Patents

Literature

262results about How to "Improve riveting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

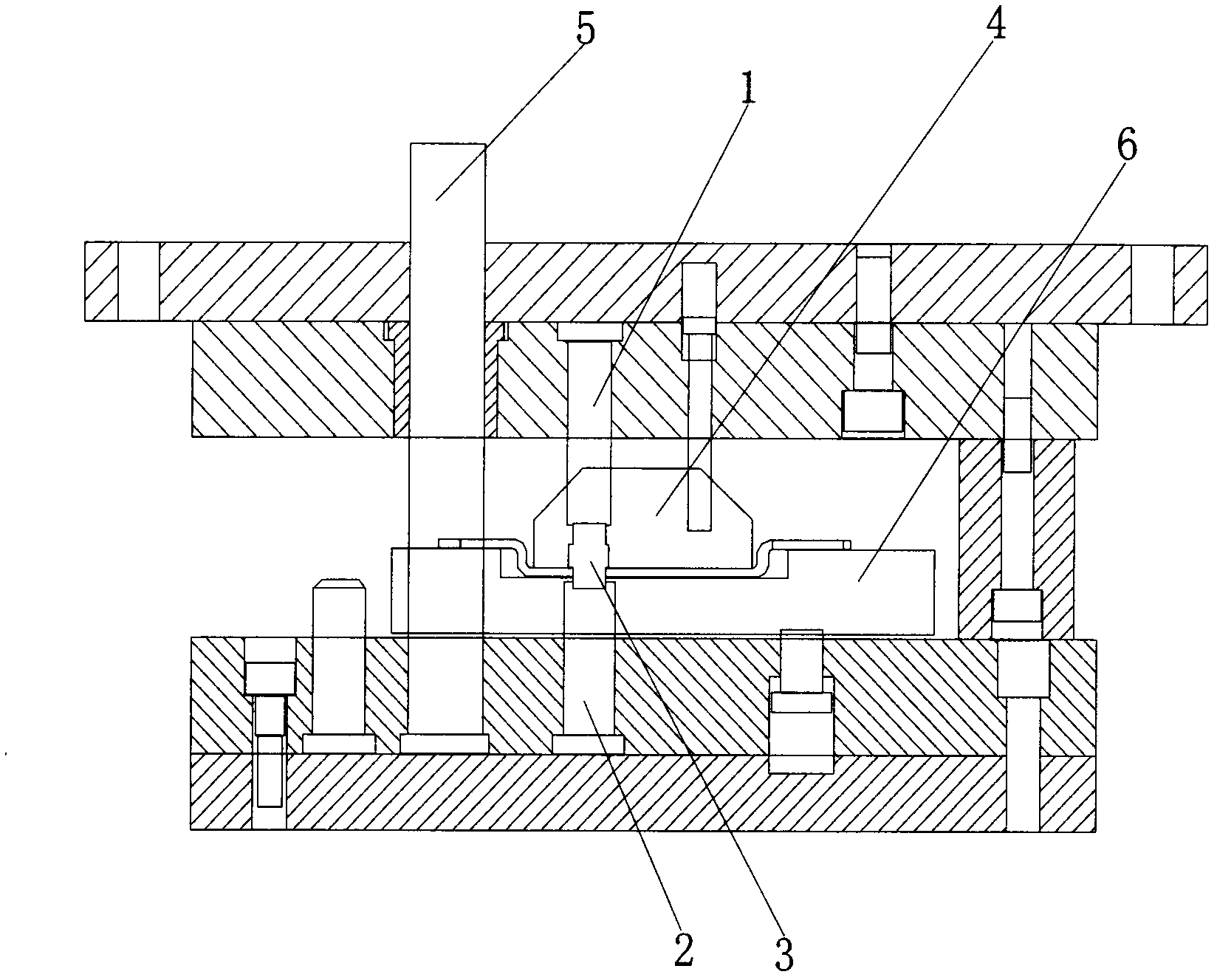

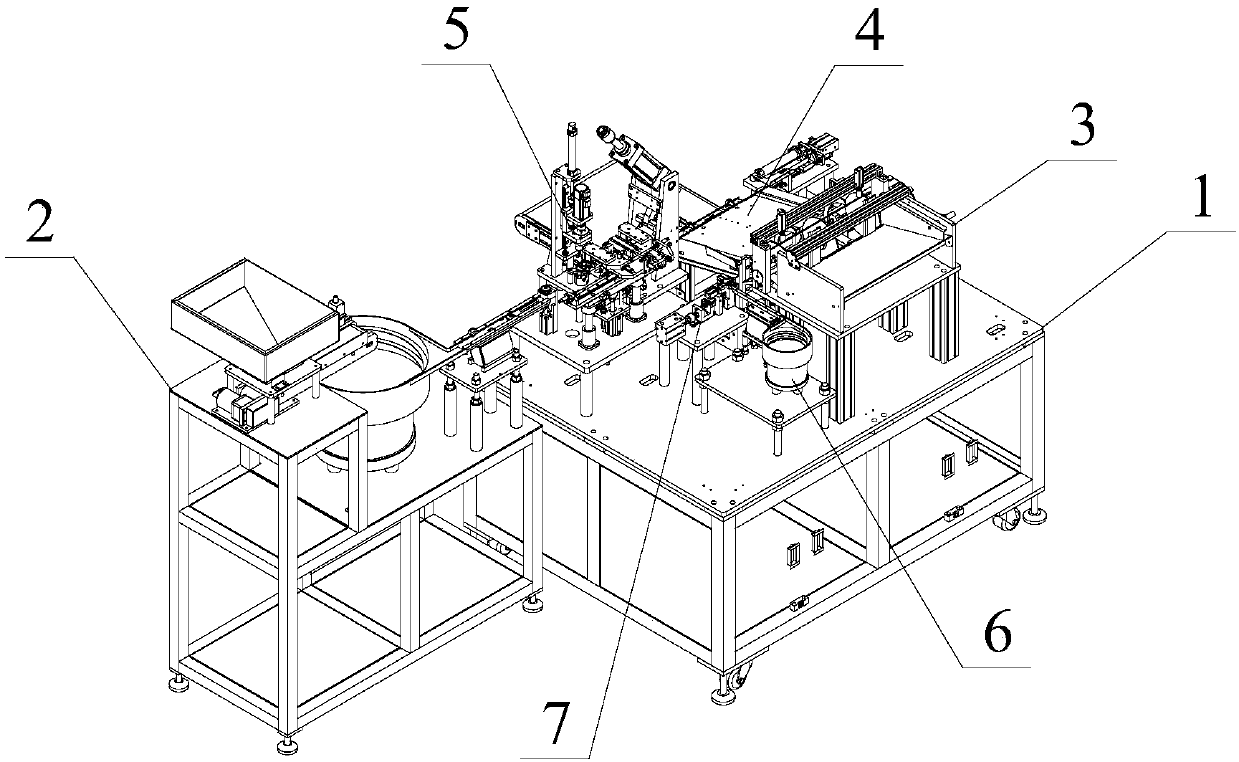

Riveting machine

ActiveCN104439020AHigh precisionQuality improvementProgramme-controlled manipulatorIndustrial engineeringAutomation

