Preparation method of low noise GaN HEMT device

A low-noise, device technology, applied in the field of preparation of low-noise GaN HEMT devices, to prevent the deterioration of frequency characteristics, facilitate process integration, and reduce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

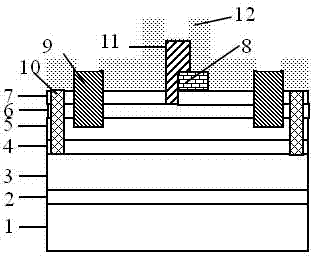

[0028] control Figure 2-1-Figure 2-6, a fabrication method of a low-noise GaN HEMT device, comprising:

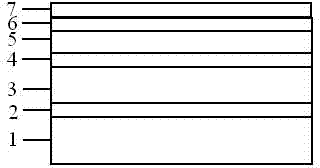

[0029] Step 1) Use MOCVD equipment to grow AlGaN / GaN heterojunction materials with composition graded back barriers on semi-insulating SiC or sapphire substrates, such as diagram 2-1 shown;

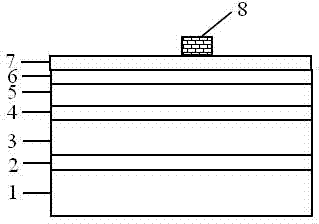

[0030] Step 2) On the clean AlGaN / GaN heterojunction material with compositional graded back barrier, define a dielectric field plate pattern on the sample by throwing the positive resist, exposing, and developing, and deposit multiple layers on the sample by low-temperature dielectric deposition method A layer of high dielectric constant dielectric material is used to form a dielectric field plate through the method of positive resist peeling, such as Figure 2-2 shown;

[0031] Step 3) On the sample obtained in step 2), define the source and drain regions on the sample by throwing the positive glue, exposing and developing, and use the plasma etching method to remove the source ...

Embodiment

[0037] 1) On the semi-insulating 4H-SiC substrate 1, use MOCVD equipment to epitaxy the AlGaN / GaN heterojunction material with a composition gradient back barrier, first grow a 50nm low-temperature AlN nucleation layer 2, and then grow a 1 micron AlGaN composition Graded layer 3, composition graded AlGaN back barrier layer from AlN interface to GaN interface, Al composition is linearly graded from 0.5 to 0.04, and then grows 200nm GaN channel layer 4; 20nm Al 0.25 Ga 0.75 N barrier layer 5, Si doping concentration 1E18 cm thick 2nm -3 doped GaN capping layer 6 and a thickness of 2nm Si 3 N 4 protective layer 7;

[0038] 2) Clean the surface of the grown AlGaN / GaN heterojunction sample first, ultrasonically clean it in acetone and ethanol solutions for 5 minutes, rinse it in deionized water, and blow it dry with nitrogen;

[0039] 3) Coat AZ7908 positive-type photoresist on the sample by spin coating method, the uniform rotation speed is 5000rpm, and the uniform time is 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com