Half-round head rivet

A semi-circular head and rivet technology, applied in rivets and other directions, can solve the problems of high strength, scrapped rivets, bending, etc., and achieve the effect of preventing bending, not easy to bend, and reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

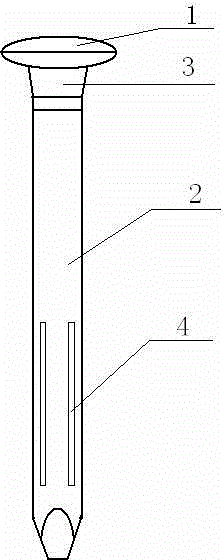

[0019] A half-round head rivet, comprising a rivet cap 1 and a rivet rod 2 connected with the rivet cap 1, the rivet rod 2 includes a joint transition end 3, and the rivet cap 1 connects to the willow through the joint transition end 3 The nail rod 2 is connected, and the diameter of the connecting transition end 3 is larger than that of the rivet rod 2; the peripheral surface of the lower end of the rivet rod 2 is evenly distributed in the axial direction with a number of reinforcing ribs 4 protruding from the peripheral surface of the riveting rod 2. The rivet cap 1 is in an inverted hemispherical shape. The reinforcing rib 4 is a rectangular strip formed by protruding from the surface of the rivet rod 2 . The rivet shank 2 has a conical penetration. The length of the rivet rod 2 is defined as L1, and the length of the connecting transition end 3 is defined as L2, then L1=15cm, L2=1.5cm. .

[0020] In the above scheme, the rivet cap and the rivet rod are connected by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com