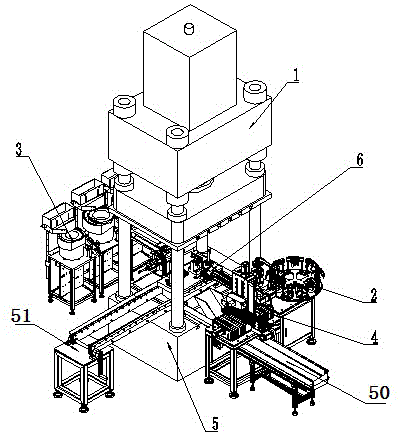

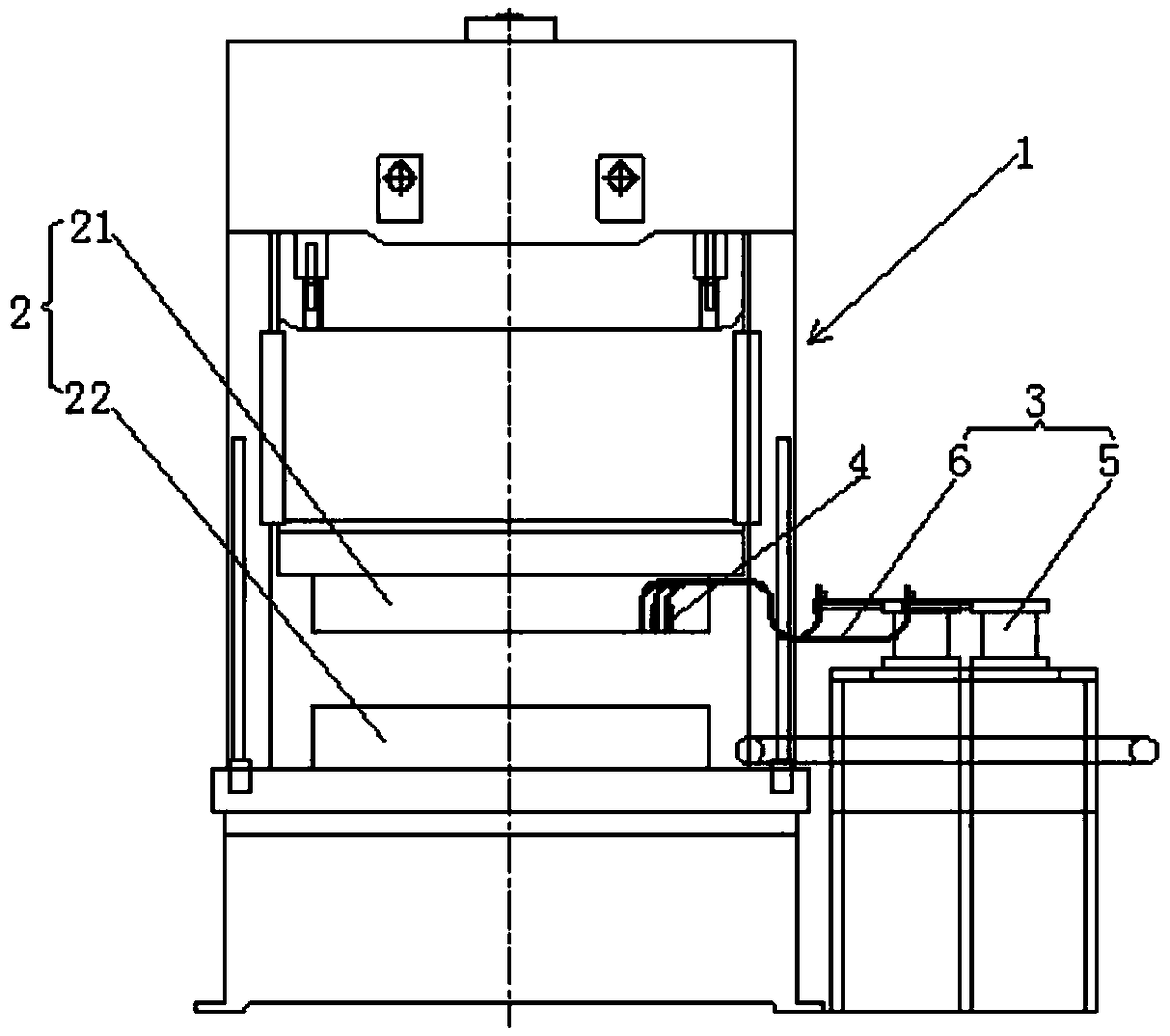

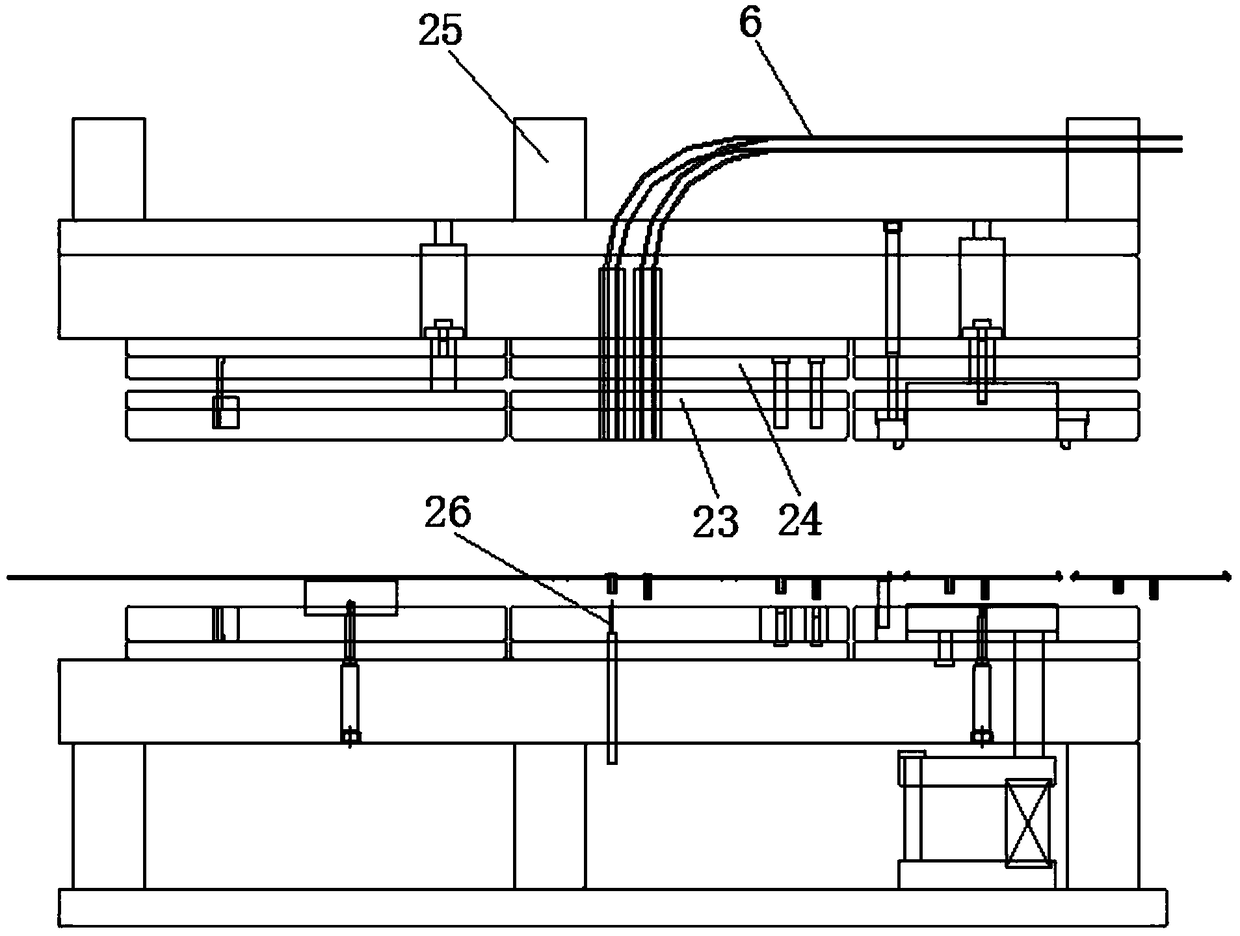

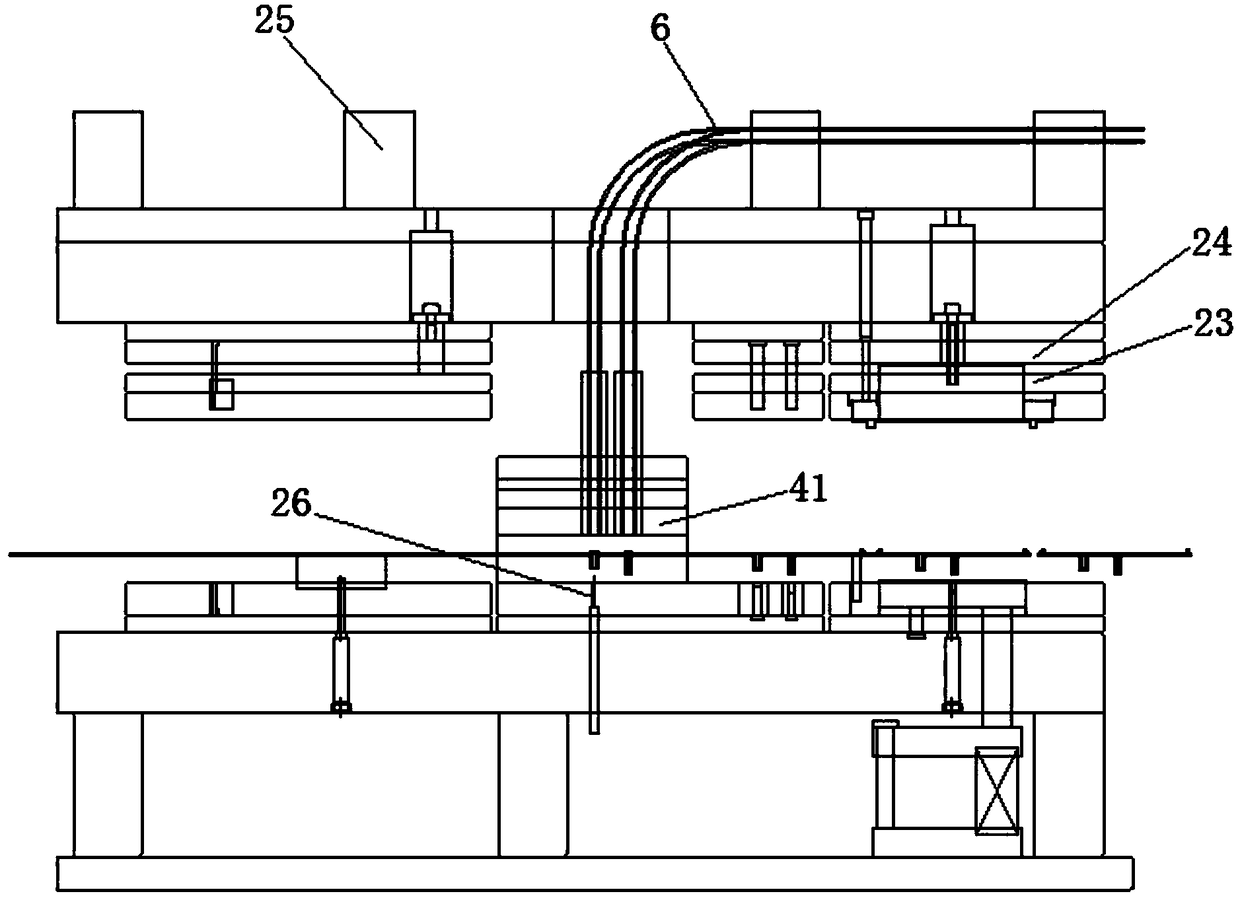

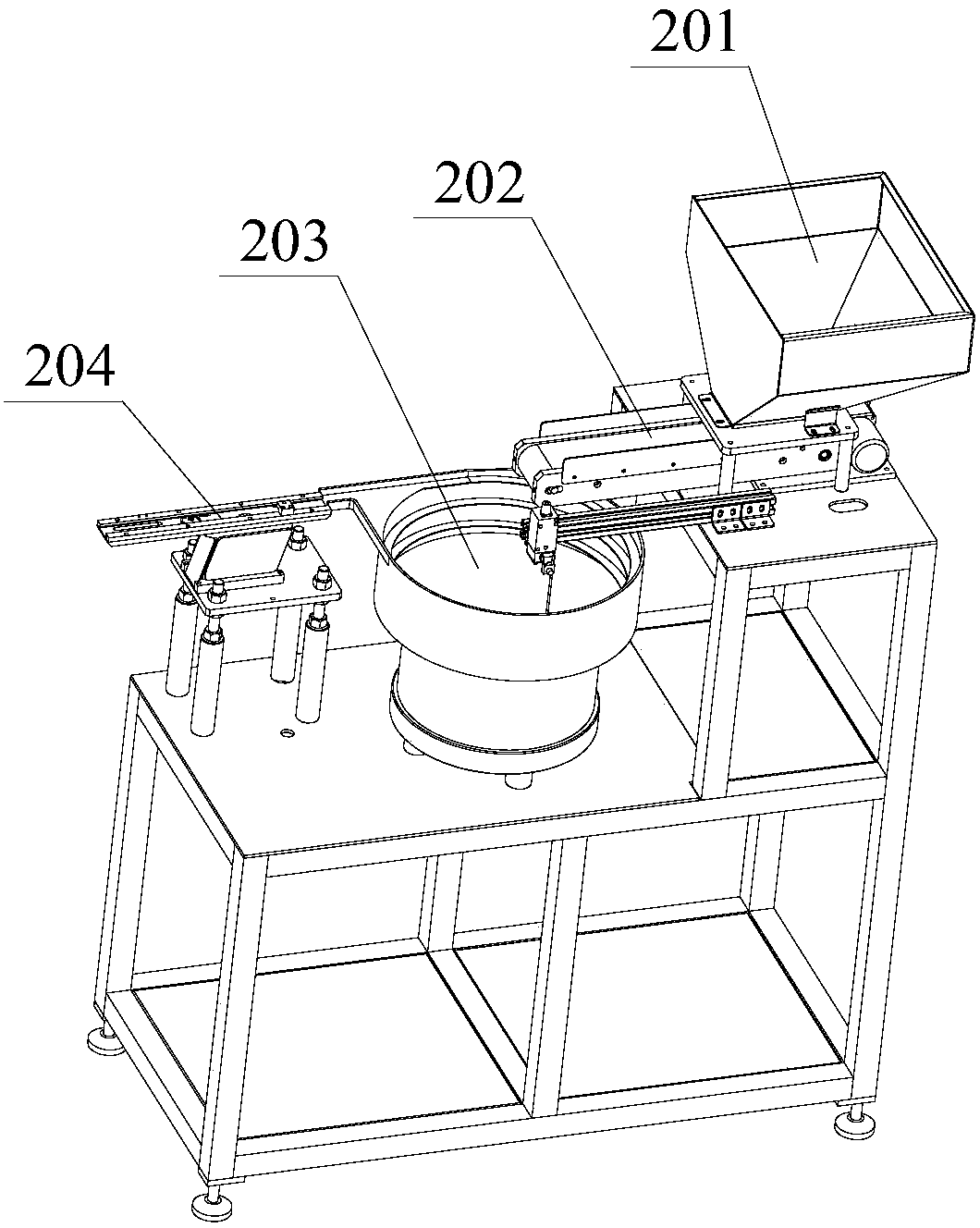

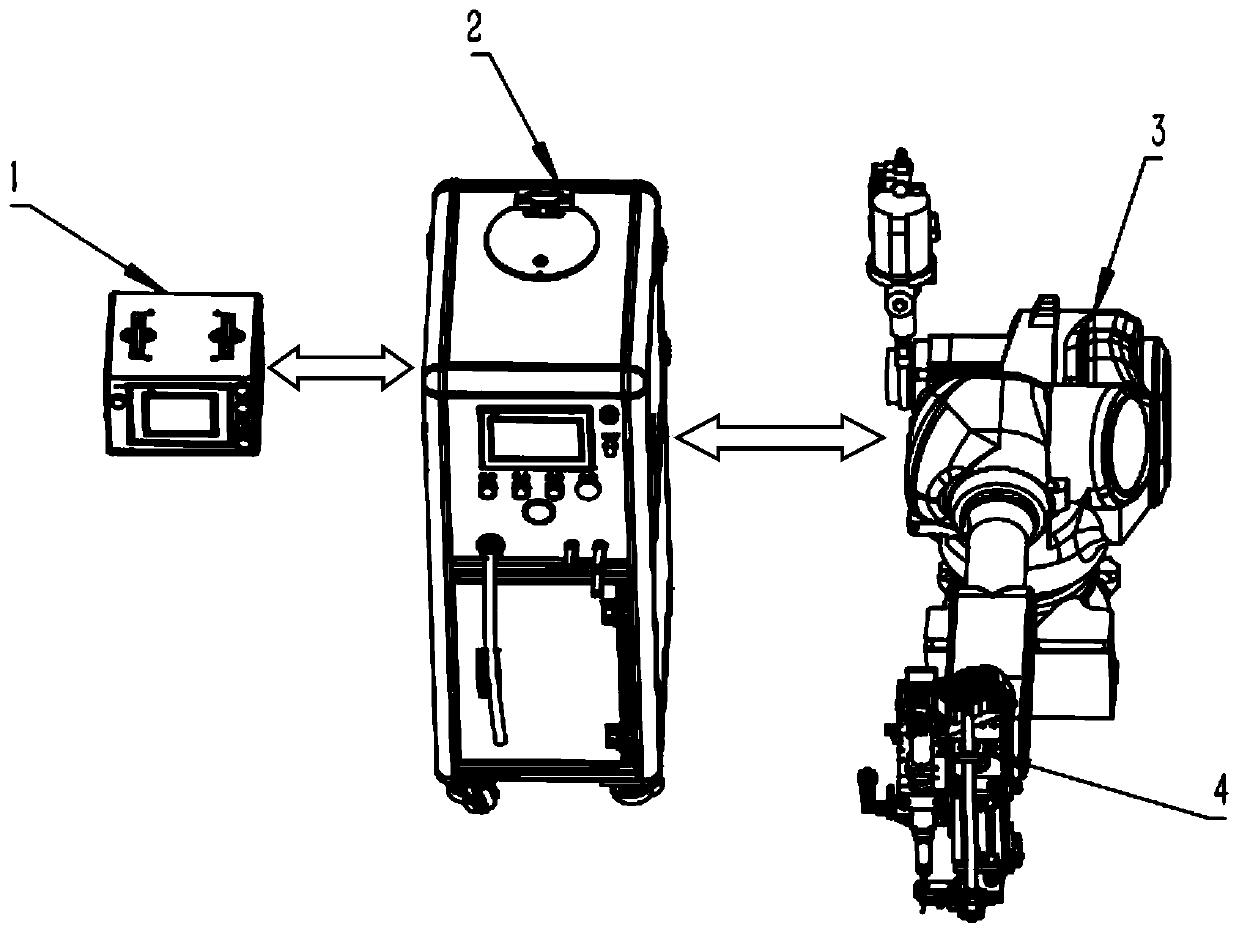

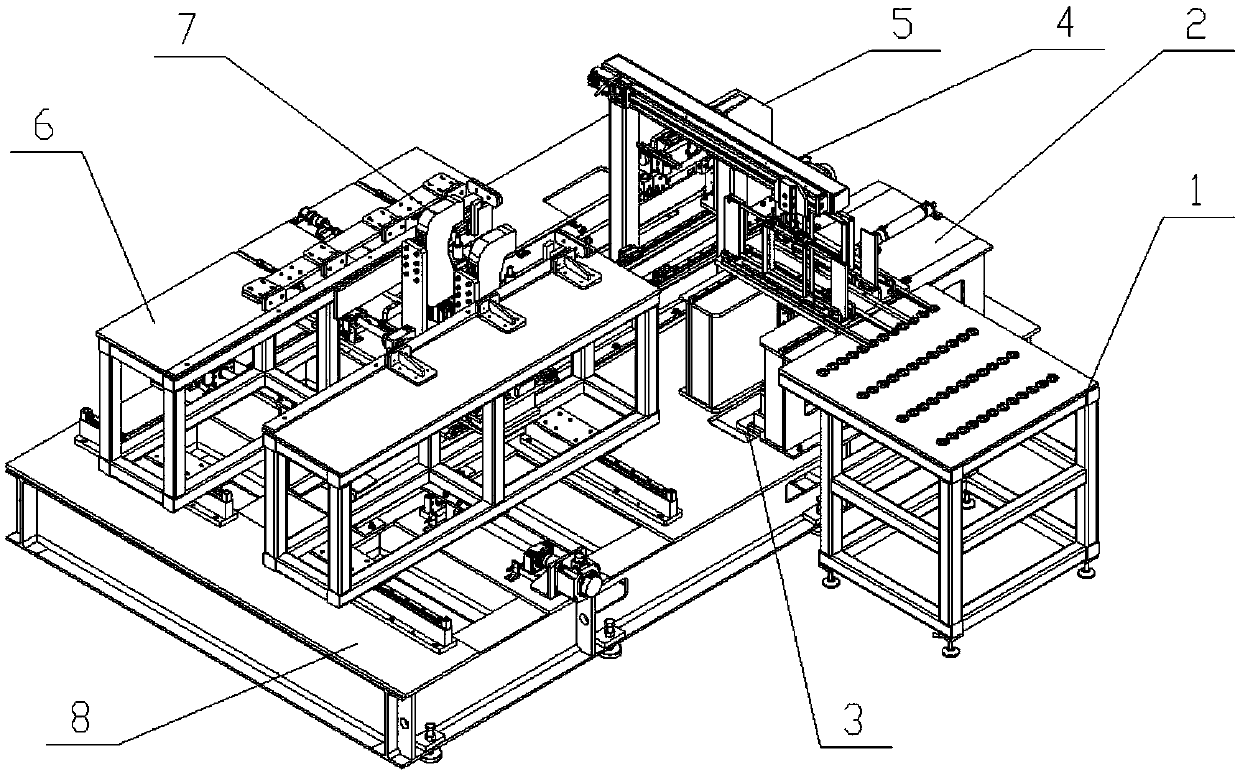

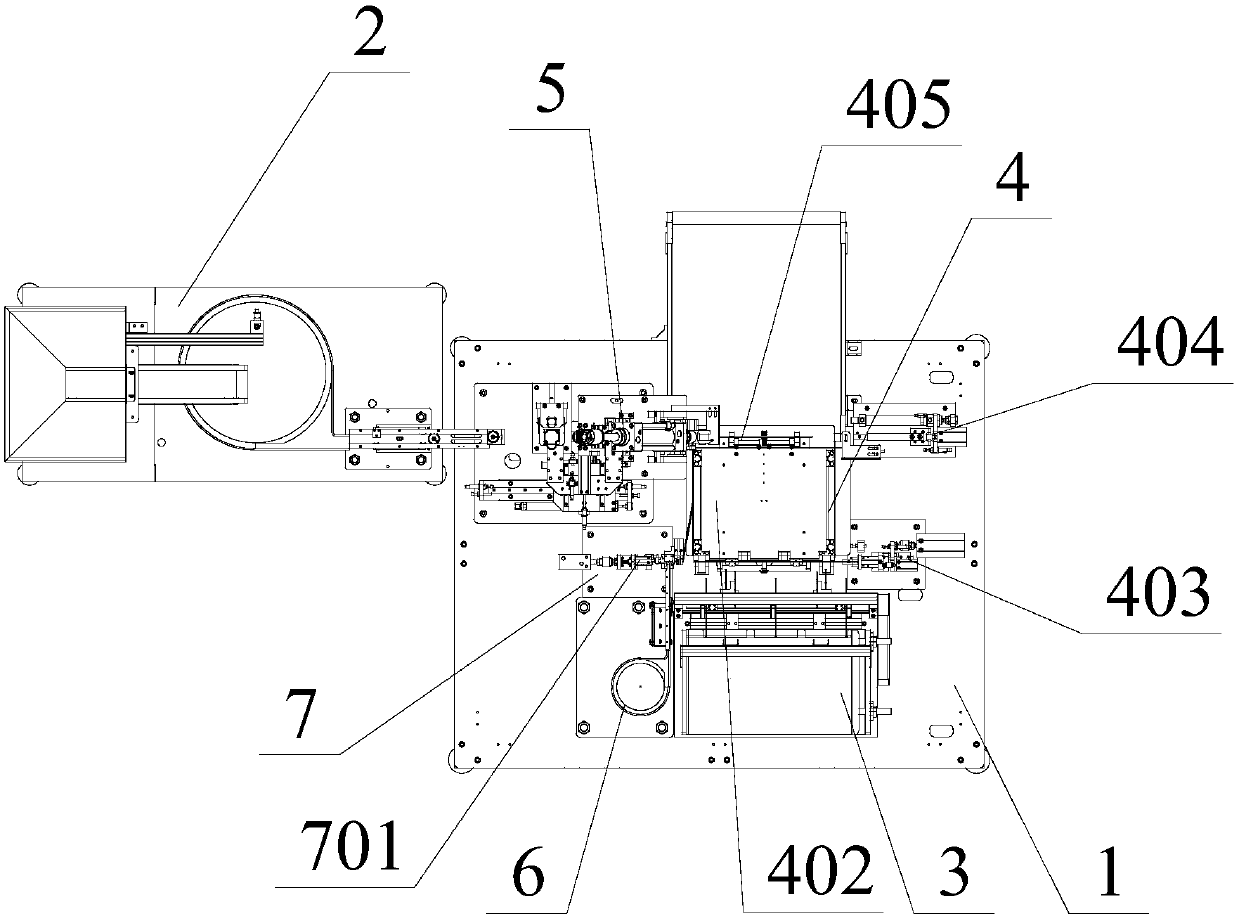

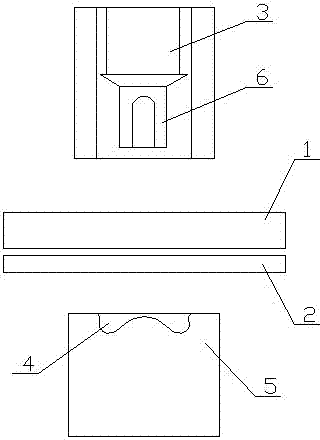

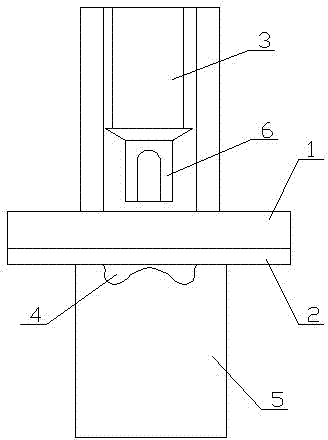

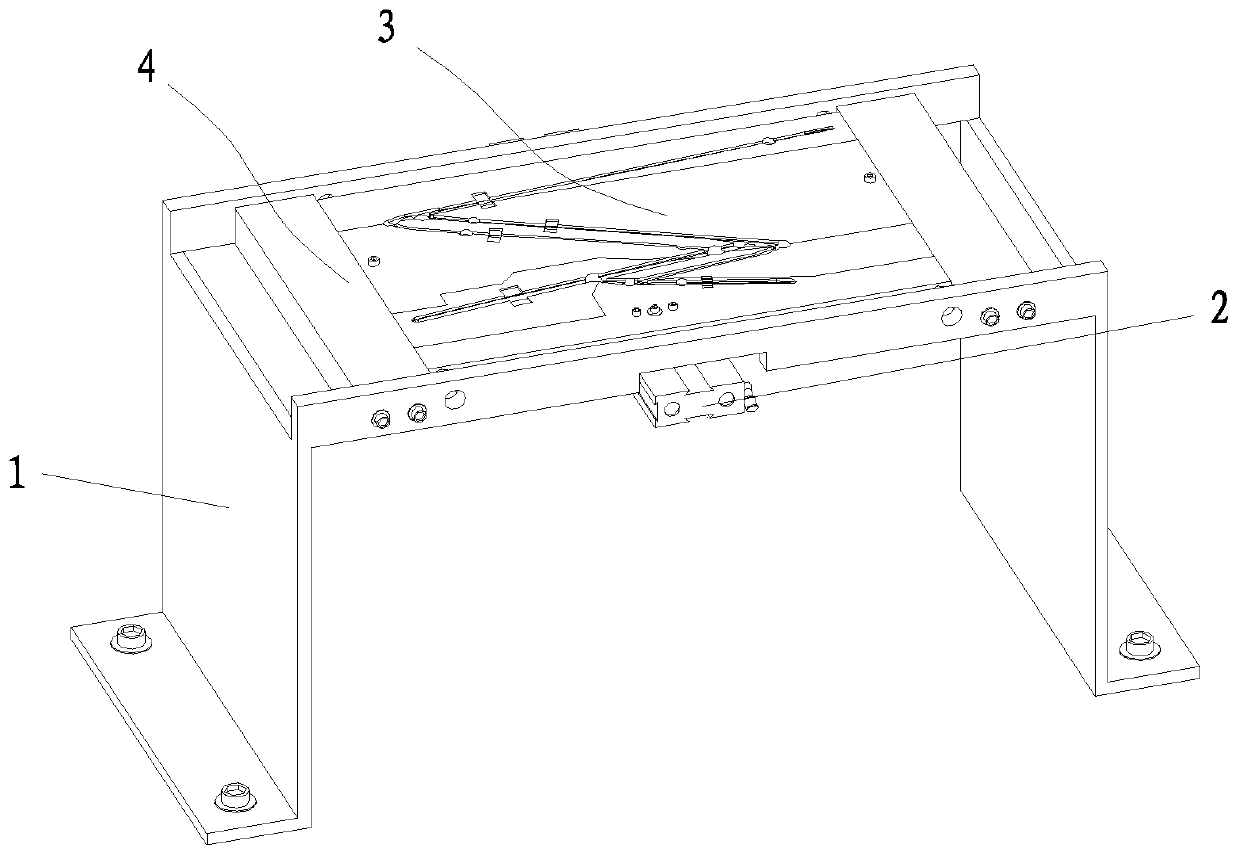

The invention discloses a riveting machine. The riveting machine comprises a press (1), a material loading device (2), a rivet placing device (3) and a material taking device (4), wherein the press (1) is provided with a base (5) on which a riveting station (6) is arranged; the material loading device (2), the press (1) and the rivet placing device (3) are transversely arranged in parallel; the material taking device (4) and the material loading device (2) are longitudinally arranged in parallel. According to the riveting machine, material loading automation, rivet loading automation and material taking automation during riveting are realized, and the effects of automatic riveting and high efficiency are achieved; due to the fact that artificial errors are avoided, the riveting accuracy and the riveting quality are improved; in addition, the labor cost can be reduced.

Owner:CHONGQING LANGZHENG TECH

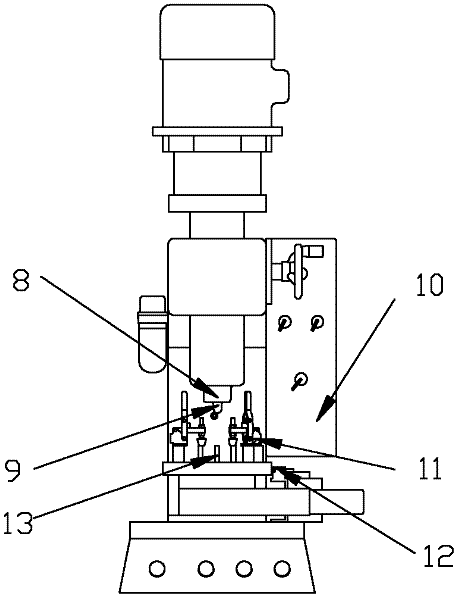

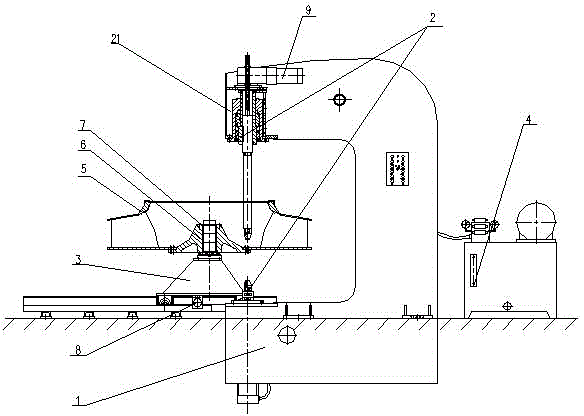

Multi-station full-automatic pneumatic rotating riveting machine

The invention provides a multi-station full-automatic pneumatic rotating riveting machine, which comprises a machine base and further comprises an indicator lamp, a pressure adjusting valve, a motor, a manual lifting turntable, a graduated disk, an air cylinder and an electric box which are mounted on the machine base, wherein a rotating riveting head is mounted on the motor and a rotating riveting rod is mounted on the rotating riveting head. The multi-station full-automatic pneumatic rotating riveting machine is characterized in that the air cylinder and the graduated disk are mounted on the machine base under the rotating riveting rod; the graduated disk is connected to the air cylinder and is driven to rotate by the air cylinder; a position-limit switch is mounted between the air cylinder and the graduated disk; the position-limit switch is driven by the air cylinder and is matched with limit teeth on the graduated disk for positioning; a control line of the air cylinder is connected to a signal output end of a master control board in the electric box; and an instruction input end of the master control board is connected to various operation keys on the surface of the electric box. The multi-station full-automatic pneumatic rotating riveting machine has the advantages that accuracy and efficiency for riveting a workpiece are promoted, structure is simple, maintenance is convenient, processing cost is low, and the like.

Owner:TIANJIN RENYIHE AUTOMATION TECH

Riveting device

Owner:GREE ELECTRIC APPLIANCES INC

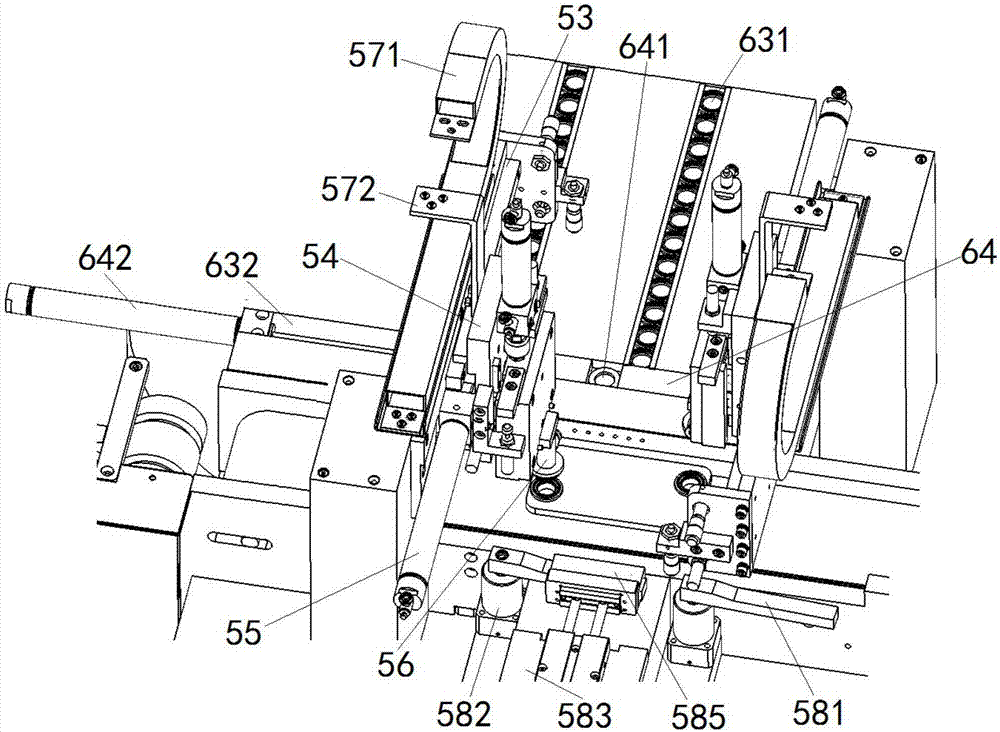

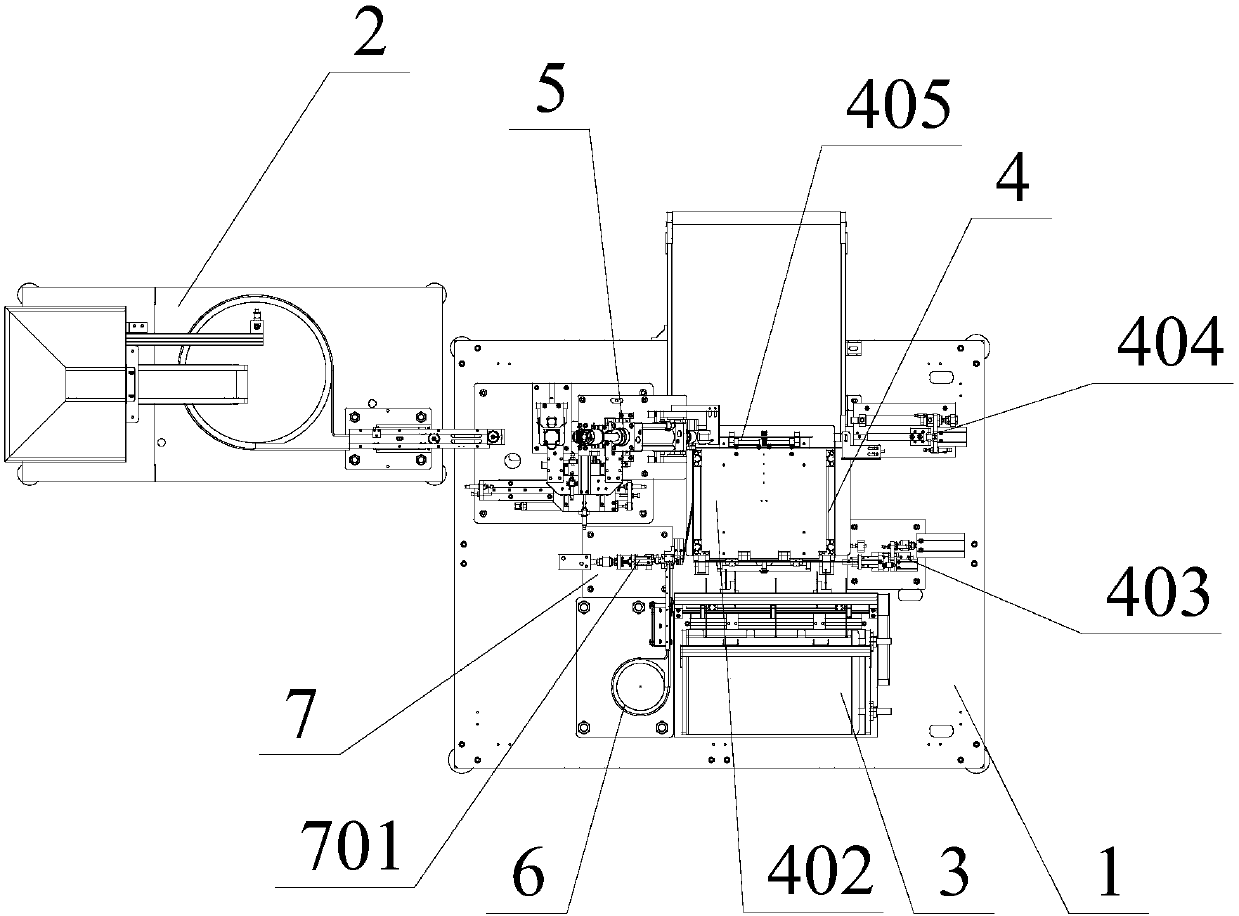

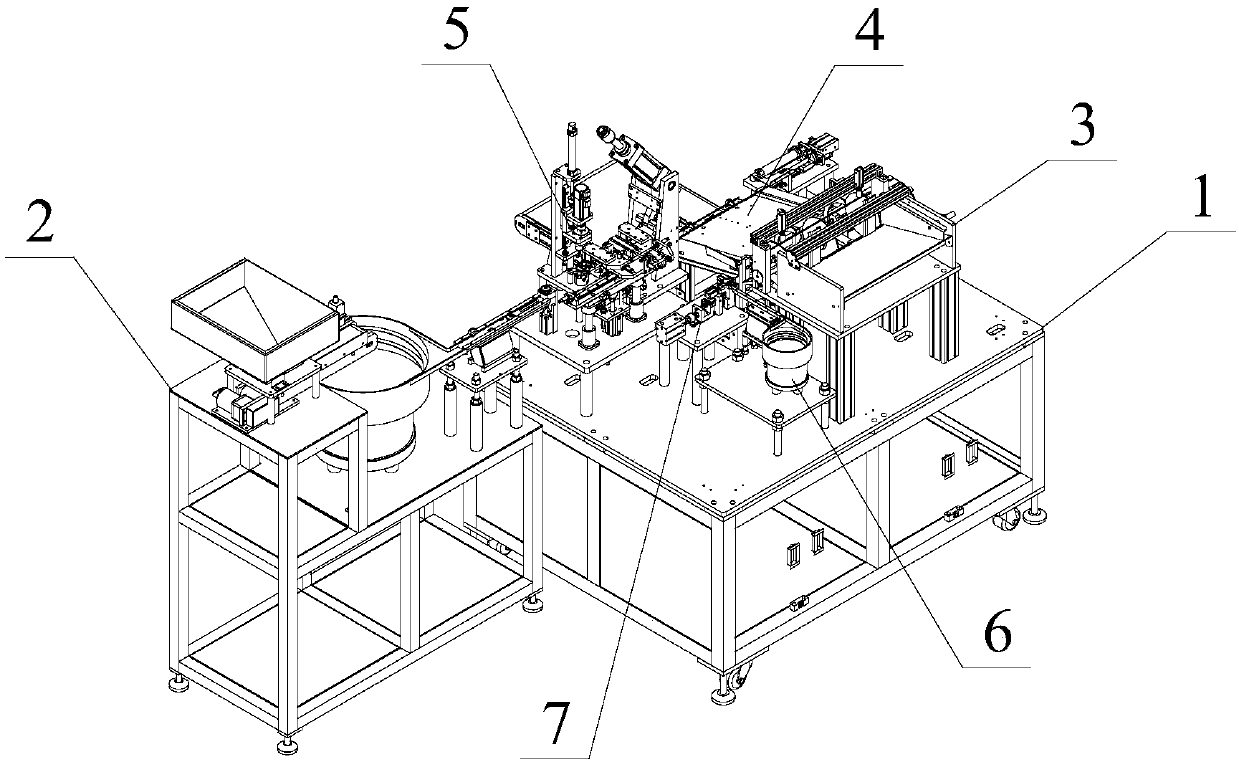

Automatic assembly riveting machine of USB interfaces

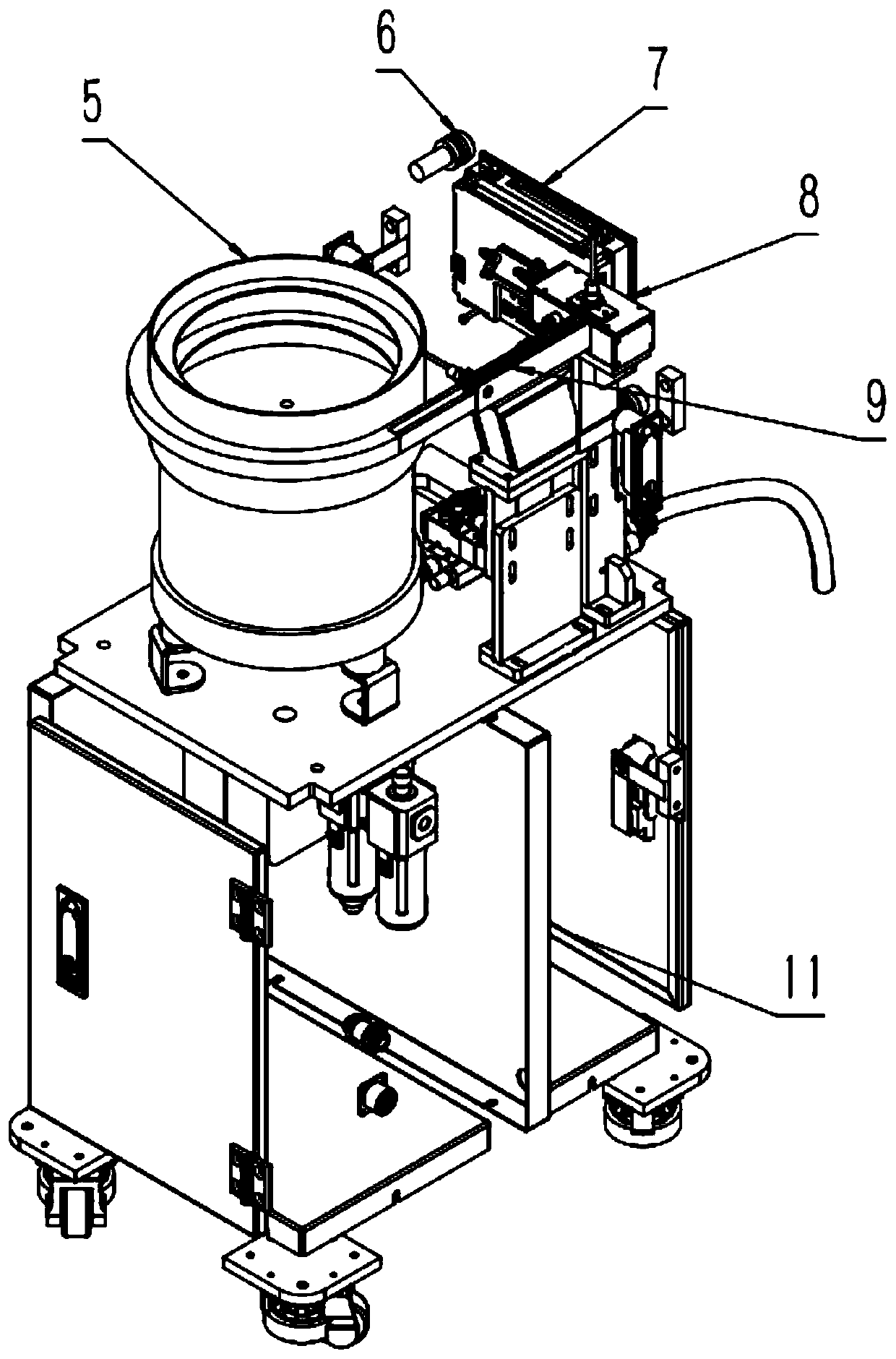

ActiveCN107745254APrecise and continuous feedingRiveting automatic continuousOther manufacturing equipments/toolsEngineeringManipulator

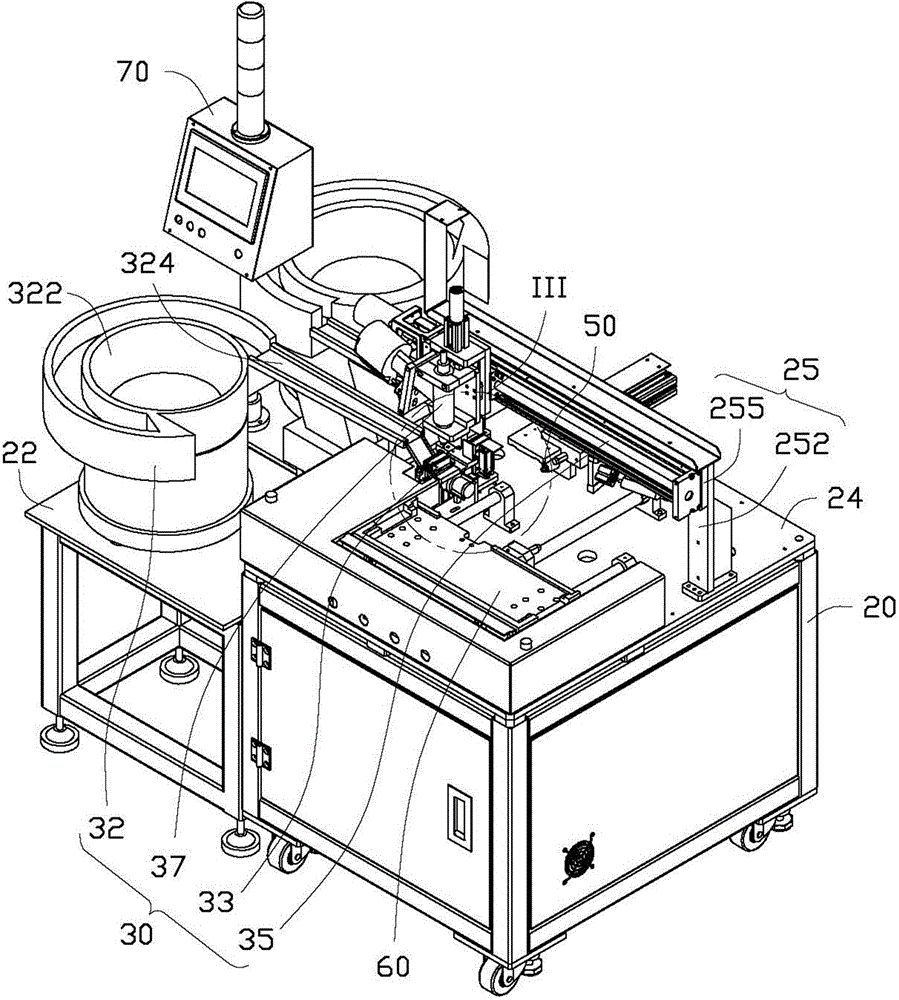

The present invention relates to an automatic assembly riveting machine of USB interfaces. A canning butting apparatus, a butting conveying apparatus and a riveting apparatus are disposed on a frame.The riveting apparatus comprises a riveting conveying apparatus, a second pick-and-place manipulator, a rivet discharge apparatus, a rivet compacting apparatus and a second pick-and-place manipulator.The butting conveying apparatus is cooperated with the canning butting apparatus via a first discharge manipulator. The rivet discharge apparatus comprises a rivet discharge seat. The rivet dischargeseat is provided with a rivet conveyer trough cooperated with a rivet vibration feed tray. The tail end of the rivet conveyer trough is provided with a rivet feed butting port. An upper side of the rivet feed butting port is cooperated with a rivet pushing bar and a lower side of the rivet feed-in butting port is cooperated with a rivet feed apparatus. The rivet pushing bar is disposed on a rivetpushing block. The rivet pushing block is positioned right above a conveying carrier and provided with rivet press-in bars cooperated with a product thereon. Automatic and continuous riveting is achieved by the rivet discharge apparatus and the rivet compacting apparatus, accurate and continuous rivet discharge is achieved, and riveting efficiency is improved.

