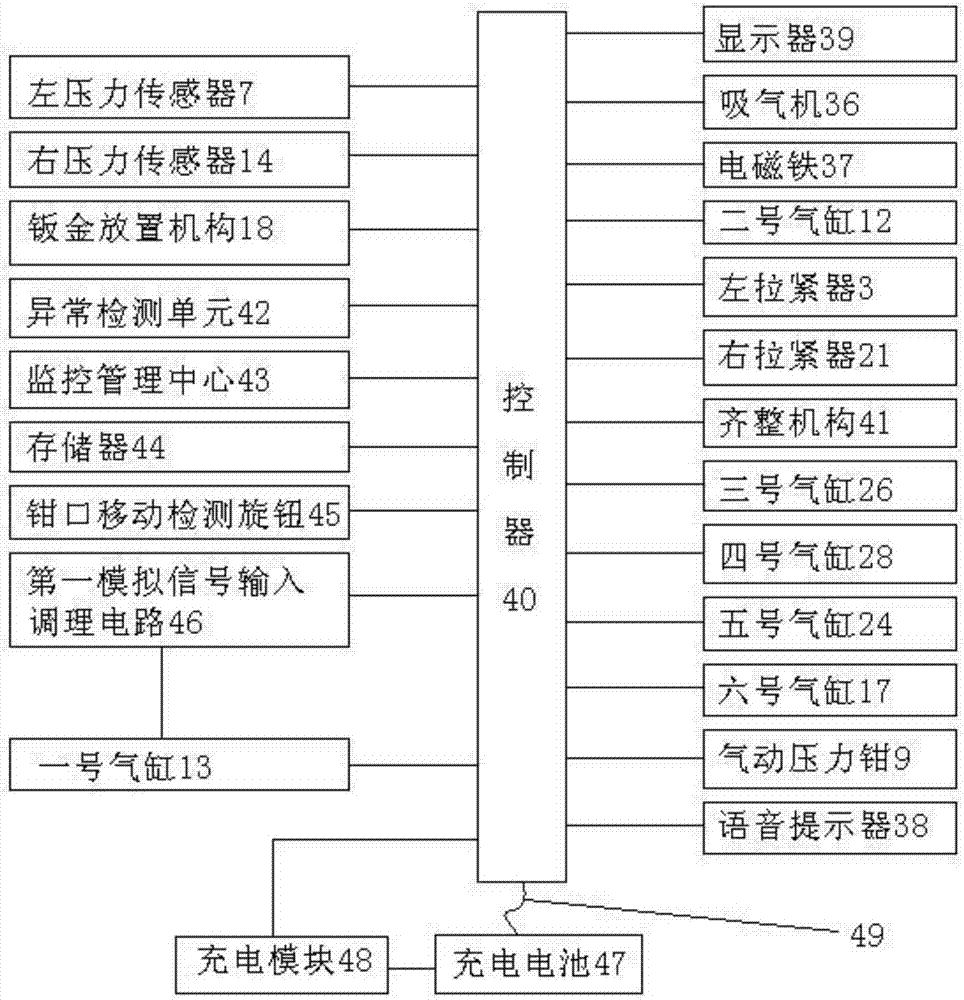

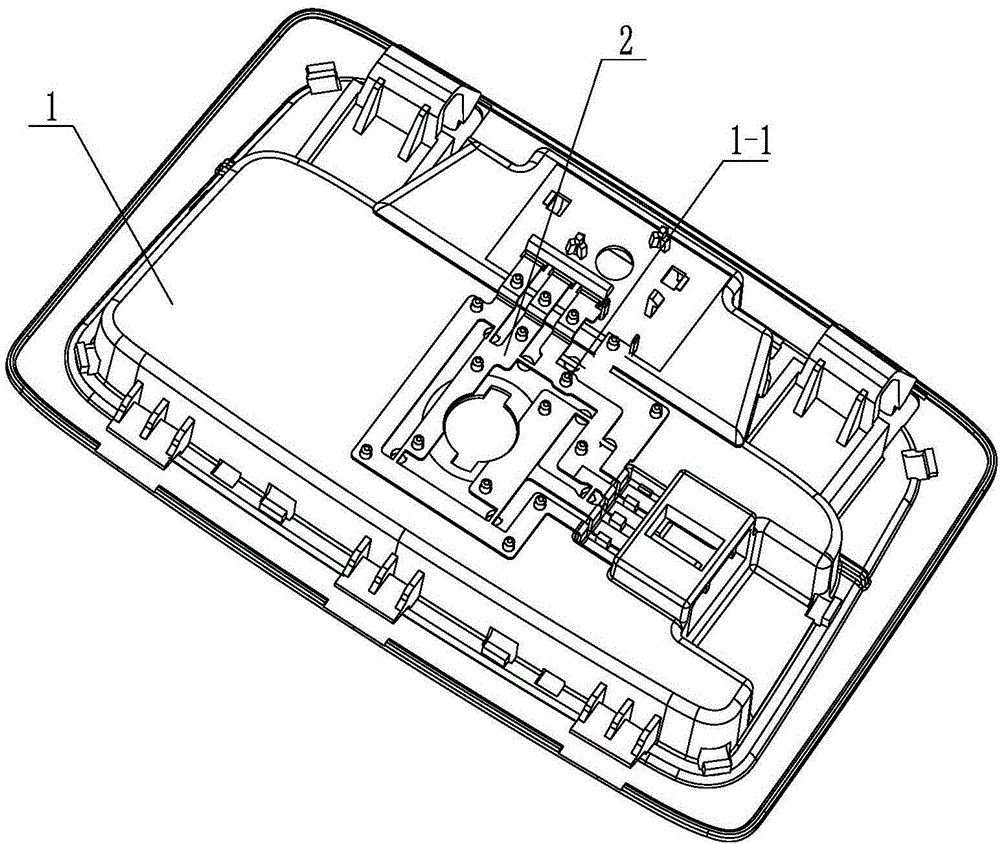

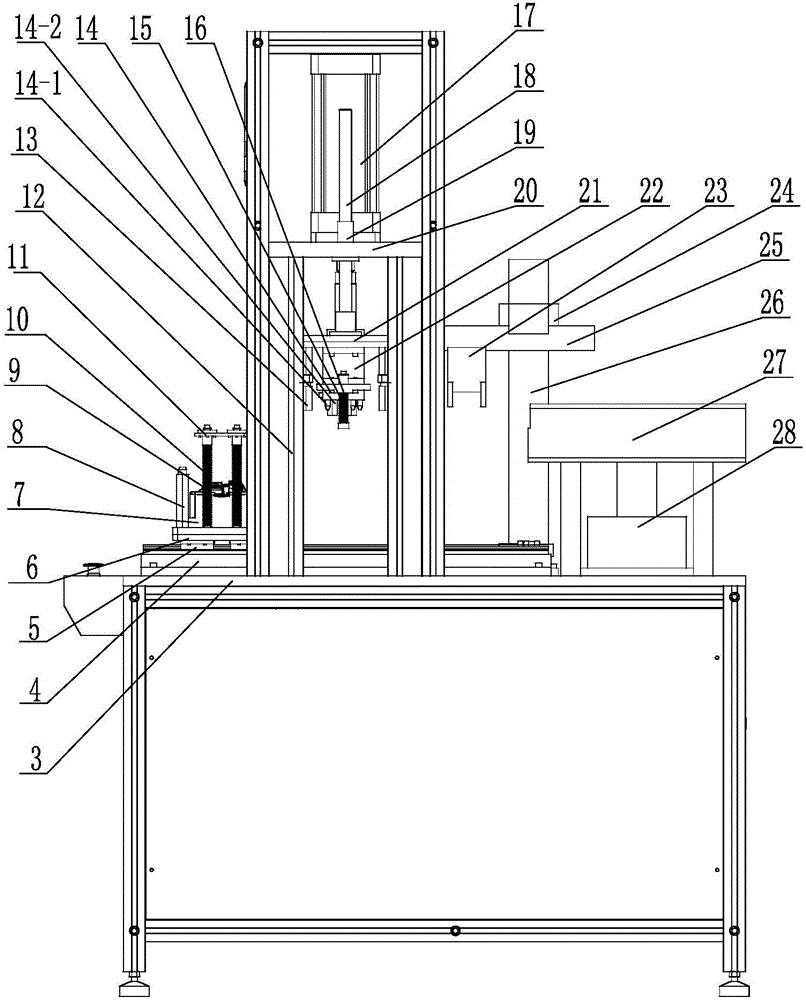

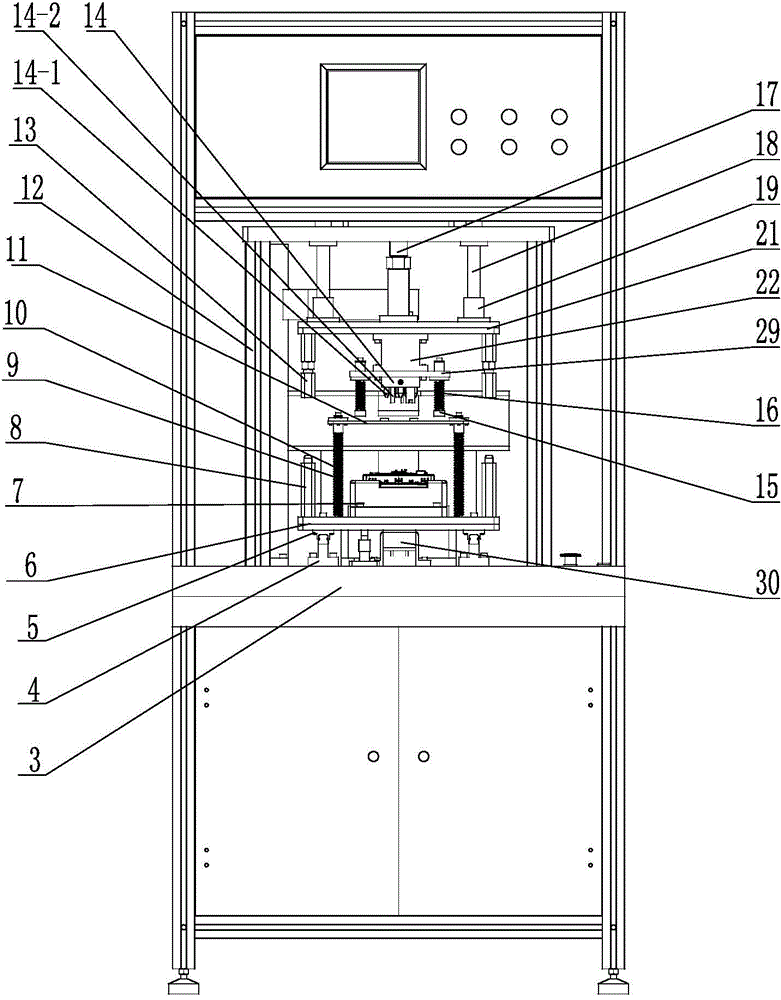

Wire harness sheet metal riveting equipment and use control method

ActiveCN105665543BImprove riveting qualityHigh degree of intelligenceLine/current collector detailsAnomaly detectionMetal

Owner:宁波拓普电器有限公司

Plastic hot riveting device for automobile lamp

The invention relates to a plastic hot riveting device for an automobile lamp. A workbench is provided with a lamp body positioning mechanism, a press riveting mechanism, a rivet head grabbing mechanism and a heating mechanism. The lamp body positioning mechanism comprises a push air cylinder, a lamp body positioning base and a floating positioning base. The push air cylinder installed on the workbench is connected with the lamp body positioning base. The floating positioning base is connected with the lamp body positioning base and arranged at the upper portion of the lamp body positioning base. A rivet head positioning plate on the floating positioning base is borne on a lower elastic body. The press riveting mechanism comprises a rivet pressing air cylinder, guide columns and a rivet pressing mechanism, wherein the rivet pressing air cylinder is connected with the rivet pressing mechanism. A pressing base of the rivet pressing mechanism is provided with pressing columns and air blowing pipes, and elastic push rods connected to the pressing base are opposite to the rivet head positioning plate. The rivet head grabbing mechanism comprises a support, a lifting rod and a movable rod which are connected. The heating mechanism comprises a heating furnace and a rotary disc, and the heating furnace and the rotary disc are fixed to the workbench. The plastic hot riveting device is reasonable in structure, rapid hot riveting and cooling can be achieved during multi-point riveting, the riveting quality can be ensured, and the riveting efficiency can be improved as well.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

