Patents

Literature

48results about How to "Fast riveting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

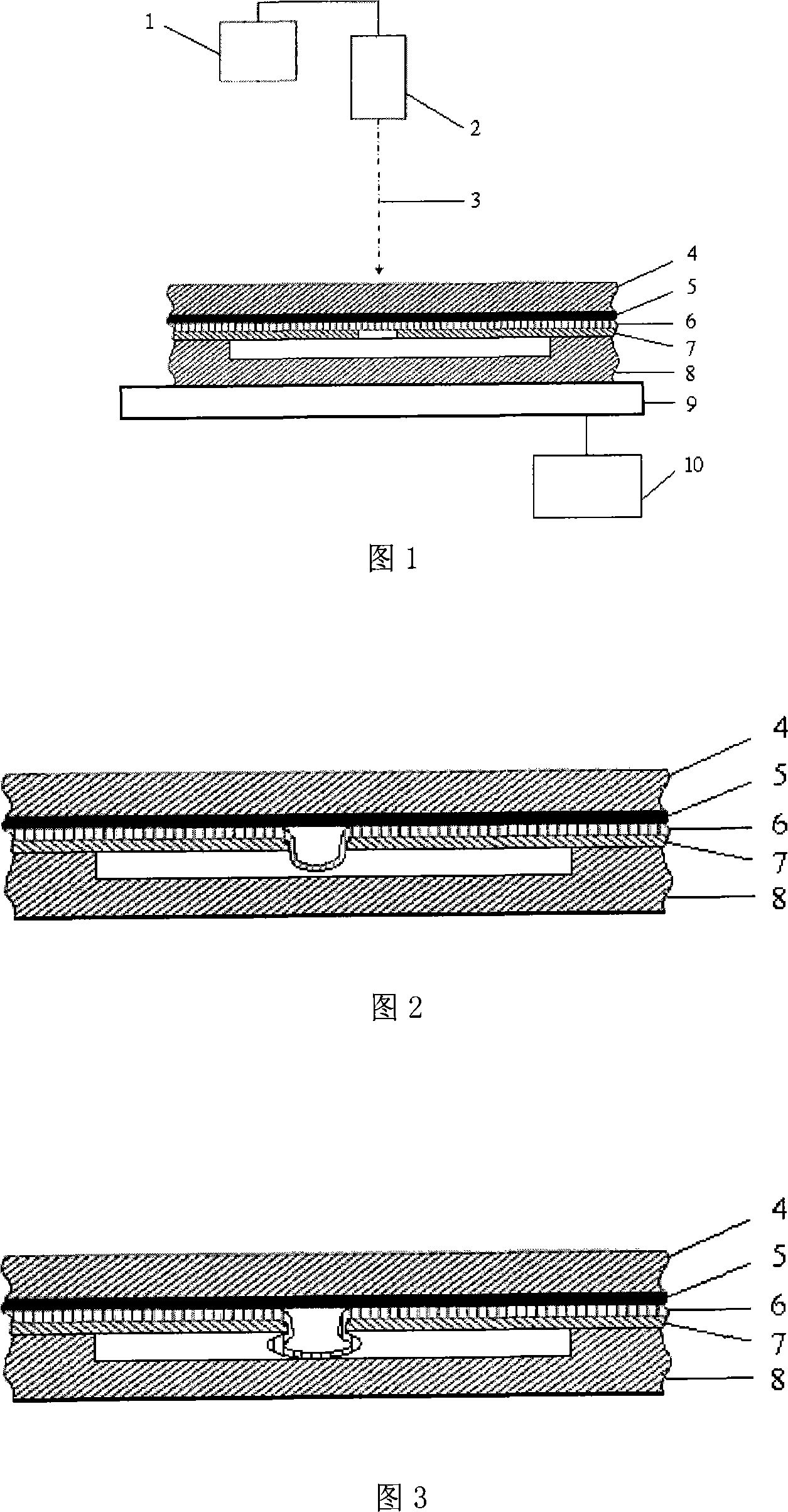

Ultra-thin sheet material pulsed laser micro rivet connection method and special-purpose device thereof

InactiveCN101214580AGuaranteed tightnessNice appearanceLaser beam welding apparatusDetonationEnergy absorption

The invention discloses an ultrathin plank stuff pulse laser micro-riveting method and a special device for realizing the method. The method relates to a method which leads laser acted on a plank stuff to form a flexible convex mold and pivots double-layer or multi-layer plank stuff together. An optimized scheme is to lead laser on an energy absorption layer covered on the surface of the plank stuff under the action of a restraint layer to generate plasma detonation waves which are used as a flexible convex mold and then act on the plank stuff to pivot double-layer or multi-layer plank stuff together. The special device realizing the ultrathin plank stuff pulse laser micro-riveting method consists of a laser generator system, a frock clamper system and a working platform system. Through the method can process the metal materials like steel, aluminum and copper, etc., and can also process the non-metal material like silicon and plastic. The invention is in particular suitable for micro-apparatus part manufacture like the fields of pivoting of a metal contact of a micro-switch and forming the micro-electric packaging for the contact area.

Owner:SHANDONG UNIV

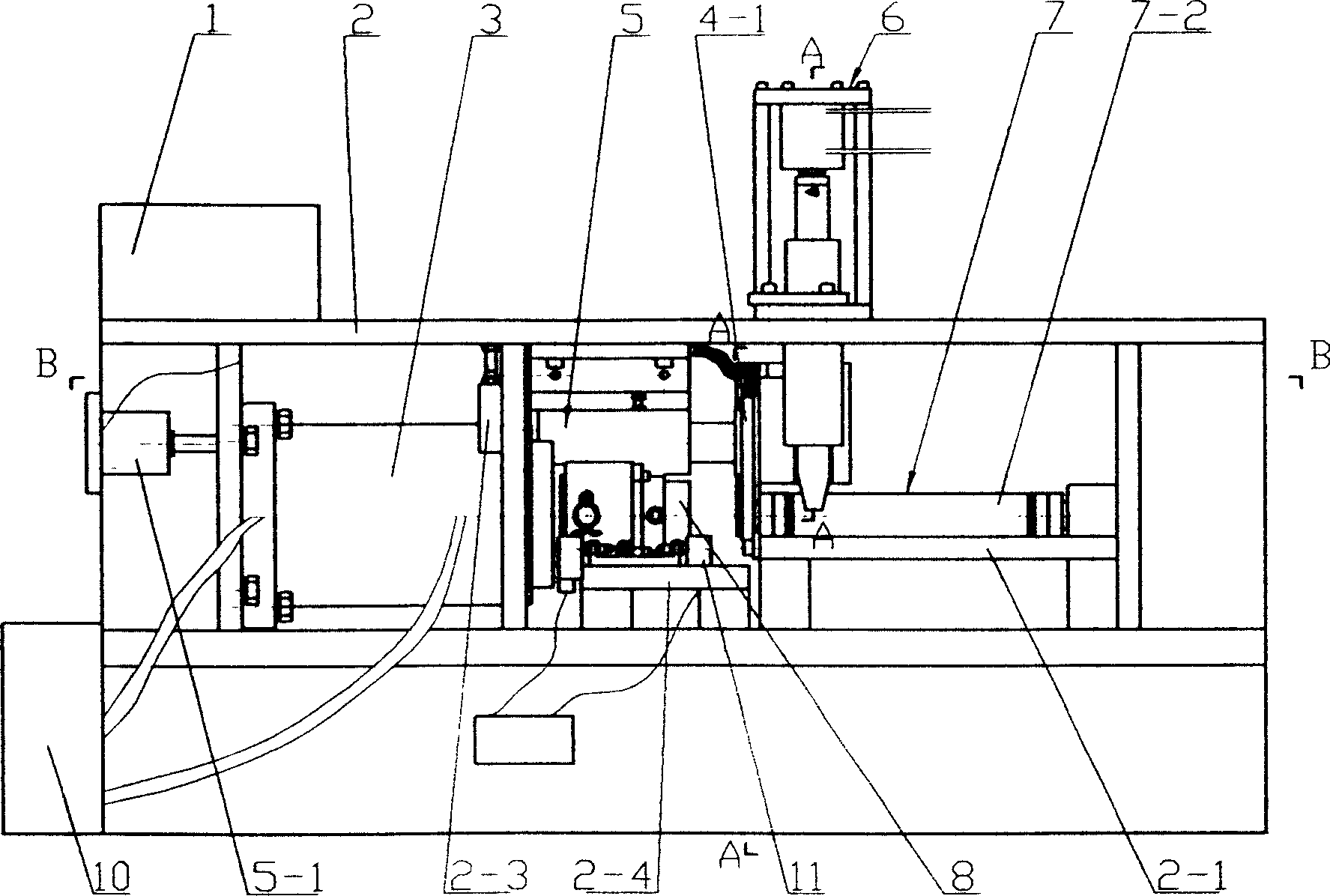

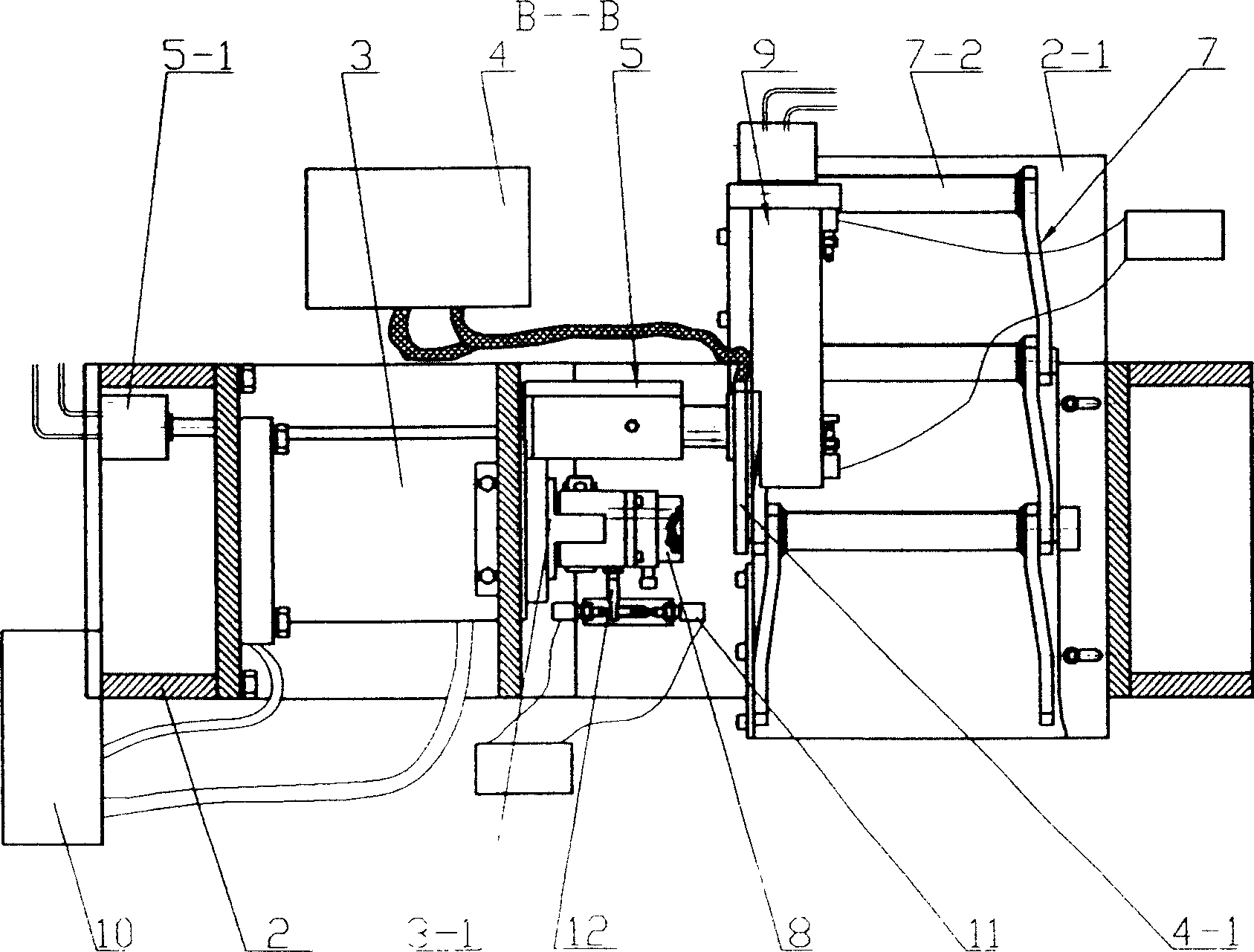

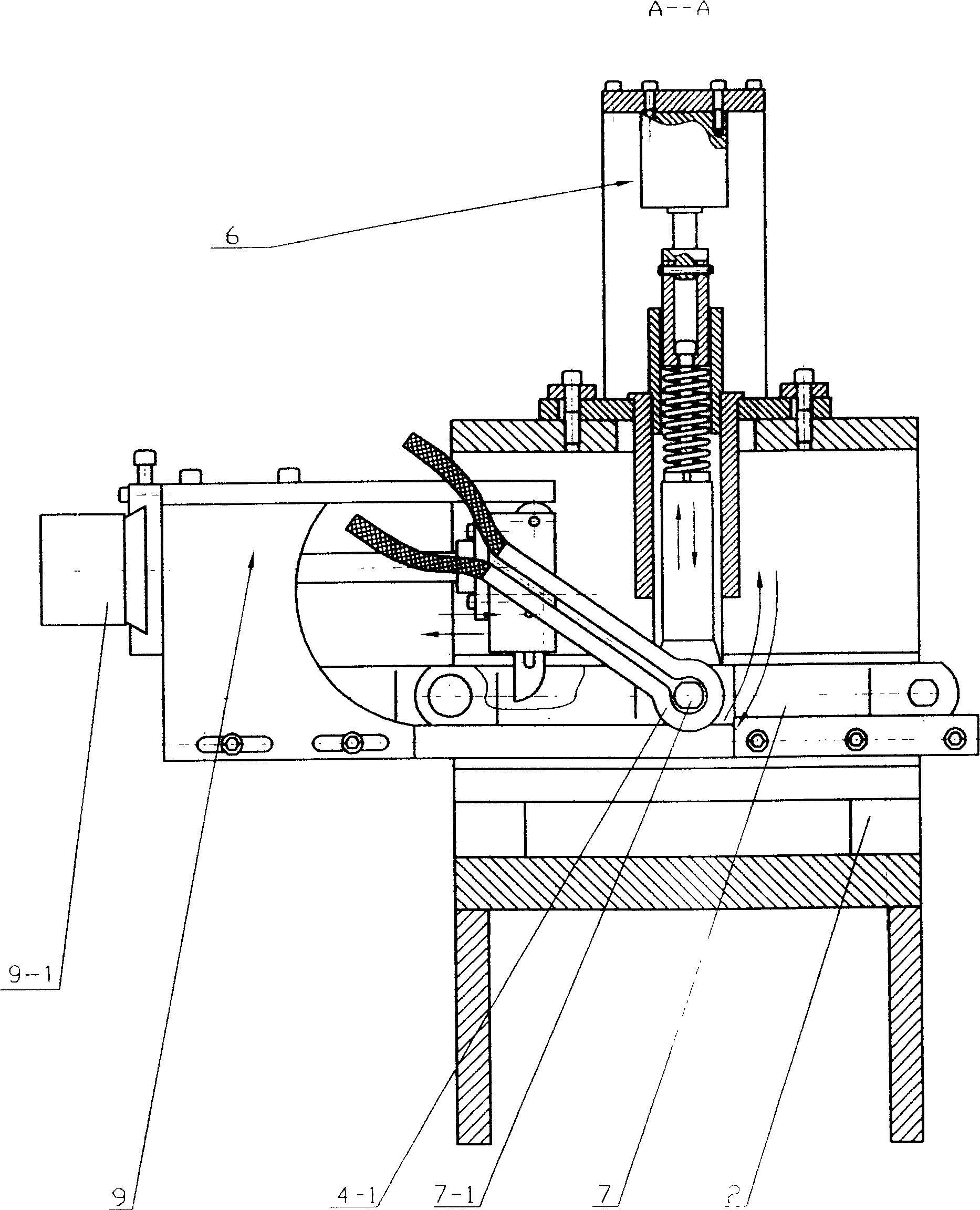

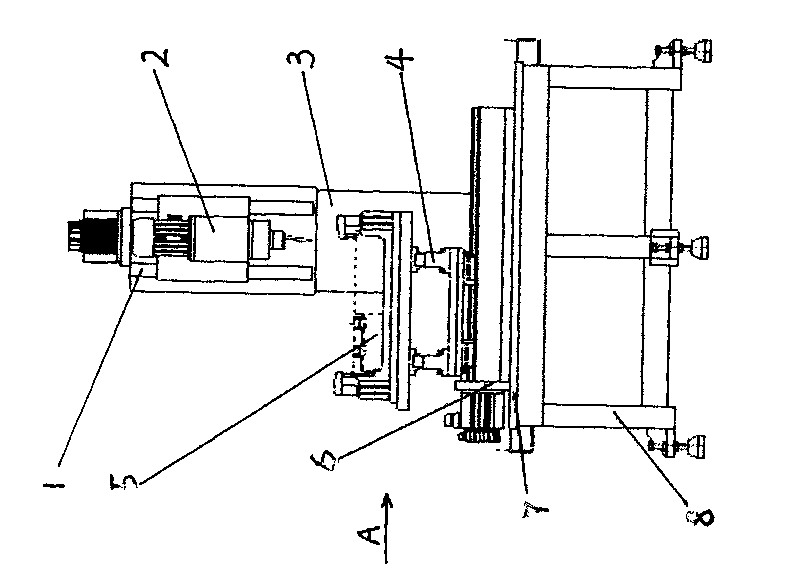

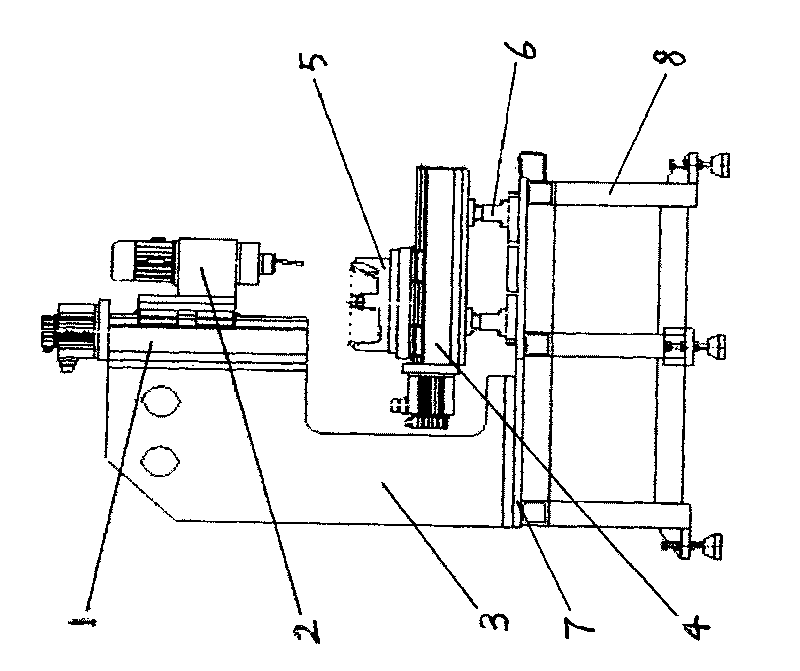

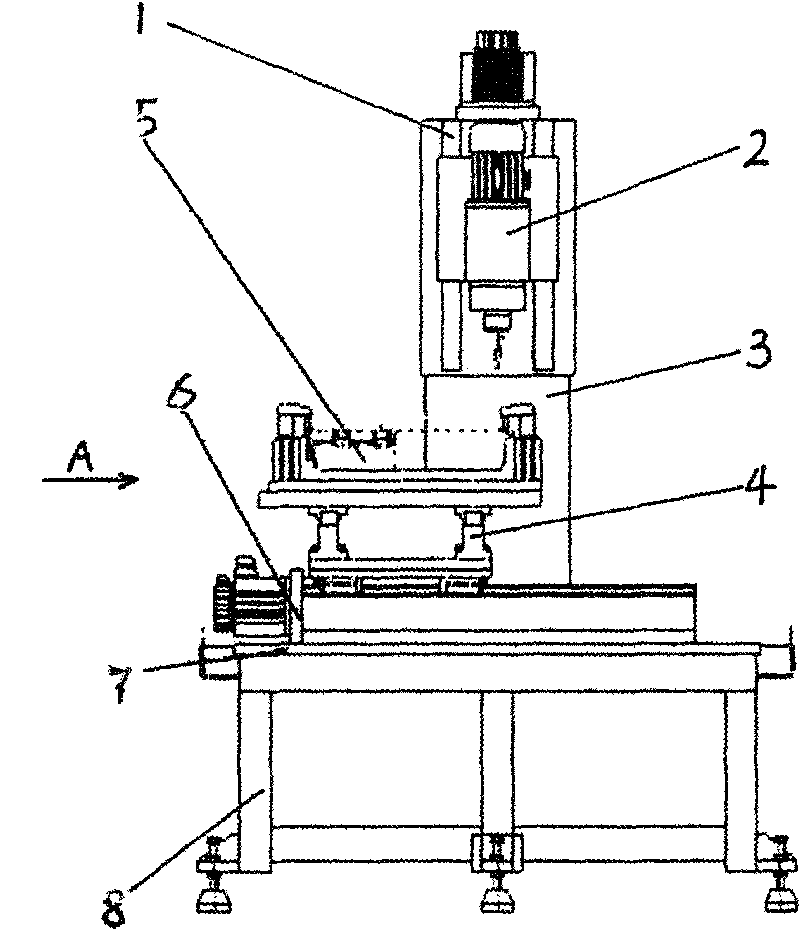

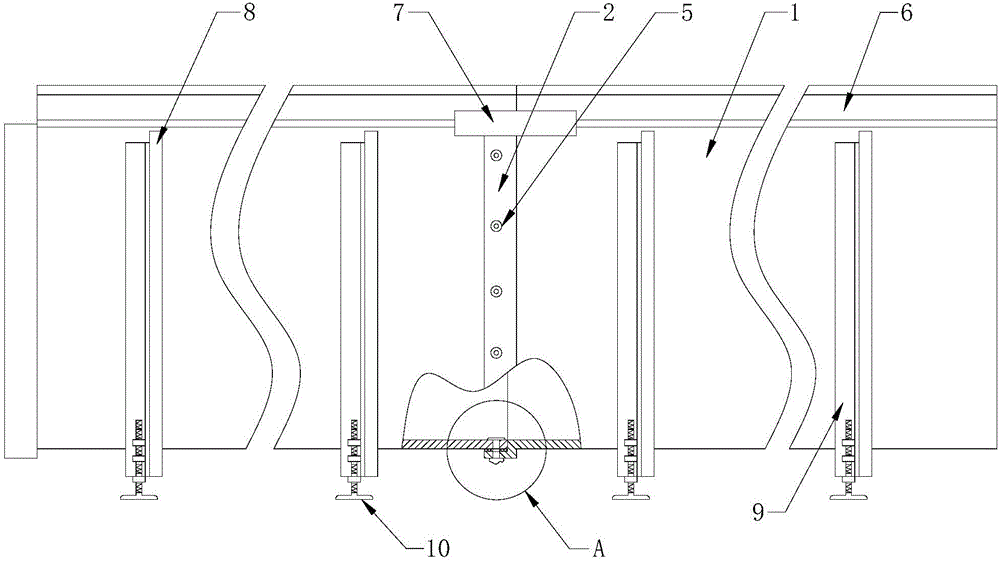

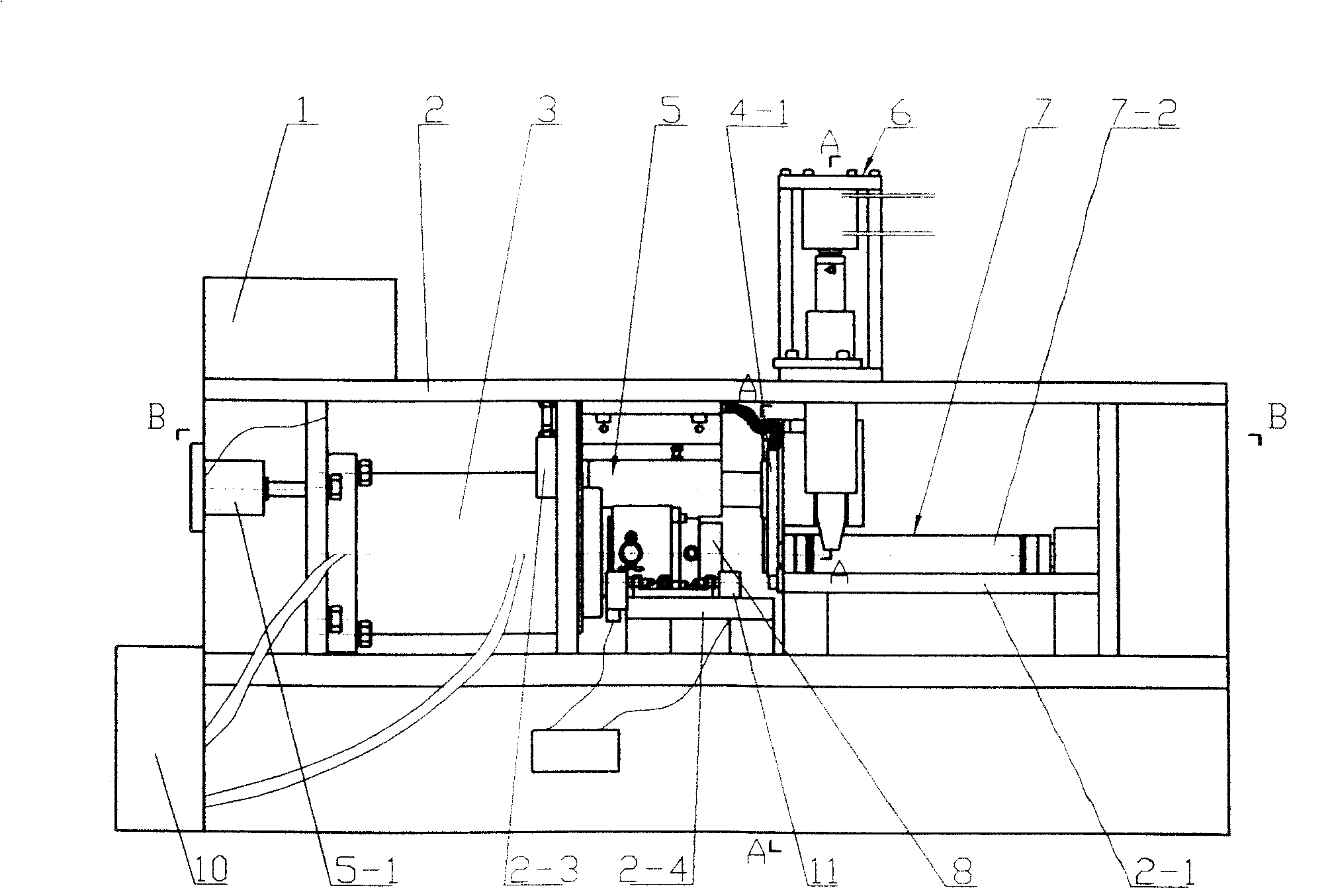

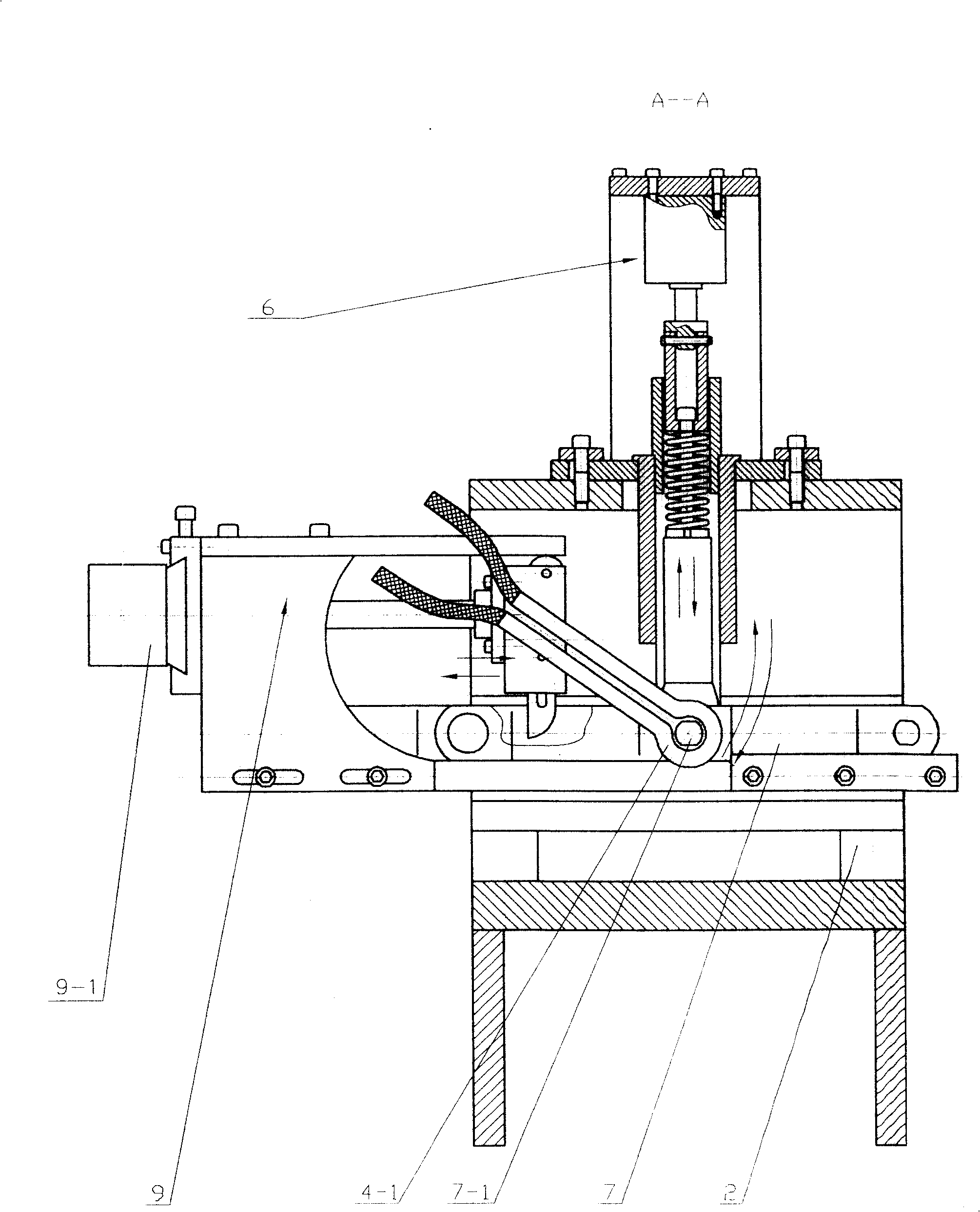

Automatic thermal riveting method and automatic thermal riveting machine for chain pin shaft

The invention relates to an automatic hot rivet method of chain pin axle and a relative rivet machine, wherein said method comprises: arranging several chain sections on the work bench; positioning the chain section of riveted pin axle, to aim the end of pin axle to the rivet mould and aim the tail of pin axle axially; then moving the electromagnetic induction heating coil to be end of pin axle, to heat the end; heating to the rivet temperature, removing the electromagnetic induction heating coil; riveting the pin axle end with rivet mould; returning the rivet mould; loosing the chain section; then moving the chain section to make the next pin axle on site. The heat riveter comprises a frame, a hydraulic cylinder, a controller, an electromagnetic induction heating coil feeder and a chain positioning device. And the invention has high rivet speed and high working efficiency.

