Riveting stamping mechanism for pulley retaining rings

A stamping riveting and retaining ring technology, which is applied in the field of stamping riveting mechanism for pulley retaining rings, can solve the problems of low processing efficiency, affecting product appearance, poor reliability of hammering riveting processing, etc., achieves low cost of cast iron, improves riveting efficiency, and plasticity The effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

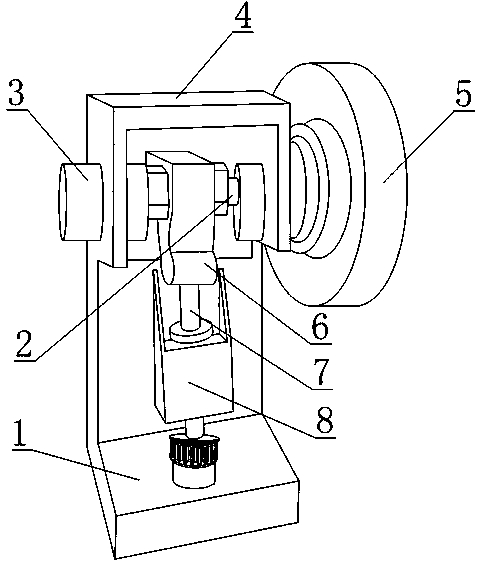

[0026] like figure 1 As shown, the pulley retaining ring punching riveting mechanism includes a drive shaft 2, a frame 4, two bearing boxes 3, a cam system 6, a rivet head rod 7 and a rivet head seat 8, and the two bearing boxes 3 are fixed Connected to the frame 4 , bearings are provided in the bearing housings 3 , the transmission shaft 2 and the inner rings of the bearings in the two bearing housings 3 are in an interference fit, and the cam system 6 includes a shell fixed on the frame 4 . The body and the cam fixedly connected with the transmission shaft 2, the rivet head seat 8 is fixedly connected to the frame 4, the rivet head rod 7 is partially located in the rivet head seat 8, and the rivet head rod 7 is located at any diameter of the cam up direction.

[0027] One end of the drive shaft 2 is connected to the drive motor, the rotational motion of the drive motor rotor is finally transmitted to the drive shaft 2, the drive shaft 2 drives the cam to rotate, and the cam...

Embodiment 2

[0029] This embodiment is further improved on the basis of Embodiment 1, such as figure 1 As shown, the rivet head seat 8 is a hollow structure, the rivet head rod 7 is also provided with an annular protrusion, and also includes a spring, the rivet head rod 7 is partially located in the center hole of the spring, and the spring is located in the rivet head In the hollow structure of the seat 8, both ends of the spring are in contact with the rivet head seat 8 and the annular protrusion respectively.

[0030] The purpose of the spring is that when the large diameter section of the cam is separated from the rivet head rod 7, the spring rebounds, and the rivet head rod 7 moves in the direction of the cam under the action of the spring force, that is, the rivet head rod 7 automatically resets, which is convenient for the next riveting. .

[0031] A flywheel 5 is also included, and the flywheel 5 is fixedly connected to the transmission shaft 2 .

[0032] The provided flywheel 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com