Full-automatic riveting machine

The invention relates to the technical field of full-automatic riveting machines, in particular to a full-automatic riveting machine. The full-automatic riveting machine comprises a stander, a material supply device, a piece insertion base plate and a piece insertion sleeve, wherein an insertion rod is arranged on the piece insertion sleeve; the material supply device comprises a conveying pipe for outputting a rivet; a needle barrel is arranged at the lower end of the insertion rod, and a ventilating hole is formed in the middle of the needle barrel; an air joint is arranged on the insertion rod; a positioning block and a material clamp fixing seat are arranged on the insertion piece base plate; a left material feeding seat and a right material feeding seat are arranged on the lower part of the material clamp fixing seat; and cambered half slots are formed on the inner sides of the left material feeding seat and the right material feeding seat. The full-automatic riveting machine can automatically supply the rivets, accurately insert the rivet conveyed into a material feeding pipe joint into a riveting hole of a plate piece and finish stamping action, and has the advantages of high riveting quality, high production efficiency and low cost; furthermore, potential safety hazard caused by manual operation is avoided; and the practicability is relatively high.

Owner:DONGGUAN SCIENCGO MACHINERY MFG

Riveting machine of wiring harness terminal

ActiveCN103545687ANo movementReduce the burden onLine/current collector detailsState of artEngineering

The invention discloses a riveting machine of a wiring harness terminal. The riveting machine comprises a base and a slant plate. The riveting machine is characterized in that a back air cylinder is arranged on the base, a conveying plate is connected to the front end of the back air cylinder, the slant plate for feeding is arranged on the lateral face of the conveying plate, a feeding plate is arranged on the base, a lateral air cylinder is arranged on one side of the feeding plate, conveying grooves capable of being butted with each other are formed in the conveying plate and the feeding plate, a carrying tool plate is arranged at the front end of the feeding plate, a pressing plate is arranged at the upper end of the carrying tool plate, the pressing plate is driven by a driving mechanism, and a linkage riveting pressing plate is arranged at the bottom of the pressing plate and located above the wiring harness riveting position of the carrying tool plate. According to the riveting machine, the problems that the riveting position has the deviation and the riveting accuracy is low due to the fact that a riveting device in the prior art is low in automation degree and low in machining speed and a wiring harness can move when the wiring harness is machined are solved. A linkage riveting pressing mechanism of the riveting machine of the wiring harness terminal is high in automation degree, high in machining speed, high in riveting accuracy and excellent in riveting quality.