Owner:JIANGSU SHUANGLING CHAIN TRANSMISSION

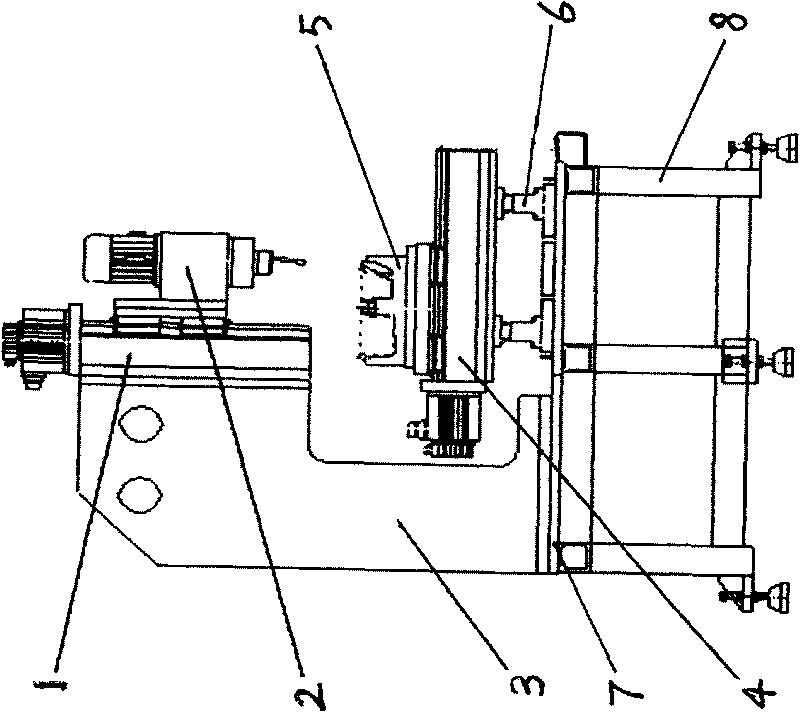

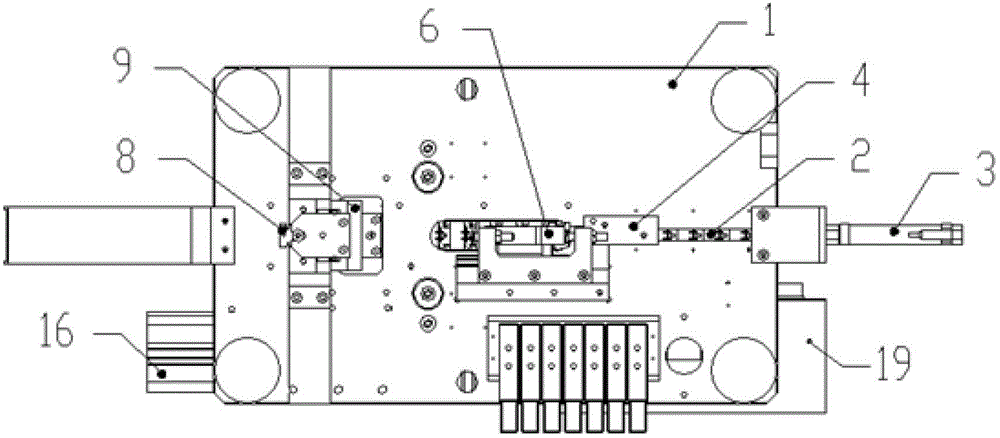

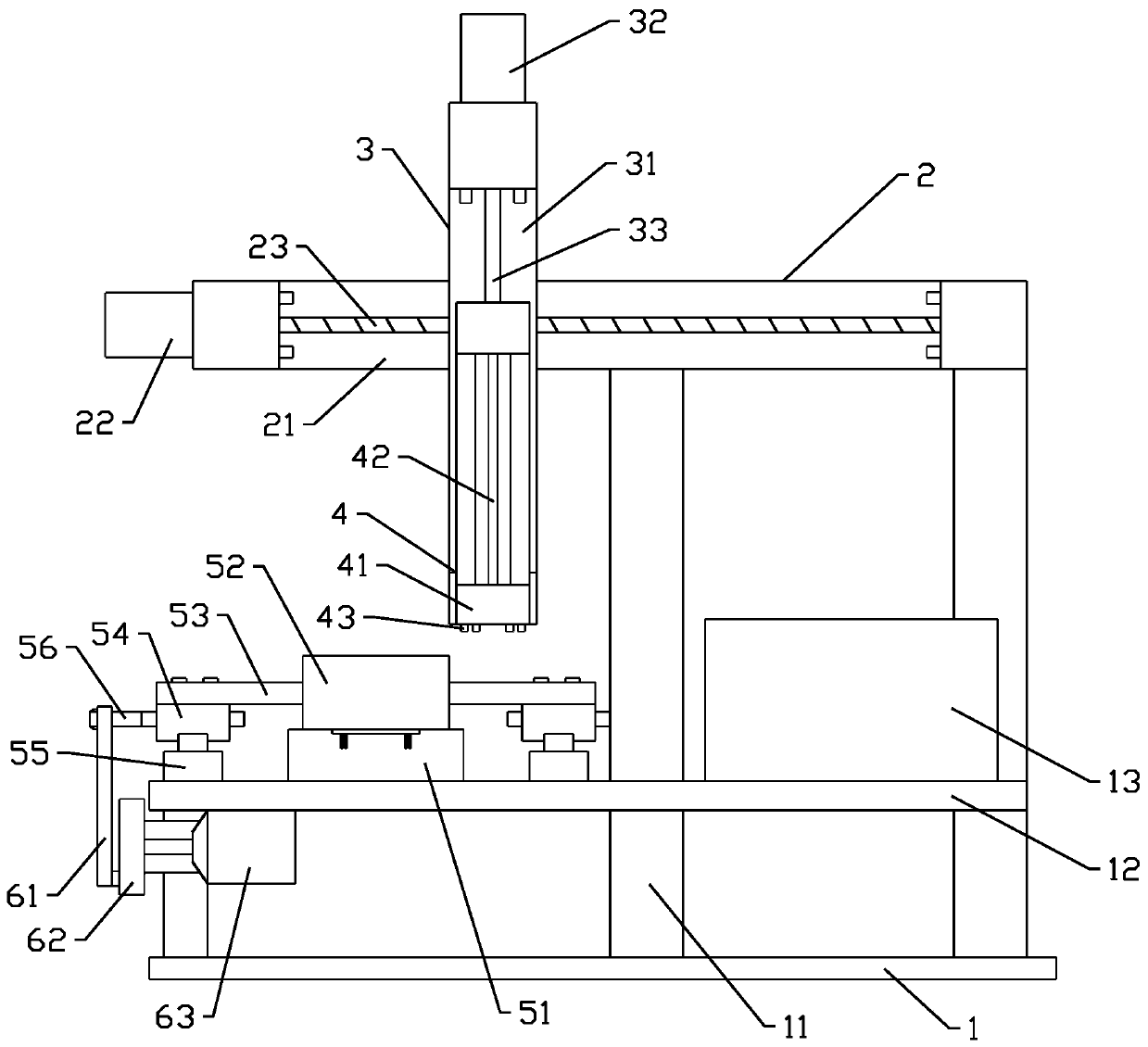

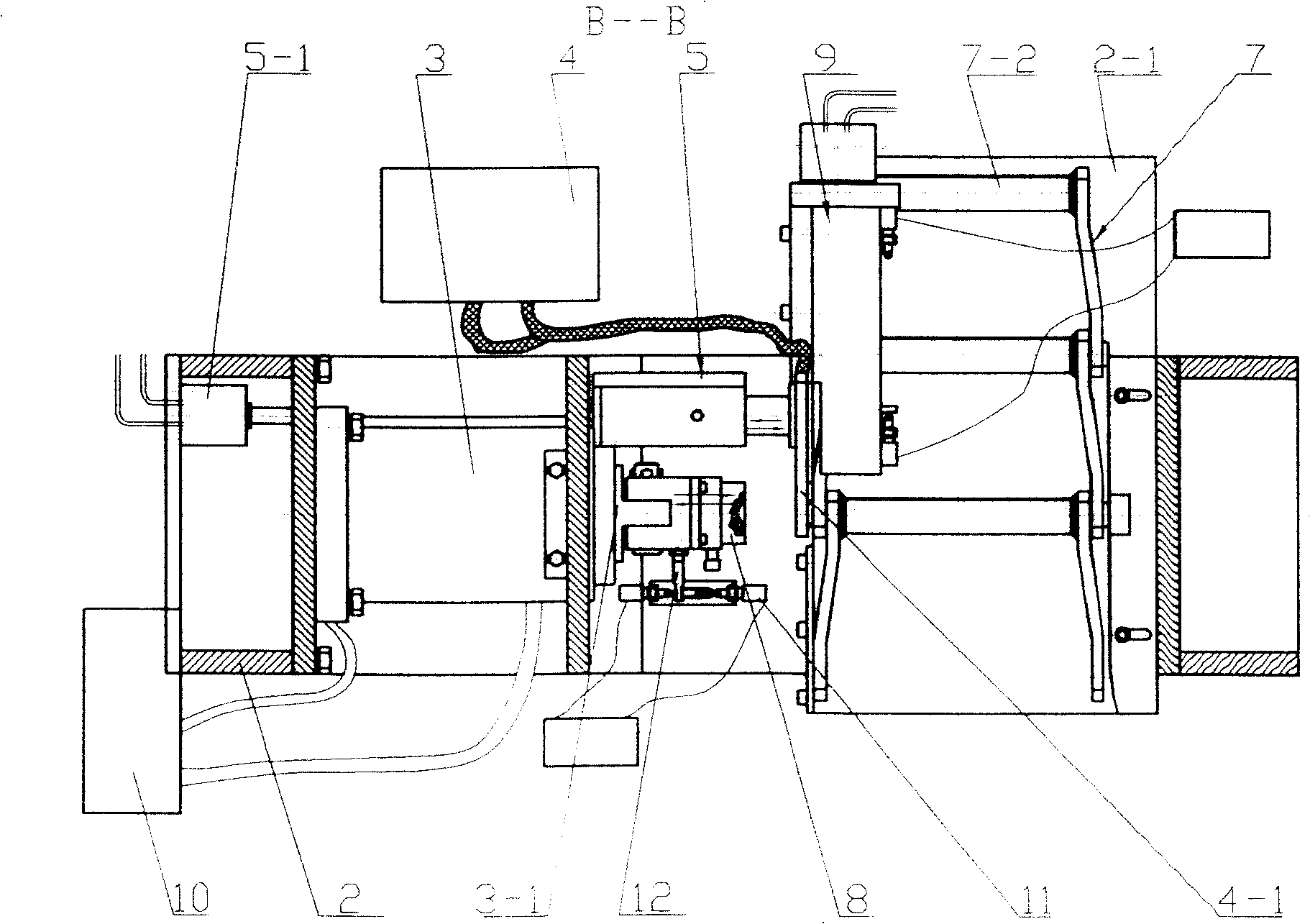

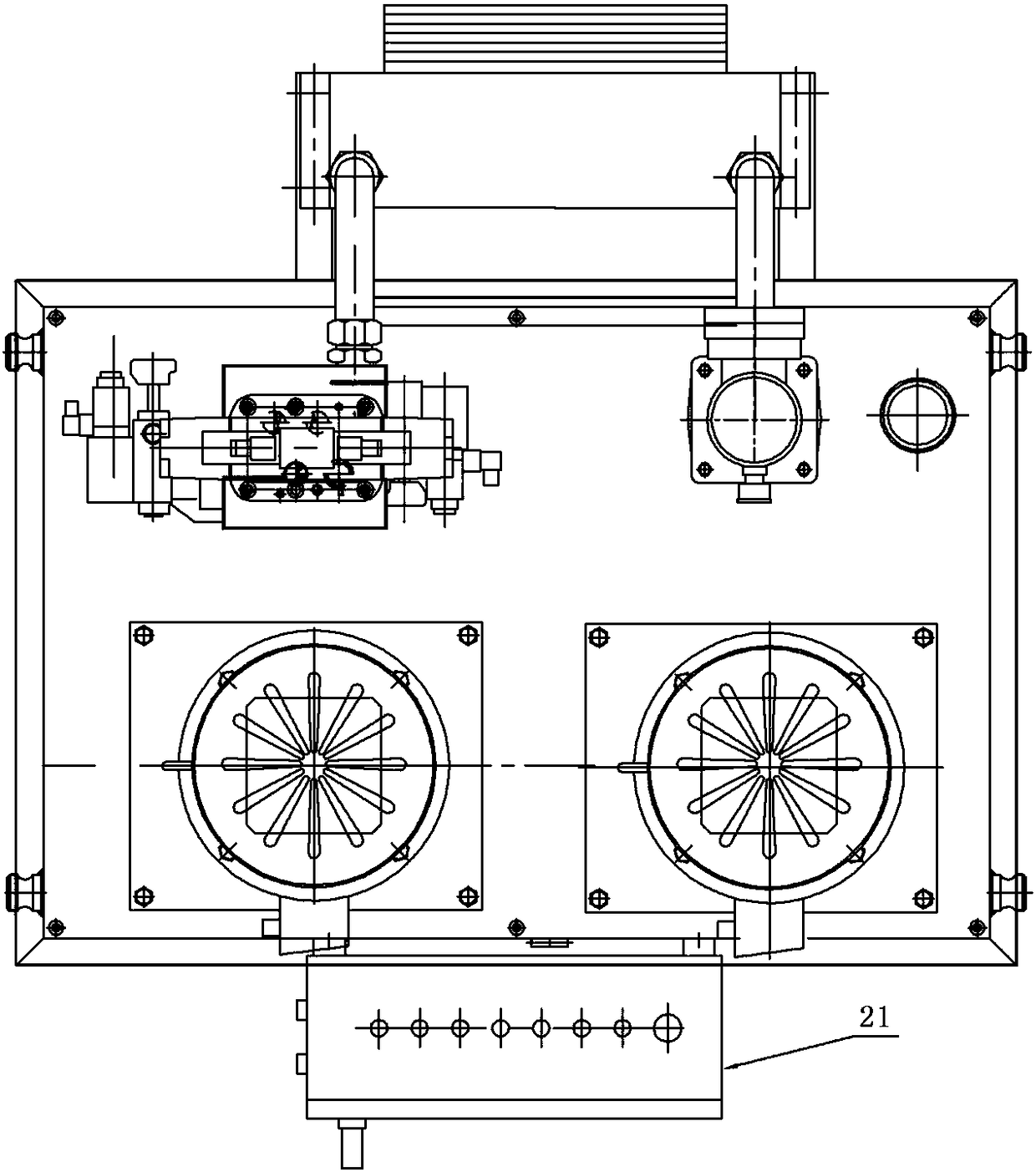

Full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy

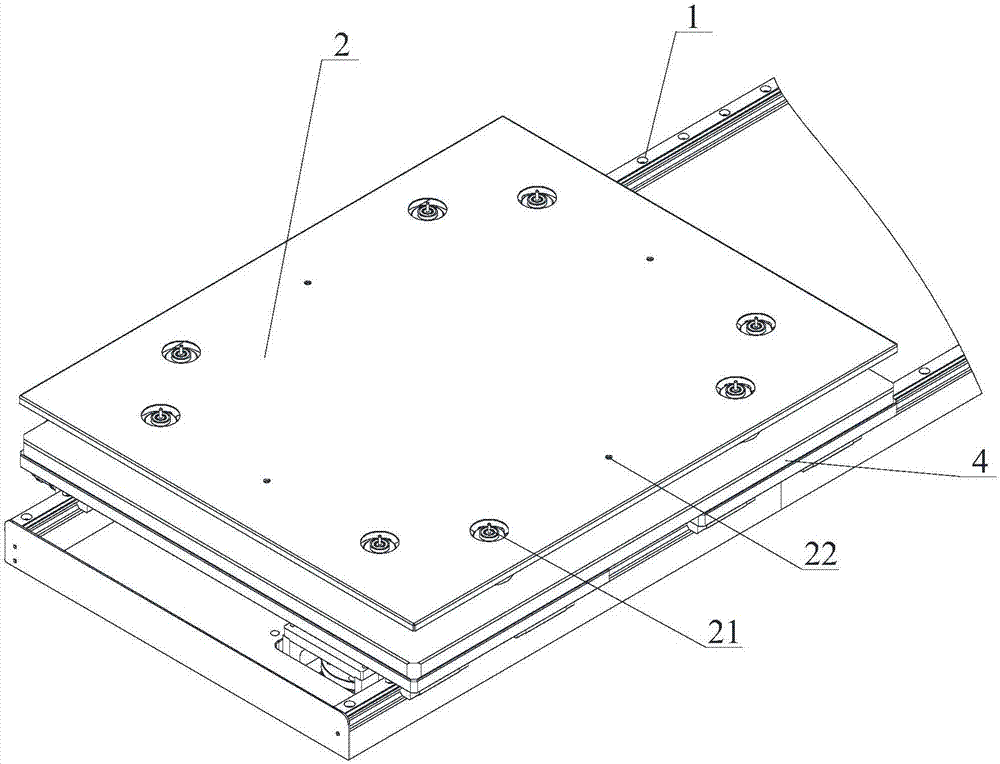

The invention discloses a full-automatic three-dimensional multipoint cold riveting assembly process engineering of die-casting aluminum alloy which relates to a full-automatic three-dimensional multipoint cold riveting special device. In the special device, a sliding table power mounting base and a workbench panel are respectively installed on a rack, a spin rivet power system is installed on a vertical Z-direction servo linear sliding table which is installed on the sliding table power mounting base, a workpiece spin rivet gripper is installed on a horizontal Y-direction servo linear sliding table which is installed on a horizontal X-direction servo linear sliding table, the X-direction servo linear sliding table is installed on the workbench panel, and the spin rivet power system is positioned above the workpiece spin rivet gripper. Compared with the prior art, the riveting speed of the invention is improved by 1.5-2 times, and the invention has the advantages of high riveting quality, high connection soundness, low error probability, wide adaptation range of product specification, high production efficiency, long life of snap heads, high riveting accuracy and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

