Riveting method of ductile metal

A plasticity, metal technology, applied in the field of metal connection, can solve the problems of long processing cycle, expensive riveting punch and die, metal surface quality, surface coating damage, etc., to avoid oxidation corrosion, simple riveting method, good appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

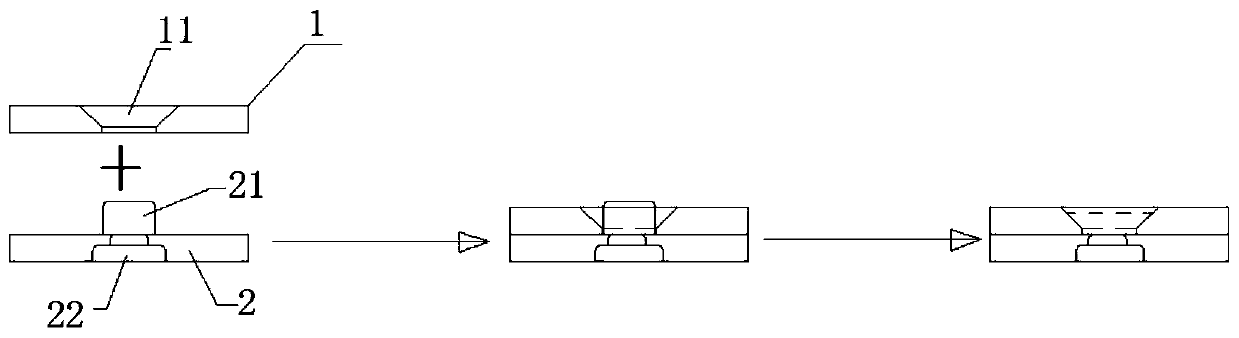

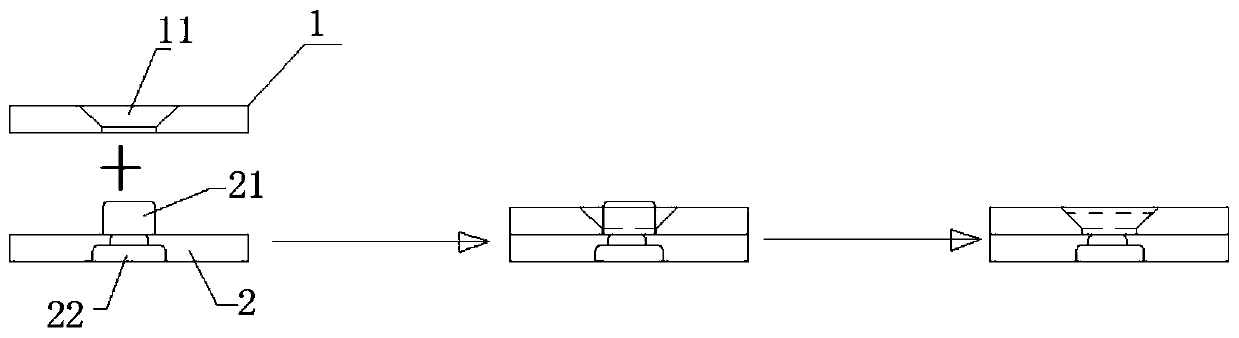

[0018] Such as figure 1 Shown, a kind of plastic metal riveting method comprises the following steps:

[0019] a) Punch at least one salad hole 11 at the pre-riveting point of the metal piece A1, the salad hole is composed of a flared part and a straight part;

[0020] b) At least one convex hull 21 is punched at the pre-riveting point of the metal piece B2, the convex hull corresponds to the salad holes one by one, and the shape and radial dimension of the convex hull are consistent with the shape and shape of the straight mouth part. The radial dimensions match, and the height of the convex hull is greater than the height of the salad hole;

[0021] c) inserting the convex shell from the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com