Riveting fixture for low voltage circuit-breaker arc extinguishing chambers

A low-voltage circuit breaker and riveting fixture technology, which is applied in the manufacture of circuits, electrical components, emergency protection devices, etc., can solve the problems of low manufacturing efficiency, poor reliability, and inconvenient operation, and achieve good riveting quality, reliable action, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

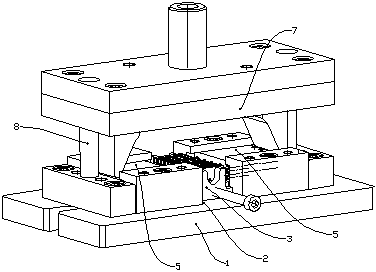

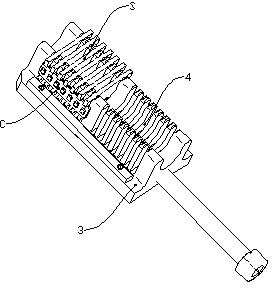

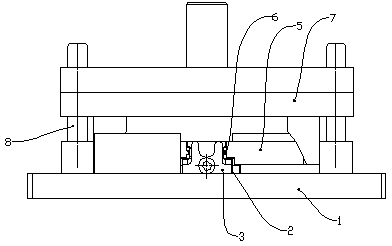

[0011] As shown in the figure, the low-voltage circuit breaker arc extinguishing chamber riveting fixture includes a mold base 1, a drawer groove 2 is arranged in the middle of the mold base, and a drawer base 3 can be inserted and positioned in the drawer groove; There are grid grooves 4 arranged longitudinally, and multiple arc extinguishing grid pieces S to be assembled can be inserted and positioned in each grid groove 4, and sliders 5 that can move horizontally and horizontally are arranged on both sides of the drawer seat 3; the sliders The inner side of 5 is provided with a riveting head 6 with a sharp point, which is used to chisel off the bumps on both sides of the arc extinguishing grid S that has been assembled with the side plate C; the upper part of the outer end of the slider 5 is provided with an upwardly facing wedge At the same time, an upper mold 7 that can be lifted vertically is arranged above the mold base 1. Both sides of the upper mold 7 have downward wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com