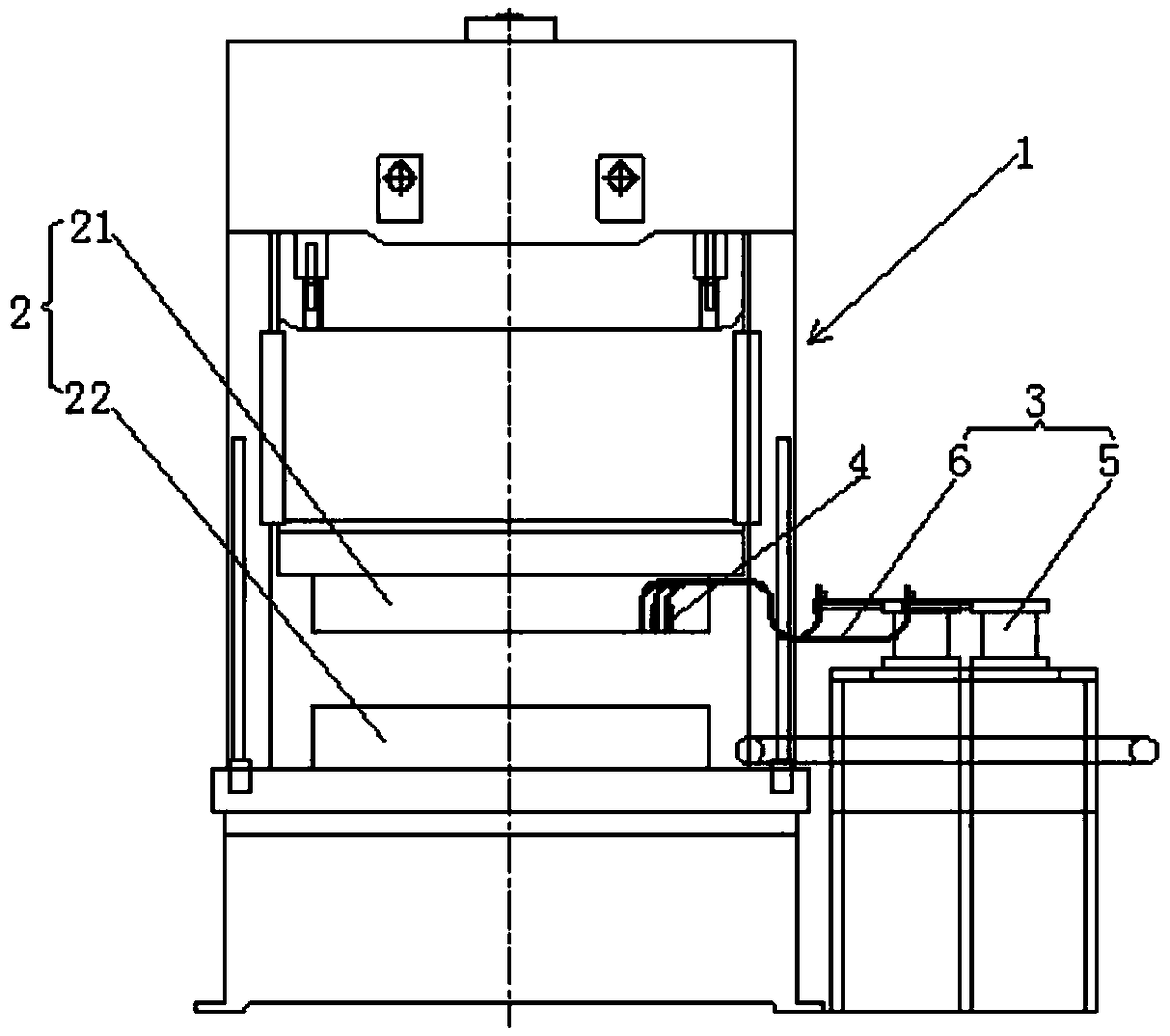

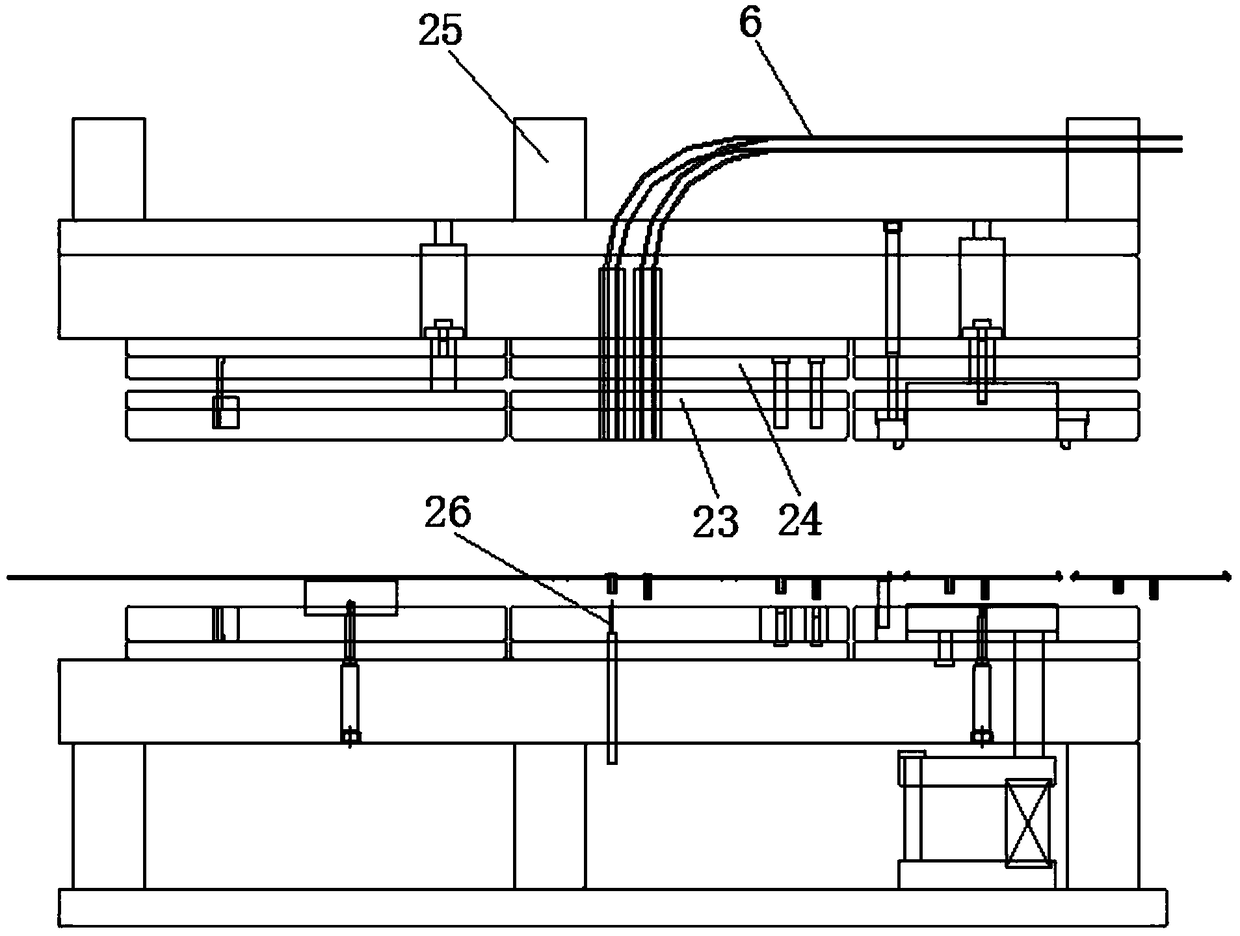

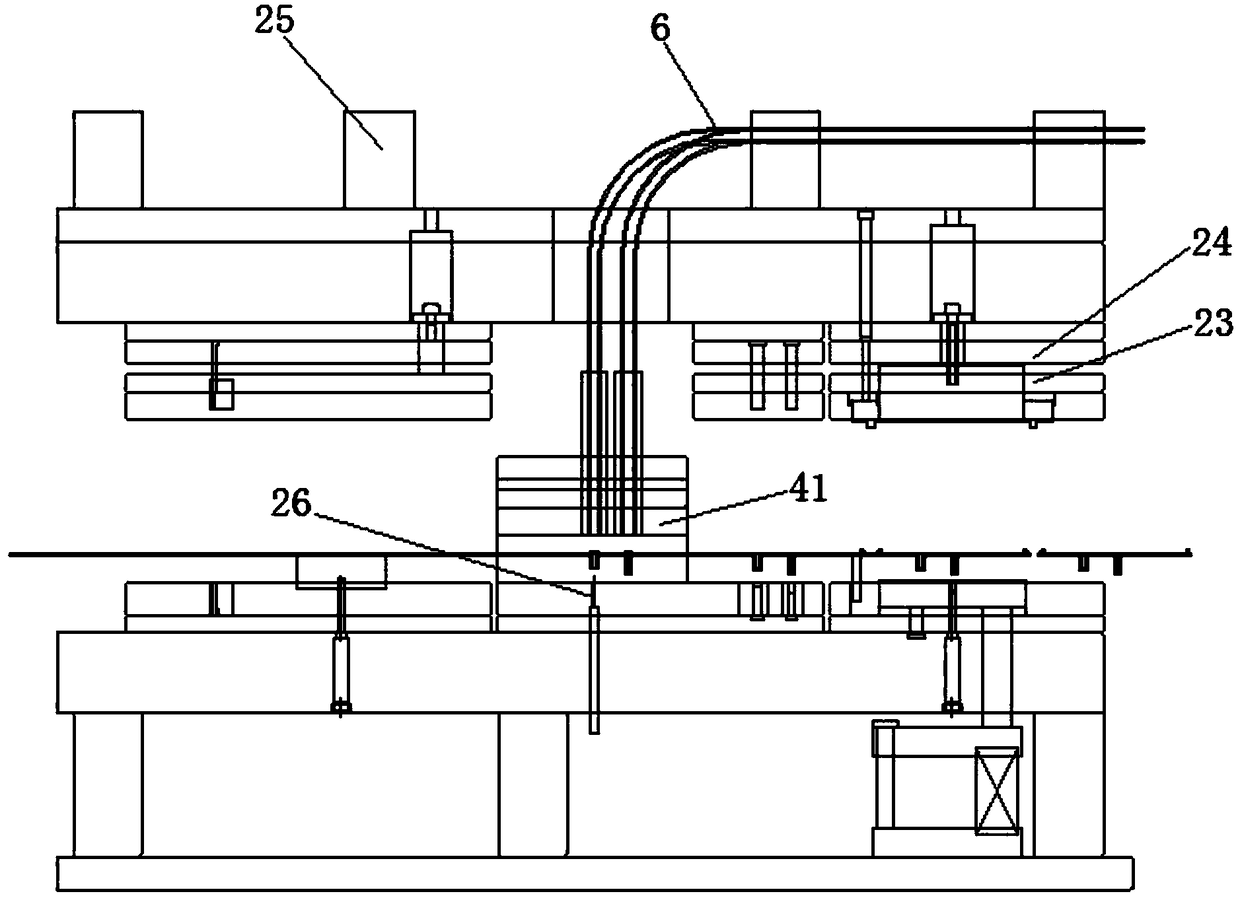

Full-automatic punching riveting system and working process thereof

PendingCN108838316AThere is no impact on punching efficiencyImprove processing efficiencyShaping toolsPunch pressCam

The invention discloses a full-automatic punching riveting system and a working process thereof. The system comprises a punching machine, a mold, a feeding machine, a finished product discharging conveying belt, a rivet conveying device, a positioning ejection device and a control center; the punching machine is an automatic punching machine, an electronic cam is arranged, the mold is a punching continuous mold, and the mold comprises an upper mold and a lower mold; and rivets are conveyed to the corresponding pneumatic ejection gun through the rivet conveying device. When the full-automatic punching riveting system works, the feeding machine conveys a to-be-matched material belt into the mold on the punching machine, riveting holes and other holes are punched in the punching continuous mold, the plurality of rivets are sent into the corresponding riveting holes through the pneumatic ejection guns, riveting is completed by using the punching pressing force of the punching machine, after punching, riveting and bending processes are completed on the material belt, a product is cut off and slides to the finished product discharging conveying belt, and the product is sent out of the punching machine. According to the full-automatic punching riveting system, the machining efficiency is high, and the finished product yield is high.

Owner:SUZHOU KEYTEC PRECISION COMPONENTS

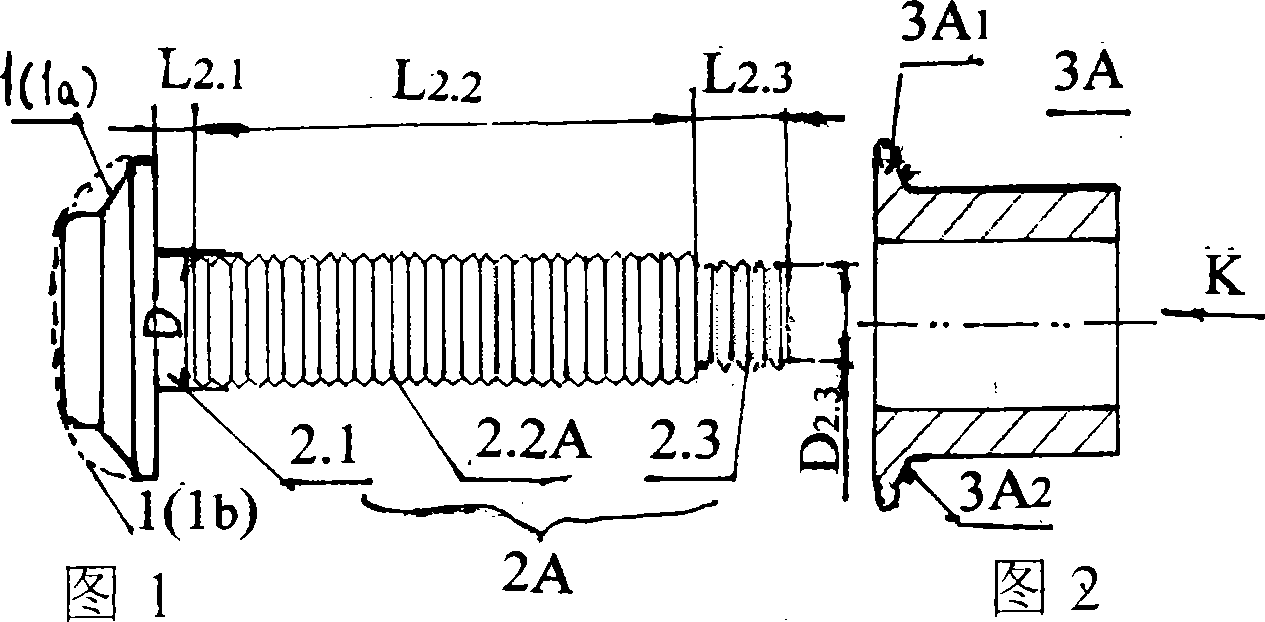

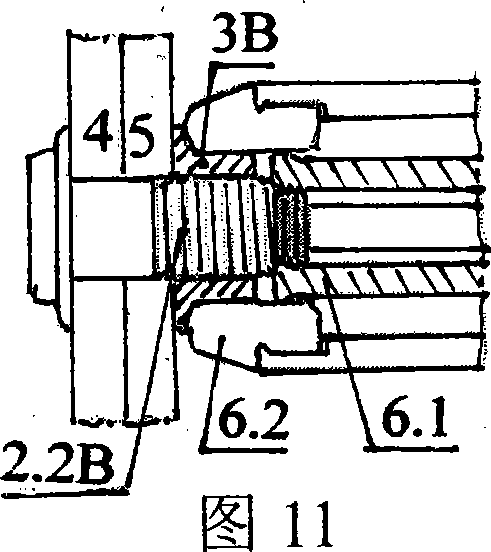

Bobtail tension rivet and riveting method

The invention discloses a short-tail tension rivet and a riveting method thereof. The tension rivet consists of a rivet head, a rivet rod and a sleeve ring. The rivet rod is provided with a feed rod section, a ring groove section which is extruded and matched with the sleeve ring, and a short and thin ring groove section clamped by a riveting device collet from the front to the back. Compared to the prior tension rivet, a separating groove on the rear end of the tension rivet and a groove section tension rod are removed, so that the rivet rod is shortened and the material is saved by one third; when the rivet is riveted, the separating groove can not be broken; the riveting steps are reduced from the prior four steps to three steps, and the riveting is accelerated; and riveting can not cause impact, and the assembling place has no noise. If the prior same riveting device and the riveting stroke are adopted, the length of the ring groove section or a thread section can be lengthened correspondingly, so that rivets with the same specification can be applied to multiple riveting thicknesses, and the range of application is widen. The rear end of an inner hole of the sleeve ring for thread riveting is provided with a small section of screw thread; before the start of the riveting device, the sleeve ring is rotated manually and moved advance on the screw thread section, and positioned and sleeved on the screw thread section, so that when the riveting device is operated by operating staff for next step, the sleeve ring is not required to be held manually, and further the rivet is riveted relaxedly, conveniently and quickly. The screw thread and the groove riveting can be selected according to occasions.

Owner:CRRC MEISHAN

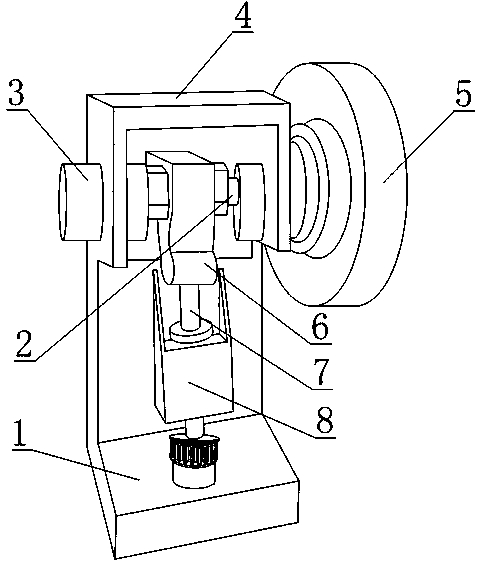

Riveting stamping mechanism for pulley retaining rings

The invention discloses a stamping riveting mechanism for pulley retaining rings. The stamping riveting mechanism comprises a transmission shaft, a frame, two bearing boxes, a cam system, a rivet shank and a rivet holder. The bearing boxes are fixed at corresponding positions on the frame. Each bearing box is provided with a bearing inside. The transmission shaft is in interference fit with inner rings of the bearings. The cam system comprises a housing fixed on the frame and a cam fixedly connected to the transmission shaft. The rivet holder is fixedly connected to the frame. The rivet shank partly locates in the rivet holder. The axial direction of the rivet shank is along the radial direction of the cam. The stamping riveting mechanism is simple in structure, convenient to produce and use, effective in riveting and high in riveting efficiency.

Owner:CHENGDU SILVERTECH TIMING PULLEYS MFG

Press riveting device

ActiveCN104028991AAccurate riveting positionAvoid harmMetal working apparatusEngineeringMechanical engineering

The invention discloses a press riveting device. A carrier pushing positioning channel is arranged on a frame in a penetrating mode; a carrier pushing driving device can drive a carrier pushing device to convey carriers along the carrier pushing driving device; the carrier positioning driving device can drive a carrier positioning device to fix and position the carriers; a staggered riveting driving device can drive symmetrically-distributed staggered riveting blocks to move opposite to each other; rotating riveting blocks are rotatably positioned right above the carrier pushing positioning channel, and a rotating riveting driving device drives the rotating riveting blocks to rotate; a pressing shaping device which is slidingly positioned on the frame in a press mode is arranged right above the carrier pushing positioning channel; a pressing shaping driving device drives a pressing shaping device to act; a controller controls all the driving devices to act. The press riveting device achieves automated continuous operation and is high in pressing and riveting speed, accurate in riveting position of iron casings, free from damage to products, harmless for workers, high in production efficiency and low in production cost.

Owner:KUNSHAN FULIRUI ELECTRONICS TECH

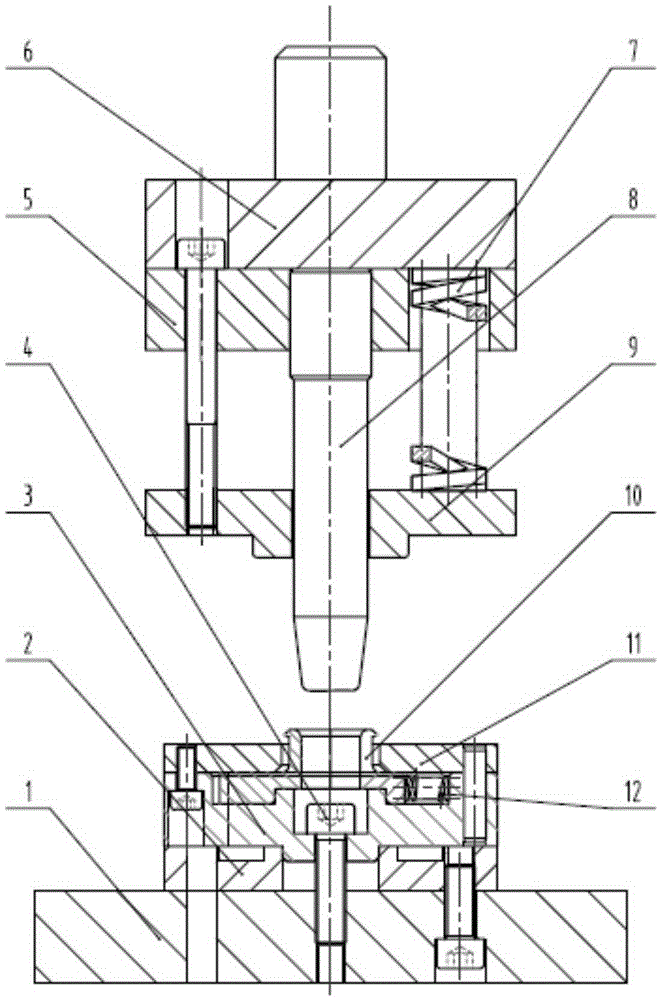

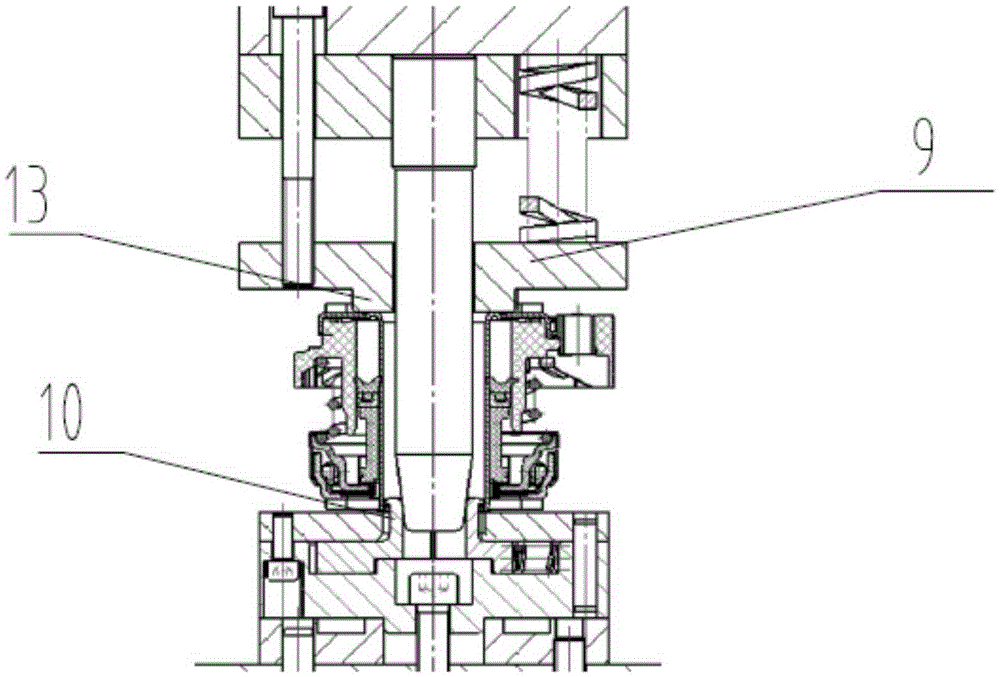

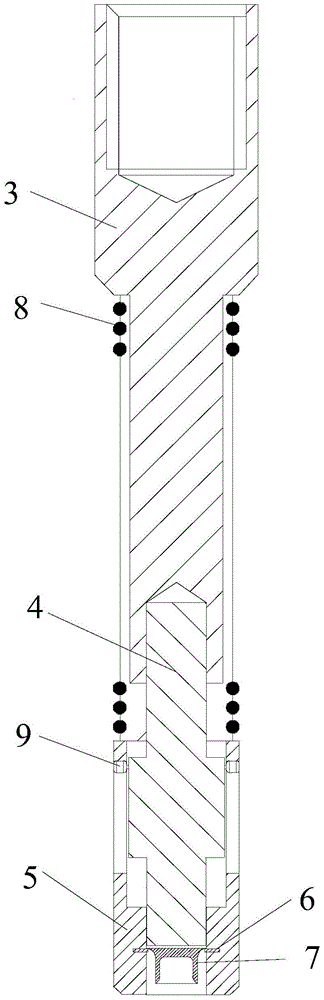

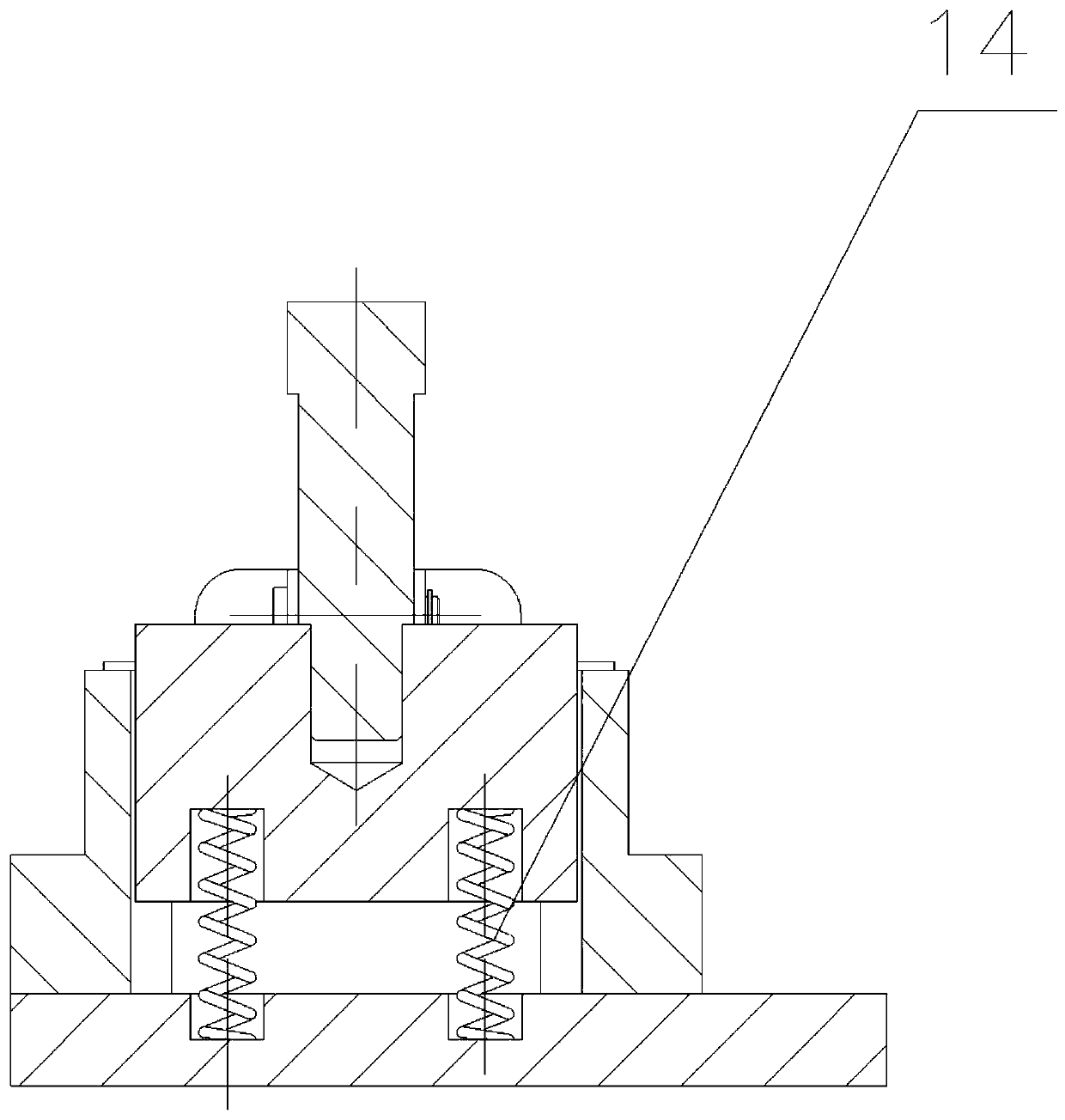

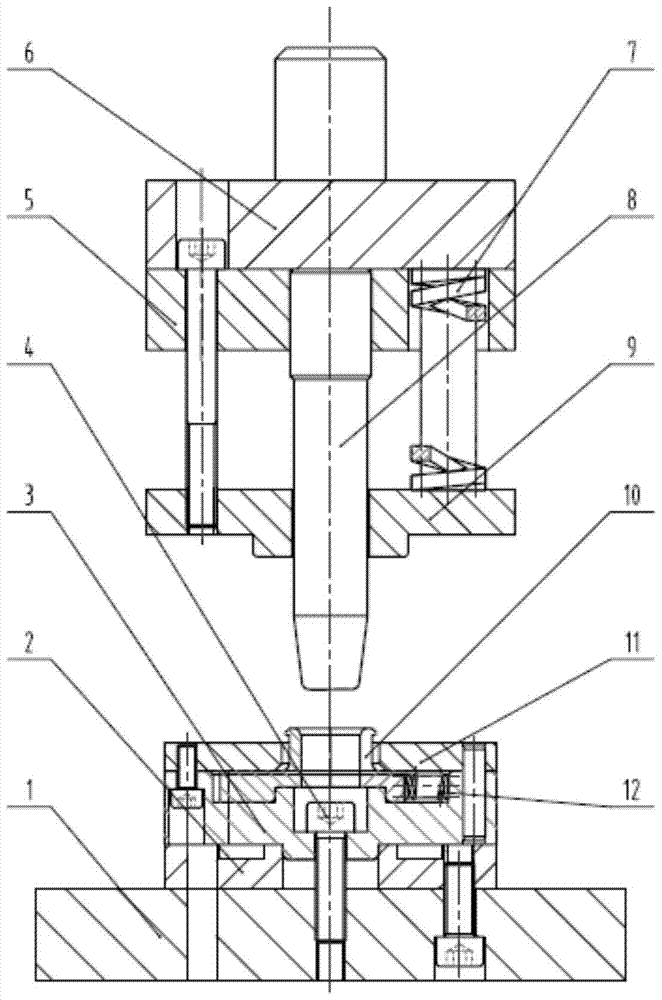

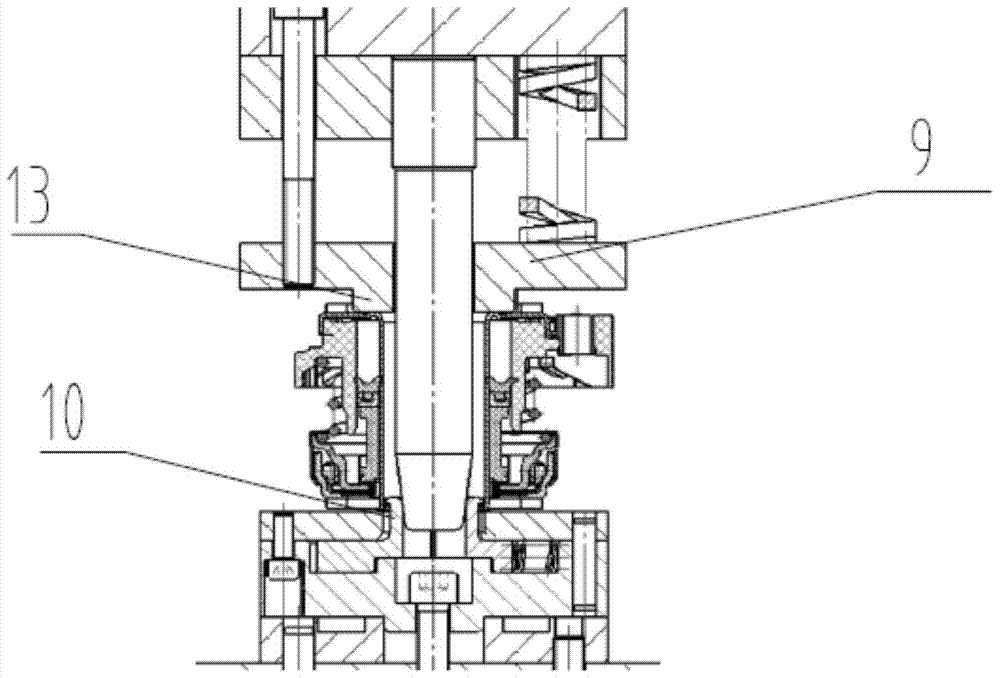

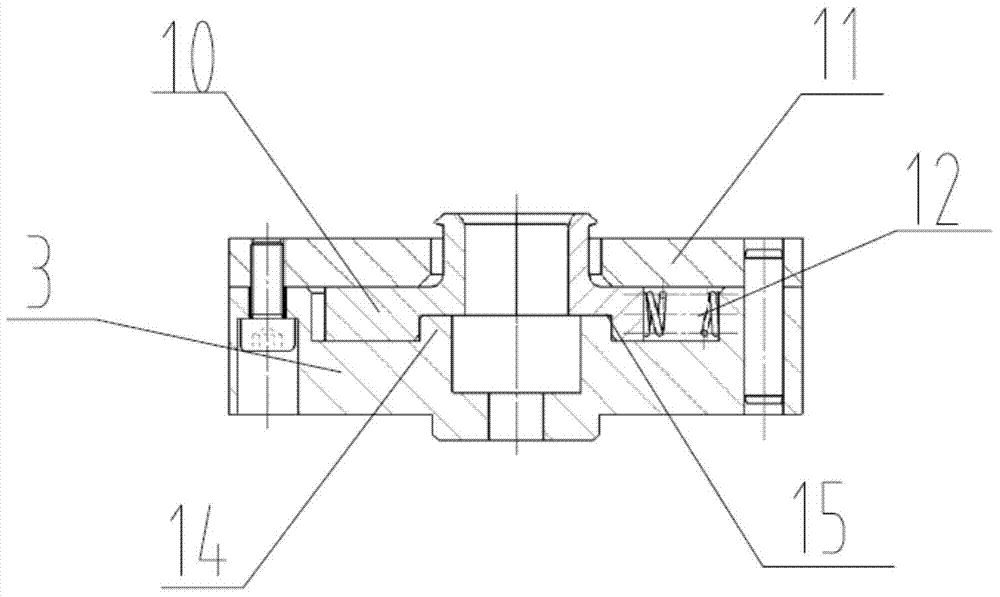

Inside riveting die of hydraulic clutch bearing gland

The invention relates to an inside riveting die of a hydraulic clutch bearing gland. A lower fixing plate is arranged on the upper end face of a bottom plate. A lower die fixing plate is arranged on the upper end face of the lower fixing plate. A split lower die insert is embedded in the middle of the upper end face of the lower die fixing plate. A cylindrical protrusion is arranged in the middle of the upper end face of the split lower die insert. The outer ring of the upper end of the cylindrical protrusion is bent outwards. A locating through hole is formed in the cylindrical protrusion of the split lower die insert. The split lower die insert is evenly divided into multiple fan-shaped columns. The lower portion of each column is transversely provided with a reset spring. A core rod moving up and down is arranged above the locating through hole in the split lower die insert. The lower end of the core rod is of a circular truncated cone columnar structure matched with the locating through hole, wherein the diameter of the lower end of the structure is smaller than that of the upper end of the structure. The inside riveting die of the hydraulic clutch bearing gland has the beneficial effects of being simple in structure, convenient to use, capable of being suitable for hydraulic release bearings of different models, increasing the riveting speed of the bearing glands greatly and meanwhile, improving the riveting strength of the glands and the like.