Owner:安徽瑞尔特仪表科技有限公司

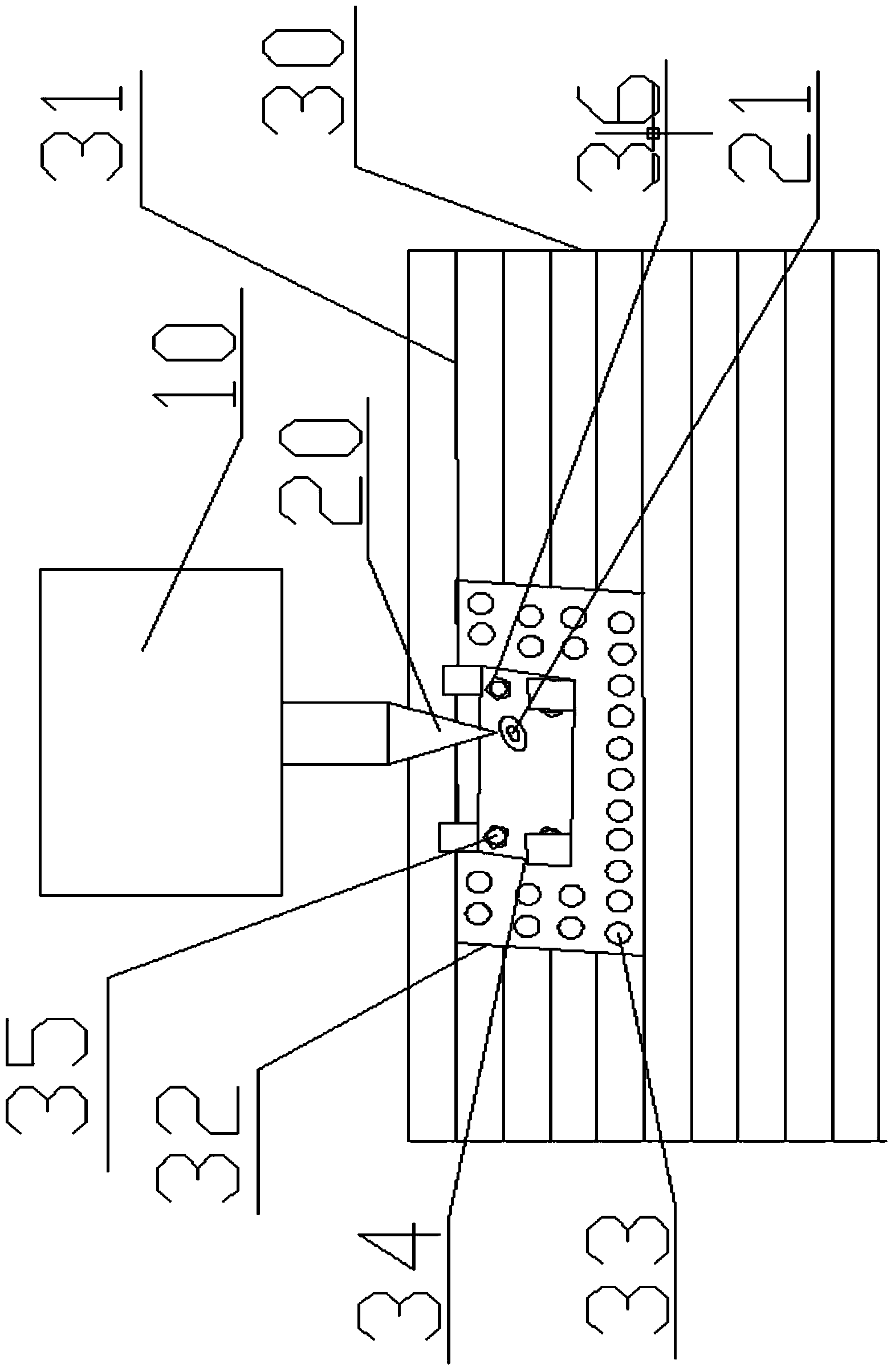

Full-automatic punching riveting system and working process thereof

PendingCN108838316AThere is no impact on punching efficiencyImprove processing efficiencyShaping toolsPunch pressCam

The invention discloses a full-automatic punching riveting system and a working process thereof. The system comprises a punching machine, a mold, a feeding machine, a finished product discharging conveying belt, a rivet conveying device, a positioning ejection device and a control center; the punching machine is an automatic punching machine, an electronic cam is arranged, the mold is a punching continuous mold, and the mold comprises an upper mold and a lower mold; and rivets are conveyed to the corresponding pneumatic ejection gun through the rivet conveying device. When the full-automatic punching riveting system works, the feeding machine conveys a to-be-matched material belt into the mold on the punching machine, riveting holes and other holes are punched in the punching continuous mold, the plurality of rivets are sent into the corresponding riveting holes through the pneumatic ejection guns, riveting is completed by using the punching pressing force of the punching machine, after punching, riveting and bending processes are completed on the material belt, a product is cut off and slides to the finished product discharging conveying belt, and the product is sent out of the punching machine. According to the full-automatic punching riveting system, the machining efficiency is high, and the finished product yield is high.

Owner:SUZHOU KEYTEC PRECISION COMPONENTS

Automatic riveting device

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

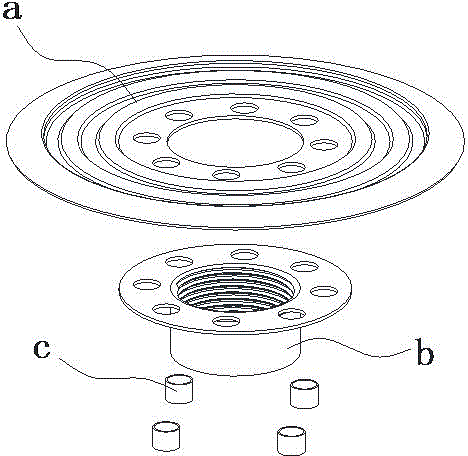

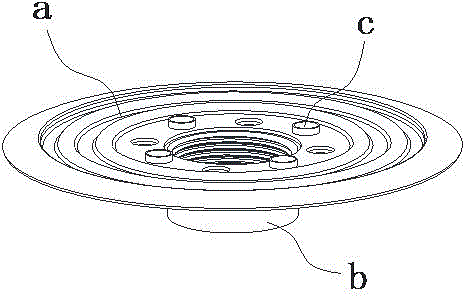

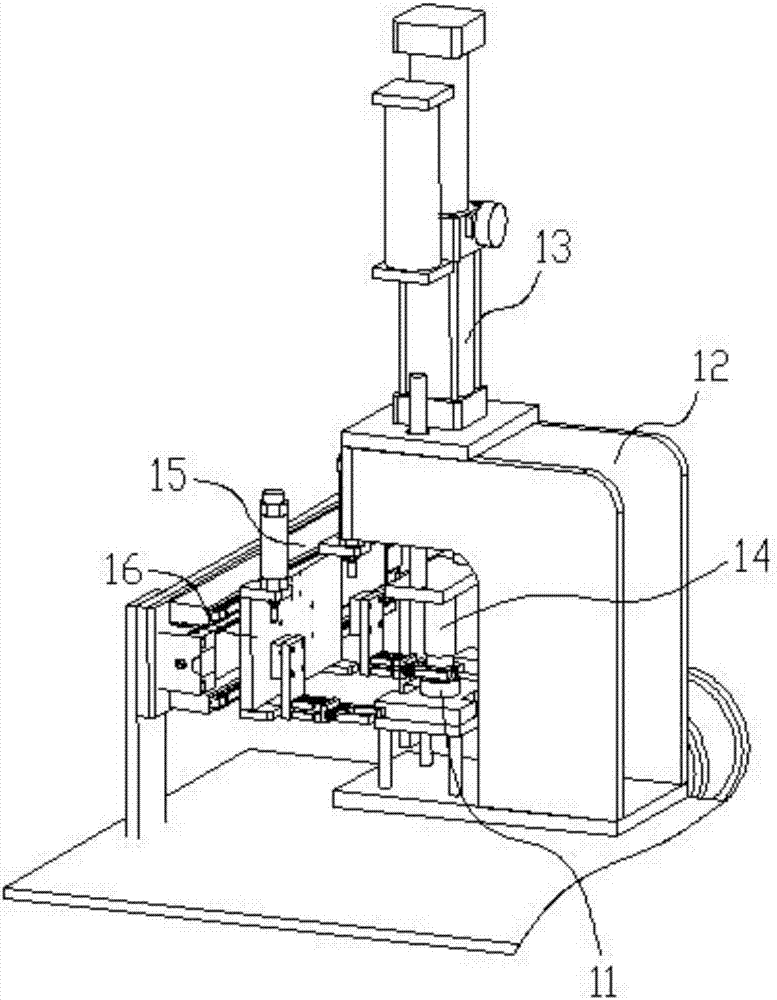

Directional riveting mechanism for motor end cover and electric power pipe fitting

InactiveCN107900232AReduce circulation proceduresReduce time consumptionMetal-working feeding devicesManufacturing dynamo-electric machinesButt jointPipe fitting

The invention provides a directional riveting mechanism for a motor end cover and an electric power pipe fitting. The directional riveting mechanism for the motor end cover and the electric power pipefitting includes an end cover material-collecting device, a displacement unit, a location unit and a riveting unit, the end cover material-collecting device is connected with an end cover direct-shaking feeder and also arranged at the tail end of the end cover direct-shaking feeder, and the end cover material-collecting device is used to collect an end cover which is transported by the end coverdirect-shaking feeder; the end cover material-collecting device includes a material-collecting support, a material-collecting notch, a step-shaped mandril and a jacking driving air cylinder, wherein,the material-collecting notch is formed in the top end of the material-collecting support, and the material-collecting notch rightly faces the end cover direct-shaking feeder and is flush with a guiding rail, for transporting the end cover, on the end cover direct-shaking feeder; and the jacking driving air cylinder is used to drive the step-shaped mandril to jack the end cover which is located inthe material-collecting notch. According to the directional riveting mechanism for the motor end cover and the electric power pipe fitting, the motor end cover can be accurately collected, located and transferred, and the motor end cover and the electric power pipe fitting are in butt joint accurately are riveted.

Owner:CHONGQING RYAN PAINT CO LTD

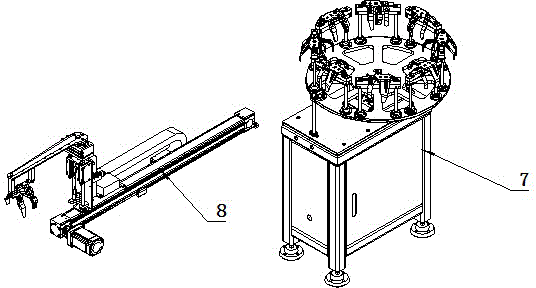

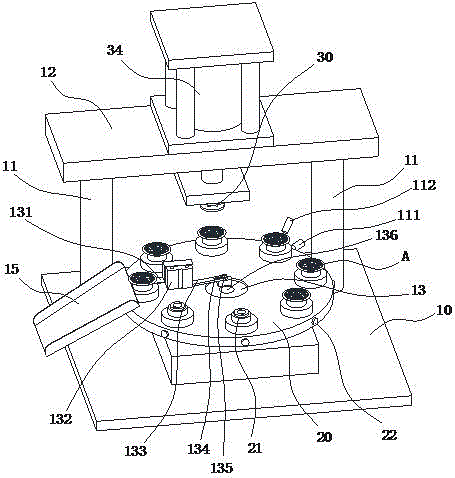

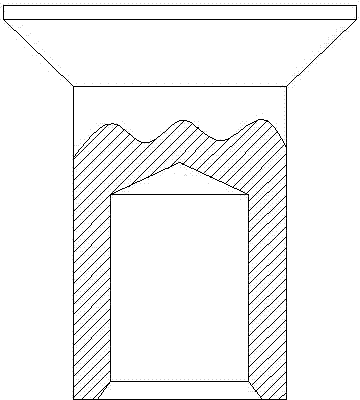

Multi-station rotary riveting machine

The invention belongs to the field of filter manufacture, and particularly relates to a multi-station rotary riveting machine. A plurality of positioning seats are arranged on a rotating plate, an operation worker can continuously perform feeding operation, and the machine is controlled through an automatic system; the positioning seats can automatically enter punching stations for riveting, and the riveting efficiency is greatly improved; meanwhile, an unloading mechanism can automatically eject out riveted end covers from the positioning seats and enables the end covers to fall into a material collecting unit, the production efficiency is greatly improved, and the labor intensity of the operator is reduced; besides, in the down pressing process of a punch, a press plate is firstly attached with one end cover and tightly presses the end cover, a mold plate and a flange on a thread tube cannot rub with each other in the riveting process, the riveting quality is good, and the rivet appearance is attractive.

Owner:蚌埠威诺过滤器有限公司

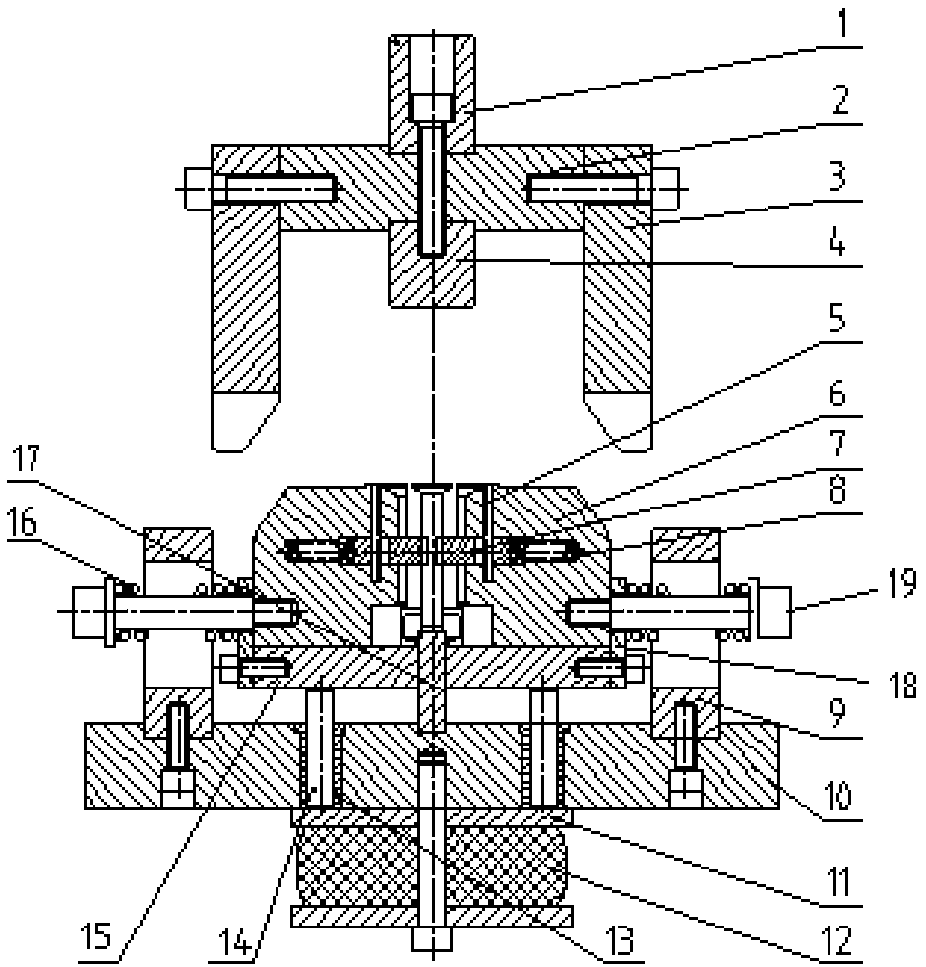

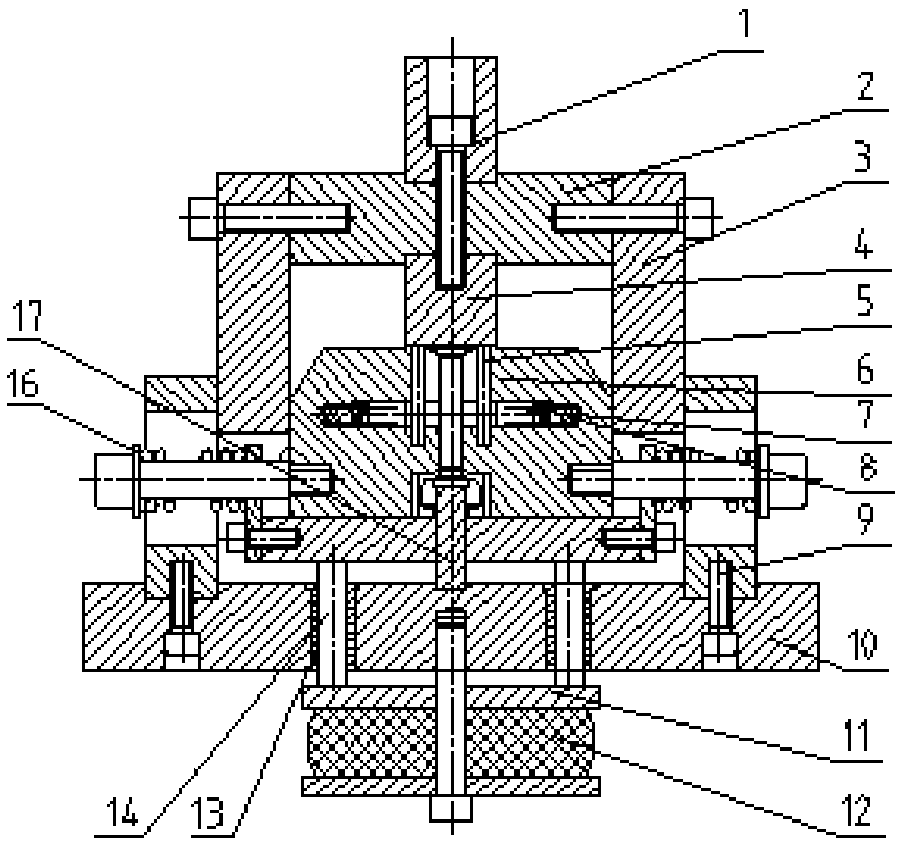

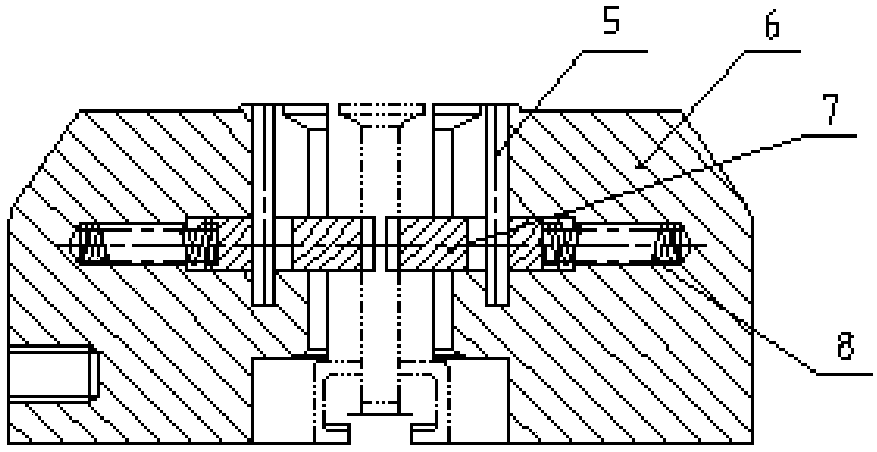

Double-end pressure riveting method, riveting pin and pressure riveting device

Owner:SUZHOU DONGFENG FINEBLANKING ENG

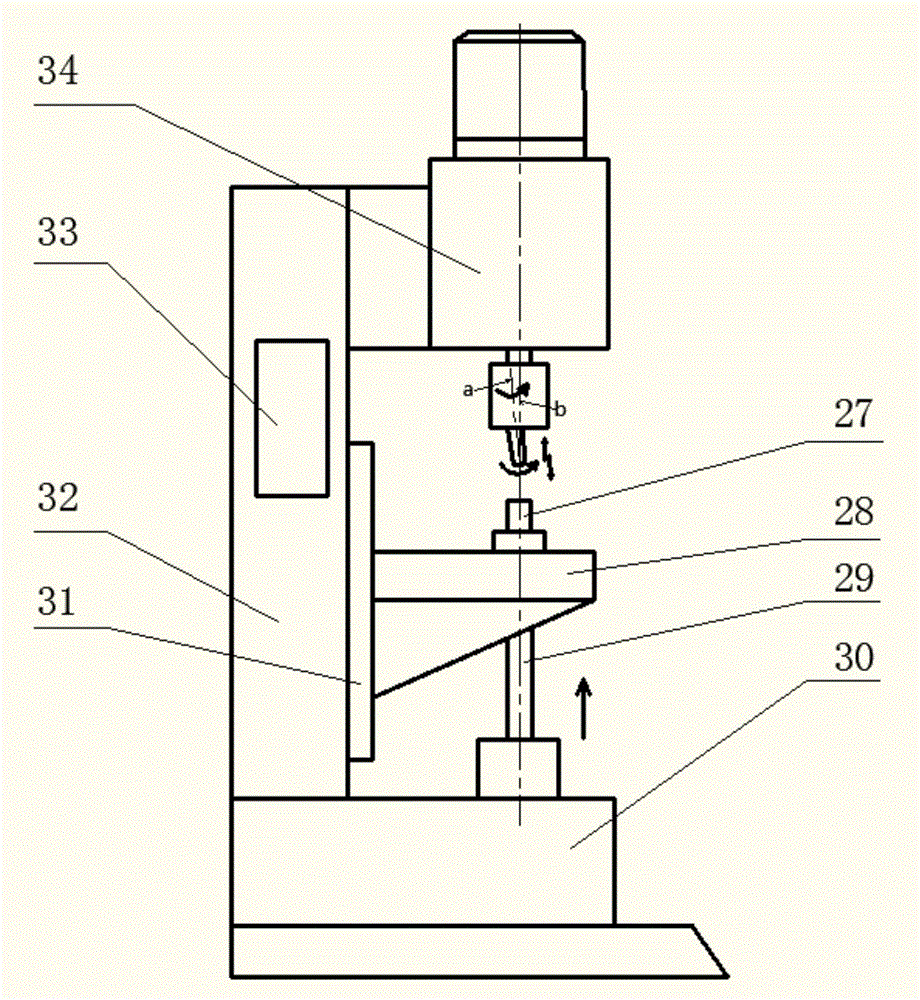

Vertical hydraulic riveting machine

ActiveCN104057009AReduce labor intensityImprove riveting efficiencyHydraulic pumpPulp and paper industry

A vertical hydraulic riveting machine comprises an engine body, a riveting hydraulic mechanism, a bearing trolley and a hydraulic pump station, wherein the hydraulic pump station is connected onto the hydraulic riveting structure arranged on the engine body through a hydraulic pipeline, the riveting mechanism comprises an upper riveting hydraulic mechanism and a lower riveting hydraulic mechanism, the upper riveting hydraulic mechanism comprises an upper oil cylinder, the upper oil cylinder comprises a cylinder body and an upper piston rod arranged inside the cylinder body, the upper piston rod is a double shaft extension piston rod, the upper end of the double shaft extension piston rod is provided with an anti-rotation board, a trapezoid inner screw thread through hole is formed in the center of the double shaft extension piston rod along the length direction, a trapezoid screw rod is in female connection with the trapezoid inner screw thread through hole, a riveting rod is connected onto one end of the trapezoid screw rod, the lower end of the riveting rod is provided with an upper riveting head, the trapezoid screw rod is provided with a flat key, one end of the flat key is inserted into an inner hole in a speed reducing motor, the lower riveting hydraulic mechanism comprises a lower oil cylinder and a lower piston rod arranged inside the lower oil cylinder, and a lower riveting head is connected onto the upper end of the lower piston rod. The vertical hydraulic riveting machine has the characteristics of being high in working efficiency and good in riveting quality.

