Quick disassembly and assembly of building formwork frame

A building formwork and fast technology, which is applied in construction, building structure, connection parts of formwork/formwork/work frame, etc., can solve the problems of low construction efficiency, time-consuming building formwork, inconvenient dismantling of building formwork, etc. The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

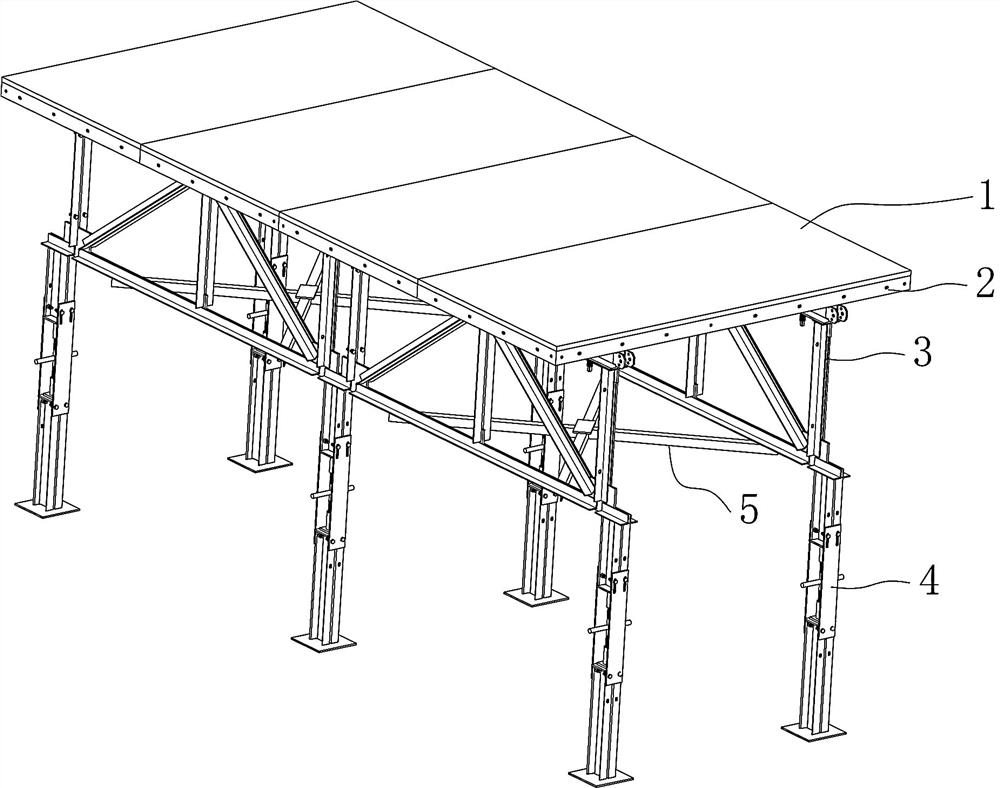

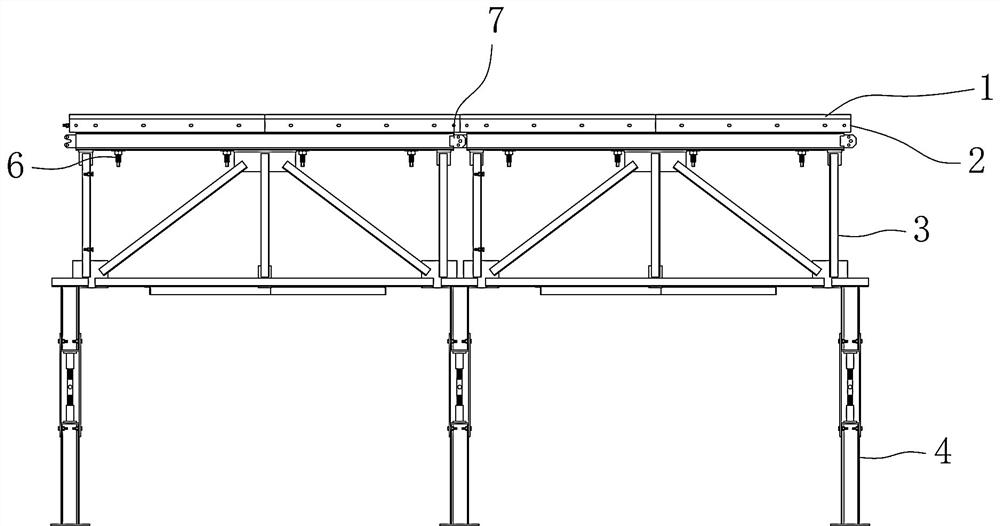

[0043] Such as Figure 1~17 As shown, a quick disassembly and assembly building formwork frame includes a formwork 2, a formwork 1 is arranged above the formwork 2, and a support frame 3 composed of a plurality of connecting rods 302 is provided below the formwork 2. The support frame 3 and the formwork 2 A plurality of parallel beams 301 are arranged between them, and the template 1 is fixed on the formwork 2 through a tensioning mechanism 6. Threaded connection, the other end passes through the formwork 2 and the parallel beam 301, and is reversely locked by the lock nut 603, a limit plate 602 is provided between the lock nut 603 and the beam 301, and the end of the lock nut 603 A locking part 604 is provided, and a plurality of bottom support rods 4 are arranged below the support frame 