Owner:NINGBO HONGXIE CLUTCH

Feeding mechanism of riveting machine

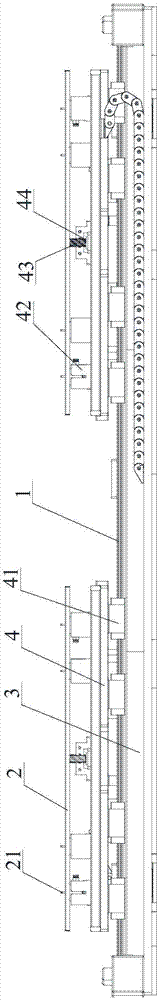

The invention discloses a feeding mechanism of a riveting machine. The feeding mechanism comprises a feeding zone A, a feeding zone B and a feeding guide rail. The feeding zone A and the feeding zone B are mounted on the feeding guide rail and can move along the feeding guide rail. Riveting jigs are arranged on the feeding zone A and the feeding zone B correspondingly. The feeding mechanism of the riveting machine is high in riveting quality and production efficiency and low in cost, the defects that in the prior art, the manual labor amount is high, and the working efficiency and the reliability are low are overcome, and thus the low manual labor amount and high working efficiency and reliability are achieved.

Owner:庄召国

A gas-hydraulic pressurized self-piercing riveting machine

Owner:EAST CHINA JIAOTONG UNIVERSITY

Riveting head mechanism

Owner:SUZHOU SHUNGE INTELLIGENT TECH

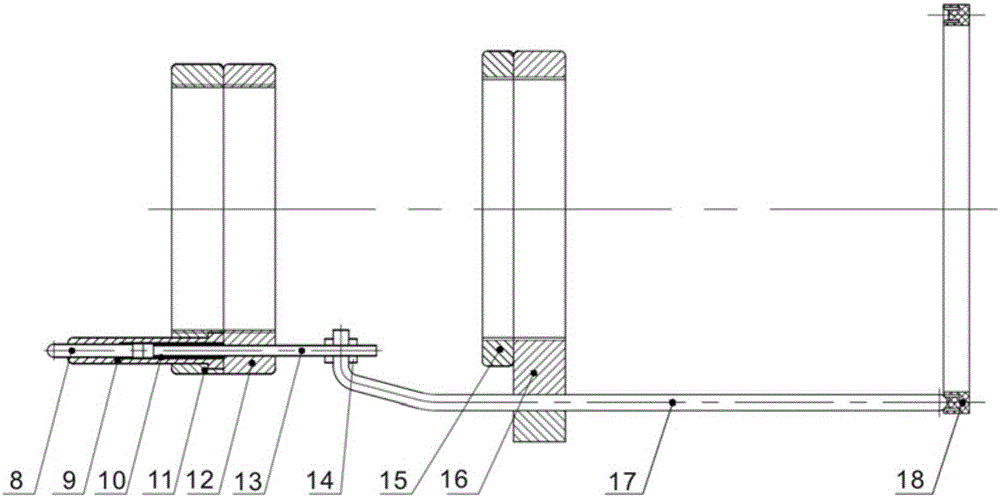

Terminal post riveting device and breaking tool

The invention relates to a terminal post riveting device and a breaking tool. A strut is arranged at the center of a cylinder body; a grabbing rod is tightly sheathed outside the strut; the bottom ends of the strut and the grabbing rod are inserted in a T-shaped groove formed on the upper plane of the terminal post of a battery; the strut has a horn-shaped bottom end; and the bottom end of the grabbing rod is a three-flap centripetal clamping body matched with the strut and the T-shaped groove. The oil cylinder consists of a cylinder body on the upper end, a jacket on the lower end, wherein the cylinder body is connected with the jacket through threads; a strut piston fixed with the upper end of the strut and a rivet piston at the periphery are arranged in the cylinder body; and the lower end of the rivet piston is connected with the grabbing rod through threads to form a single-oil-path double-piston structure. When the oil cylinder is started, the two pistons act to drive the strut and the grabbing rod to move upwards, and drive the jacket and the cylinder to move downwards so as to extrude the outer liner ring of the terminal post, thereby achieving the riveting. When a cutting head is mounted on the bottom end of the jacket, the pistons drive the cutting head to cut the liner ring as a breaking tool. By adopting cold riveting, the terminal post riveting device can solve the problem of bolt looseness of the terminal post. The invention also provides a riveting breaking tool, which facilitates the maintenance. The overall dimension of the terminal post riveting device isPhi40*100, the weight is about 1.5 kg, the cylinder pressure is about 12 Mpa; and the terminal post riveting device has high riveting speed and is convenient in operation.

Owner:MEISHAN HENGSHENG MECHANICAL EQUIP

Riveting machine

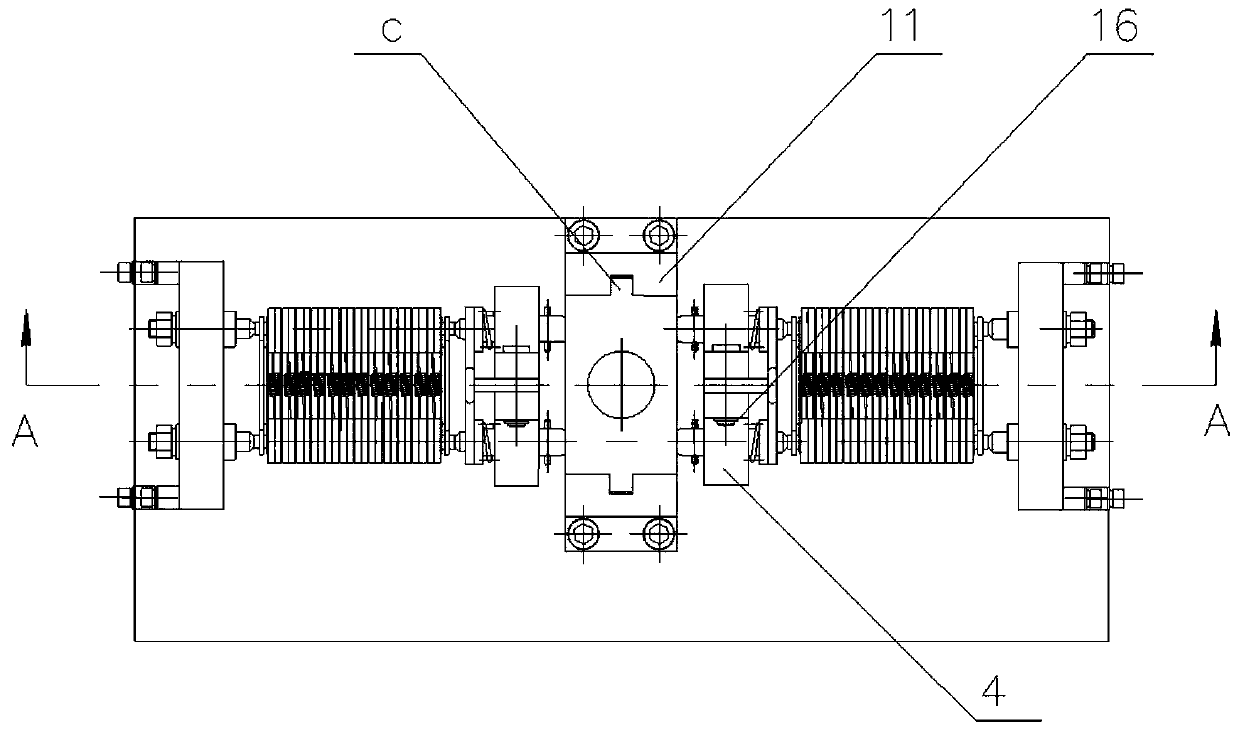

InactiveCN102280795AFast rivetingAccurate riveting positionLine/current collector detailsEngineeringElectric control

The invention discloses a riveting machine comprising a baseframe, as well as a fixed frame and an electric control device which are mounted on the baseframe, wherein a sliding chute extending along the left-and-right direction is formed on the fixed frame, a positioning groove which extends along the front-and-back direction and is used for mounting a connector is formed at the middle of the sliding chute, a first riveting die is mounted in the sliding chute on the left side of the positioning groove, a second riveting die is mounted in the sliding chute on the right side of the positioning groove, a transmission mechanism and a driving device for providing original power for the transmission device are arranged aiming at each of the first riveting die and the second riveting die, and each transmission device is used for pushing the first riveting die or the second riveting die to move left and right in the sliding chute, therefore, under the coordination of all the devices, the first riveting die and the second riveting die move towards each other and prop against the two groups of terminals to be riveted till the terminals are firmly riveted with corresponding wires, the riveting operation can be fast completed on the two groups of terminals and the corresponding wires of the same connector once, and the riveting position is precise.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