Owner:昆山鑫泰利汽车电子科技有限公司

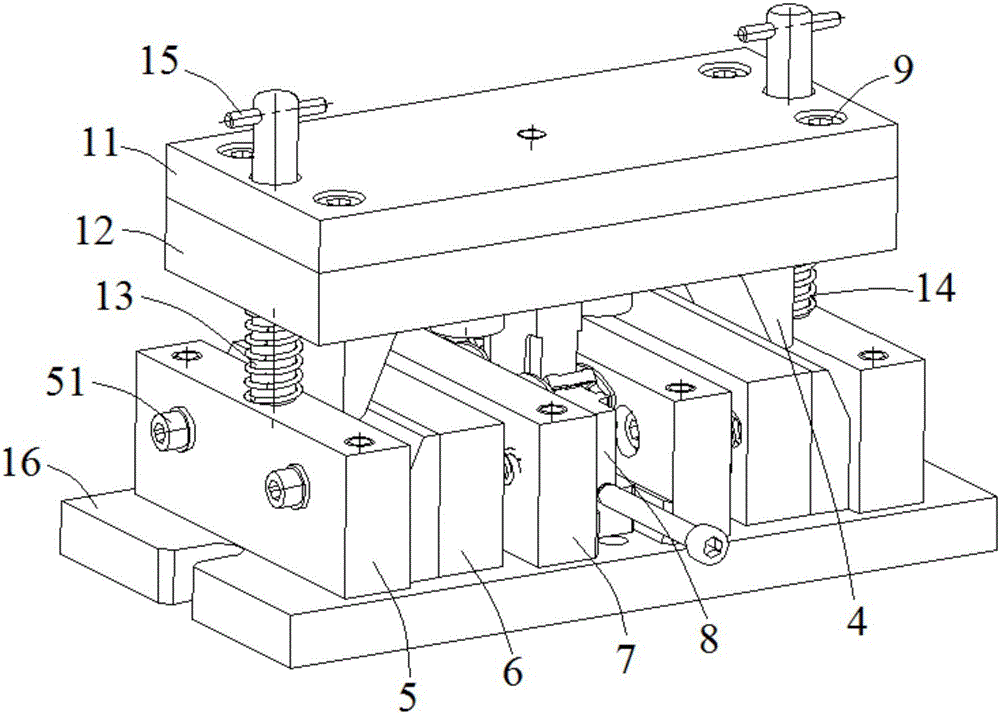

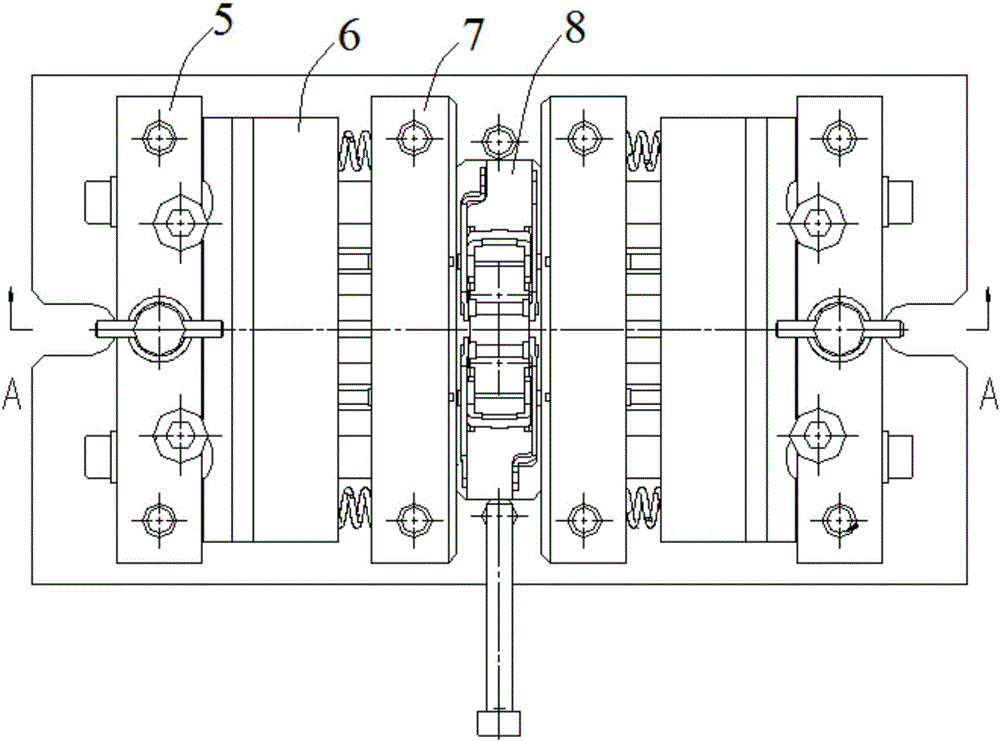

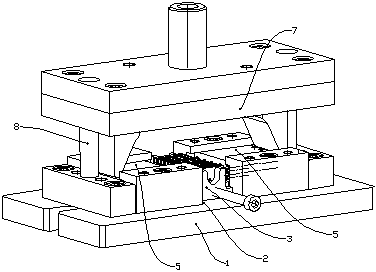

Rivet punching die

The invention relates to the field of dies, in particular to a rivet punching die. A riveting punch is arranged on an upper die plate, an overhanging concave die is fixedly connected to a bracket, a spring is arranged between a pressure plate and the upper die plate, a guide mechanism is arranged between the upper plate and the bracket, the riveting punch passes through the pressure plate and thehead of the riveting punch is in punching fit with the concave die, the overhanging part of the concave die is provided with a support mechanism, and the concave die counteracts most of punching force under the action of the support mechanism, therefore the deformation of the concave die is effectively improved, the riveting quality is improved, a flat riveting surface is ensured and the service life of the die is prolonged.

Owner:HEFEI HUALIN MOLD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com