3, and the bottom support rods 4 include a first support foot 402 and a second support foot 404, between the first support foot 402 and the second support foot 404 An adjustment rod 8 is pro...

Embodiment 2

[0057] Further illustrate in conjunction with embodiment 1, as Figure 1~17 As shown, when the quick detachable building formwork frame is in use, a large number of connecting rods 302 , mounting plates 303 , beams 301 , bottom support rods 4 and formwork 1 are transported from the factory.

[0058] After arriving at the construction site, the connecting rod 302, the mounting plate 303 and the beam 301 are installed as Figure 6 In the structure of the supporting frame 3 shown, the bottoms of two side-by-side supporting frames 3 are connected by a stabilizing frame 5 .

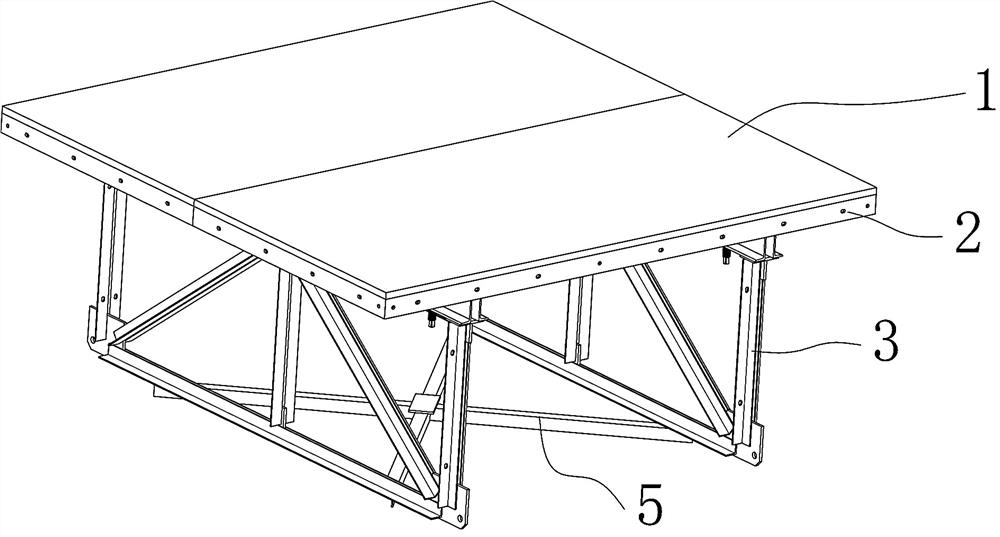

[0059] After the supporting frame 3 is installed, the formwork 2 is installed on the beam 301, the template 1 is spread on the formwork 2, and the template 1 is locked on the supporting frame 3 by the tension rod 601 and the locking nut 603. Support frame 3 forms an integral body with formwork 2 and template 1 like this, as image 3 As shown, two templates 1 can be installed on one whole, the size of one tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com