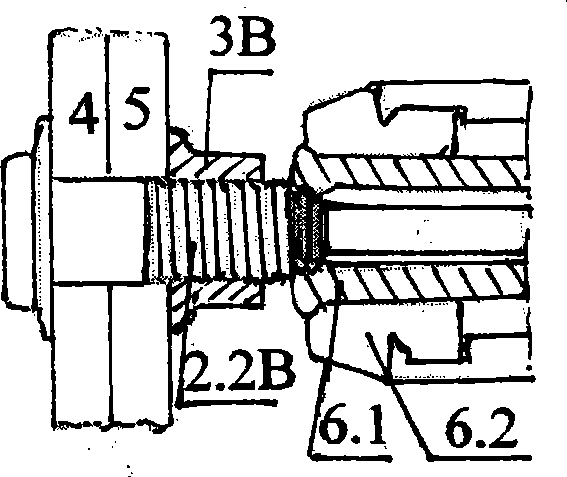

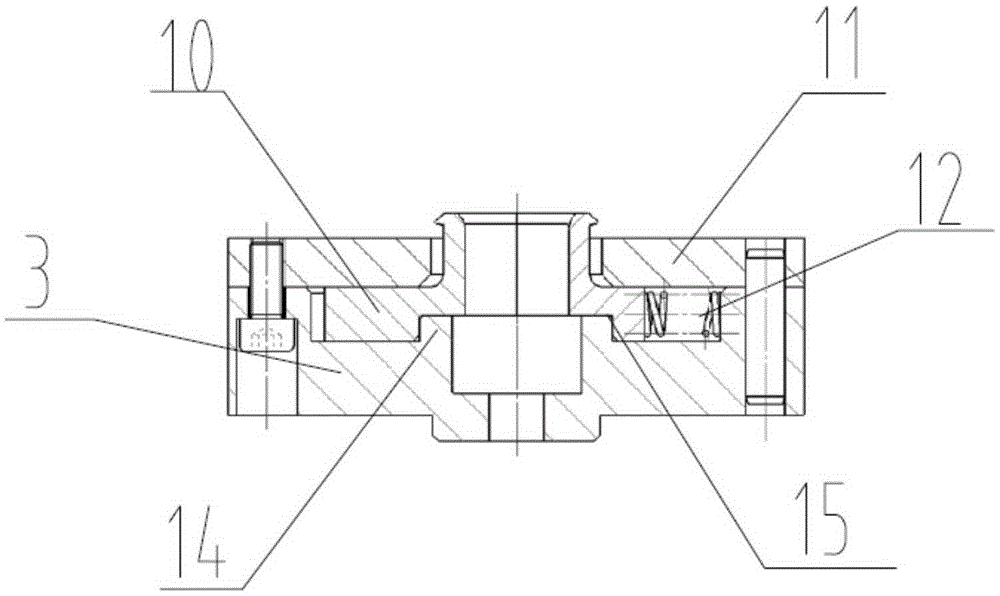

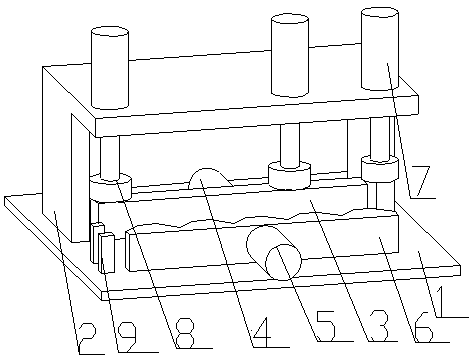

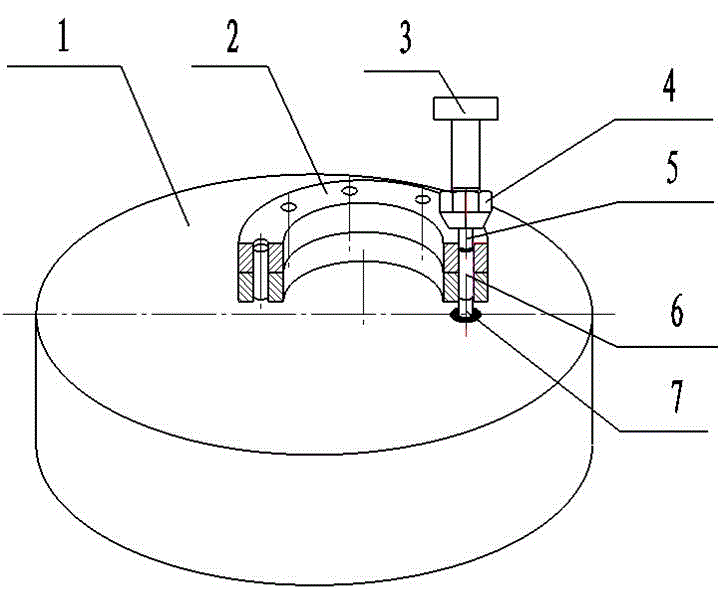

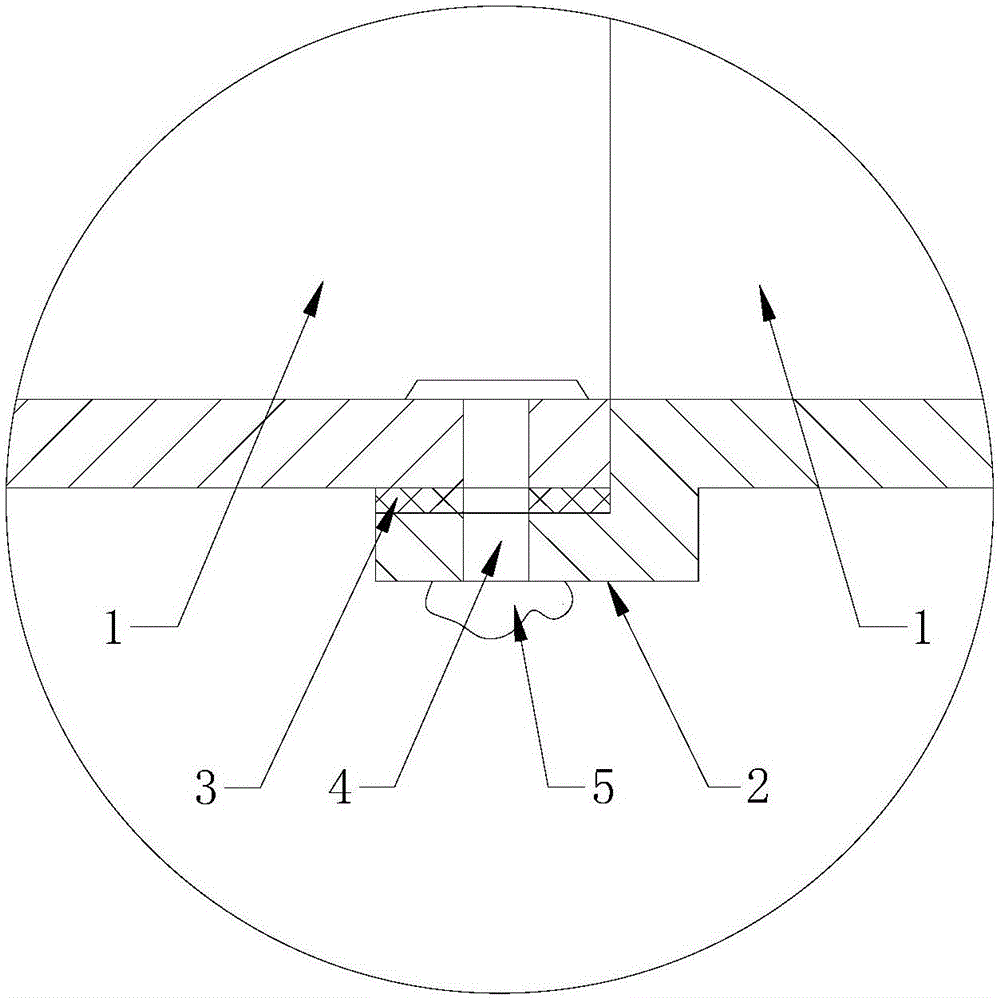

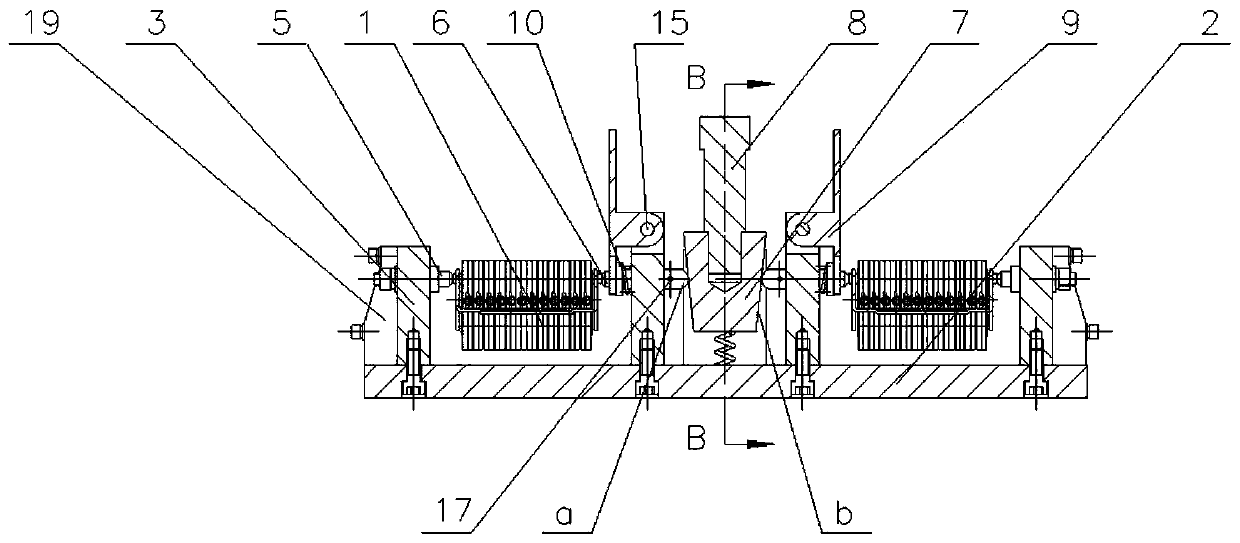

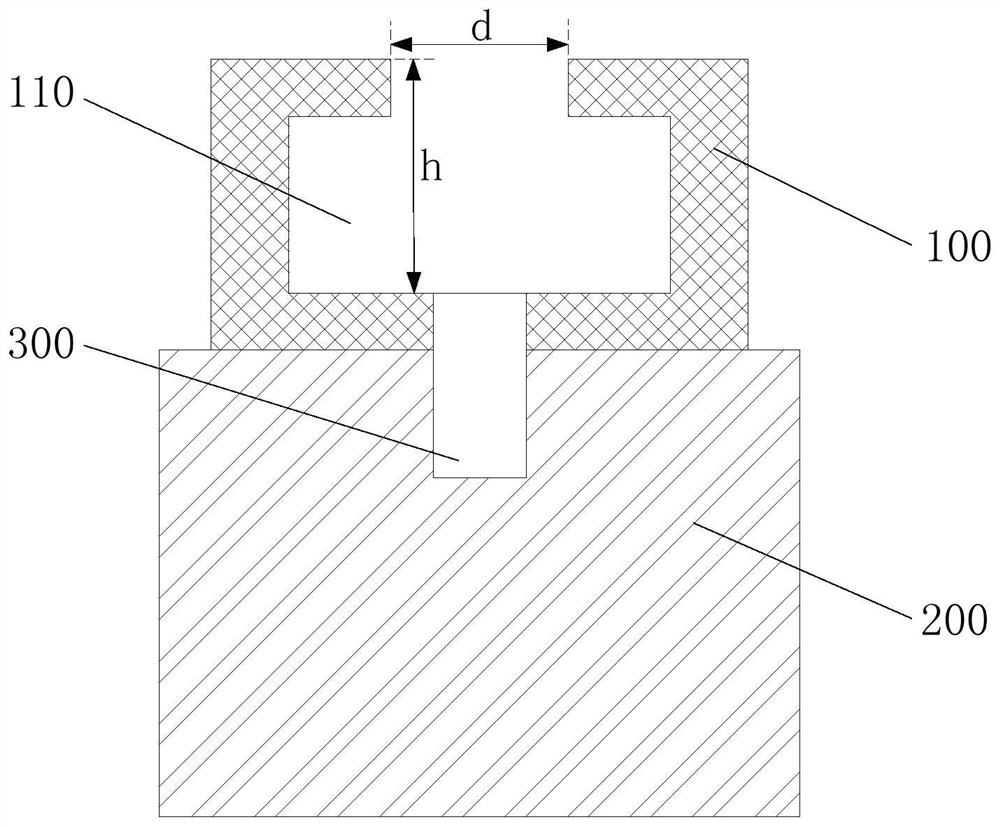

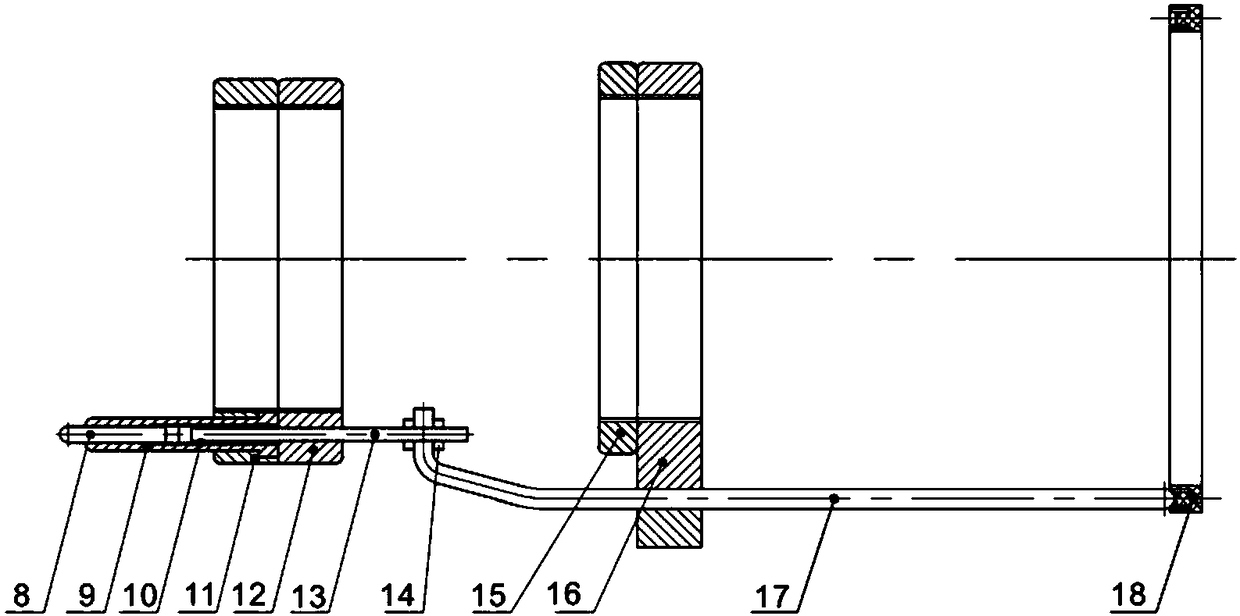

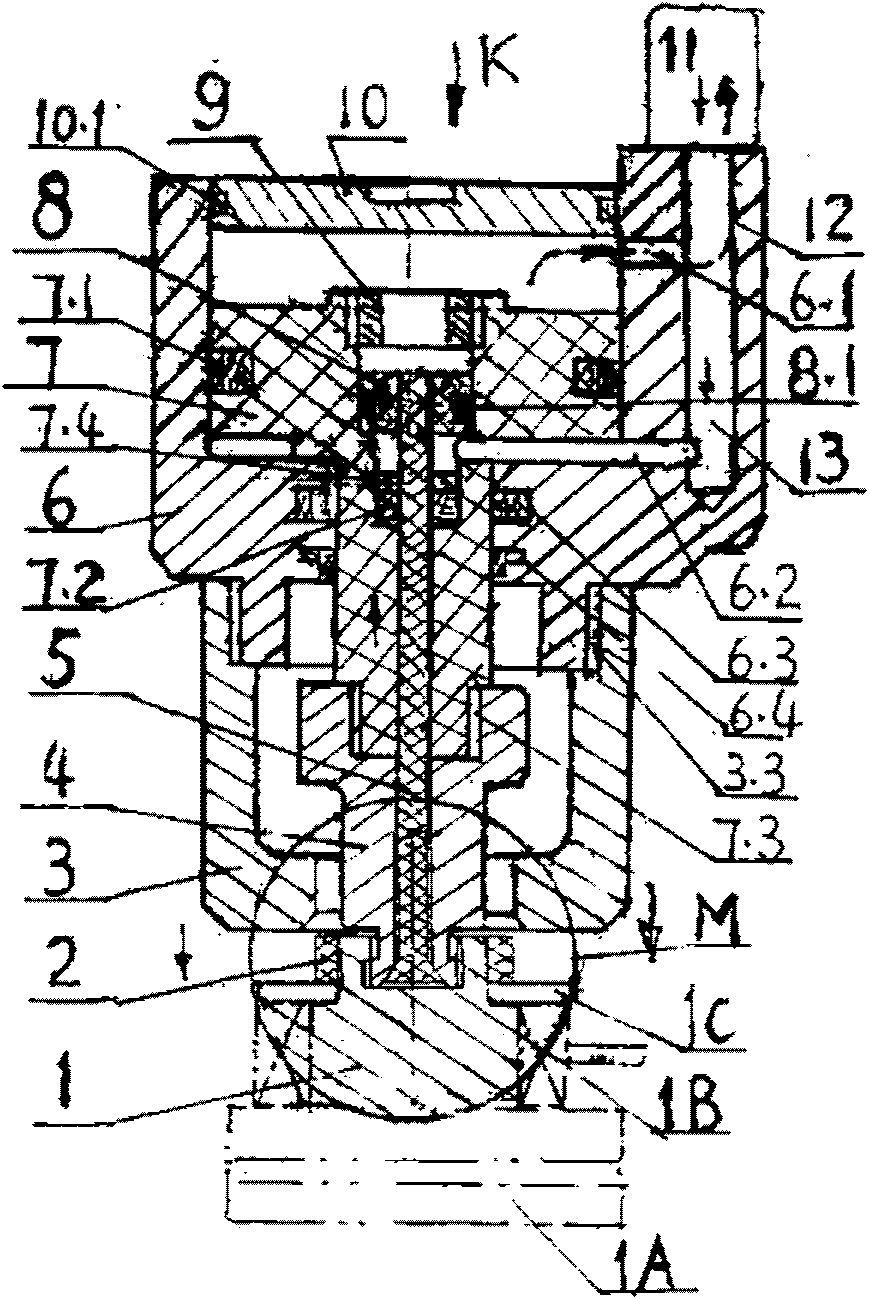

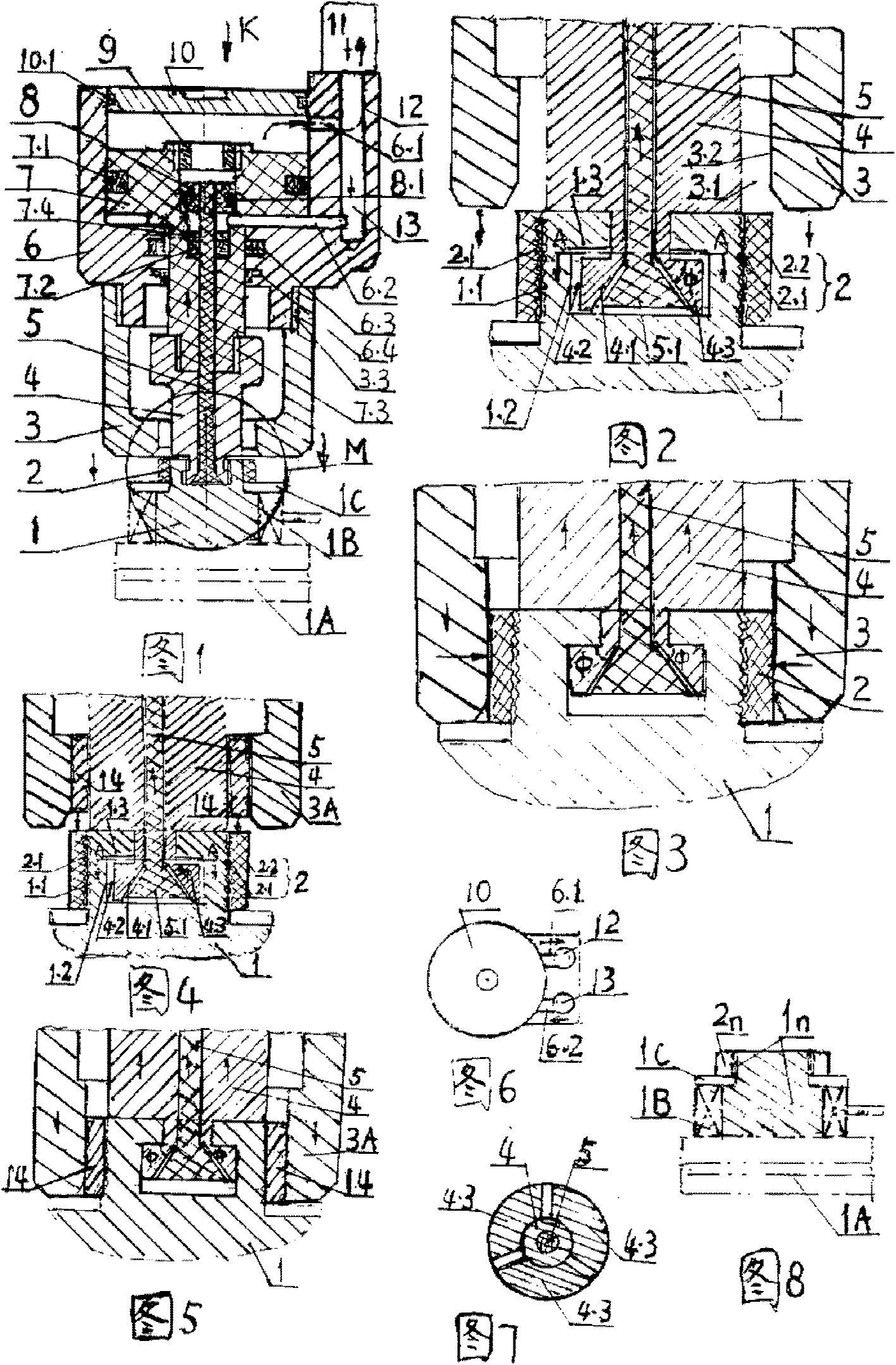

Processing method for integrally riveting separated type retainer

InactiveCN102615230AWith accurate positioningUniform riveting forceBearing componentsPunchingEngineering

The invention relates to a processing method for integrally riveting a separated type retainer. The processing method is characterized in that a punching head (5) is arranged in a clamping jaw (3); the diameter of the punching head is matched with that of a rivet hole of a retainer (2); the punching head is fixed through a locknut (4); the distance between the head part of the punching head and the end face of the locknut is H2; a supporting head (7) is arranged at one end of a round supporting platform (1); the diameter of the supporting head is matched with that of the punching head; the height of the head part of the supporting head extending out of the plane of the supporting platform is H2, wherein 2H2 plus H1 equals to H; a rivet (6) is inserted into the rivet hole of the retainer and sleeved on the supporting head; the clamping jaw is inserted in the upper part of the rivet hole of the retainer; a pressure frame is arranged at the end of the supporting platform, which is near the supporting head; the stroke of the pressure frame is set; the pressure frame aligns with the upper part of the clamping jaw; in the downward motion process, a cone of the head part of the punching head and a cone of the head part of the supporting head rivet the rivet at the same time; after riveting is finished, the pressure frame returns to the original position; and the rivet in the rivet holes of all the retainer can be riveted in the same manner.

Owner:LUOYANG BEARING RES INST CO LTD

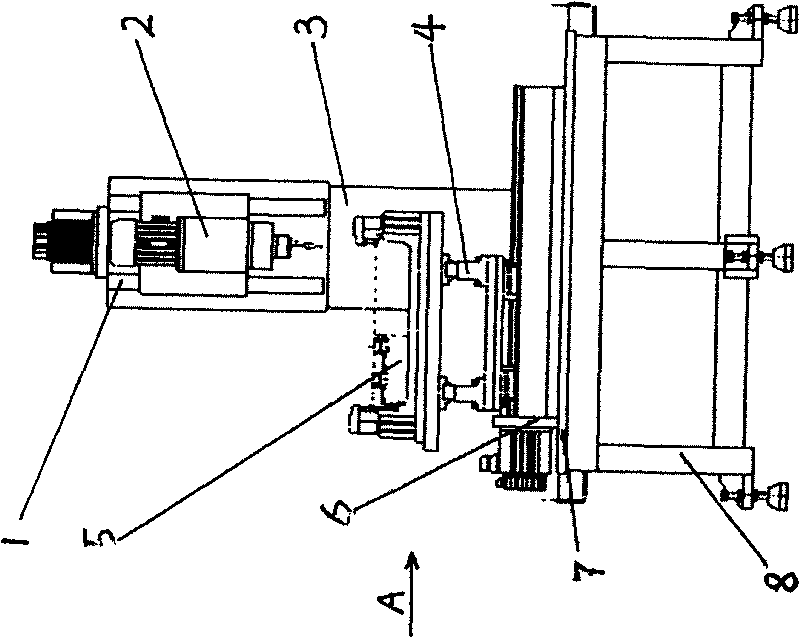

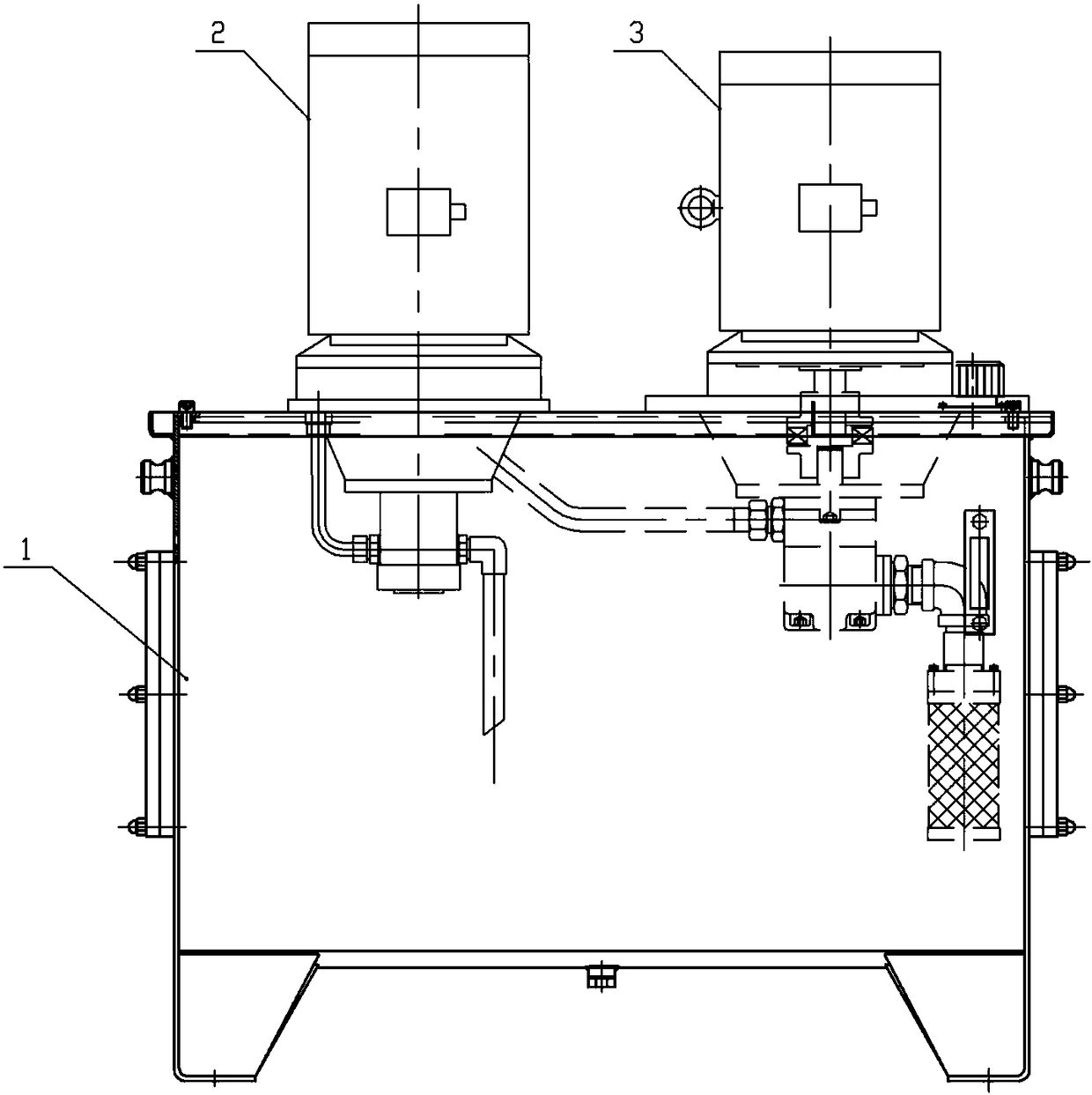

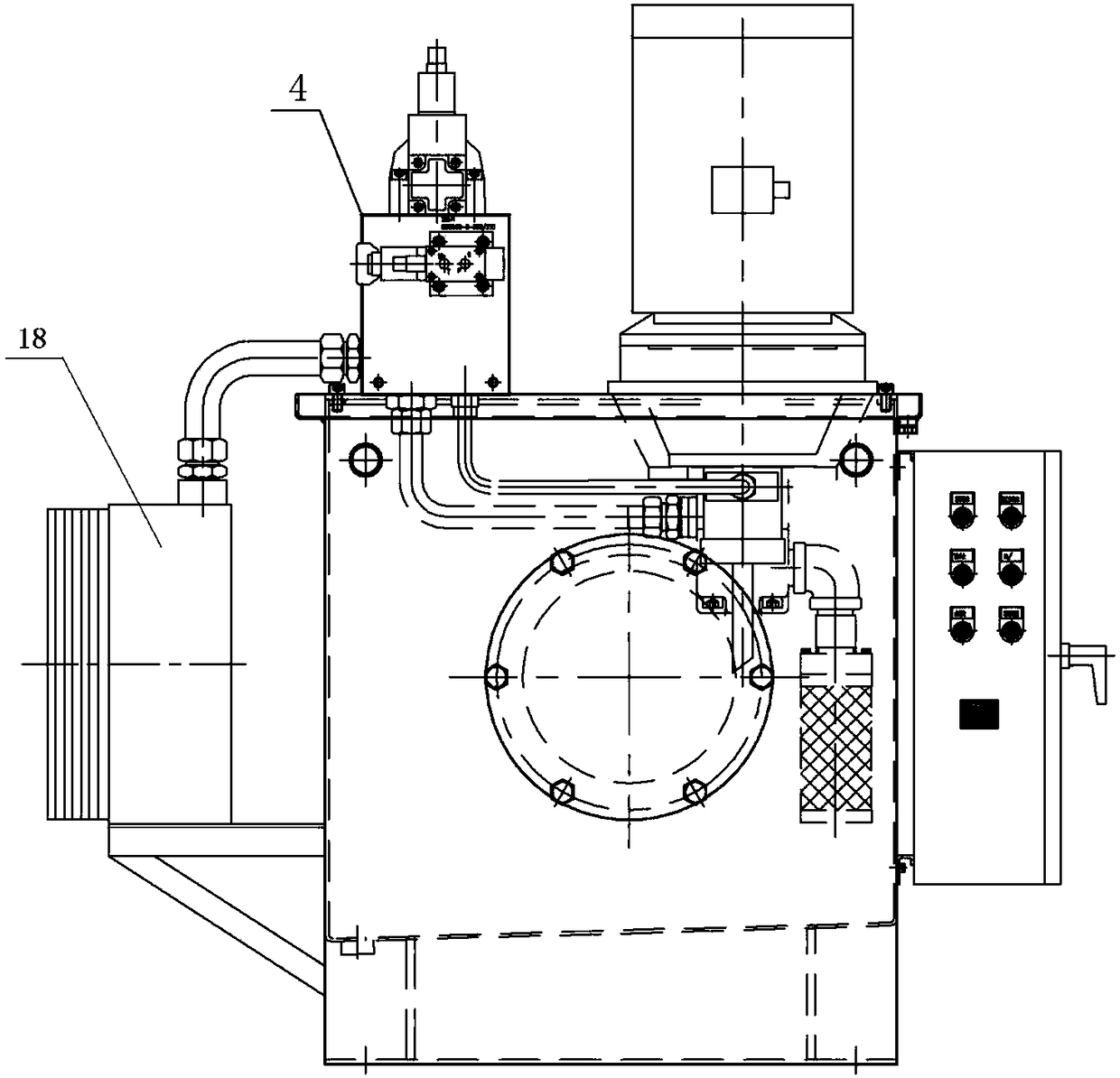

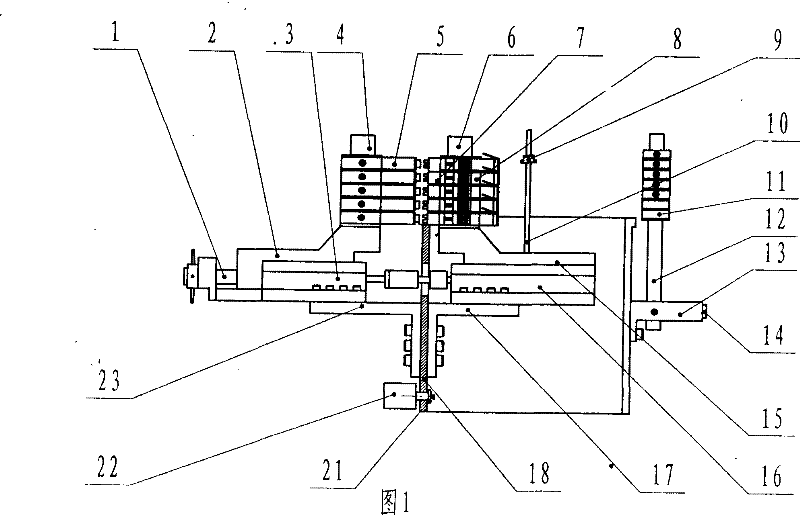

Full automatic three-dimensional multipoint hot riveting assembling process technique for die casting of magnesium alloy

The invention relates to a full automatic three-dimensional multipoint hot riveting assembling process technique for the die casting of magnesium alloy, which is provided with a full automatic three-dimensional multipoint cold riveting special device for the die cast of aluminum alloy, wherein the special device mainly comprises a vertical Z-direction servo linear sliding table, a rotary riveting power head system, a sliding table power mounting base, a horizontal Y-direction servo linear sliding table, a workpiece rotary riveting clamping apparatus, a horizontal X-direction servo linear sliding table, a working table panel and a frame, wherein the sliding table power mounting base and the working table panel are arranged on the frame respectively; the rotary riveting power head system is arranged on the vertical Z-direction servo linear sliding table; the vertical Z-direction servo linear sliding table is arranged on the sliding table power mounting base; the workpiece rotary riveting clamping apparatus is arranged on the horizontal Y-direction servo linear sliding table; the horizontal Y-direction servo linear sliding table is arranged on the horizontal X-direction servo linear sliding table; the horizontal X-direction servo linear sliding table is arranged on the working table panel; and the rotary riveting power head system is positioned above the workpiece rotary riveting clamping apparatus. Compared with the prior art, the riveting speed of the full automatic three-dimensional multipoint hot riveting assembling process technique is improved by 1.5 to 2 times, and the technique has the advantages of high riveting quality and connecting fastness, low fault rate, wide product specification adaptive range, high production efficiency, long riveting head service life, high riveting accuracy and the like.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

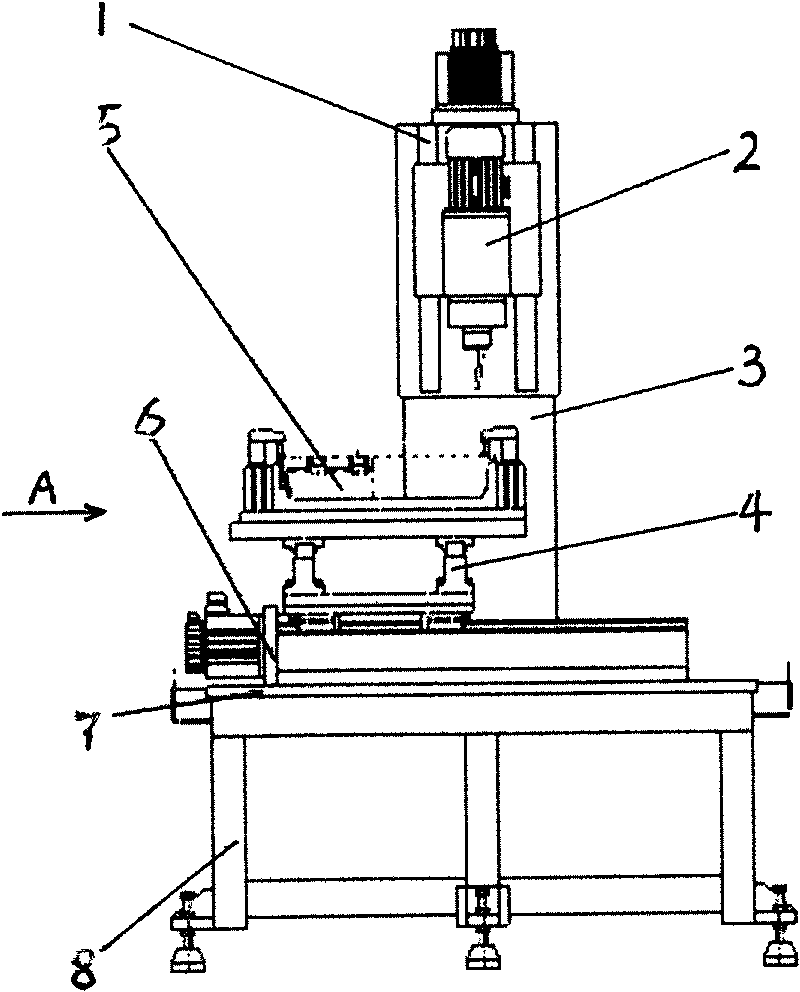

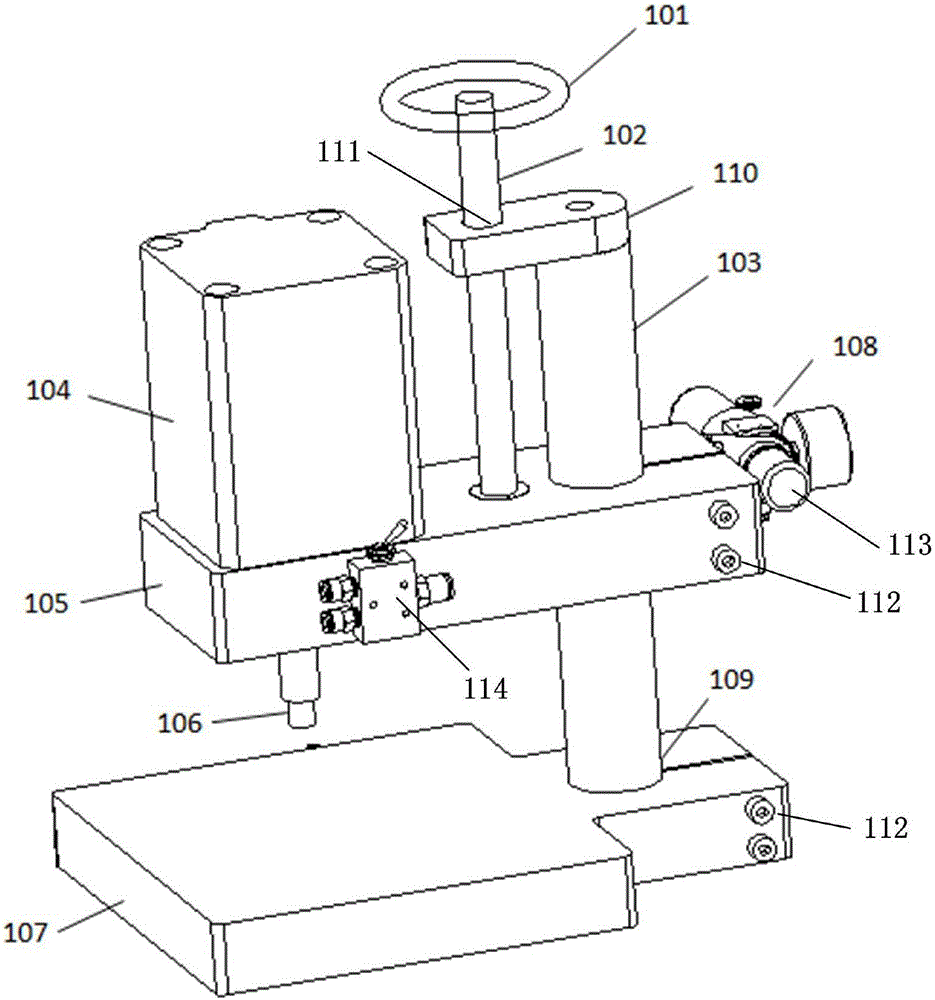

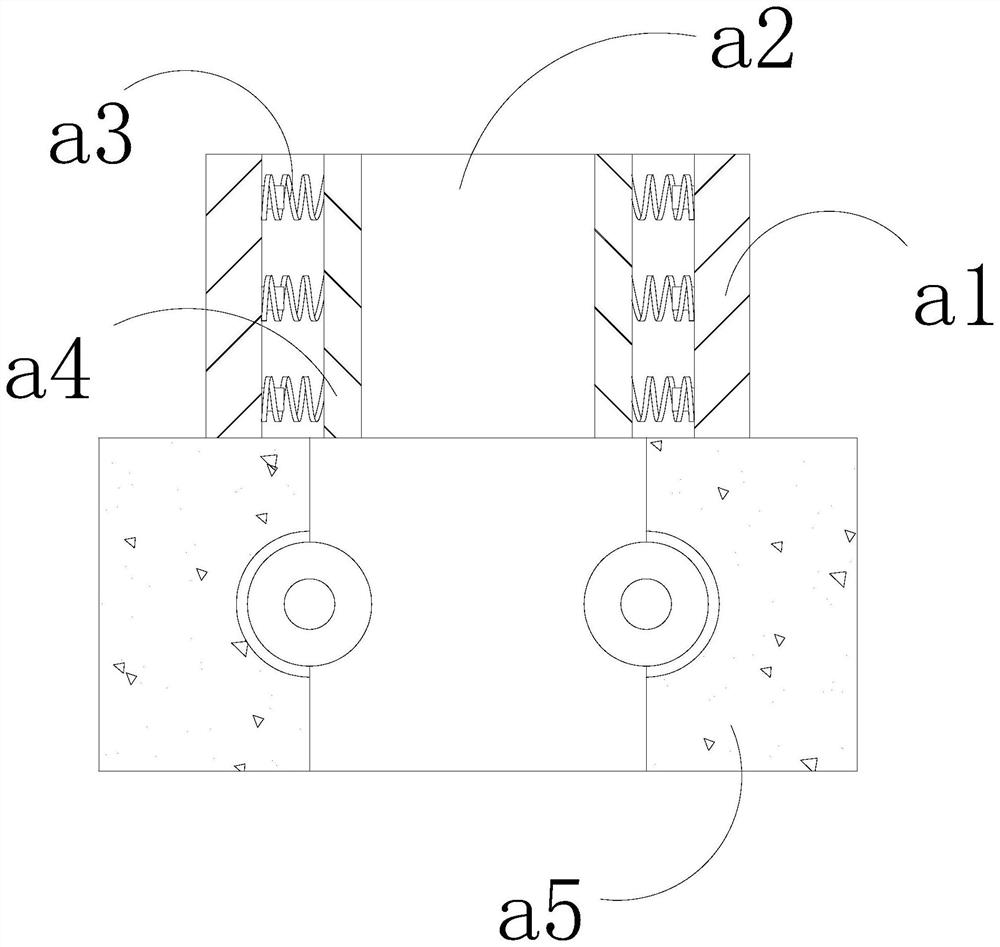

Pneumatic rapid press-riveting tool

The invention relates to a pneumatic rapid press-riveting tool. The pneumatic rapid press-riveting tool comprises an upper pressing assembly and a base. The upper pressing assembly is composed of a vertical adjusting mechanism and a pneumatic mechanism. The vertical adjusting mechanism comprises a lead screw, a fixing block, a supporting column and a support stand, wherein the fixing block is fixed to the supporting column, a threaded hole is formed in the fixing block, one end of the lead screw penetrates through the threaded hole to be connected with the support stand, and the support stand is arranged on the supporting column in a sleeving mode and is in sliding fit with the supporting column. Thus, according to the pneumatic rapid press-riveting tool, a pneumatic device is adopted, torque is transmitted to pressed parts through a driving rod pressing head, and rapid press-riveting of the product parts can be achieved, so that installation efficiency is improved, installation difficulty is lowered, product installation uniformity is guaranteed, and product quality is improved. The support stand and the supporting column can slide relative to each other, and thus the vertical direction and position can be adjusted in the tool clamping process; the support stand can rotate around the center axis of the supporting column, and thus the horizontal direction and position can be adjusted in the tool clamping process; the use range is wide.