Owner:SHANDONG ZHANGQIU BLOWER

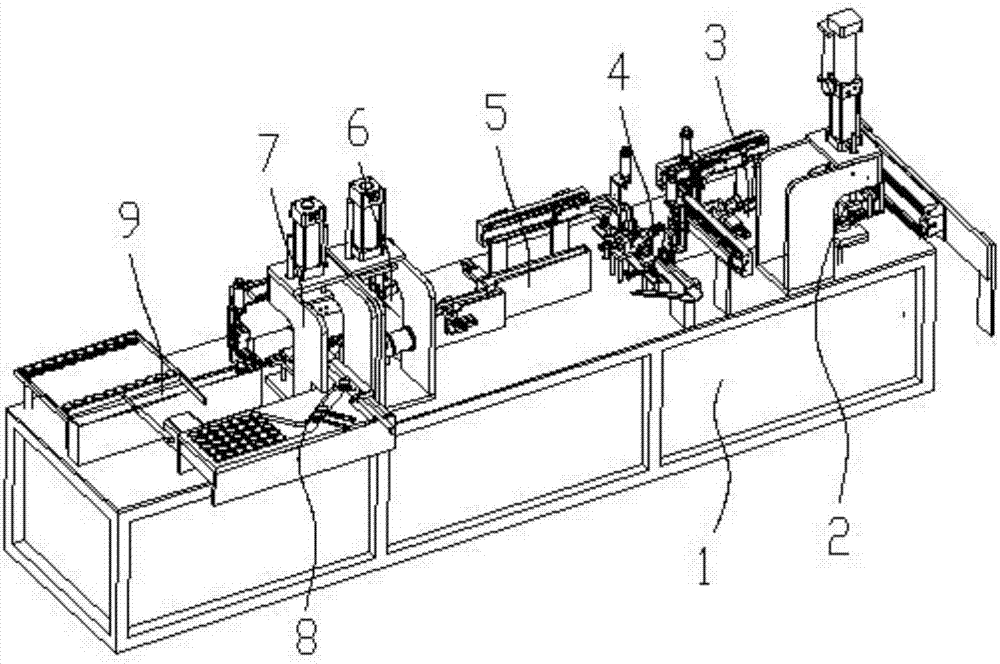

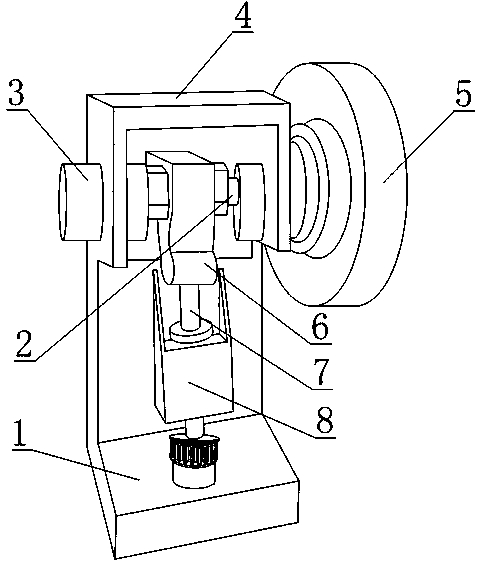

Automated riveting device

ActiveCN107297609AImprove riveting qualityImprove riveting efficiencyPolishing machinesMetal working apparatusEngineeringMachining

The invention discloses an automated riveting device. The automated riveting device comprises a delivering belt, a polishing mechanism, a riveting mechanism, a feeding mechanism and a controlling mechanism, the polishing mechanism comprises a polishing table, an X-axis slide rail, a Y-axis slide rail, a lifting slide rail, a motor mounting plate, a polishing motor and a positioning component; the riveting mechanism comprises a riveting table, a riveting frame, a riveting motor, a horizontal slide rail, a longitudinal slide rail and a rotary pressing strip, the riveting motor is installed on a riveting bottom plate, and the riveting bottom plate is longitudinally and slidably arranged on the longitudinal slide rail; the feeding mechanism comprises a feeding disc, a connecting groove, a feed guiding plate and a feeding arm, and the feed guiding plate is provided with a feed guiding groove and a feeding groove which are horizontally formed and mutually vertically formed; the feeding groove is internally provided with a feeding strip, and the feeding strip is provided with a feed storage hole. The automated riveting device is compact in structure, can automatically load feed and unload feed, automatically conduct polishing and riveting, drastically lower the labor intensity of workers, and simplify the machining procedure, the riveting quality of an end plate is good, and the riveting efficiency is high.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

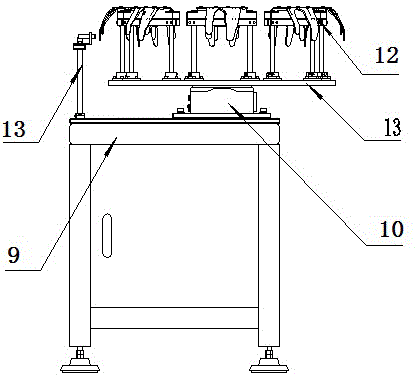

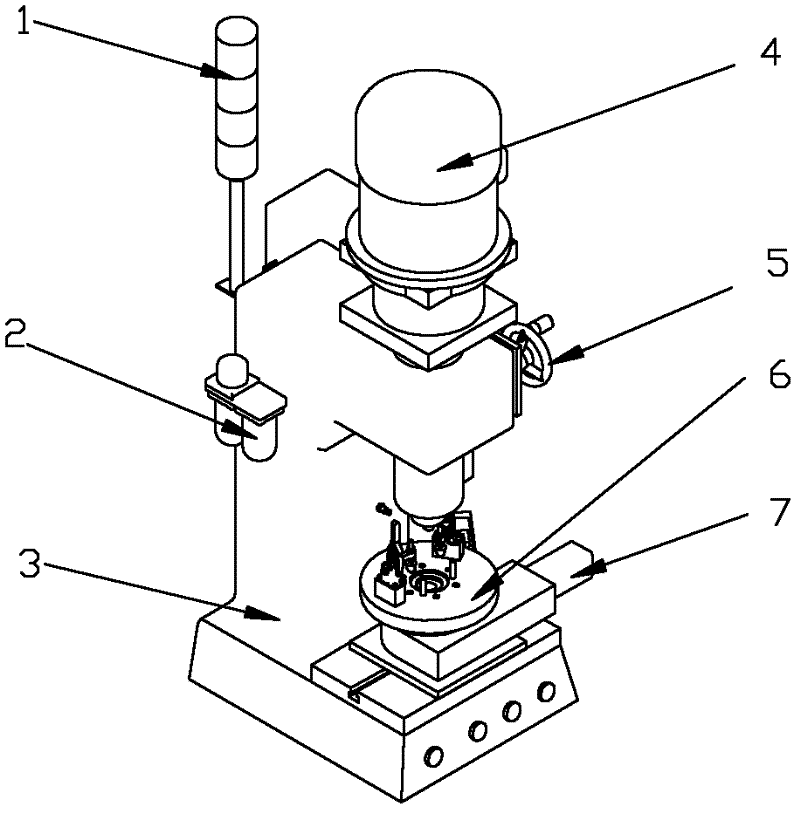

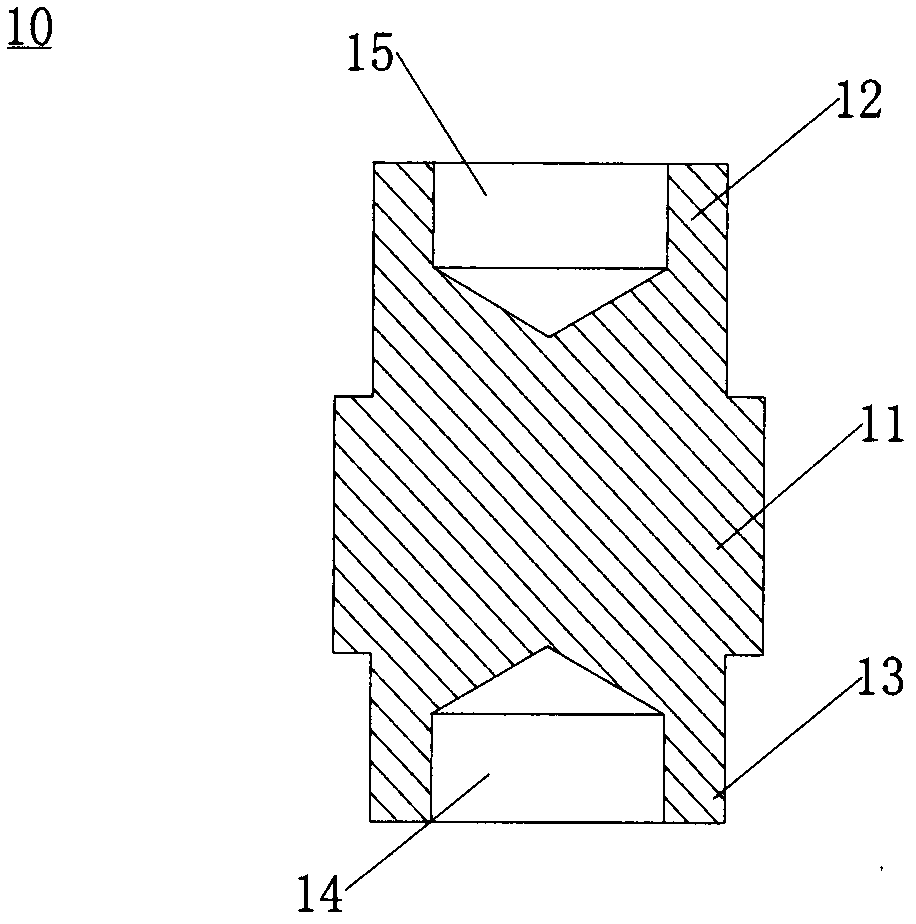

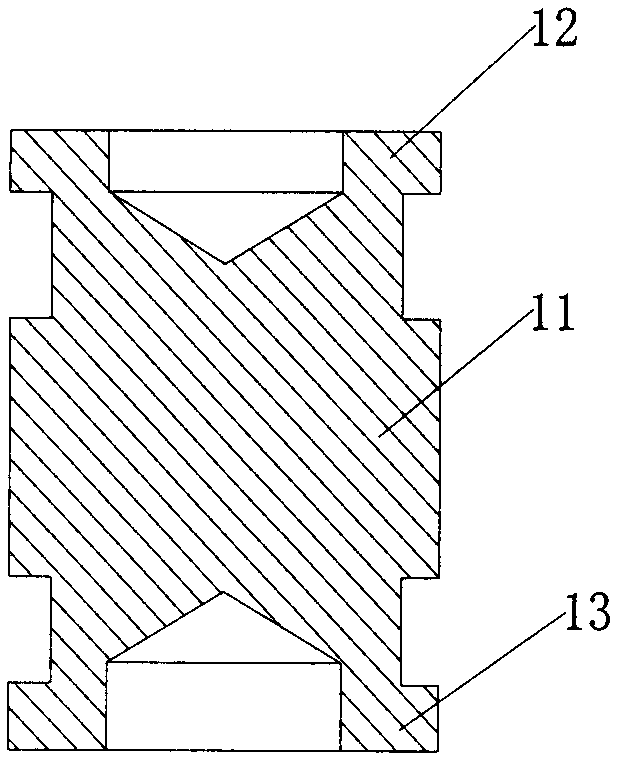

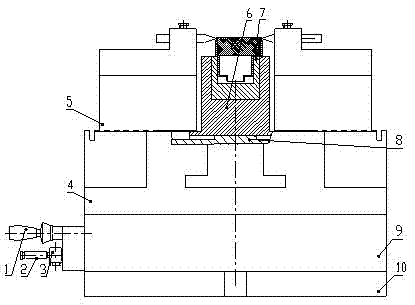

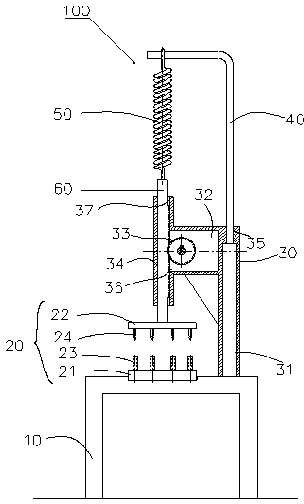

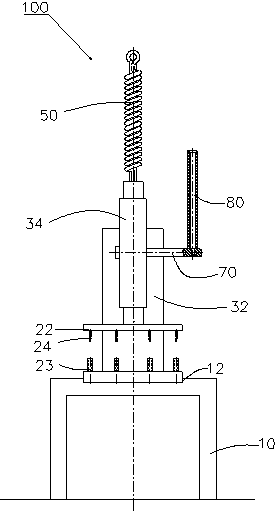

Automatic press-riveting device for collecting element

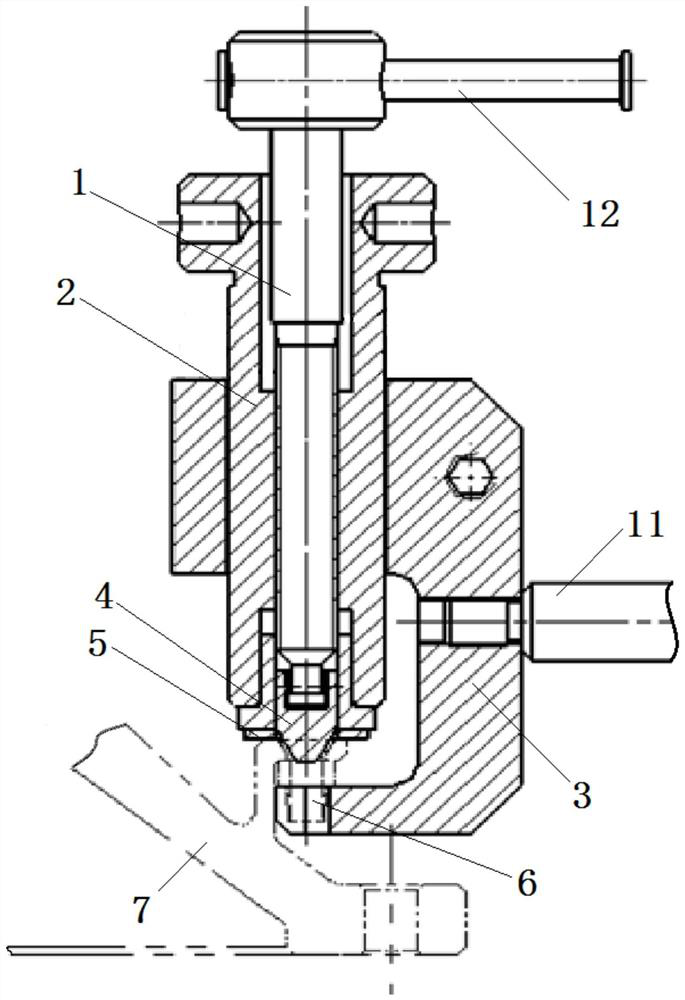

ActiveCN102416423ASimple and fast operationImprove riveting efficiencyAtmospheric pressureCheck valve

The invention discloses an automatic press-riveting device for a collecting element. The automatic press-riveting device comprises a pneumatic mechanism (9), a check valve (2), a switching handle (1), an air pressure meter (3), a fixing plate (4), a press-riveting mechanism (5), a fixing base (6), a switching base (7), an installation base (8) and a base, wherein T-shaped slide blocks (11) at the lower end of the press-riveting mechanism (5) are arranged in four T-shaped slide rails of the fixing plate (4) respectively. In the working process of the automatic press-riveting device, the T-shaped slide blocks (11) are used for driving a claw (12), a carrier block (13) and a thimble (15) to move towards the axle center of the automatic press-riveting device under the pushing action of a cylinder to finish the press-riveting action; the switching handle (1) is switched to an initial position to finish the quitting action; and after press-riveting work is finished, press-riveted collecting elements are taken down. Due to the adoption of the automatic press-riveting device, press-riveting work of collecting units of various profiles can be finished; the press-riveting point depth and the press-riveting position can be adjusted freely; and the automatic press-riveting device is easy and convenient to operate, and has high press-riveting efficiency.

Owner:中国航天科工集团第二研究院二十三所

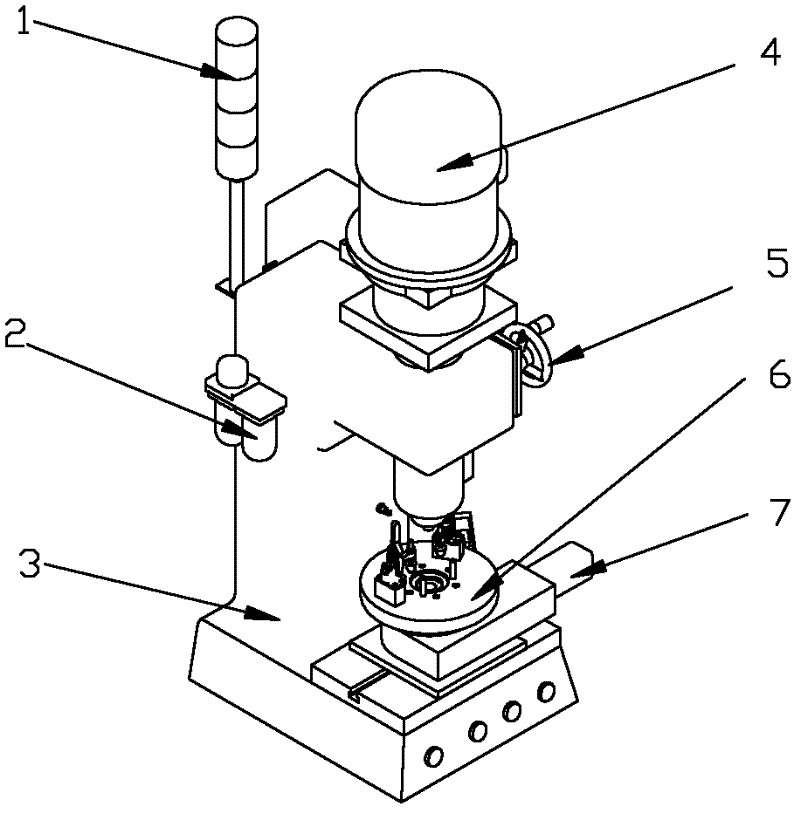

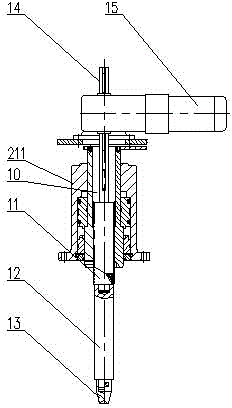

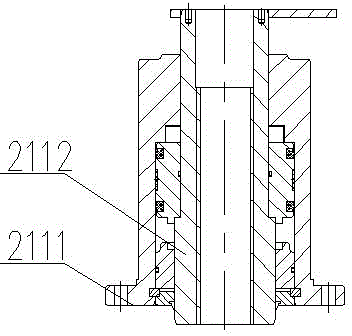

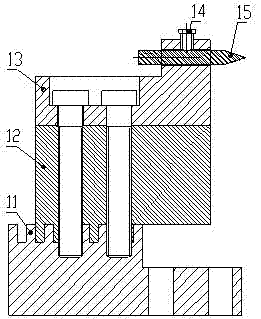

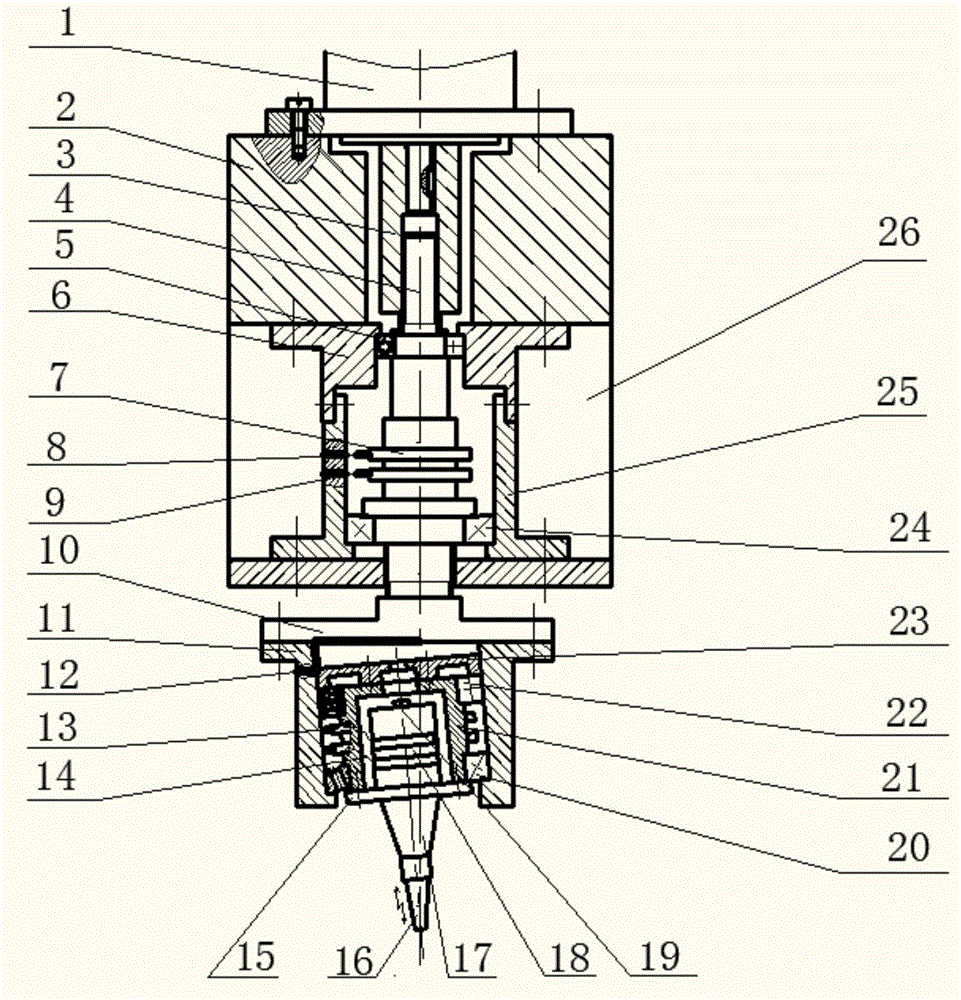

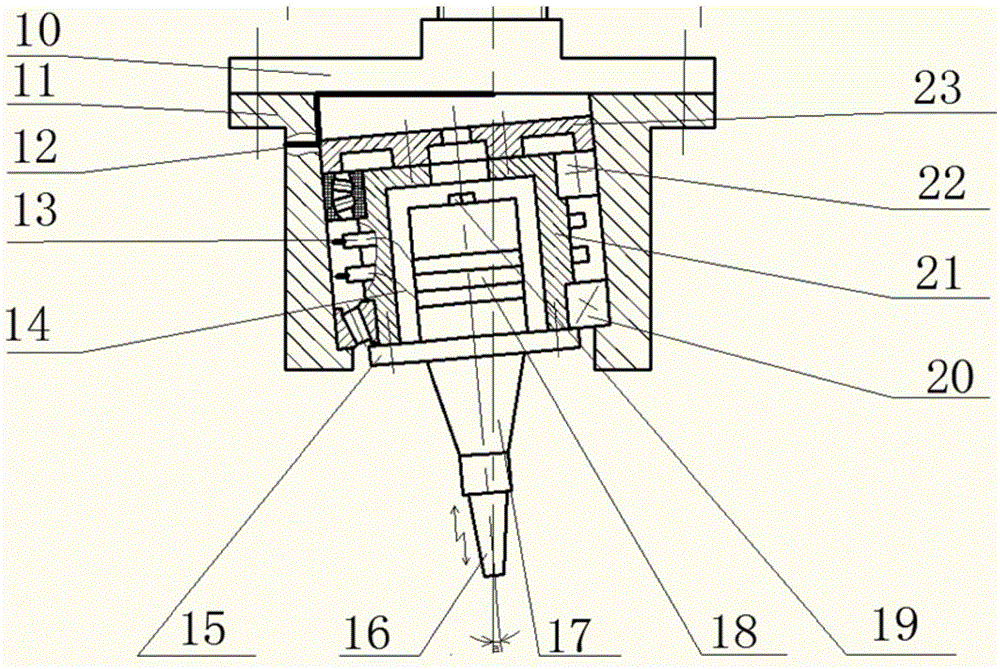

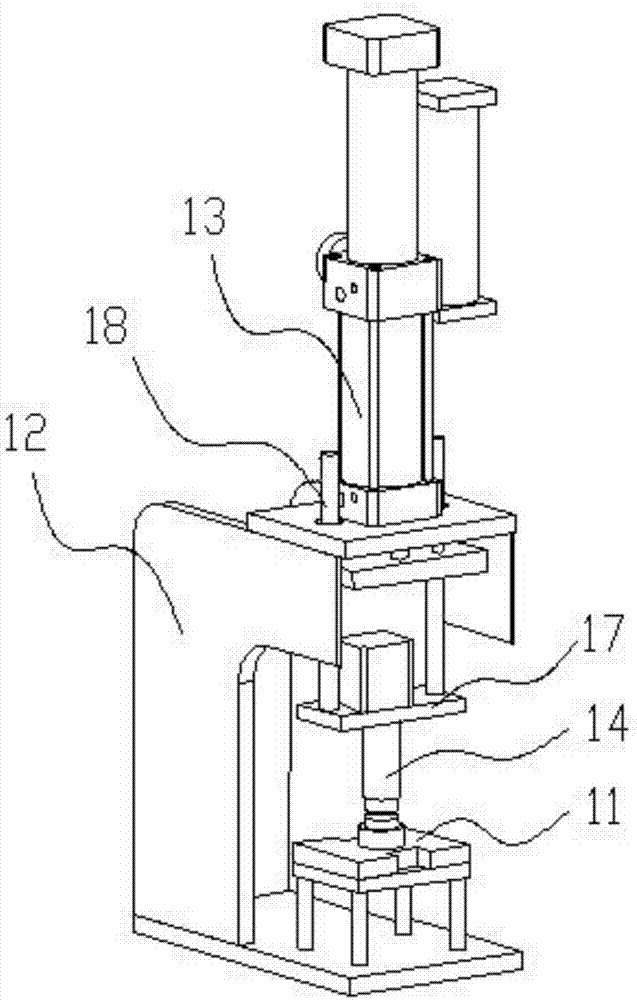

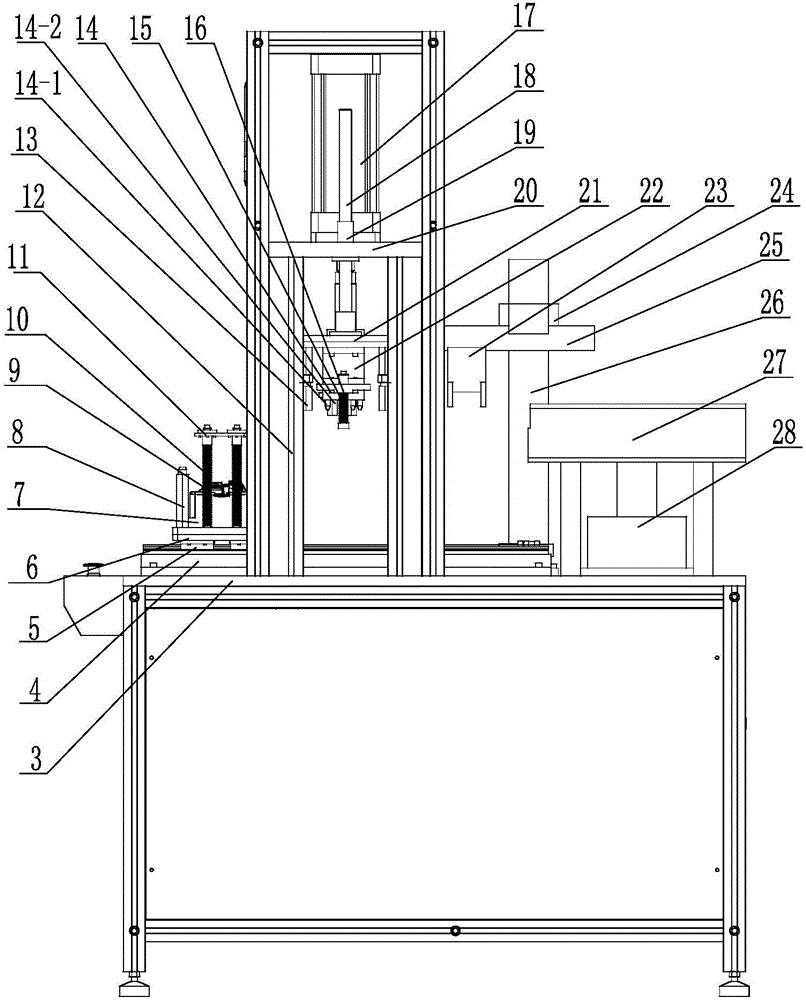

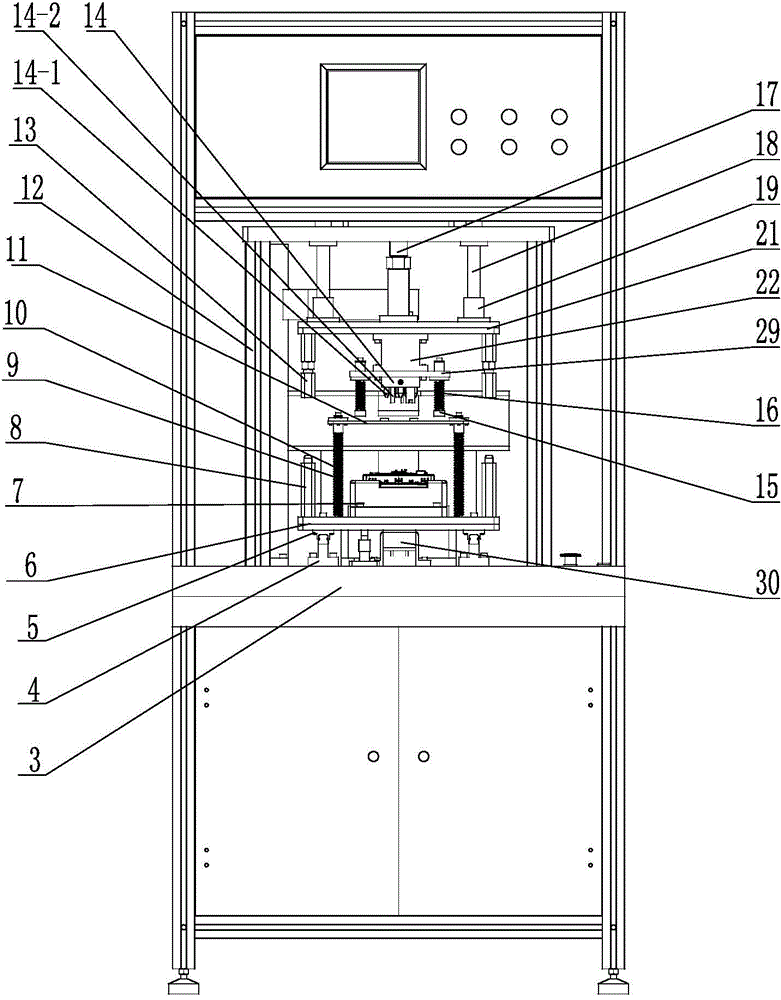

Supersonic vibration spin riveting machine

The invention discloses a supersonic vibration spin riveting machine. The supersonic vibration spin riveting machine comprises an upper riveting head (16) which is connected with an amplitude transformer (17). The supersonic vibration spin riveting machine is characterized in that the amplitude transformer (17) is connected with a high frequency transducer (18), and the high frequency transducer (18) is installed in an inner sleeve (21); the inner sleeve (21) is installed in a cylindrical lower bearing pedestal (11) and connected with a connecting end base (10), the connecting end base (10) is connected with the lower end of a main shaft (4), and the upper end of the main shaft (4) is connected with a motor (1); a first electricity collecting ring (7) is installed in the middle of the main shaft (4) and connected with a first wire (9) and an outer guide line through a carbon brush (8) and transmits high frequency electrical signals obtained from an ultrasonic generator; and a second electricity collecting ring (13) transmits the high frequency electrical signals of the first electricity collecting ring (7) to the transducer (18) through a second wire (12), so that the transducer (18) generates high frequency mechanical vibration to drive the amplitude transformer (17) to do high-frequency vibration. By means of the supersonic vibration spin riveting machine, the riveting force can be reduced, and the riveting efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

