Smart riveter for reusable rivets

A riveter and intelligent technology, applied in the field of cold extrusion rivet riveting tools, reusable rivet intelligent riveter, can solve the problem of not being able to automatically determine whether the riveting is in good condition, losing the reuse function of short tail rivets, damaging small short tails, etc. problems, to achieve the effect of facilitating automatic control and recording, facilitating effective molding, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

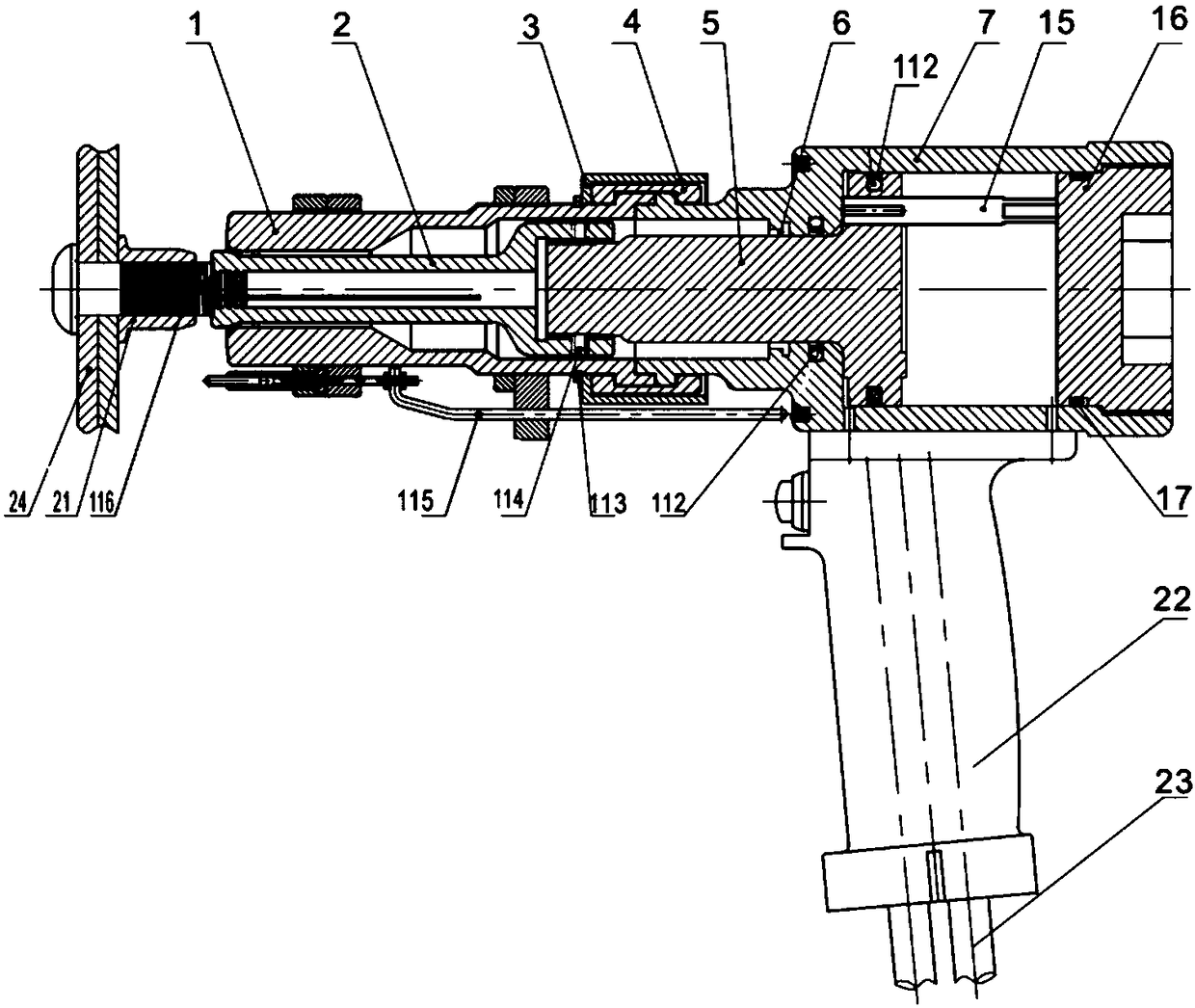

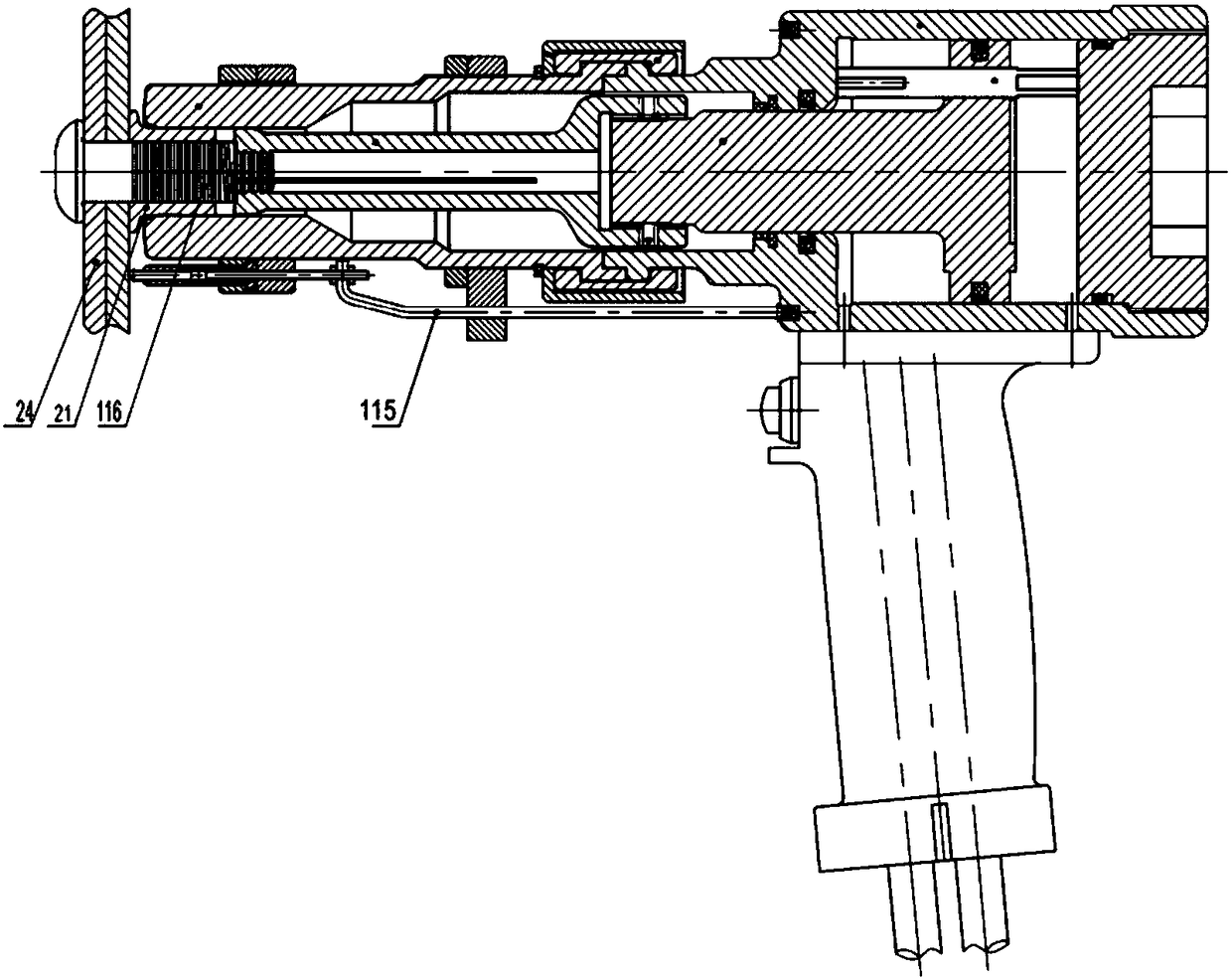

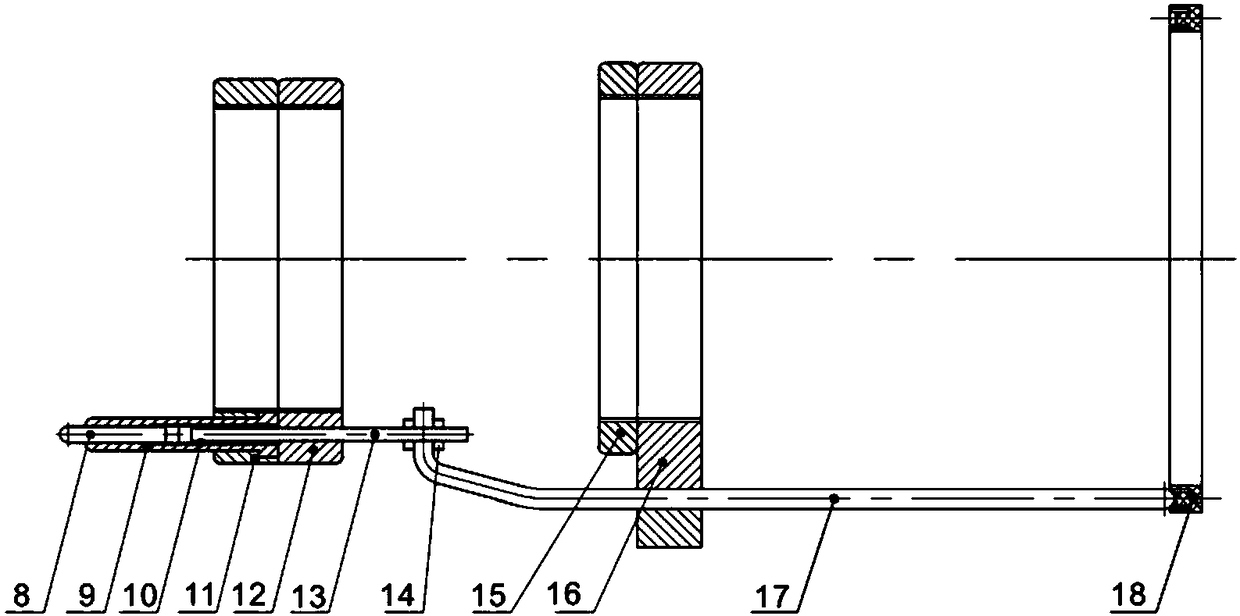

[0017] See figure 1 , the present invention presses the U-shaped combined seal and dust-proof ring at the front end of the oil cylinder into the ring groove of the oil cylinder, then presses the combined seal on the piston into the piston ring groove, puts the piston into the oil cylinder, and inserts the unloading rod into the piston hole Inside, pay attention to the direction; then press the combined seal on the back cover into the groove of the back cover, and screw it into the rear end of the oil cylinder, install two oil pipes at the handle of the oil cylinder, connect the hydraulic station, let the piston move repeatedly several times, check Check whether there is any leakage in the oil cylinder, and carry out a pressure test on the oil cylinder under the rated pressure at the same time. After the above process is completed, retract the piston to figure 1 Install the nail catcher on the piston and lock it with screws; then put the jacket on the oil cylinder mouth, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com