Owner:迈特通信设备(苏州)有限公司

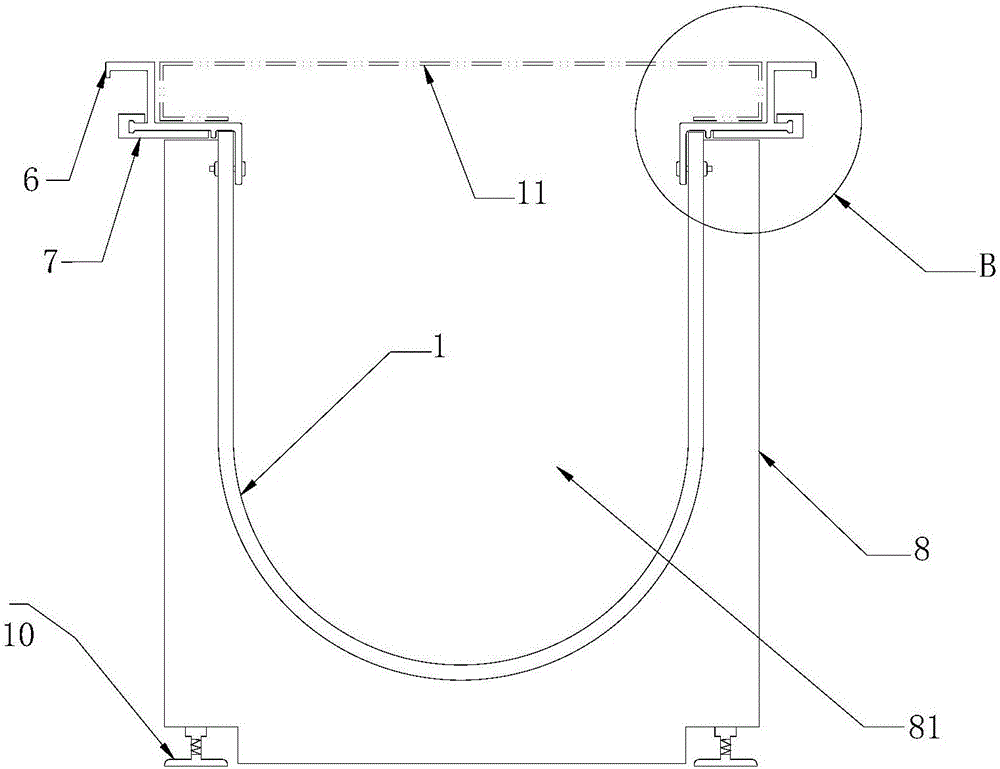

Trench

ActiveCN106320499AFast rivetingThere are no unfavorable factors such as welding deformationSewer pipelinesWater leakageButt joint

The invention discloses a trench which is formed by sequentially connecting a plurality of trench bodies. The trench body is formed by stainless steel plates through die pressing, the cross section perpendicular to the axial direction of the trench body is U-shaped, the axial end of the trench body is radially and outwards expanded to form an outward expanded portion, the other end is a smooth end, the inner size of the outward expanded portion is not smaller than the outer size of the smooth end, the outward expanded portion of the trench body is in sleeved connection with the smooth end adjacent to the trench body, a sealing part for preventing water leakage of junctures is arranged between the outward expanded portion and the smooth end, riveting holes corresponding in a one-to-one mode are respectively formed in the outward expanded portion and the smooth end, and the adjacent trench bodies are mutually and fixedly connected through rivets in the riveting holes. The butt joint of the adjacent trench bodies is field riveting, the butt-jointjunctures are sealed are by utilizing sealing parts, the technical effect of fireless butt joint is achieved, the riveting speed is higher than welding speed, and welding deformation and other adverse factors do not exist. Therefore, the construction cost can be remarkably reduced.

Owner:江苏爱拼食品设备有限公司

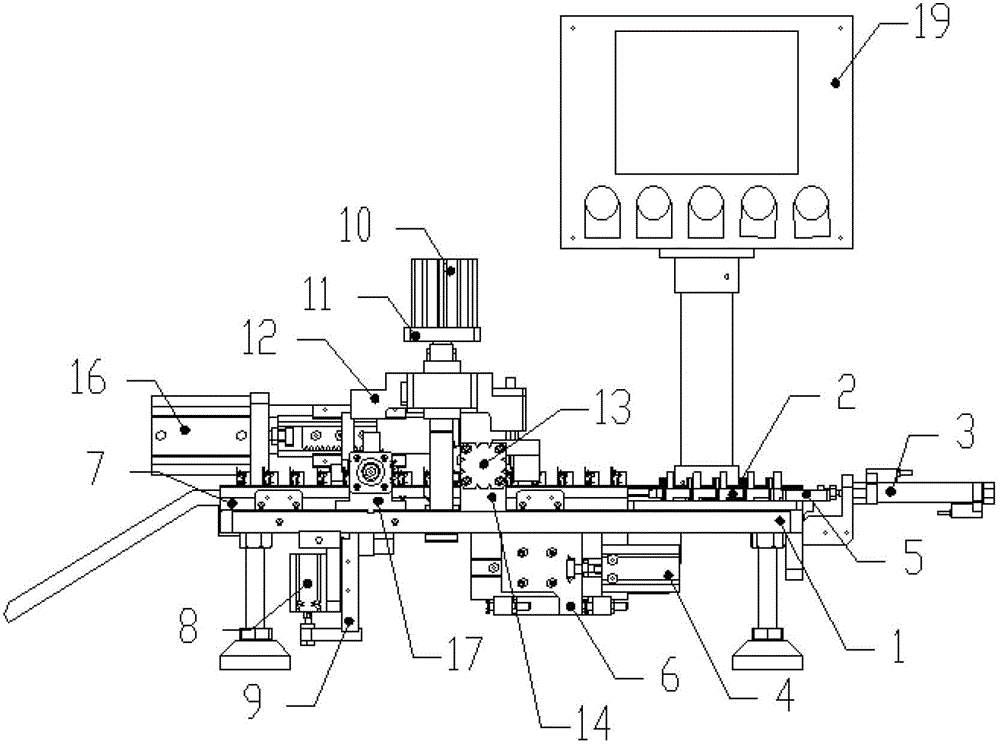

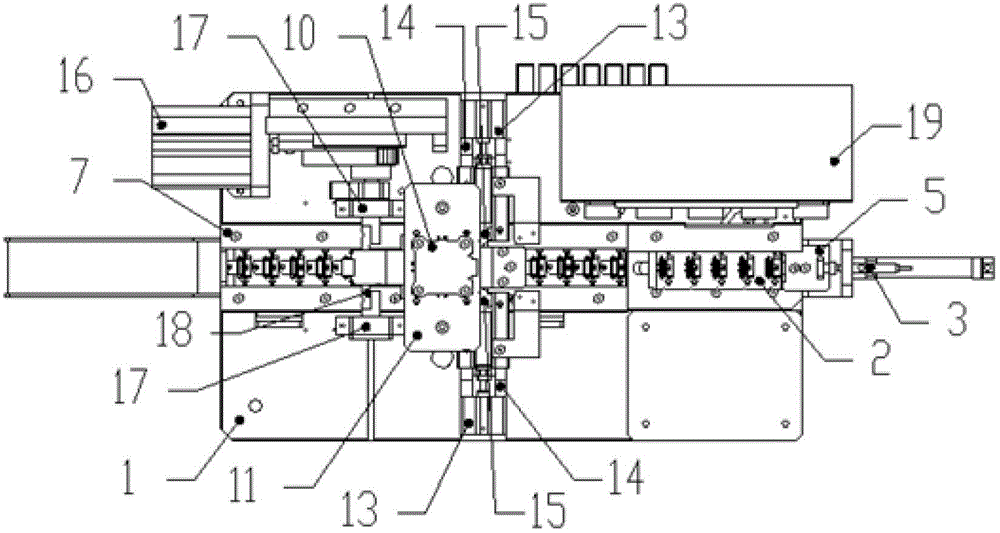

Rivet rolling substrate machine of potentiometer

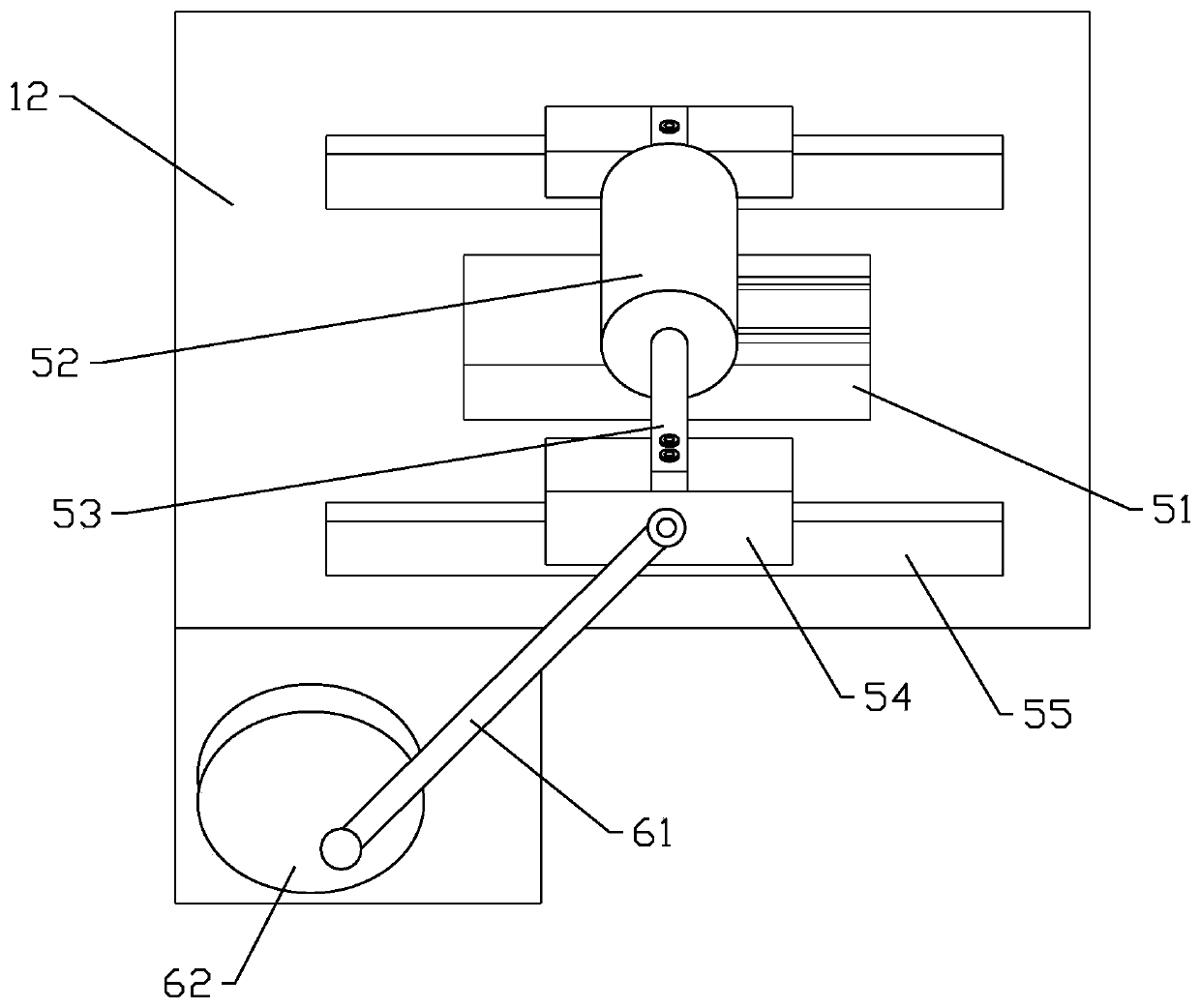

PendingCN110223813AFast rivetingImprove structural firmnessResistor manufactureEngineeringVertical displacement

The invention discloses a rivet rolling substrate machine of a potentiometer. The rivet rolling substrate machine comprises a machine body, a horizontal displacement device, a vertical displacement device, an absorber, a rivet rolling assembly and a driving assembly, wherein the horizontal displacement device is arranged at the machine body, the vertical displacement device is arranged at the horizontal displacement device, the absorber is arranged at the vertical displacement device, the rivet rolling assembly is arranged at the machine body, the driving assembly is connected with the rivet rolling assembly and the machine body, the machine body comprises a rack, a table plate and a collection box, the horizontal displacement device comprises a horizontal seat, a horizontal servo motor and a horizontal threaded shaft, the vertical displacement device comprises a vertical seat, a vertical servo motor and a vertical threaded shaft, the absorber comprises an absorption substrate, an absorption air pipe and a nozzle, the rivet rolling assembly comprises a workbench, a working roller, a rolling shaft, a rivet rolling sliding block, a sliding rail and a pin shaft, and the driving assembly comprises a driven rod, an eccentric rotation disc and a rotation disc motor. By the machine, the substrate can be rapidly riveted, the structure firmness of the substrate is effectively reinforced, the workload of manual riveting is omitted, and the workshop production efficiency is greatly improved.

Owner:CHENGDU GUOSHENG TECH

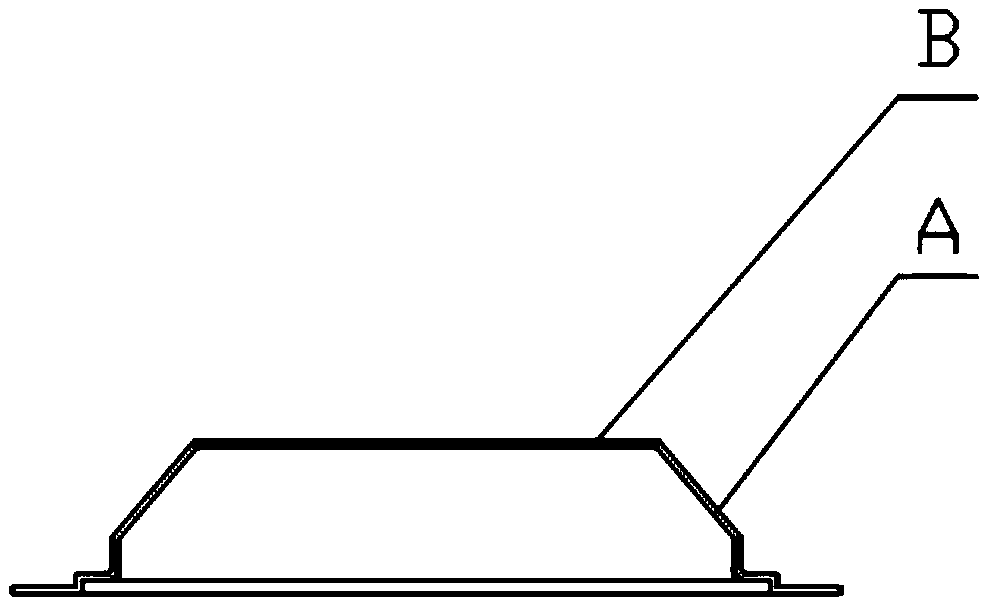

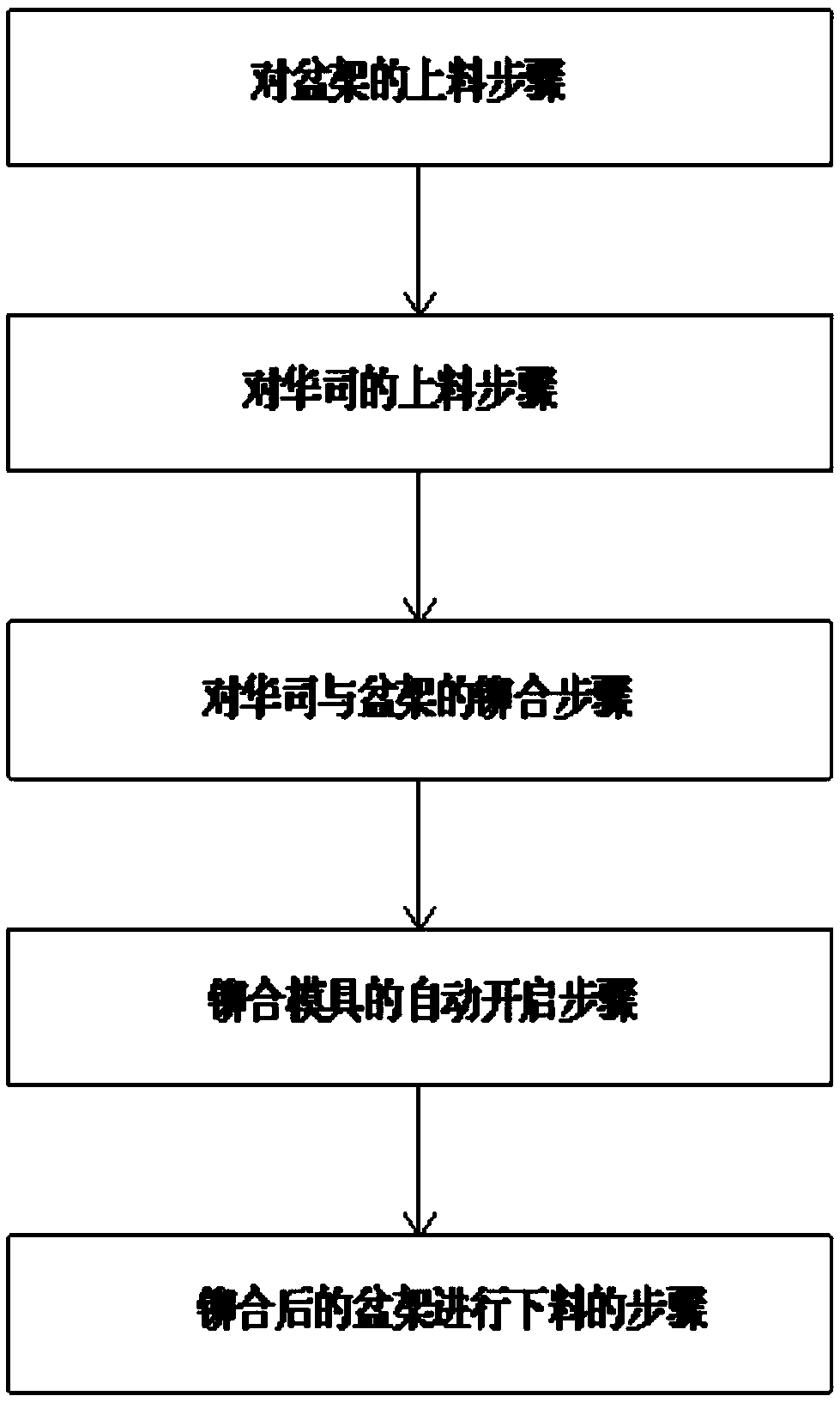

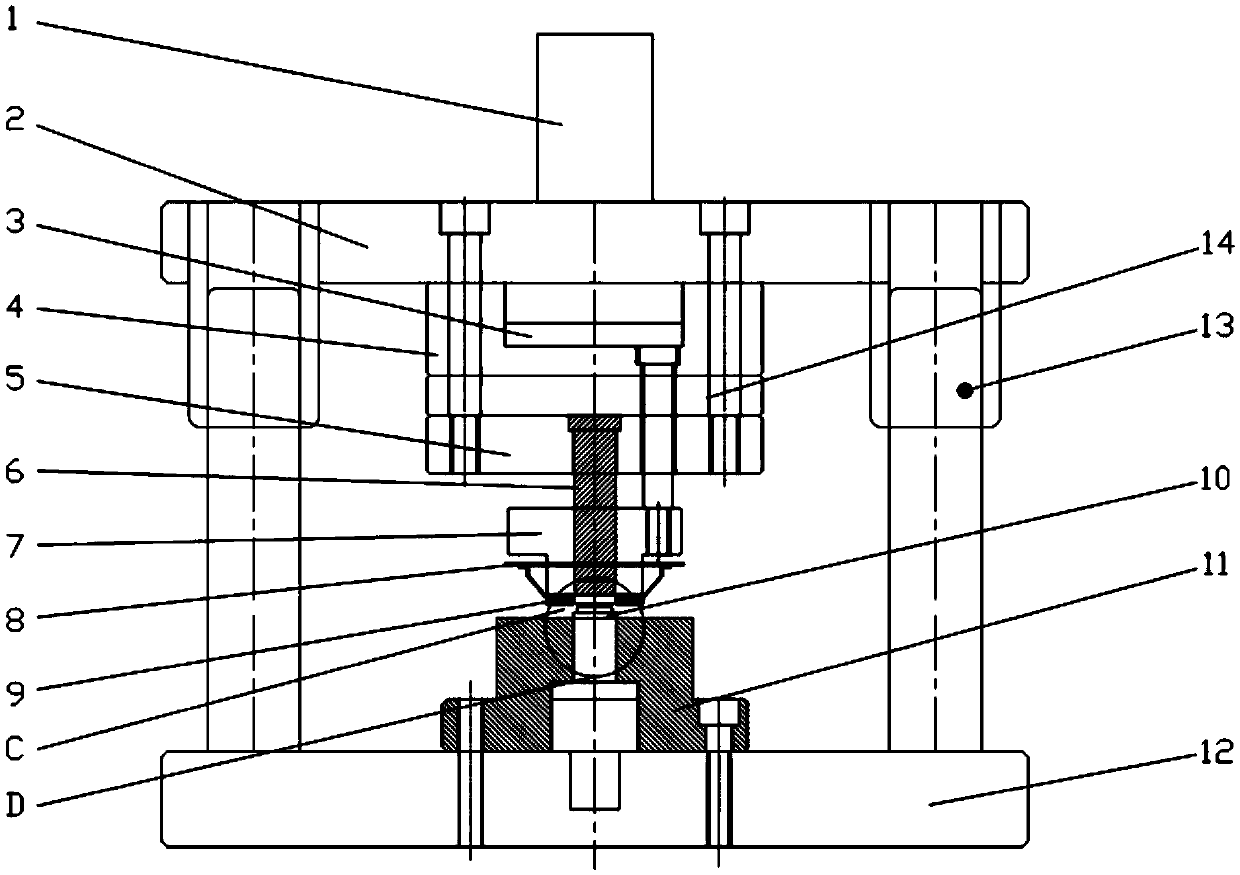

A rapid riveting process for washer and basin frame

The invention relates to the technical field of a mold, and discloses a fast riveting process of a spring washer and a basin stand. The fast riveting process is used for fast riveting the spring washer on the basin stand and comprises a basin stand feeding step, a spring washer feeding step and a spring washer and basin stand riveting step, wherein in the riveting step, a riveting mold is adopted for riveting, a positioning rod used for storing the basin stand and a riveting station used for storing the spring washer are arranged in the riveting mold, and when the riveting mold is used for riveting, the spring washer arranged in the riveting station and the basin stand arranged on the positioning rod realize fast riveting. According to the riveting process, firstly, the spring washer and the basin stand are respectively stored on the riveting station and the positioning rod of the riveting mold, and then, the riveting mold is driven to realize the fast riveting of the basin stand and the spring washer in the riveting station. Compared with the existing single riveting, the fast riveting process has the advantages that the riveting efficiency is high, the time is short, the riveting force is uniform, and the product quality is high.