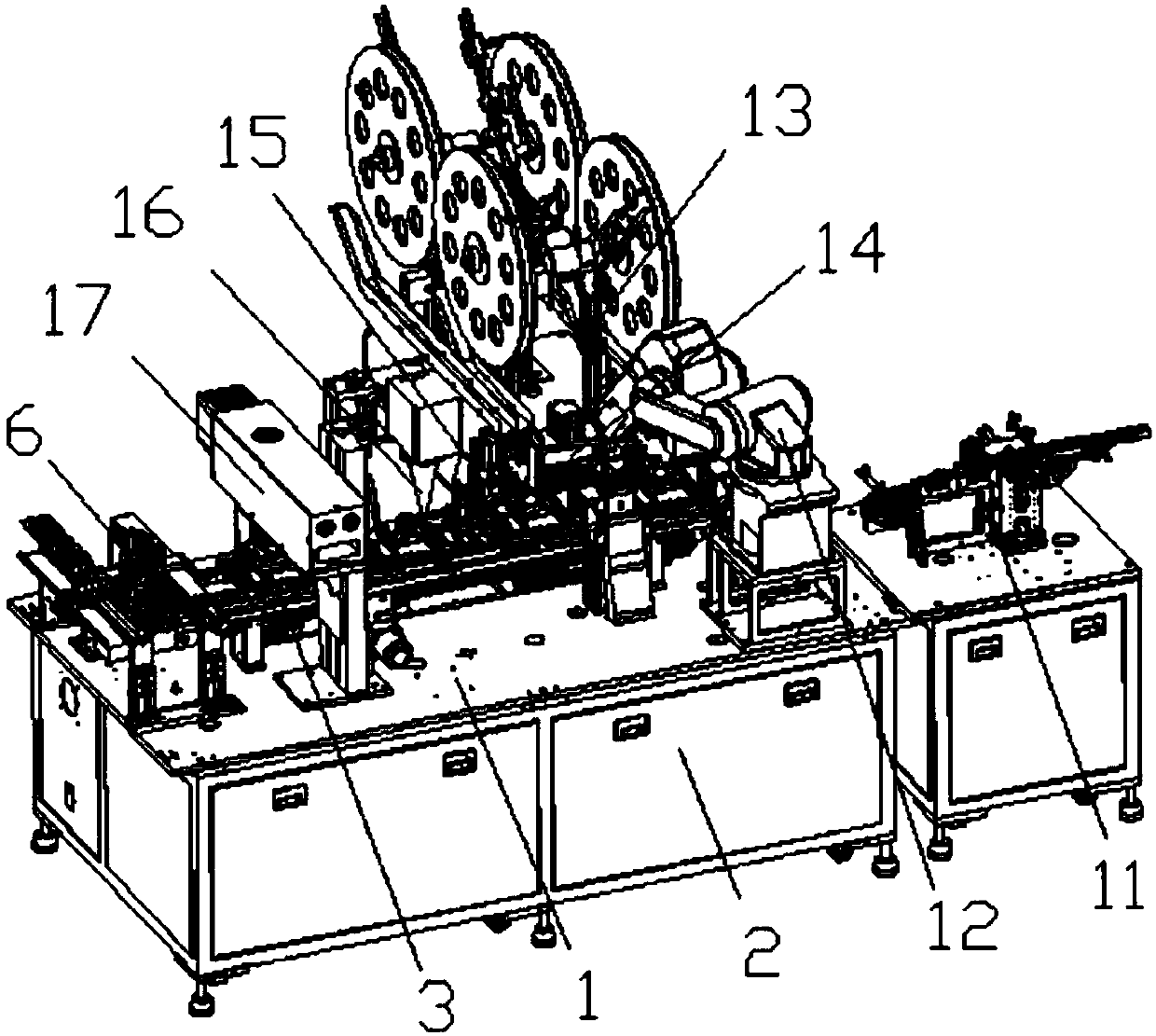

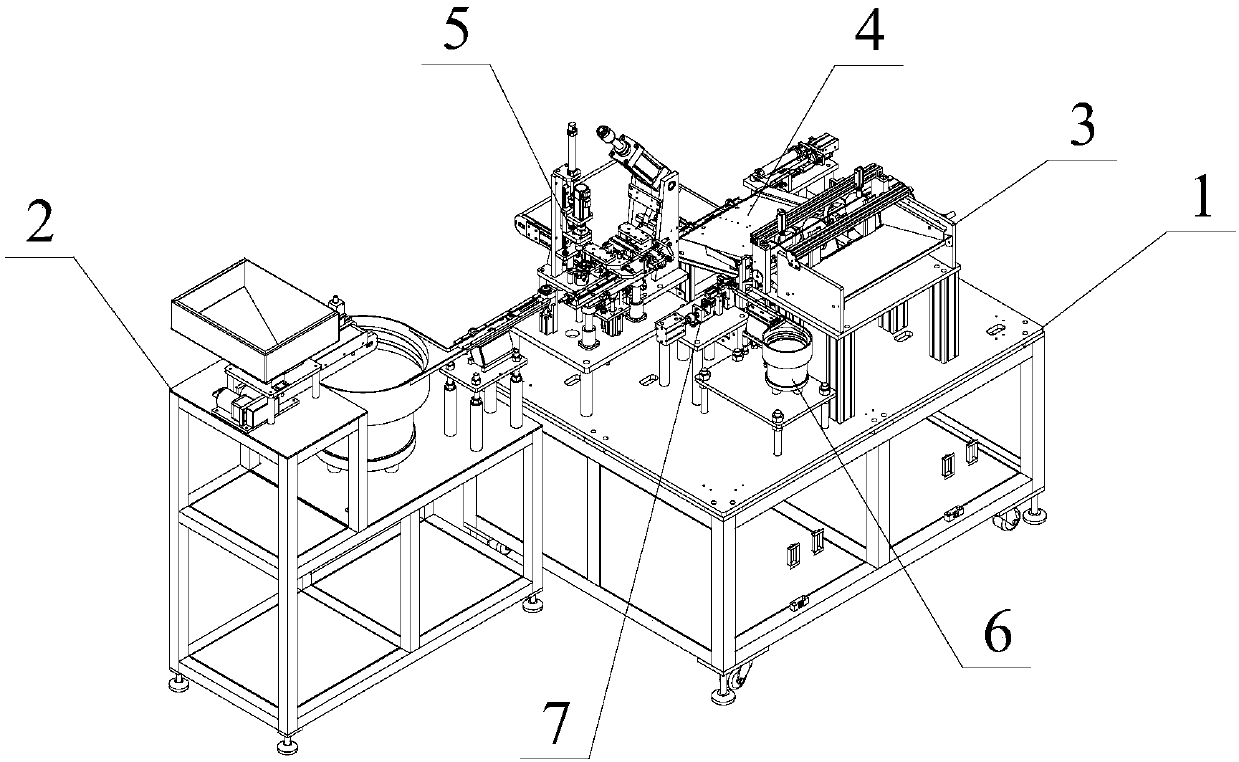

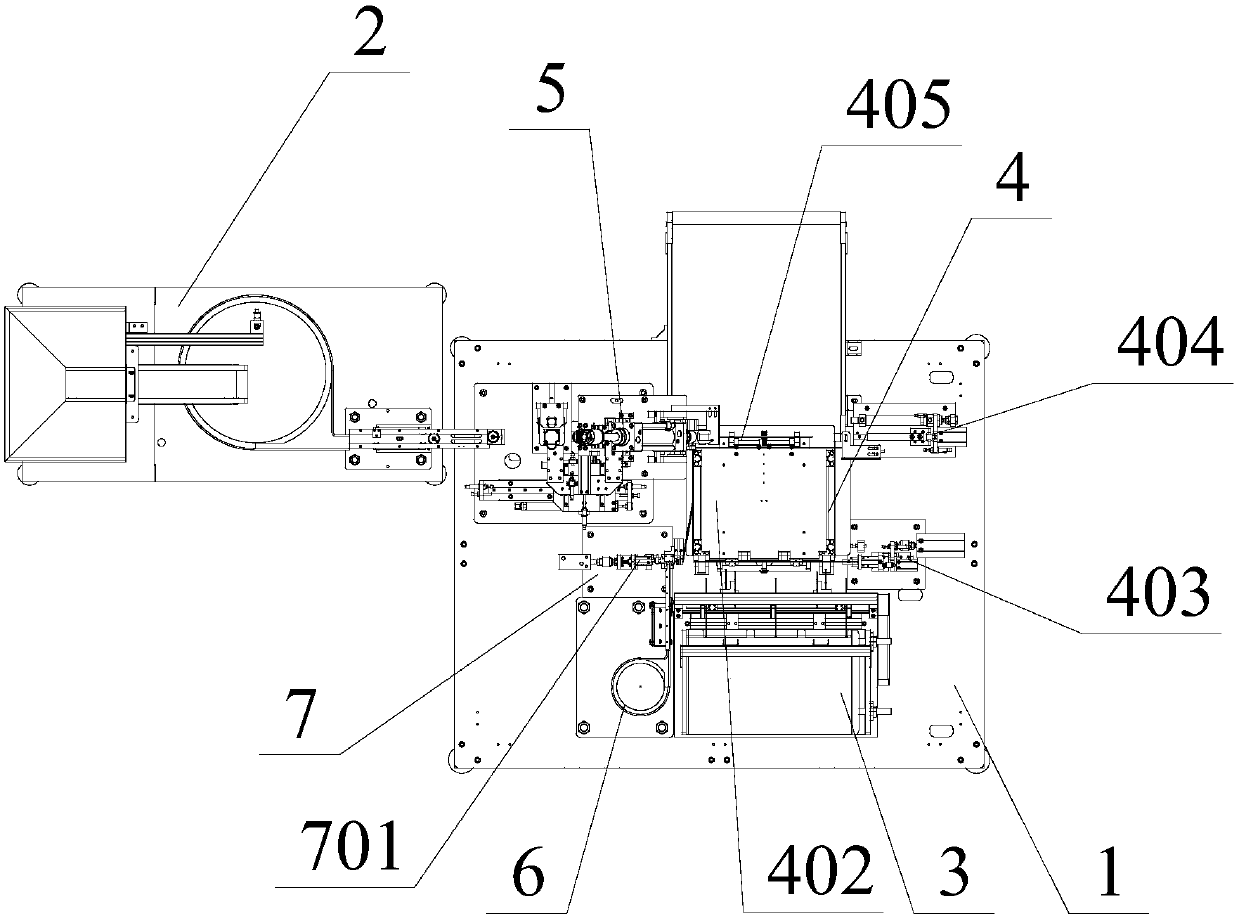

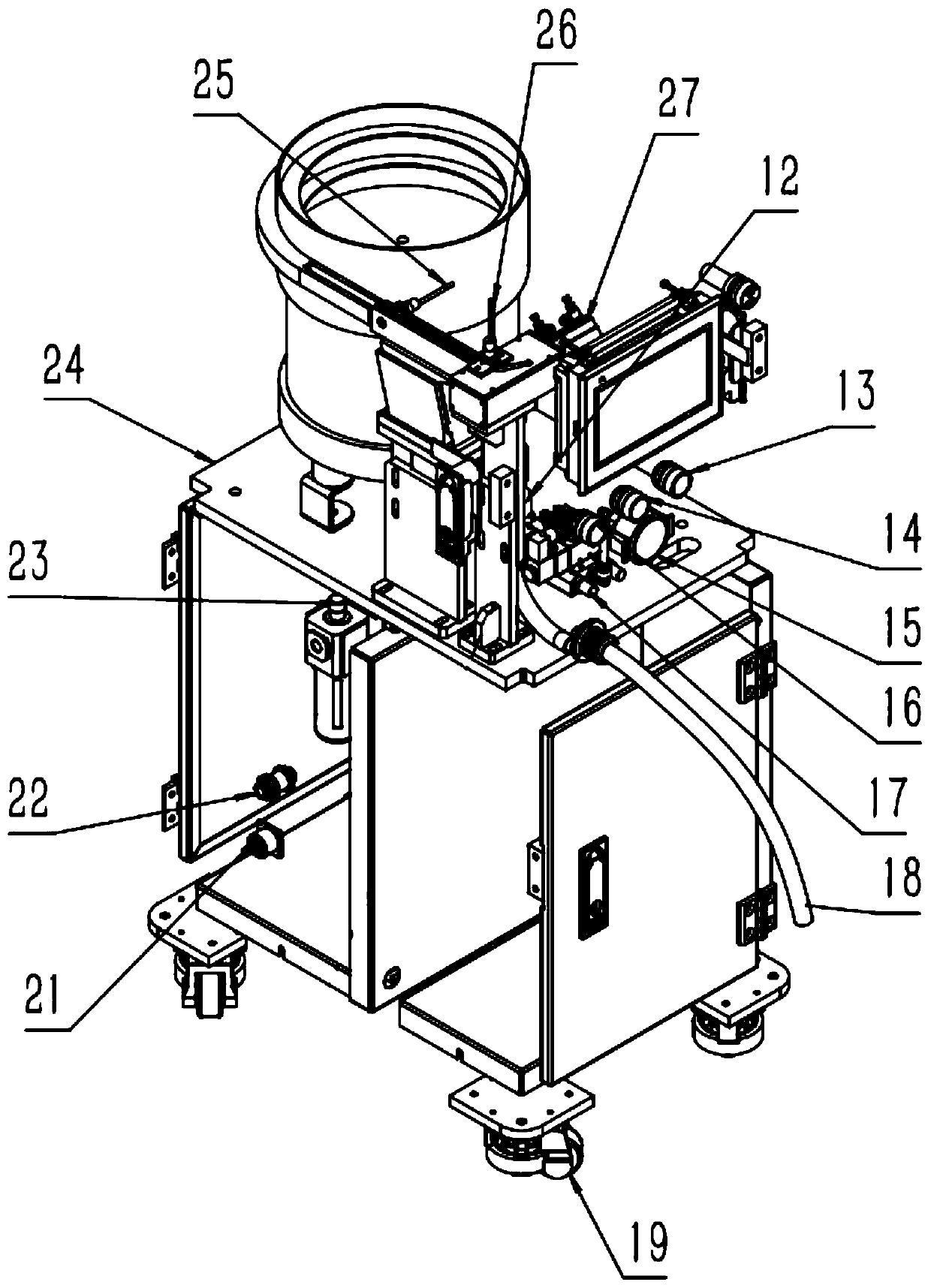

Riveting equipment for motor end covers and electric power pipe fittings

ActiveCN107900231AReduce circulation proceduresReduce time consumptionMetal-working feeding devicesPositioning devicesPipe fittingElectric machinery

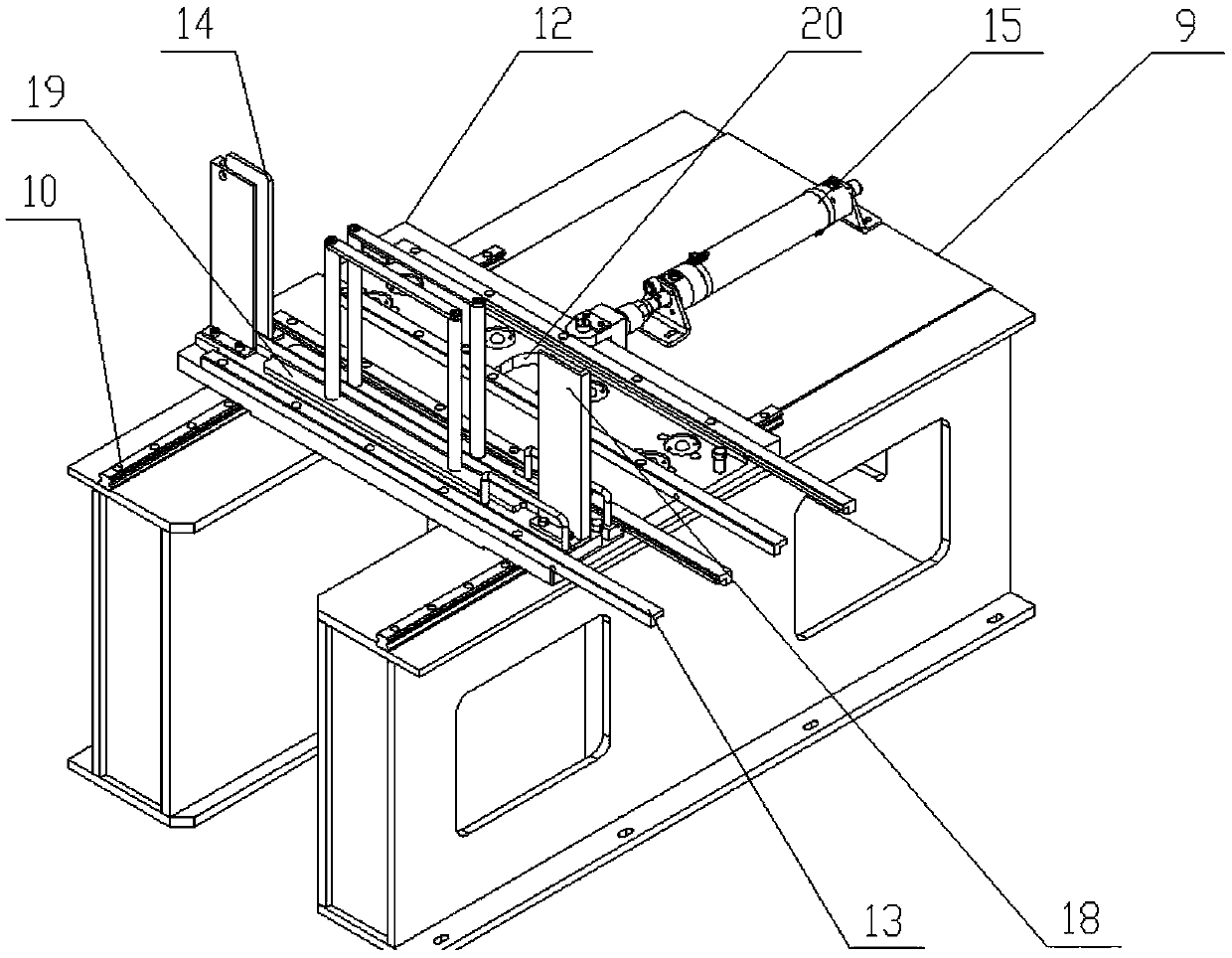

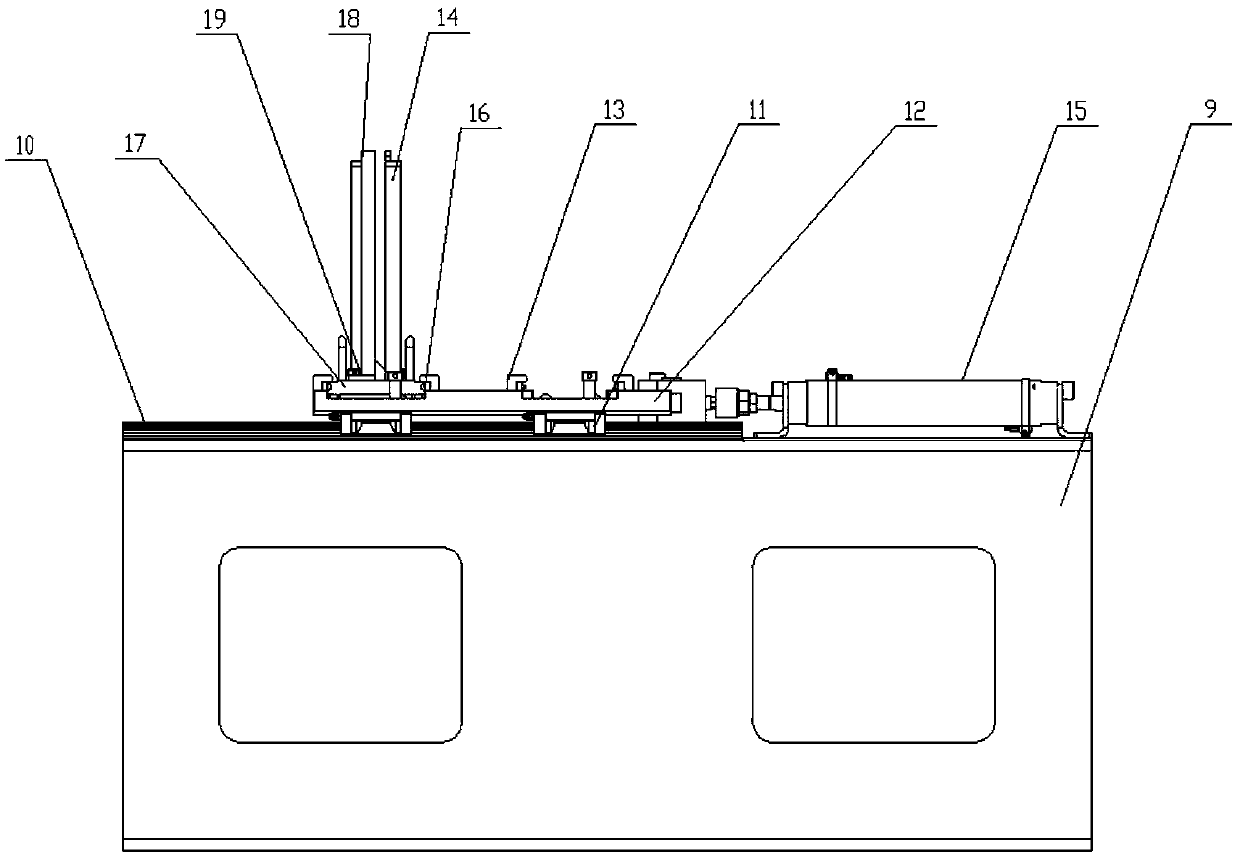

The invention provides riveting equipment for motor end covers and electric power pipe fittings. The equipment comprises a machine case and an end cover feeding mechanism, wherein a pipe fitting sorting mechanism for sorting the pipe fittings, a transferring mechanism for transferring the pipe fittings and a directional riveting mechanism for riveting the pipe fittings transferred by the transferring mechanism are arranged on the machine case; the directional riveting mechanism comprises a shifting unit for shifting end covers conveyed by the end cover feeding mechanism to the directional riveting mechanism; and the directional riveting mechanism is used for riveting the end covers with the pipe fittings. The riveting equipment provided by the invention has the beneficial effects that theway of artificial feeding and riveting is changed to the way of automatic feeding and riveting by utilizing the cooperation of every mechanism, so that the time consumption in the feeding process is reduced, the riveting efficiency is increased and the circulating procedure of workpieces in the processing process is reduced and the processing time is shortened at the same time; and the pipe fittings and the end covers can be adjusted to appropriate angles to be riveted by utilizing the directional riveting mechanism and manual inspection is not needed, so that the qualified rate of products isincreased while the production efficiency of the products is improved at the same time.

