Self-punching riveting method for full tubular rivet

A self-punching and riveting technology, applied in the field of rivets, can solve the problems of damaging the sealing performance of riveted parts, difficult to improve the riveting efficiency, and the riveting effect is not beautiful enough, and achieves the effects of simple riveting method, improved riveting efficiency and beautiful effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

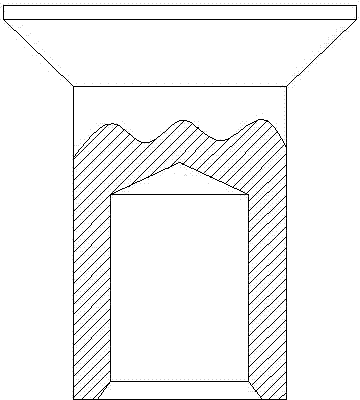

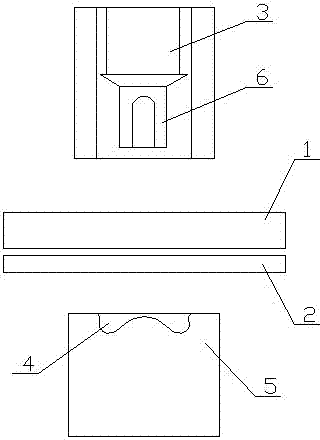

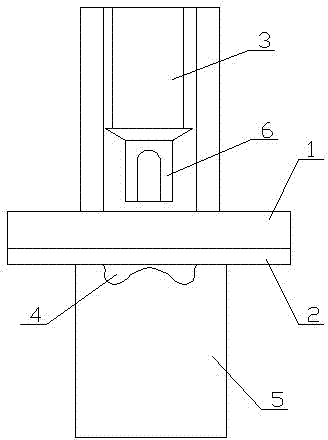

[0015] As shown in Figure 1, Figure 2, Figure 3, Figure 4 and Figure 5, a self-piercing riveting method for hollow rivets, the materials to be riveted by this method are two plastic thin plate parts 1 and 2, when this method is riveted The upper end of the tool used is a punch 3, and the lower end is a base 5 with a "W"-shaped annular groove 4 in the longitudinal section. When riveting, the riveted part is located between the upper punch 3 and the lower base 5, and the hollow rivet The brim of the brim of the rivet 6 is in contact with the upper punch 3, and the riveting body with the open end is downward, and the hollow rivet 6 runs downward under the action of the upper punch 3, and continues after the lower end of the hollow rivet 6 is in contact with the riveted piece. Running downward, the riveted part will be plastically deformed under the action of the upper punch 3 until the upper riveted part is pierced by the hollow rivet 6, and the lower riveted part will also be pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com