Owner:启东市稷兵农副产品专业合作社

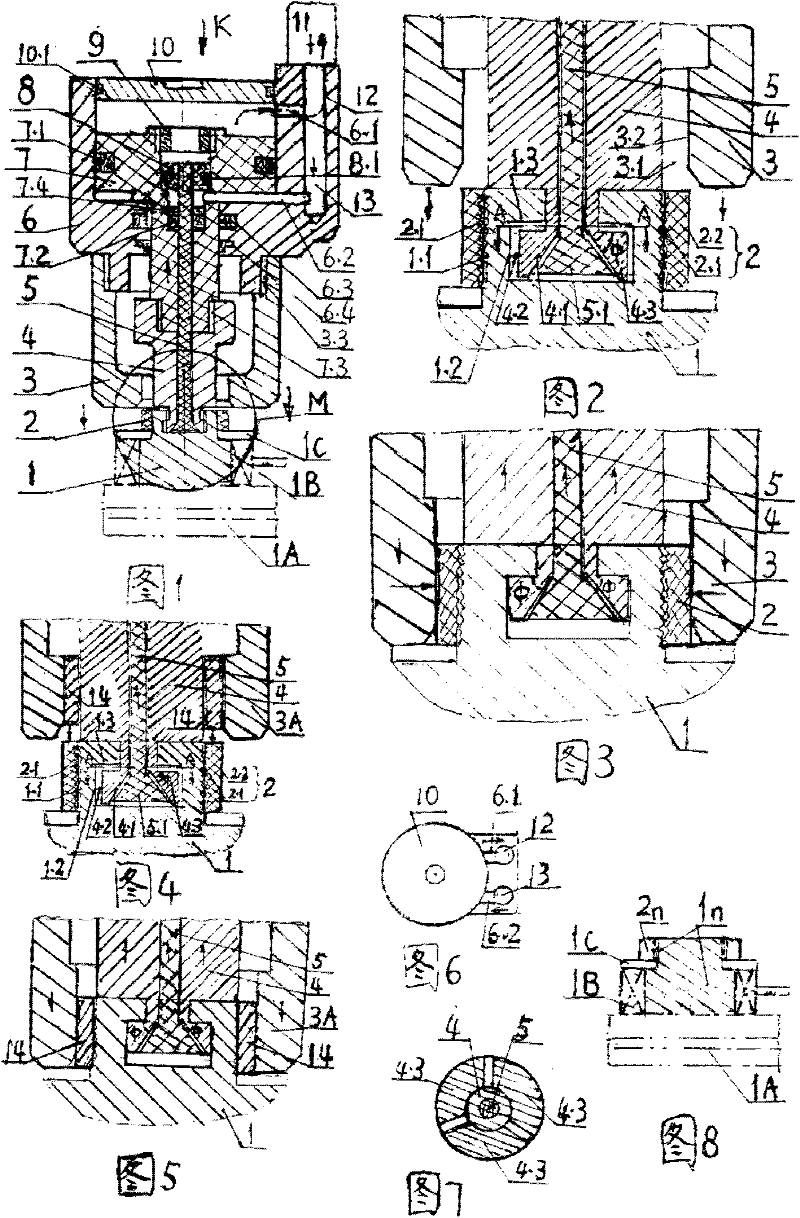

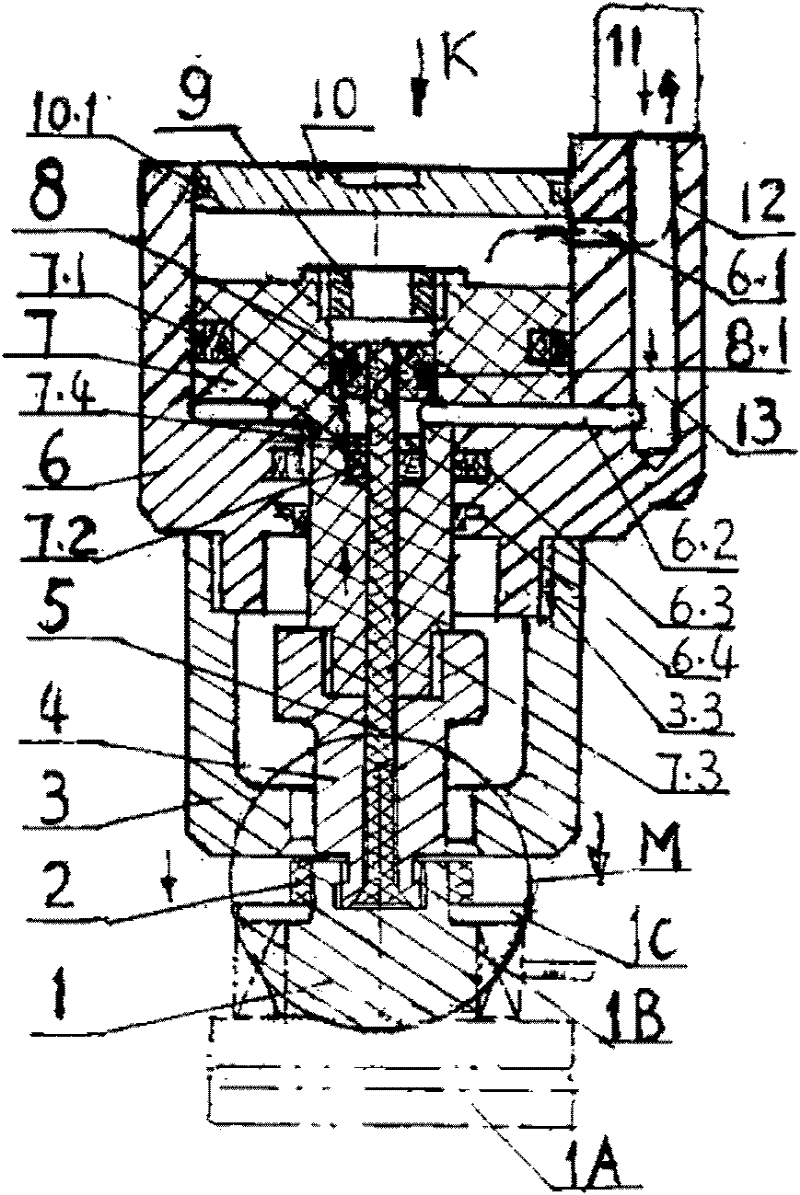

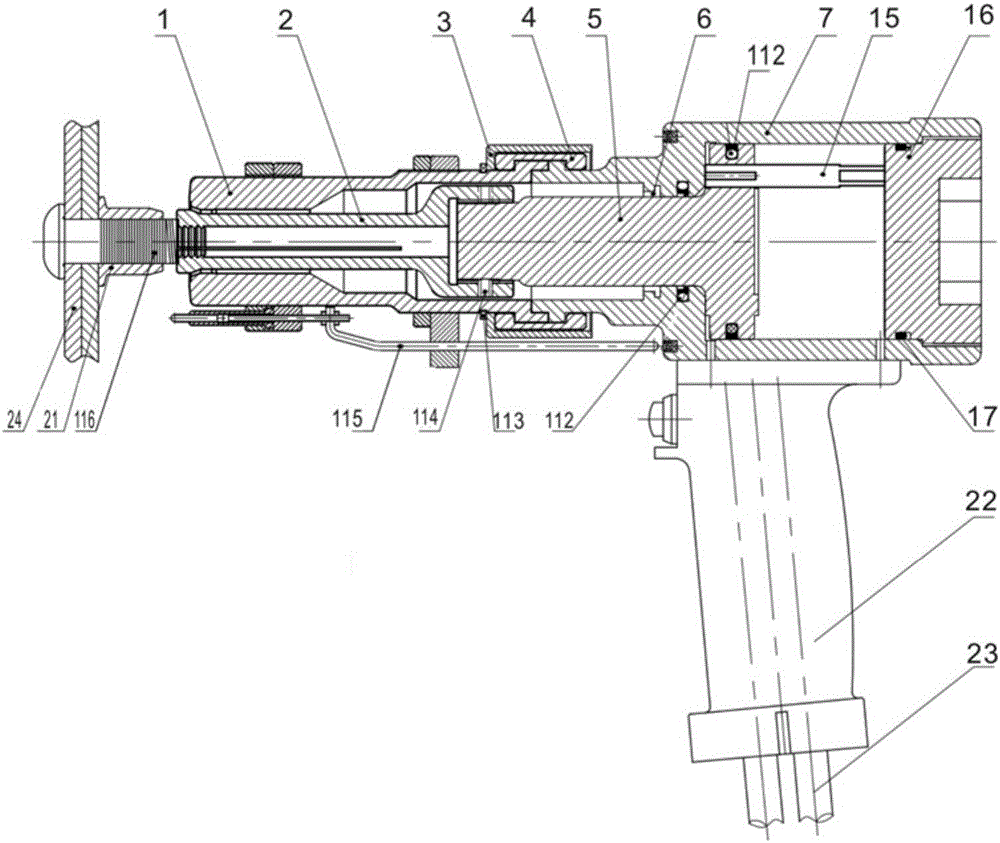

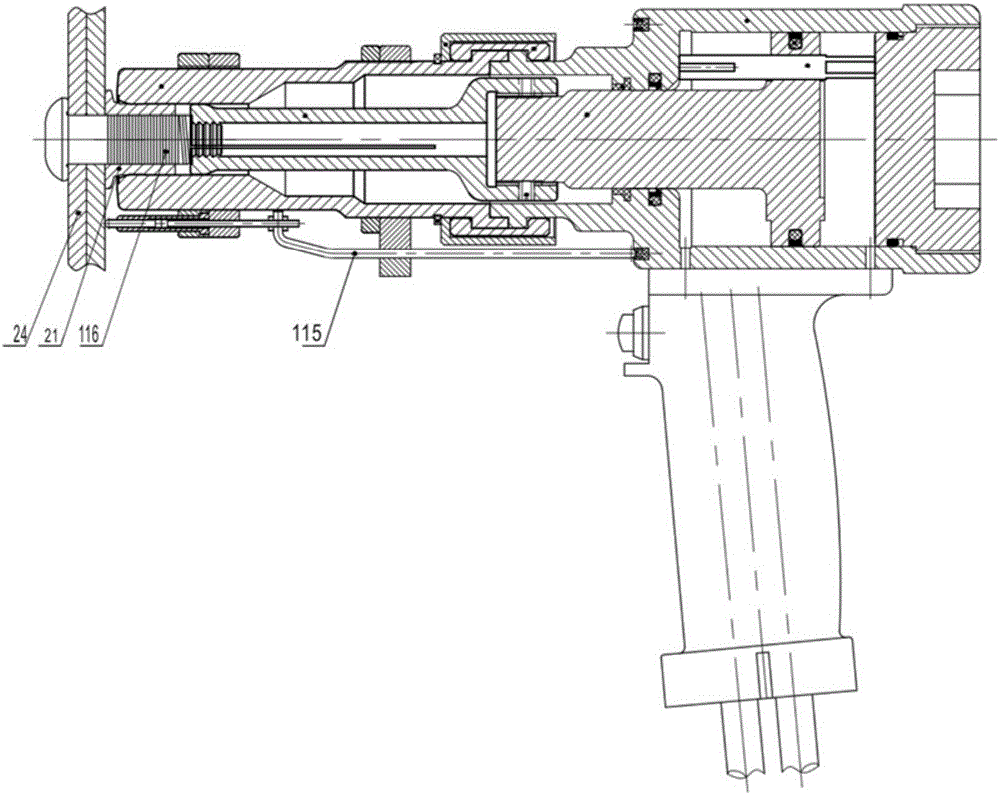

Reusable rivet intelligent riveting machine

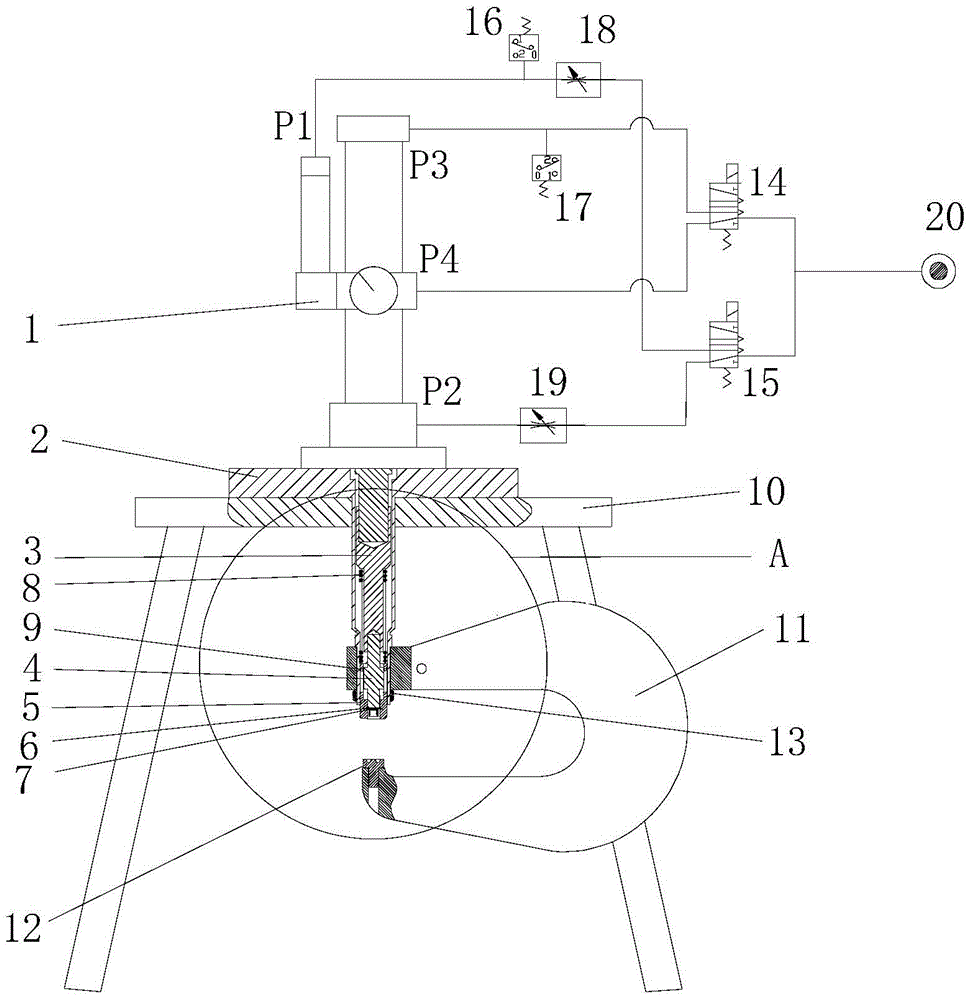

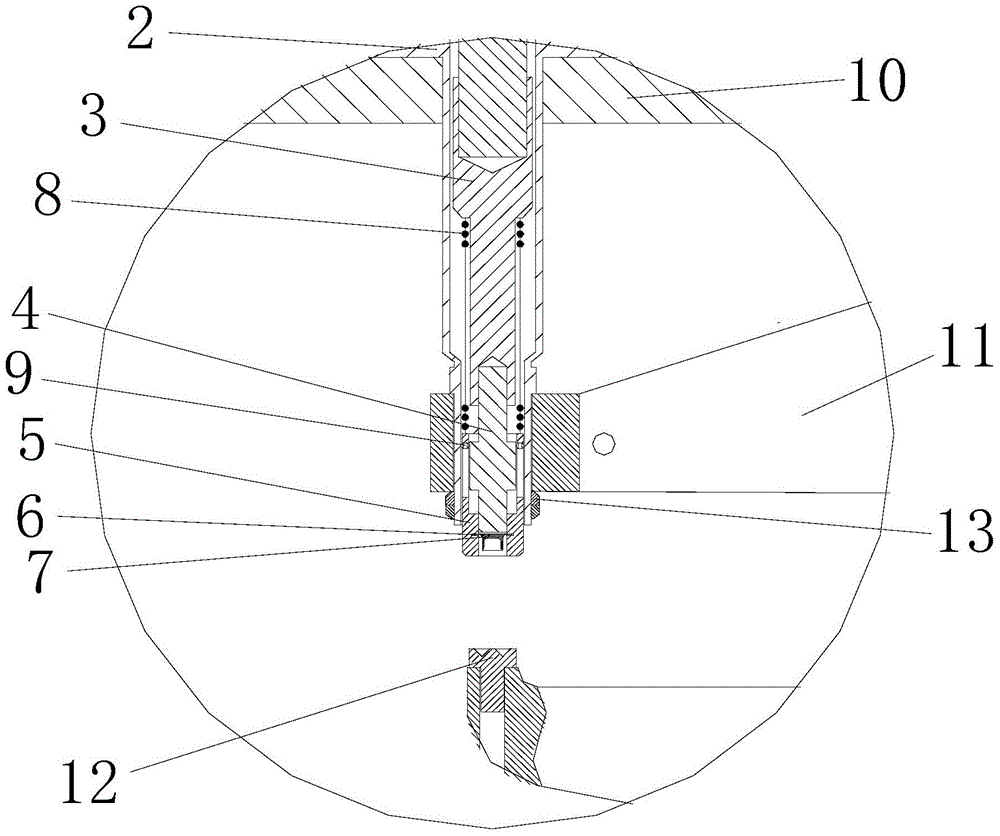

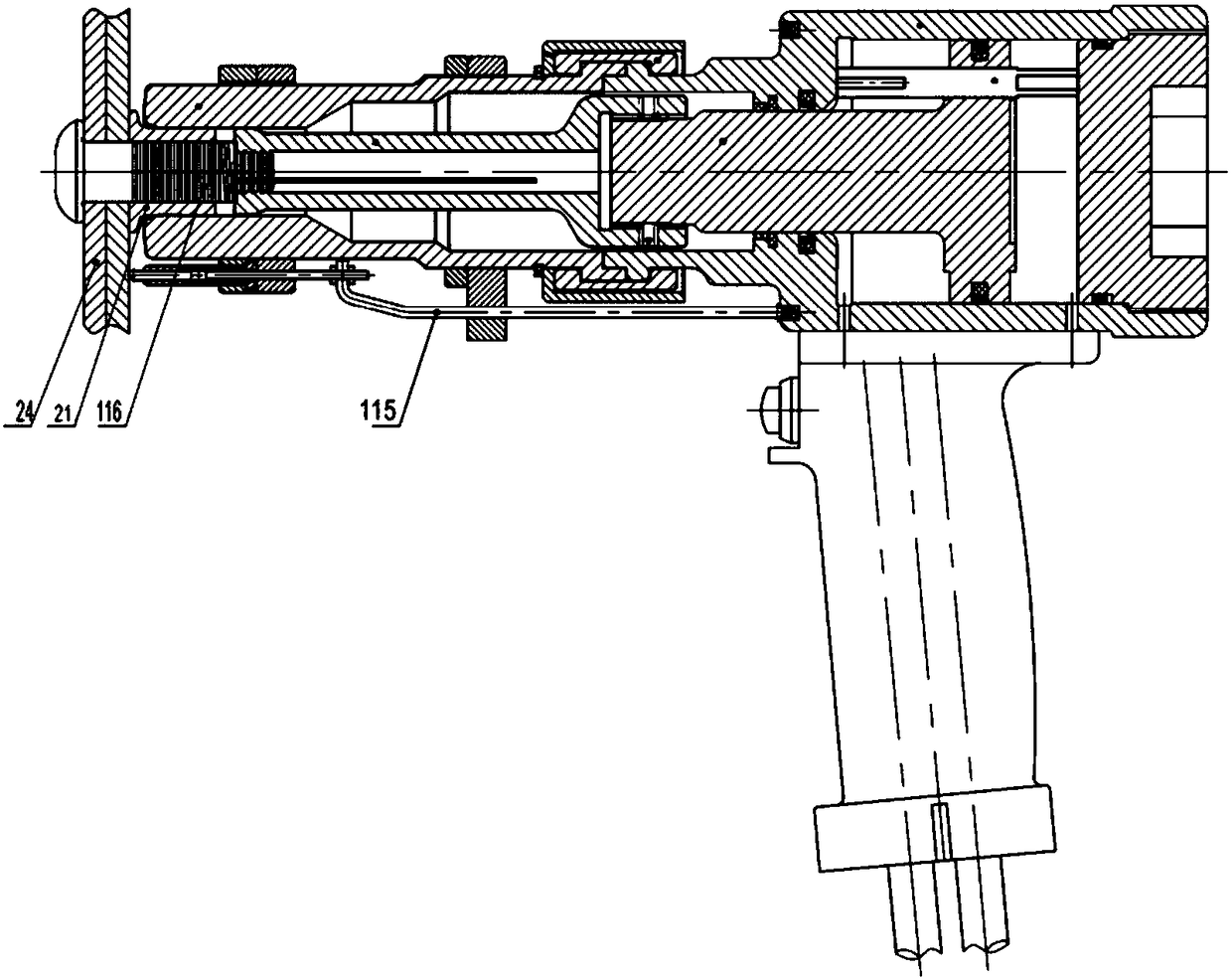

The invention discloses an intelligent riveting machine. The intelligent riveting machine comprises a cover, a rivet grabber, an automatic positioning device and a hydraulic system; the back end of the river grabber coats the front end of a piston, and the two are connected as a whole by a thread and locked through a screw; an oil cylinder and the cover are at the outer periphery of the piston; the cover is connected with the oil cylinder through a connecting clamping part, a connecting sleeve and a retainer ring; meanwhile, the oil cylinder is connected with a back cover through a thread; an unloading rod is arranged in a large-head end surface of the piston; the piston slides on the unloading rod; a compensation seal is mounted at the back end of the piston, and a radial seal is mounted at the front end of the back cover; a dustproof ring and a rod seal are mounted in the front end of the oil cylinder; the automatic positioning device is connected with the cover through a thread, and a signal ring thereof is inlaid in the outer front end surface of the oil cylinder; a handle is mounted at the lower part of the oil cylinder; the internal of the handle passes through a high-pressure oil pipe; and the oil cylinder is connected with a hydraulic station through the high-pressure oil pipe. The intelligent riveting machine has the advantages of fast riveting speed, good riveting molding, stable riveting process, accurate riveting effect judgment and convenience for automatic control and recording.

Owner:GUANGDONG NACRE HYDRAULIC CO LTD

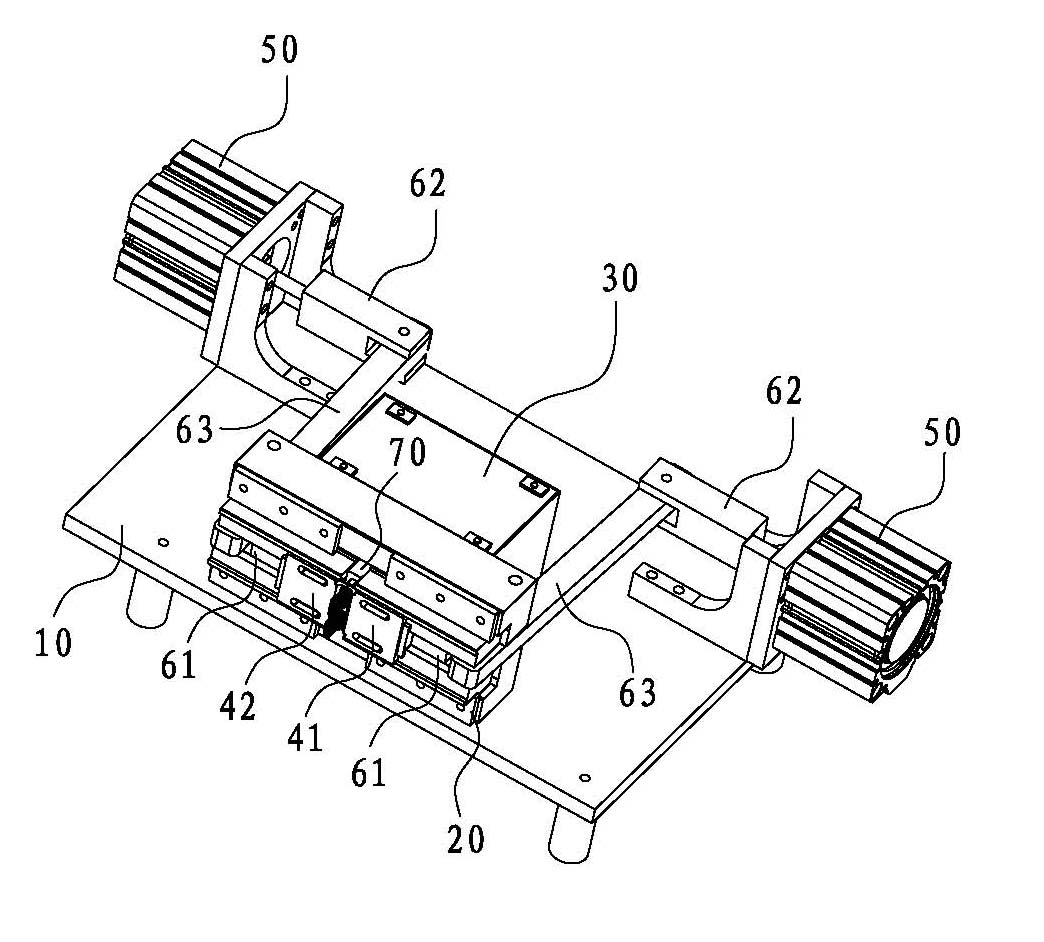

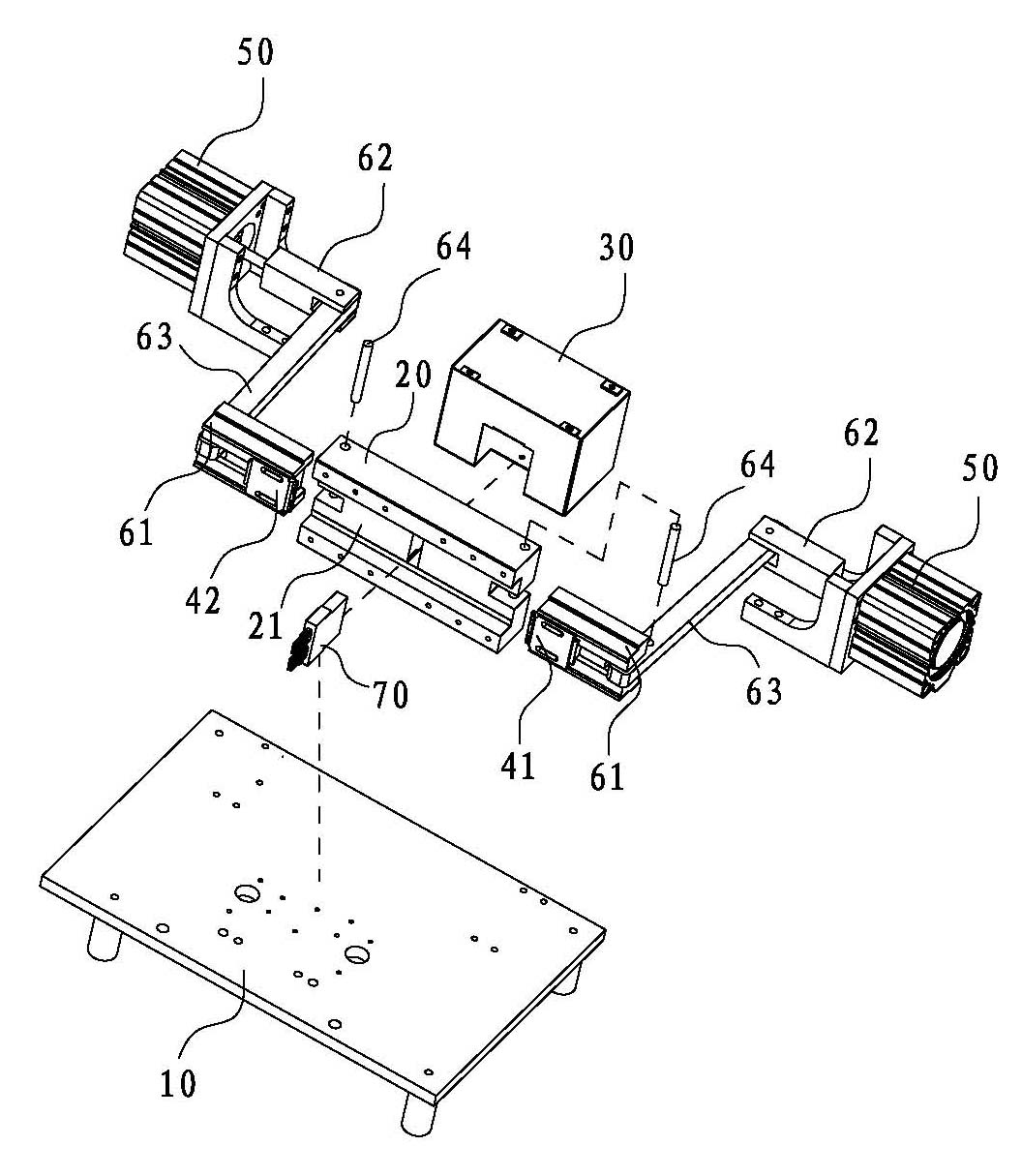

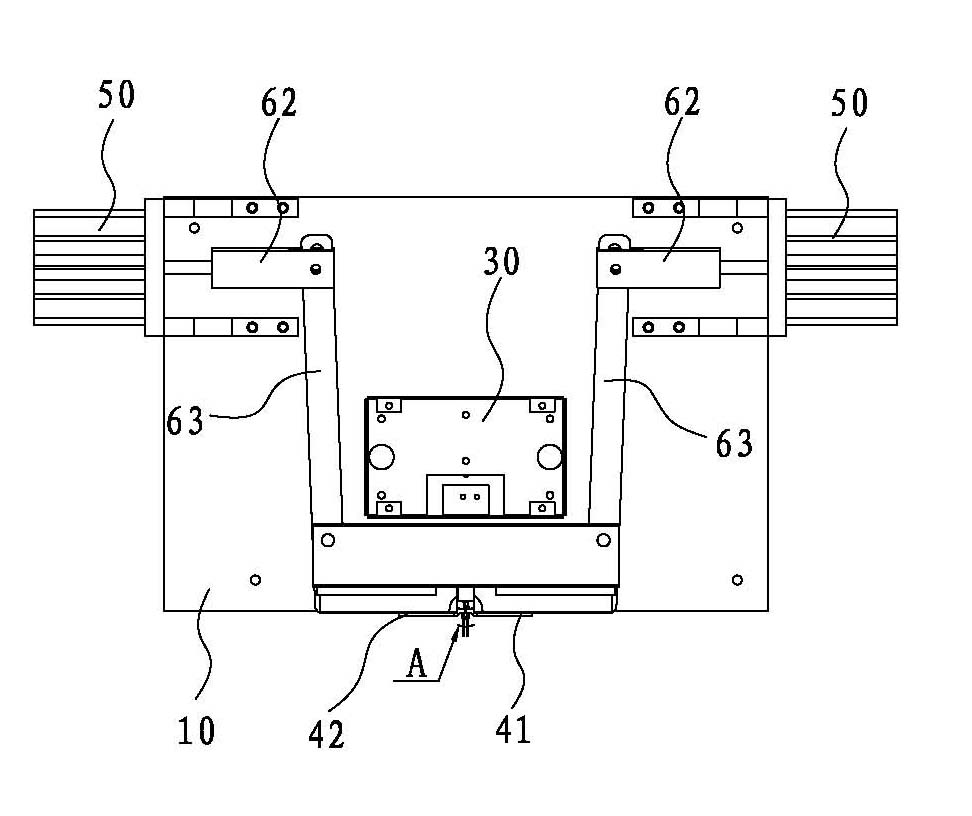

Bridge-shaped contact riveting clamp of frame circuit breaker and assembly operation method of bridge-shaped contact riveting clamp

PendingCN110877077AFast rivetingImprove efficiencyMetal-working feeding devicesElectric switchesBackplaneStructural engineering

The invention relates to a riveting clamp, and in particular to an assembly operation method of a bridge-shaped contact riveting clamp of a frame circuit breaker. The riveting clamp comprises bridge-shaped contacts and a bottom plate; two clamping devices which are distributed at an interval are arranged on the bottom plate; the bridge-shaped contacts which are detachably fixed are respectively arranged in the clamping devices; a punch riveting device is arranged between the two clamping devices; and the punch riveting device synchronously controls the two clamping devices. The high riveting speed is fast, and efficiency is high.