Owner:南阳防爆(苏州)特种装备有限公司

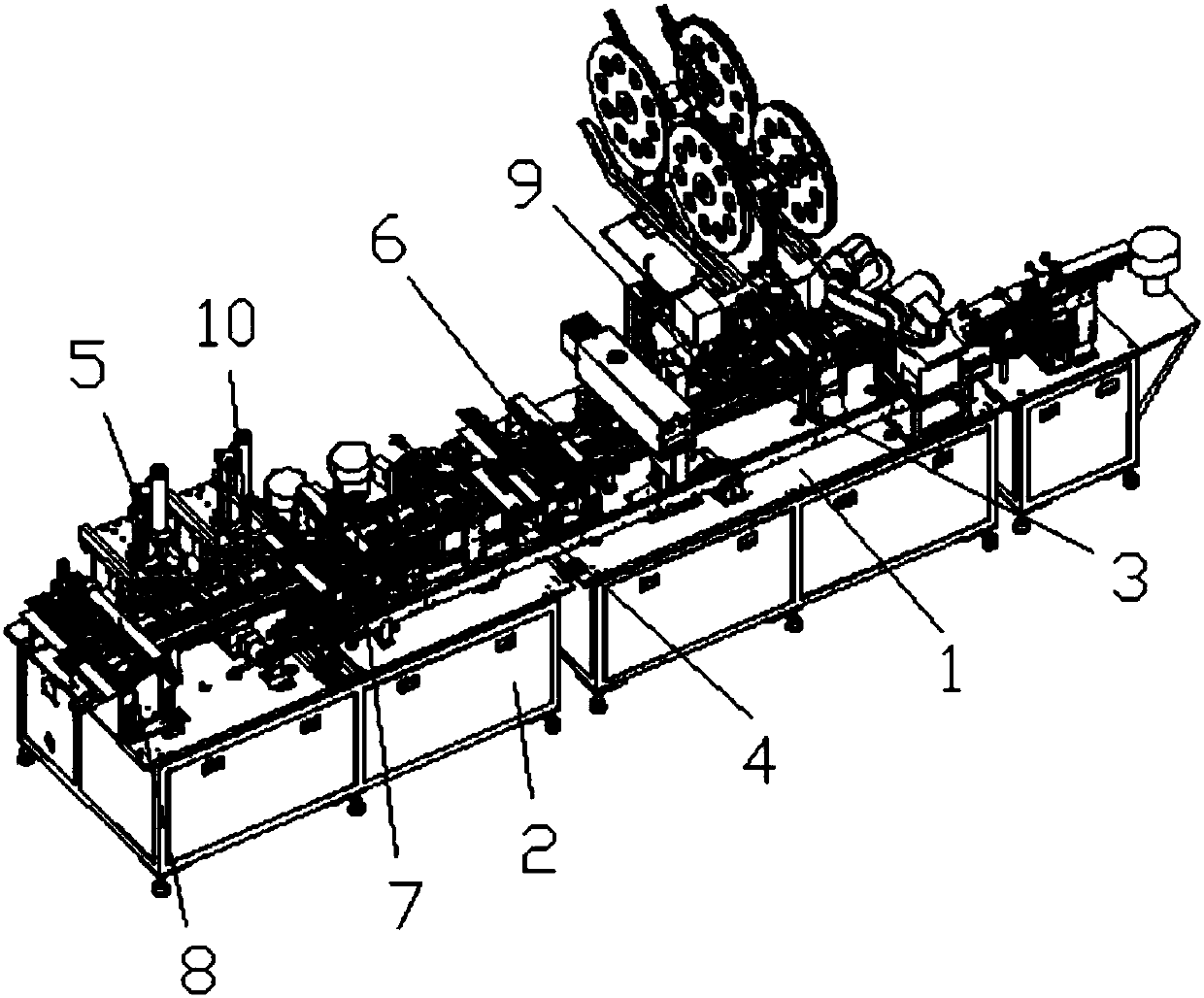

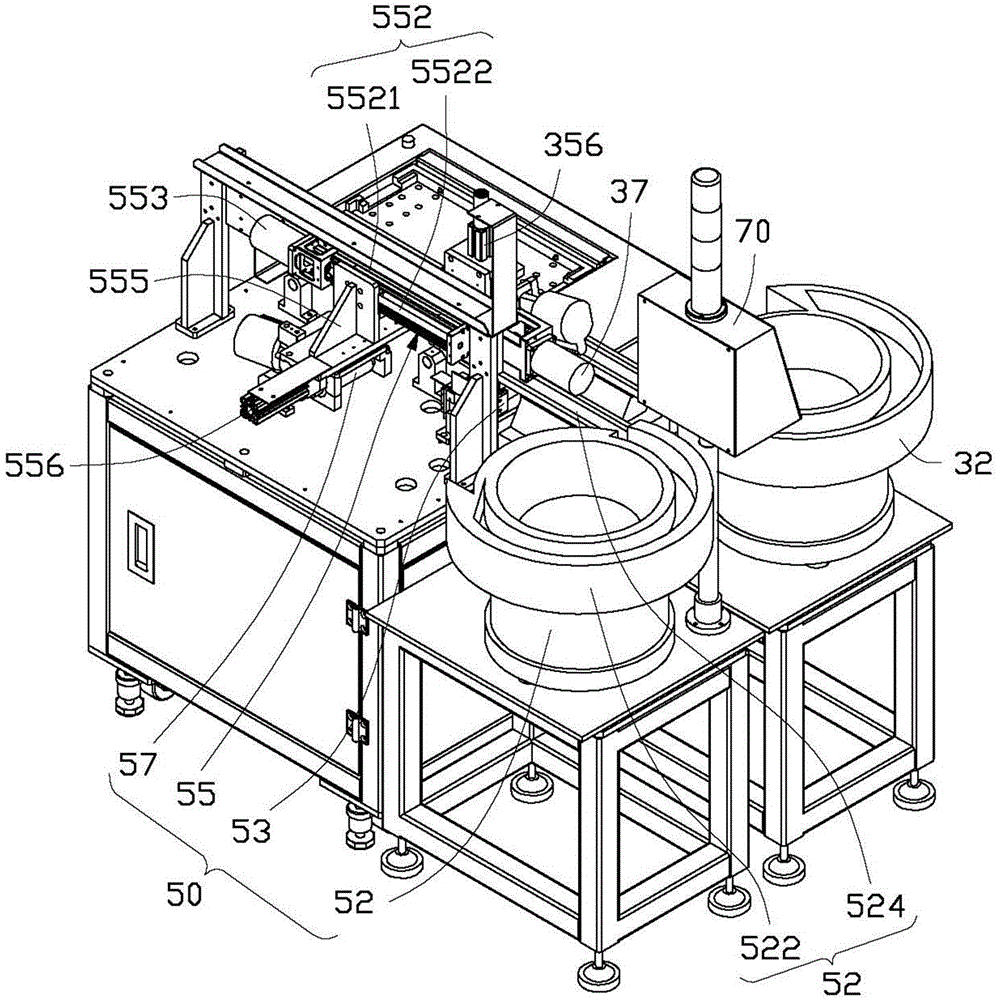

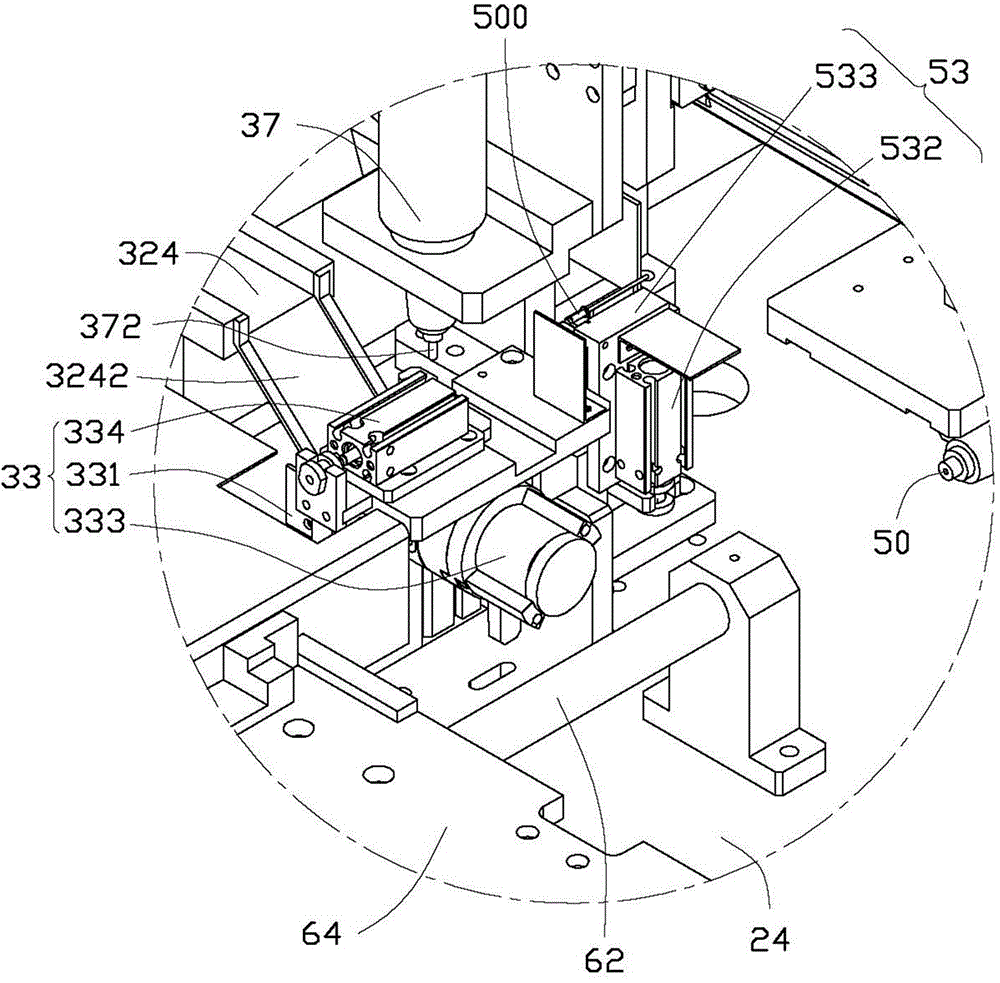

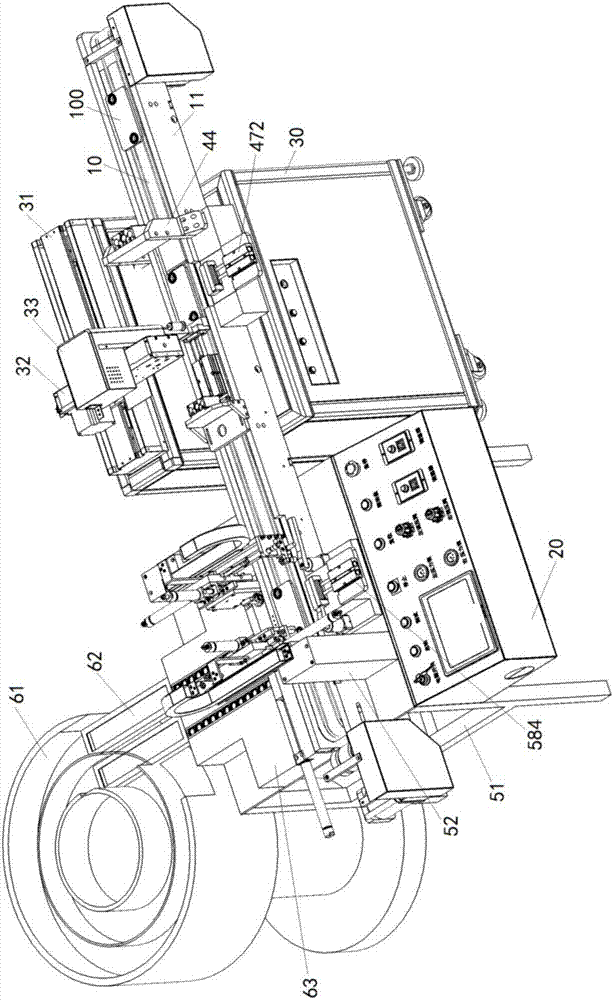

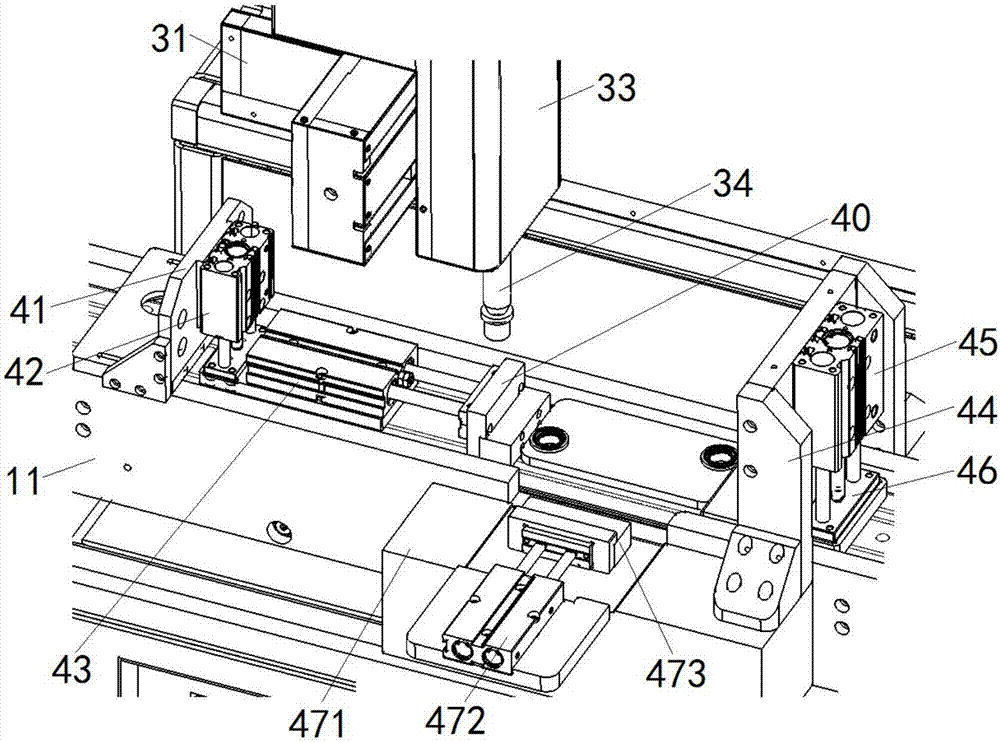

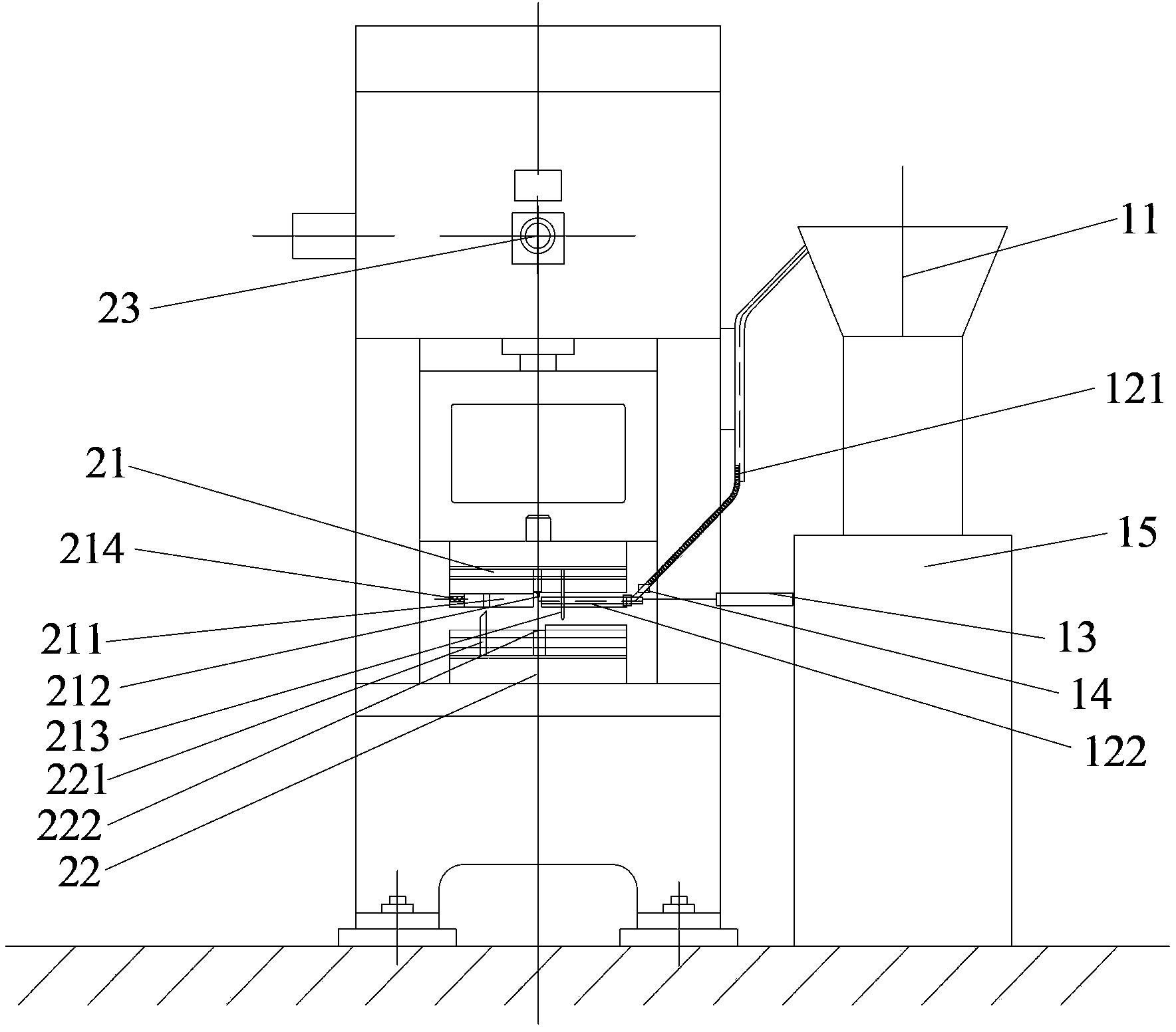

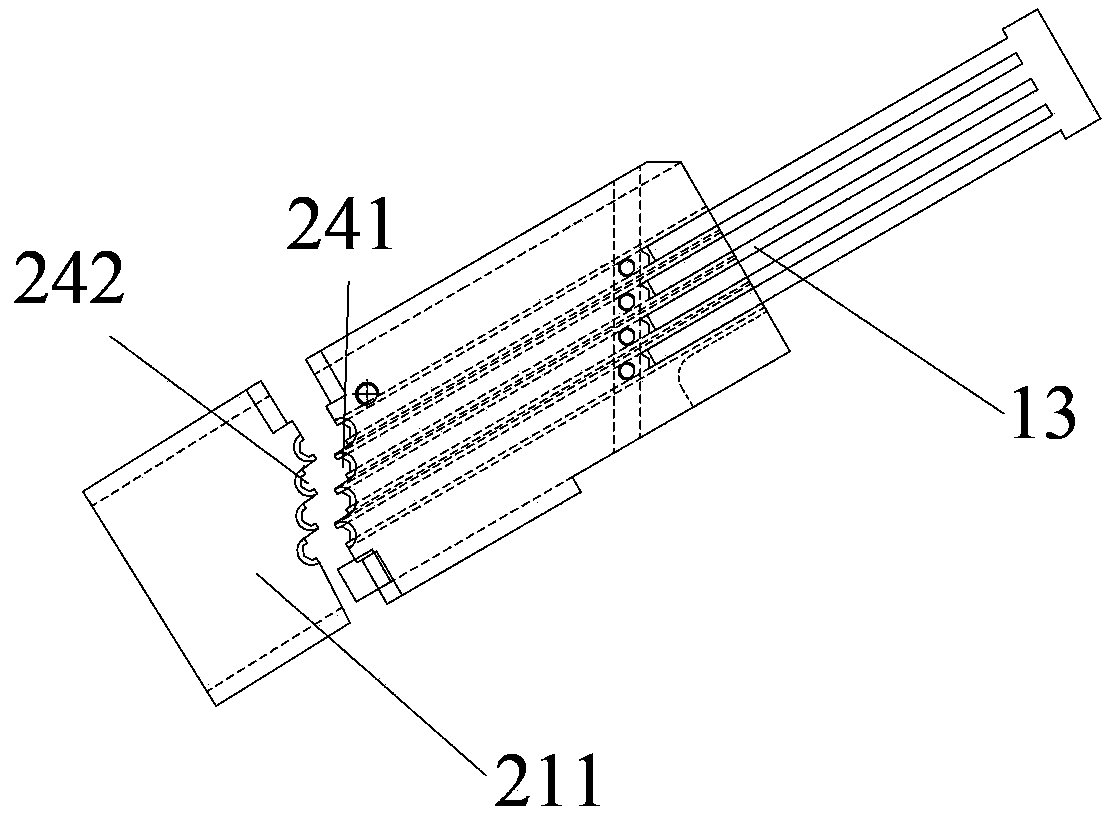

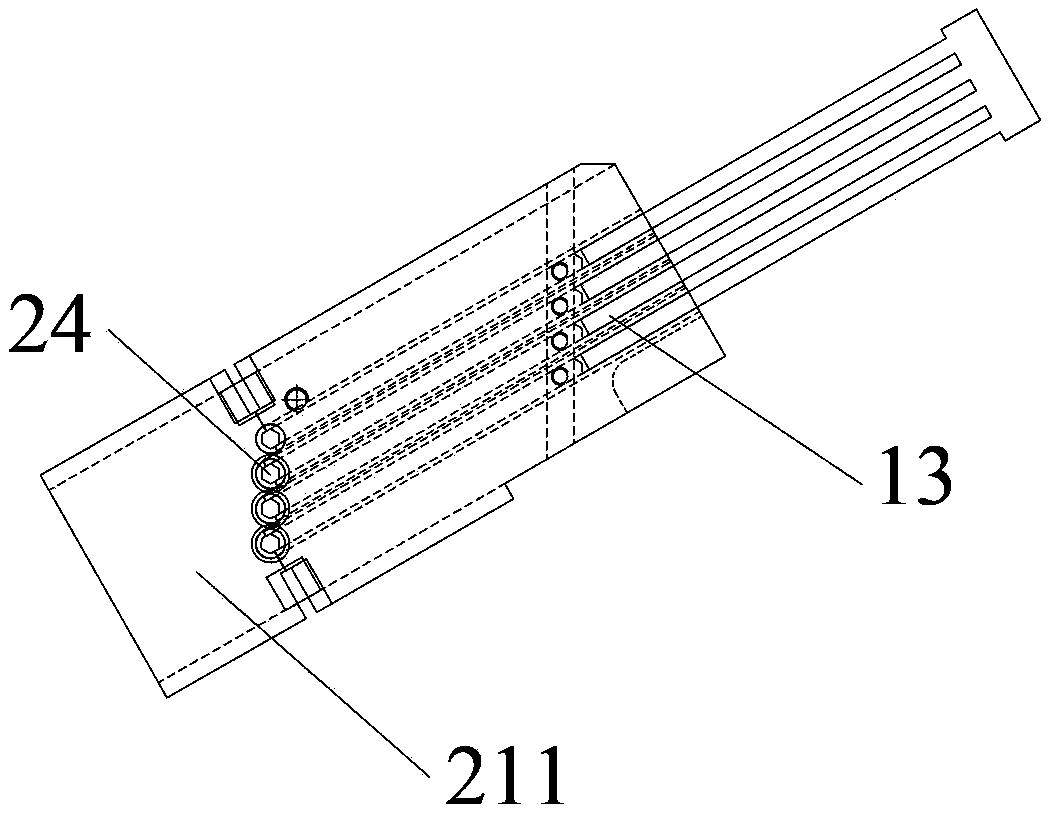

Automatic assembling machine for anode parts

ActiveCN106862930AComply with welding wire requirementsShorten production hoursOther manufacturing equipments/toolsMetal working apparatusDistribution controlEngineering

The invention relates to an automatic assembling machine for anode parts. A riveting device is arranged on the right portion of a power distribution control box. A welding wire device and a pressing sleeve device are arranged on the left portion of the power distribution control box. A conveying device is arranged between the riveting device and the welding wire device. The riveting device and the welding wire device are both matched with the conveying device through a grab mechanical hand. The conveying device comprises a conveying groove. The conveying groove is provided with two right-angle corner parts. The two right-angle corner parts are provided with two overturning devices in the opposite overturning directions respectively. Each overturning device comprises an overturning base arranged on the outer wall of the conveying groove, wherein the overturning base is provided with an overturning air cylinder, and the overturning air cylinder is provided with an overturning push block. Material picking is carried out through the grab mechanical hand, riveted parts are conveyed to a welding wire station through the conveying device, the conveying device is provided with the two overturning devices, thereby being capable of being turned by 180 degrees, the welding wire requirements of the welding wire station are directly met, the production hours are greatly shortened, and production efficiency is improved.

Owner:天长市捷俊精密模具有限公司

Full-automatic rivet nut feeding and riveting monitoring system

InactiveCN110170580AEasy maintenanceEasy to troubleshootMetal-working feeding devicesPositioning devicesMonitoring systemRivet gun

The invention discloses a full-automatic rivet nut feeding and riveting monitoring system which comprises a rivet nut feeder, a rivet nut receiving mechanism, riveting moving equipment and a rivetingmonitoring meter. The rivet nut feeder arranges and separates rivet nuts and conveys the rivet nuts to the rivet nut receiving mechanism through a nail feeding pipe, a rivet nut gun is arranged on therivet nut receiving mechanism, the rivet nut receiving mechanism conveys the received rivet nuts to a rivet rod of the rivet nut gun, and the riveting monitoring meter detects riveting tension and displacement through a riveting sensor connected to the rivet nut gun and displays riveting information. The full-automatic rivet nut feeding and riveting monitoring system is modular in design and convenient to maintain and troubleshoot, loads the rivet nuts automatically to the rivet gun of the rivet nut gun to improve the riveting efficiency, judges the riveting quality in real time to improve the riveting quality, and is connected to and combined with the rivet nut moving equipment in use to achieve a full-automatic riveting process.

Owner:铁藤机电技术(上海)有限公司

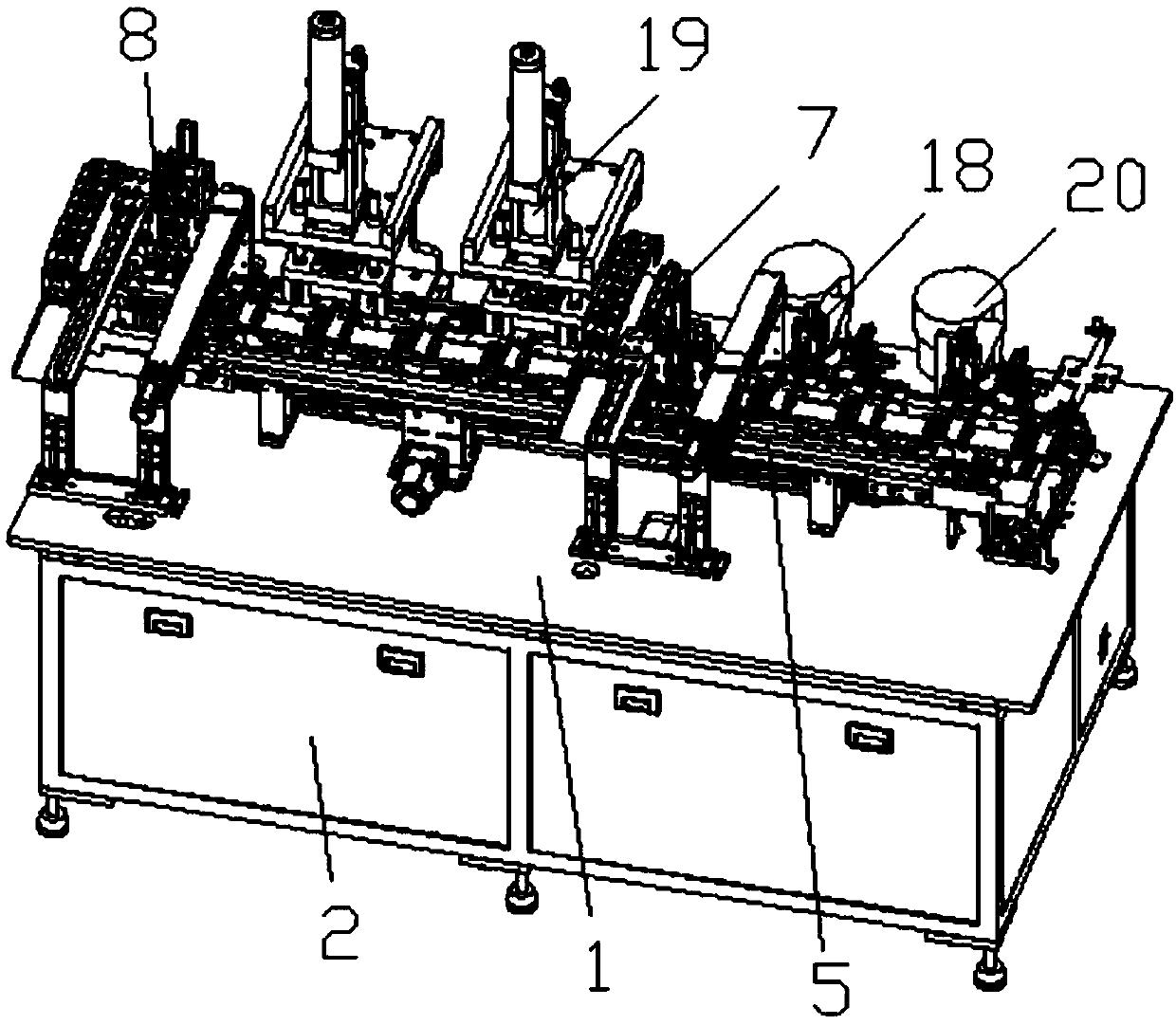

Automatic conveying and riveting device and riveting method thereof

PendingCN110640028AImprove riveting efficiencyCompact layoutMetal-working feeding devicesPositioning devicesElectric machineVertical edge

The invention relates to an automatic conveying and riveting device and a riveting method of the automatic conveying and riveting device. The automatic conveying and riveting device comprises a feeding table, a bullet bin, a material box lifting assembly, a feeding assembly, a conveying assembly, a supporting positioning and motor adjusting assembly, a riveting assembly and a lathe bed. The invention further relates to an automatic conveying and riveting method. The method comprises the following processes including material box conveying to the bin, feeding, box body positioning, conveying and riveting. According to the automatic conveying and riveting device and the riveting method, special-shaped material sheets can be accurately conveyed into the positions to be riveted on the verticaledges of box bodies through rotating air cylinders and electromagnets, and riveting is completed; and the problem that an existing riveting device cannot avoid conveying of the vertical edges of thebox bodies is solved, the automation degree of the riveting device is increased greatly, and the production efficiency of the riveting device is greatly improved.

Owner:北京长征火箭装备科技有限公司 +1

Riveting mechanism of automobile skylight

The invention provides a riveting mechanism of an automobile skylight. The riveting mechanism comprises a riveting machine, a riveting head and a riveting machine base, wherein the riveting machine base is provided with a plurality of slide passages, a slide seat is arranged on the slide passages in a matching way, and is provided with a plurality of screw holes, an U-shaped base is arranged on the slide seat, the two sides of the U-shaped base are provided with a plurality of screw holes, and a screw rod is arranged in the corresponding screw hole in a matching way, and is connected with the corresponding screw hole of the slide seat. The riveting mechanism has the advantage that the riveting machine is provided with the slide passages, the slide seat is arranged on the slide passages in the matching way, and the U-shaped base which is conveniently detached and replaced is arranged on the slide seat, so the required base can be replaced in the riveting process of the automobile skylight, and the riveting efficiency and the riveting quality can be effectively improved.

Owner:ANHUI DIKUN AUTO SKYLIGHT TECH CO LTD HEFEI

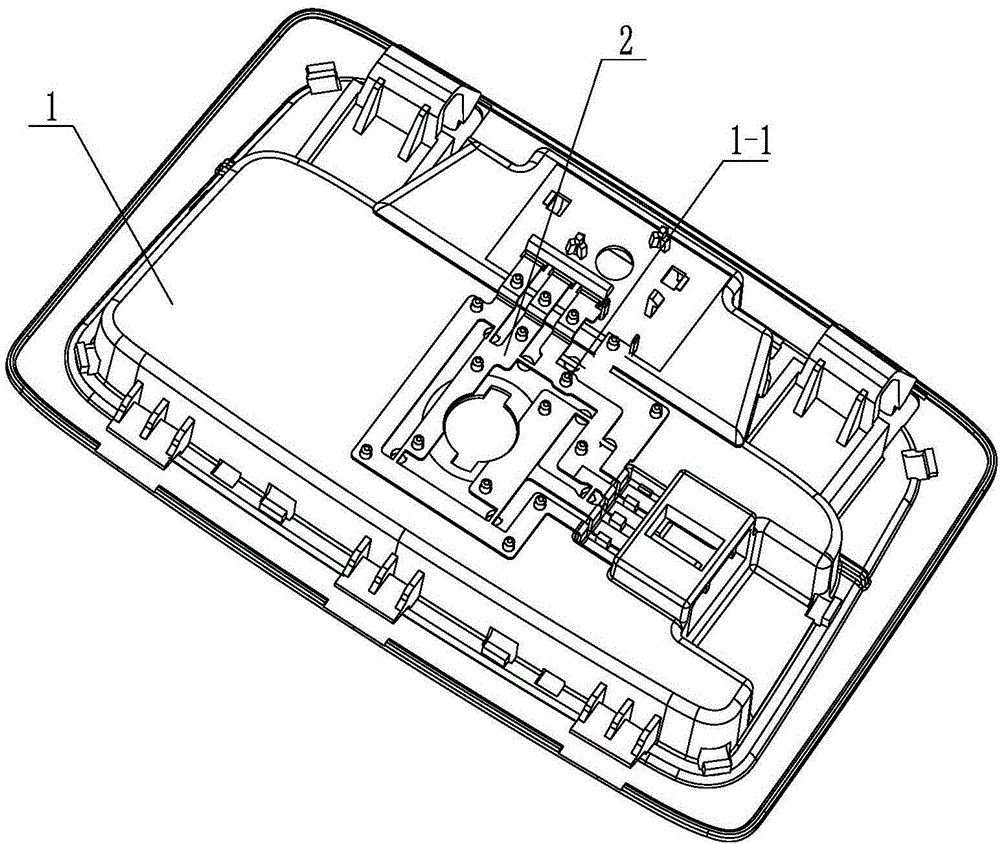

Plastic hot riveting device for automobile lamp

The invention relates to a plastic hot riveting device for an automobile lamp. A workbench is provided with a lamp body positioning mechanism, a press riveting mechanism, a rivet head grabbing mechanism and a heating mechanism. The lamp body positioning mechanism comprises a push air cylinder, a lamp body positioning base and a floating positioning base. The push air cylinder installed on the workbench is connected with the lamp body positioning base. The floating positioning base is connected with the lamp body positioning base and arranged at the upper portion of the lamp body positioning base. A rivet head positioning plate on the floating positioning base is borne on a lower elastic body. The press riveting mechanism comprises a rivet pressing air cylinder, guide columns and a rivet pressing mechanism, wherein the rivet pressing air cylinder is connected with the rivet pressing mechanism. A pressing base of the rivet pressing mechanism is provided with pressing columns and air blowing pipes, and elastic push rods connected to the pressing base are opposite to the rivet head positioning plate. The rivet head grabbing mechanism comprises a support, a lifting rod and a movable rod which are connected. The heating mechanism comprises a heating furnace and a rotary disc, and the heating furnace and the rotary disc are fixed to the workbench. The plastic hot riveting device is reasonable in structure, rapid hot riveting and cooling can be achieved during multi-point riveting, the riveting quality can be ensured, and the riveting efficiency can be improved as well.

Owner:CHANGZHOU XINGYU AUTOMOTIVE LIGHTING SYST CO LTD

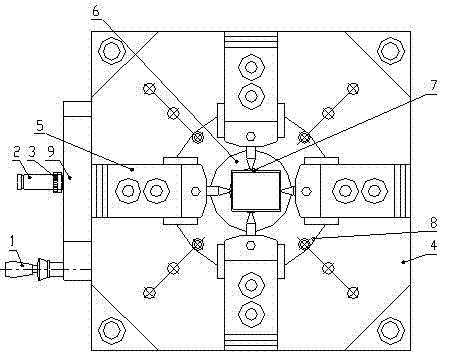

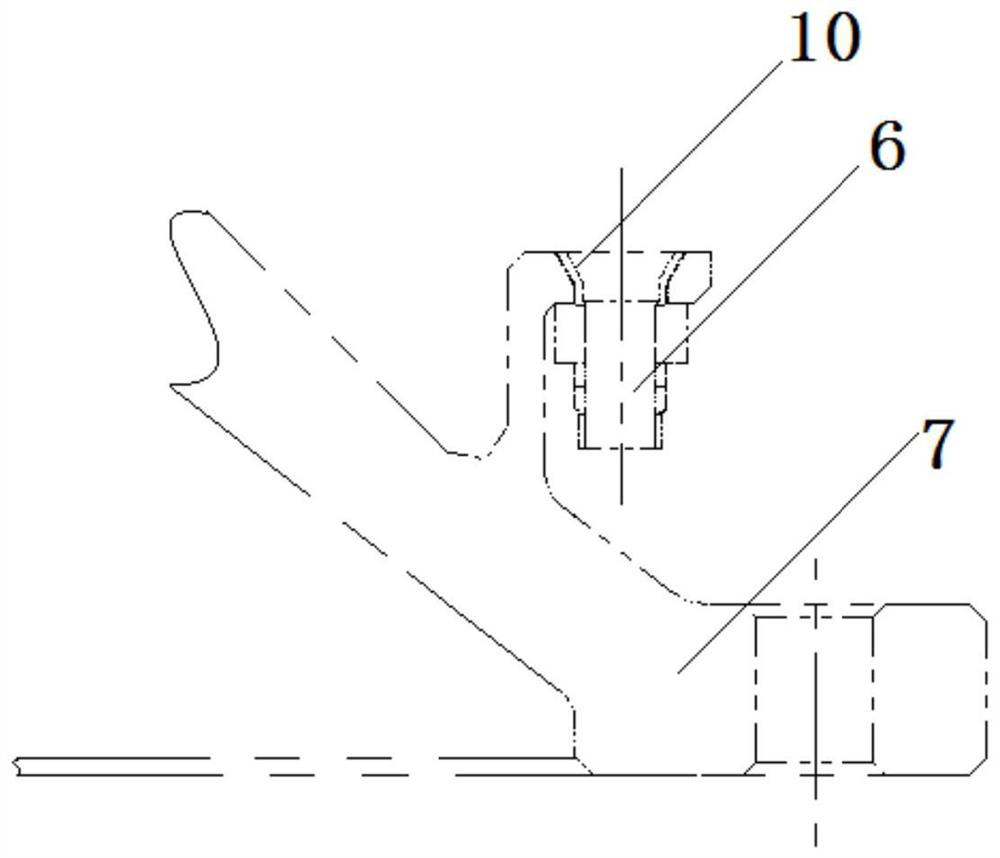

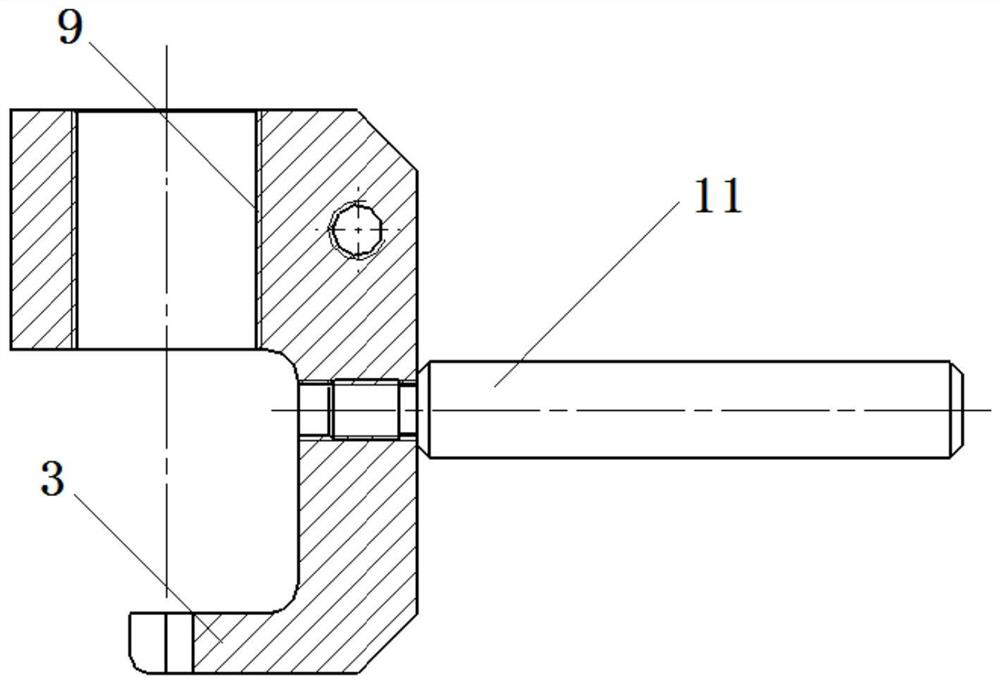

Riveting unit for motor end cover and electric pipe fitting

ActiveCN107649597AReduce circulation proceduresReduce time consumptionMetal-working feeding devicesMetal working apparatusEngineeringPipe fitting

The invention provides a riveting unit for a motor end cover and an electric pipe fitting. The riveting unit comprises a pipe fitting riveting permanent seat for clamping the pipe fitting, a pipe fitting riveting and punching control mechanism for driving the pipe fitting riveting permanent seat to clamp or loosen the pipe fitting, an end cover riveting permanent seat for fixing the end cover, anend cover riveting and punching control mechanism for driving the end cover riveting permanent seat and a riveting supporting block, wherein the pipe fitting riveting permanent seat comprises a pipe fitting guide permanent seat for fixing the pipe fitting. The riveting unit can realize the accurate abutting joint between the motor end cover and the electric pipe fitting and completes riveting.

Owner:南阳防爆(苏州)特种装备有限公司

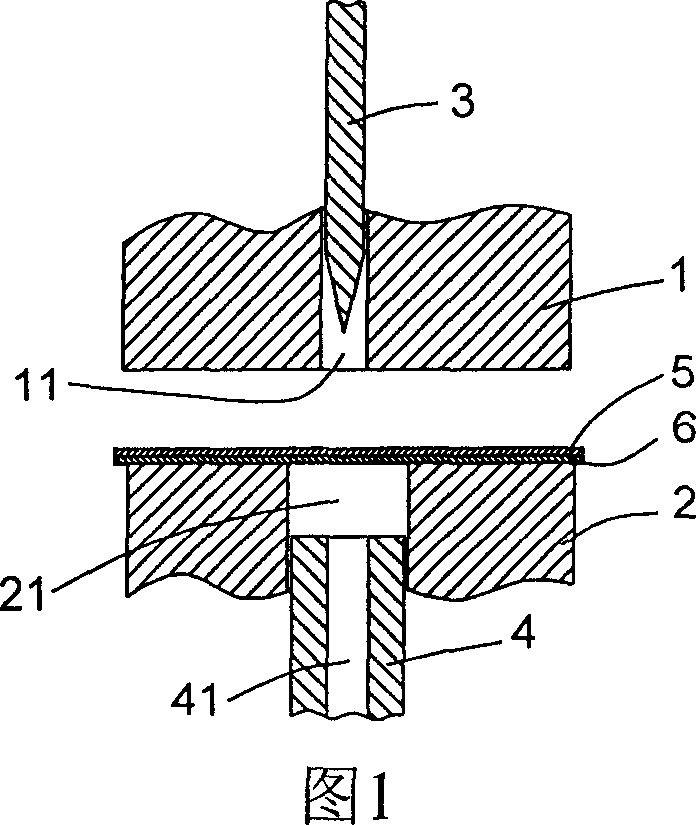

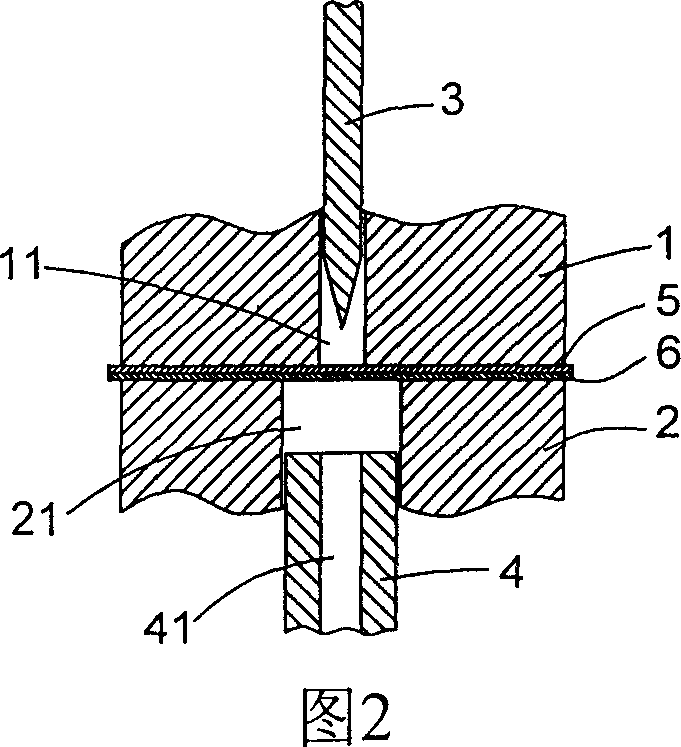

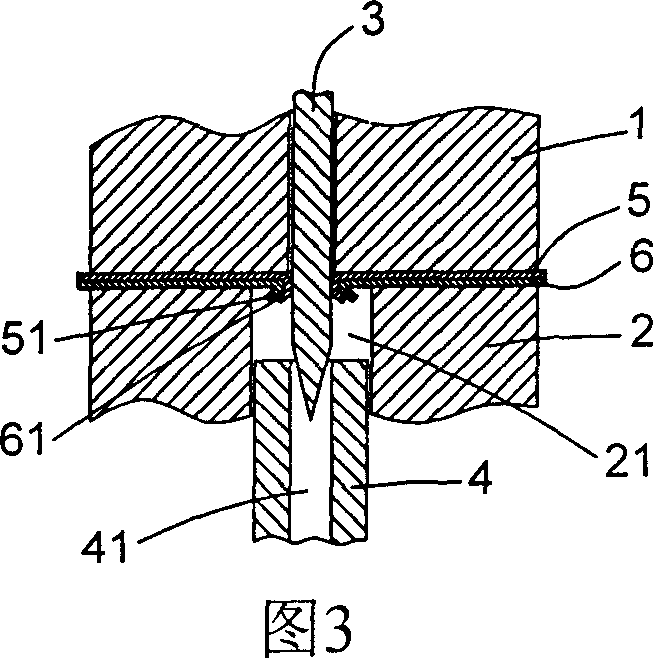

Pallet part riveting device and method for riveting the pallet using the device

The invention relates to a plate rivet device and relative method, wherein said device comprises upper mould, lower mould, punch needle and edge folder; the upper mould has punch needle hole while the punch needle is movably in the hole; the lower mould has guide hole aligned with punch needle hole; the edge folder is movable in the guide hole; the edge folder has the channel inserted by punch needle. And the method comprises that: layering and positioning the plate between upper and lower moulds; closing the upper and lower moulds; contacting the plate; moving the punch needle along the punch needle hole downwards, to pierce the plate, to form rivet part; moving the edge folder upwards along the guide hole to fold and rivet the rivet part. The invention can save time and improve efficiency.

Owner:SHENZHEN BAK BATTERY CO LTD

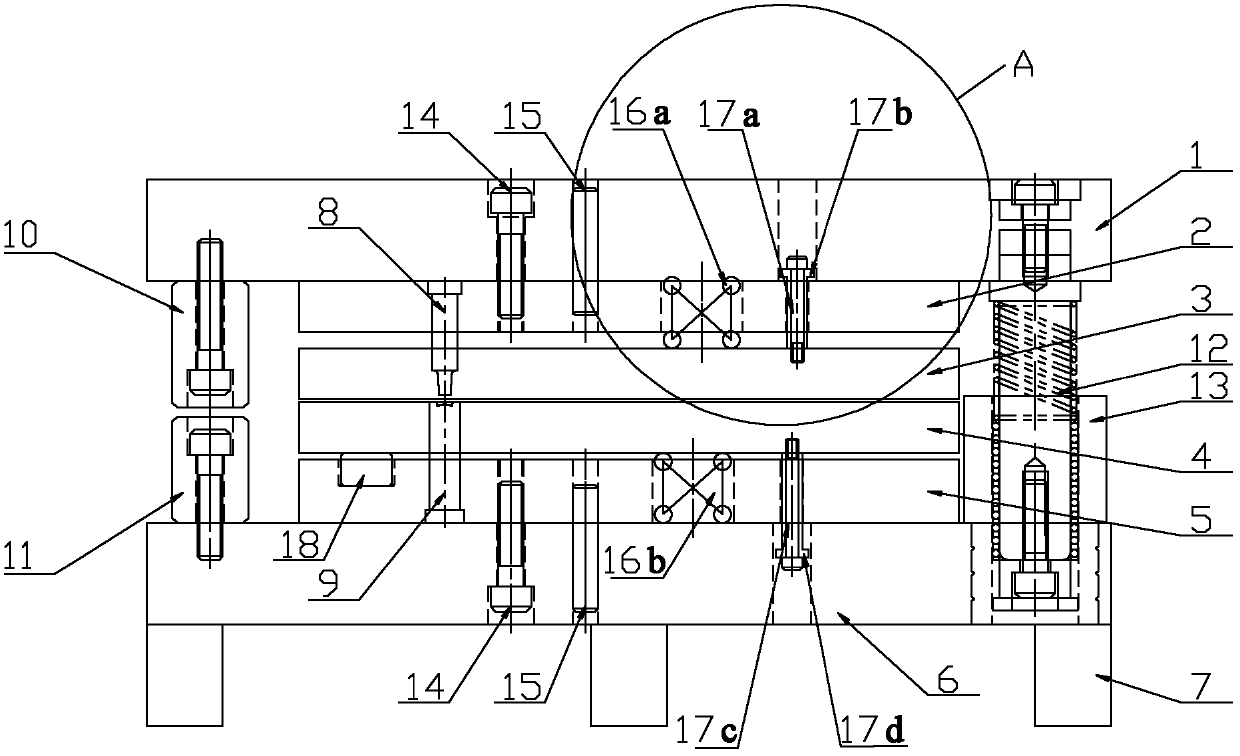

Nut locking plate press riveting fixture

The invention discloses a nut locking plate press riveting fixture, which is used for riveting a locking plate into a nut. The nut locking plate press riveting fixture comprises a workbench, a press riveting device, a rack and a gear device arranged on the workbench, wherein the press riveting device comprises a press riveting seat and a press riveting plate matched with the press riveting seat; the gear device comprises a gearbox, a gear arranged in the gearbox, and a guiding piece connected with the gearbox; the press riveting seat is arranged on the workbench; the press riveting plate is connected with one end of the rack; the rack is meshed with the gear, and is driven by the gear to move in the guiding piece; the rack drives the press riveting plate to move to the press riveting seat so as to rivet the locking plate into the nut. The nut locking plate press riveting fixture has high press riveting efficiency and can accurately mount the locking plate in the nut; the position where the locking plate is riveted in the nut is integrally consistent, the locking plate hardly falls off the nut, and the reliability is high.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +1

Riveting stamping mechanism for pulley retaining rings

The invention discloses a stamping riveting mechanism for pulley retaining rings. The stamping riveting mechanism comprises a transmission shaft, a frame, two bearing boxes, a cam system, a rivet shank and a rivet holder. The bearing boxes are fixed at corresponding positions on the frame. Each bearing box is provided with a bearing inside. The transmission shaft is in interference fit with inner rings of the bearings. The cam system comprises a housing fixed on the frame and a cam fixedly connected to the transmission shaft. The rivet holder is fixedly connected to the frame. The rivet shank partly locates in the rivet holder. The axial direction of the rivet shank is along the radial direction of the cam. The stamping riveting mechanism is simple in structure, convenient to produce and use, effective in riveting and high in riveting efficiency.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

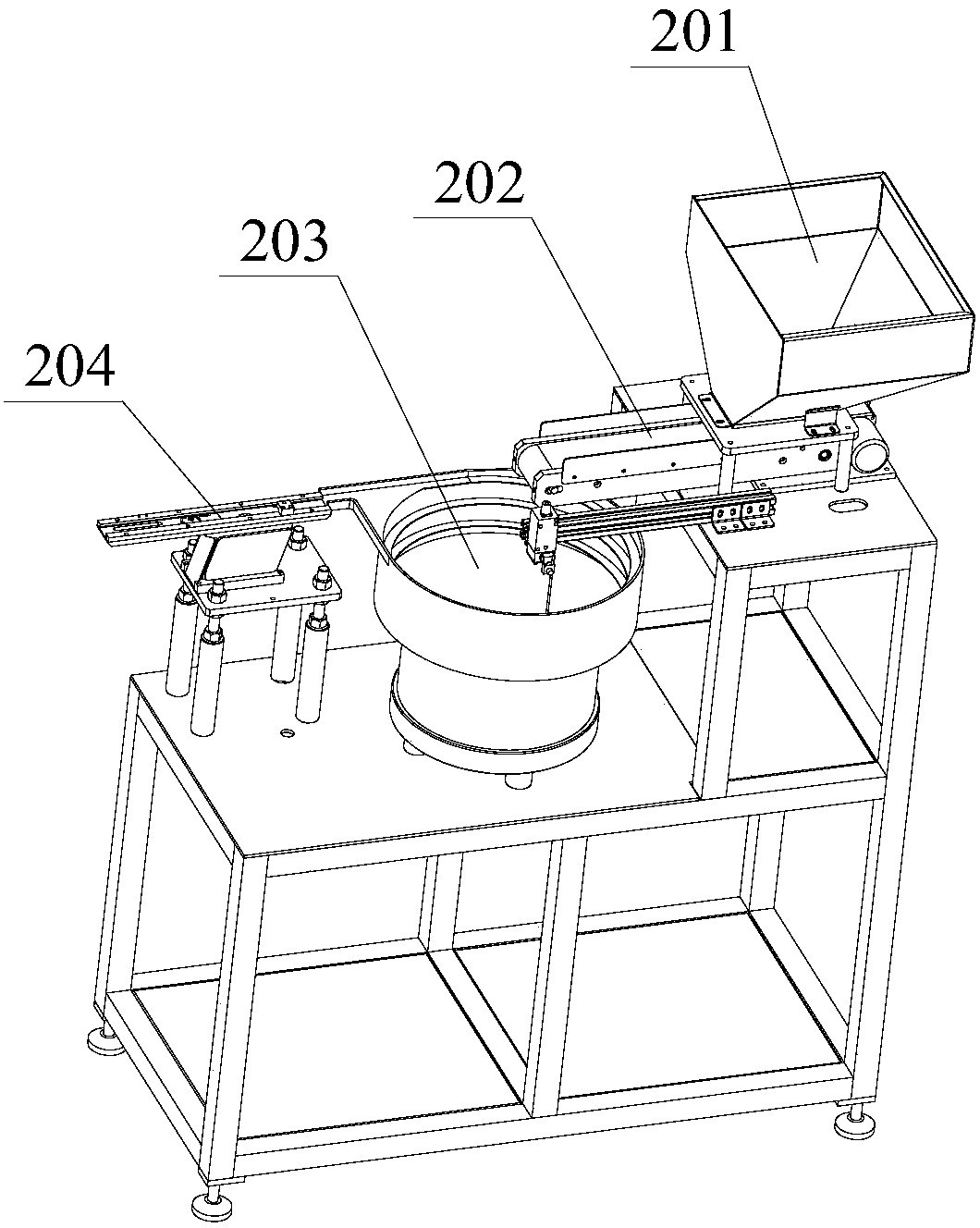

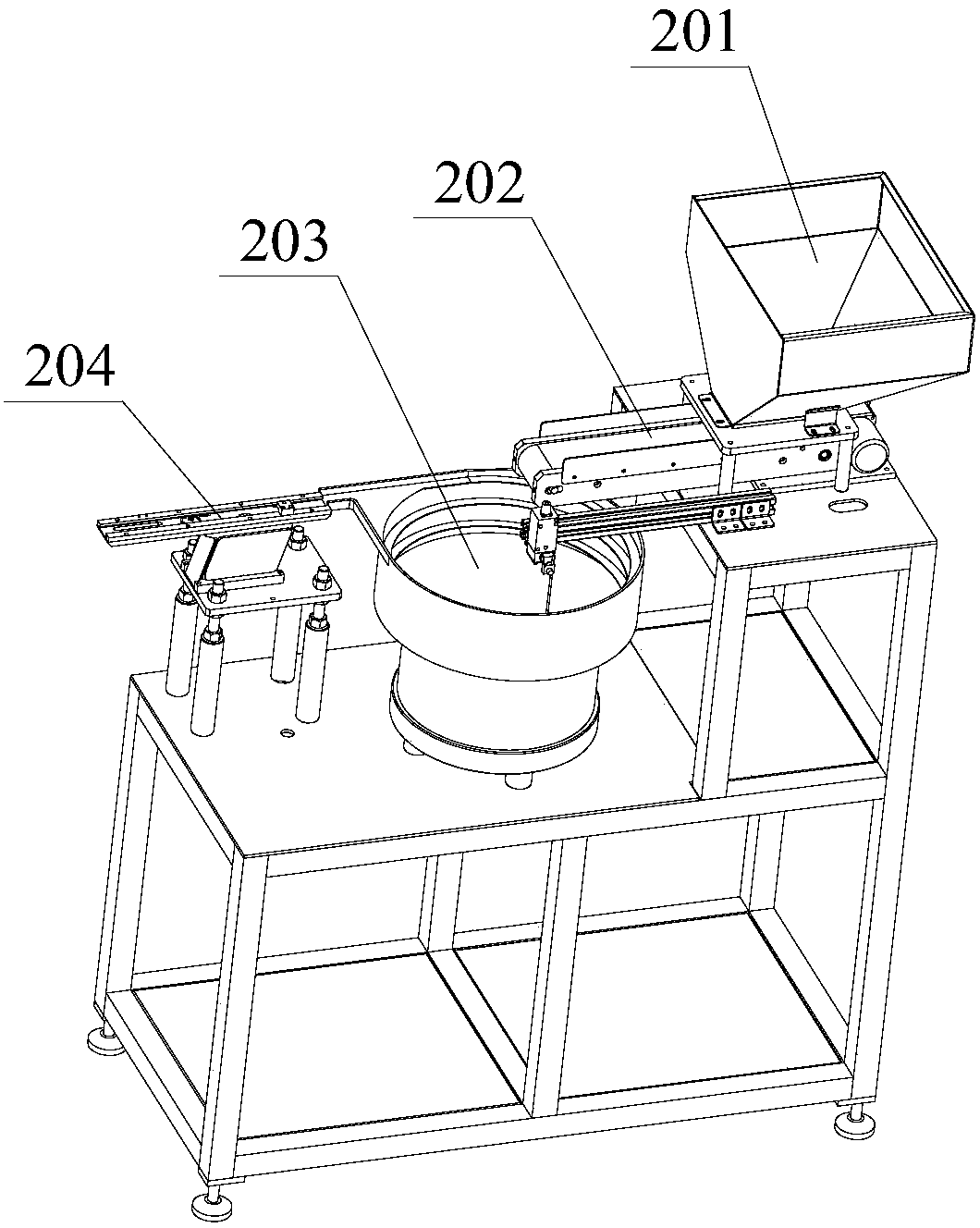

Automatic riveting machine

The invention provides an automatic riveting machine, comprising a feeding device, wherein the feeding device comprises a material arraying mechanism and a conveying mechanism; the material arraying mechanism is used for receiving and arraying materials and outputting the arrayed materials in sequence; the conveying mechanism is connected between a riveting mold of the automatic riveting machine and the material arraying mechanism and is used for conveying the materials from the material arraying mechanism to the riveting mold. According to the automatic riveting machine, the manual feeding mode is changed into the automatic feeding mode through utilizing the matching of the conveying mechanism and the material arraying mechanism, time waste in the feeding process can be reduced, the feeding time is consistent with the riveting time, and the riveting efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Self-punching riveting method for full tubular rivet

The invention discloses a self-punching riveting method for a full tubular rivet. In a riveting process, riveted pieces are located between an upper plunger tip and a lower base, the edge of the full tubular rivet is in contact with the upper plunger tip, a rivet body with an opening end is downward, the full tubular rivet moves downwards under the action of the upper plunger tip and keeps moving downwards after the lower end of the full tubular rivet is in contact with the riveted pieces, and the riveted pieces is subjected to plastic deformation under the action of the upper plunger tip until the upper riveted piece is pierced by the full tubular rivet and the next riveted piece is also subjected to plastic deformation under the action of the upper plunger tip to match with an annular groove in the lower base to finish the riveting work. The riveting method disclosed by the invention has the advantages that the riveting method is simpler, the sealing performance of the riveted pieces is greatly improved, the shapes of the riveted pieces are consistent after the riveting operation, and the riveted pieces are very beautiful.