Owner:杭州杰涵机械科技有限公司

Automatic thermal riveting method and automatic thermal riveting machine for chain pin shaft

The invention relates to an automatic hot rivet method of chain pin axle and a relative rivet machine, wherein said method comprises: arranging several chain sections on the work bench; positioning the chain section of riveted pin axle, to aim the end of pin axle to the rivet mould and aim the tail of pin axle axially; then moving the electromagnetic induction heating coil to be end of pin axle, to heat the end; heating to the rivet temperature, removing the electromagnetic induction heating coil; riveting the pin axle end with rivet mould; returning the rivet mould; loosing the chain section; then moving the chain section to make the next pin axle on site. The heat riveter comprises a frame, a hydraulic cylinder, a controller, an electromagnetic induction heating coil feeder and a chain positioning device. And the invention has high rivet speed and high working efficiency.

Owner:JIANGSU SHUANGLING CHAIN TRANSMISSION

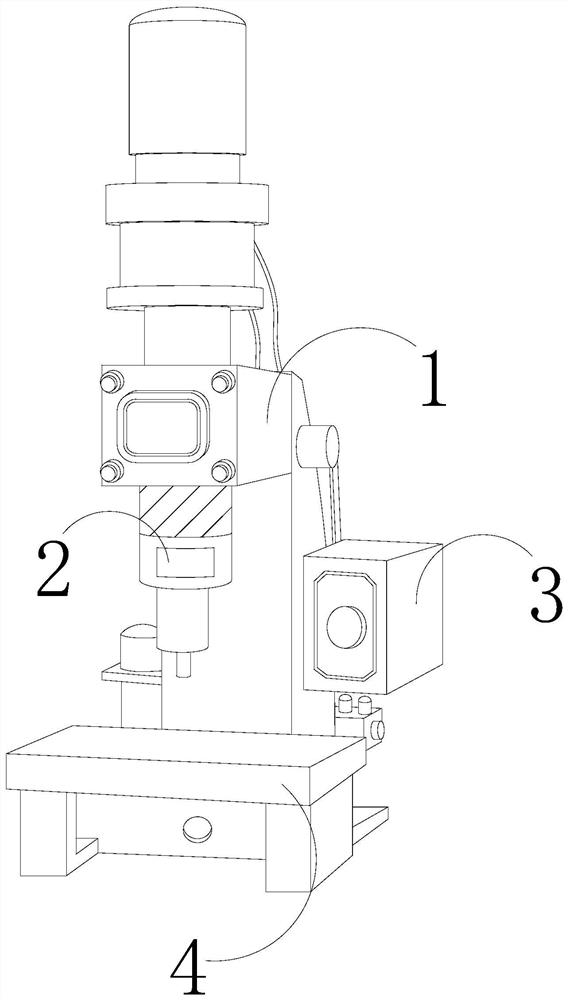

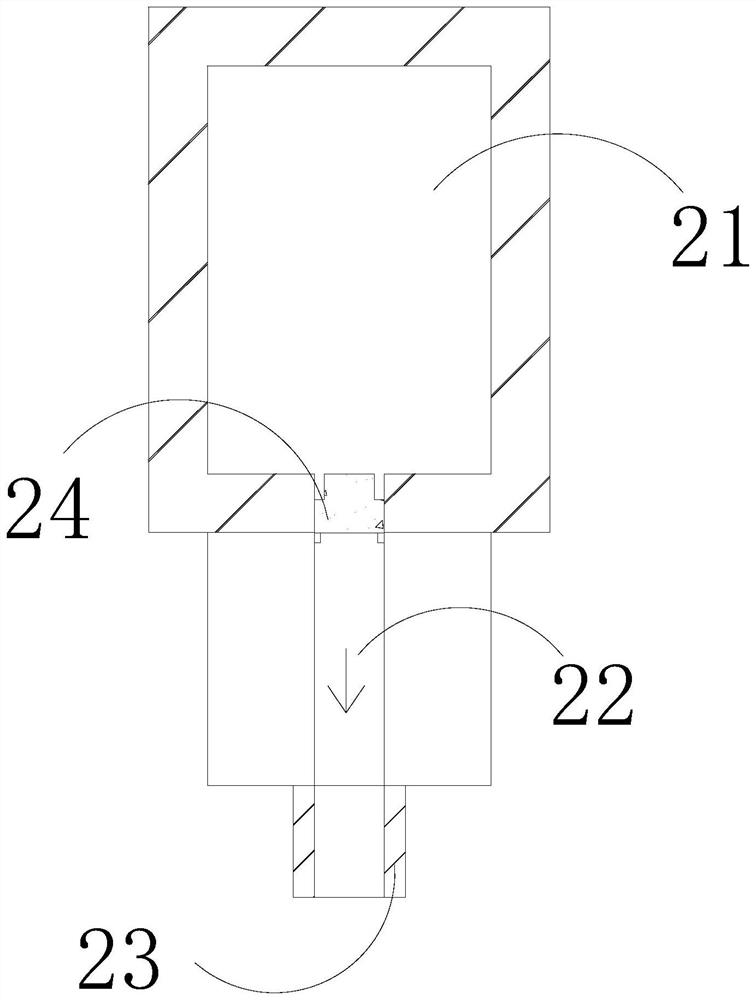

Automatic rivet supply riveting machine

The invention discloses an automatic rivet supply riveting machine which structurally comprises a machine body, a riveting device, a control box and a workbench. The riveting device is installed at the bottom of the front face of the machine body, the control box is arranged on the right side of the machine body, and the workbench is located below the riveting device. Due to the fact that the size of rivets is small, the phenomenon that two rivets fall down at the same time is likely to happen, the diameter between ring bodies of an expansion ring of a guide mechanism is changed along with the sizes of the rivets, so that it is ensured that only one rivet falls down when the rivets are discharged every time, the phenomenon that two rivets fall down simultaneously and are clamped in a riveting pipe is reduced, normal rivet discharging is facilitated, and the riveting machine can rivet bags normally; and due to the fact that the outer walls of part of the rivets are uneven, the friction force between the rivets and limiting blocks is increased, the rivets are likely to be clamped between the limiting blocks, the rivets are pushed downwards through rotation of a pushing ring in a pushing mechanism, the falling speed of the rivets can be increased, the situation that the rivets are clamped in an opening is reduced, and the speed of riveting luggage through the riveting pipe is further increased.

Owner:曾爱民

An internal riveting die for hydraulic clutch bearing gland

Owner:NINGBO HONGXIE CLUTCH

Digital display high and low pressure pump riveting machine hydraulic station and riveting process

ActiveCN106151128BSimple structureFast rivetingServomotorsServometer circuitsElectro hydraulicElectrical control

Owner:安阳市三兴机械工业有限责任公司

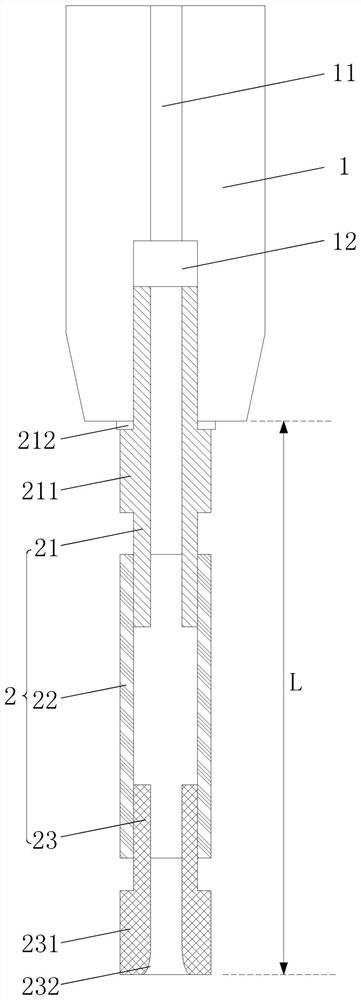

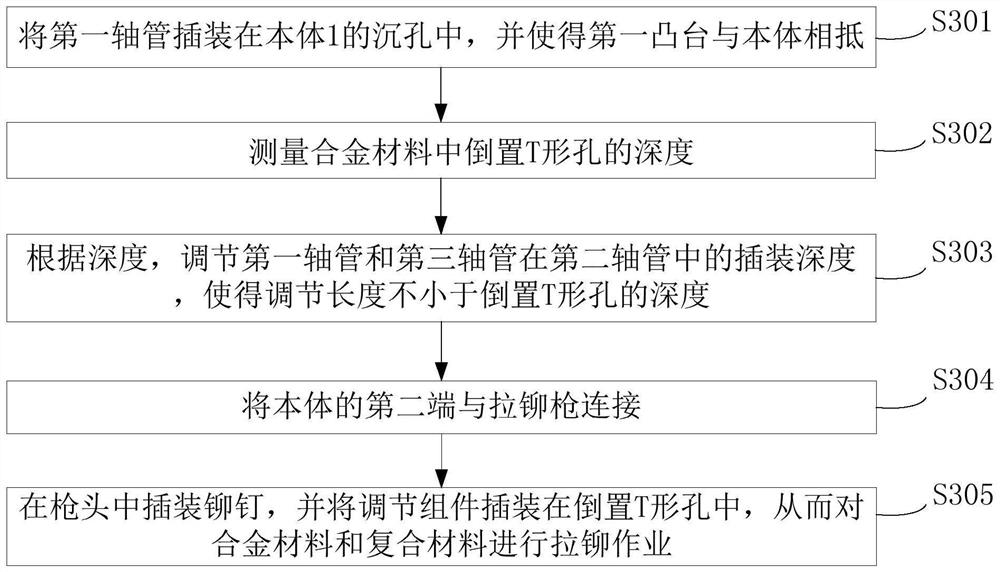

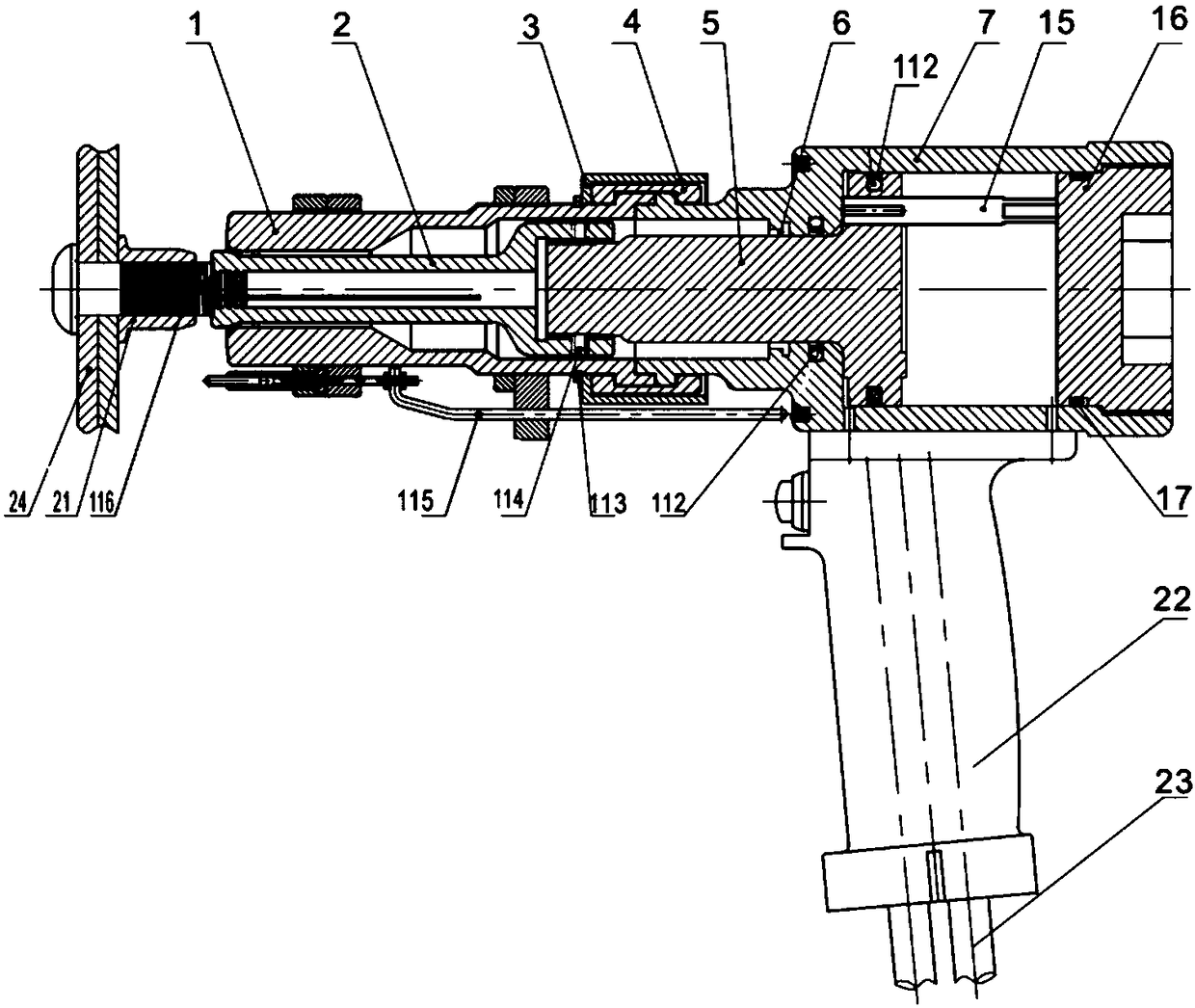

A kind of gun head for riveting gun and using method

The invention discloses a gun head for a riveting gun and a using method thereof, belonging to the field of riveting tools. The gun head includes a body and an adjustment assembly, the body has a through hole for inserting rivets, the through hole runs through the body, the first end of the body has a counterbore, the counterbore and the through hole are coaxially arranged, and the other end of the body is used for connecting Riveting gun. The adjustment assembly includes a first shaft tube, a second shaft tube and a third shaft tube. There is a first boss on the outer wall of the middle part of the first shaft tube, and the first boss protrudes from the body. The first end of the first shaft tube is The shaft is detachably inserted into the counterbore, the second end of the first shaft tube is coaxially inserted into the first end of the second shaft tube, and the first end of the third shaft tube is coaxially inserted into the second shaft In the second end of the tube, and the first shaft tube and the third shaft tube are threadedly engaged with the second shaft tube respectively. The invention provides a gun head for a rivet gun, which can not only ensure the strength of the rivet, but also increase the application range of the gun head.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

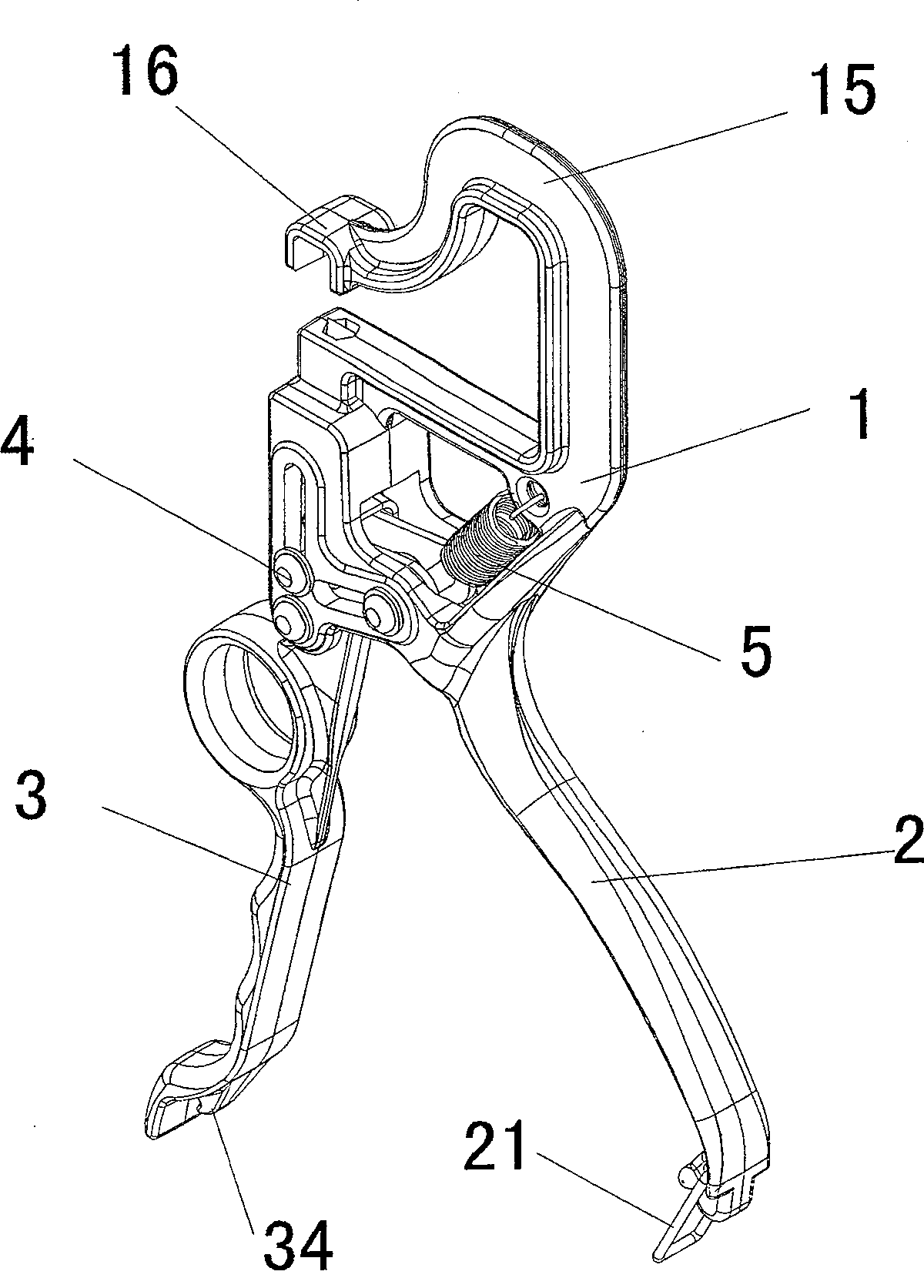

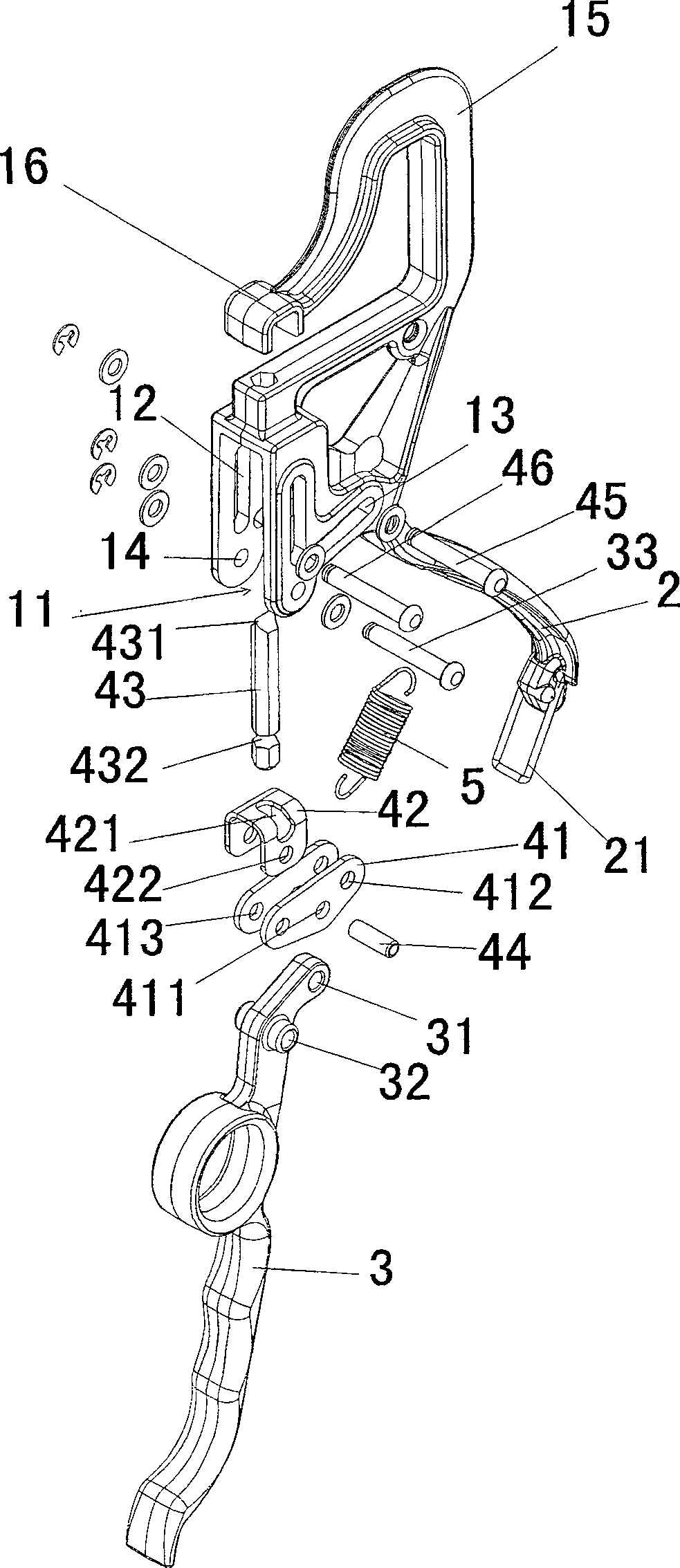

Single manual manipulation riveting clamp

The invention discloses a single hand operated riveting clamp, comprising a clamp body, a fixed clamp handle and a movable clamp handle; the fixed clamp handle is connected with the clamp body to form a whole; the movable clamp is rotatably connected with the clamp body. The invention is characterized in that the riveting clamp also comprises a set of triangular transmission mechanism and a reduction spring, wherein the triangular transmission mechanism connects the movable clamp handle and the clamp body to realize the rotationally connection; the reduction spring is connected between the triangular transmission mechanism and the clamp body and the reduction of the clamp handle can be driven by the triangular transmission mechanism. The riveting clamp has the advantages of good appearance and less fatiguing. Rapid riveting can be realized through single hand operation and the clamp handle can be folded, thus saving space and convenient to carry.

Owner:SHANGHAI KUNJEK HANDTOOLS & HARDWARE

Smart riveter for reusable rivets

The invention discloses an intelligent riveting machine. The intelligent riveting machine comprises a cover, a rivet grabber, an automatic positioning device and a hydraulic system; the back end of the river grabber coats the front end of a piston, and the two are connected as a whole by a thread and locked through a screw; an oil cylinder and the cover are at the outer periphery of the piston; the cover is connected with the oil cylinder through a connecting clamping part, a connecting sleeve and a retainer ring; meanwhile, the oil cylinder is connected with a back cover through a thread; an unloading rod is arranged in a large-head end surface of the piston; the piston slides on the unloading rod; a compensation seal is mounted at the back end of the piston, and a radial seal is mounted at the front end of the back cover; a dustproof ring and a rod seal are mounted in the front end of the oil cylinder; the automatic positioning device is connected with the cover through a thread, and a signal ring thereof is inlaid in the outer front end surface of the oil cylinder; a handle is mounted at the lower part of the oil cylinder; the internal of the handle passes through a high-pressure oil pipe; and the oil cylinder is connected with a hydraulic station through the high-pressure oil pipe. The intelligent riveting machine has the advantages of fast riveting speed, good riveting molding, stable riveting process, accurate riveting effect judgment and convenience for automatic control and recording.

Owner:GUANGDONG NACRE HYDRAULIC CO LTD

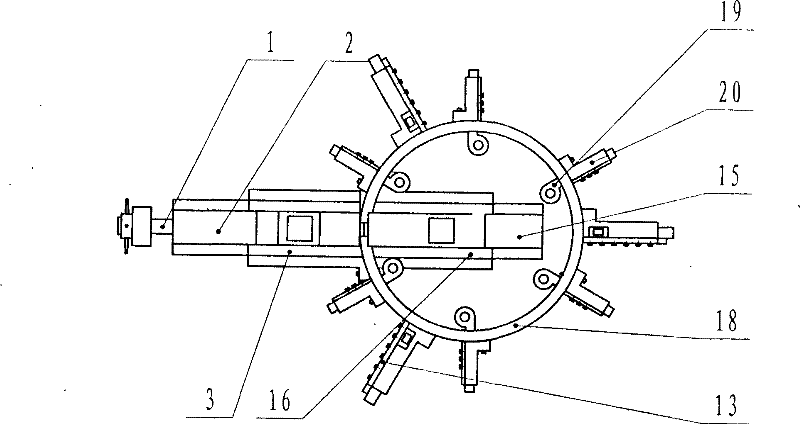

Cylindrical shape automatic riveted-joint apparatus

The present invention provides a cylindrical shape automatic riveted-joint apparatus which riveted joints a screen drum U-shaped loop with a screen bar in manufacturing a pressure screen. The apparatus is mainly used for solving problem of micro deformation caused by welding the screen drum U-shaped loop with the screen bar in the prior art. The apparatus comprises a transmission pair composed bya bidirectional leading screw and a positioning block nut, the positioning block nut is fixed on an outer wall of a main body through a guide rail and a support, a positioning block guide rail and a positioning block are arranged on the positioning block nut, a pneumatic-rivet gun nut is fixed on an inner wall of the main body through the guide rail and the support, the pneumatic-rivet gun nut and the bidirectional leading screw comprise the transmission pair, the pneumatic-rivet gun is arranged on the pneumatic-rivet gun nut through the pneumatic-rivet gun positioning block and the guide rail; an U-shaped loop positioning rule holder is arranged on the outer wall of the main body of the riveted-joint apparatus, an U-shaped loop limiter is arranged on the U-shaped loop positioning rule holder through the U-shaped loop positioning rule and a slide block, the U-shaped loop limiter is arranged on a slide block holder of an U-shaped loop limiting pile through the U-shaped loop limiting pile and the slide block. The apparatus has advantages of processing circumference riveted joint automatically and no deformation.

Owner:赵仁理

Terminal post riveting device and breaking tool

The invention relates to a terminal post riveting device and a breaking tool. A strut is arranged at the center of a cylinder body; a grabbing rod is tightly sheathed outside the strut; the bottom ends of the strut and the grabbing rod are inserted in a T-shaped groove formed on the upper plane of the terminal post of a battery; the strut has a horn-shaped bottom end; and the bottom end of the grabbing rod is a three-flap centripetal clamping body matched with the strut and the T-shaped groove. The oil cylinder consists of a cylinder body on the upper end, a jacket on the lower end, wherein the cylinder body is connected with the jacket through threads; a strut piston fixed with the upper end of the strut and a rivet piston at the periphery are arranged in the cylinder body; and the lower end of the rivet piston is connected with the grabbing rod through threads to form a single-oil-path double-piston structure. When the oil cylinder is started, the two pistons act to drive the strut and the grabbing rod to move upwards, and drive the jacket and the cylinder to move downwards so as to extrude the outer liner ring of the terminal post, thereby achieving the riveting. When a cutting head is mounted on the bottom end of the jacket, the pistons drive the cutting head to cut the liner ring as a breaking tool. By adopting cold riveting, the terminal post riveting device can solve the problem of bolt looseness of the terminal post. The invention also provides a riveting breaking tool, which facilitates the maintenance. The overall dimension of the terminal post riveting device is Phi40*100, the weight is about 1.5 kg, the cylinder pressure is about 12 Mpa; and the terminal post riveting device has high riveting speed and is convenient in operation.

Owner:MEISHAN HENGSHENG MECHANICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com