Owner:HUBEI BOSHILONG TECH

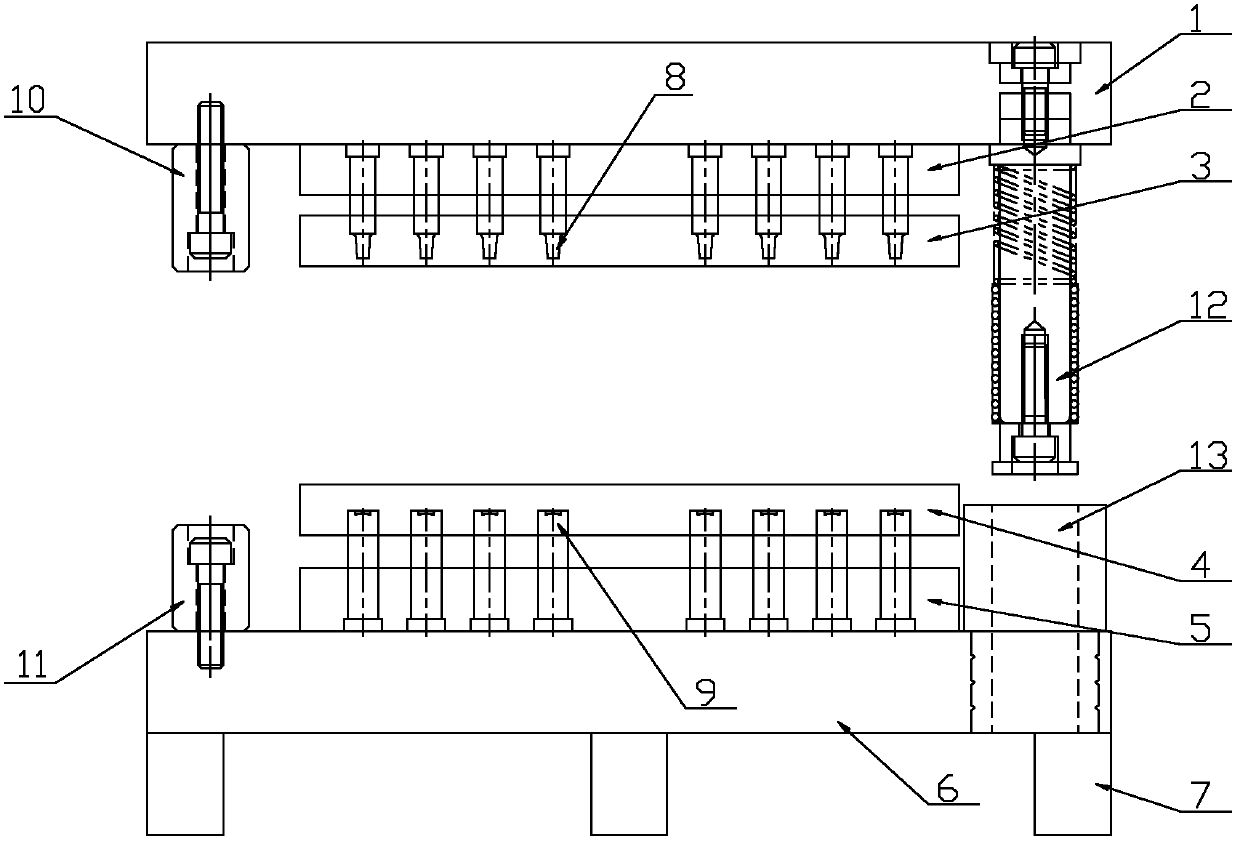

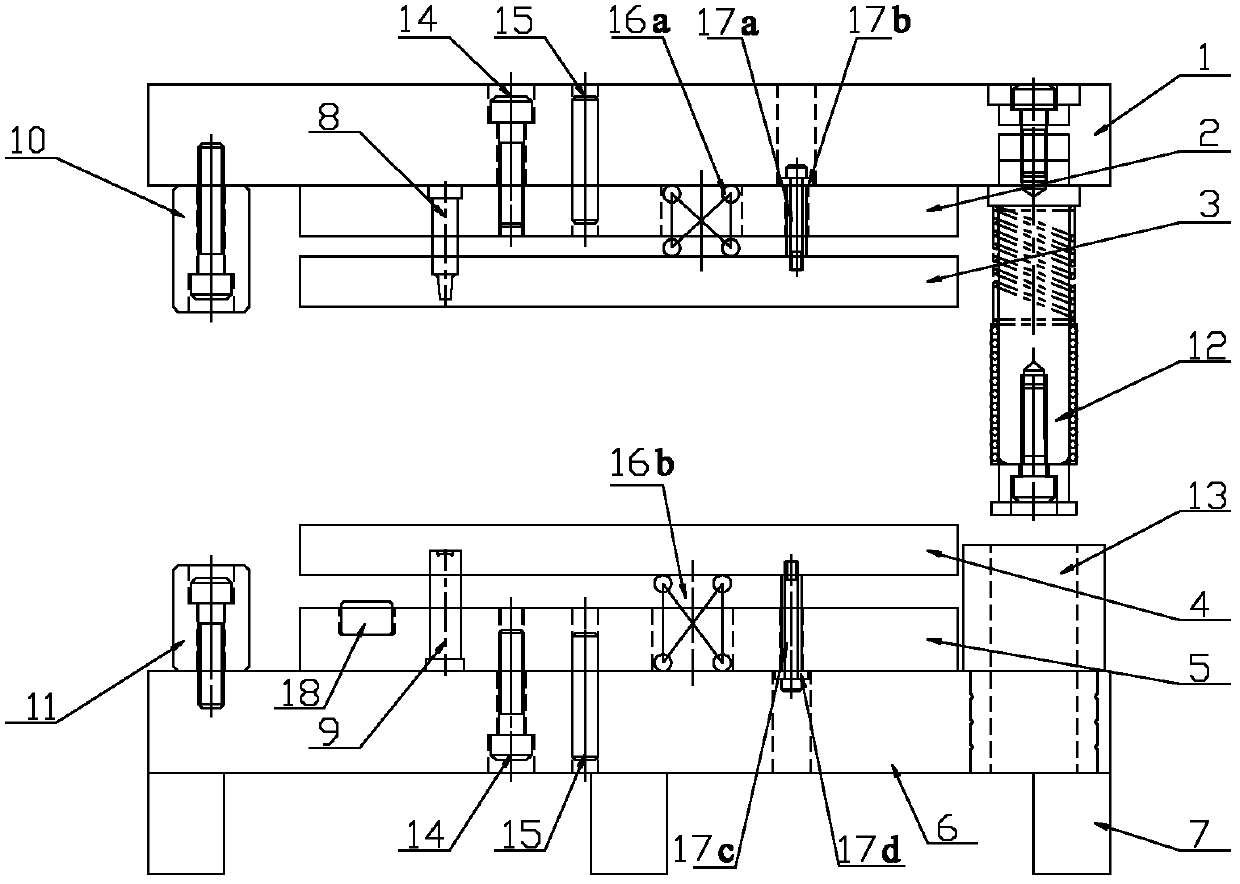

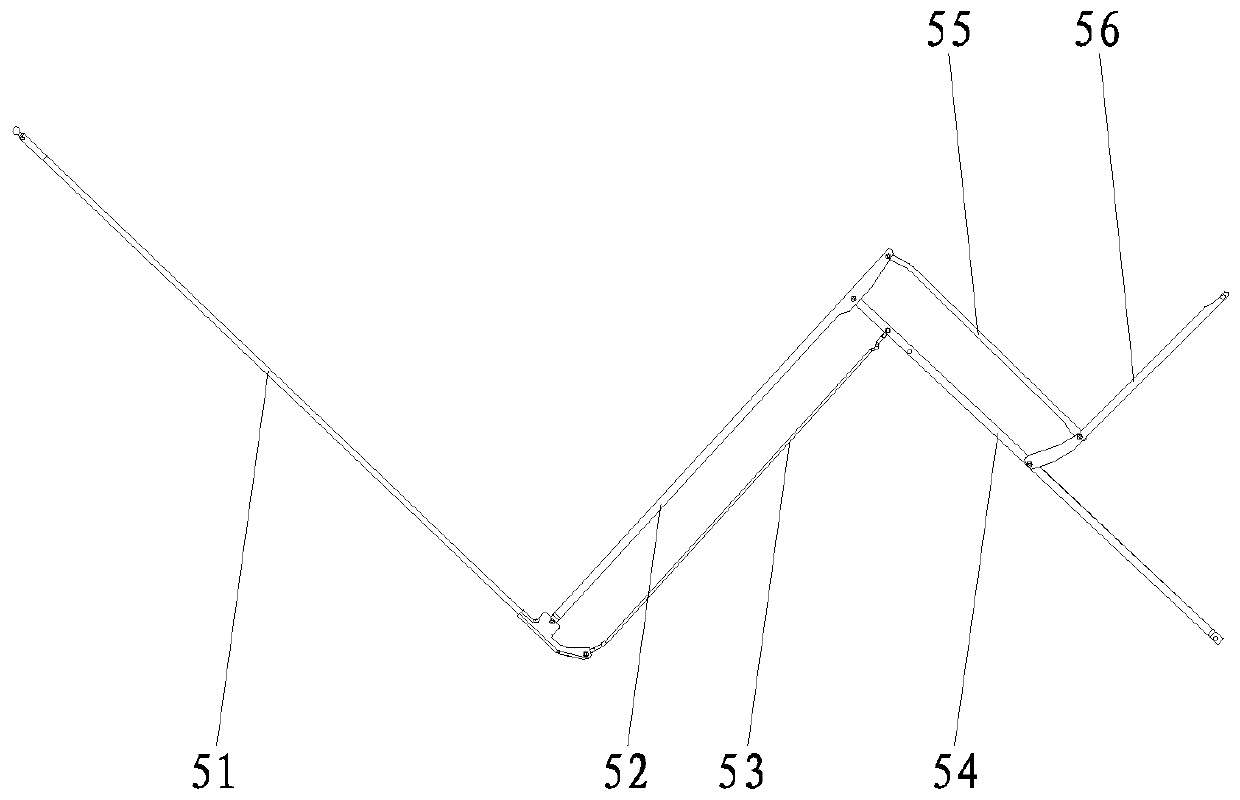

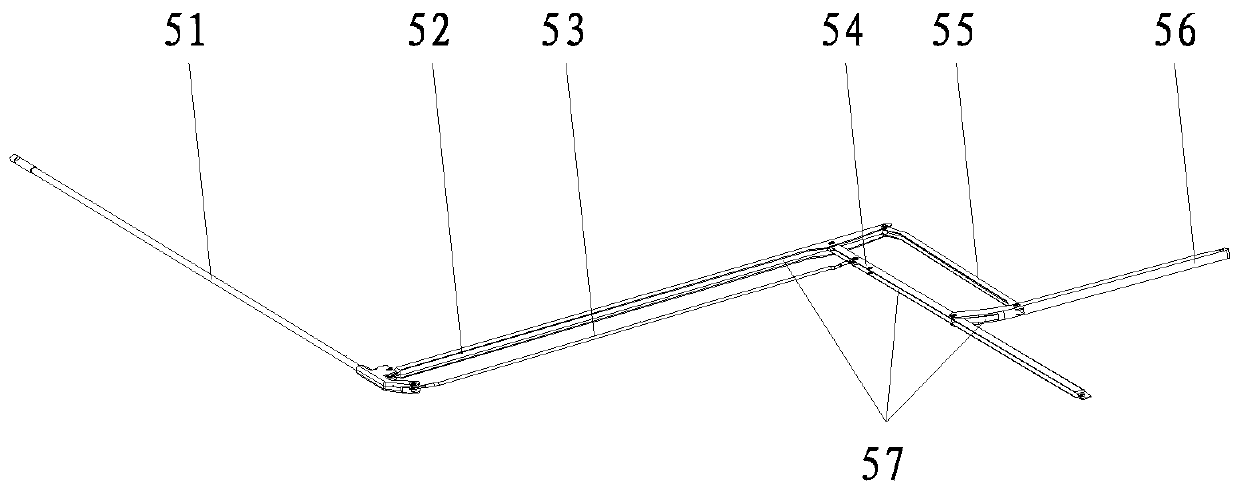

Riveting die for automatic production of umbrella rib

The invention discloses a riveting die for automatic production of an umbrella rib. The riveting die for automatic production of the umbrella rib comprises a supporting rack, a die driving device anda plurality of positioning dies, the positioning dies are slidably connected with the supporting rack, and the die driving device is arranged on the supporting rack and used for driving the positioning dies to be combined or separated. After the structure is adopted, when the umbrella rib is ready to be riveted, the positioning dies of the die are in a separated state, each umbrella rib section isput into a corresponding positioning groove through manual operation or manipulator operation, then the positioning dies are combined, the umbrella rib sections are inserted together, riveting holesof each pair of the connected umbrella rib sections are quickly aligned, and lastly all the aligned riveting holes are riveted at a time through a riveting machine. Compared with the prior art, the umbrella rib riveting efficiency is greatly improved, and meanwhile the riveting quality of the umbrella rib is effectively improved.

Owner:福建优安纳伞业科技有限公司

Self-adaptive positioning nut riveting tool and method

PendingCN112246987ASolve the problem of low qualified rate of rivetingGuaranteed coaxialityMetal-working feeding devicesPositioning devicesEngineeringScrew thread

The invention discloses a self-adaptive positioning nut riveting tool and method. The self-adaptive positioning nut riveting tool comprises an ejector rod, a positioning pressing sleeve, a tool base,a conical ejector head and an end face positioning sleeve. The tool base is of an opening structure, and a through hole is formed in one side of an opening and used for containing a rivet shaft nut. Athreaded through hole is formed in the other side of the opening, and the axis of the through hole is coaxial with that of the threaded through hole. The positioning pressing sleeve is cylindrical, athreaded through hole is formed in the central axis of the positioning pressing sleeve, the positioning pressing sleeve is rotationally connected with the end face positioning sleeve, and a through hole is formed in the central axis of the end face positioning sleeve. The positioning pressing sleeve penetrates the threaded through hole to press the end face positioning sleeve against the circumferential mounting face of a rivet shaft nut mounting hole in a workpiece, and the positioning pressing sleeve is in threaded connection with the tool base through the positioning sleeve. The ejector rod is cylindrical and is rotationally connected with the conical ejector head. The ejector rod penetrates the threaded through hole in the center of the positioning pressing sleeve to press the conicalejector head against the rivet shaft nut of the workpiece, and the ejector rod is in threaded connection with the positioning pressing sleeve through the ejector rod.

Owner:AECC AVIATION POWER CO LTD

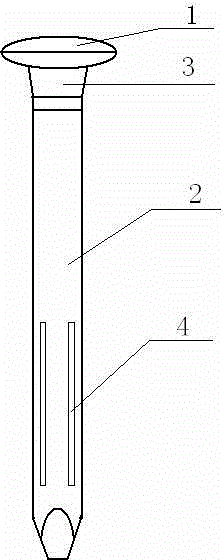

Half-round head rivet

InactiveCN104533912AIncrease the carrying capacityNot easy to bendRivetsStress strengthRejection rate

The invention discloses a half-round head rivet. The half-round head rivet comprises a rivet cap (1) and a rivet rod (2) connected with the rivet cap (1). The rivet rod (2) comprises a linkage transition end (3), and the rivet cap (1) is connected with the rivet rod (2) through the linkage transition end (3); the diameter of the linkage transition end (3) is larger than that of the rivet rod (2); and a plurality of reinforcing protruding ribs (4) protruding out of the circumferential face of the rivet rod (2) are evenly distributed in the circumference face of the lower end of the rivet rod (2) in the axial direction. The rivet cap is connected with the rivet rod through the linkage transition end, the reinforcing protruding ribs are arranged on the circumferential face of the lower end of the rivet rod in the axial direction, force borne by the rivet rod can be reduced, stress strength of the rivet rod is enhanced, the rivet rod is effectively prevented from bending, and therefore the riveting efficiency is improved, and the rejection rate of the rivet is reduced.

Owner:CHANGZHOU JINHAIJI MACHINERY MFG

Pre-buried groove channel rivet rod riveting device

PendingCN108405735AEasy to installFast rivetingShaping toolsMetal-working feeding devicesEngineeringRivet

The invention discloses a pre-buried groove channel rivet rod riveting device which comprises a pressing connection structure; the pressing connection structure comprises an upper die, a lower die anda base; a holding mechanism is arranged between the upper die and the lower die and comprises a supporting plate; a lower die groove is arranged at the middle part of the supporting plate; the holding mechanism is arranged on the two sides of the supporting plate; the lower end of the lower die is fixed on the base; the upper end of the lower die is arranged in the lower die groove and can slideup and down relative to the lower die groove; the base is provided with a plurality of guide holes; and a plurality of guide holes which are matched with the guide holes respectively are arranged on the lower end surface of the supporting plate and are charged into the guide holes respectively. By adopting the pre-buried groove channel rivet rod riveting device provided by the invention, when a rivet rod is riveted, a pre-buried groove channel needs to be put on the lower die only, the rivet rod after being heated is put in the holding mechanism, the upper die moves downward through holding ofthe holding mechanism, and the rivet rod is riveted to the groove channel, so that operation is convenient, and riveting efficiency is high.

Owner:HENAN DASEN MECHANICAL & ELECTRICAL CO LTD

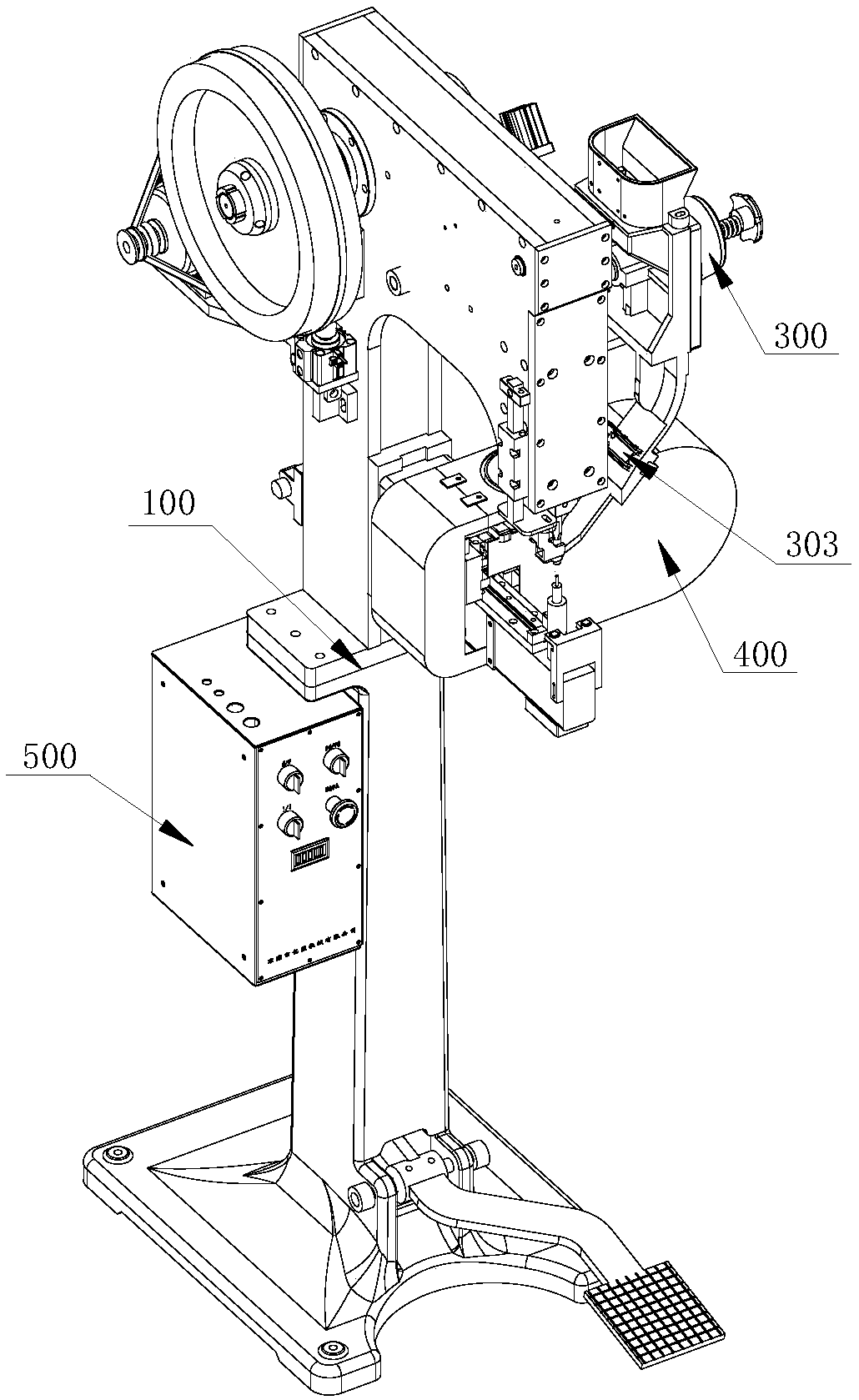

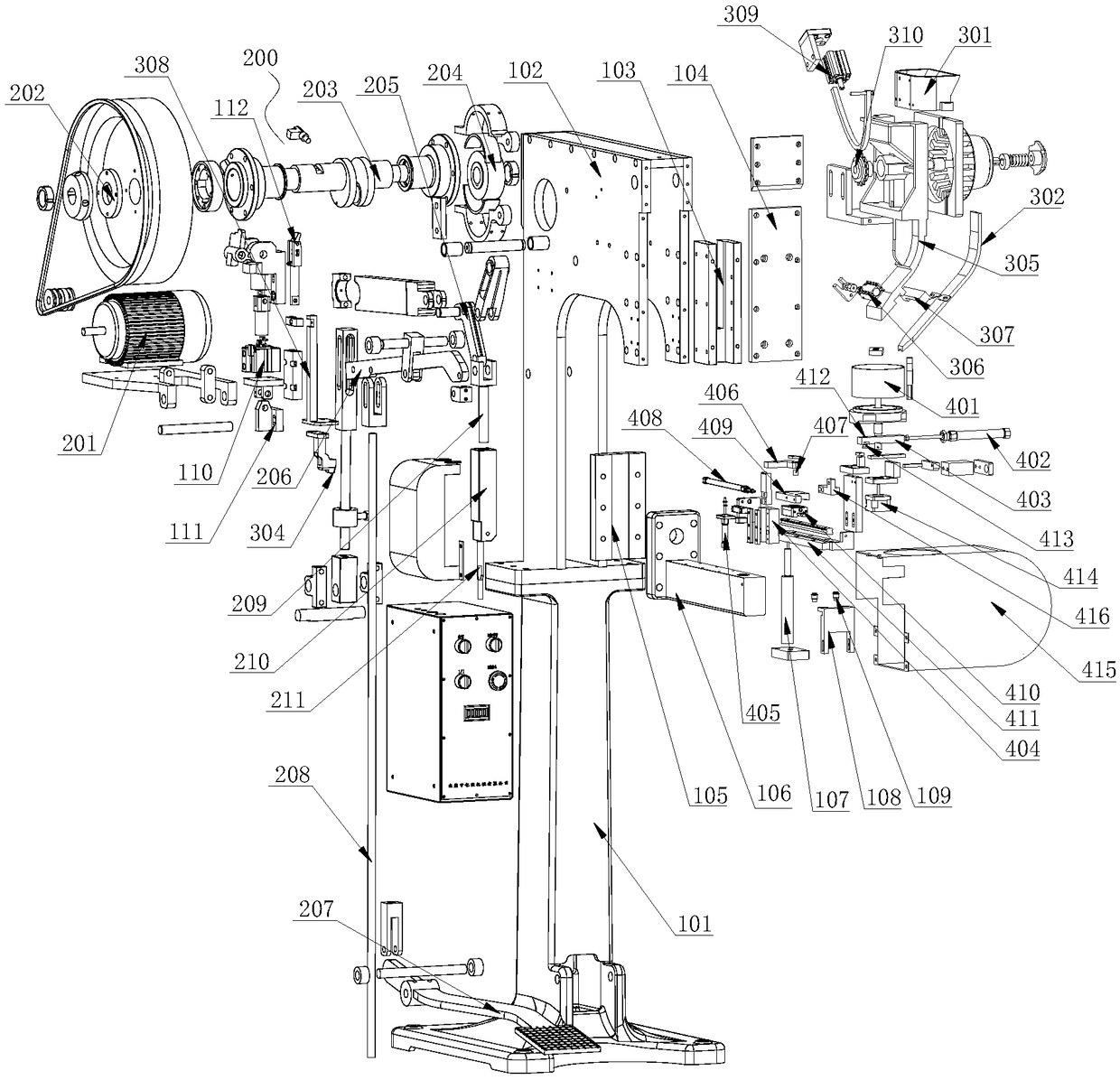

Riveting machine capable of automatically sending gaskets

A riveting machine capable of automatically feeding gaskets comprises a main machine body, a power device, a rivet selecting and sending device, a gasket selecting and sending device and a PLC controlbox. The power device, the rivet selecting and sending device and the gasket selecting and sending device on the main machine body are controlled to work by the PLC control box, there is no need to put rivets or the gaskets manually, automatic rivet selection and gasket selection are achieved, manpower is reduced, the labor intensity is reduced, the riveting efficiency is greatly improved, and meanwhile large space riveting for large parts is met.

Owner:东莞市达发启强机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com